Cement sheath structural integrity mechanics experiment device

A technology of integrity mechanics and experimental equipment, applied in the direction of construction, etc., to achieve the effect of automatic temperature adjustment, easy operation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

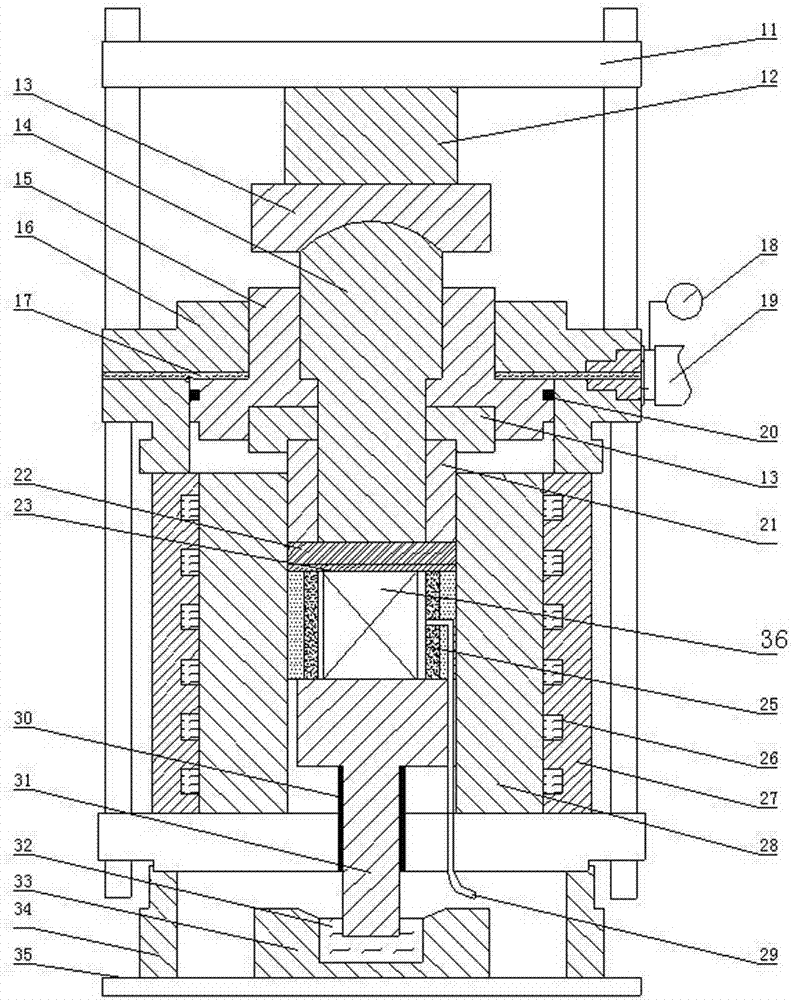

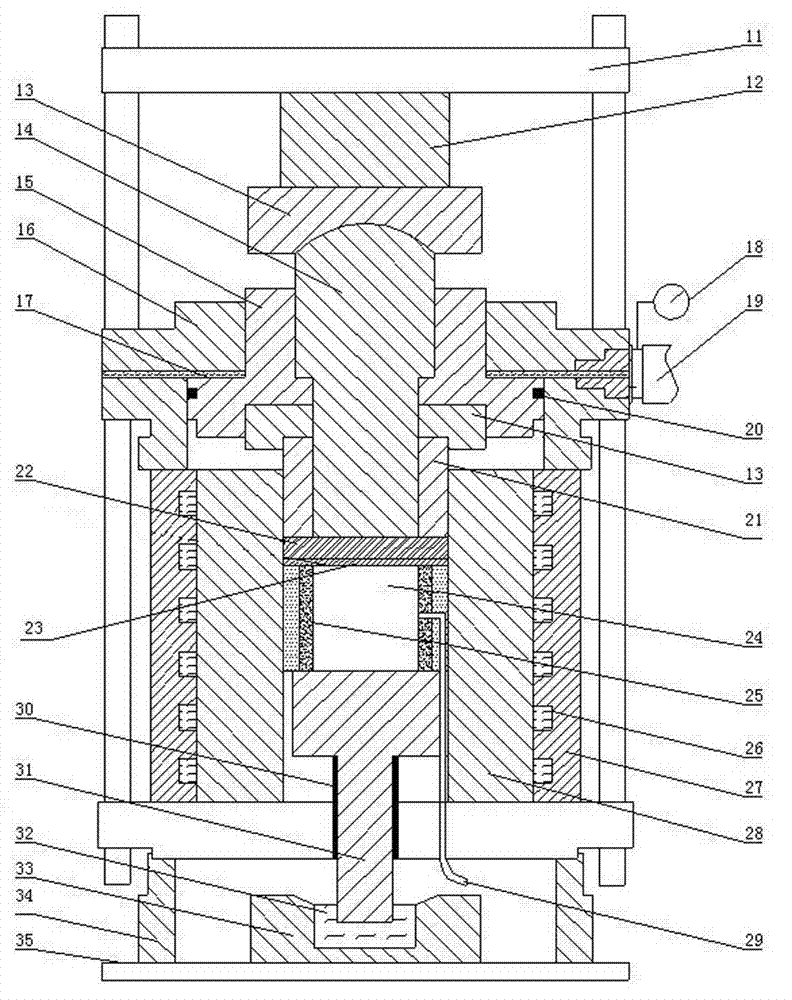

[0021] Such as figure 1 As shown, the cement sheath structural integrity mechanical experiment device is composed of a cement sheath curing mold 36 and a triaxial stress curing kettle. The cement sheath curing mold 36 is set in the inner cavity 24 of the triaxial stress curing kettle. The