Patents

Literature

34results about How to "The transmission runs smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

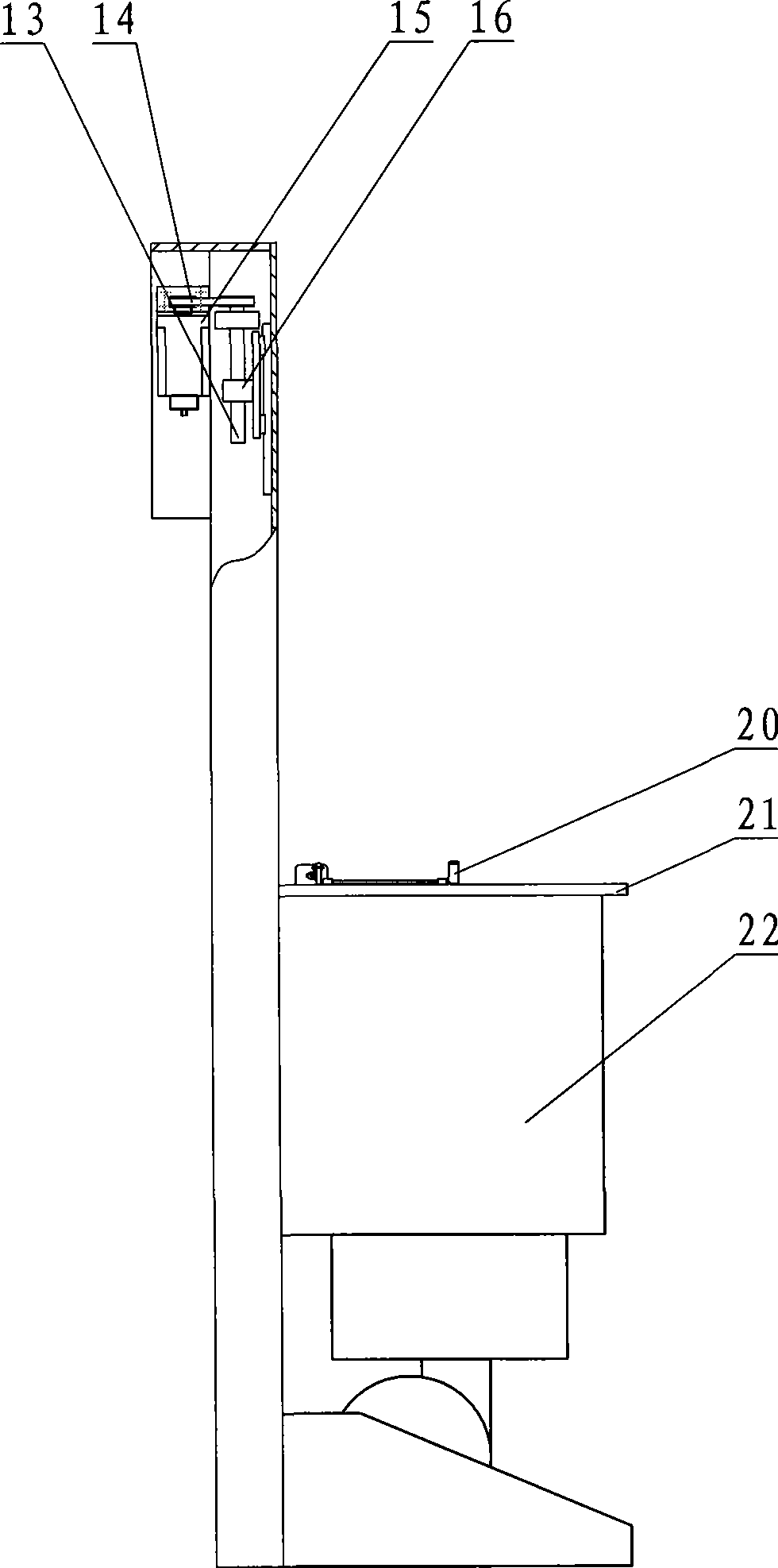

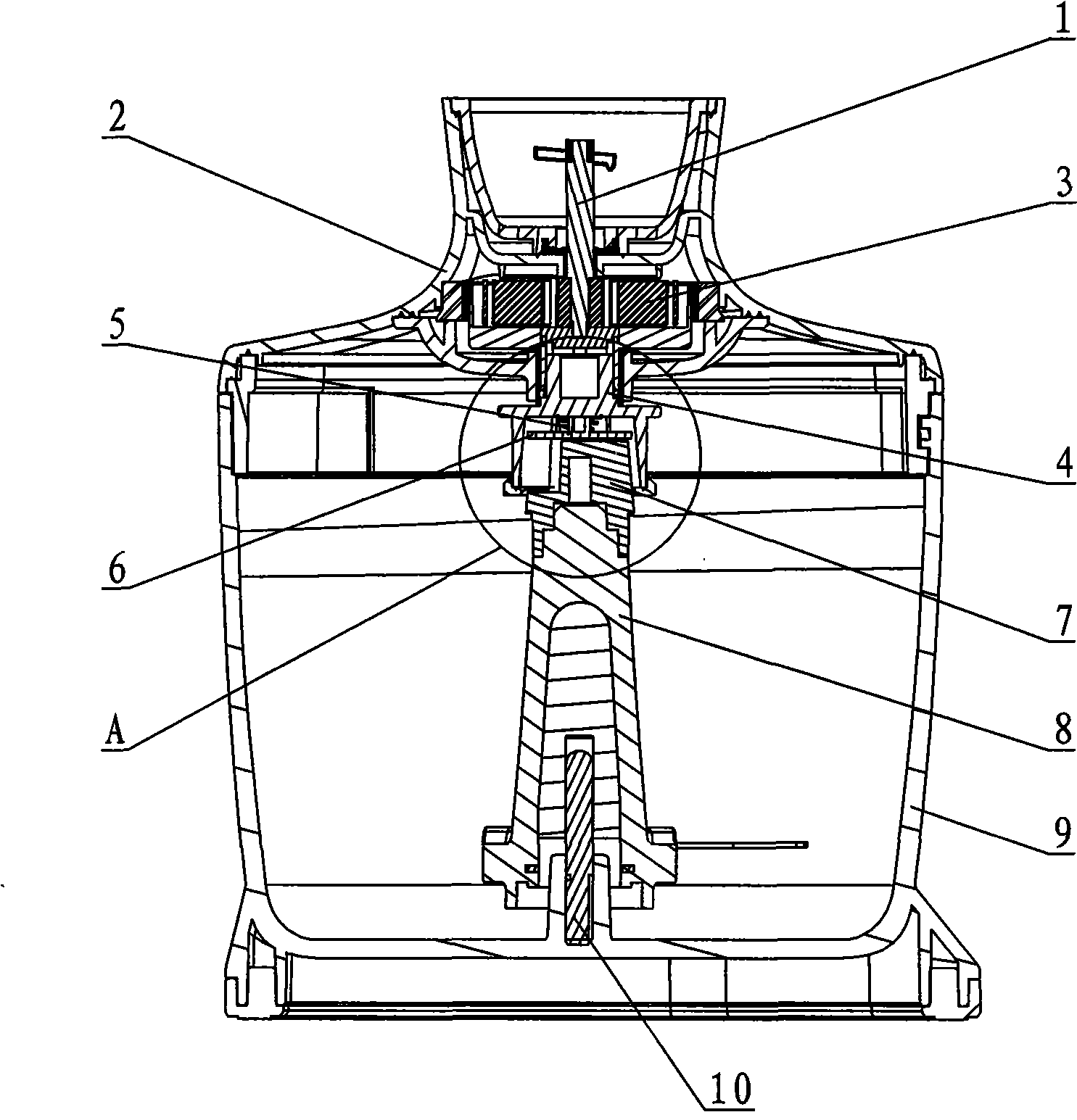

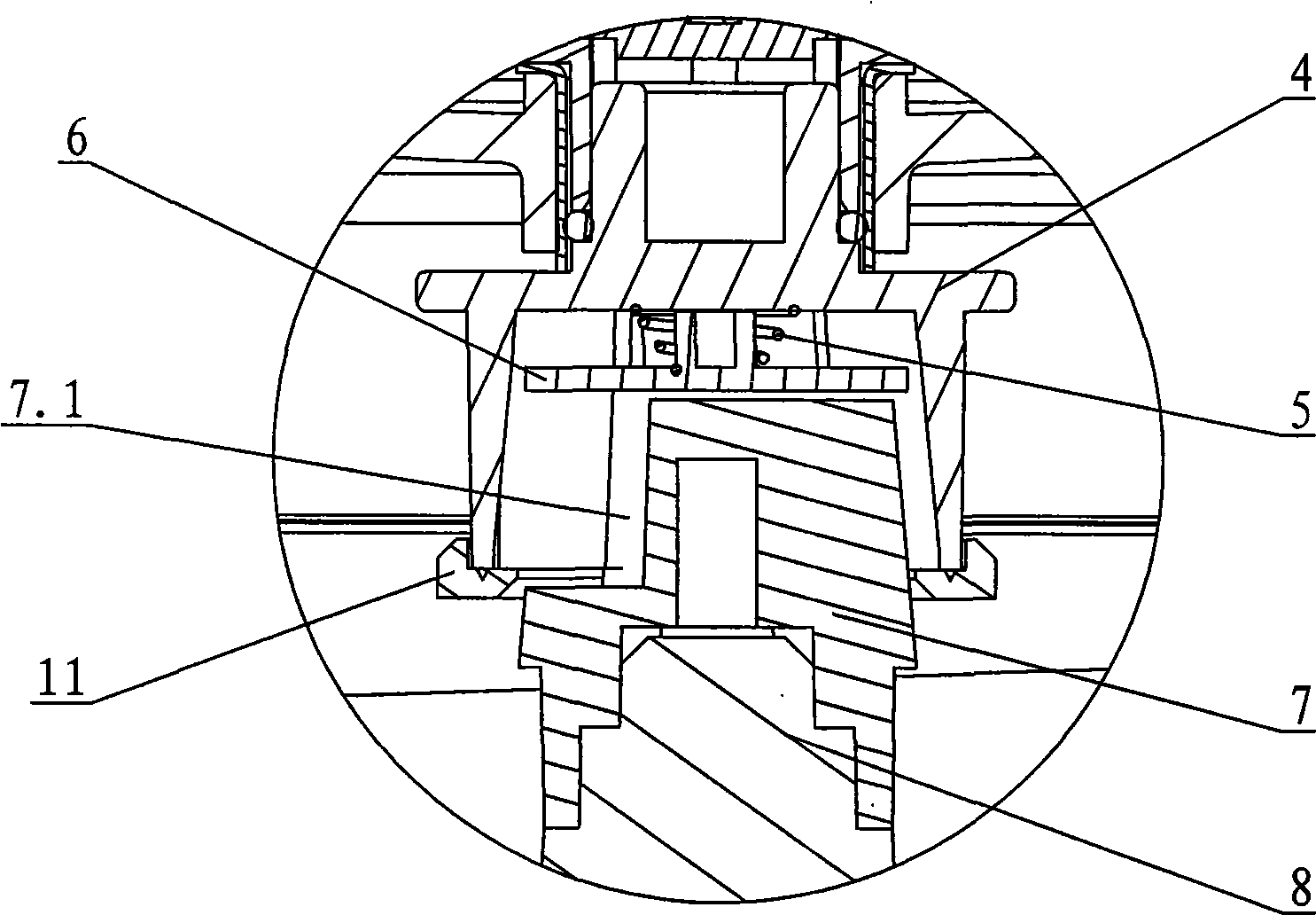

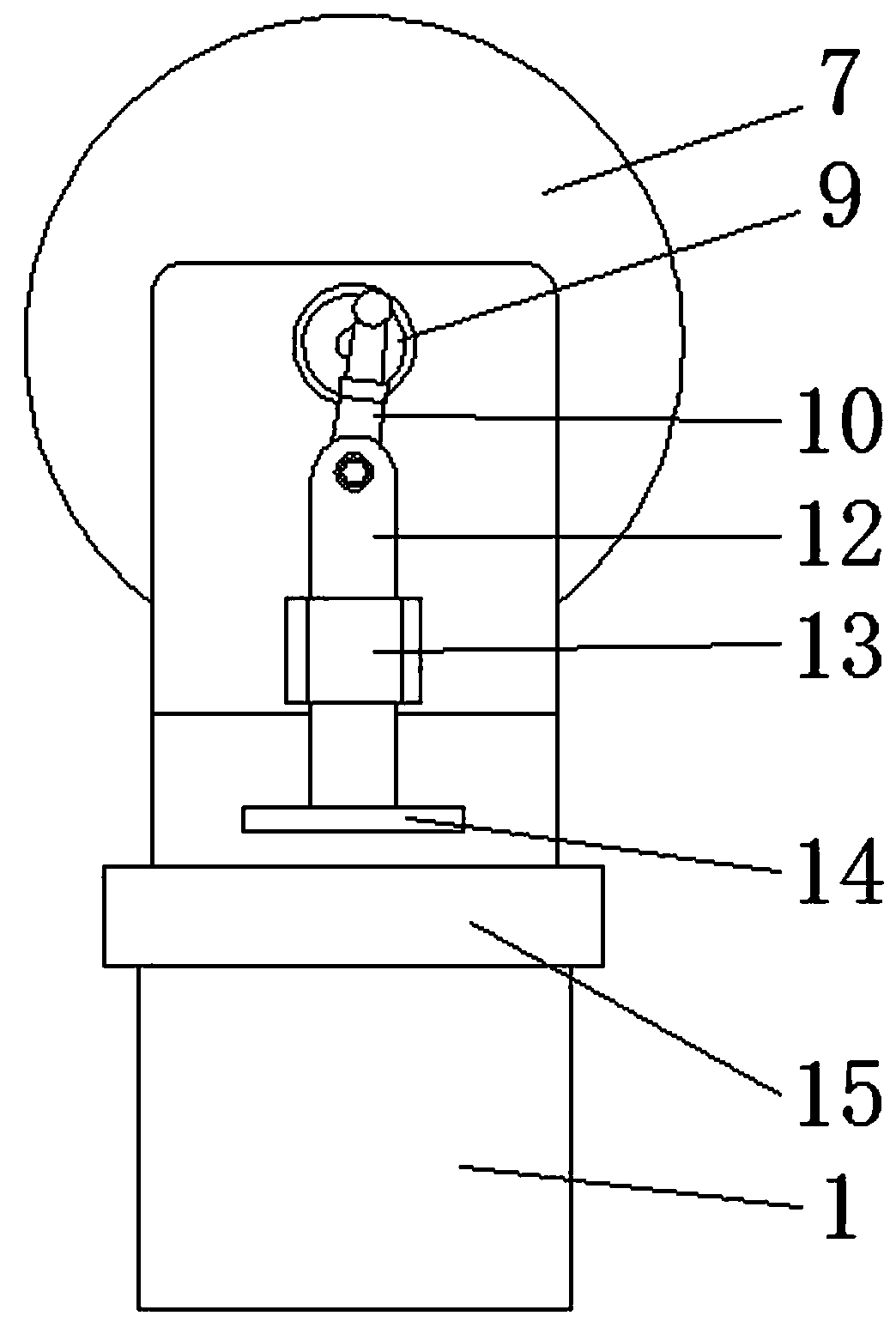

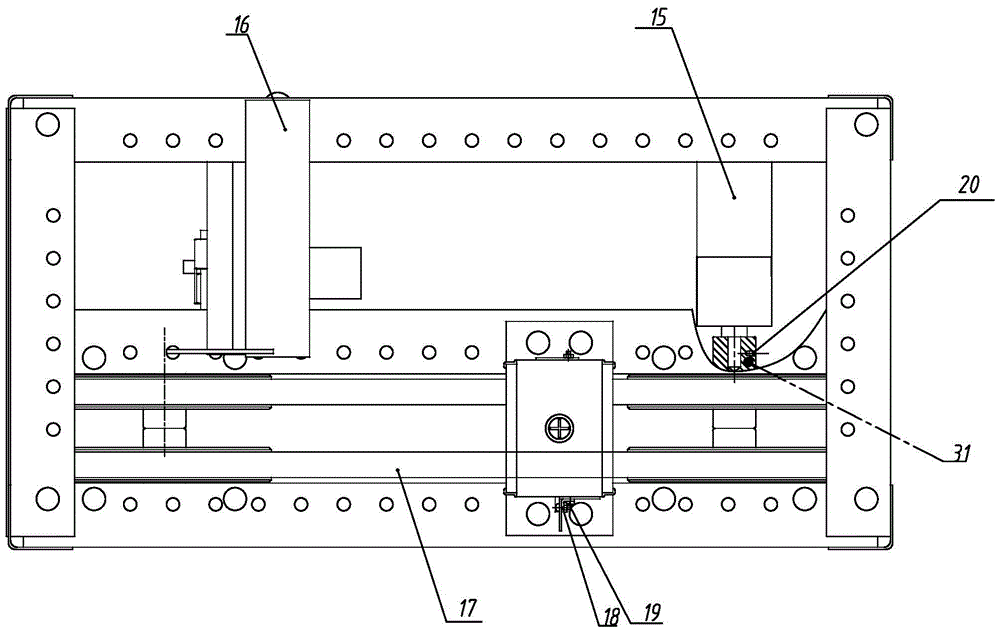

Translational overturn type automatic conveying device for silicon wafer

InactiveCN101465309AWon't fall offReasonable structural designConveyor partsState of artAutomatic transmission

