Patents

Literature

183results about How to "Easy assembly and adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

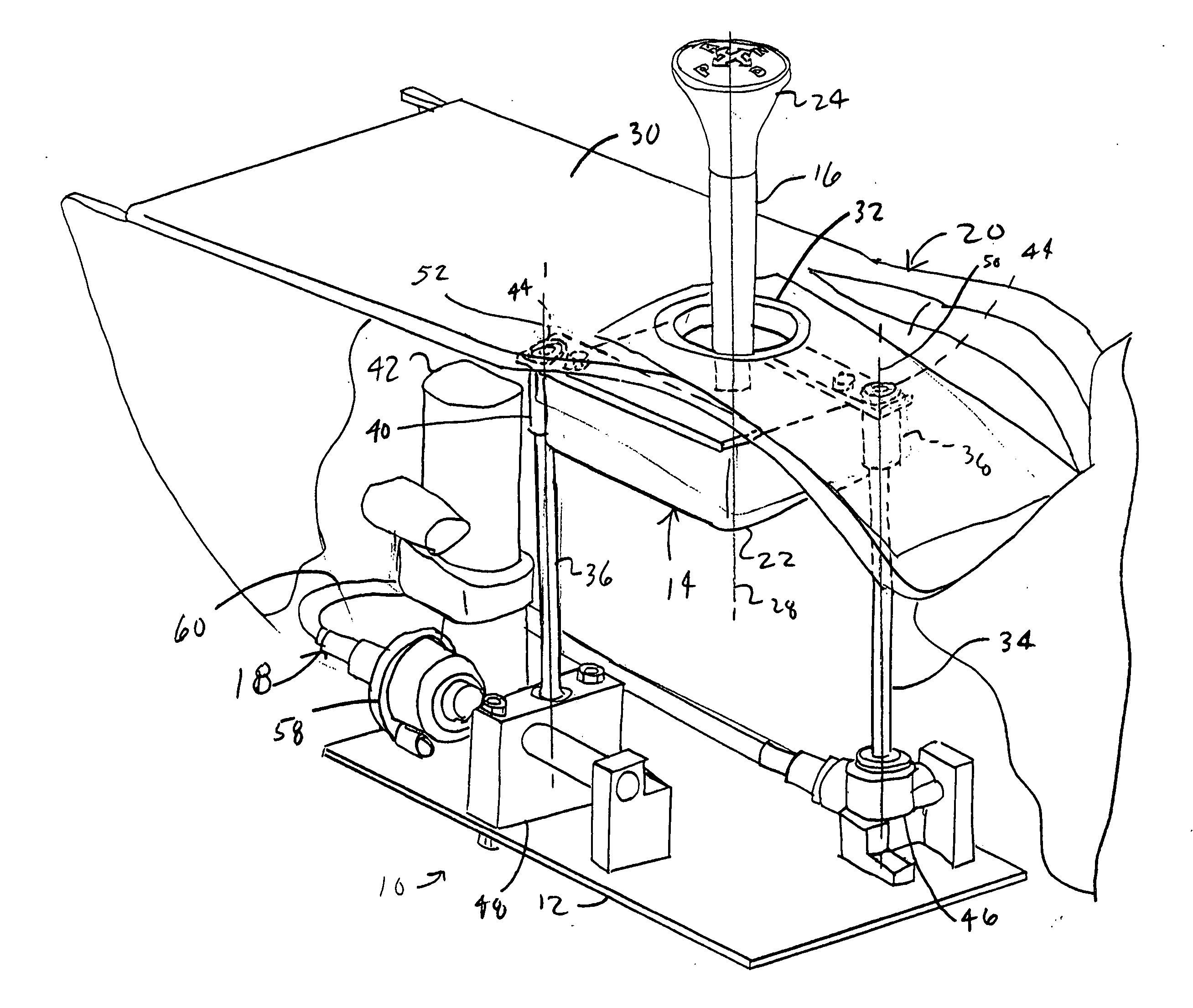

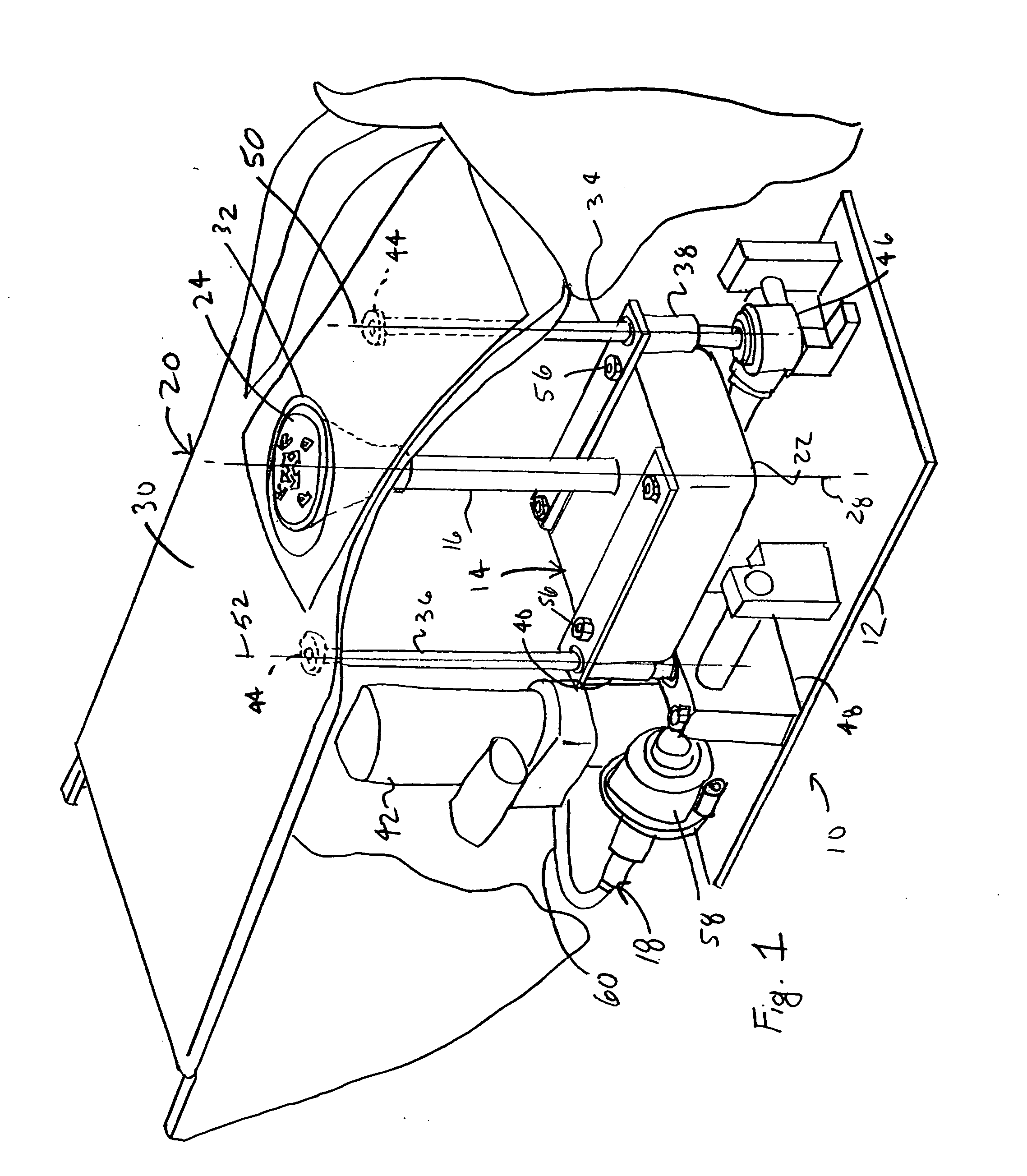

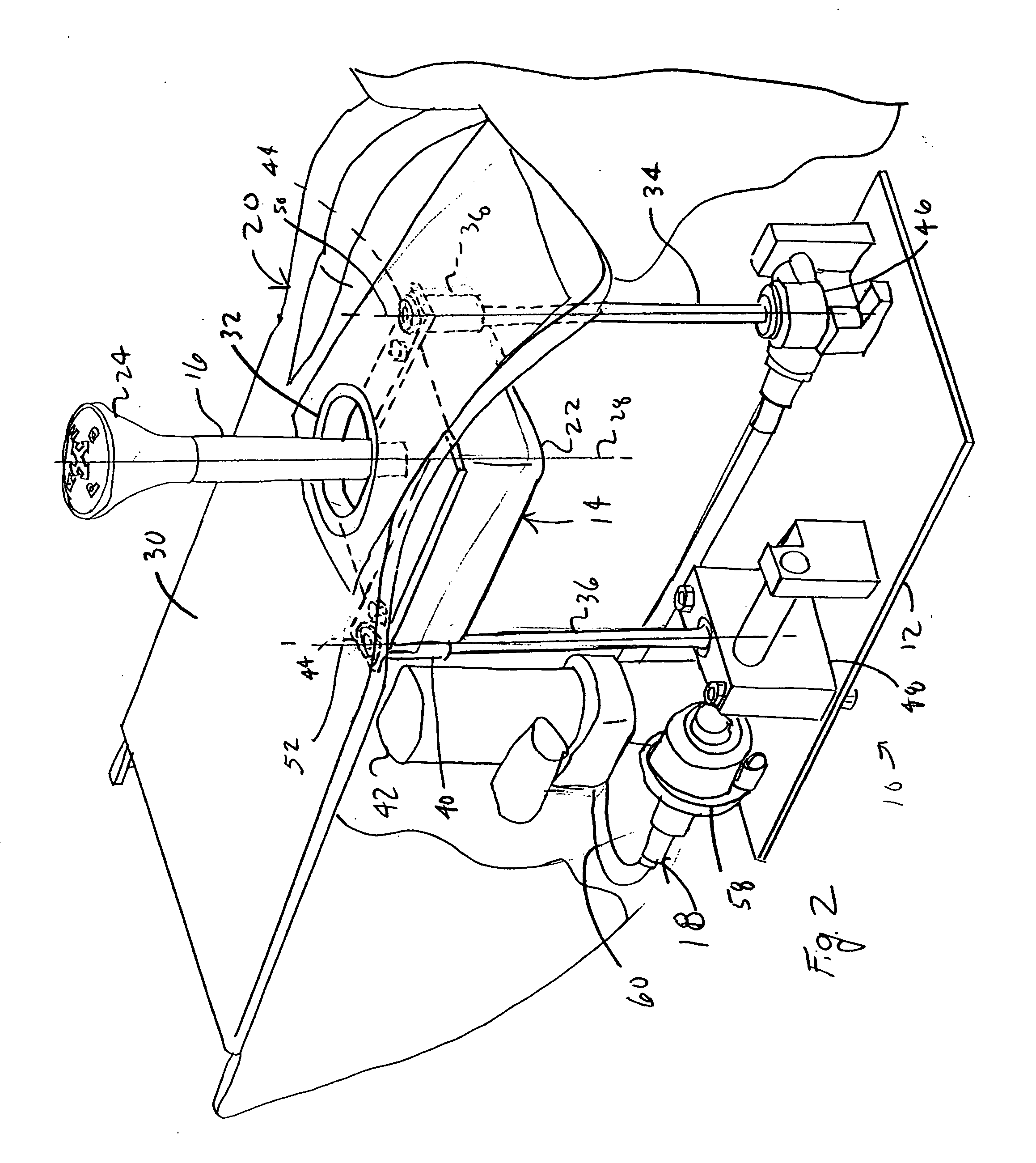

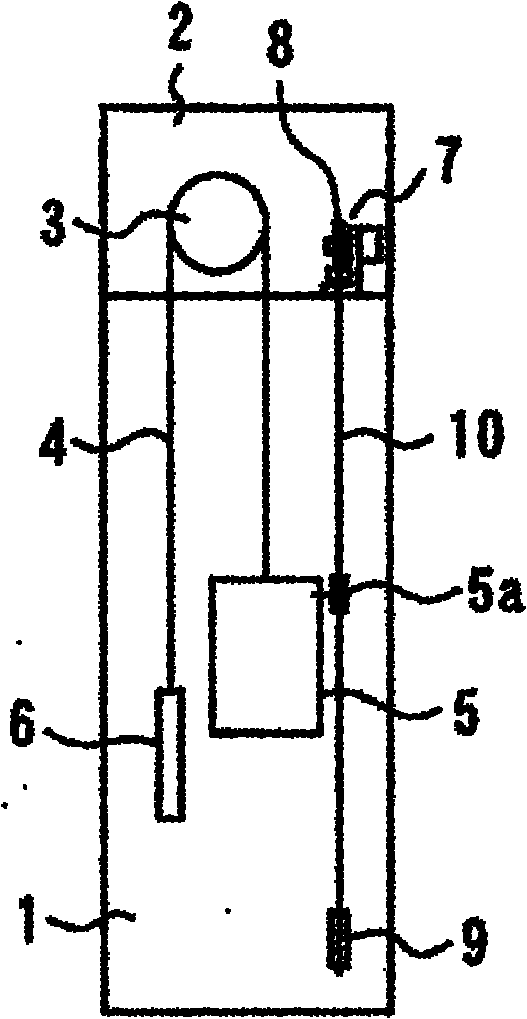

Self presenting electronic shifter

InactiveUS20070204718A1Quality improvementEasy assembly and adjustmentControlling membersManual control with multiple controlled membersControl theoryMechanical engineering

A shifter assembly includes an electronic shifter mechanism having a shift lever movable between a plurality of gear positions and an electrically powered drive system operatively connected to the shifter mechanism to selectively move the shifter mechanism between a first location wherein the shifter lever is located substantially within a housing and a second location wherein the shifter lever is located substantially outside the housing. The drive system moves the shifter mechanism along a vertical, linear path substantially parallel to a longitudinal axis of the shift lever such that the shift lever moves through an opening in the housing.

Owner:DURA GLOBAL TECH

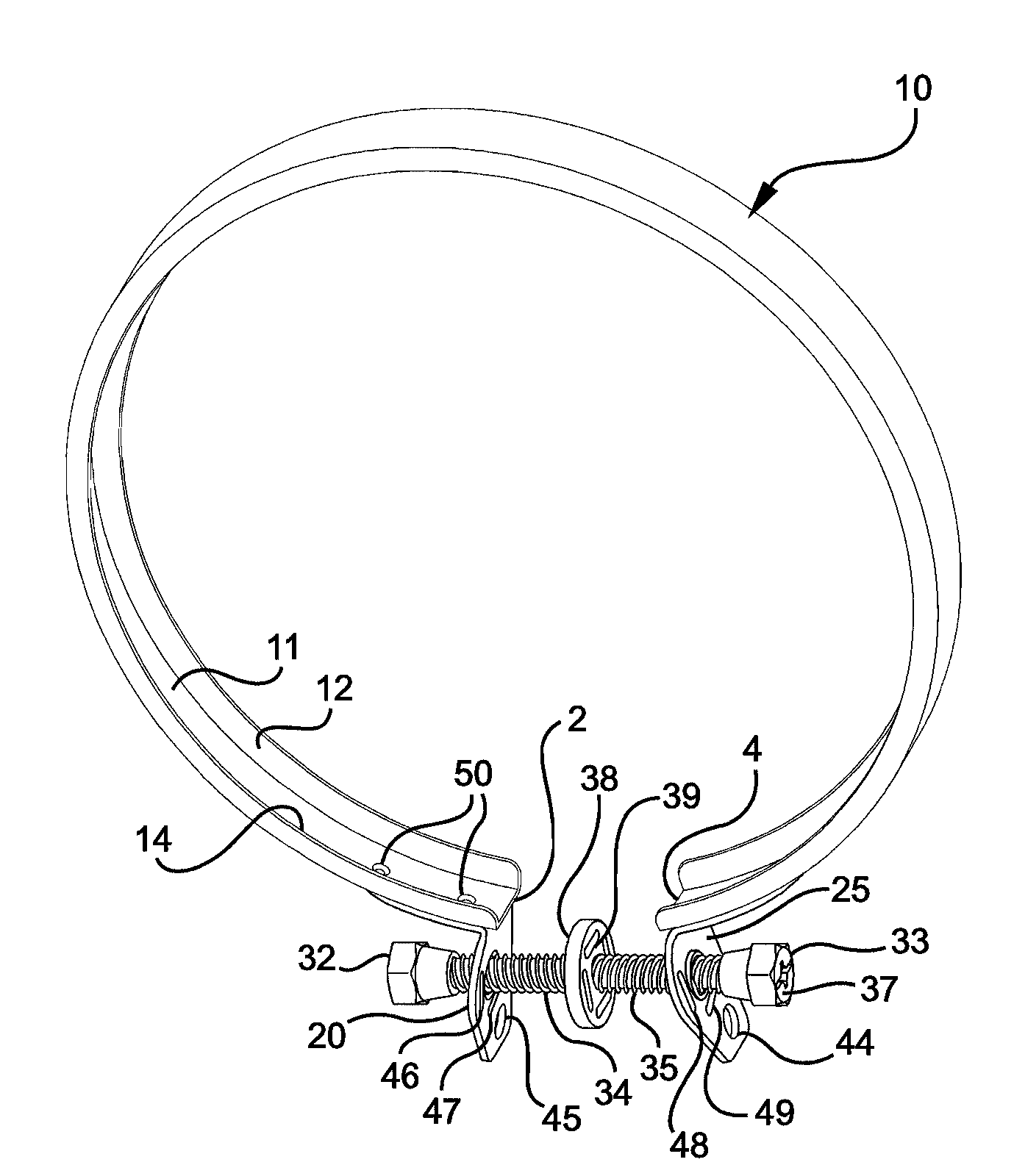

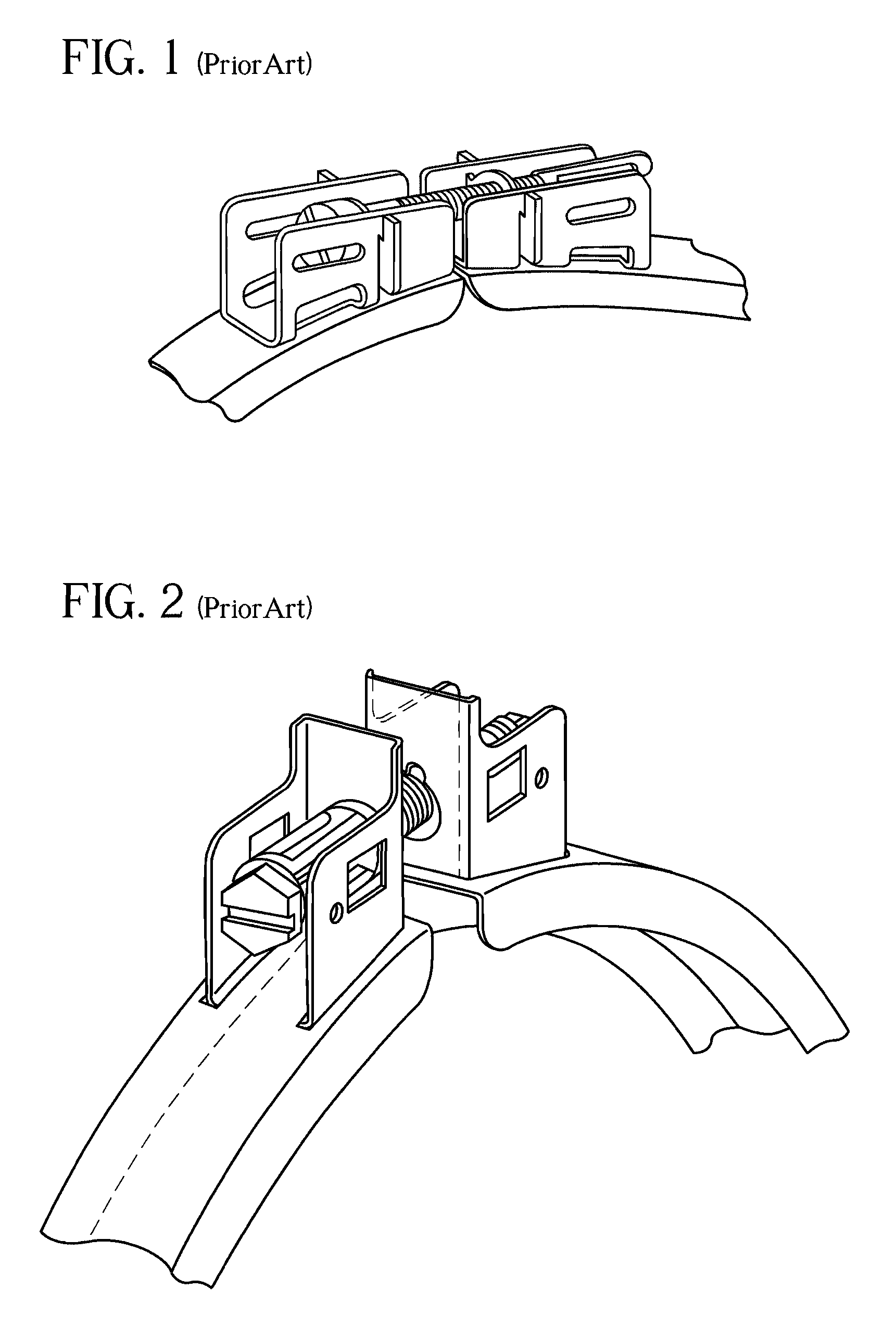

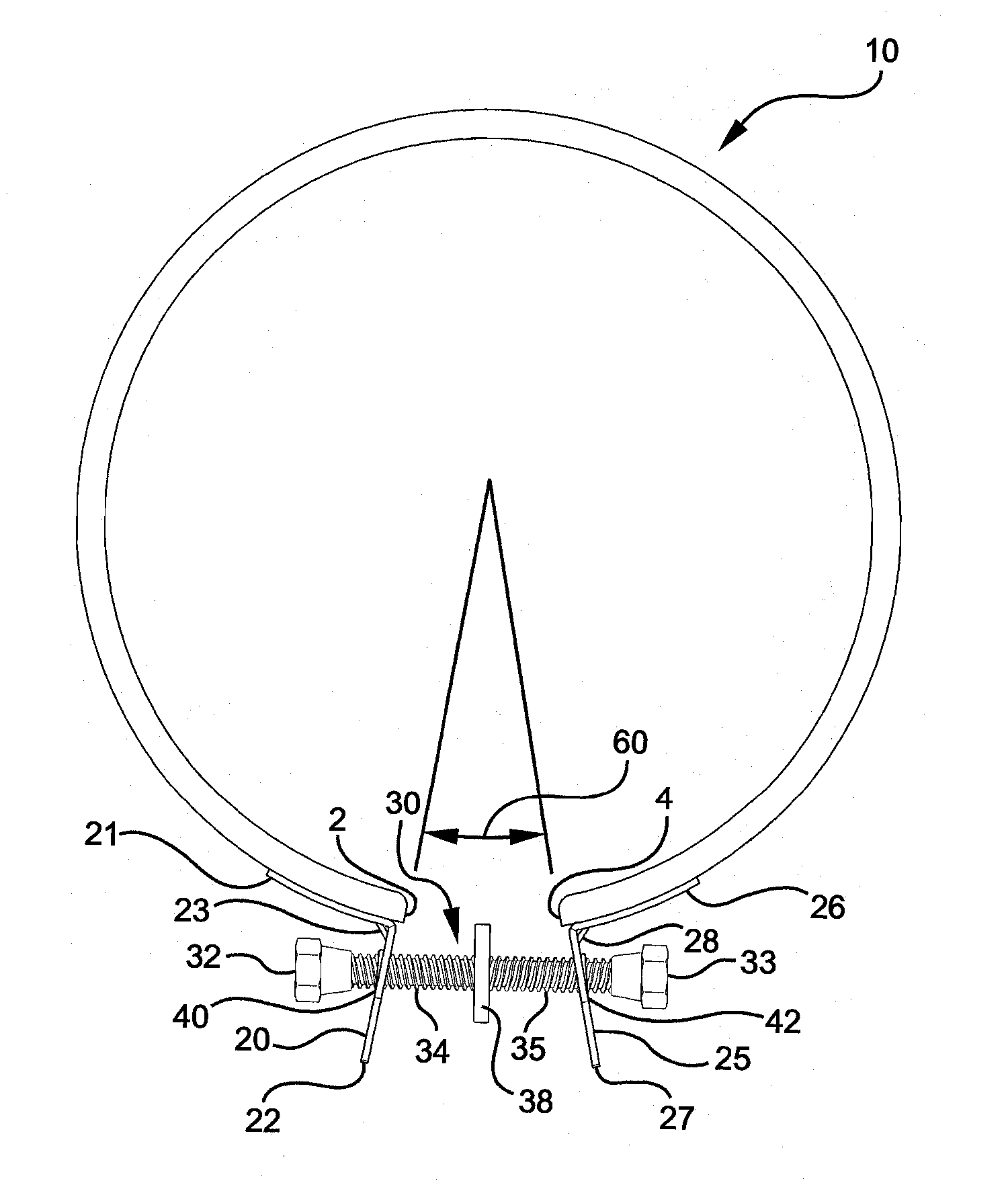

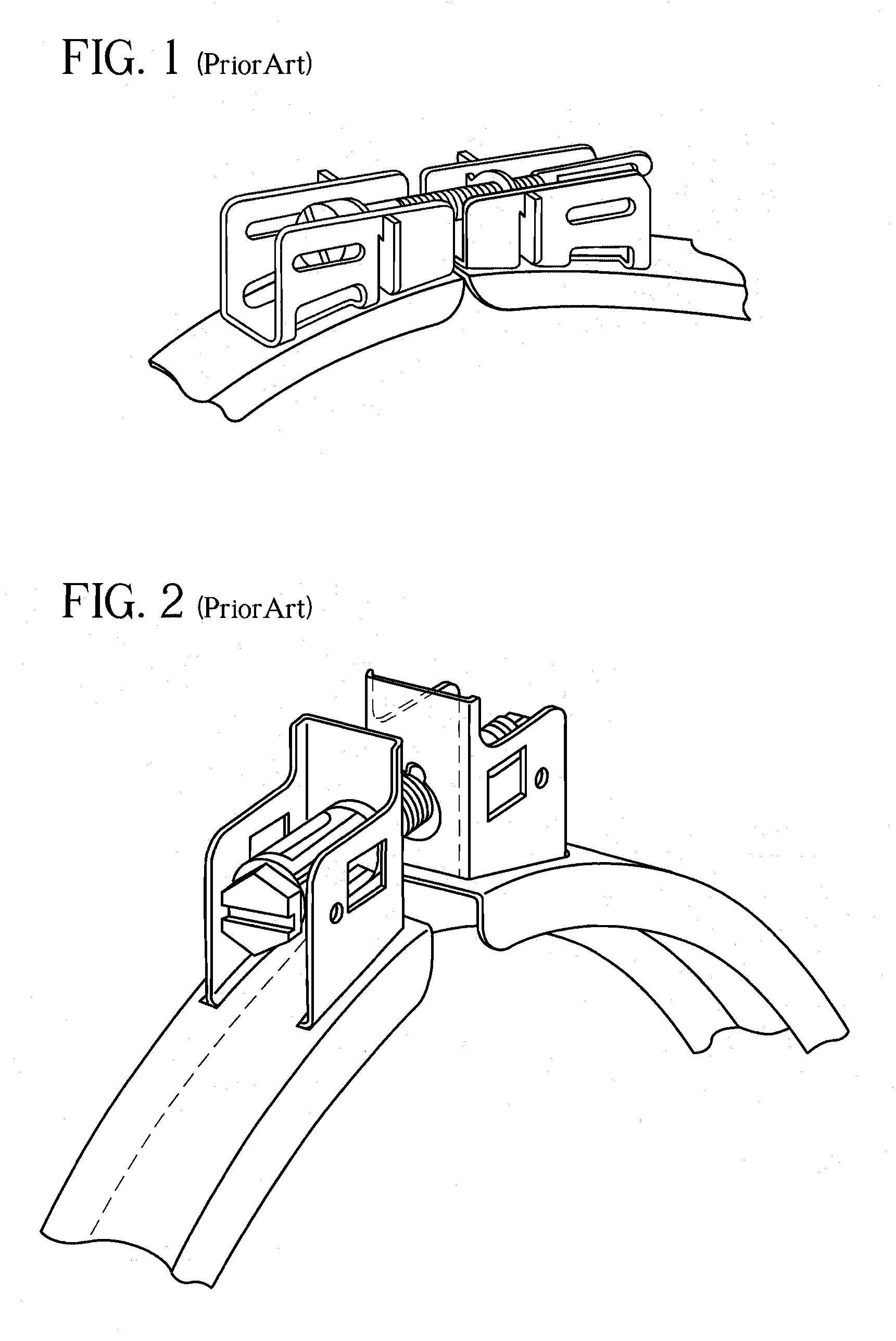

Sealing ring with improved fastener

ActiveUS7500701B2Preventing and detecting unauthorized tampering and removalEasy to adjustSheet joiningClamping mechanismSplit ringFastener

One aspect of the present invention includes a sealing ring having a split-ring annular band which includes a first and second end. A first tab is disposed at the first end, with the first tab extending away from the annular band. The first tab also includes a first threaded aperture. A second tab is disposed at the second end, with the second tab also extending away from the annular band The second tab also includes a second threaded aperture. Additionally, a thread of the first aperture is different from a thread of the second aperture. Further, the sealing ring includes a fastener threadedly engaged with the first and second apertures. Rotation of the fastener adjusts a radial dimension of the annular band.

