Rectorite saturated brine drilling fluid for drilling under rock salt deep stratum

A brine drilling fluid and rectorite technology, applied in the field of rectorite saturated brine drilling fluid, can solve the problems of rheological performance deterioration, drilling fluid rheological performance deterioration, poor sand return, etc., and achieve high temperature resistance The effect of good, good sand-carrying ability, good sand-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the drilling fluid of the present embodiment, each component and the mass volume ratio (unit: Kg / m3) of the drilling fluid and the drilling fluid 3 ) are: 4% sodium-based rectorite, 14% binary copolymer PAMS601, 0.1% sodium carboxymethyl starch (CMS), 0.1% coating agent FA367, 0.2% sulfonated asphalt powder FT-1, 2.5% Broad-spectrum wall protection agent GSP, 3% solid lubricant RH-2 for drilling fluid, 1% lubricant CNS for drilling fluid, 0.1% silicone oil, 0.1% NaOH, the rest is NaCl and water, of which NaCl is saturated.

[0029] According to the above ratio, mix sodium-based rectorite with water, stir evenly to obtain sodium-based rectorite slurry, then add various other additives and stir, add NaCl to fully dissolve and make NaCl saturated in the drilling fluid, mix After uniformity, the rectorite-saturated brine drilling fluid used for drilling in the rock-salt deep formation can be obtained.

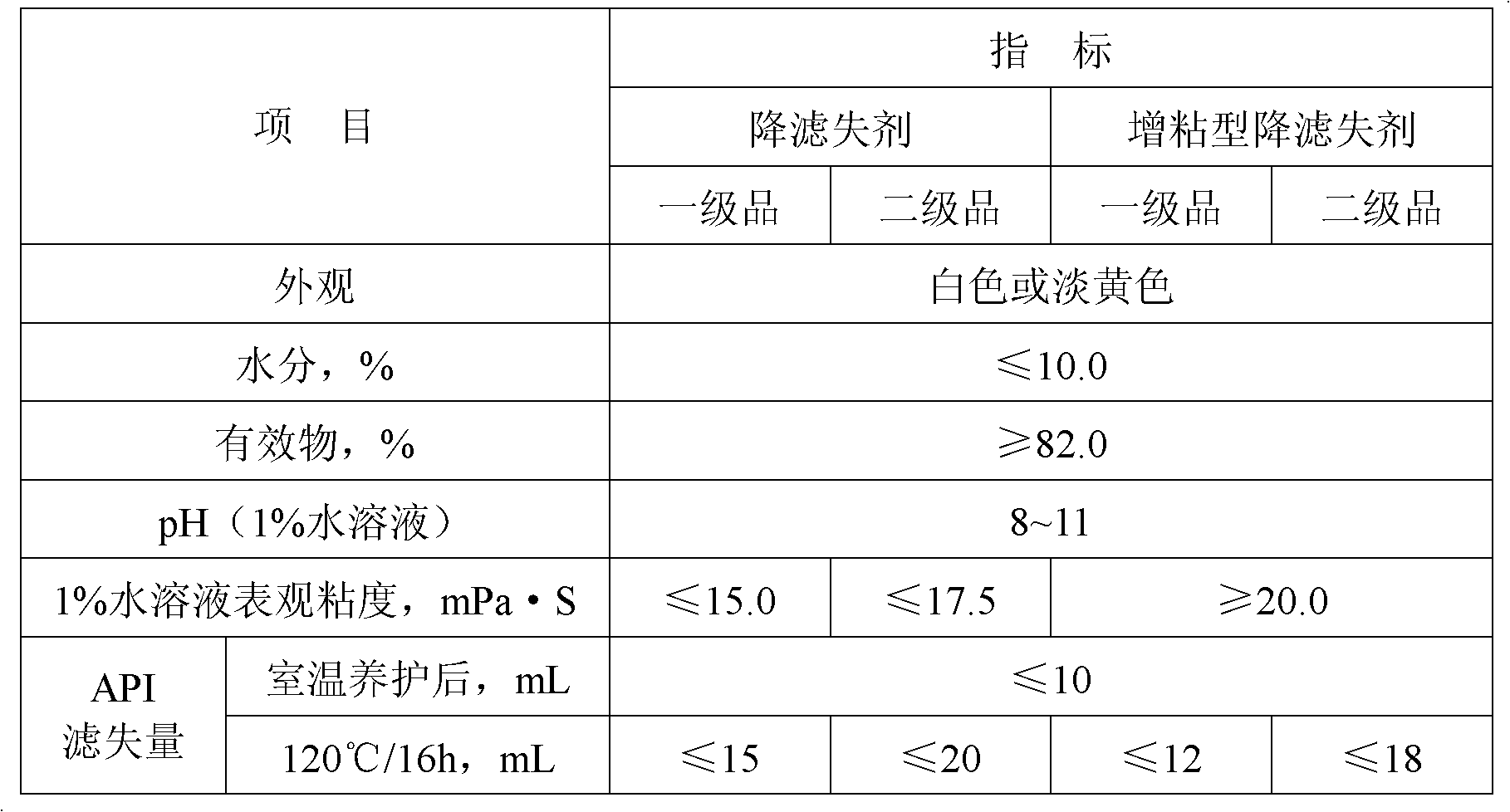

[0030] The performance index (executive standard GB / T 16783-1997) o...

Embodiment 2

[0032] In the drilling fluid of the present embodiment, each component and the mass volume ratio (unit: Kg / m3) of the drilling fluid and the drilling fluid 3 ) are: 8% sodium-based rectorite, 0.5% polymer fluid loss control agent COP-LFL, 2.5% binary copolymer PAMS900, 4% polyacrylamide (PAM), 0.1% coating agent KPAM, 0.5% Coating agent PAC141, 1% broad-spectrum wall protection agent GSP, 1% drilling fluid lubricant TNH-2, 0.5% defoamer, 0.5% NaOH, the rest is NaCl and water, of which NaCl is saturated.

[0033] According to the above proportions, the same method as in Example 1 was used to prepare, and the rectorite-saturated brine drilling fluid for drilling in deep formations of rock salt was obtained.

[0034] The performance index of the drilling fluid prepared in this example (implementation standard GB / T 16783-1997): the density is 1.20g / cm 3 , the viscosity is 53s, and the medium pressure filtration loss at room temperature is FL API 4.8mL, high temperature and high ...

Embodiment 3

[0036] In the drilling fluid of the present embodiment, each component and the mass volume ratio (unit: Kg / m3) of the drilling fluid and the drilling fluid 3 ) are: 1% sodium-based rectorite, 0.2% polymer fluid loss reducer COP-LFL, 5% HV-CMC, 1% coating agent KPAM, 0.5% sulfonated asphalt powder FT-1, 5% drilling Liquid lubricant CNS, 0.3% defoamer, 0.2% NaOH, the rest is NaCl and water, of which NaCl is saturated.

[0037] According to the above proportions, the same method as in Example 1 was used to prepare, and the rectorite-saturated brine drilling fluid for drilling in deep formations of rock salt was obtained.

[0038] The performance index of the drilling fluid prepared in this example (implementation standard GB / T 16783-1997): the density is 1.20g / cm 3 , the viscosity is 51s, and the medium pressure filtration loss at room temperature is FL API 4.7mL, high temperature and high pressure filtration loss FL hthp is 13.8mL, plastic viscosity PV is 23mPa·S, dynamic she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com