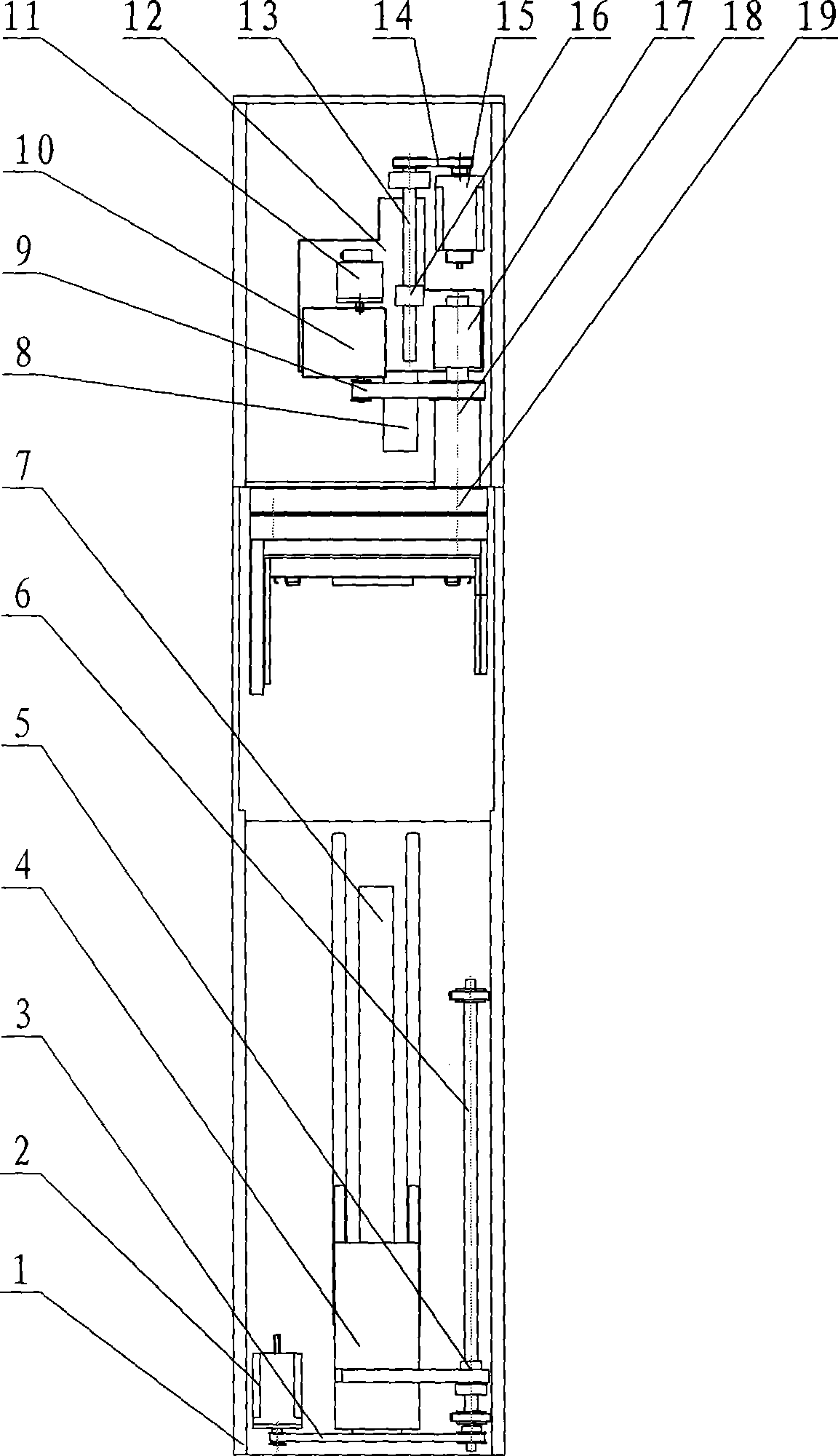

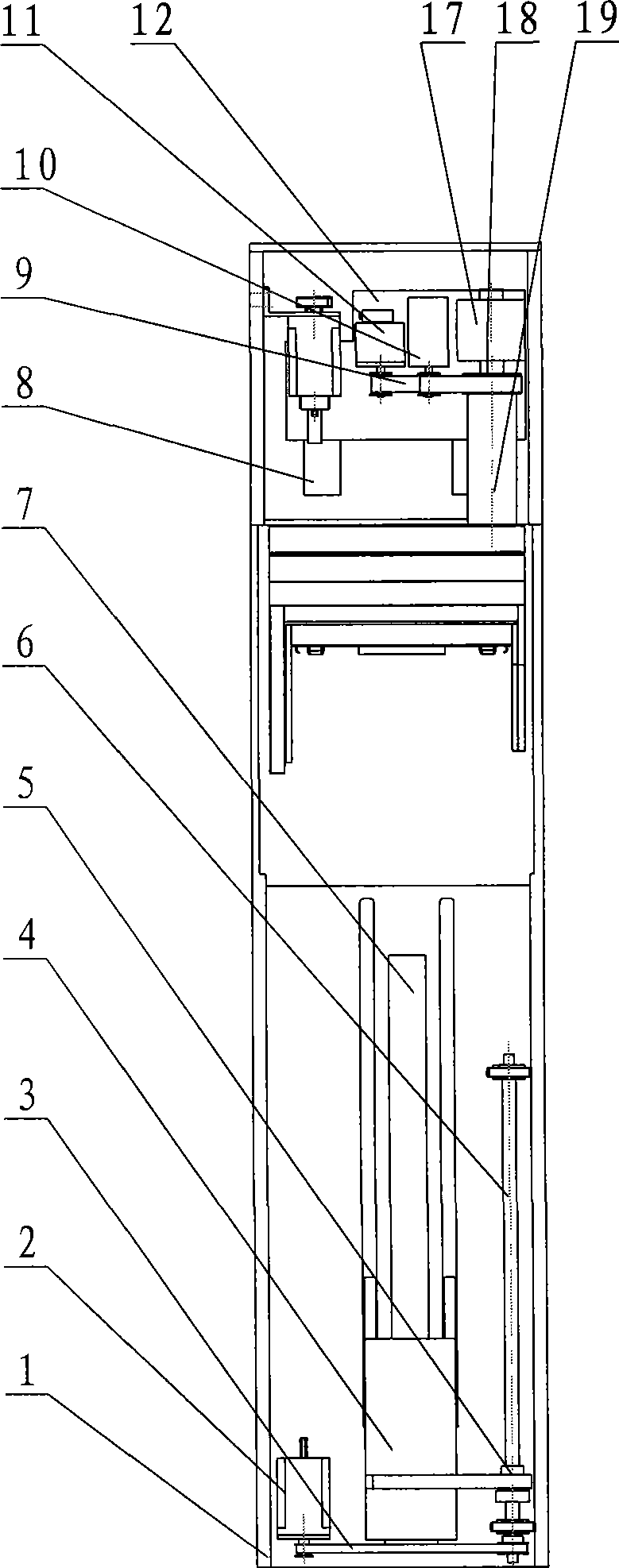

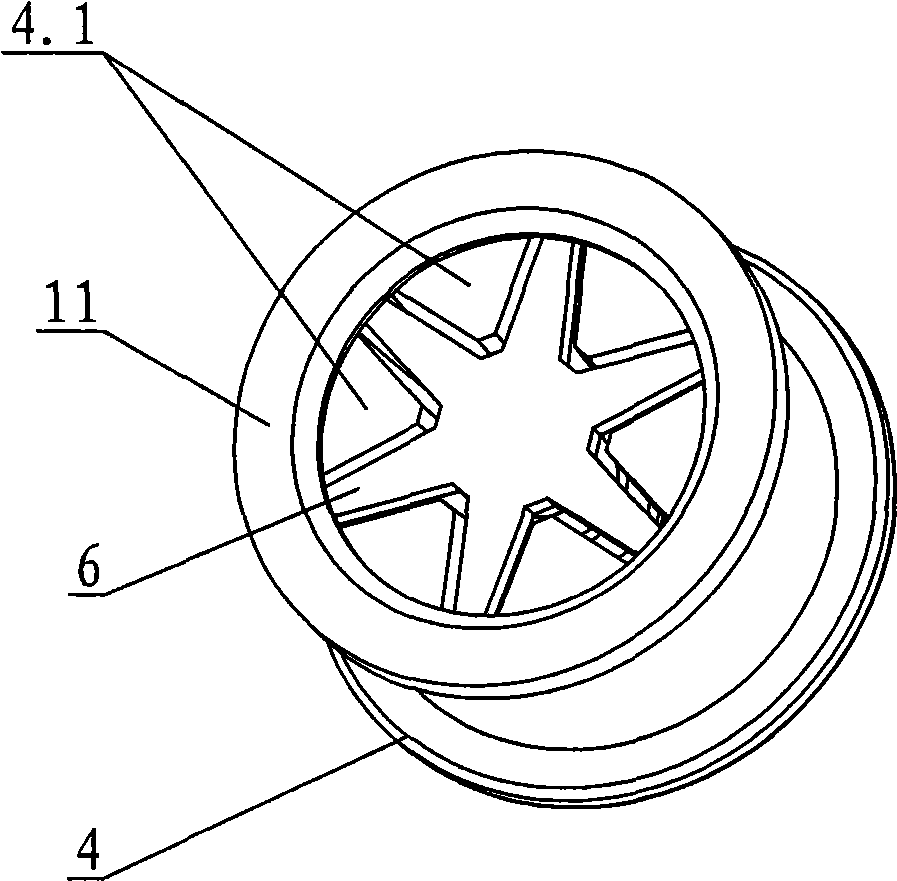

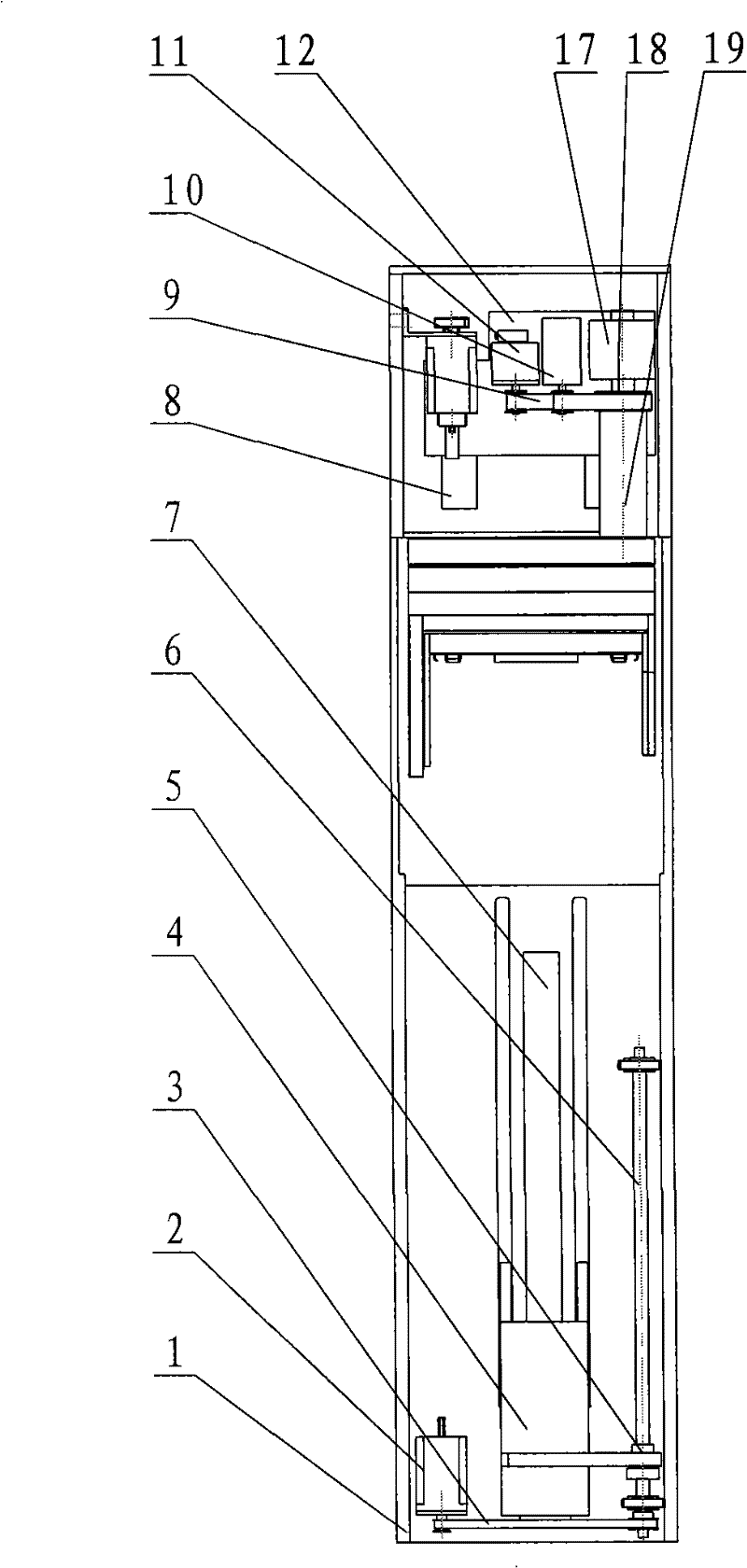

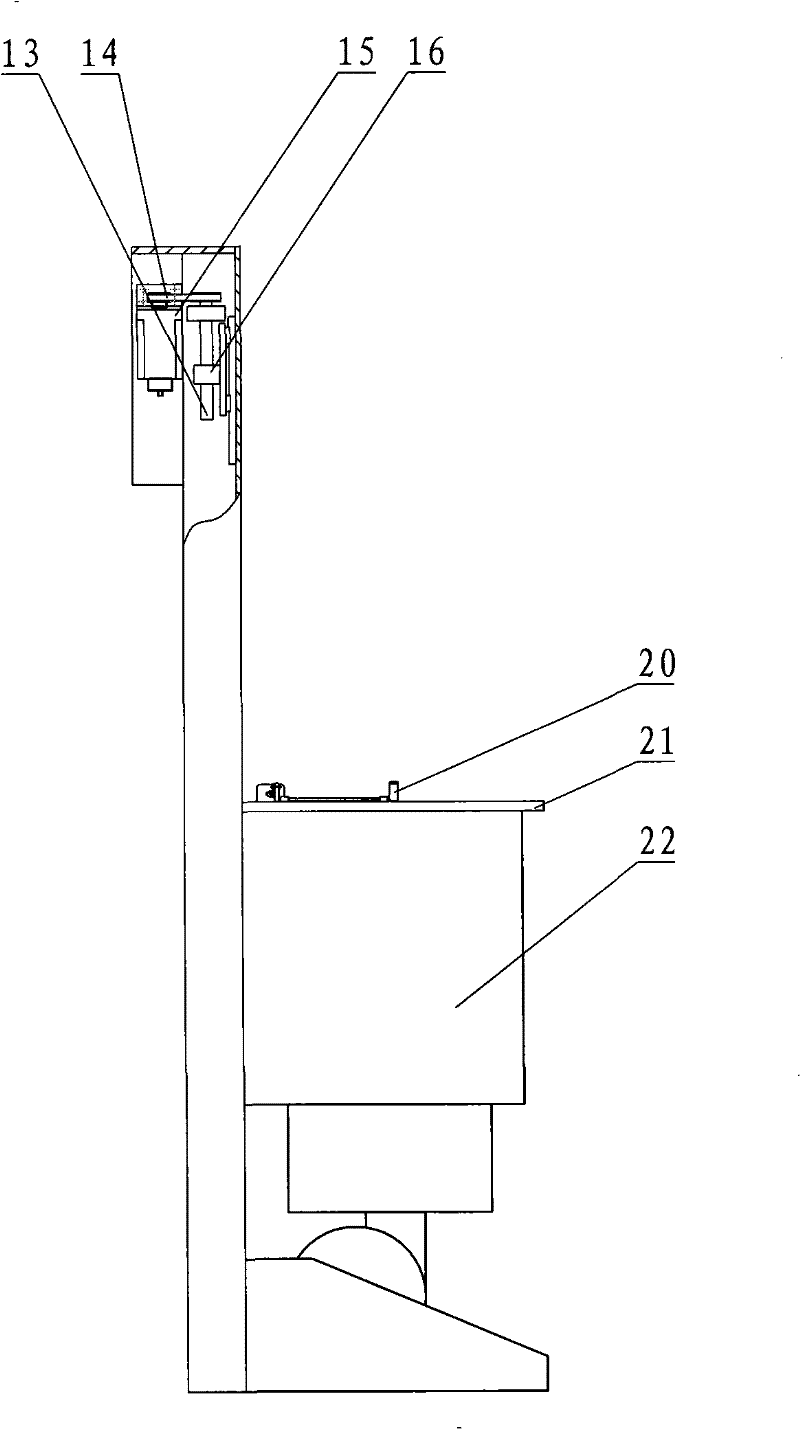

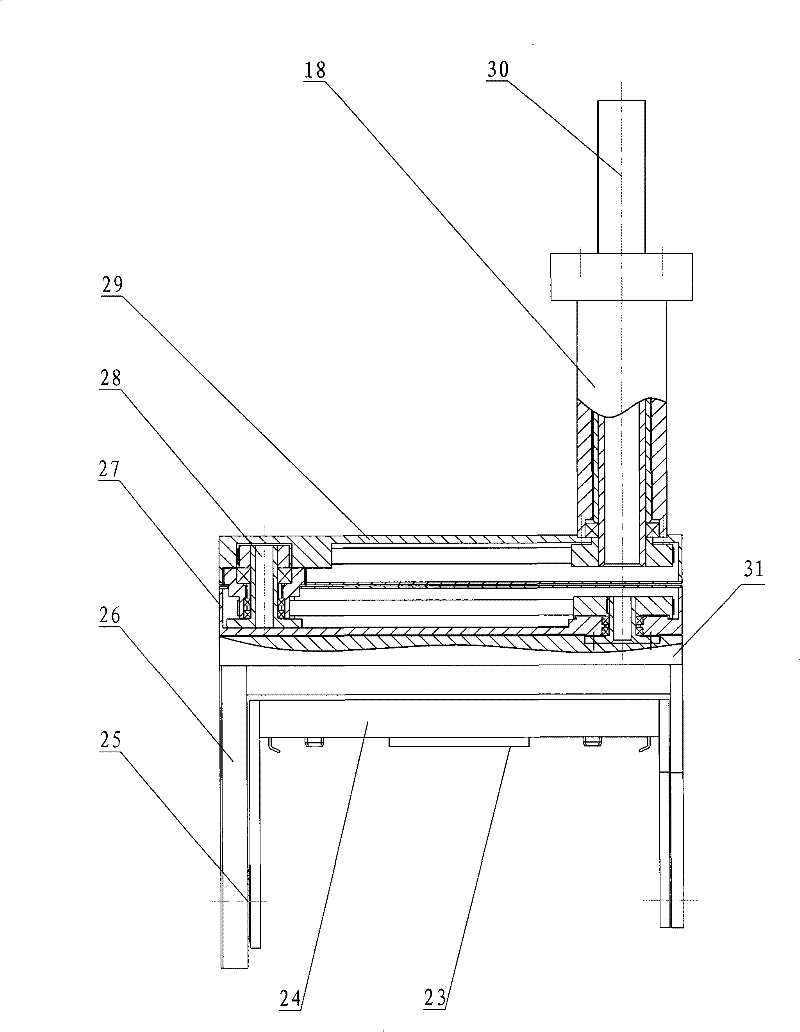

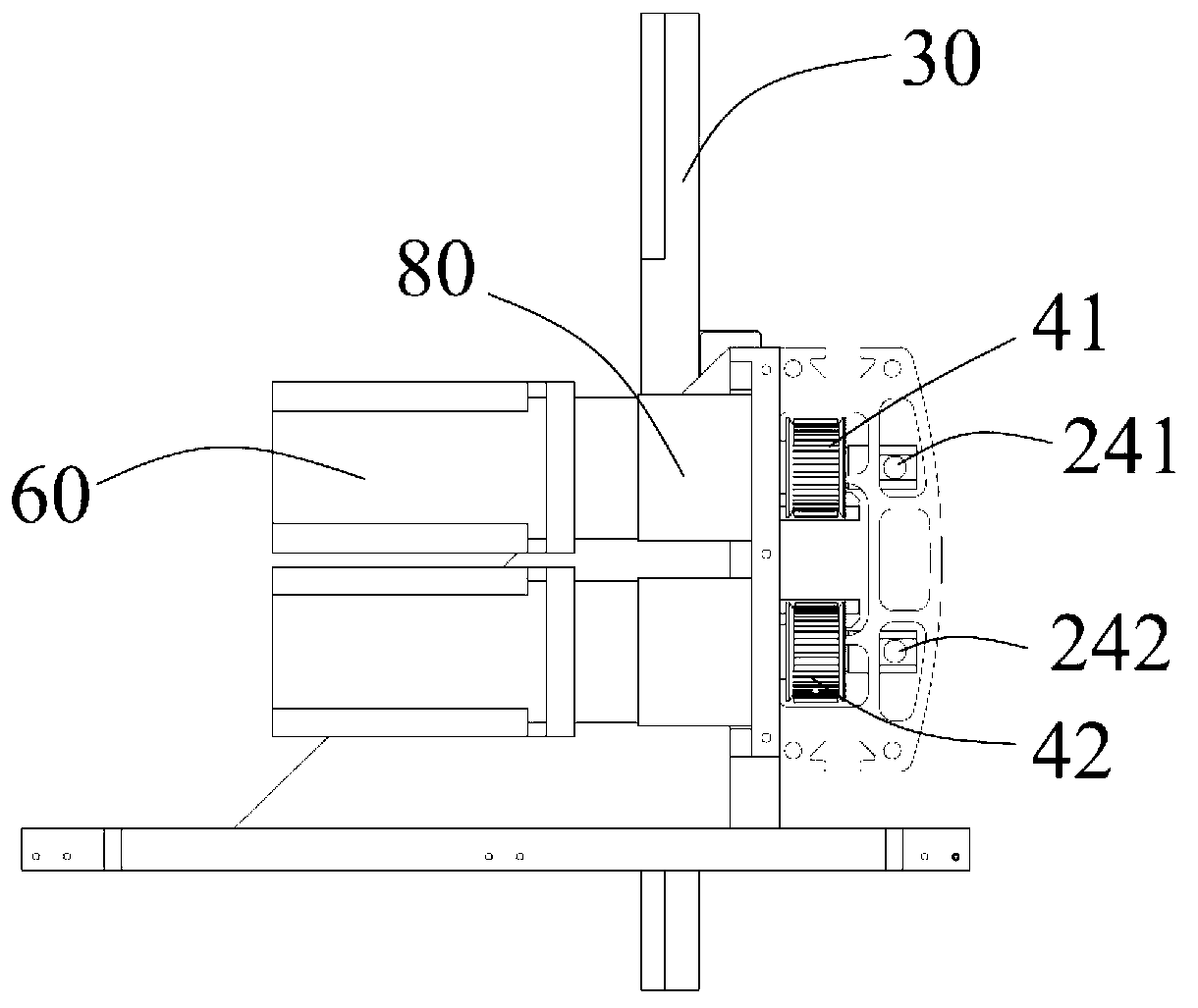

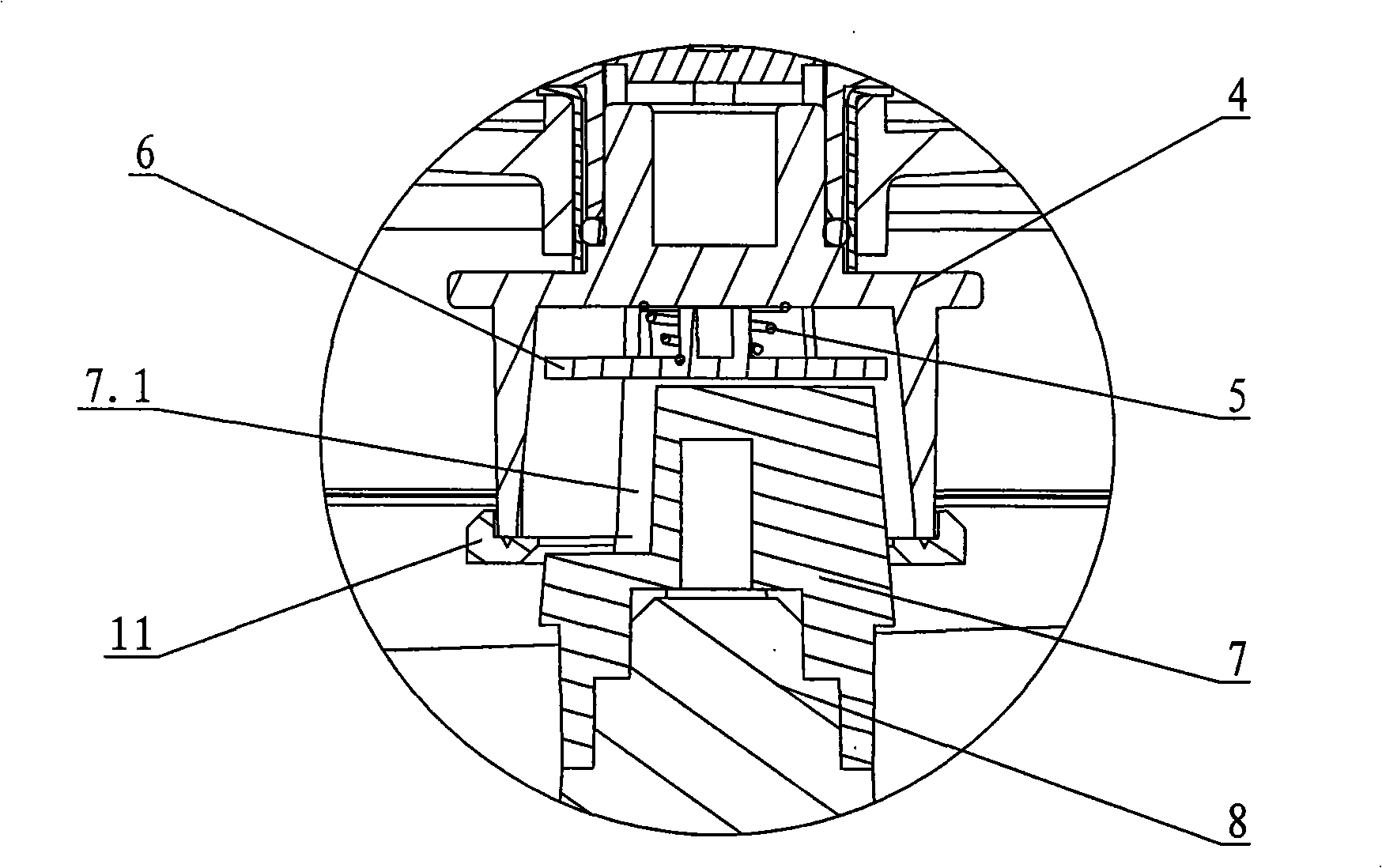

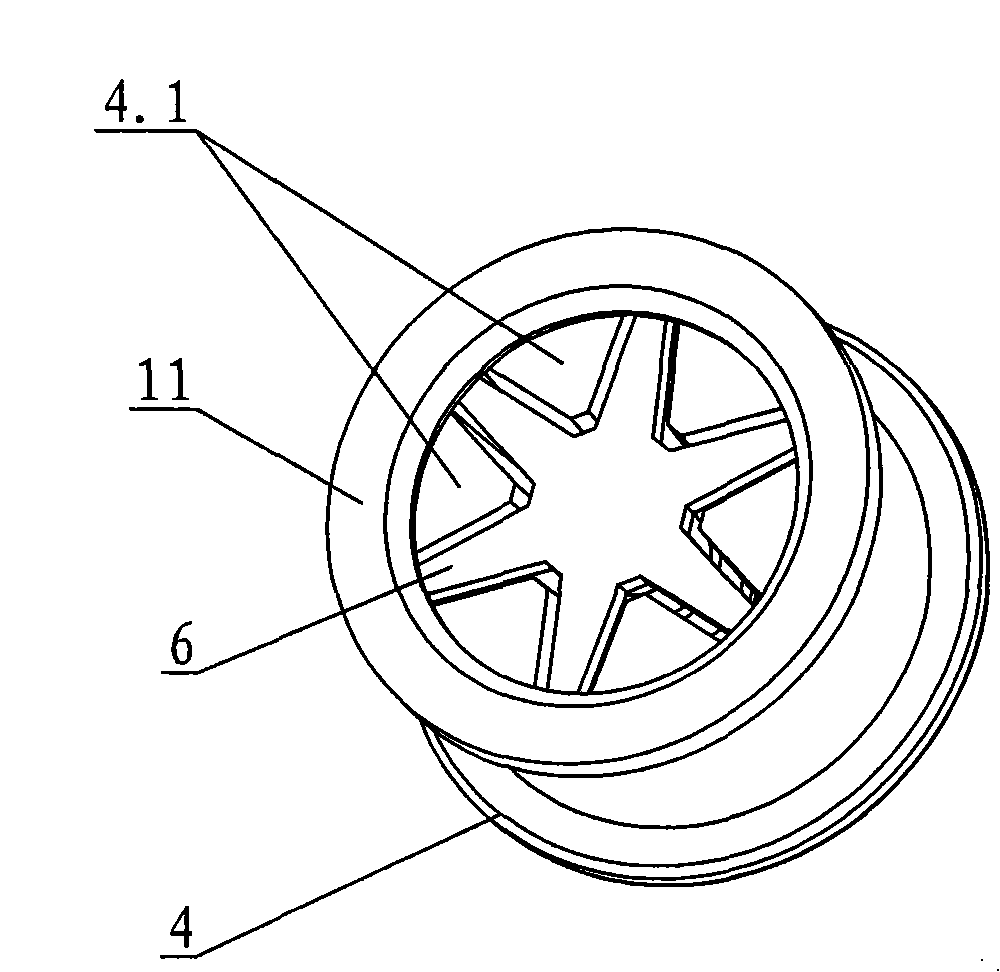

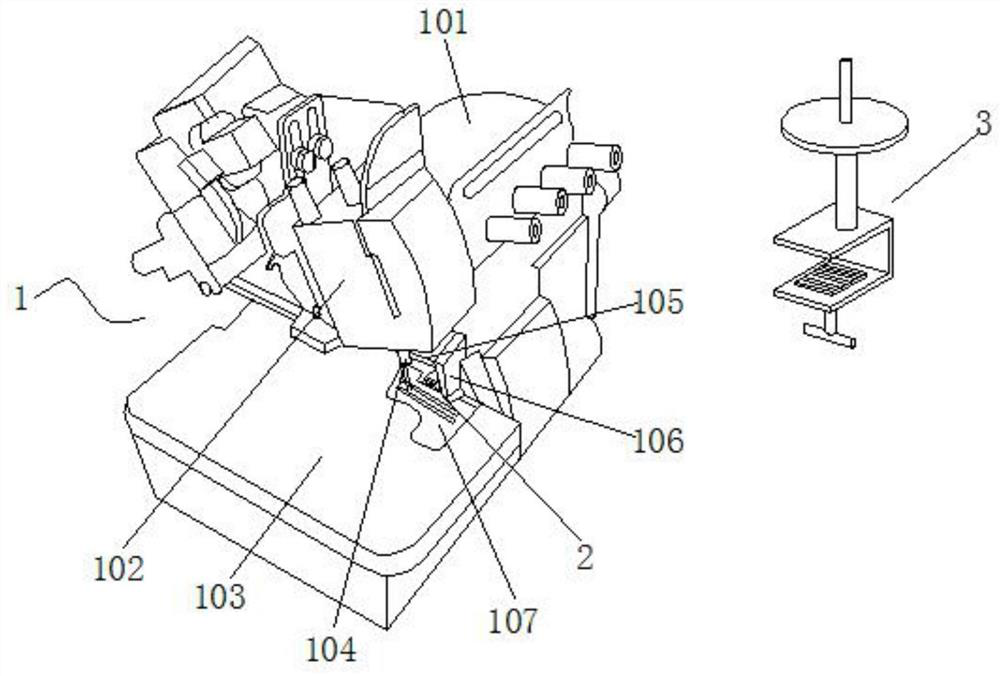

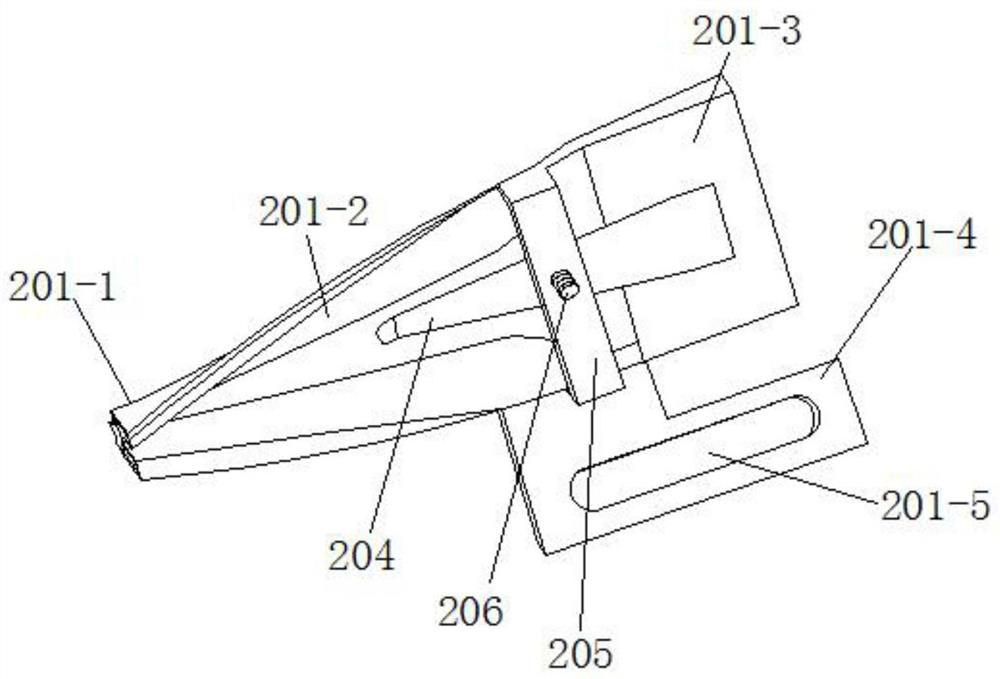

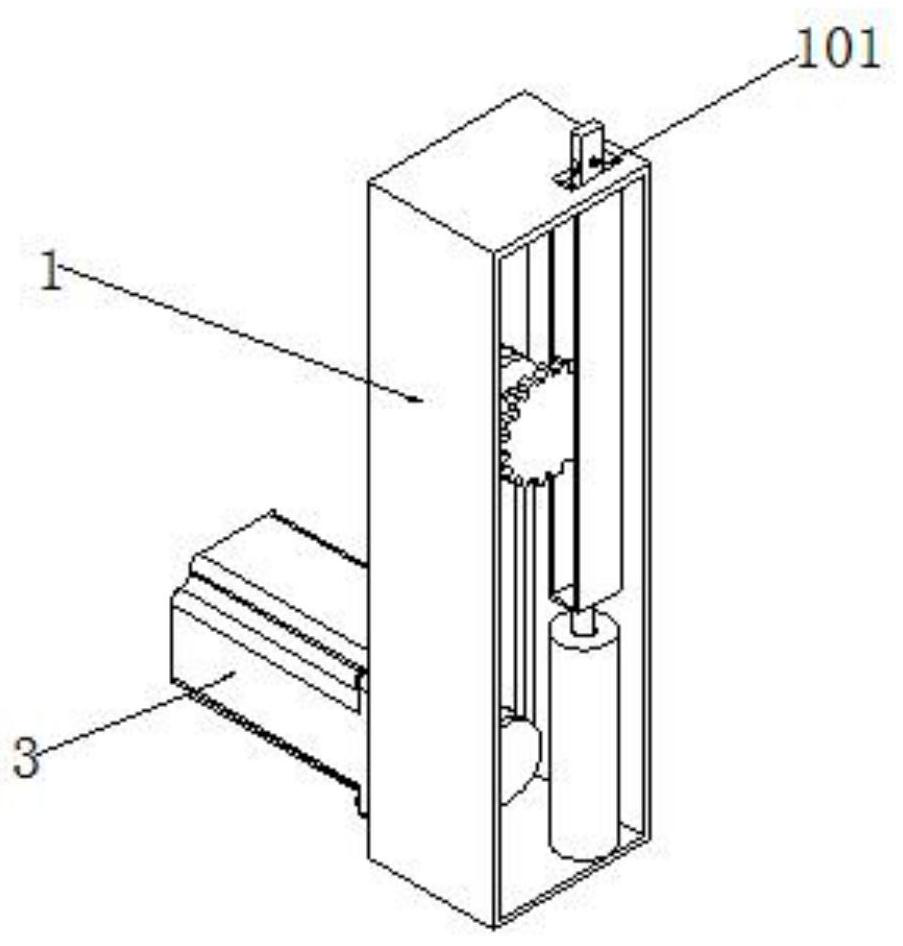

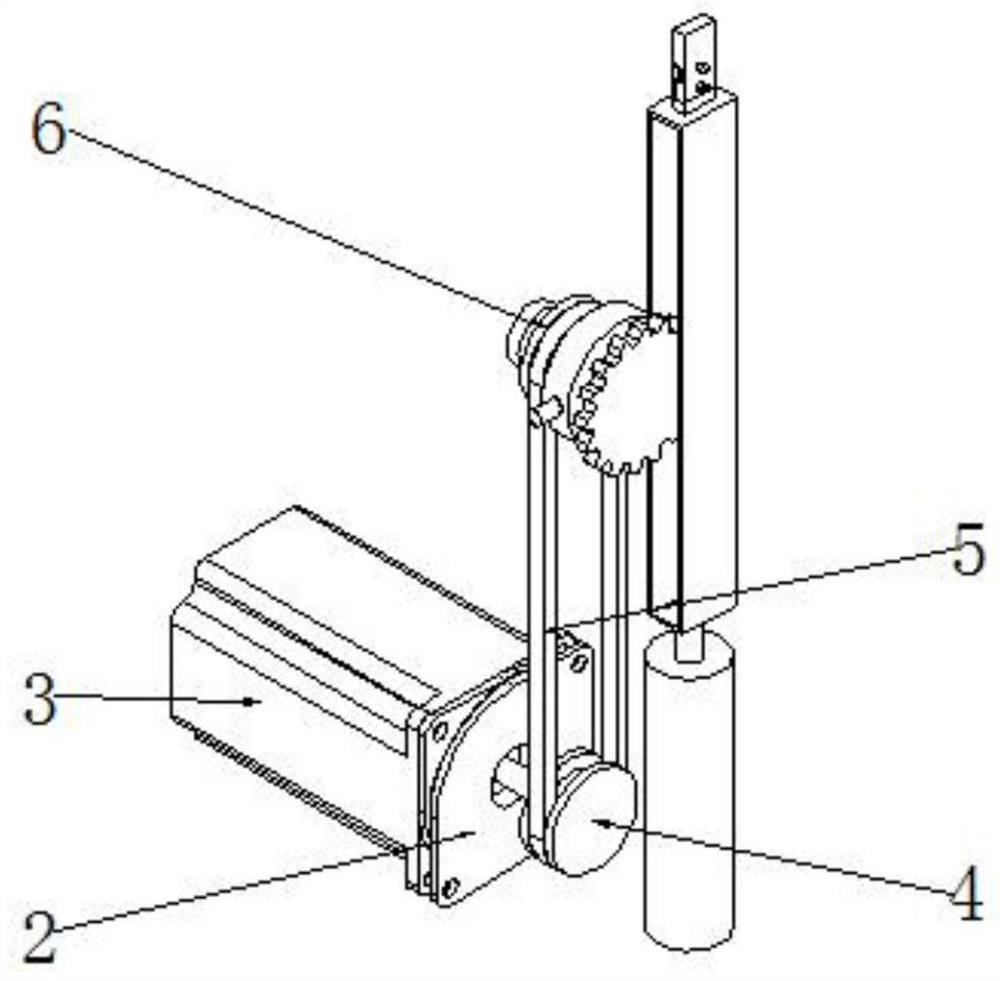

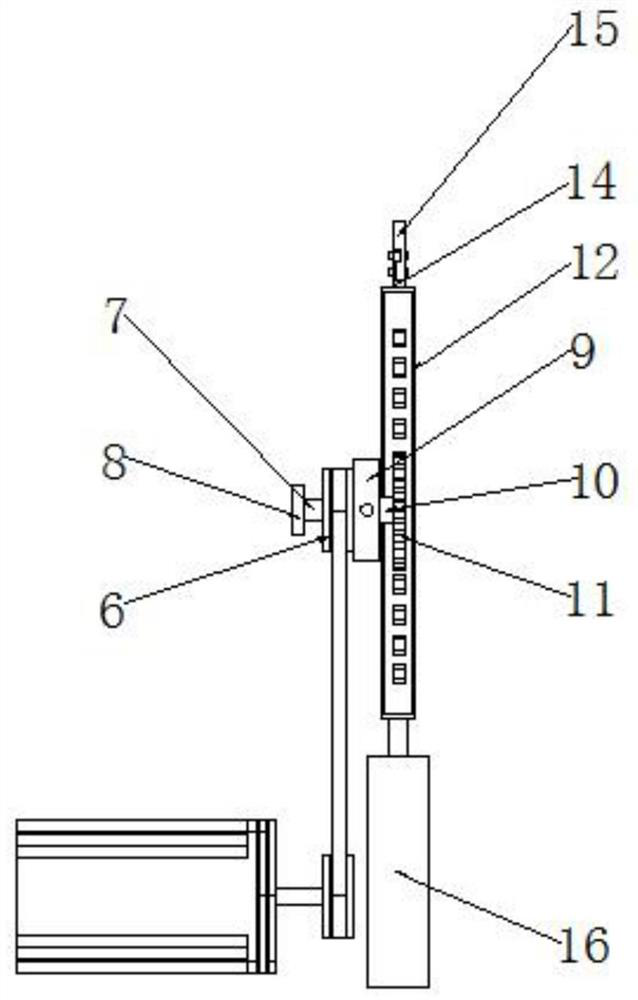