Owner:THOMAS & BETTS INT INC

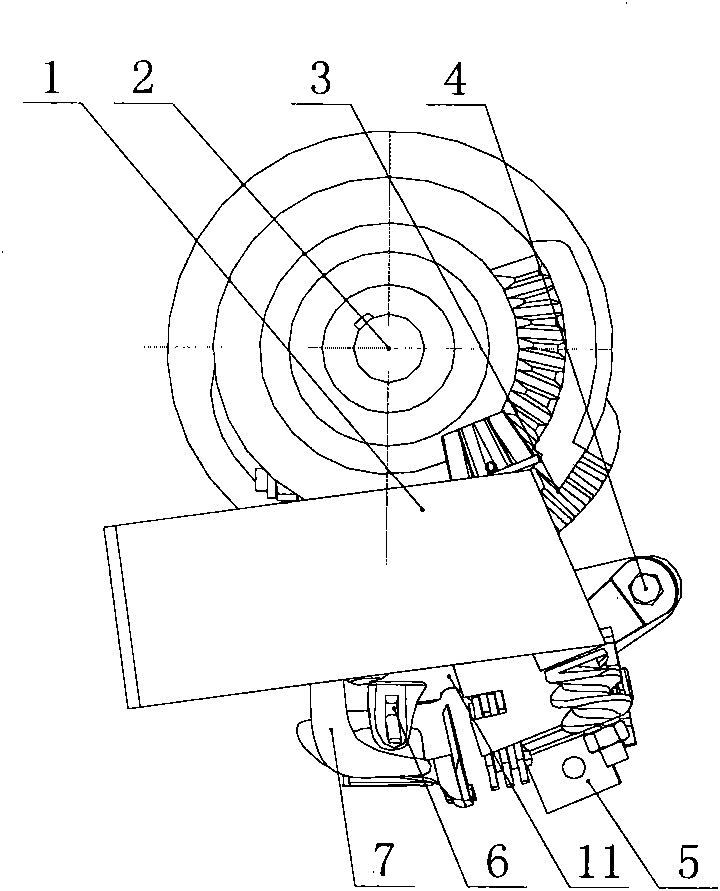

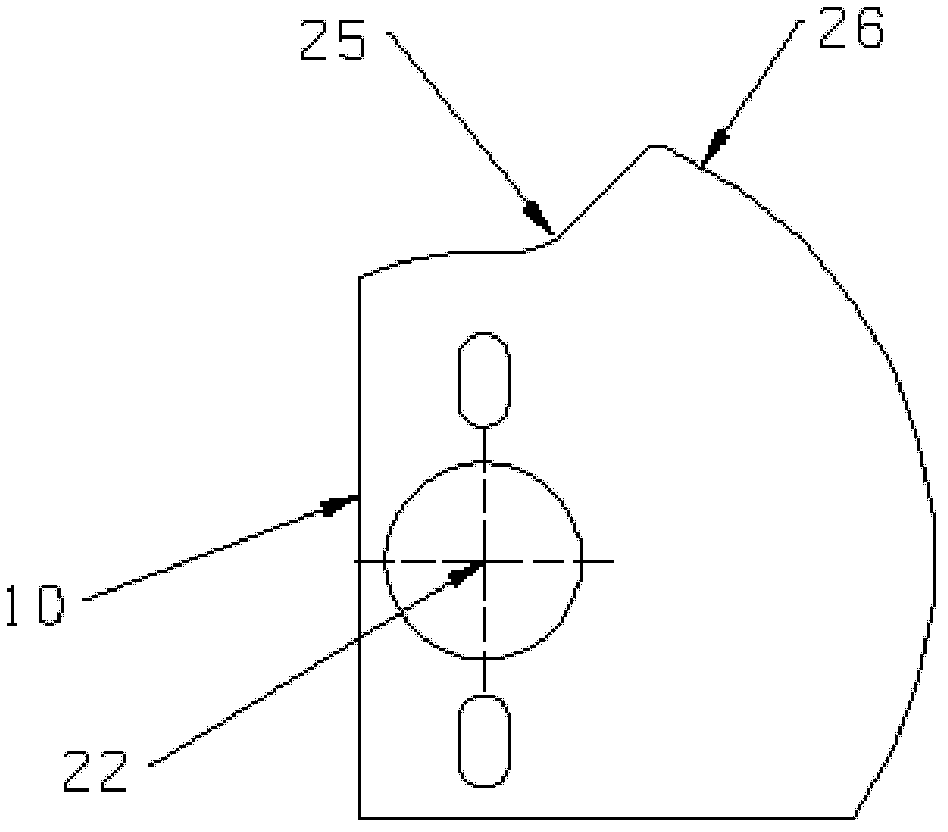

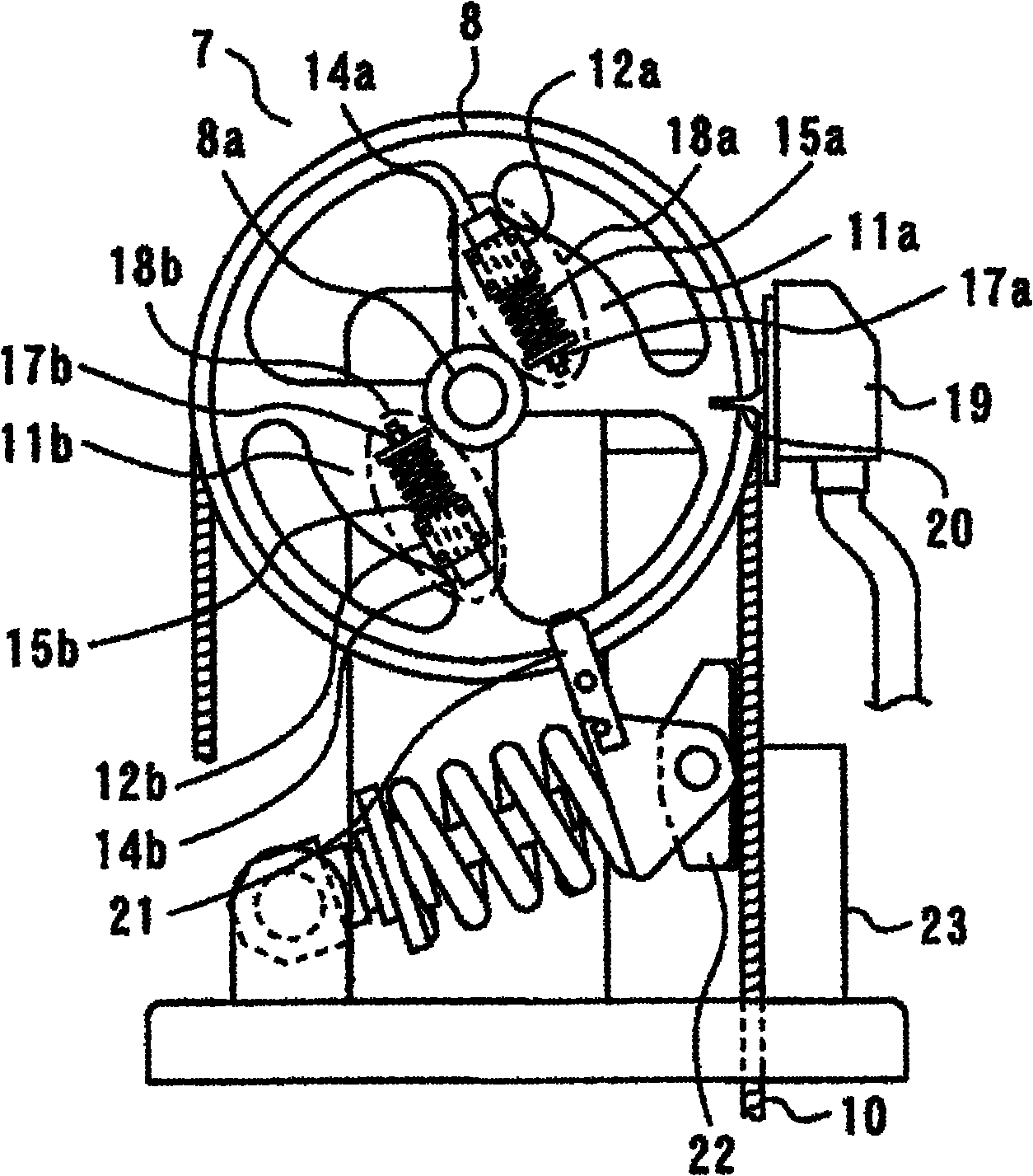

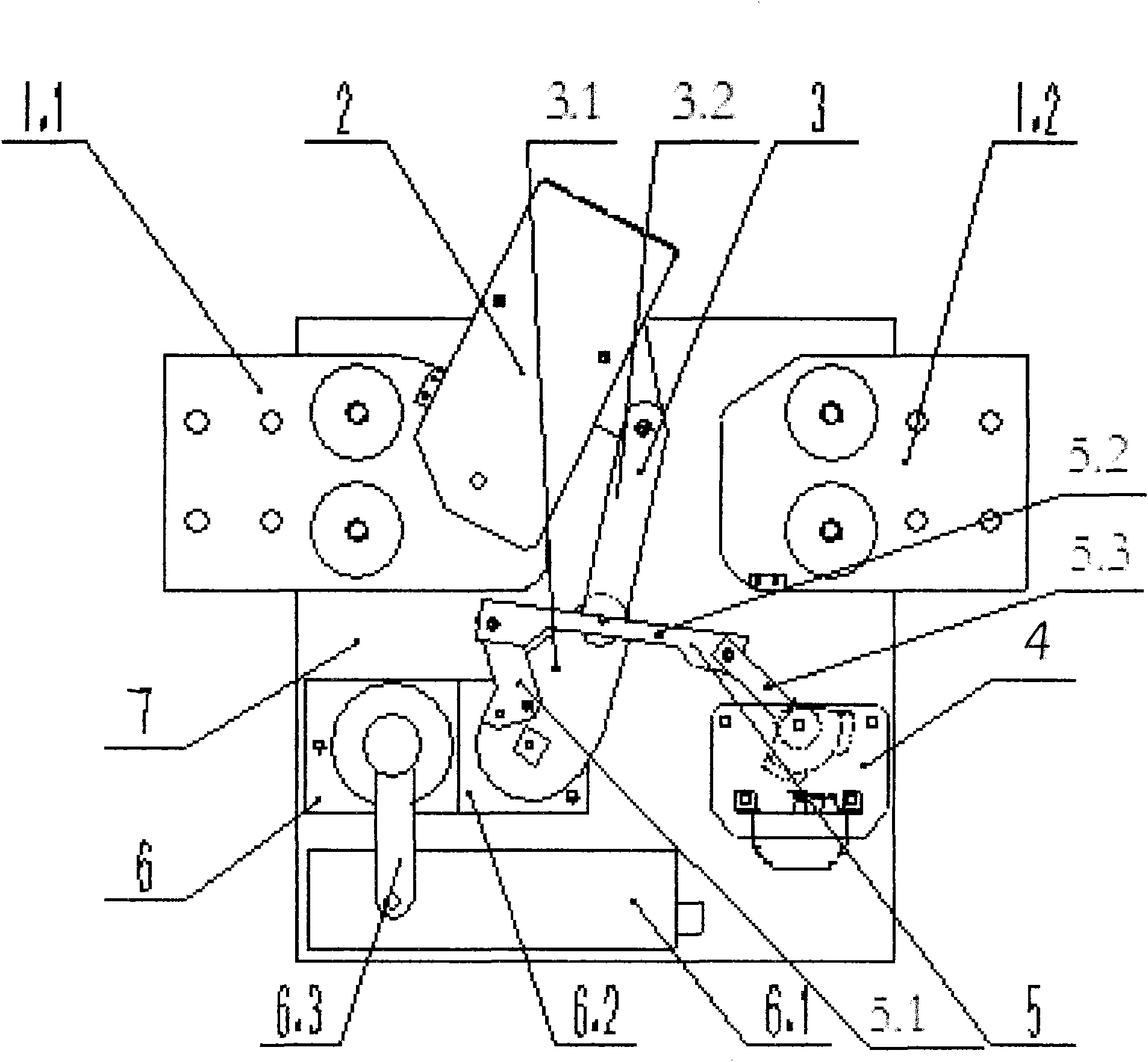

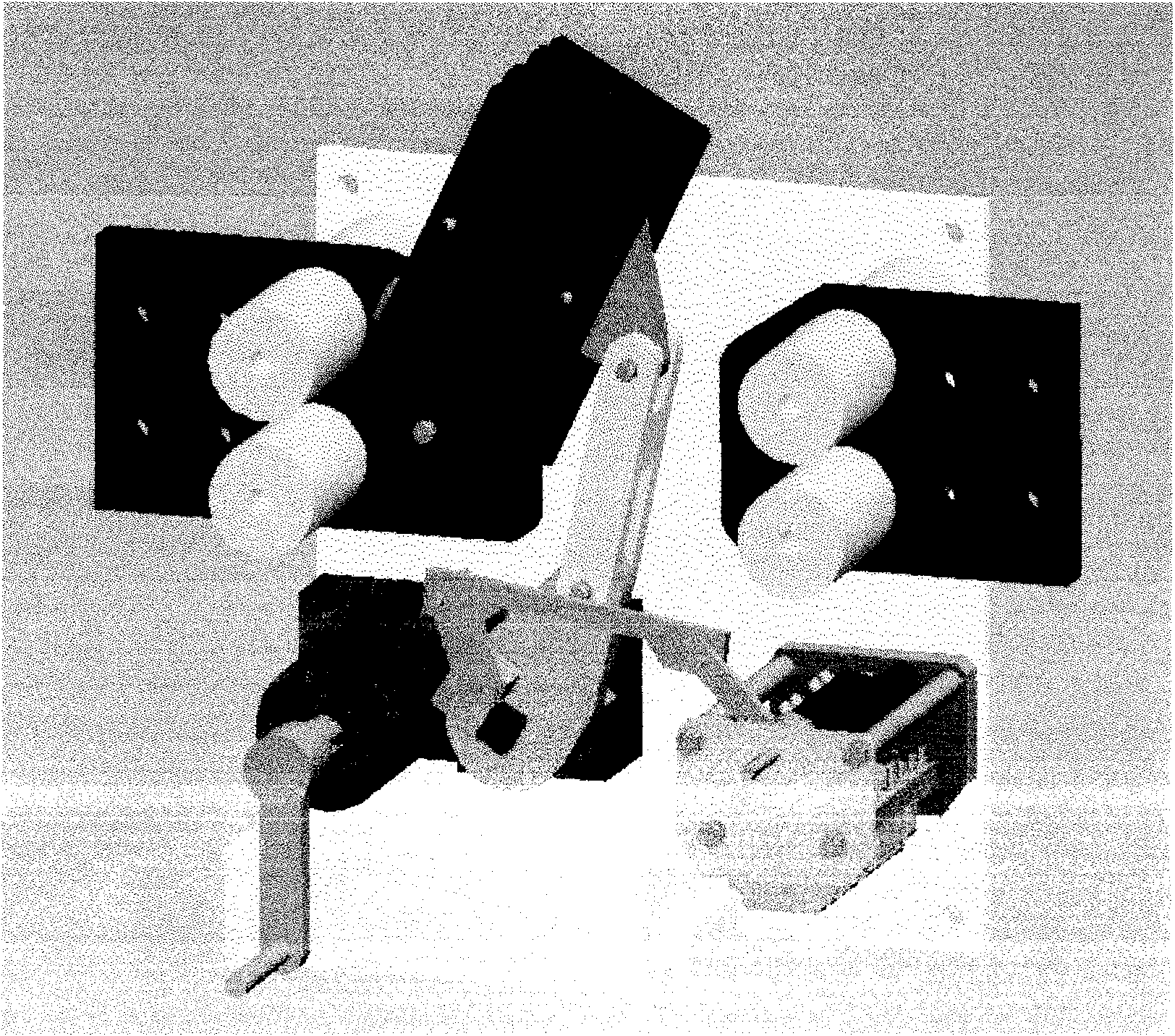

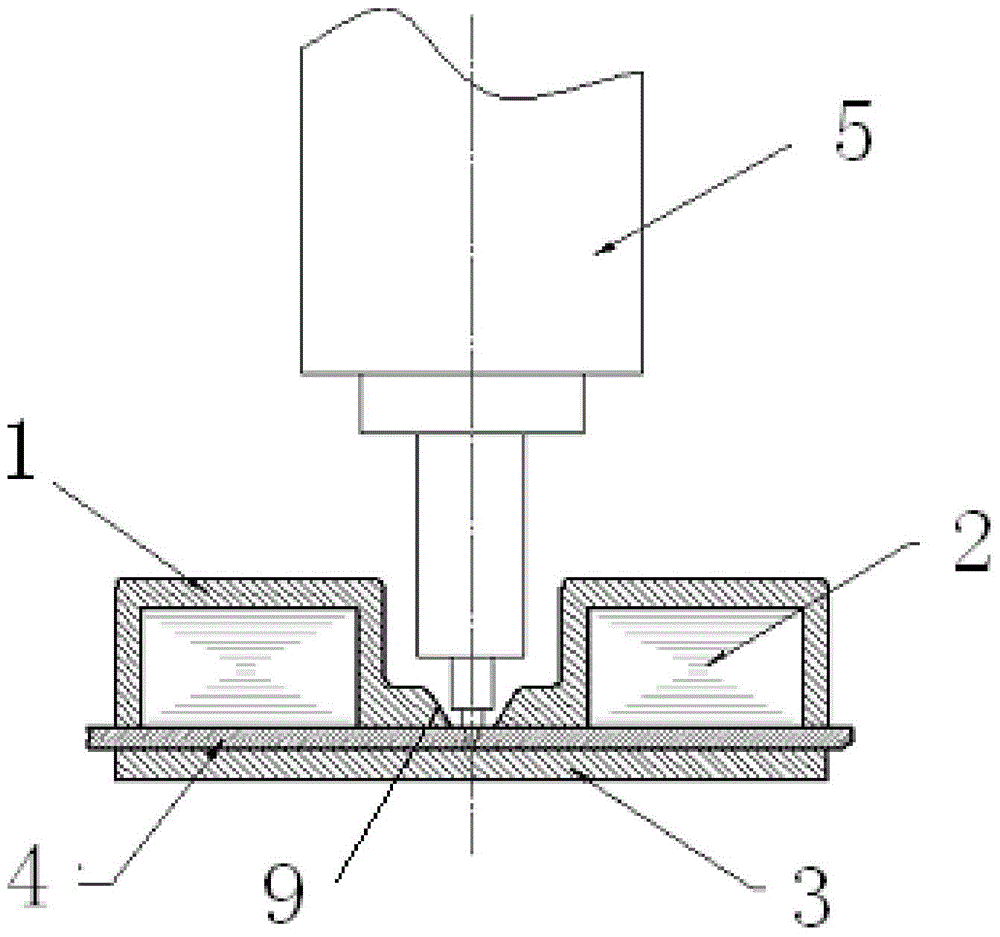

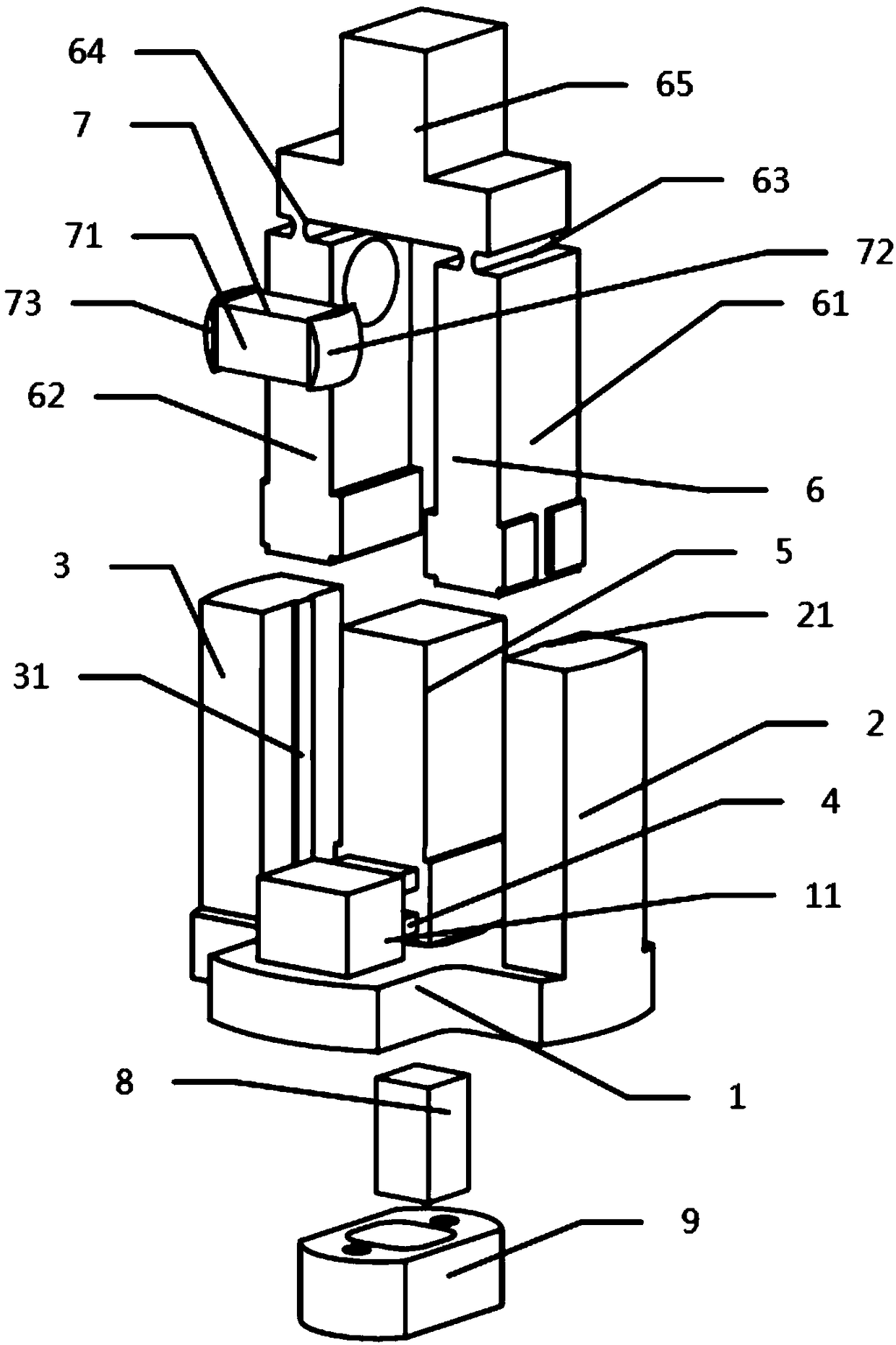

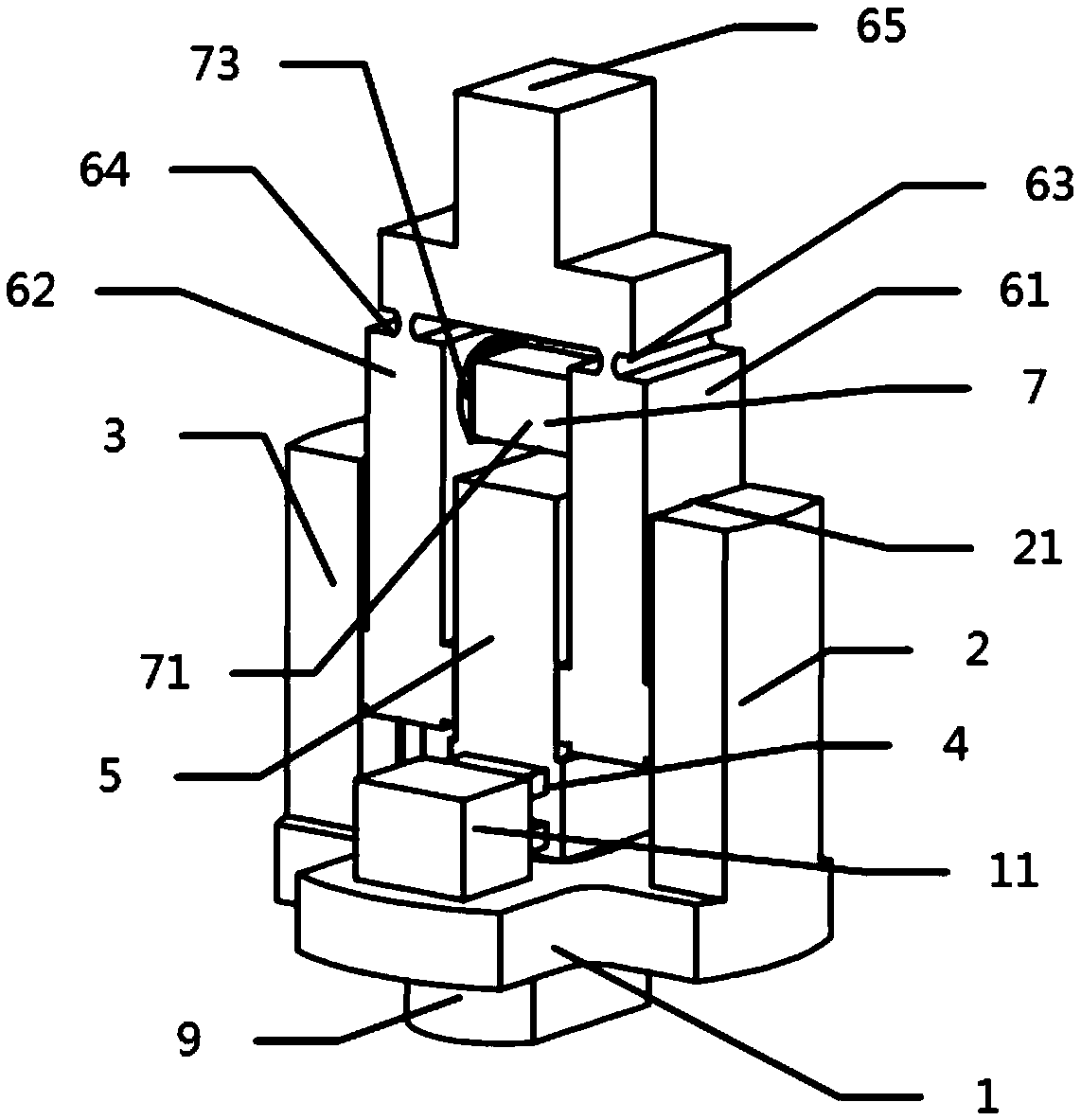

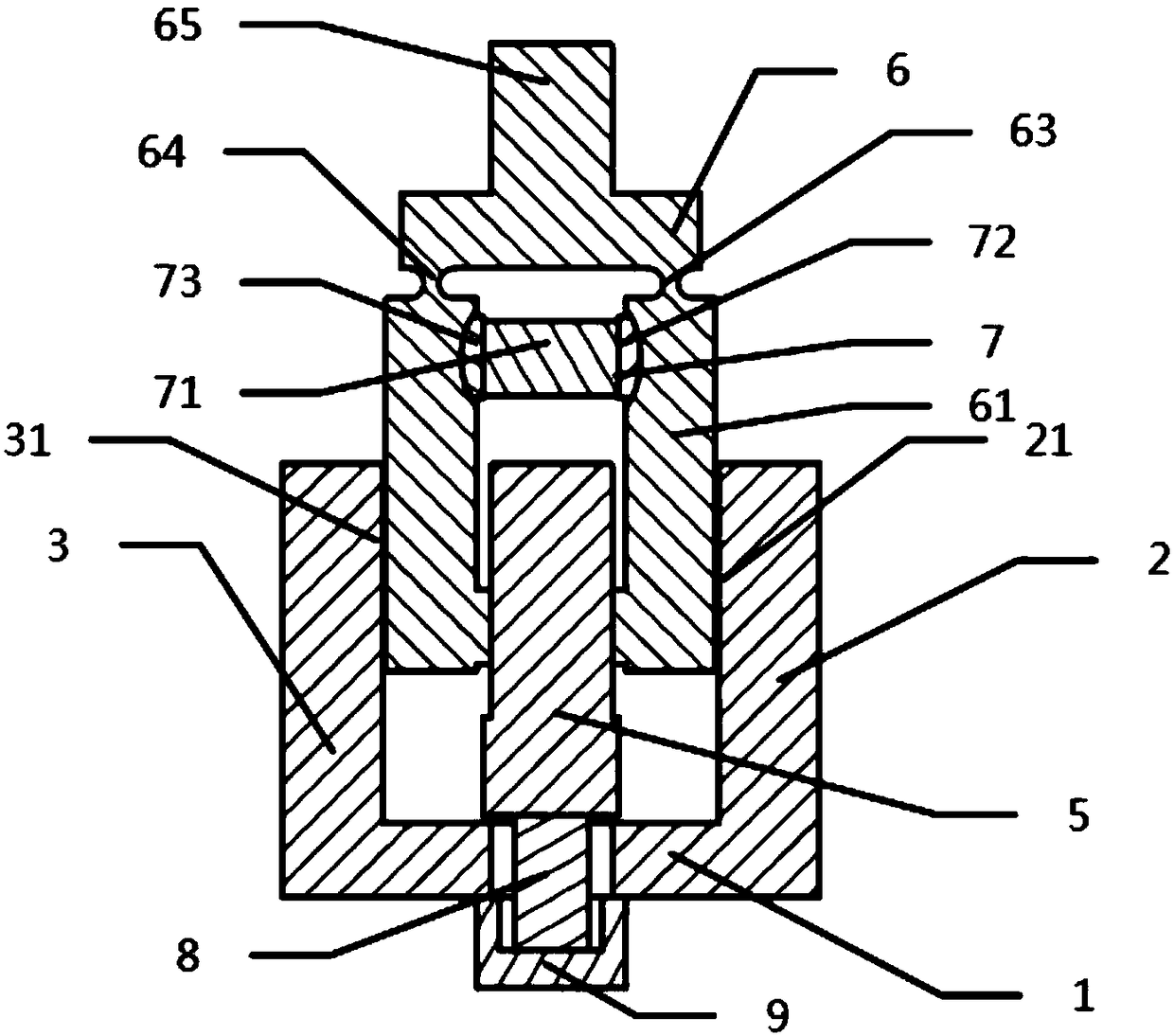

Split knotter

InactiveCN101953259ALower replacement costsReduce manufacturing costsHarvestersBalingDrive shaftEngineering

The invention relates to a split knotter which belongs to the field of agricultural mechanical equipment. A drive shaft is installed in a shaft hole I of a main installation frame; a rope clamping drive mechanism and a split drive disk mechanism are coaxially installed at both ends of the drive shaft; a cam swinging rod is installed on a shaft hole III of the main installation frame, and the cam swinging rod and the split drive disk mechanism form a cam mechanism; the rope clamping mechanism and a rope clamping right helical gear are coaxial and are installed on a shaft hole V of the main installation frame; a rope clamping left helical gear is installed on a shaft hole VI of the main installation frame; an olecranon intermittent gear and an olecranon tongue are axially connected with an olecranon shaft respectively and installed on a shaft hole II of the main installation frame; and the olecranon tongue and the main installation frame form a small cam mechanism. Key mechanisms of the invention are formed by combining split parts, thereby reducing the processing deformation of integrated parts and the manufacture and maintenance cost of a press baler, being beneficial to the adjustment of relative positions during assembly, overcoming the defect of replacing the whole part due to the damage of a structure, prolonging the service life of the knotter and enhancing the processing strength of the parts.

Owner:CHINA AGRI UNIV

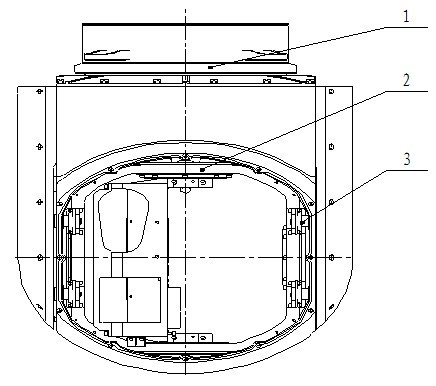

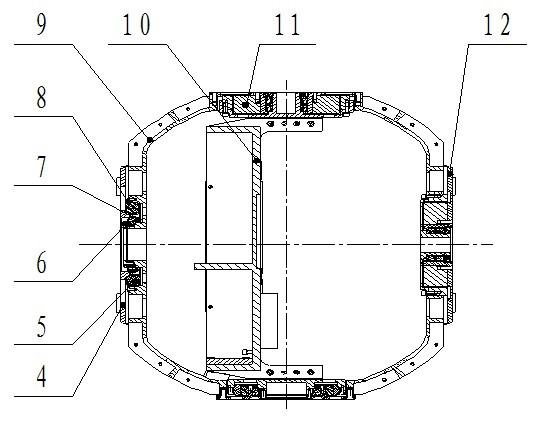

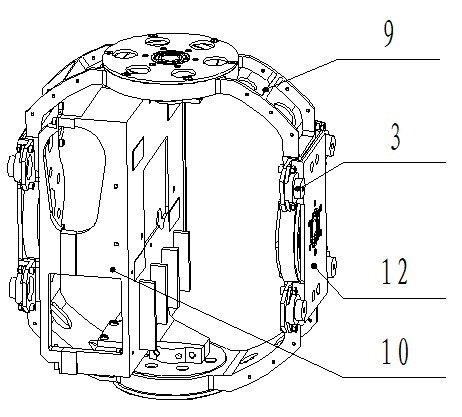

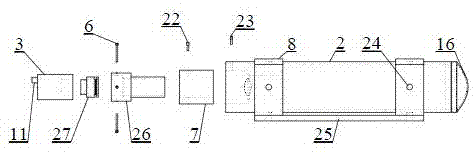

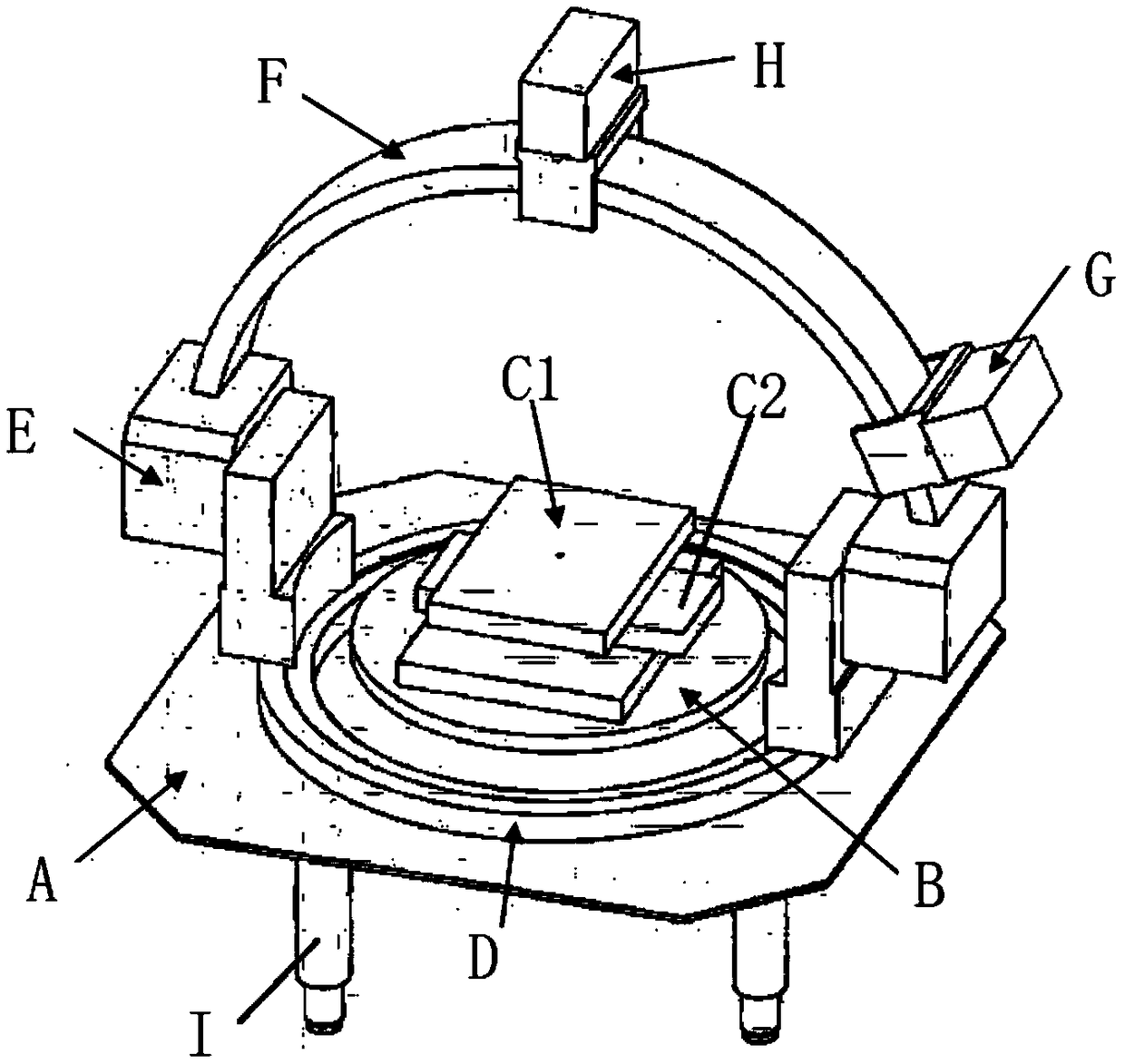

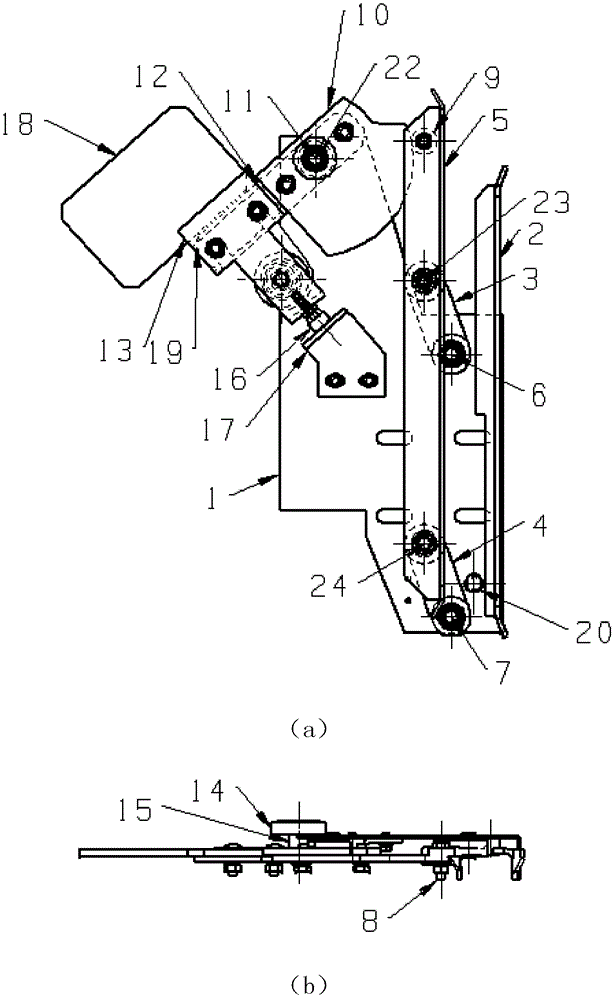

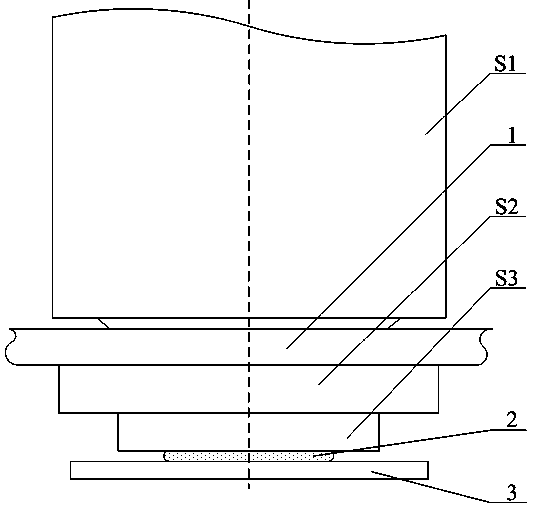

Photoelectric stable platform

InactiveCN102155517AOutstanding FeaturesHighlight significant effectNon-rotating vibration suppressionIsolation effectImaging quality

The invention relates to a photoelectric stable platform, which has a vibration-isolating inner ring and a plurality of frames. The photoelectric stable platform comprises an outer ring frame, an inner ring frame and an even number of vibration isolators of the same specifications, wherein various sensors are placed on the inner ring frame; and the vibration isolators are symmetrically installed relative to the centre of mass of the integration of the inner ring frame in which the various sensors which are installed. The invention has the advantages that: an isolation effect of the photoelectric stable platform on external interference is good; imaging quality and stabilization precision are high; the photoelectric stable platform is small in size, light in weight, large in bearing capacity, and convenient for assembly and disassembly; the weight of the platform can be reduced effectively; the assembly of the photoelectric stable platform can be adjusted quickly and conveniently according to requirements; and the photoelectric stable platform is characterized by simple structure, wide application range and the like.

Owner:武汉华中天经通视科技有限公司

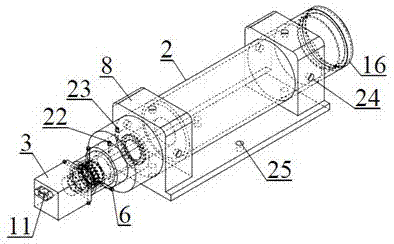

Laser demarcation device calibration system

InactiveCN103499355AReduce the impactEasy to assemble and adjustReference line/planes/sectorsMachine visionSmall footprint

The invention provides a laser demarcation device calibration system which comprises a base, a support and eight sampling light tubes. The support is fixed on the base, the sampling light tubes are fixed on the support, each sampling light tube comprises a collimator, a digital camera, a lens positioning sleeve and a light tube sleeve, each collimator is fixed on the support through the corresponding light tube sleeve, each lens positioning sleeve is fixed on the corresponding collimator, each digital camera is connected with the corresponding lens positioning sleeve sequentially through an interface converting member and a lens sleeve, and a USB (universal serial bus) interface is arranged at the front end of each digital camera. The laser demarcation device calibration system is combined with technology of light tube small angle measuring, machine vision measuring, data fusion and the like to perform accuracy detection and calibration on a laser demarcation device, and detection results can be quantified, stored and subjected to database creating management. The laser demarcation device calibration system is convenient to assemble and disassemble, simple to calibrate and small in occupied area, damage of laser to human eyes can be greatly reduced, workload of personnel can be reduced, influences of subjective factors of human beings can be avoided, and efficiency and accuracy of detection and calibration are improved.

