Belt transmission structure for mechanical arm

A belt drive and mechanical arm technology, applied in the field of mechanical transmission, can solve the problems of high noise, large vibration, easy wear, etc., and achieve the effect of smooth operation of belt pulley transmission, ease of load impact, and convenient assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

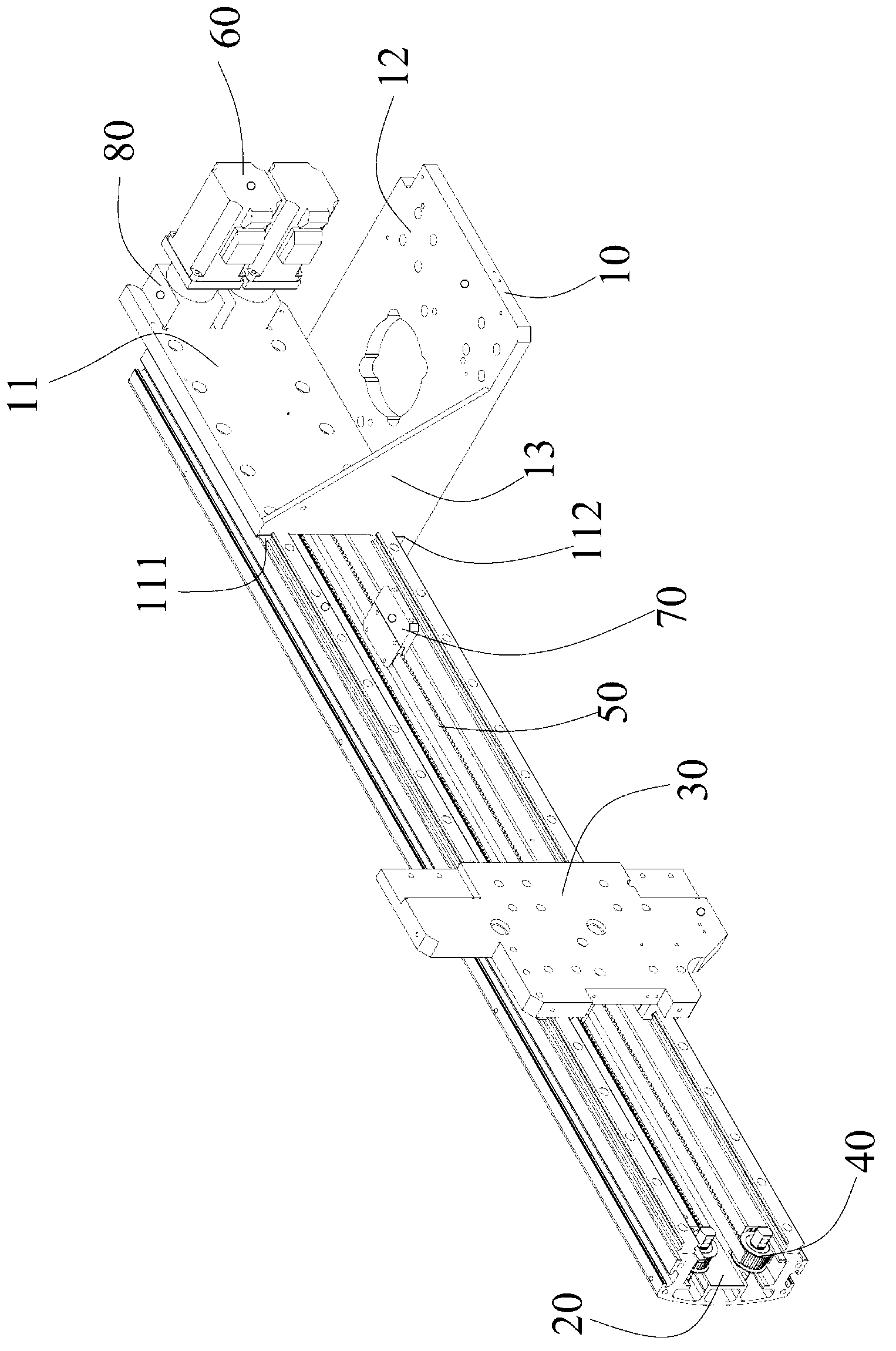

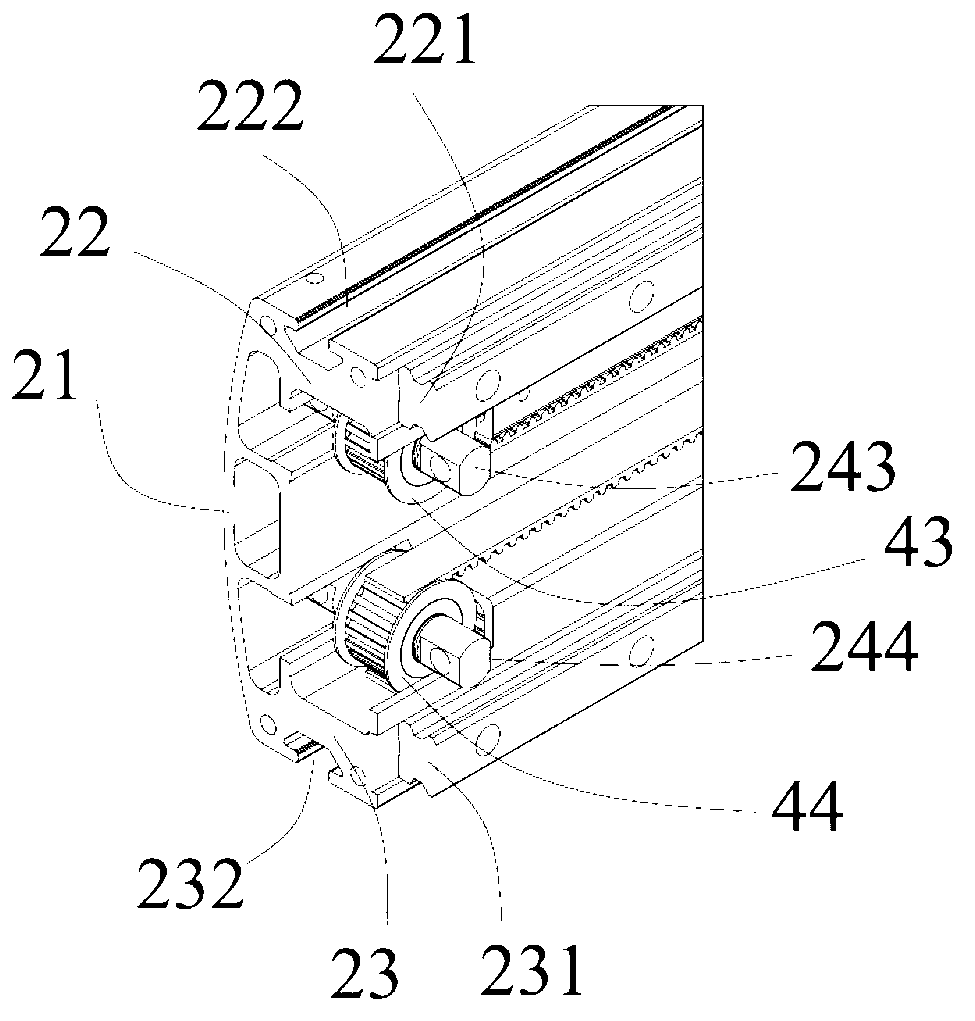