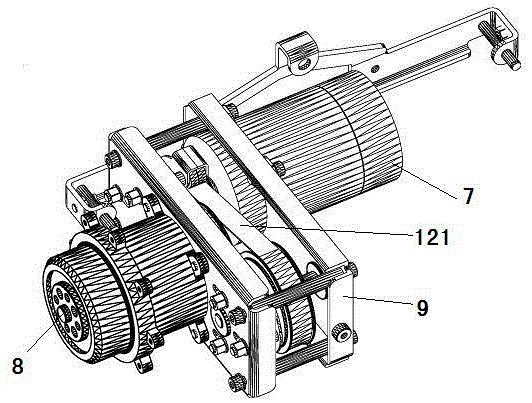

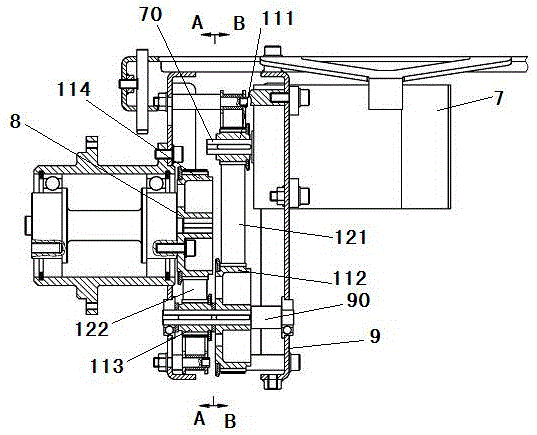

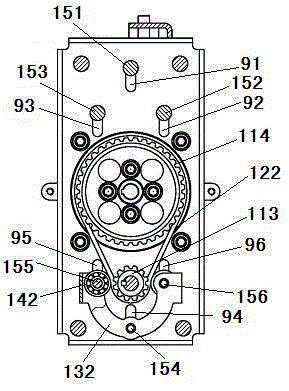

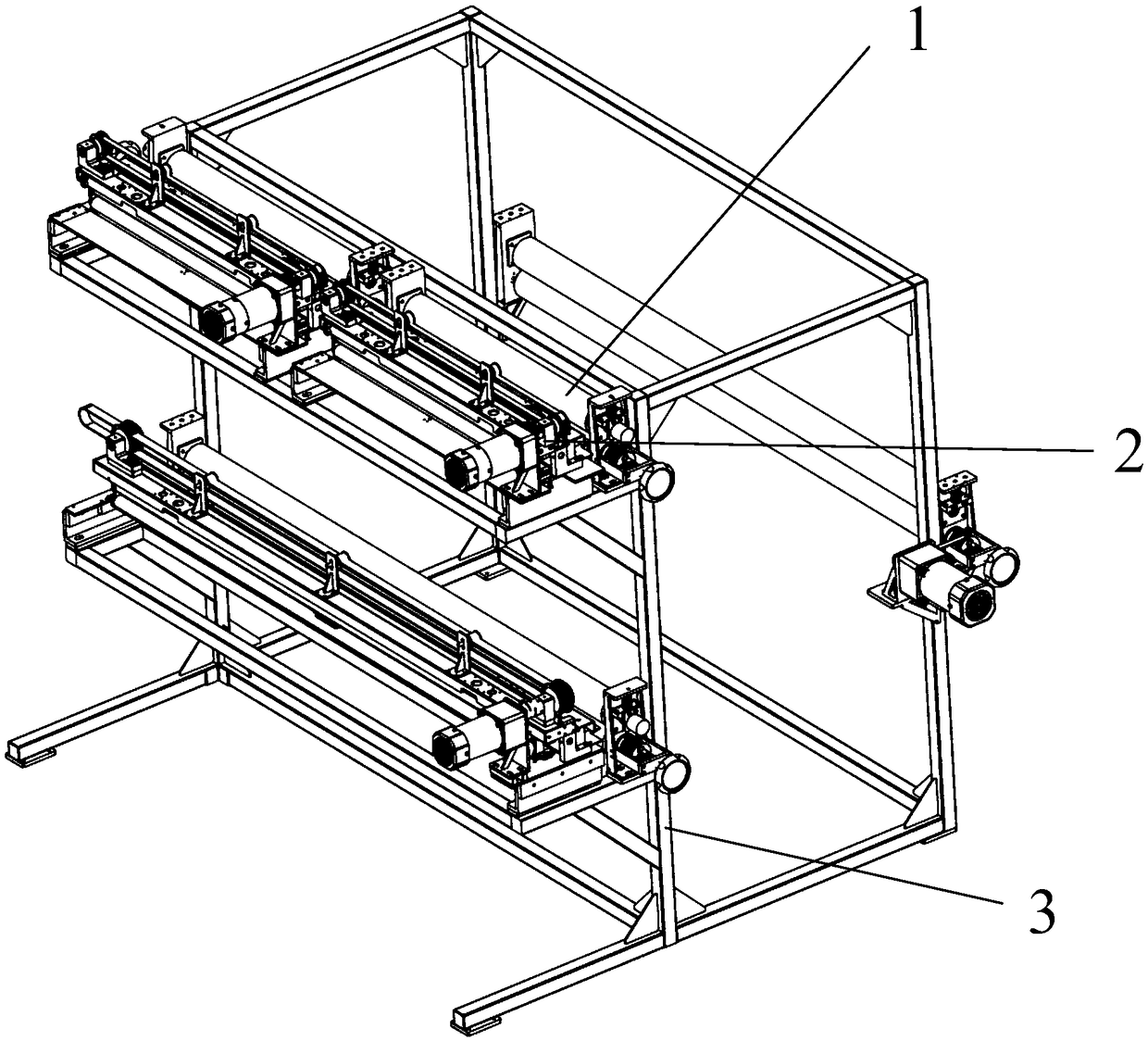

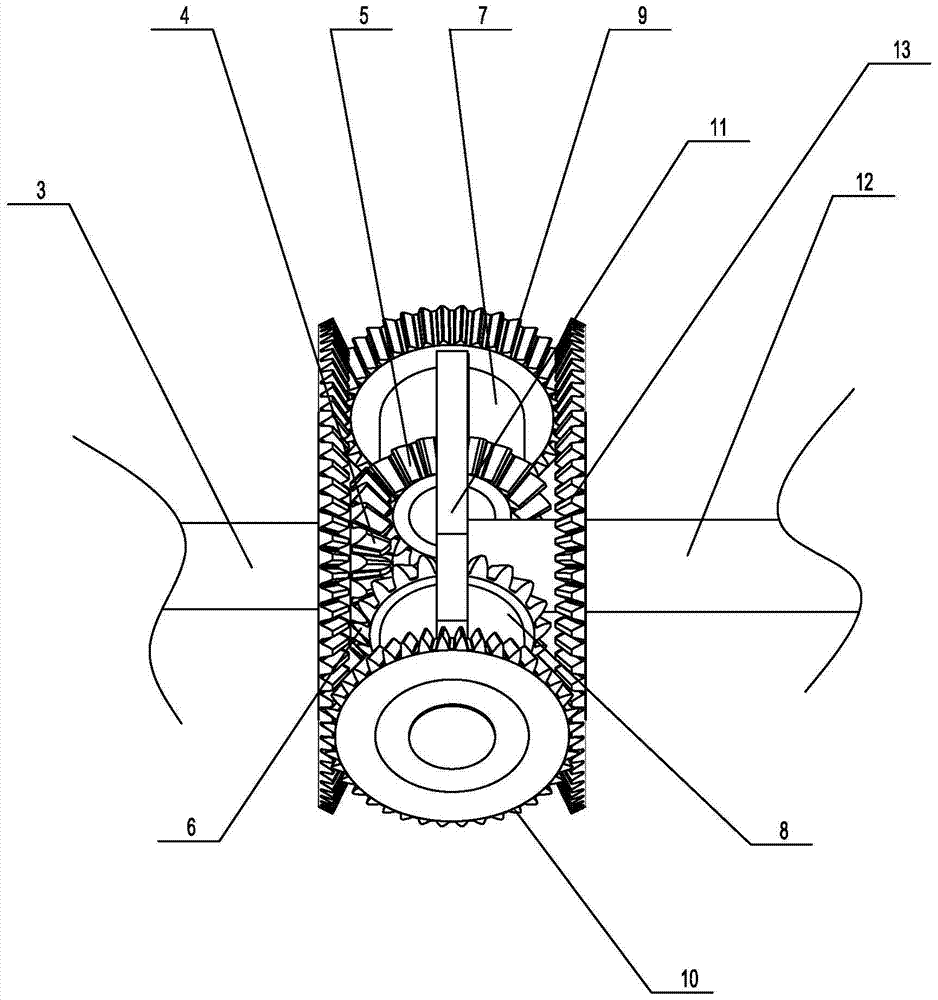

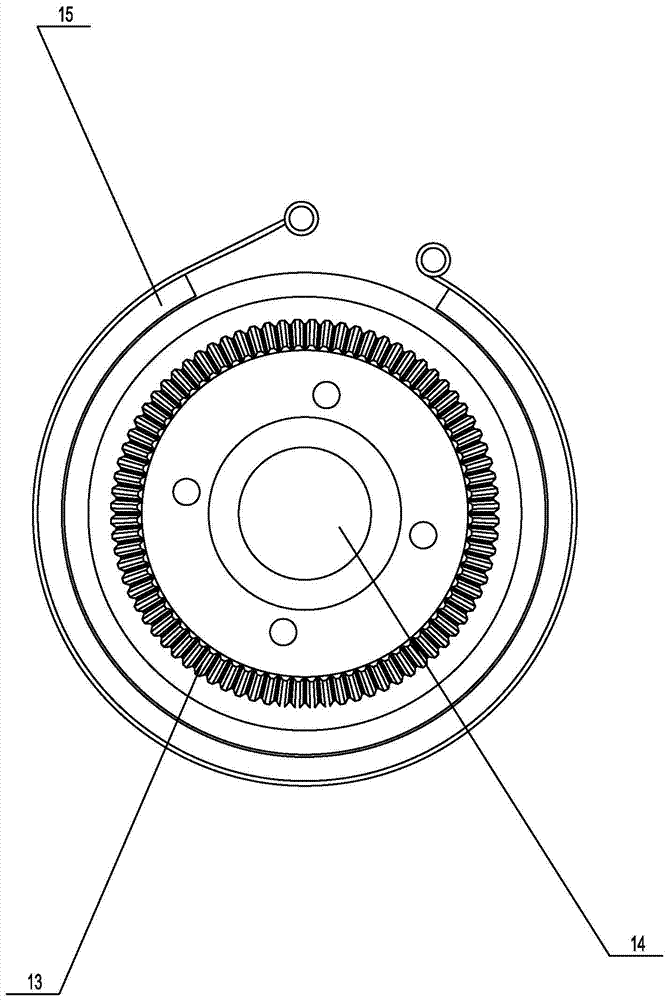

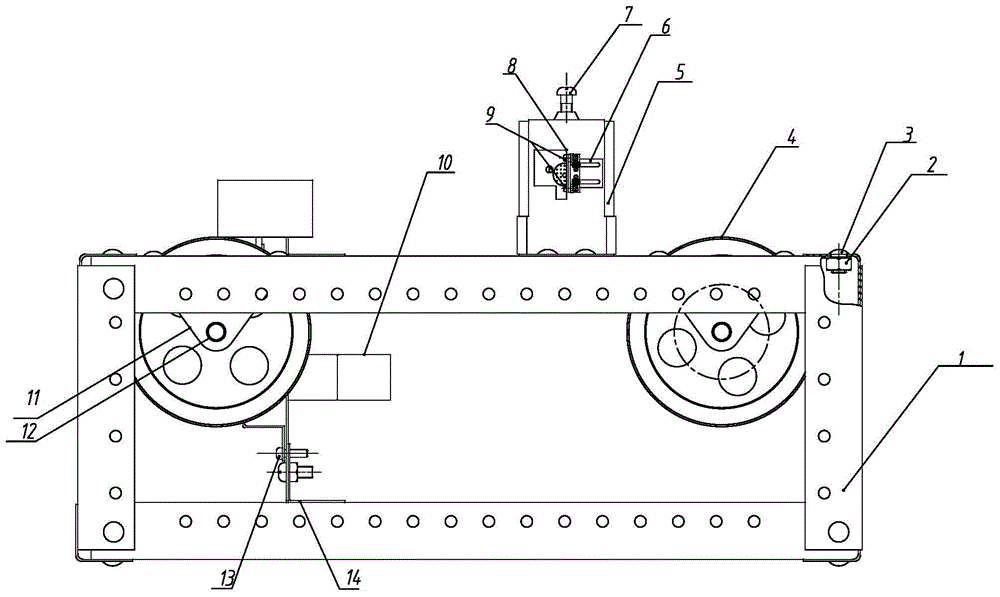

A shift tilting-type wafer automatic transmission device overcomes the shortcomings that the prior art can not make complex movements in the narrow space of the manufacturing process; the wafer automatic transmission device comprises a machine frame, a feeding platform, a bellows body and an arm mechanism and is technically characterized in that a lower arm of the arm mechanism is connected with a grasping mechanism through a shift mechanism and a tilting mechanism which are assembled together; an assembly gear connecting rod transmission mechanism is used to drive the grasping mechanism to rotate around the axis; a grasping motor of the grasping mechanism drives a gripping claw to move back and forth; and a positioning mechanism on the grasping mechanism is provided with an adjustable positioning block. The device has rational design and stable transmission and running in the production process, as well as flexible and reliable movement; the device expands the scope of application and can realize bilateral shift and tilting of a wafer box while the device completes the automatic wafer transmission in the horizontal or vertical state of the wafer so as to fully realize the automatic transmission in a small space in which the center distance of the parallelly arranged process equipment is less than the center distance of the transmission equipment; moreover, the device can flexibly stop in the face of external interference to achieve the precisely controlled transmission effect.