Owner:WUHAN UNIV

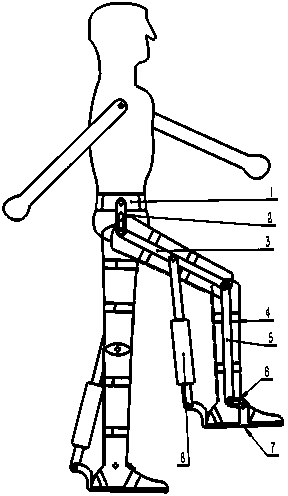

Walking device assisting in walking upstairs and walking downstairs

ActiveCN104000708AAchieve coordinated movementStable structure and performanceWalking aidsHuman bodyThigh

The invention discloses a walking device assisting in walking upstairs and walking downstairs. The device comprises a waist supporting element, a sliding groove lifting belt, a thigh rod, a shank rod, an ankle sliding groove rod, a foot element, a compressed spring energy-storing telescopic rod and a bandage. The device solves the problem that it is difficult for elder people to go upstairs and downstairs and walk, and has the functions of correcting walking postures and coordinating motions for middle aged and elderly people with physical structure disfigurement and moving in an uncoordinated mode. According to the device, the waist supporting element, the thigh rod, the shank rod, the foot element and the compressed spring energy-storing telescopic rod serve as supports and are connected through the sliding groove lifting belt and the ankle sliding groove rod to achieve coordinated moving among the rods. The bandage serves as a component and is used for fixing a human body to achieve mutual force application and mutual help. The walking device has the advantages of being simple, light, economical, practical, environmentally friendly, stable in structure performance, good in adjustability, convenient to assemble and adjust and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Concentric double-layer sprayer

The invention provides a concentric double-layer sprayer, which has a hollow sleeve shape, wherein one end of the sprayer is provided with a medium inlet, and the other end of the sprayer is closed; a nozzle is arranged on a side wall of the sprayer and is a gap which is annularly formed along the circumference of the sprayer; and a secondary nozzle is arranged on the side wall of the sprayer along the length direction. The concentric double-layer sprayer is a novel sprayer suitable for a spraying device and is used for putting out a fire, diluting and covering leakage media and the like under temperature reduction, dust removing or emergency of equipment. A double-injection cavity and dual nozzles are arranged on the sprayer, so that concentric double-layer spraying is realized, and the aim of replacing or optimizing the sprayer of the spraying system is fulfilled. The sprayer has a wide spraying range; the spraying angle is adjustable, and different spraying angles and ranges on each layer can be realized; the concentric double-layer sprayer has the characteristics of large density of sprayed water mist, high water flow, and simple structure, is convenient to install and regulate, has an antifouling design and is hardly blocked, and the concentric double-layer sprayer is high in operating maintenance, attractive in spray appearance, and particularly suitable for overall coverage of large and medium equipment and devices.

Owner:SICHUAN MEIFENG CHEM IND

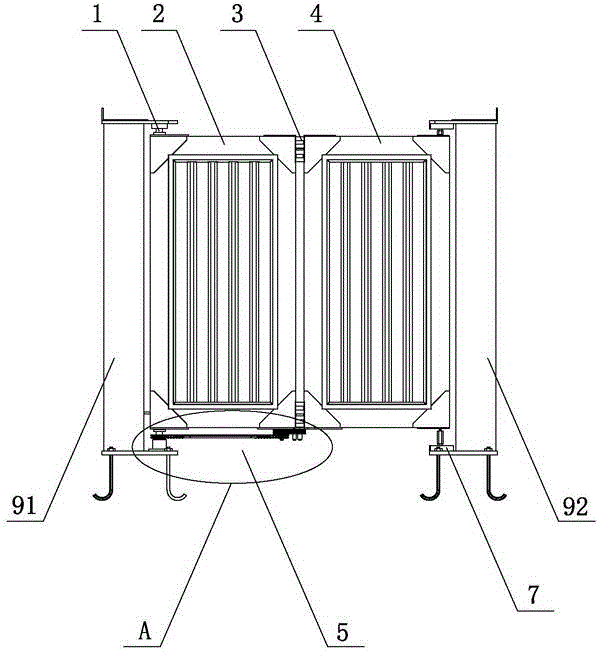

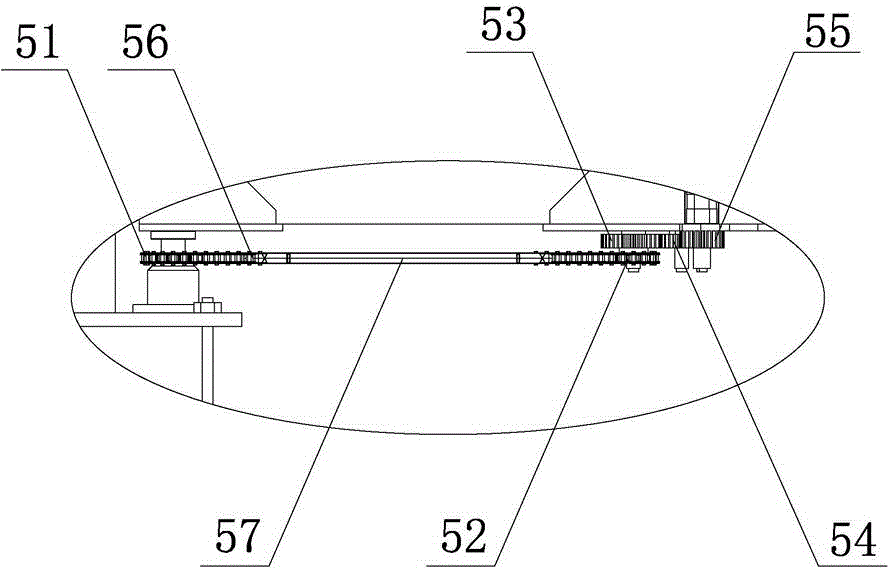

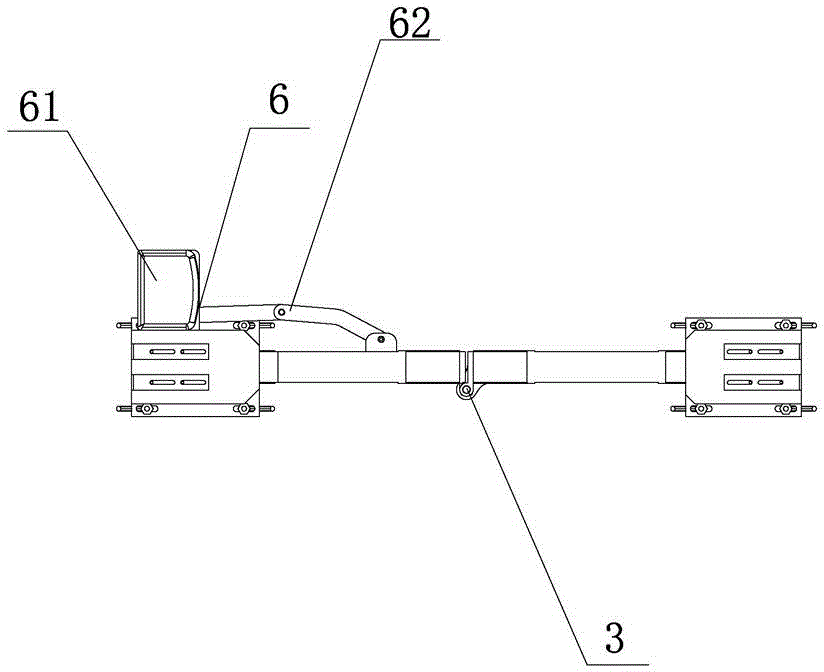

Folding door with linkage folding mechanism

ActiveCN104832077AEasy to processEasy to assemble and adjustGates/doorsPower-operated mechanismDrive wheelMachine parts

The invention discloses a folding door with a linkage folding mechanism. The folding door comprises at least one movable unit. Each movable unit comprises a door shaft, a driving door leaf, a connecting shaft, a driven door leaf and a linkage mechanism, one end of each driving door leaf is hinged to the corresponding door shaft, the other end of each connecting shaft is hinged to the corresponding driven door leaf, each linkage mechanism comprises a first chain wheel, a second chain wheel, a chain, a driving wheel, a transmission wheel set and a driven wheel, each first chain wheel is fixedly and coaxially connected with the corresponding door shaft, each second chain wheel and the corresponding driving wheel are coaxially arranged at the portion, close to the corresponding connecting shaft, of the corresponding driven door leaf, each first chain wheel and the corresponding second chain wheel are connected in a fastened mode through the corresponding closed chain, each driven wheel and the corresponding connecting shaft are coaxially and fixedly connected, each transmission wheel set comprises multiple straight gears meshed with the corresponding driving wheel and the corresponding driven wheel. Due to the fact that power is transmitted through chain wheel sets of the chain wheel mechanisms, the chain wheels can be directly attached to the upper sides or the lower sides of the driving door leaf, and the folding door has the advantages of being attractive, elegant, strong in associative perception, simple and reasonable in structure, capable of easily machining parts and accessories and the like.