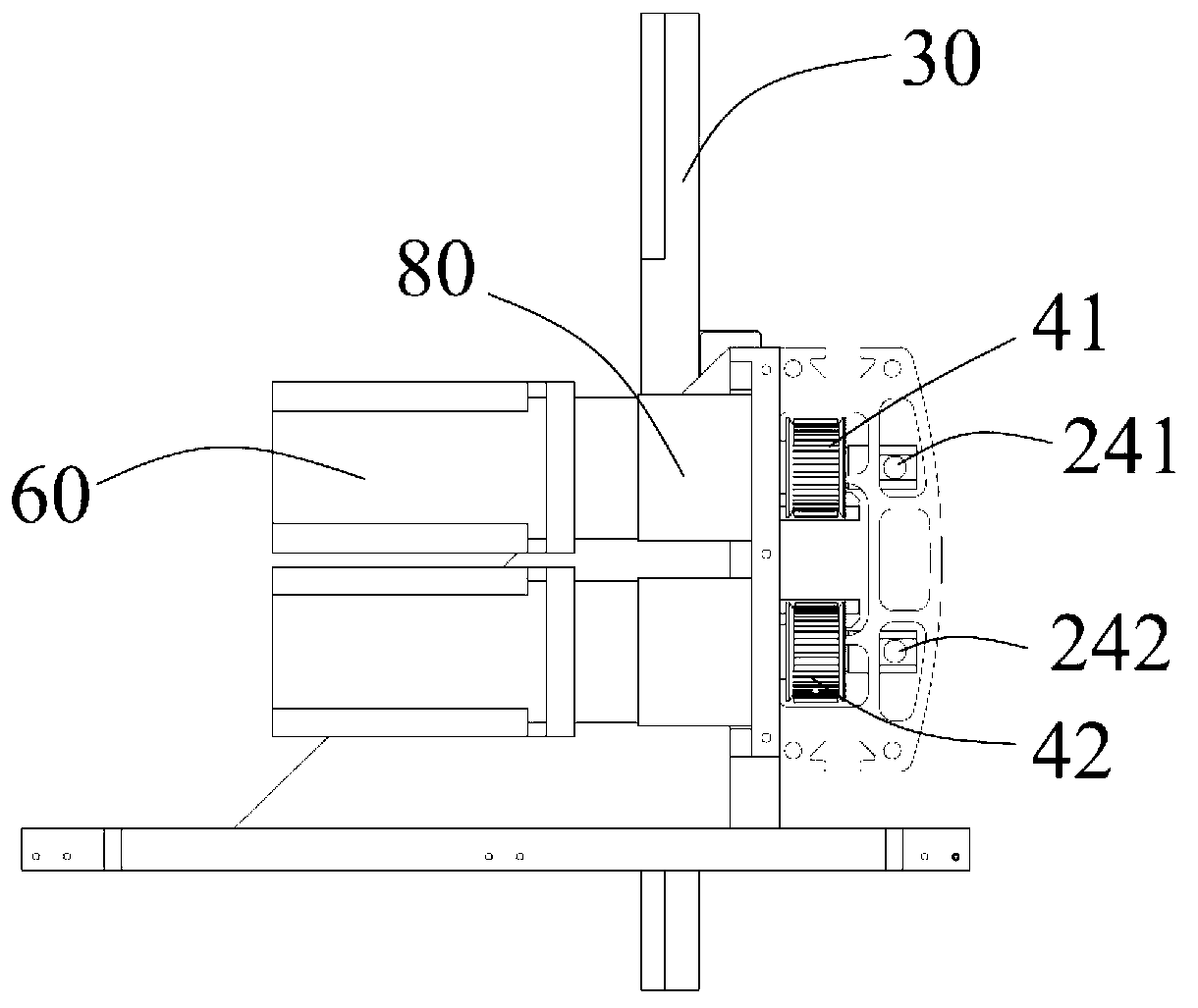

[0034] The invention discloses a belt transmission structure of a mechanical arm, which comprises a horizontal slide plate, a drawing arm installed on the horizontal slide plate, and a drawing slide plate installed on the drawing arm. At least two sets of pulleys are arranged on the drawing arm, each set A belt is installed on the outside of the pulley, and at least two servo motors are installed on the horizontal slide plate. The pulley is driven by the servo motor. The belt is provided with a belt splint. The belt splint and the drawing slide are fixedly arranged, and the reducer is driven by the servo motor. The reducer drives the belt pulley, the belt pulley drives the belt, the belt drives the belt splint, and the belt splint drives the drawing slide to complete the transmission action of the mechanical arm.

[0035] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com