Owner:FORTREND TECH SHENYANG CO LTD

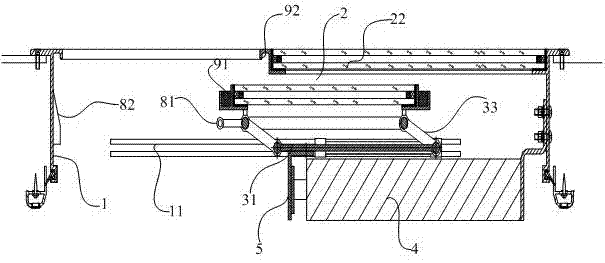

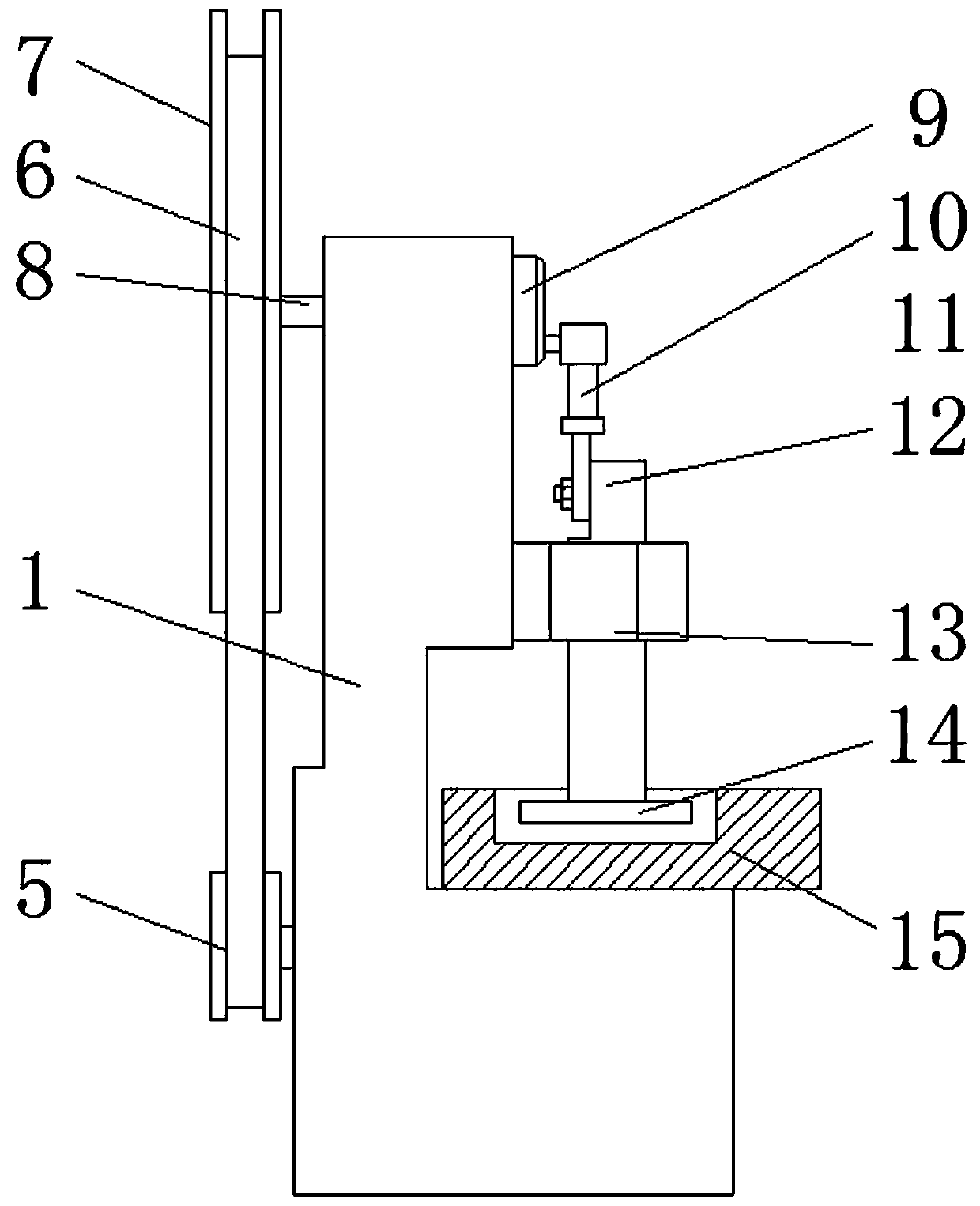

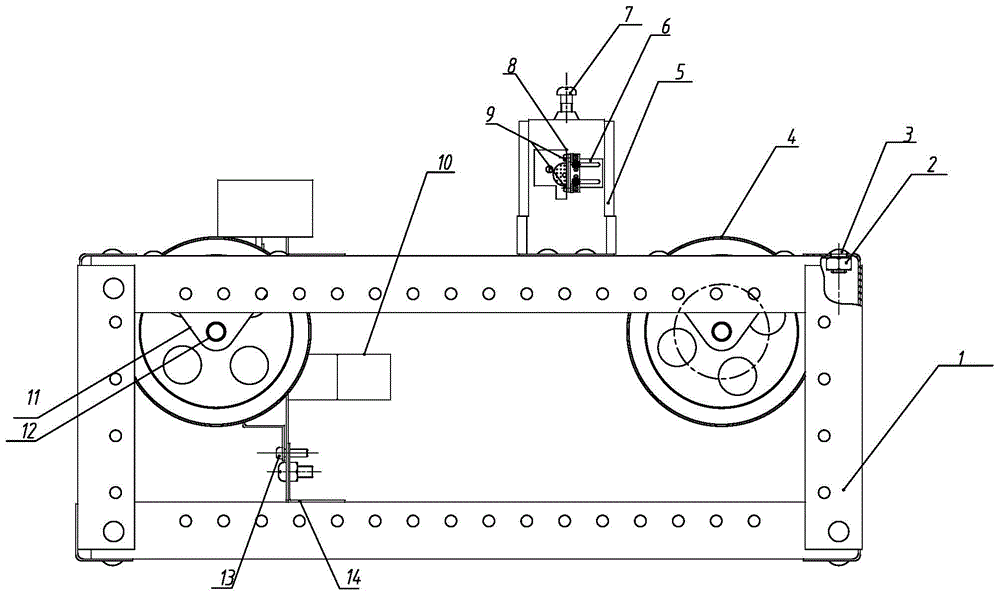

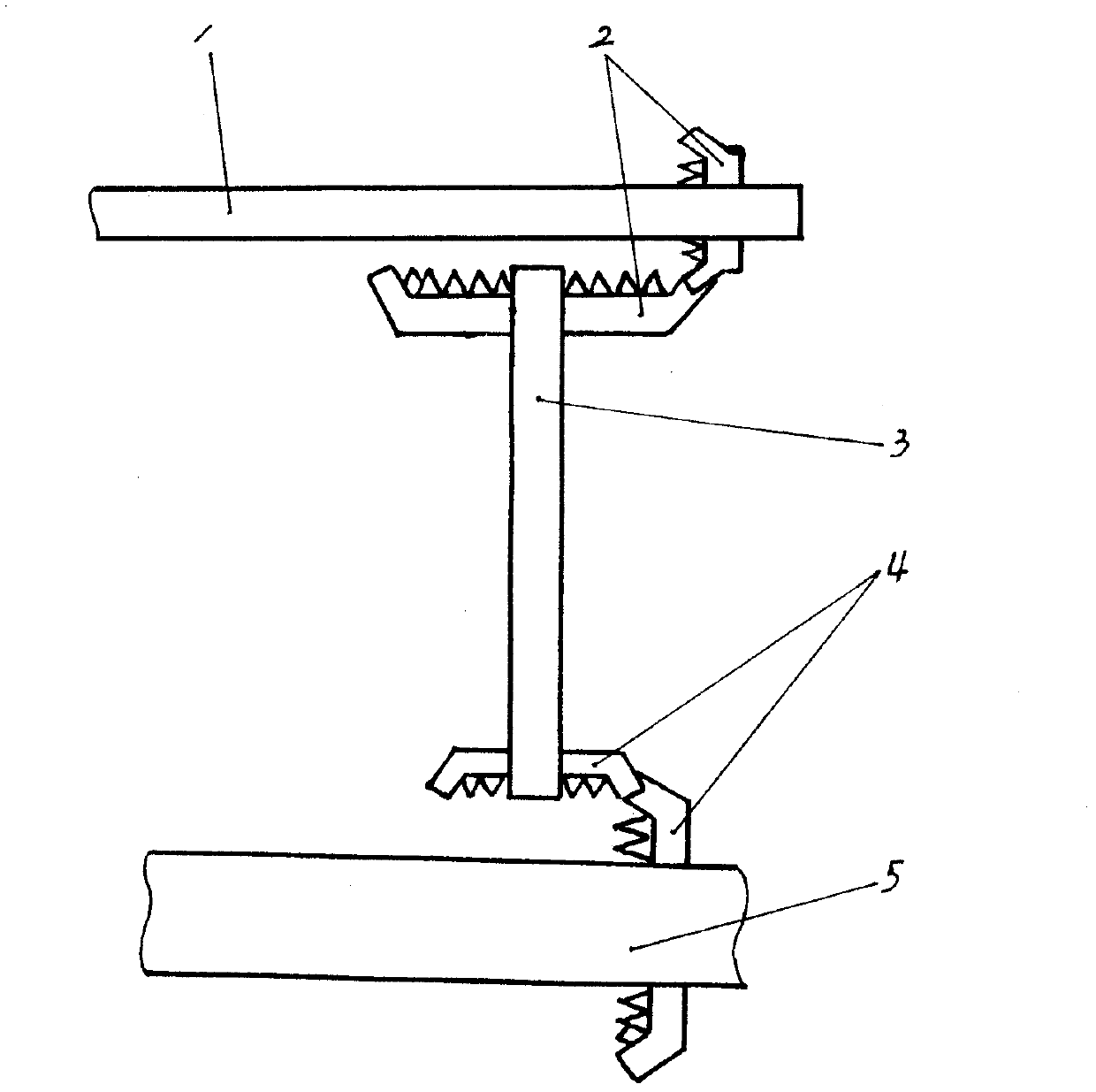

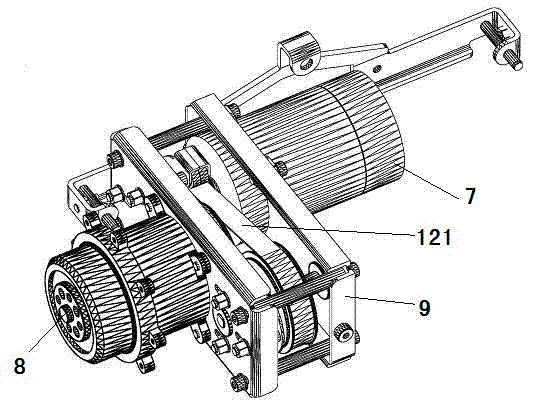

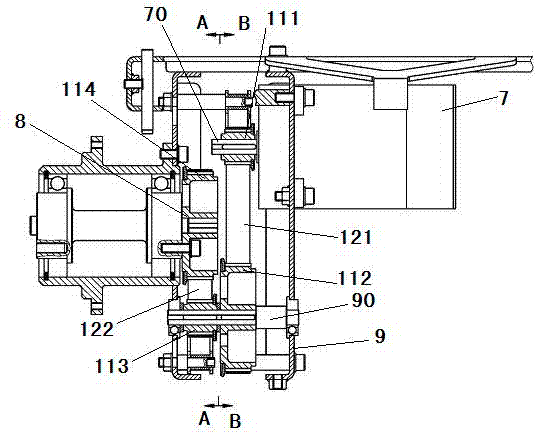

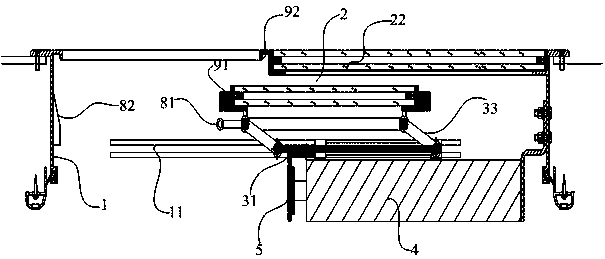

Automatic conveying device for turnover type wafer

ActiveCN101459101AWon't fall offReasonable structural designConveyor partsState of artProcess equipment