Owner:佛山市圣田智能科技有限公司

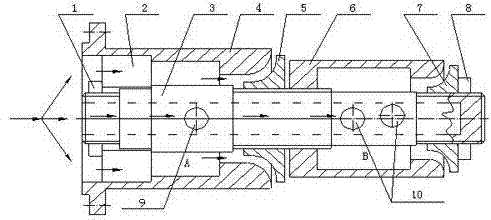

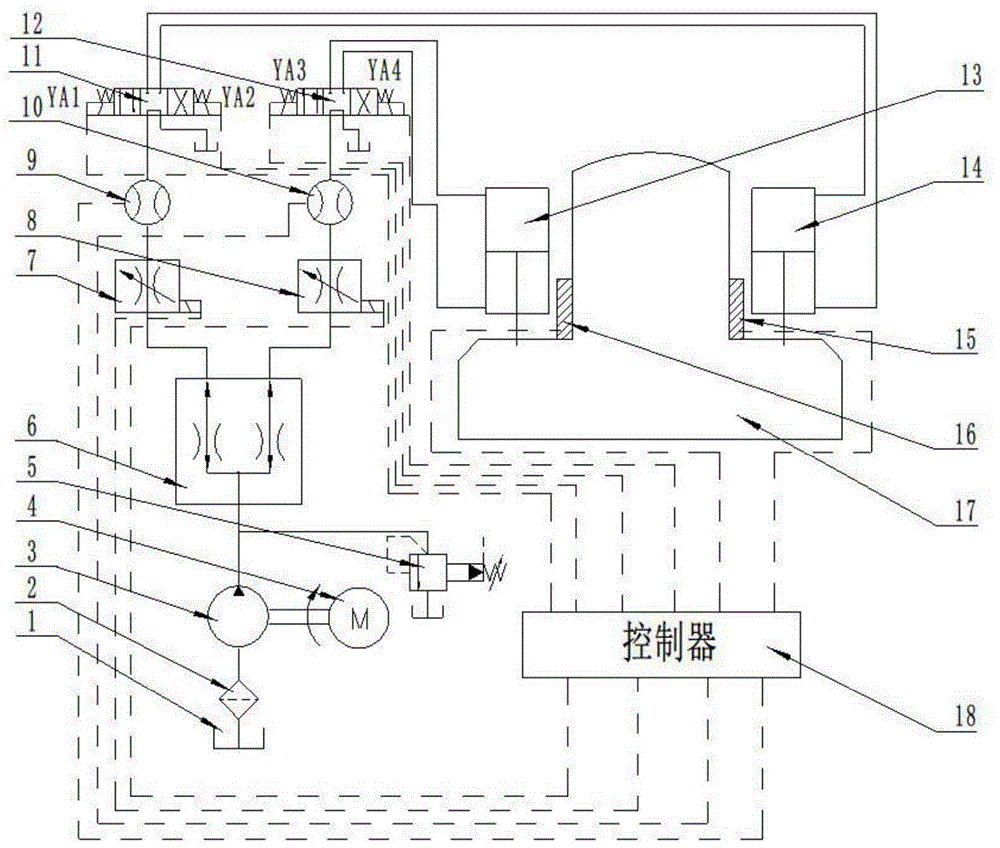

Sliding block balance electro-hydraulic servo synchronous control system of bending machine

ActiveCN104405733ASimple structureEasy assembly and adjustmentServomotor componentsServomotorsHydraulic cylinderSynchronous control

The invention discloses a sliding block balance electro-hydraulic servo synchronous control system of a bending machine. An oil tank is connected with a filter; the filter is connected with a quantitative hydraulic pump; the shaft end of the quantitative hydraulic pump is connected with a motor; the pump port of the quantitative hydraulic pump is connected with an inlet pipe of a diverter valve; and the system further comprises two electromagnetic speed regulating valves connected with two oil outlets of the diverter valve, first and second flow meters mounted on two branch oil pipes, two electromagnetic reversing valves mounted on two branches, hydraulic cylinders mounted at the two sides of the upper side of a sliding block, grating ruler displacement sensors arranged at the two sides of the sliding block, a programmable logic controller PLC with a PID adjusting function, a power supply and the like. The system is reasonable in design and simple in assembly and regulation, can realize synchronous vertical movement of the two ends of the sliding block, is excellent in balance, and has the characteristics of strong unbalance loading resistance and high control precision.

Owner:JIANGSU UNIV

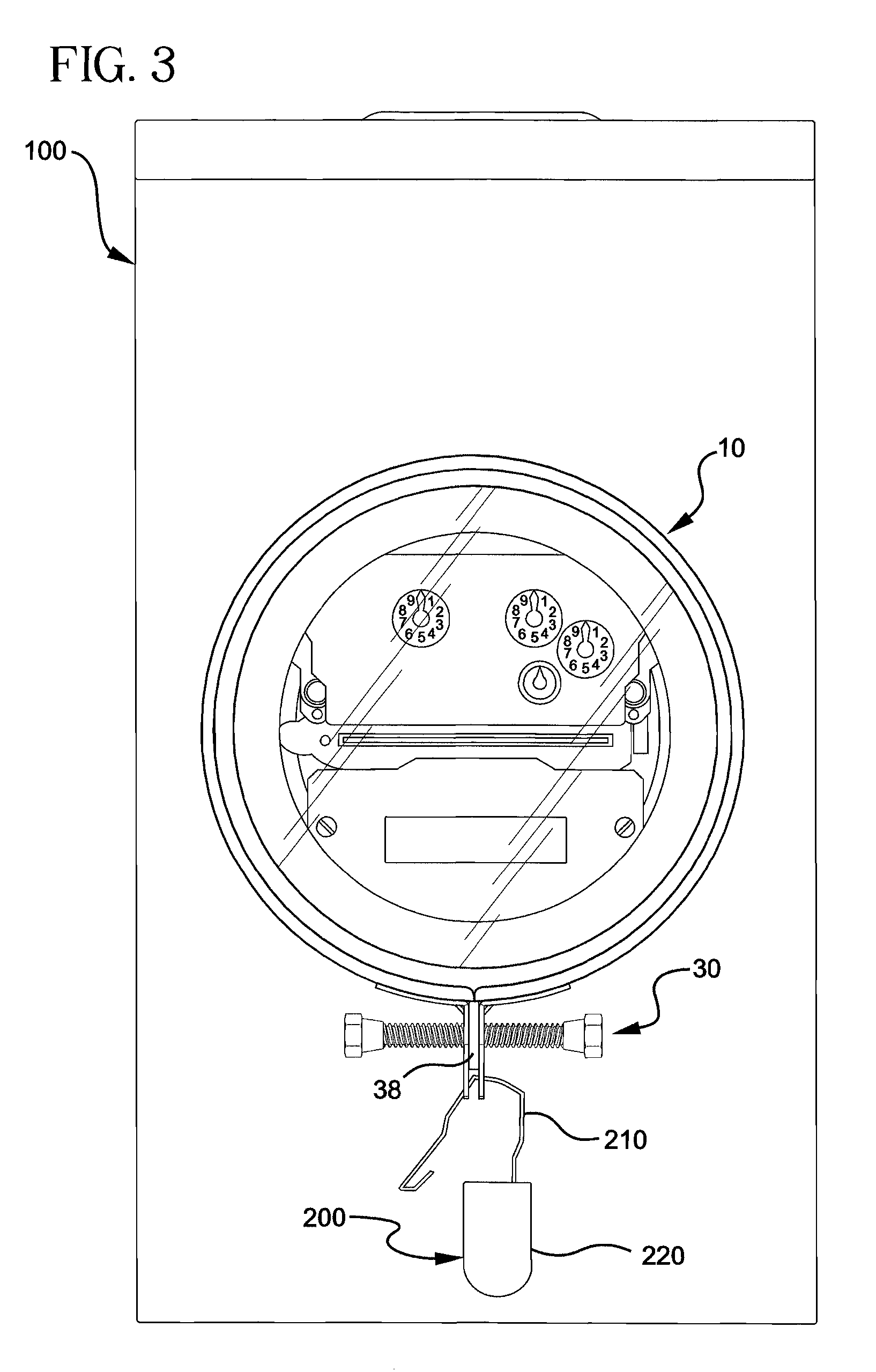

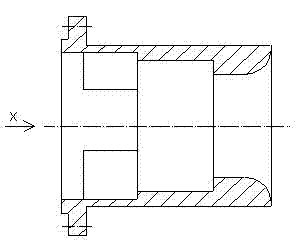

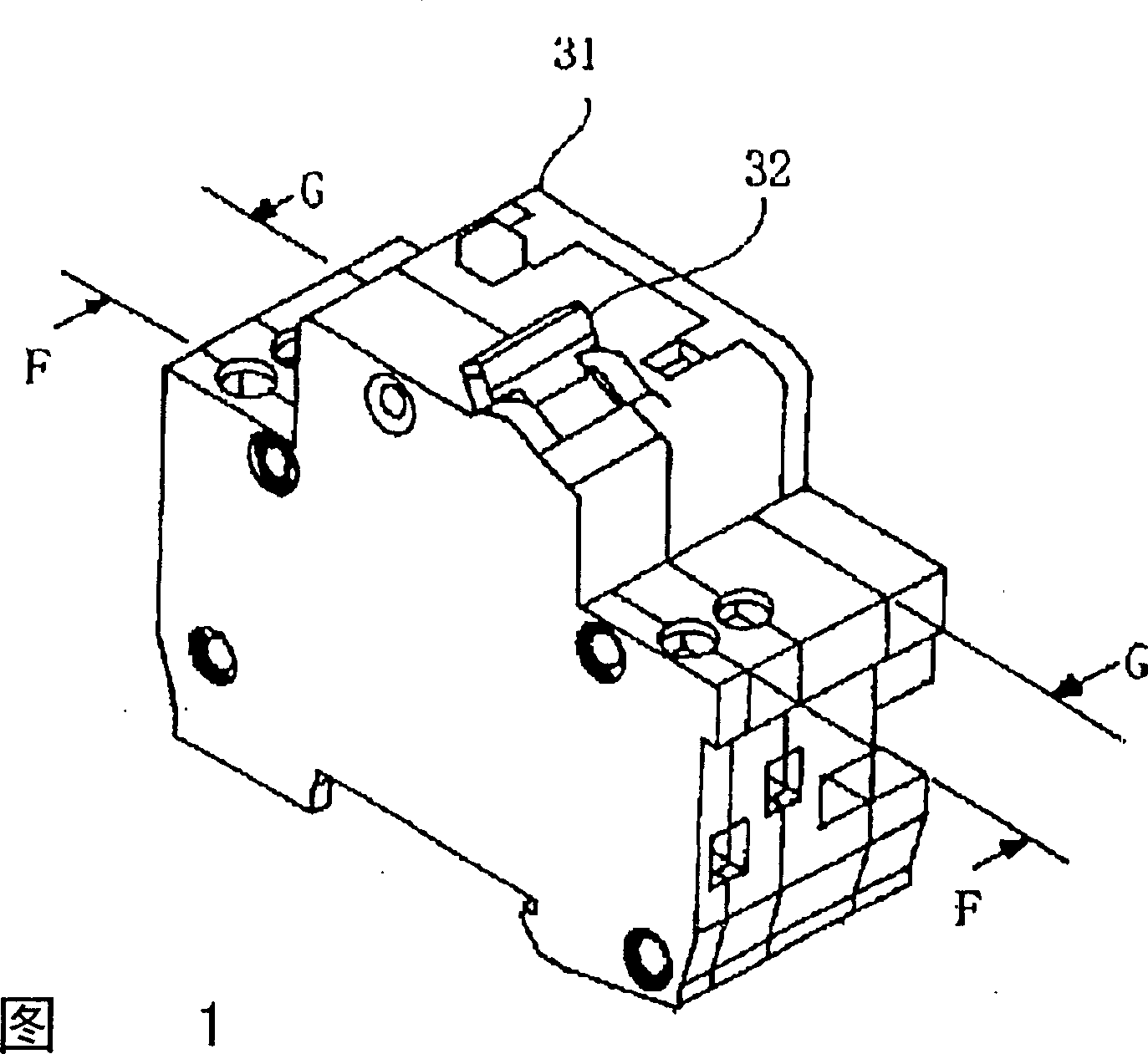

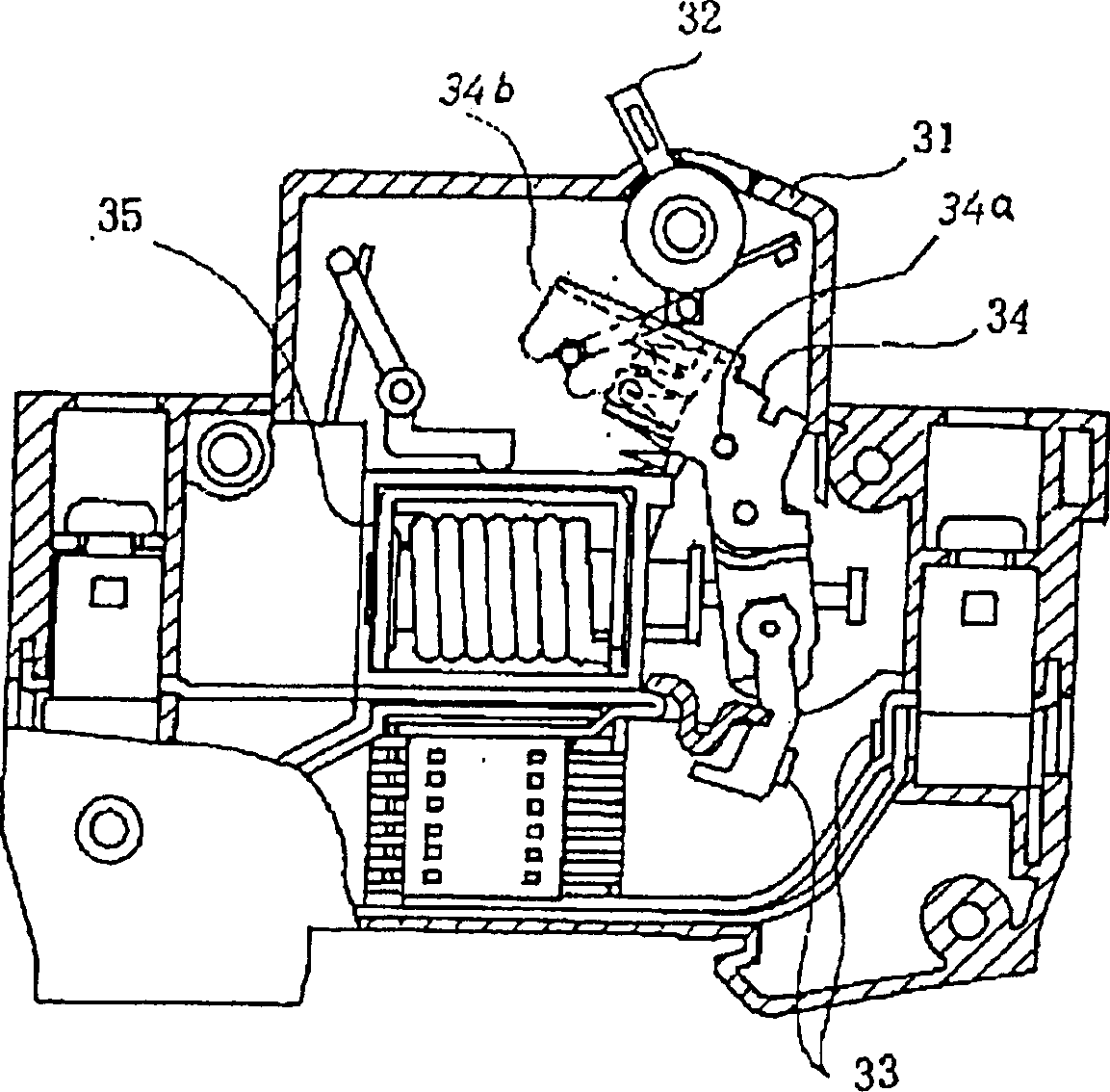

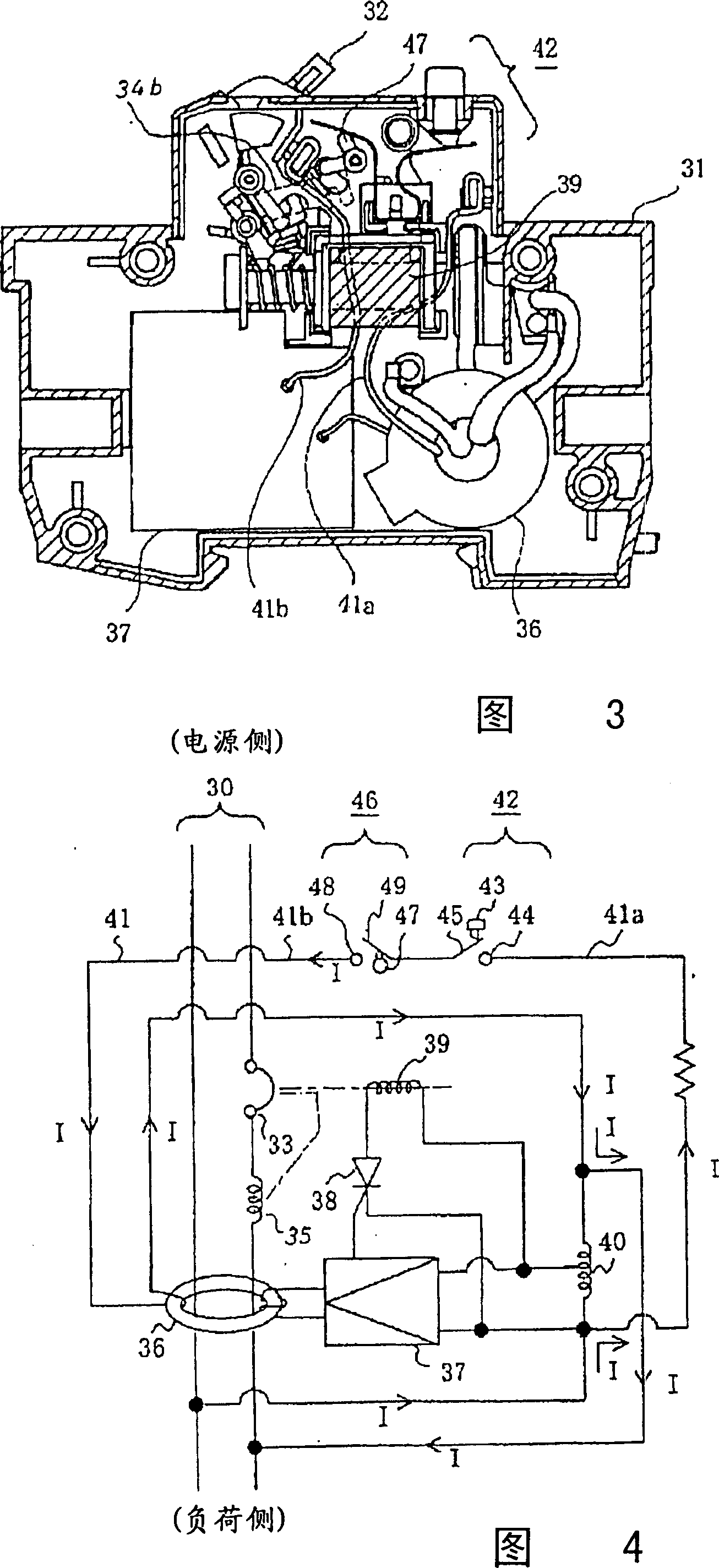

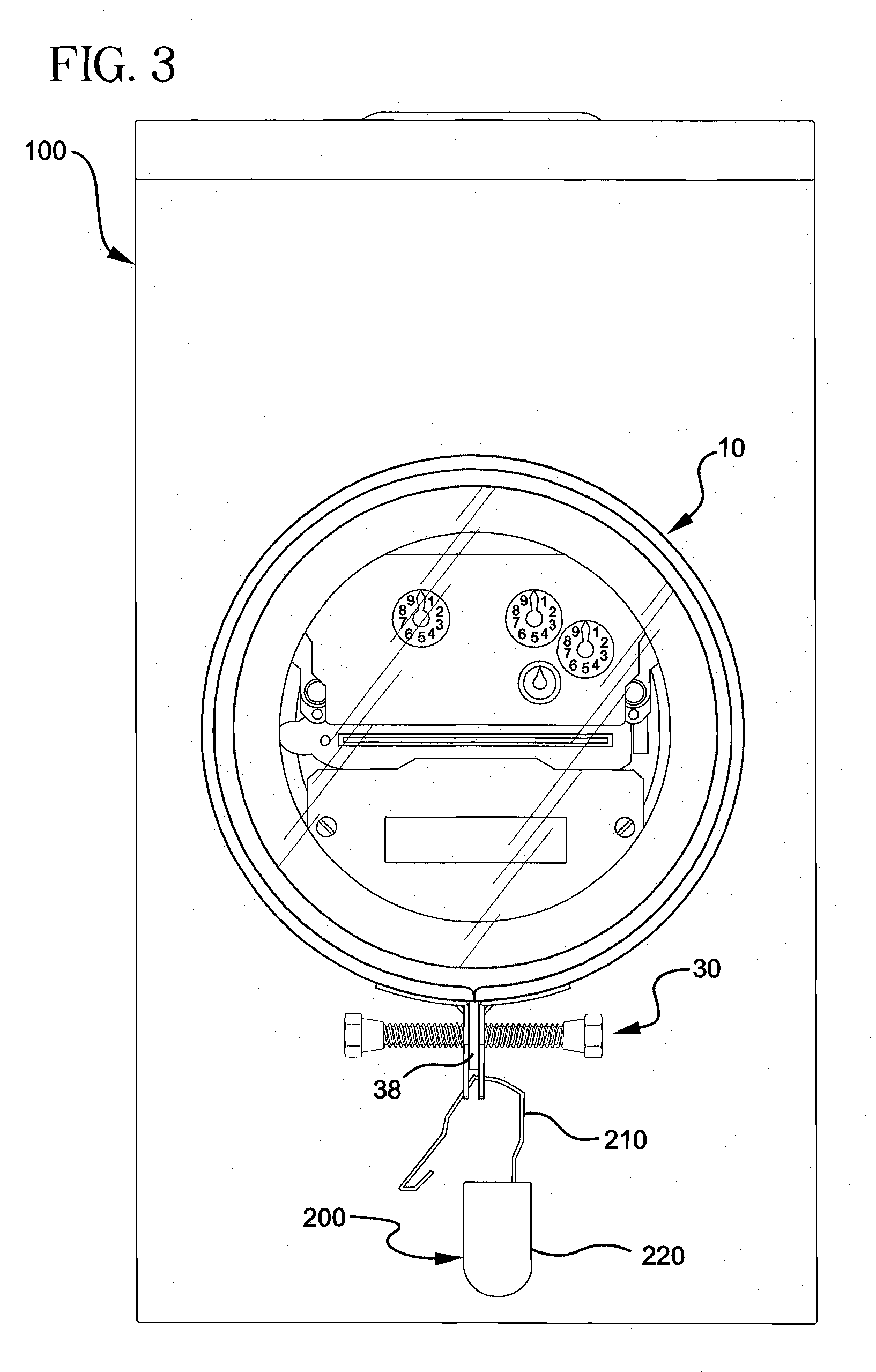

Leakage breaker

InactiveCN1400619ASimple structureEasy assembly and adjustmentSwitch operated by current/voltage unbalanceSwitch operated by earth fault currentsLeakage testDrain current

A ground-fault circuit interrupter of a simple structure and easy to assemble and adjust, can surely make an operation check without making the size larger, and will not have a protection coil damaged even if a test button is kept pushing at the operation check test. The ground-fault circuit interrupter is provided with a test circuit 41 passing dummy leak current to a zero-phase current transformer 36 with one end wound around the zero-phase current transfer 36 and the other end connected to a main circuit 30, a leakage test switch 42 connected in the test circuit 41 and making an operation check of a ground-fault circuit interrupter by putting on and off dummy leakage current flowing in the test circuit 41, and a series switch 46 connected in series with the leakage test switch 42 and put on and off according to on / off and trip operations oft the ground- fault circuit interrupter, and it is so arranged that dummy leakage current shall not flow in the test circuit 41 when the ground-fault circuit interrupter is in the off or trip state, even if the leakage test switch 42 is operated.

