Grass pressing machine for lawn

A technology for pressing grass and lawns, which is applied in planting methods, horticulture, botanical equipment and methods, etc. It can be solved quickly, and the grass stems may be rotated on the blades, and the grass stems cannot be rotated into the soil, and cannot be used instead. problems, to achieve the effect of flexible assembly, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

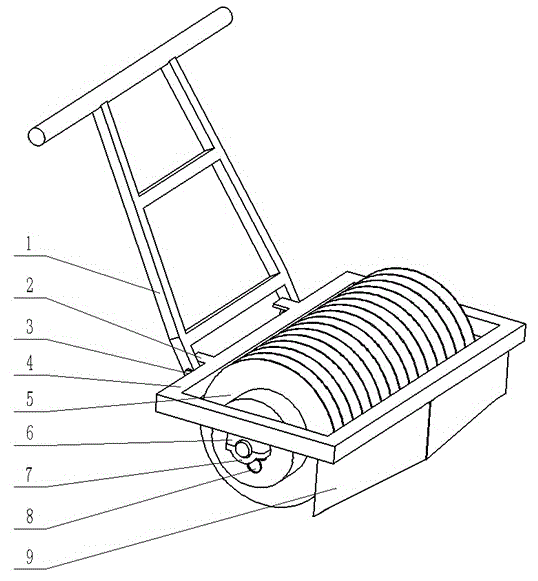

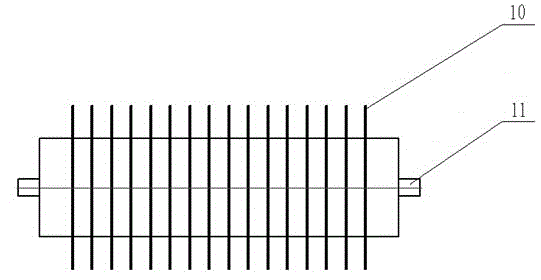

[0016] Example: A lawn mower, such as figure 1 As shown, it includes a handrail 1, a frame 4 and a grass pressing roller 5. The handrail 1 is composed of a telescopic rod, and the length can be adjusted. There are two hanging ears 2 on one side of the frame 4, and the distance between the hanging ears 2 is 570mm. There are corresponding installation holes 3 on the bottom end of the armrest 1 and the hanging lug 2. After aligning the installation holes 3 and rotating the armrest to a suitable length and angle for pushing, fasten it with the bolt 2. The both sides of frame 4 have the round hole that is used for the bearing upper seat 6 of fixed bearing and bearing lower seat 7 to cooperate, and the central shaft 11 of pressing grass round roller 5 is installed in the frame 4 by bearing and can roll around central shaft 11. The grass-pressing round roller 5 is a cylinder with a cavity, which can inject water into the cavity through the water injection hole 8 and block it with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com