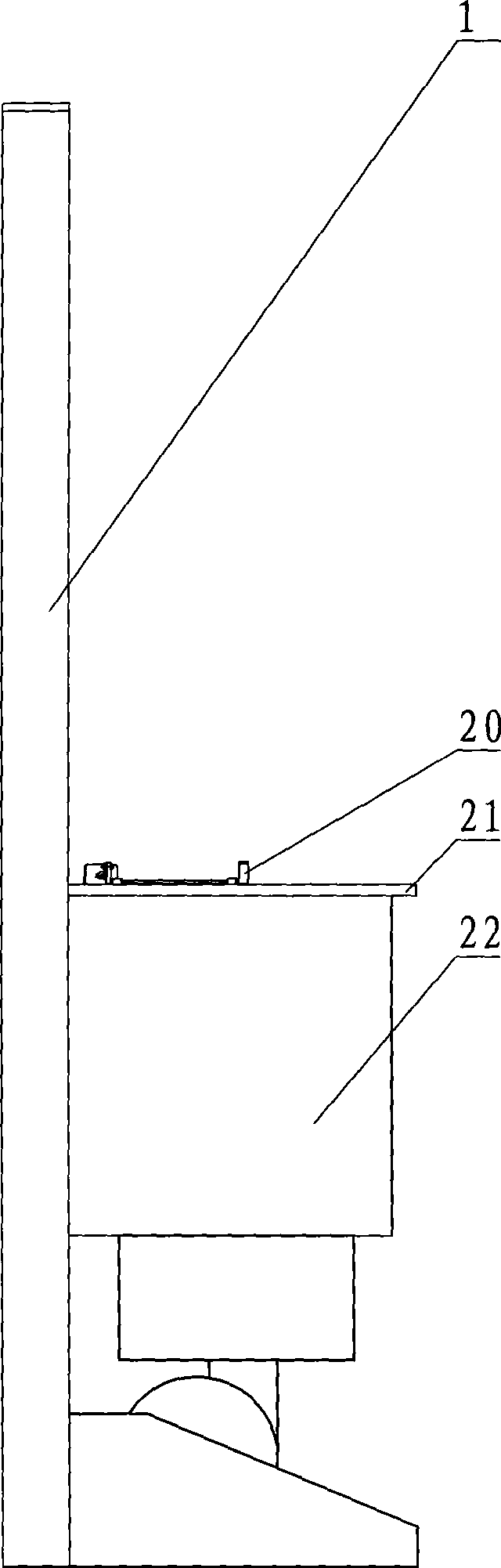

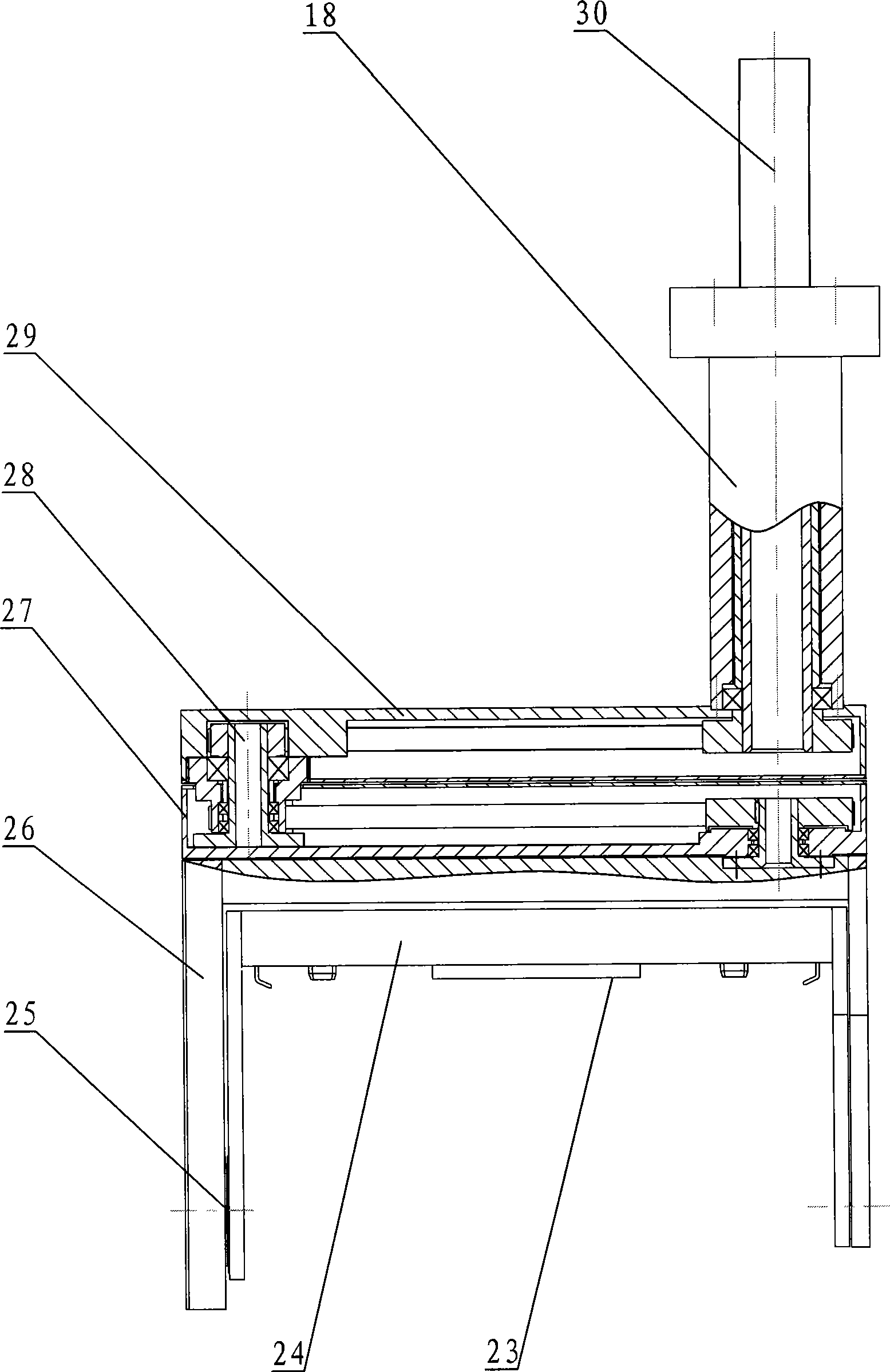

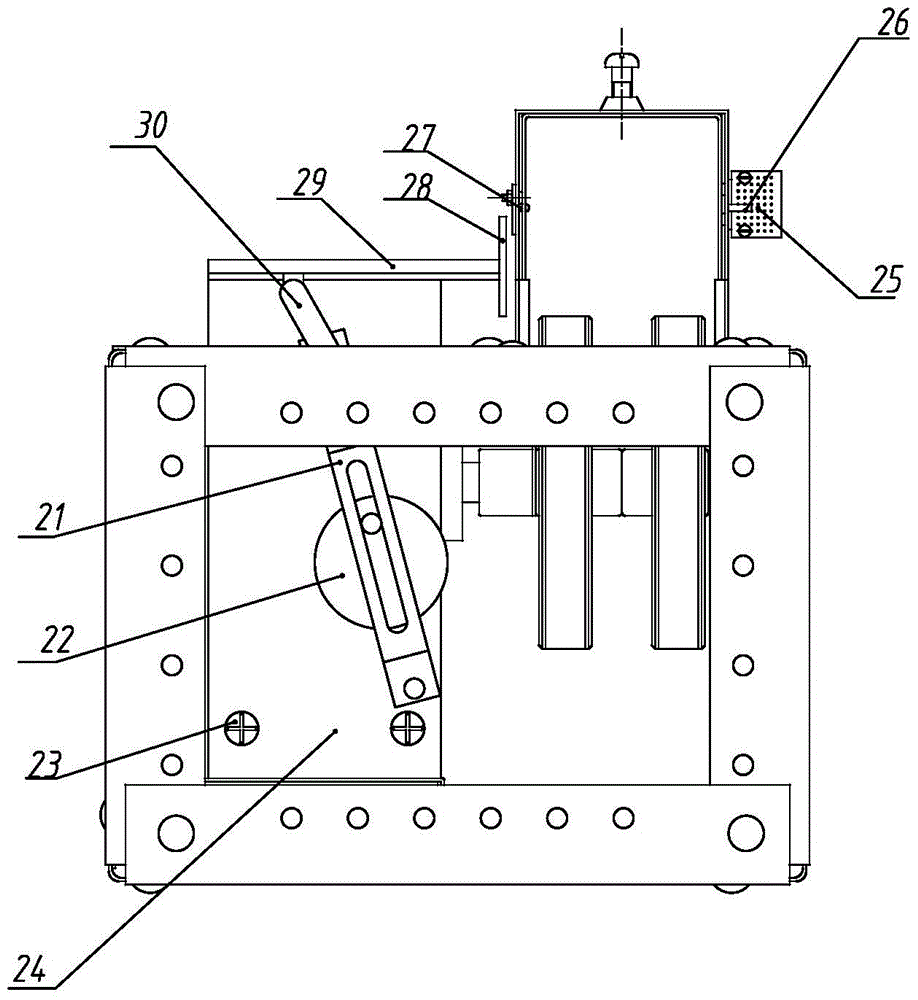

A turnover wafer automatic transmitting device overcomes shortages that the prior art can not do complicated actions in a narrow space in a processing procedure and the like, which comprises a framework, a material loading platform, a wind chest body and an arm mechanism. The technical key includes that a lower arm of the arm mechanism is connected with a catching mechanism through a turnover mechanism, a fixing plate of the catching mechanism is hinged on a turnover base through a turnover shaft, a catching motor of the catching mechanism drives a catching link lever through a turbine worm to further drive a holding jaw to reciprocate along a catching sliding rail, and a locating mechanism on the catching mechanism can