Owner:MITSUBISHI ELECTRIC CORP

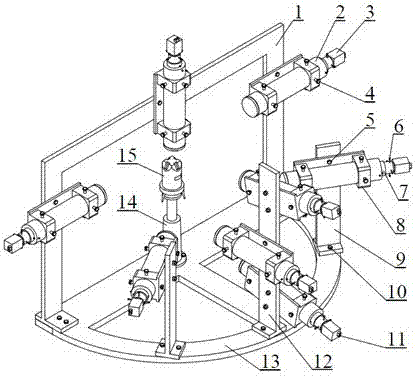

Three-dimensional universal full-angle optical measurement platform for space optical remote sensor

The invention discloses a three-dimensional universal full-angle optical measuring platform for a space optical remote sensor, comprising a stable platform, a lifting platform, a translation platform,an azimuth circular guide rail, a pitching arm, a rolling guide rail, a light source moving platform, and a detector moving platform. The lifting platform and the azimuth circular guide rails surrounding the lifting platform are mounted on the stable platform. The lifting platform is provided with the translation platform which comprises a stacked X-direction and Y-direction translation platform.A pair of pitching arms are mounted symmetrically and slidably on the azimuth circular guide rail. The two pitching arms are erected with the rolling guide rail which has a semicircular structure. Alight source moving platform and a detector moving platform are slidably mounted on the rolling guide rail. In the process of measurement, assembly and calibration, a tested instrument is placed on the translation platform, and independent changes in seven variables such as the three-dimensional coordinates of the position of the tested instrument, the incident azimuth angle and the zenith angle of the light source, and the receiving azimuth and zenith angle of the detector are achieved by an automatic control system and an actuator. The function of the platform is easy to expand and has highpracticability.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

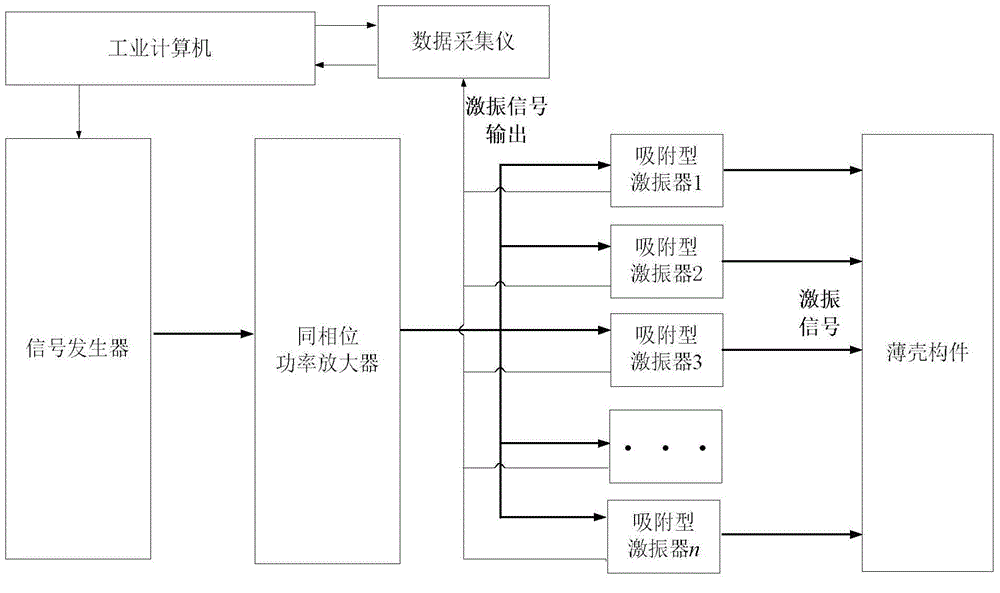

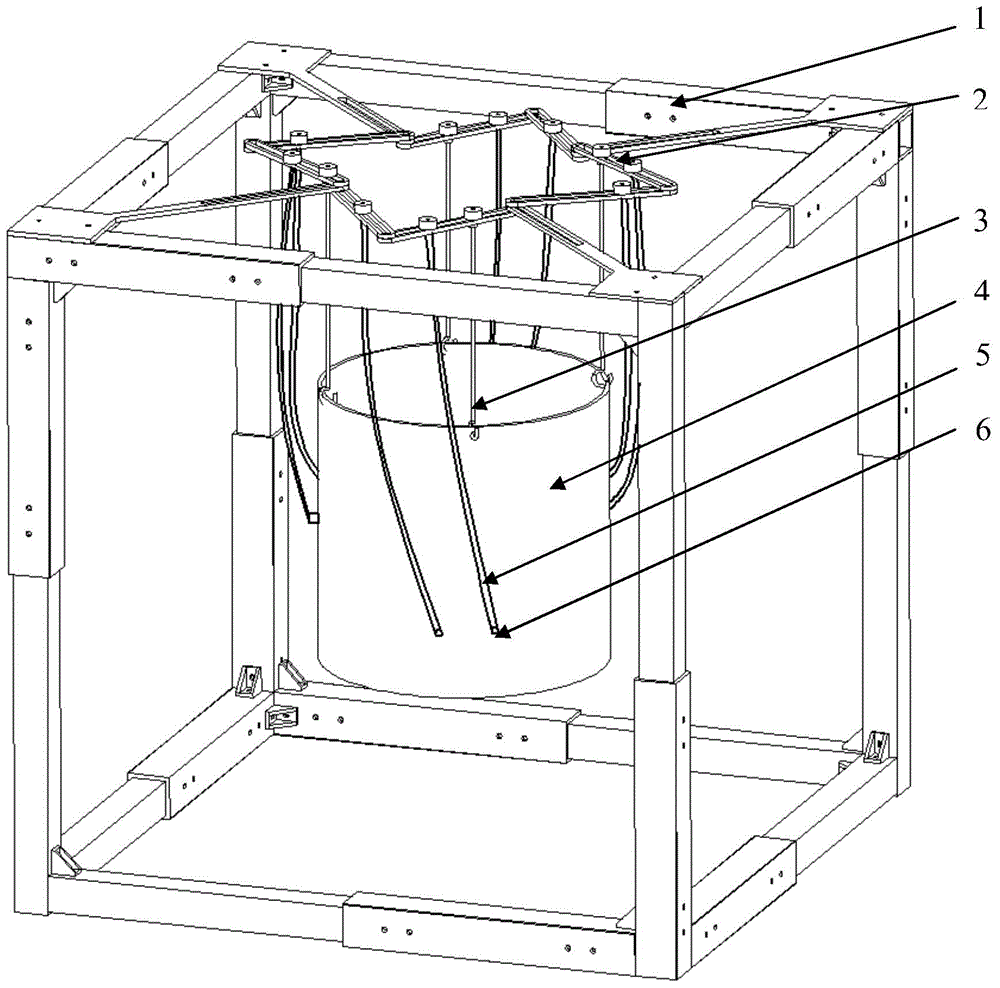

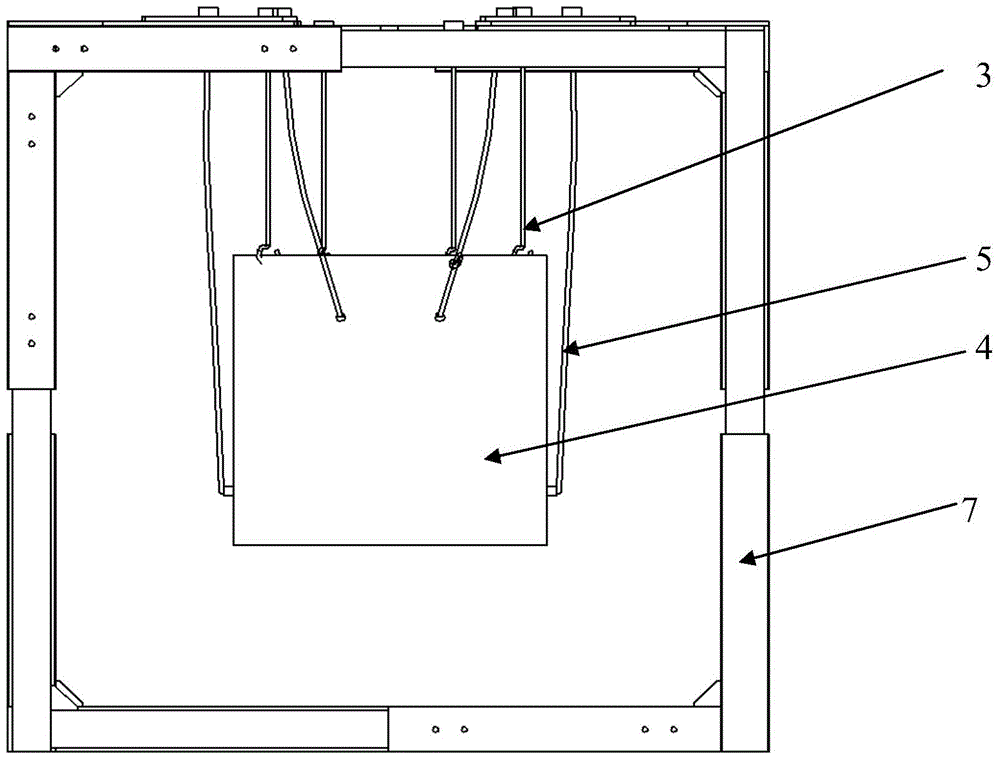

Synchronous excitation system used for thin shell high-order modal shape test and test method

InactiveCN105043698AEasy to processEven energy distributionVibration testingThin shellsData acquisition

The invention provides a synchronous excitation system used for a thin shell high-order modal shape test and a test method. The system comprises an industrial computer, a signal generator, an in-phase power amplifier, adsorption type vibration exciters and a data acquisition instrument. The output end of the industrial computer is connected with the input end of the signal generator. The output end of the signal generator is connected with the input end of the in-phase power amplifier. The output end of the in-phase power amplifier is respectively connected with the input ends of the adsorption type vibration exciters. The adsorption type vibration exciters absorb on the side wall of a thin shell component. Excitation signals outputted by the adsorption type vibration exciter affect on the side wall of the thin shell component. Meanwhile, the output ends of the adsorption type vibration exciters are connected with the input end of the data acquisition instrument. The data acquisition instrument is connected with the industrial computer. The synchronous excitation system used for the thin shell high-order modal shape test is simple and compact in structure without gap, small in profile, low in cost, high in load capacity and convenient in part processing, and beauty of the overall structure is enhanced and assembling is facilitated so that assembling and adjustment of the system are enabled to be quite convenient.

Owner:NORTHEASTERN UNIV

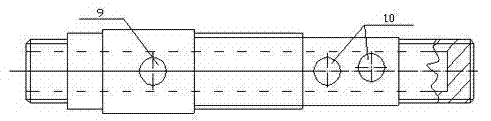

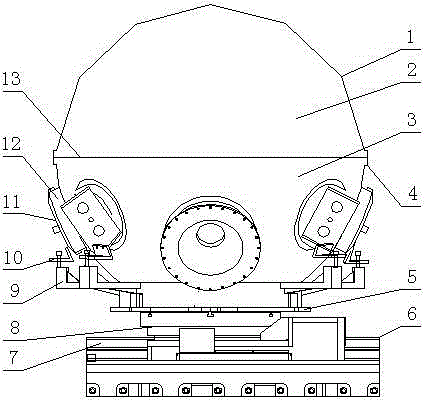

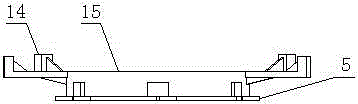

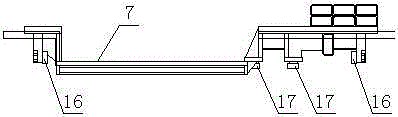

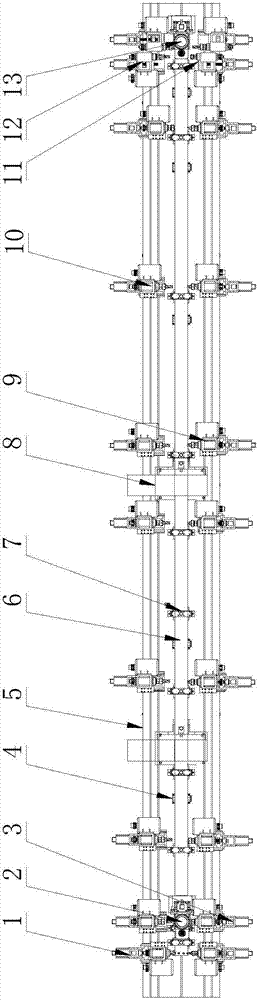

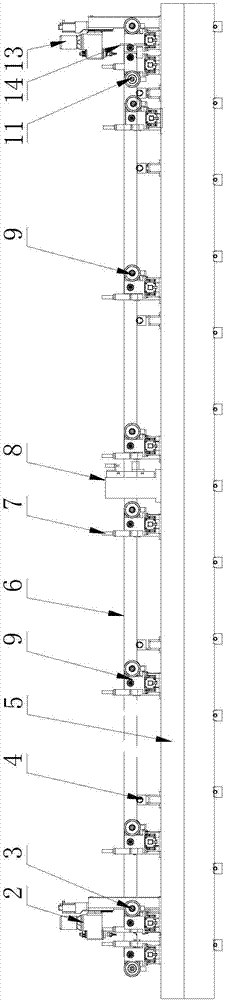

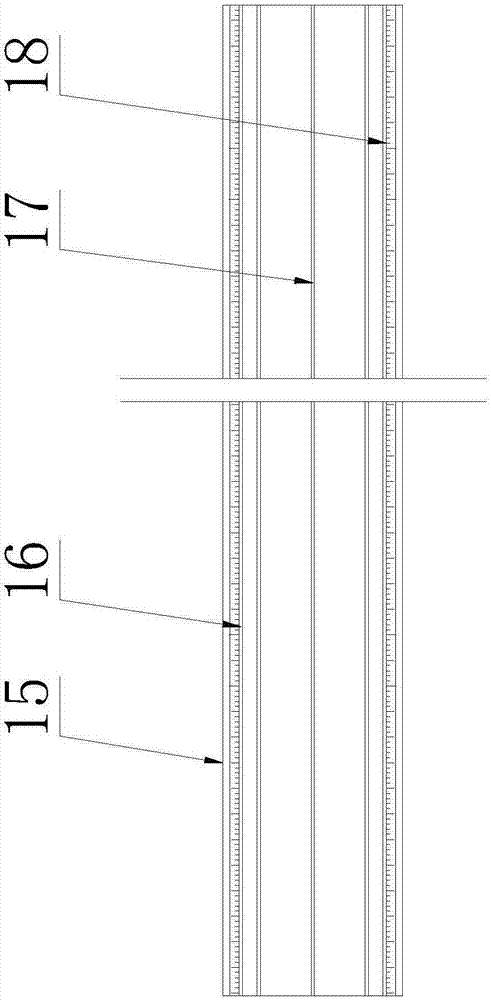

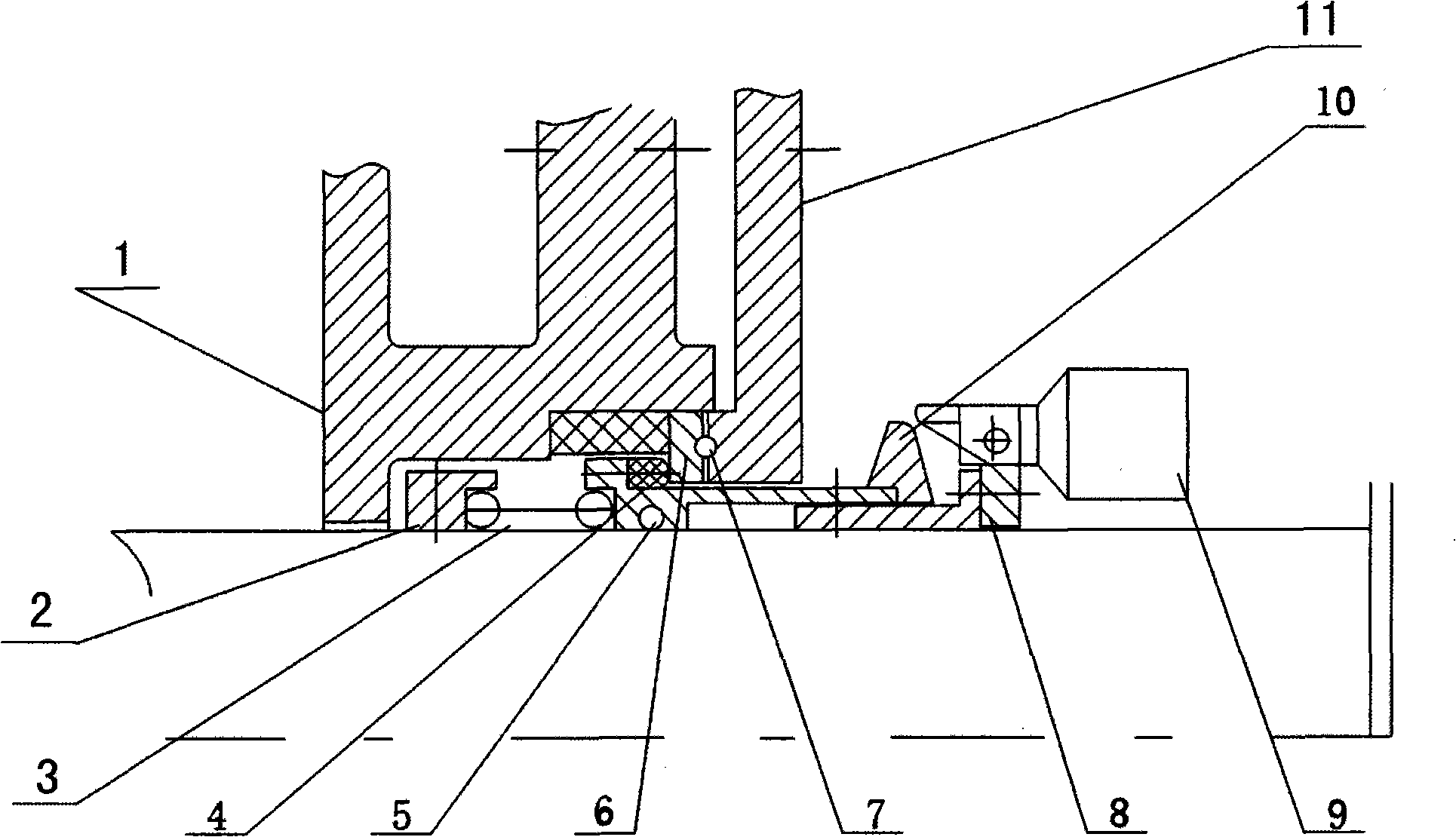

Twisting shaft synchronizing device of bending machine

The invention relates to the technical field of a bending machine, in particular to a twisting shaft synchronizing device of the bending machine. The twisting shaft synchronizing device comprises a synchronous twisting shaft, a swing arm connected with the two ends of the synchronous twisting shaft and a connecting rod connected with the swing arm, wherein one end of the swing arm is movably connected with the synchronous twisting shaft, the other end of the swing arm is movably connected with the connecting rod, a swing arm pier is arranged at the bottom end of the connecting rod, a slider reinforcing rib is arranged below the swing arm pier, and the slider reinforcing rib is arranged at the inner side of a slider and supports the slider. Through the adoption of the structure, the two ends of the synchronous twisting shaft can synchronously move, and the two ends of the slider can synchronously move up and down to meet a balance requirement. Besides, the twisting shaft synchronizing device has the characteristics of reasonability in design, simplicity in assembly and regulation, simplicity and convenience in part processing, improvement on product quality and the like.

Owner:HT METALFORMING EQUIP MFG

Tool clamp for transverse automatic welding of large spherical shell structure and assembling method

ActiveCN106695213AGuaranteed support effectIncrease dimensional processing marginWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a tool clamp for transverse automatic welding of a large spherical shell structure and an assembling method. The tool clamp is characterized by comprising a clamp body; the clamp body comprises a spherical shell and a welding clamp; the spherical shell comprises an upper half spherical shell body and a lower half spherical shell body; an equator welding joint is arranged between the upper half spherical shell body and the lower half spherical shell body; a boss is arranged on the equator welding joint; and the welding clamp comprises a lifting clamp connected with the lower half spherical shell body. The assembling method includes the steps that a platform trolley is loaded to a vacuum chamber guide rail; the lifting clamp is assembled to a rotary table; the lower half spherical shell body is loaded to a supporting cylinder bevel structure of the lifting clamp; a bolt between an L-shaped joint plate and the lifting clamp is synchronously and symmetrically locked; the upper half spherical shell body is assembled to the lower half spherical shell body; the welding position on the boss between the upper half spherical shell body and the lower half spherical shell body is subjected to spot welding through argon arc welding after assembling is completed; and then the welding position in the spherical shell is subjected to spot welding through argon arc welding, and assembling of the upper half spherical shell body and the lower half spherical shell body is completed. By the adoption of the technical scheme, the assembling requirements for welding position precision, welding gaps, welding order differences and the like are met.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

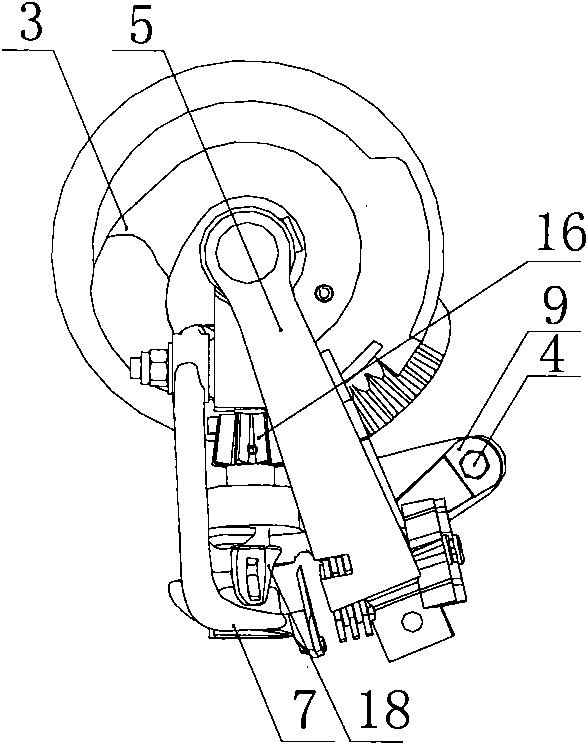

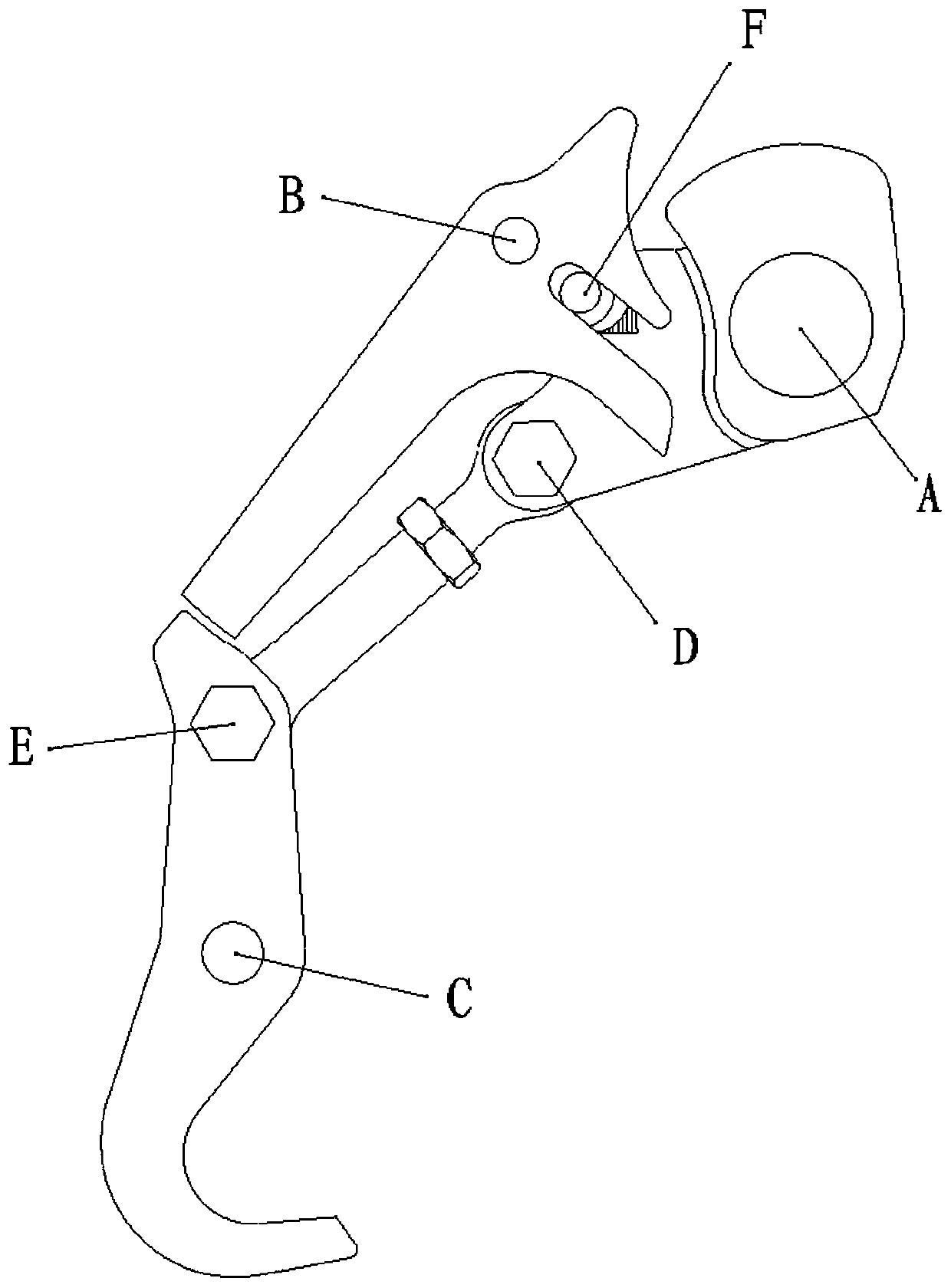

Asynchronous door knife of elevator door machine

ActiveCN102862904AStable output forceMeet the needs of large stroke door openingBuilding liftsEngineeringElectrical and Electronics engineering

The invention discloses an asynchronous door knife of an elevator door machine. The clamping action for a landing door linked door ball is realized through the cooperation of a door knife assembly and a cam device, so that the linkage of a carriage door and the landing door can be realized. The door knife assembly is installed on a movable part, and the cam device is installed on a stationary part. In the closing process for opening and closing the linked door, the door knife assembly clamps the landing door linked door ball, and the asynchronous door knife is self-locked, so that the thrusting force for the landing door linked door ball can be continuously and stably supplied; when the door is about to close, the cam device acts on the door knife assembly, a gap needed by the asynchronous door knife and the landing door linked door ball is formed, and the asynchronous door knife is released; and when the door is completely closed, the door knife assembly is subjected to the cam device and cannot produce the action for clamping the landing door linked door ball, and the gap between the door knife assembly and the landing door linked door ball is reliable. The landing door linked door ball is always clamped by the asynchronous door knife in the door closing process, so that a stable drive force is supplied for a landing door.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