formed assembly cured from the cement ring curing mold was placed in a triaxial stress curing kettle and fixed for experimental measurement. The shear bond strength of the bonded interface is assisted in the test with the help of related equipment.

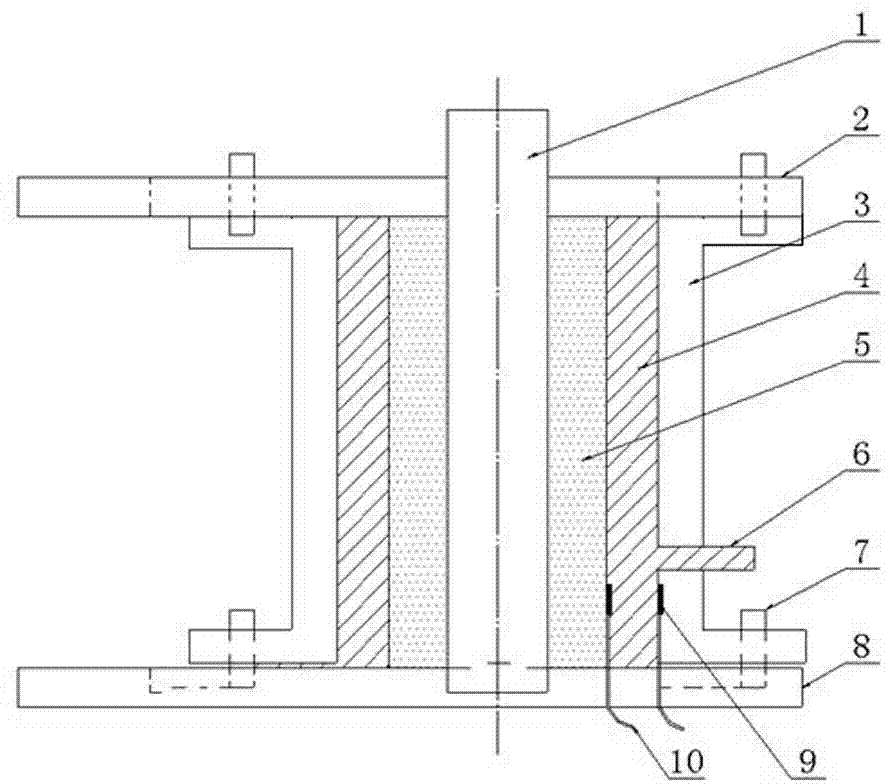

[0022] Such as figure 2 As shown, the cement sheath maintenance mold includes an adjustable eccentric upper flange cover 2, a simulated well wall 4, a simulated well wall outer casing 3, a casing 1, an adjustable eccentric lower flange 8, and a simulated well wall outer casing 3 The casing is placed outside the simulated well wall 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com