A fracturing flowback fluid treatment and reuse process

A fracturing flowback fluid and process technology, applied in natural water body treatment, multi-stage water treatment, water/sewage multi-stage treatment, etc. The problems of large land occupation, environmental pollution and high cost have achieved the effect of shortening the construction period, shortening the construction time, and simple on-site operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In order to overcome the technical problems that the fracturing flowback fluid cannot be recycled and reused online, pollute the environment and have high cost, the previous fracturing flowback fluid treatment process takes a long time, and the processing equipment and storage tank occupy a large area. The present invention provides a A fracturing flowback fluid treatment and reuse process, the invention can realize the online processing and recycling of fracturing flowback fluid, and the processing capacity is not less than 60m 3 / h, which can meet the requirements of oil and gas well discharge. The flowback liquid recovery system has the advantages of simple on-site operation, the recovery efficiency of the flowback liquid is higher than 98%, and it can be recycled. The flowback fluid recovery and treatment system can reduce the discharge of fracturing fluid waste, save fracturing water, shorten the construction period, and shorten the construction time by about 1 day...

Embodiment 2

[0039] On the basis of embodiment 1,

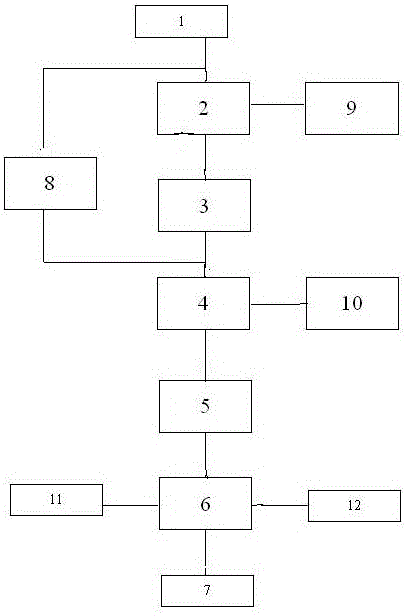

[0040] 1) After the fracturing construction of the natural gas well is completed, the fracturing flowback fluid injected from the wellhead 1 passes through the high-pressure cyclone degassing device 2, and the gas in the fracturing flowback fluid is separated to the gas pipeline 9, and the liquid and solid The proppant mixture is separated;

[0041] 2) In step 1), the liquid and solid proppant mixture treated by the high-pressure cyclone degassing device 2 is depressurized through the throttling and pressure-reducing manifold 3, and the fracturing is controlled at 2MPa;

[0042] 3) Pass the mixed liquid separated in step 2) through the low-pressure three-phase separation device 4 to separate the gas, liquid and solid proppant in the mixed liquid, and the gas is separated to the input pipeline 9, and the solid proppant passes through the proppant collection container 10 collection;

[0043] 4) Send the liquid separated in step 3) into th...

Embodiment 3

[0051] In this example, the water quality regulator of Hubei Haili Environmental Protection Technology Co., Ltd. is used. The water quality regulator mainly removes the influence of some ions in the water on the properties of the fracturing fluid. The water quality regulator can be a pH regulator, which increases the specific gravity after adjusting the pH value, so that the final pH value is less than or equal to 5, which meets the requirements for reconfiguring the fracturing fluid.

[0052] The fracturing flowback fluid sprayed out has also been pre-stored in the flowback fluid temporary storage tank 8 to achieve the ability to slow down the flow rate of the blowout, and can also directly enter the low-pressure three-phase separation device 4 to separate gas, liquid, and solid proppant.

[0053] The processing flow rate of the present invention: gas well flowback fluid processing capacity 4m 3 / min, gas 20×10 4 m 3 / d; liquid recovery rate 99%, gas-liquid separation rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com