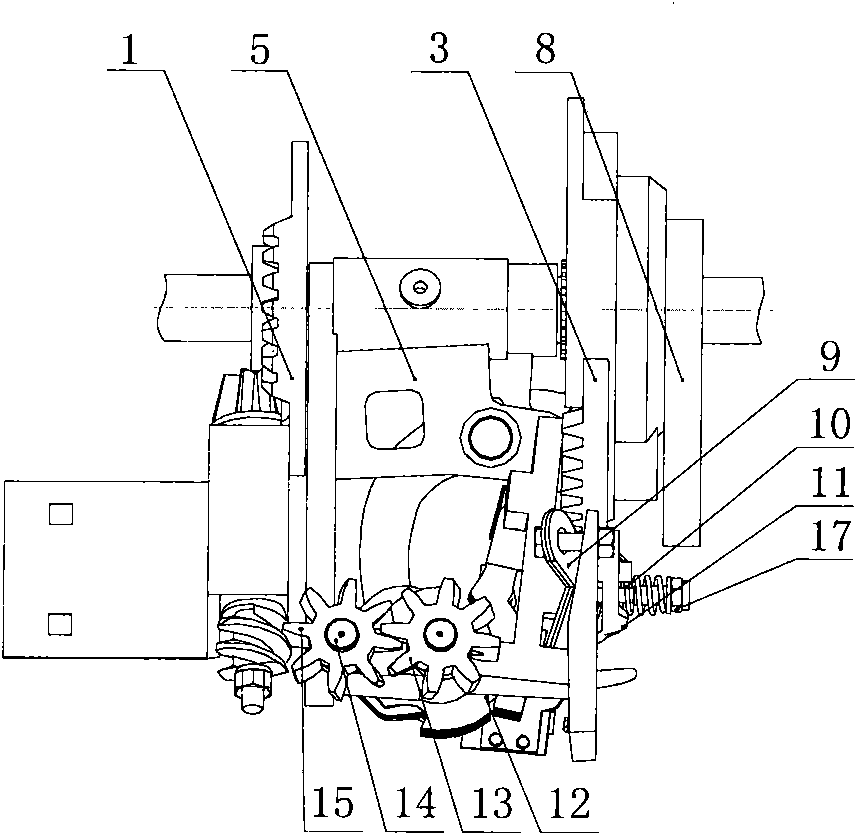

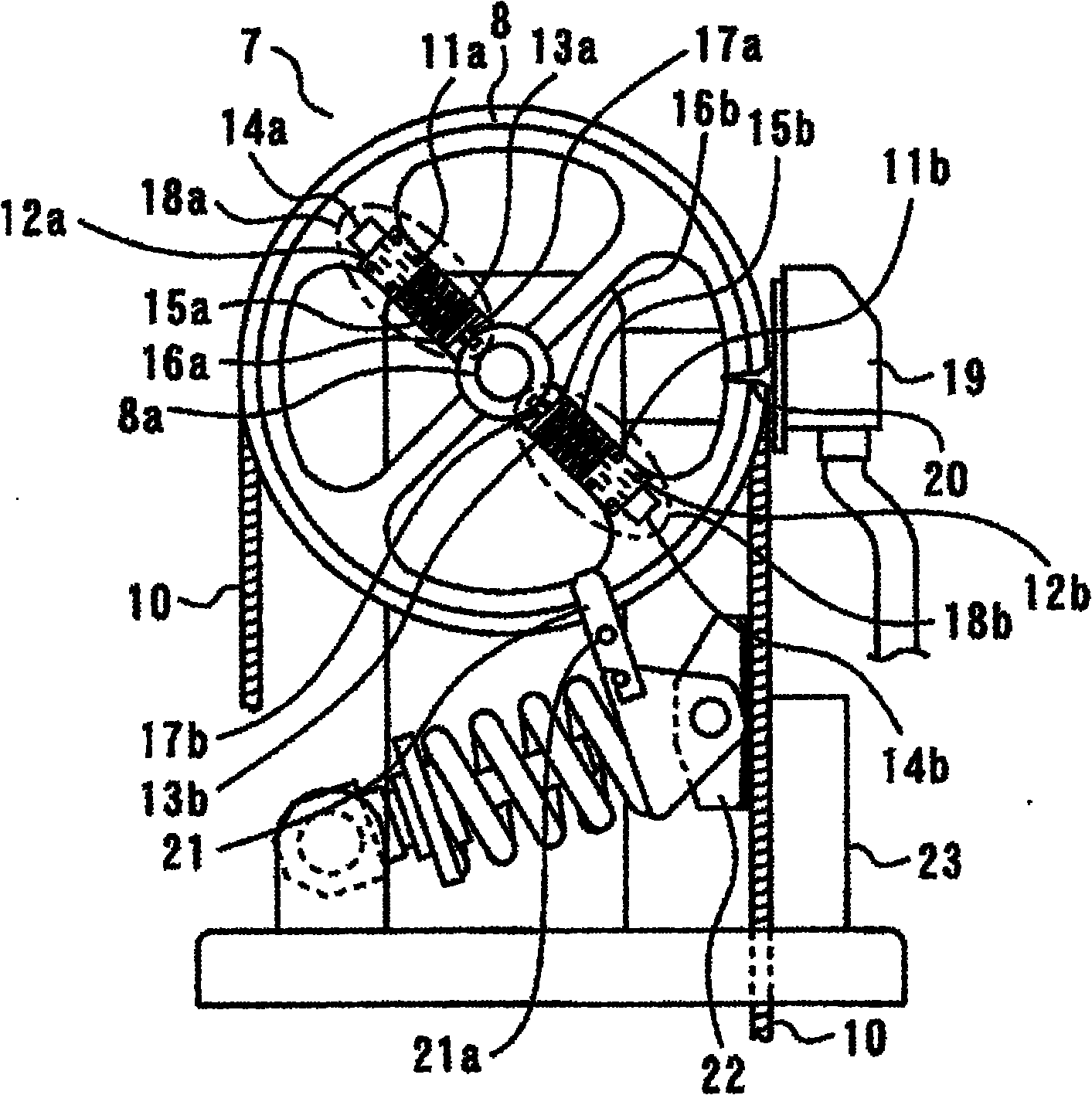

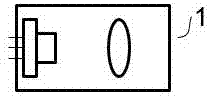

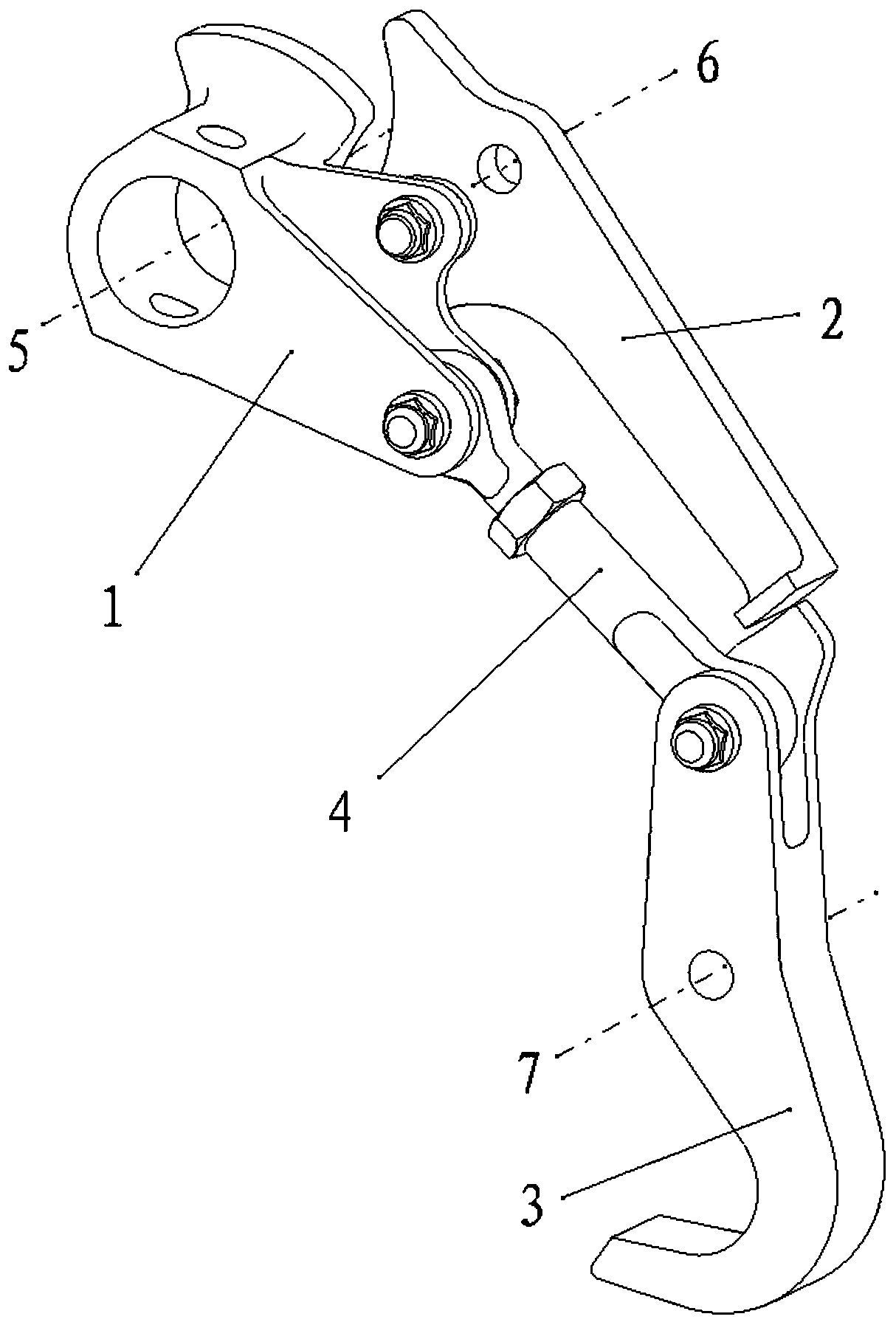

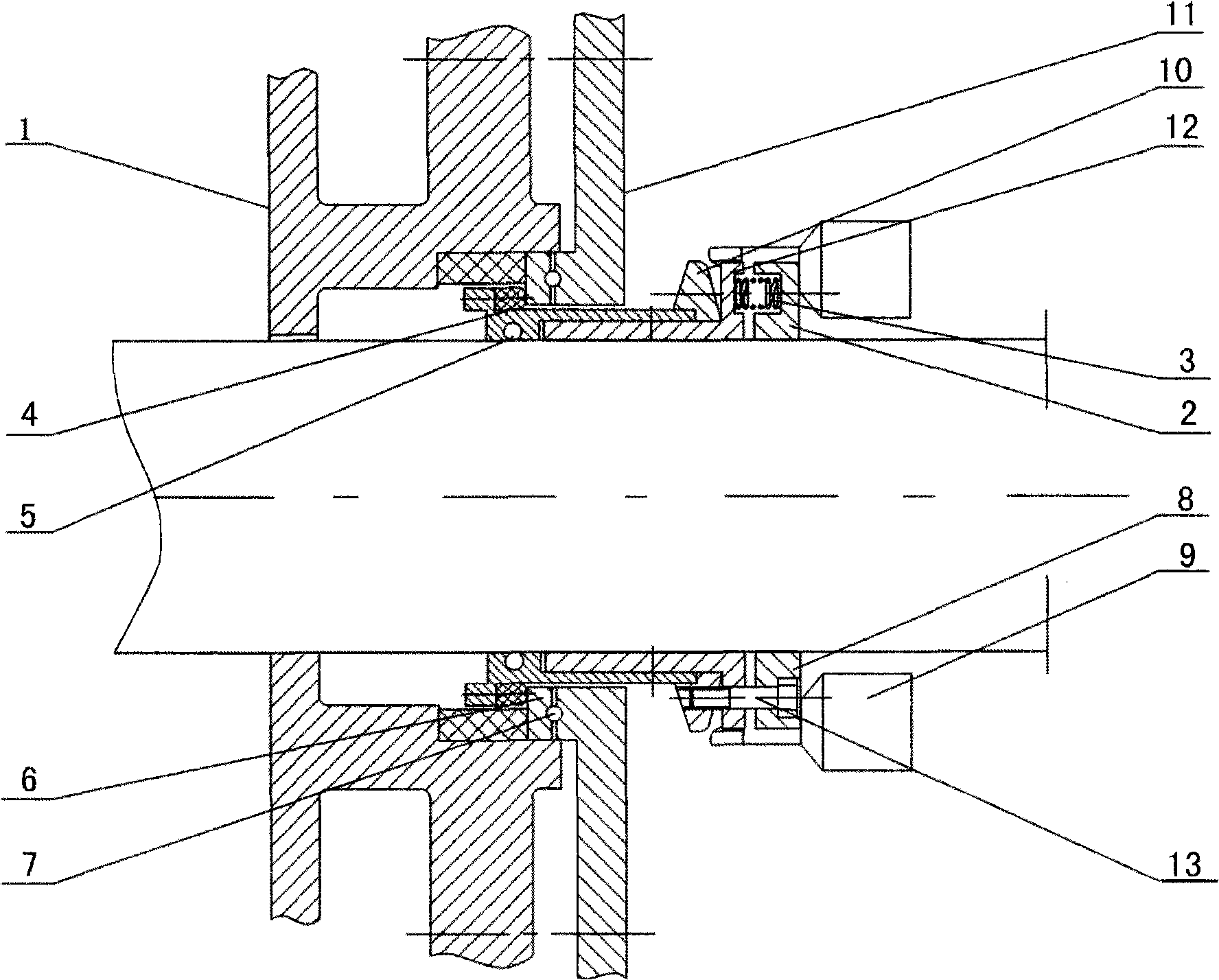

Elevator speed governor

InactiveCN102131726ASimple structureEasy assembly and adjustmentElevatorsDegrees of freedomEngineering

Provided is an elevator speed governor of simple construction that is easy to assemble and adjust and that has a high degree of freedom with respect to the arrangement of the fly weight, over-speed switch, and rope catch mechanism and setting of the fly weight mass, wherein arrangement of the fly weight, etc. and fly weight mass, etc. can be specifically determined for each of a first and a second over-speed detection speed, and which allow precise detection of each of said first and second over-speed detection speeds. Thus, the speed governor, which detects that the speed of travel of a passenger car has reached the first and second over-speed detection speeds in order to stop the passenger car, is equipped with a first over-speed detection mechanism that detects that the passenger car has reached the first over-speed detection speed and a second over-speed detection mechanism that is provided separately from the first over-speed detection mechanism and detects that the passenger carhas reached the second over-speed detection speed, and the first over-speed detection mechanism and the second over-speed detection mechanism are constituted to operate independently from one another.

Owner:MITSUBISHI ELECTRIC CORP

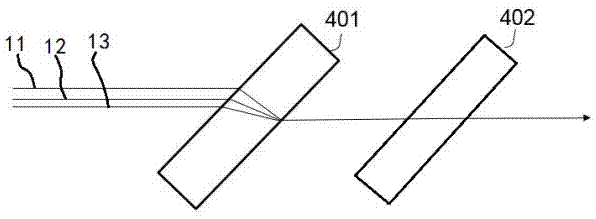

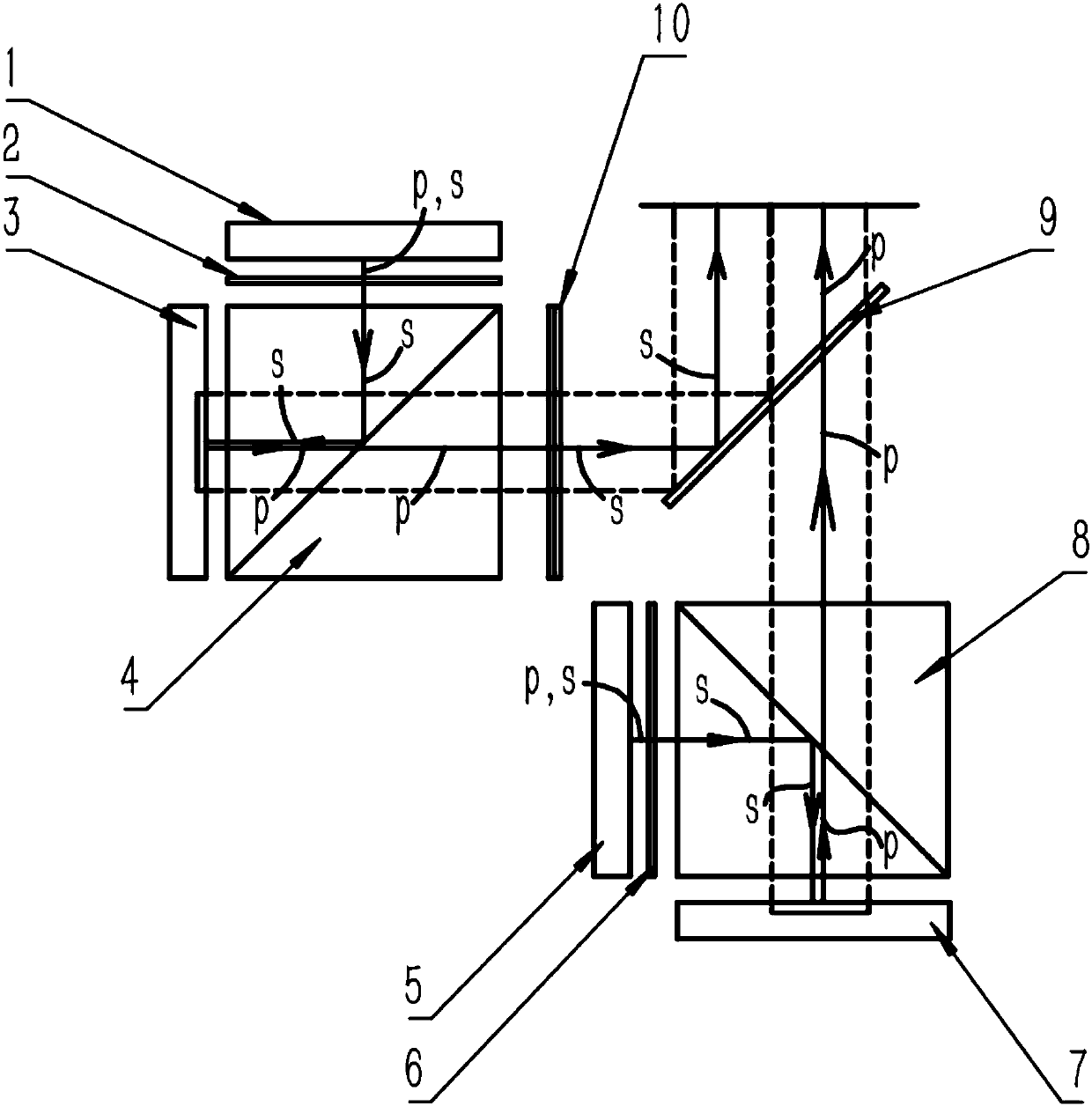

Beam combining device for multicolor semiconductor laser devices

ActiveCN103762502AGuaranteed Polarization PerformanceLow costSemiconductor laser arrangementsLaser output parameters controlLight beamWavelength

The invention discloses a beam combining device for multicolor semiconductor laser devices. The beam combining device comprises a plurality of the semiconductor laser devices which are connected in parallel and have different wave lengths, a plurality of light beam polarization improvement devices which are connected in parallel and arranged on the output light paths of the corresponding semiconductor laser devices respectively, and a beam combining mirror set used for beam combination, wherein the input ends of the beam combining mirror set are arranged on the output light paths of the light beam polarization improvement devices, and the output ends of the beam combining mirror set and a compensating mirror set are arranged on the same light path. The beam combining device for the multicolor semiconductor laser devices can effectively control the increase amount of the noise of beam combination of the multicolor semiconductor laser devices and guarantee the polarization performance of the light beams after beam combination, and has the advantages of being low in cost, easy to assemble and adjust, and stable in performance.

Owner:PAVILION INTEGRATION CORP SUZHOU

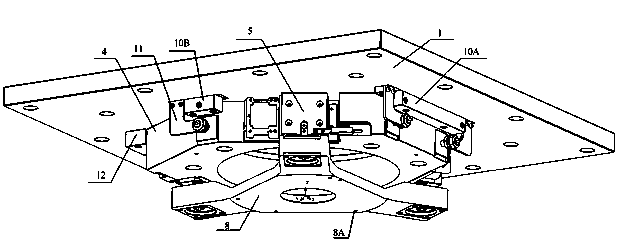

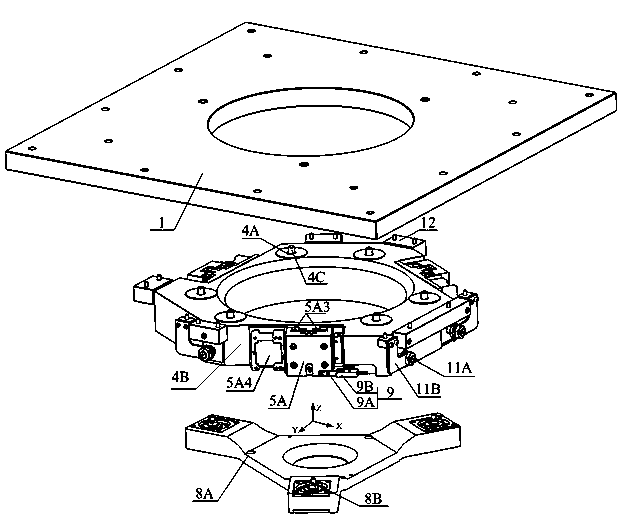

Three freedom precision control apparatus based on eccentric structure

InactiveCN104070518AFine adjustment of degrees of freedomLow movement resistanceProgramme-controlled manipulatorModular designEngineering

The invention discloses a three freedom precision control apparatus based on an eccentric structure. Three supporting arms are extended along the radial direction of a motion platform uniformly arranged along a peripheral face, eccentric circular holes are respectively arranged on ends of the three supporting arms, and the eccentric holes of the three supporting arms are connected to a mounting substrate through motion branch chains with the same structure; preloading and locating components for locating the mounting substrate are mounted under the surface of a main board, the locating components and three preloading components are surrounded around the sides of the mounting substrate among the motion branch chains, three horizontal displacement measuring components are fixedly mounted under the surface of the main board on the side of the locating component. Through the three freedom precision control apparatus, submerged units of a submerged photo-etching machine are mounted and their spatial positions are adjusted so as to realize submicron location of the submerged units; the three freedom precision control apparatus is characterized by high rigidity, wide regulation range, quick motion response, modular design, compact structure, and simple assembly and adjustment, thus the control apparatus can be applied to three freedom precision control under other occasions excluding the submerged photo-etching machine.

Owner:ZHEJIANG UNIV

Sealing ring with improved fastener

ActiveUS20070075553A1Preventing and detecting unauthorized tamperingPreventing and detecting and removalSheet joiningClamping mechanismSplit ringFastener

One aspect of the present invention includes a sealing ring having a split-ring annular band which includes a first and second end. A first tab is disposed at the first end, with the first tab extending away from the annular band. The first tab also includes a first threaded aperture. A second tab is disposed at the second end, with the second tab also extending away from the annular band The second tab also includes a second threaded aperture. Additionally, a thread of the first aperture is different from a thread of the second aperture. Further, the sealing ring includes a fastener threadedly engaged with the first and second apertures. Rotation of the fastener adjusts a radial dimension of the annular band.

Owner:THOMAS & BETTS INT INC

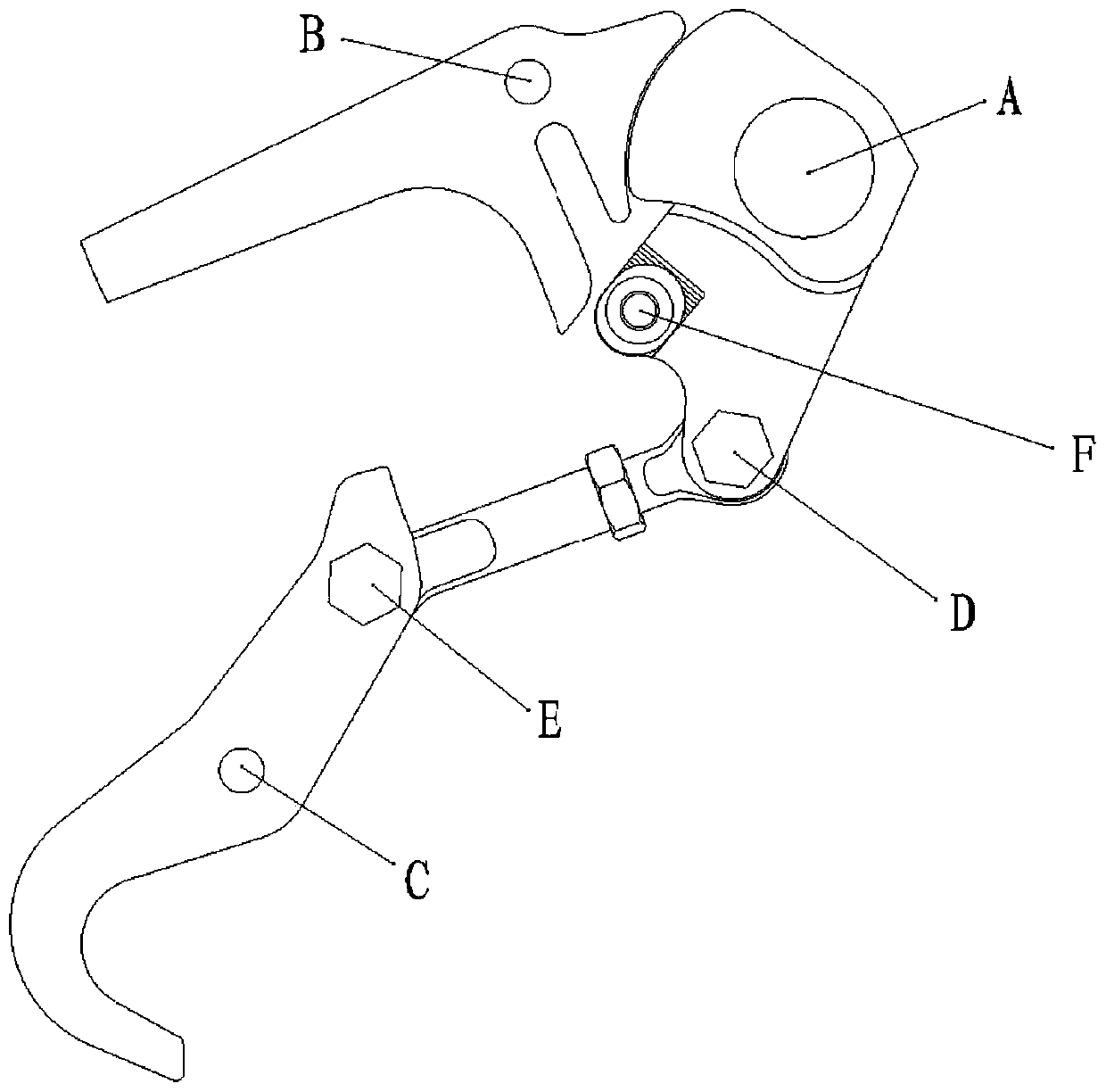

Cabin door latching mechanism

The invention relates to the field of cabin door design, and particularly discloses a cabin door latching mechanism. The cabin door latching mechanism is located on a cabin door frame and comprises arocker arm assembly, a lock, a latch and a connecting rod, the rocker arm assembly is connected to a driving source, the rocker arm assembly, the lock and the latch can rotate around the self axis, and the three axes are parallel to one another and distributed in a triangular mode. According to the cabin door latching mechanism, the rocker arm assembly and the lock adopt clearance fit so as to achieve the purpose of driving the lock and maintain the position of the lock after complete opening, meanwhile, the possibility of mislocking is avoided, the driving source and the limiting device of the lock are omitted accordingly, the weight is reduced, and the system is simplified; and the rocker arm assembly drives the latch through the connecting rod, the point of intersection connected to oneend of the rocker arm assembly adopts over-center design, the point of intersection connected to one end of the latch adopts non-over-center design, the purpose of noninterference with the lock during unlatching and latching is achieved, meanwhile, the fact that the lock locks the position of the latch can be ensured, therefore, the entire latching mechanism is simple in structure, light in weight, and high in reliability, the connecting rod and the rocker arm assembly adopt adjustable design, and assembling and adjusting are facilitated.

