Automobile sub-frame material rack

A subframe and automobile technology, applied in the field of packaging equipment, can solve the problems that the automobile subframe cannot share the same structural material rack, the edge of the automobile assembly line occupies a large space, and cannot meet the green environmental protection policy, etc., to achieve material reduction The effect of putting in racks, reducing space pressure, and facilitating assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention will be described in further detail, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

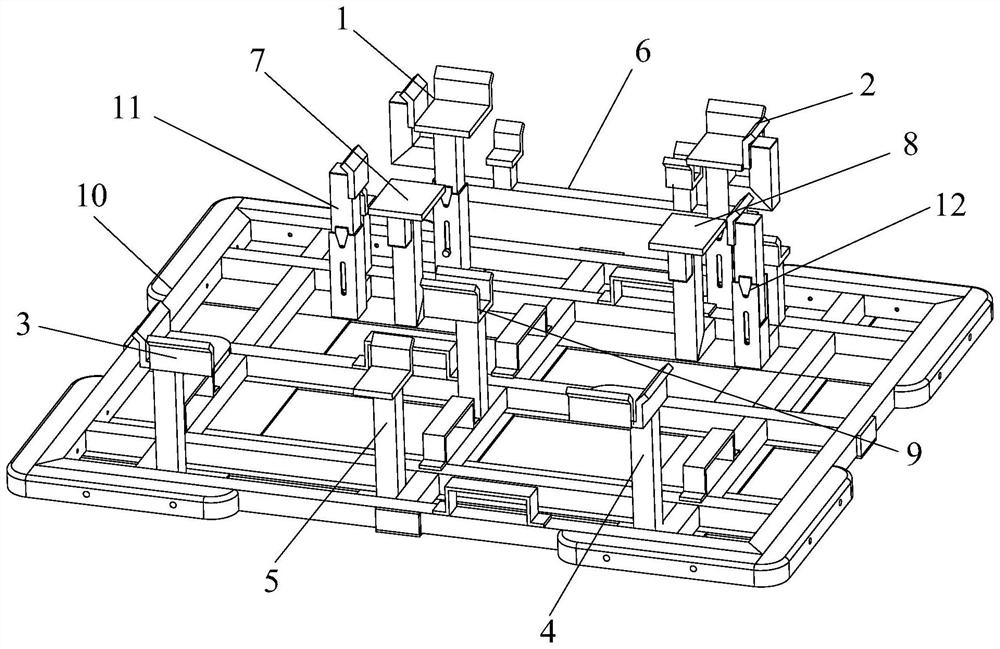

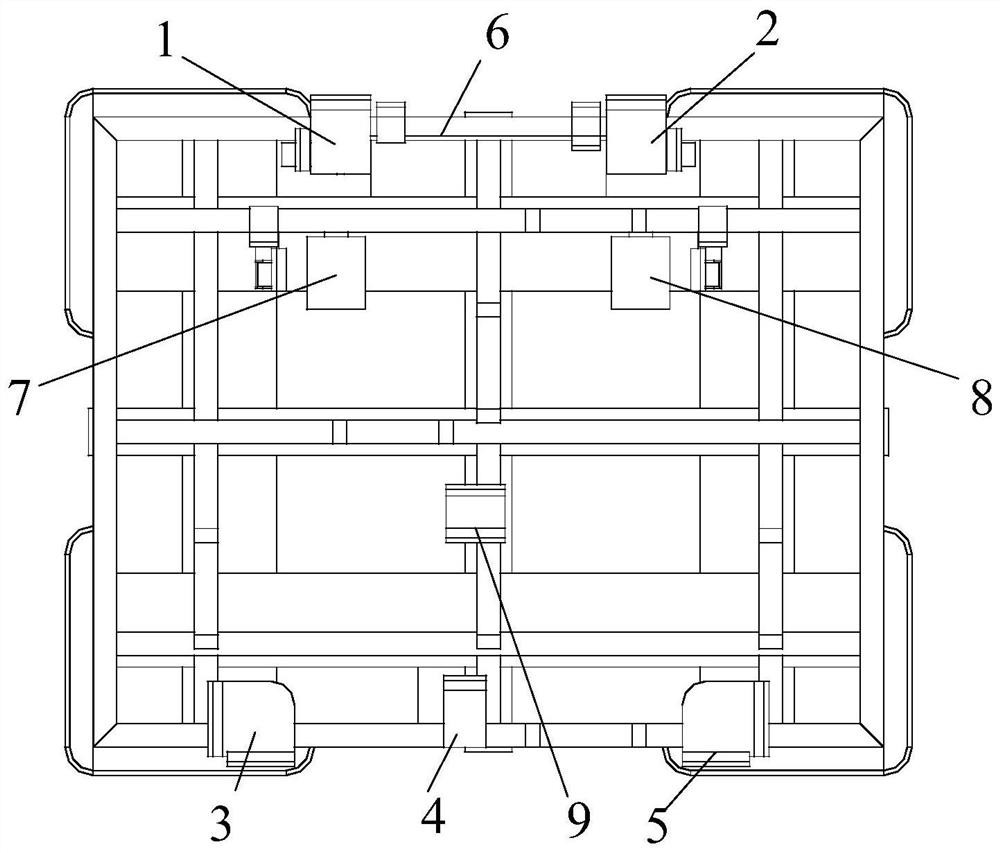

