Rotary vibratory force head main shaft device

A technology of spindle device and vibration force, which is applied in the direction of driving device, bearing elements, shafts and bearings of rotary combined drilling, can solve the problems of poor ability to withstand alternating stress, difficult assembly and adjustment, and complicated force, and achieve bearing capacity The effect of strong alternating stress ability, simple and reasonable structure, and convenient assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

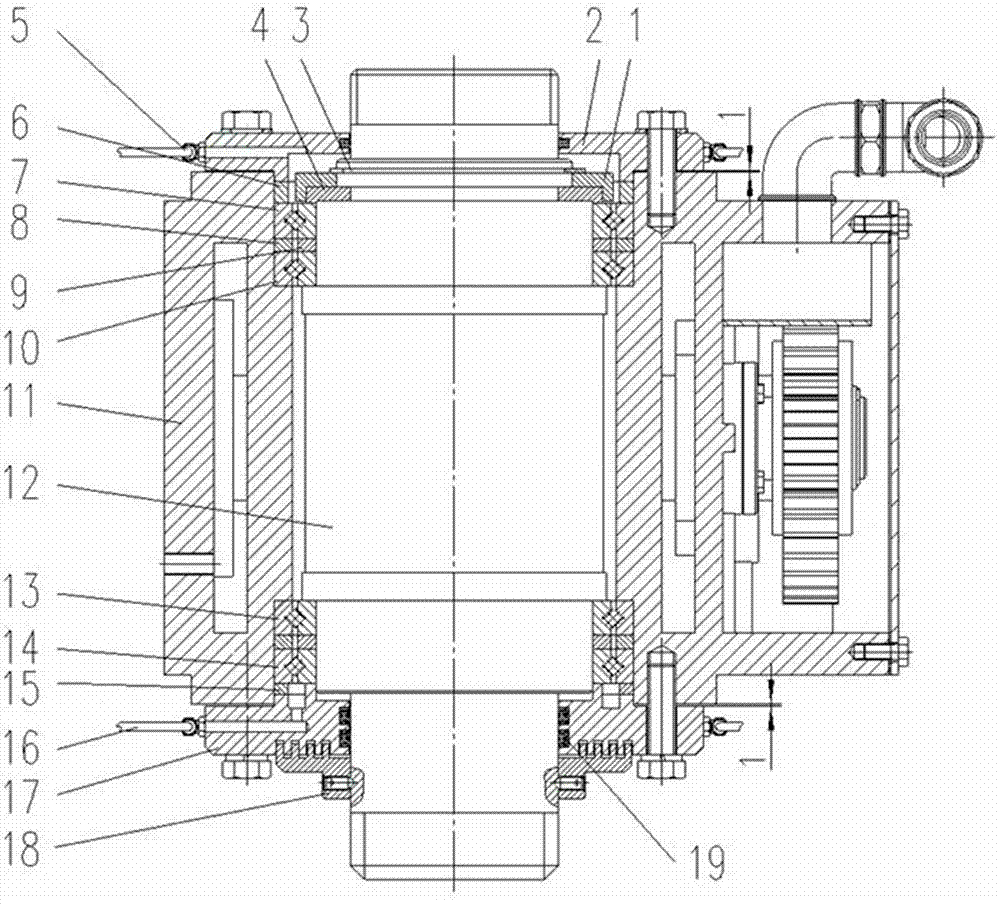

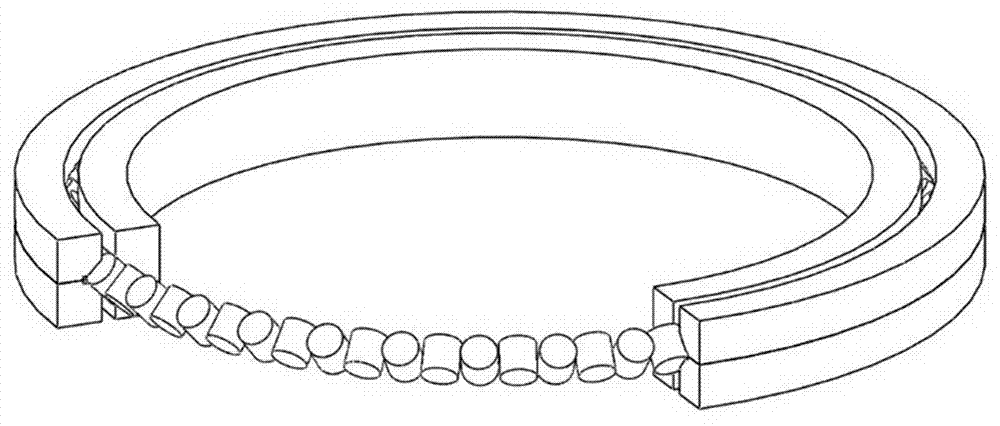

[0014] like figure 1 As shown, the rotary vibrating head spindle device of the present invention includes a spindle 12 installed in a spindle housing 11 . An upper pair of crossed roller bearings and a lower pair of crossed roller bearings are installed on the upper journal and the lower journal of the main shaft respectively. The inner end surface of the inner ring of the inner crossed roller bearing 10 in the upper crossed roller bearing pair is in contact with the end surface of the upper shaft journal, and the inner end surface of the inner ring of the inner crossed roller bearing 13 in the lower crossed roller bearing pair is in contact with the end surface of the lower shaft journal. The ends of the neck are fitted. The outer end surface of the inner ring of the outer crossed roller bearing 7 in the upper crossed roller bearing pair is locked in turn by the retaining ring 4, the hoop 1 and the shaft circlip 3, and the outer ring is locked by the upper gland 2 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com