Owner:中航通飞华南飞机工业有限公司

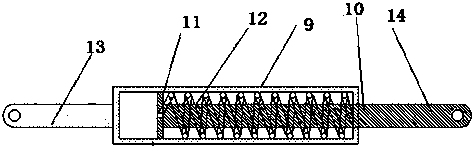

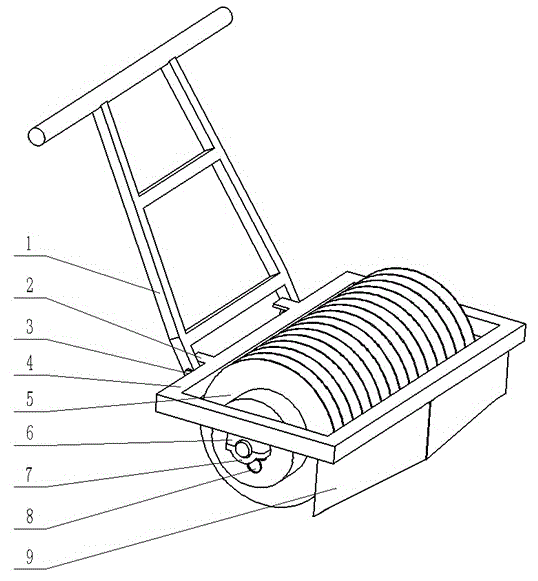

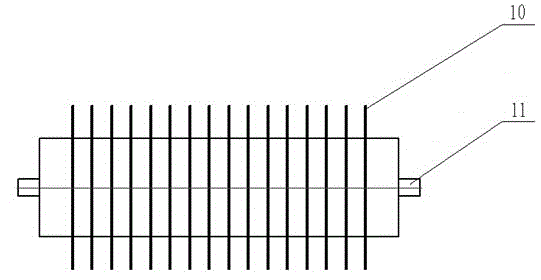

Grass pressing machine for lawn

InactiveCN104885668AConvenient distanceThe distance is easy to adjustPlantingHorticultureAgricultural engineeringLawn

The invention discloses a grass pressing machine for a lawn. The machine comprises a handrail, a frame and a grass pressing roller provided with grass pressing cutters on the surface, wherein two ends of a spindle of the grass pressing roller are mounted on the frame through a bearing to enable the grass pressing roller to be located in the frame; the handrail is fixed on the frame, and the grass pressing roller is driven to roll by pushing the handrail forwards; the grass pressing roller is provided with a cavity which is provided with a plug and capable of allowing water or sand injection. Grass blades can be pressed into soil or sand through rolling of the grass pressing roller, the pressed-in grass blades are uniform and neat, the dead weight of the grass pressing roller can be adjusted according to the compact degree of a lawn field, so that the depth of the grass blades pressed into the soil is appropriate and not too large; by means of the grass pressing machine, the grass blades are planted once, manual rolling or tractor rolling can be adopted, the operation is convenient, and the adaptability is high.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Electric isolating switch

ActiveCN101645366AImprove transmission efficiencyImprove structural compactnessSwitch power arrangementsAir-break switch detailsControl systemEngineering

The invention relates to an electric isolating switch belonging to the control technical field in an electric system. The electric isolating switch comprises a connecting bus, a contact, a contact control system, a moving contact group, a link mechanism, an operating system and an auxiliary switch module, wherein the connecting bus is mounted between a front insulating board and a rear insulatingboard; the link mechanism is connected with the moving contact group; the operating system controls and provides power for opening and closing the moving contact group and comprises a reducing motor and a switching power supply; and the auxiliary switch module is connected with the reducing motor by an auxiliary switch module transmission mechanism and the link mechanism. The invention has the advantages of high mechanism efficiency, safety, reliability, simple structure, small size, easy assembly and adjustment, simple and convenient mounting and arrangement, and the like.

Owner:中国船舶重工集团公司第七一二研究所

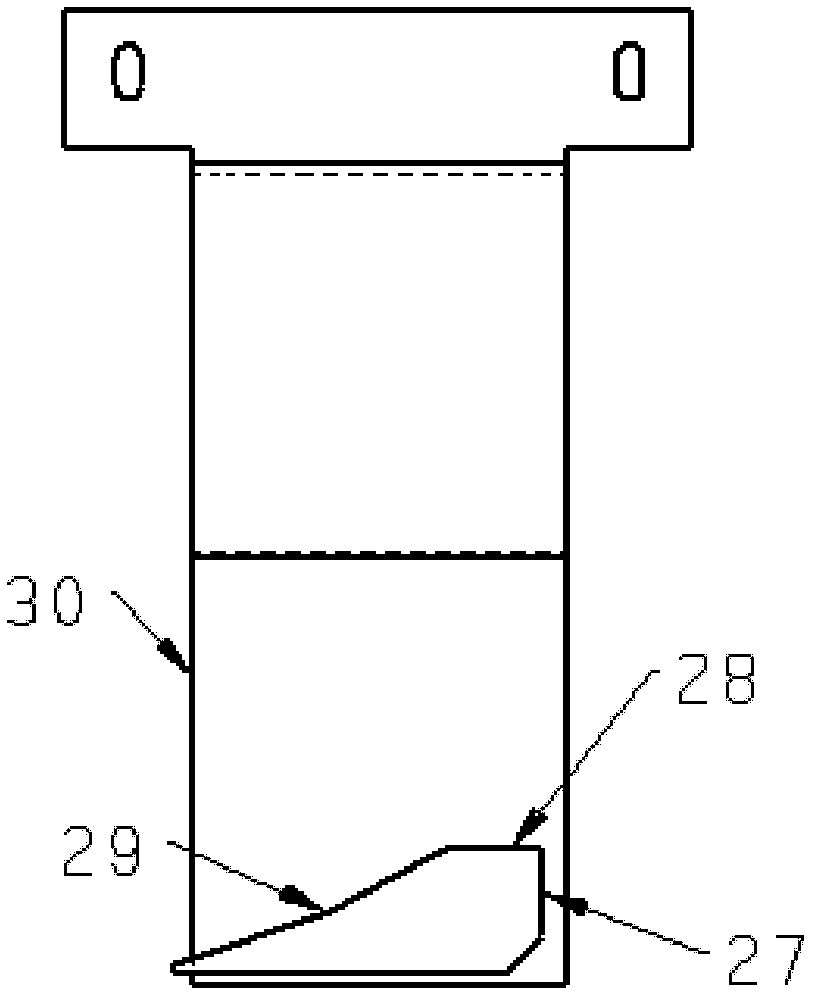

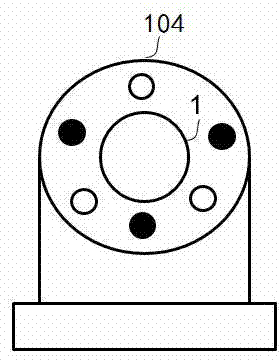

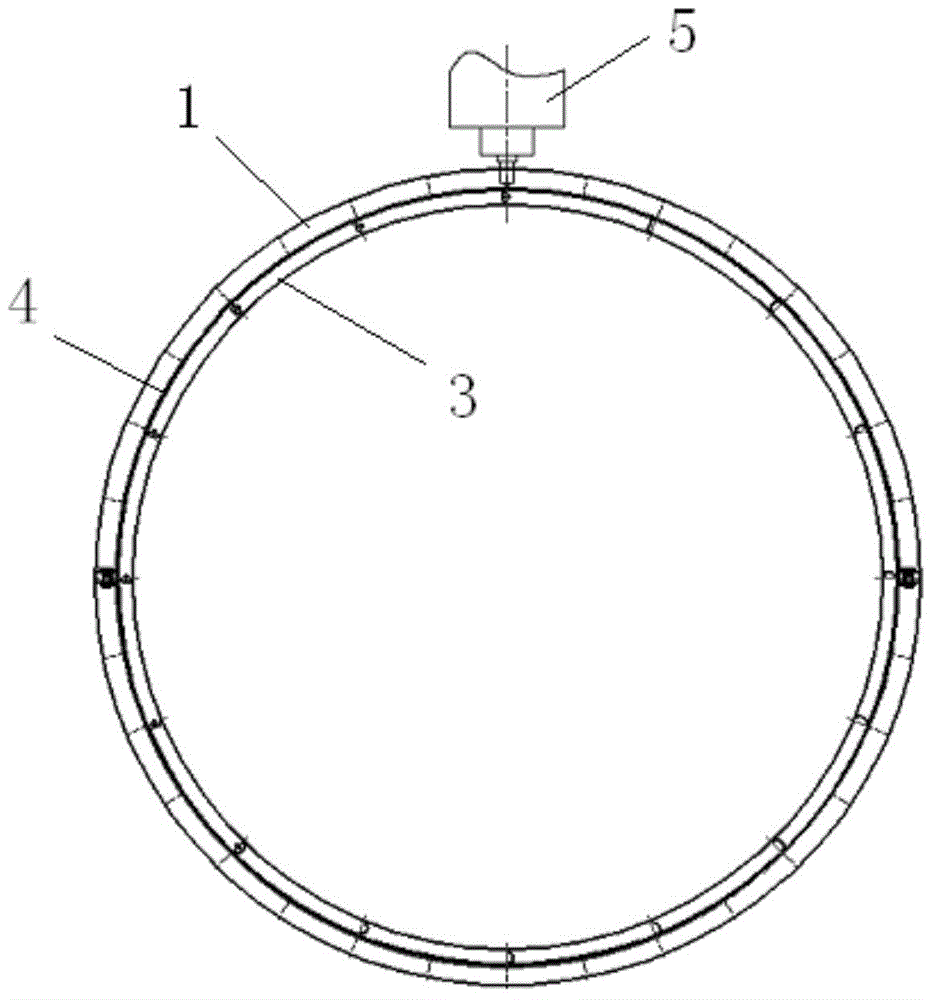

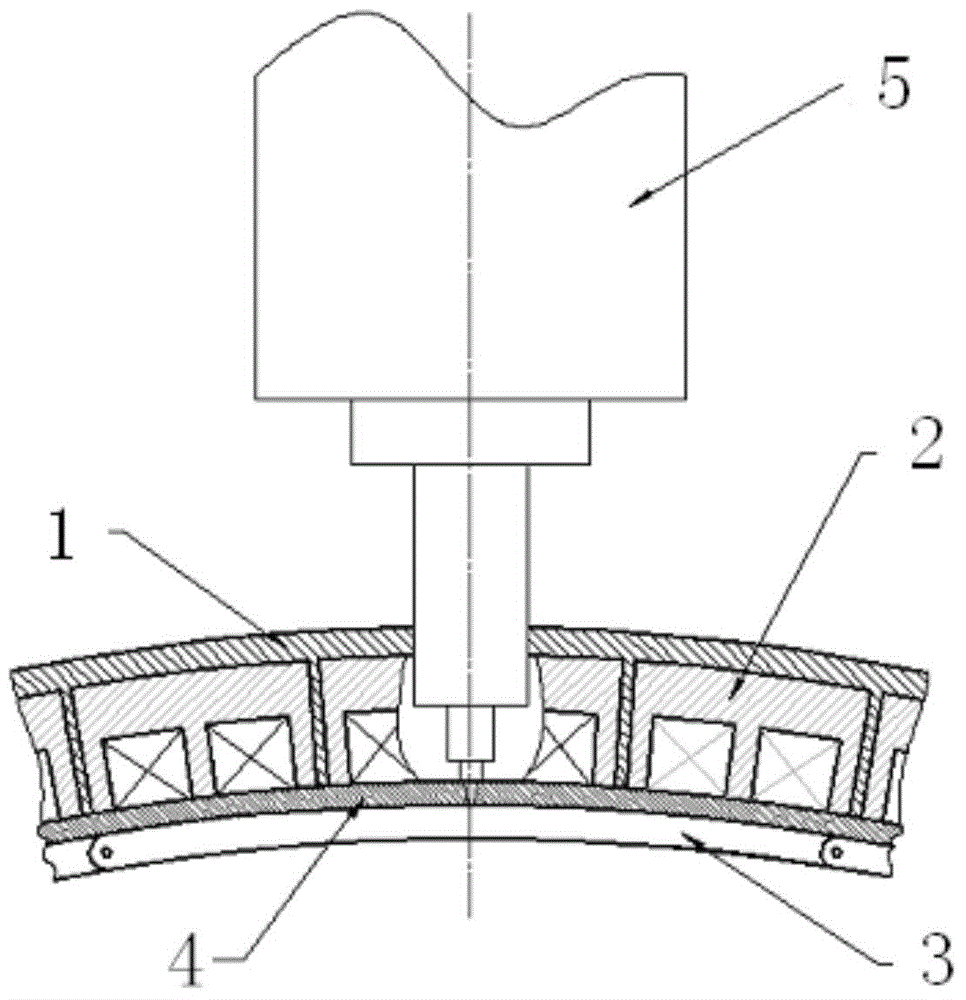

Large-diameter thin walled cylinder butt welding assembly clamping device

ActiveCN104907687AWith magnetic propertiesEasy loading and unloadingNon-electric welding apparatusButt weldingButt joint

The invention discloses a large-diameter thin walled cylinder butt welding assembly clamping device. The large-diameter thin walled cylinder butt welding assembly clamping device comprises two sets of rigid outer rings (1) and a combined type inner pad (3), the inner diameter of each set of rigid outer ring (1) is matched with the outer diameter of a large-diameter thin walled cylinder, each set of rigid outer rings (1) is formed by the connection of the at least two sets of rigid outer rings (1) through bolts (6), a slope (9) is arranged at one side of each set of rigid outer rings (1), electromagnets (2) are fixed into the rigid outer rings (1) along the two sides of a welding seam, and the combined type inner pad (3) is formed by the head-tail sequential connection of a plurality of sections of arc-shaped plates (7) through pin holes formed in the two ends of each arc-shaped plate (7) and fixing pins (8) arranged in the pin holes. According to the large-diameter thin walled cylinder butt welding assembly clamping device, when the large-diameter thin walled cylinder stirring friction butt welding installation especially the semi-closed cylinder annular welding installation is performed, complex inner supporting tools are not needed, the assembly and the disassembly of the inner supporting tools are simplified, the fixation and the location on the butt joint position of a thin walled cylinder can be performed lightly and handily and accurately, the assembly and the adjustment are simple and practicable, meanwhile, the assembly precision of large-scale cylinders is improved, and the welding quality is guaranteed.

Owner:CENT SOUTH UNIV

Stepping actuator device driven by two piezoelectric ceramics and comprising E-type rail, and method

ActiveCN108768205AHigh precisionSimple drive signalPiezoelectric/electrostriction/magnetostriction machinesLinear displacementCeramic

The invention discloses a stepping actuator device driven by two piezoelectric ceramics and comprising an E-type rail, and a method. The actuator device comprises two fixed rails fixed on a pedestal and linked with the pedestal through a flexible hinge, a driving rail capable of moving up and down in a small range, and a clamping control-displacement output structure which is mounted between the fixed rails and the driving rail and can realize transition of a clamping state with the rails. The invention also providing an actuating method, the piezoelectric ceramics and a motor are driven according to a certain order, large stroke linear displacement output between the clamping output structure and the pedestal can be realized; the device has a power failure locking function, after power isfailed, the device can keep being in the current actuating position; and the actuator has the characteristics of large output stroke, high output resolution, light weight and simple control waveform.

Owner:XI AN JIAOTONG UNIV

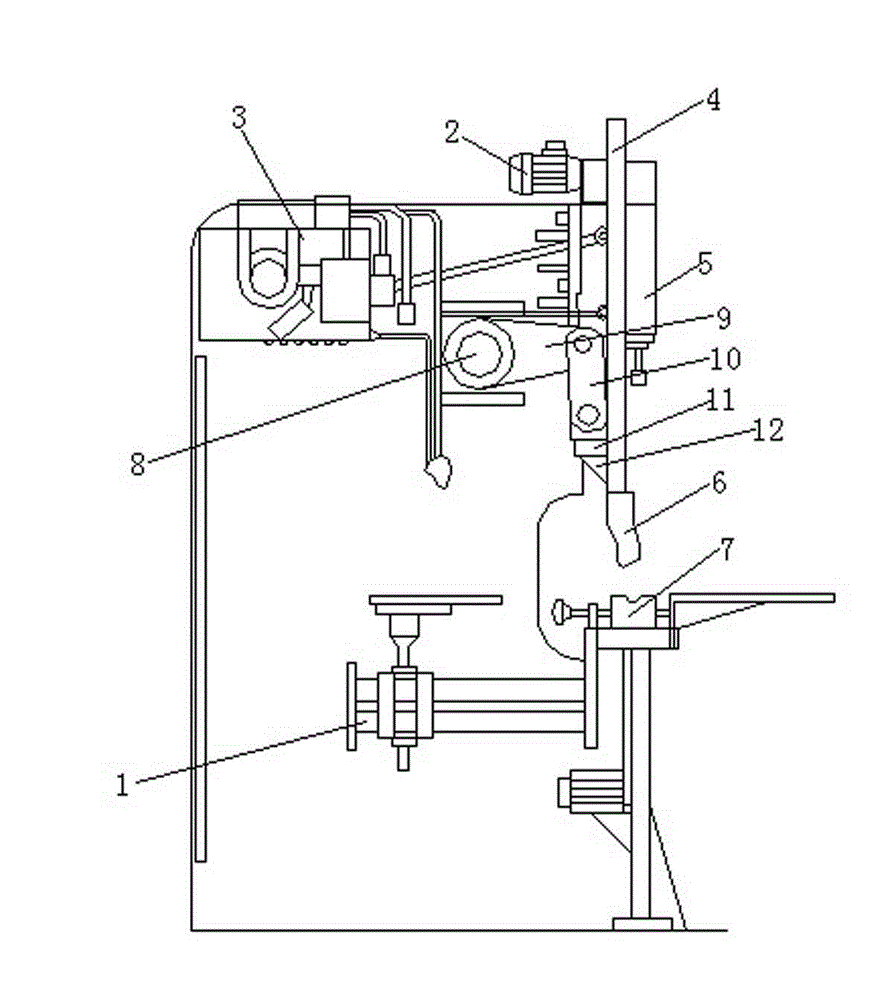

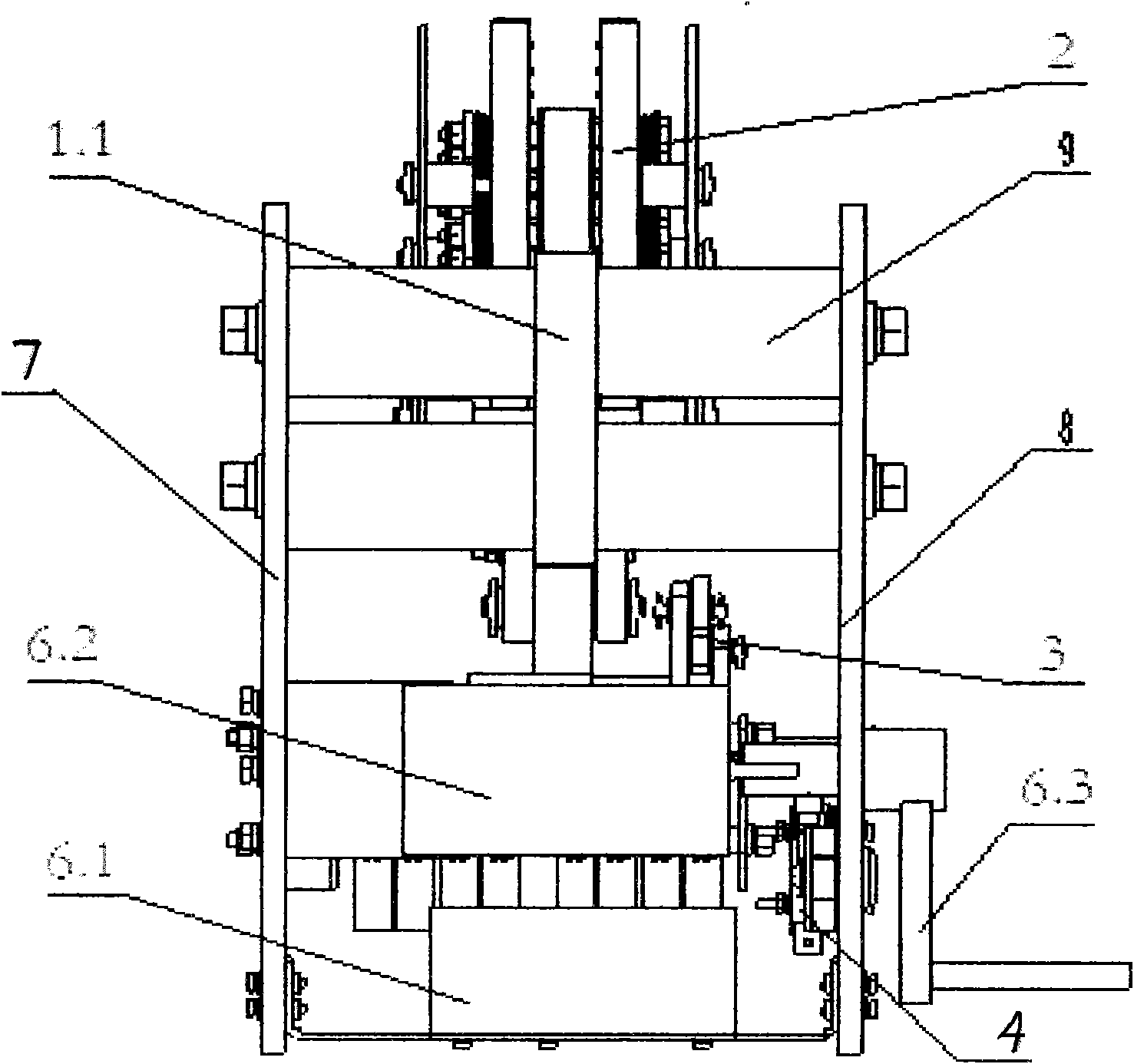

High-precision full-angle multi-station steel tube drilling machine

InactiveCN107042321AGuaranteed synchronicityGuaranteed machining accuracyTurning machine accessoriesWorkpiecesControl systemMultiple frame

The invention belongs to the technical field of steel profile drilling and machining, and relates to a high-precision full-angle multi-station steel tube drilling machine. The high-precision full-angle multi-station steel tube drilling machine is characterized in that the high-precision full-angle multi-station steel tube drilling machine is composed of a base, a transmission device, a dividing plate, a clamping device, a positioning damper, a drilling tool and a control system; the dividing plate is arranged in the middle of the top surface of the base, the transmission device, the clamping device and the drilling tool are all arranged on the top surface of the base at intervals, and the positioning damper is arranged on the back end portion of the base; and the control system is connected with the dividing plate, the transmission device, the clamping device, the positioning damper and the drilling tool in a controlling mode. The base is a cast iron integrated base with the cross section of the base being in a T shape; and the base is composed of a multiple-frame type substrate and a table board, and the table board is arranged on the top surface of the multiple-frame type substrate. The high-precision full-angle multi-station steel tube drilling machine is scientific and reasonable in structural design, has the advantages that continuous full-angle drilling can be conducted, the drilling precision is high, the product quality is good, the operation is simple and convenient, assembling adjustment is convenient, and the drilling speed and the efficiency are high, and has high innovativeness.

Owner:天津优贝斯特科技有限公司

Flushing-free centrifugal type differential pressure sealing device for pump

InactiveCN101275581AReduce pollutionGuaranteed uptimePositive displacement pump componentsPumpsDifferential pressureEngineering

Provided is a pump flush-free centrifugal type differential pressure sealing device. The invention relates to the pump flush-free centrifugal type differential pressure sealing device belonging to the fluid machinery field. The stationary ring of the device is fixed on the cover of the pump, the rotating ring and the pump shaft are in the endwise slip connection. The elastic cell acts on the direction for the rotating ring to press the stationary ring, while the pump shaft outside the pump cover is hinged with the flying iron, of which the force transferring end acts in the direction for the rotating ring to deviate from the stationary ring. When the pump stops, the centrifugal effect of the flying iron disappears, and the stationary ring and the rotating ring closely adhere under the common action of the elastic cell reset force and the medium pressure, which acts the sealing performance. The device has simple structure with any flushing and lubricating gears, which can reduce the contact friction and prolong the service life of the sealing pieces.