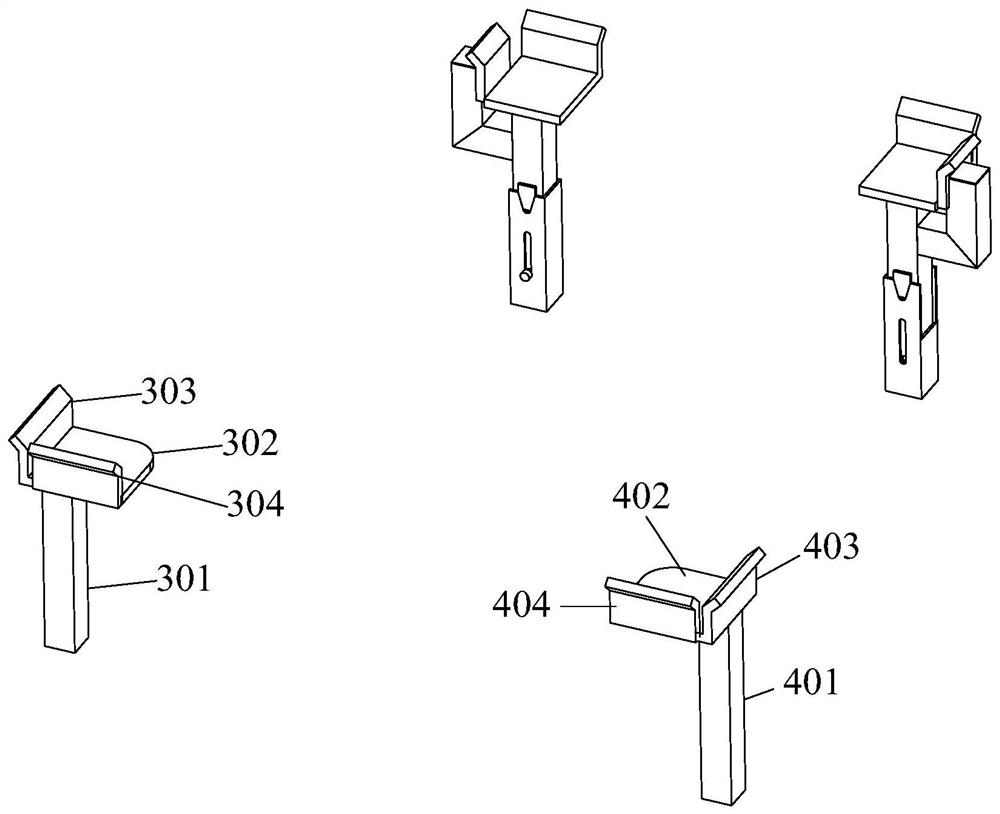

[0029] like Figure 1 to Figure 12As shown, the present invention provides an automobile sub-frame material frame, including a bottom frame 10, a first support mechanism 1 and a second support mechanism 2 for providing support for the first type of sub-frame, and for supporting the first sub-frame A third support mechanism 3 and a fourth support mechanism 4 for providing support to the second type of subframe and the second type of subframe, a fifth support mechanism 5 and a sixth support mechanism 6 for providing support to the second type of subframe, The seventh support mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com