Owner:KUNMING UNIV OF SCI & TECH +1

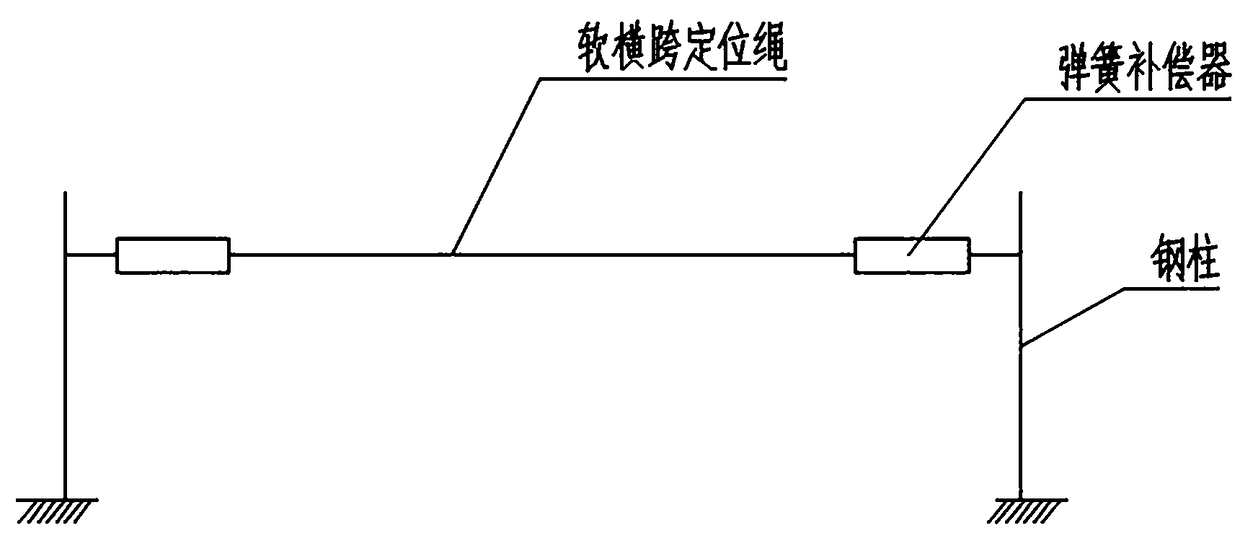

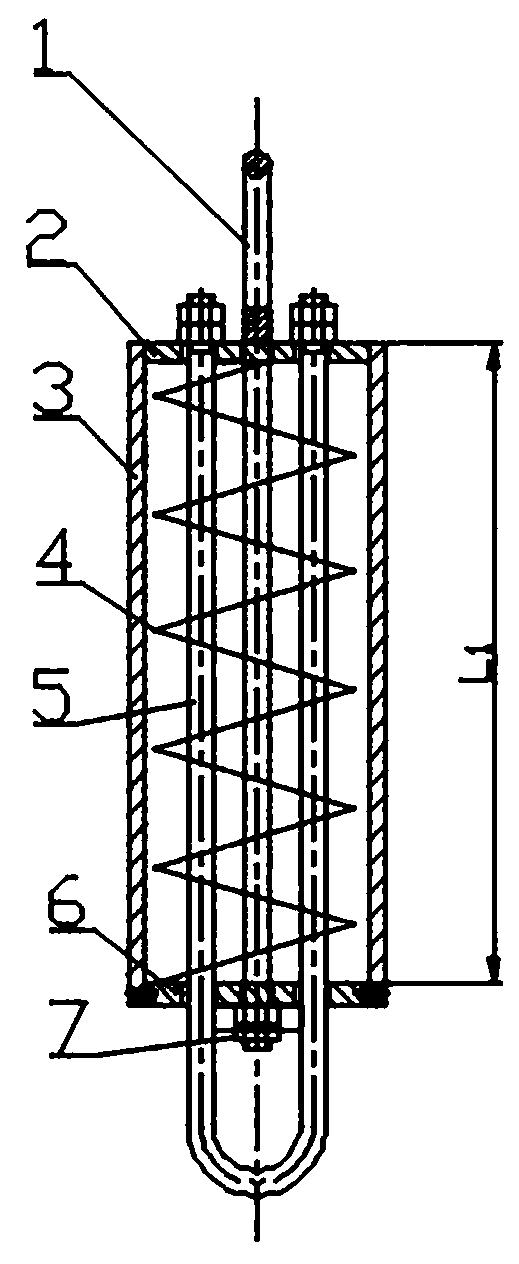

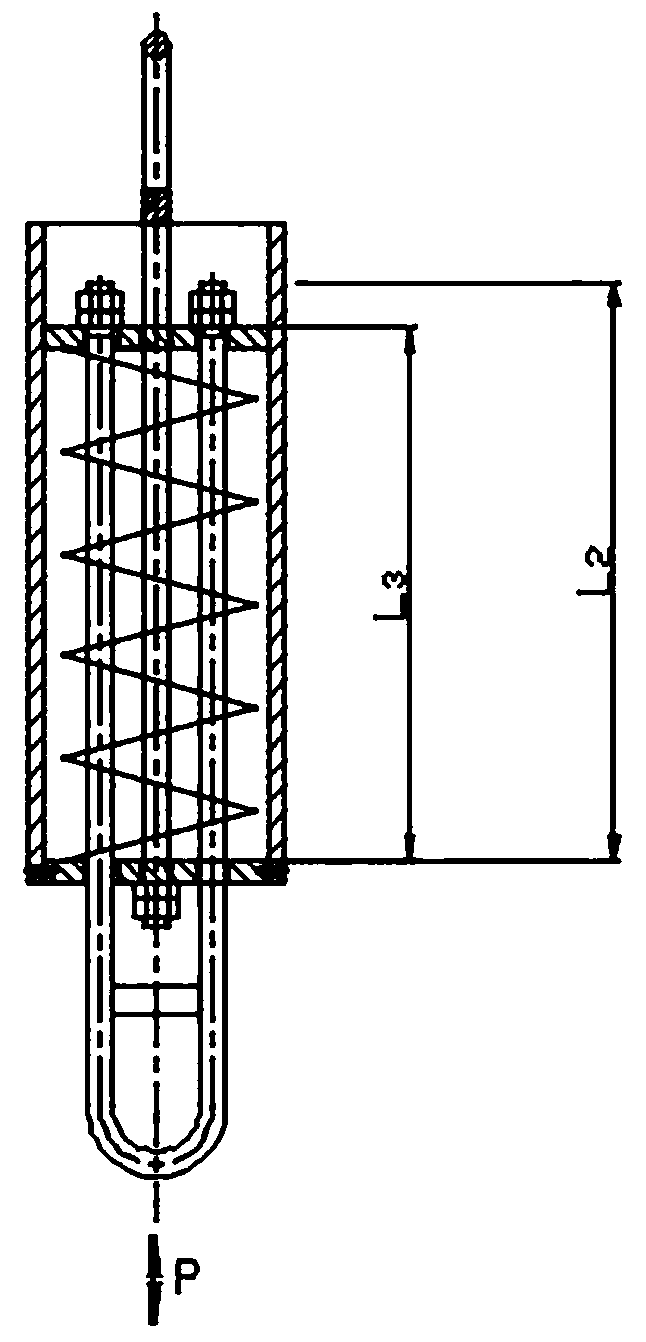

Spring compensator assembling and testing device and using method thereof

InactiveCN108225648ASave man hoursEasy assembly and adjustmentMachine part testingTension measurementEngineeringUltimate tensile strength

The invention discloses a spring compensator assembling and testing device and a using method thereof. The spring compensator assembling and testing device comprises a rack, a worktable, guide rods, compression pull rods, a pull rod connection plate, a tension sensor and a spring compensator. Through the spring compensator assembling and testing device, one machine is capable of assembling, measuring and adjusting tension value; the operating time is reduced; the assembling and adjusting operations are convenient; the labor strength is greatly reduced; the assembling and manufacturing costs are reduced; meanwhile, a hollow rectangular connection frame is used for transmitting the driving force of a speed adjusting motor in the spring compensator assembling and testing device; the driving force can be more stably and uniformly transmitted the tension sensor and the pull rod connection plate; the problem that the stress of multiple compression pull rods is uneven is avoided; the stability degree and the accuracy of tension test are improved; the tension sensor is connected with the pull rod connection plate and the hollow rectangular connection frame through threads or screws; compared with other connection manners, the threaded connection manner is capable of obviously reducing the testing errors.

Owner:四川泰禾模具锻造有限责任公司

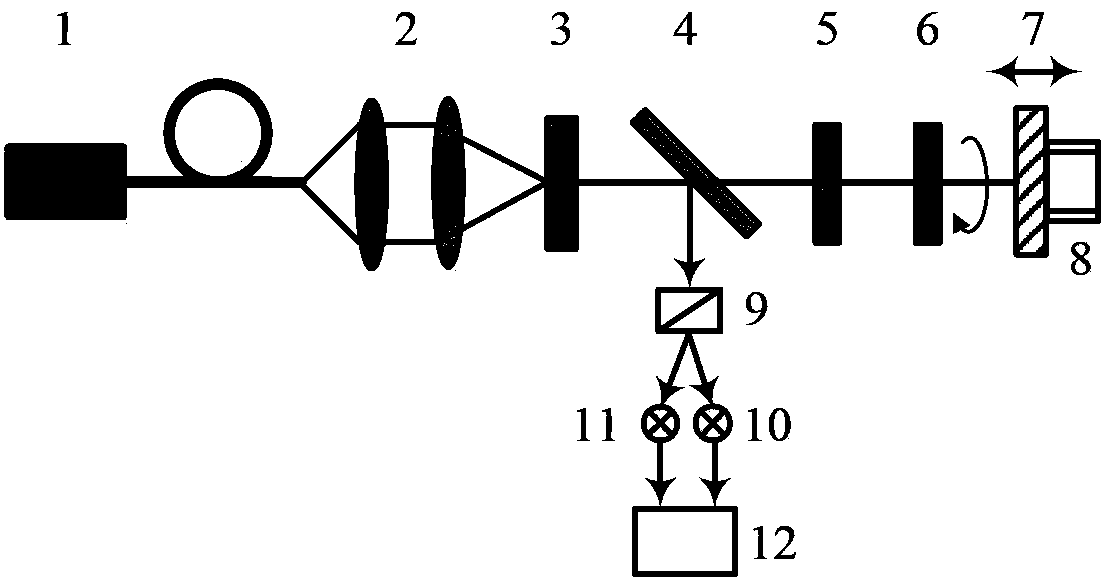

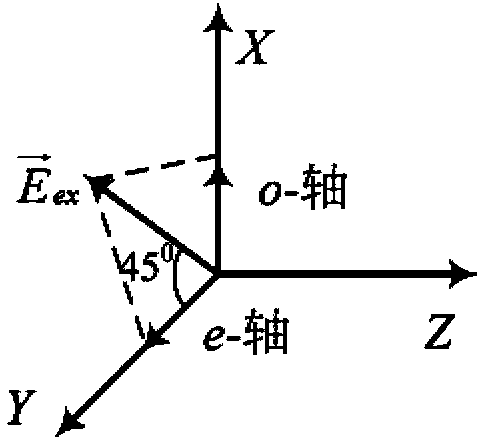

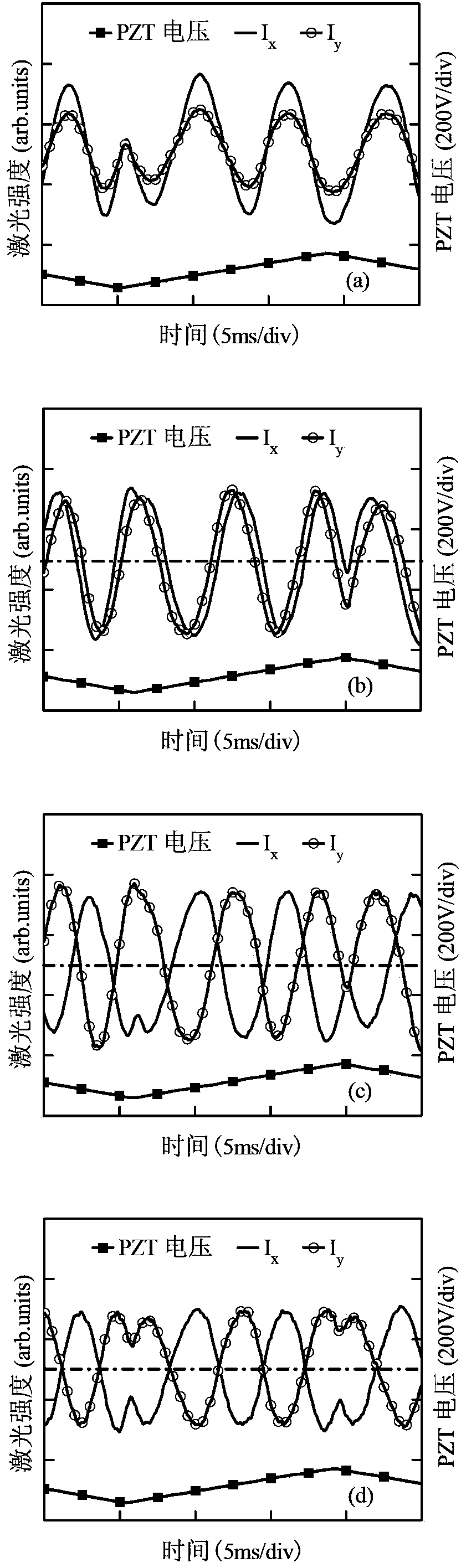

Laser exocoel feedback low-angle roll angle measuring system

ActiveCN103471527ACompact structureEasy assembly and adjustmentUsing optical meansPhase differenceNd:YAG laser

The invention discloses a laser exocoel feedback low-angle roll angle measuring system and belongs to the technical problem of laser measuring. In the roll angle measuring system, a laser feedback system composed of an LD pumped single-frequency microchip Nd: YAG laser, a stationary wave plate, a rotatable wave plate and an external reflector is adopted for measuring a roll angle. 45-degree angles are formed between the fast and slow shafts of the stationary wave plate and a laser polarization direction, the fast and slow shafts of the rotatable wave plate and the fast and slow shafts of the stationary wave plate are superposited at a zero point position. The rotatable wave plate is rotated within 45 degrees, and the phase differences among the feedback signals outputted by a laser are continuously variable and have one-to-one corresponding relations with angles, so that the roll angle can be precisely measured. The laser exocoel feedback low-angle roll angle measuring system has the advantages of simple and compact structure, easy assembling and adjusting, high measuring precision and low cost.

Owner:北京镭测科技有限公司

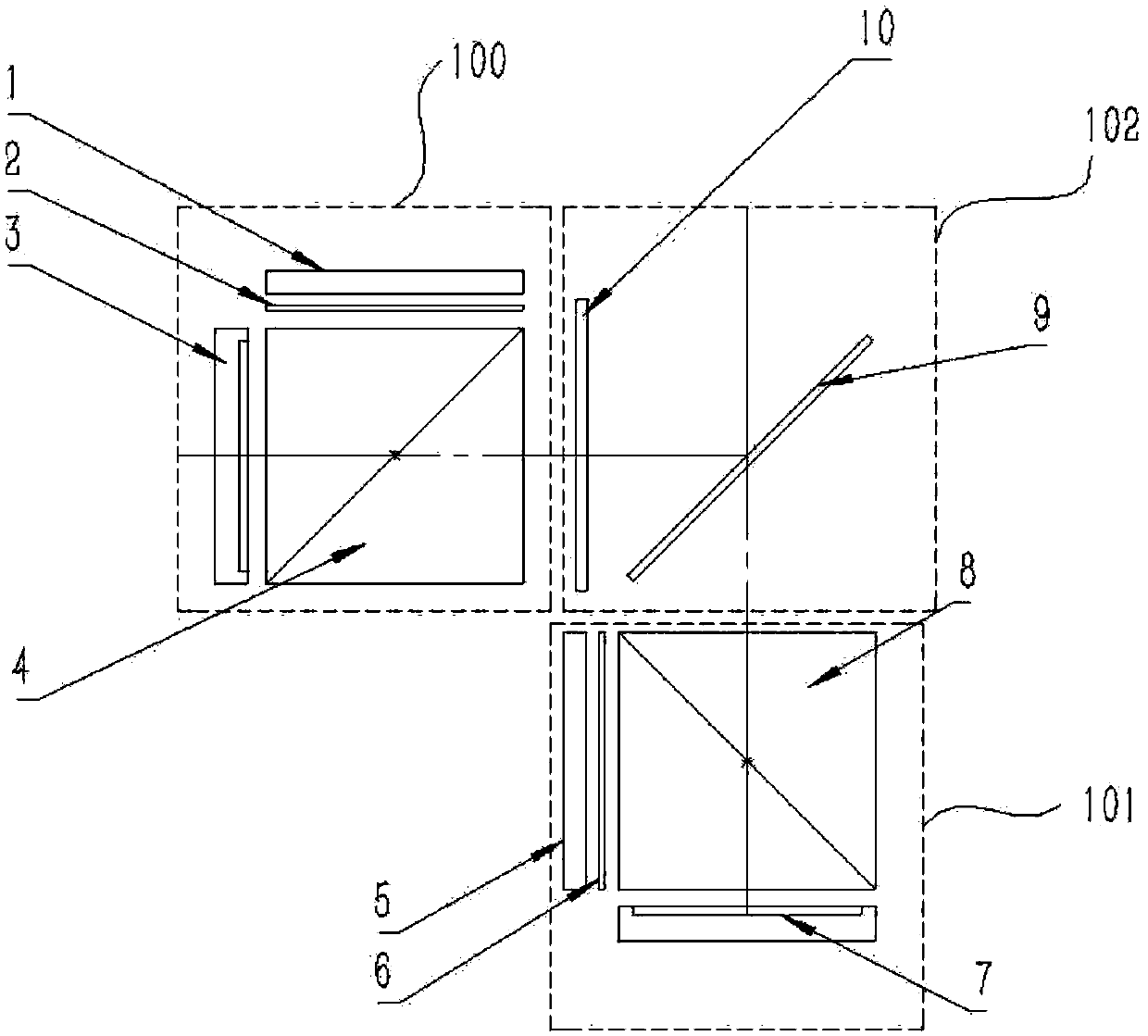

Spliced optical imaging system

PendingCN107783307ARealize seamless splicingMeet the needs of useOptical elementsHigh contrastOptical path

The invention provides a spliced optical imaging system, which comprises a first display assembly (100) provided with a first micro-display chip and arranged along a first optical path, a second display assembly (101) provided with a second micro-display chip and arranged along a second optical path, and a polarization beam combination assembly (102) located at the intersection of the first optical path and the second optical path. The first optical path and the optical path are perpendicular to each other. An image displayed by the first display assembly (100) and an image displayed by the second display assembly (101) are subjected to the polarization beam combination assembly (102) to realize the imaging on the same imaging plane. The spliced optical imaging system effectively achievesthe seamless splicing of co-focal-plane and uniform-amplitude images. Therefore, the use requirement of a larger area array can be met. Meanwhile, the splicing precision and the contrast ratio are higher.

Owner:XIAN MICROMACH TECH CO LTD

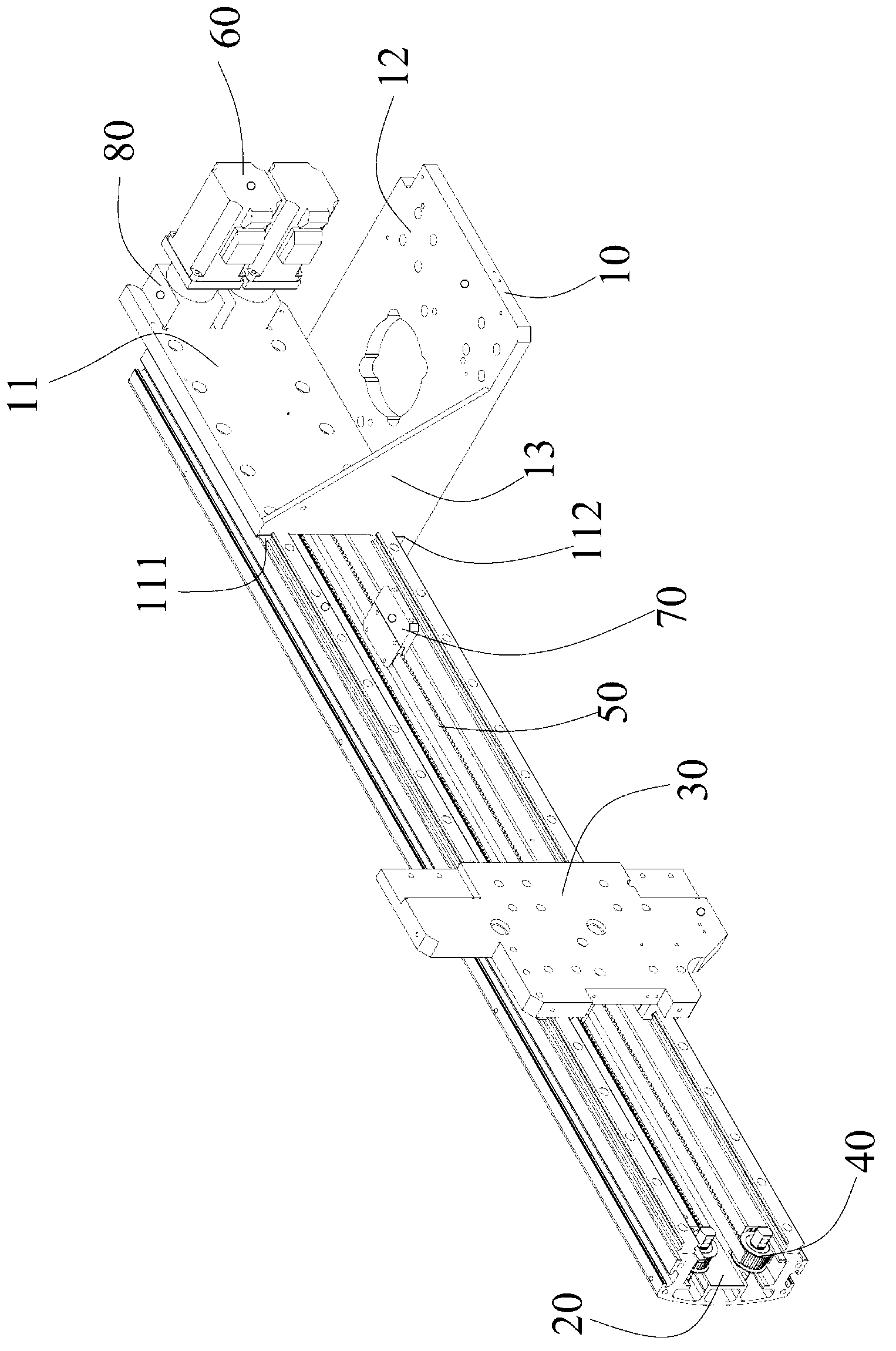

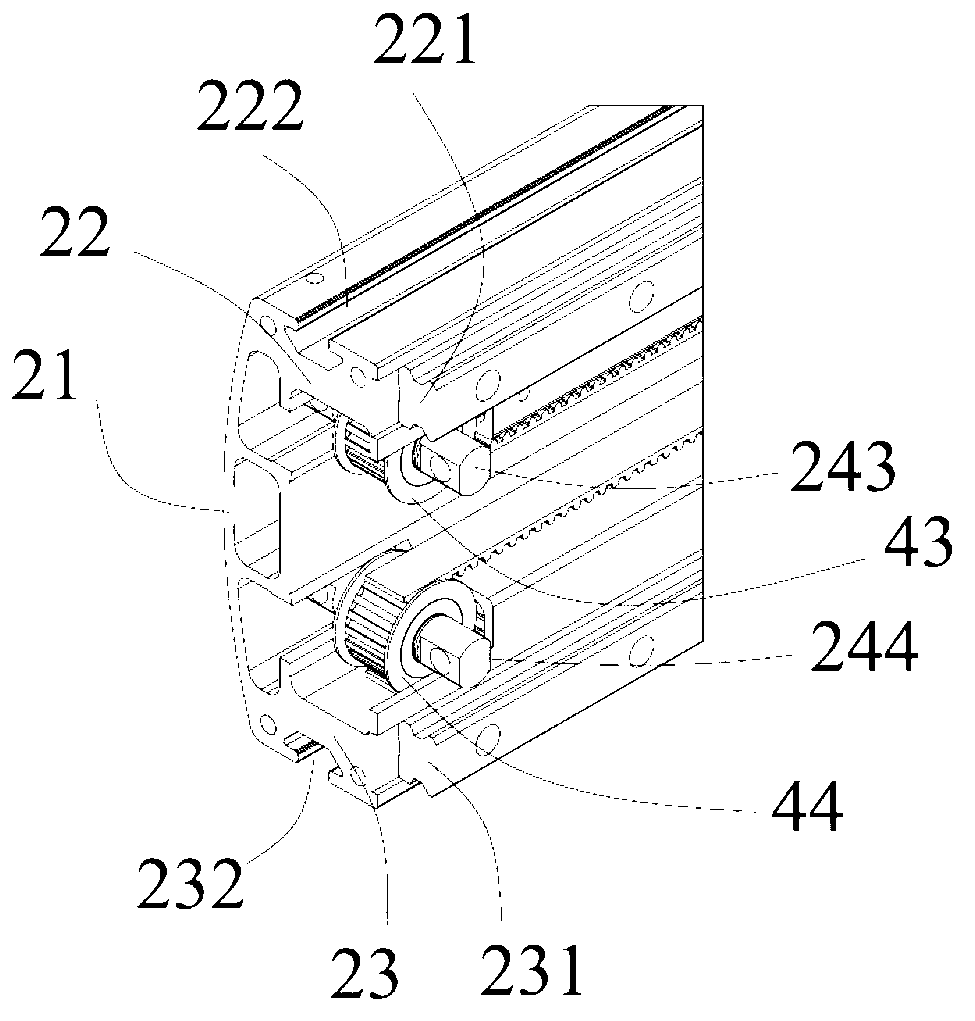

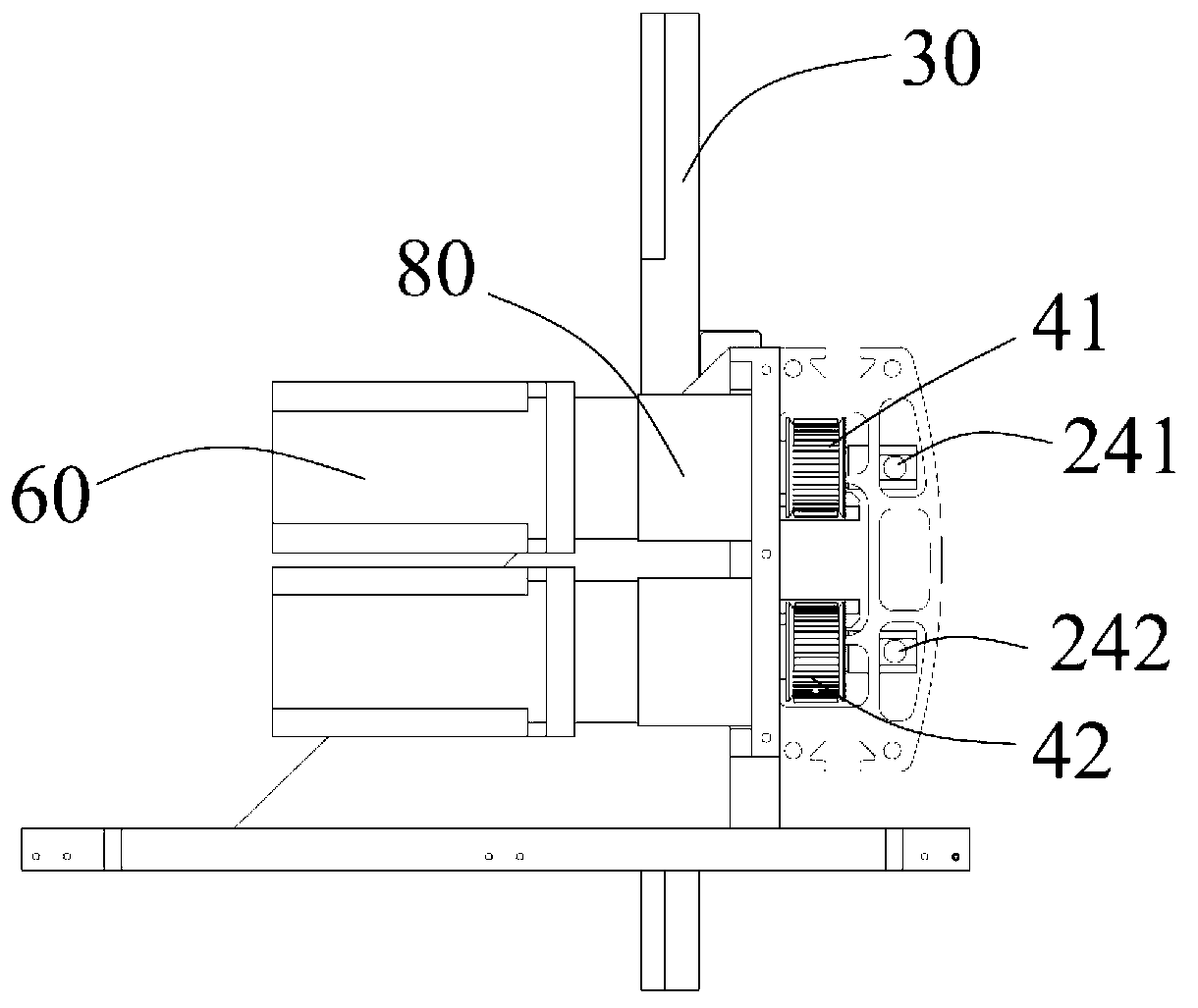

Belt transmission structure for mechanical arm

InactiveCN102699903ASimple structureEasy assembly and adjustmentProgramme-controlled manipulatorEngineeringSlide plate

The invention discloses a belt transmission structure for a mechanical arm, which comprises a transversal slide plate, a drawing arm mounted on the transversal slide plate, and a drawing slide plate mounted on the drawing arm, wherein at least two groups of belt pulleys are arranged on the drawing arm; a belt is mounted outside each group of belt pulley; at least two servomotors are mounted on the transversal slide plate; the belt pulleys are driven by the servomotors; and a belt clamp plate is arranged on each belt and is fixedly arranged with the drawing slide plate. The belt transmission structure provided by the invention has the advantages that the structure is simple; the assembly and the adjustment are very convenient; the transmission and the operation are stable; and the noise and the vibration are low.

Owner:ALFAR SUZHOU AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com