be equipped with an adjustable locating block. The turnover wafer automatic transmitting device is reasonable in design, stable in operation when transmitting during the processing procedure, and more flexible and reliable in action, expands application range, can enable a wafer cassette to turn over during the range of 0-90 degrees, can randomly set oblique angles to complete automatic transmitting of wafers in horizontal or perpendicular state, simultaneously also can be adaptable to doing more complicated actions in a narrow space of the process equipment, and can flexibly stop when encountering interference of outsides, thereby achieving transmitting effect of accurate control.

Owner:SHANGHAI FORTREND TECH CO LTD

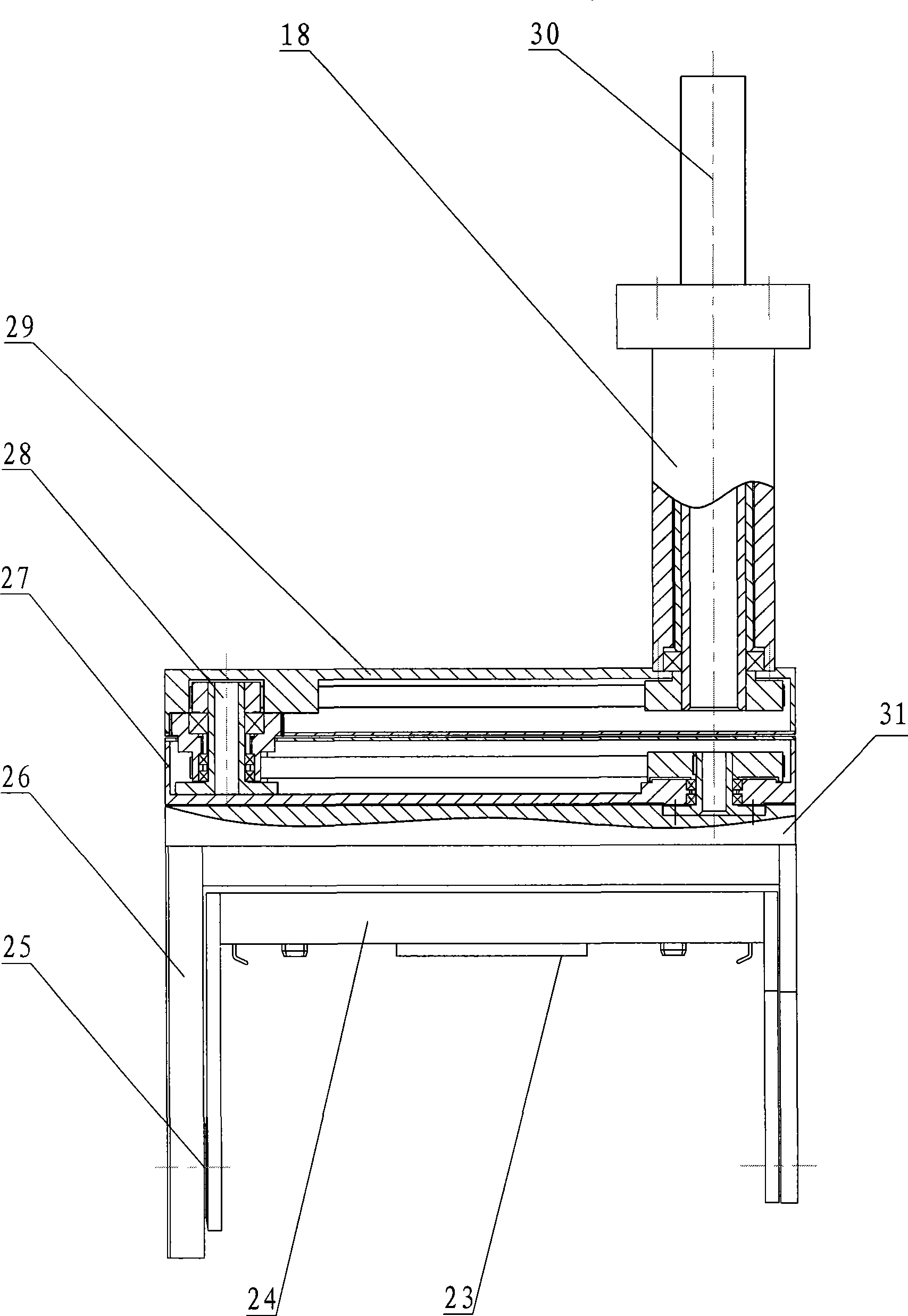

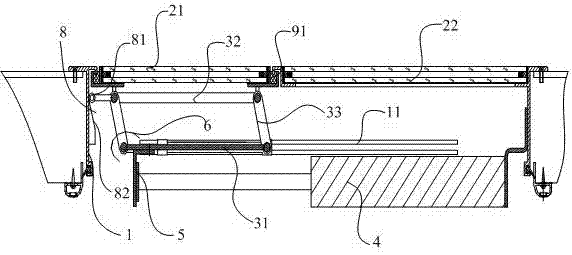

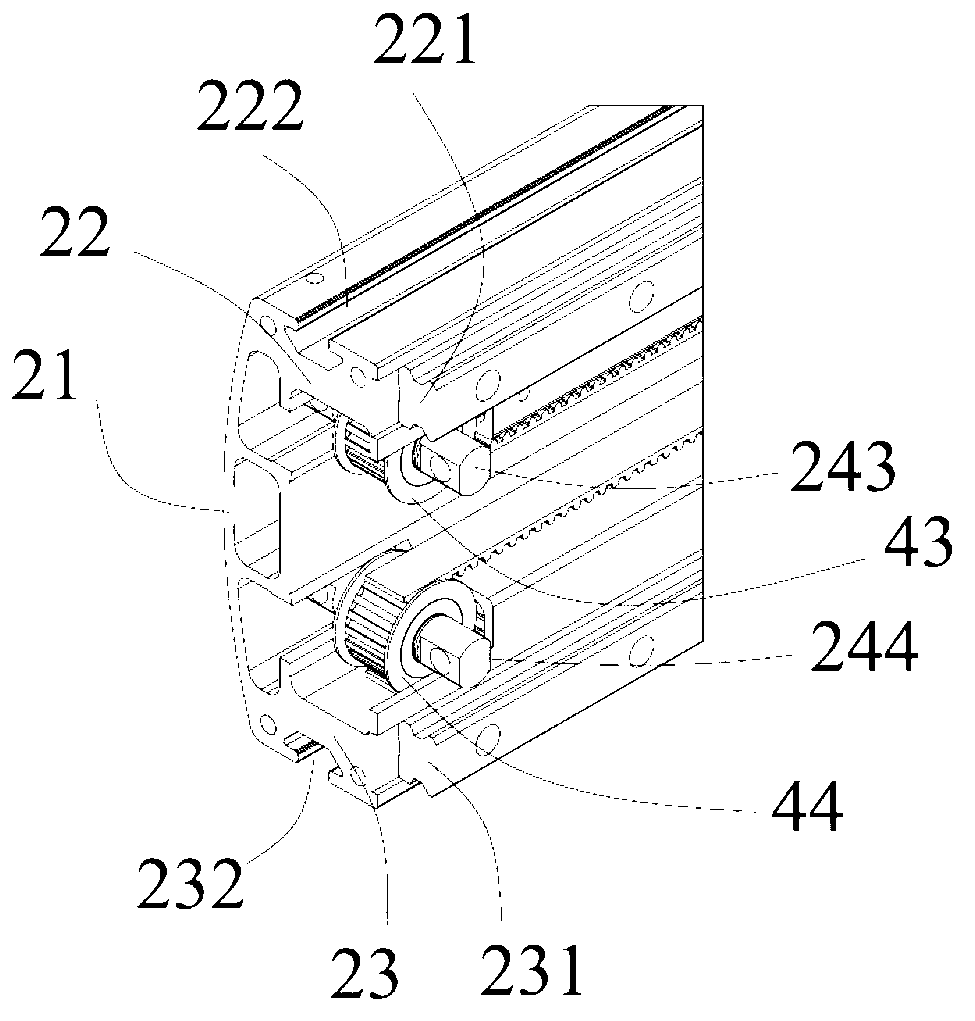

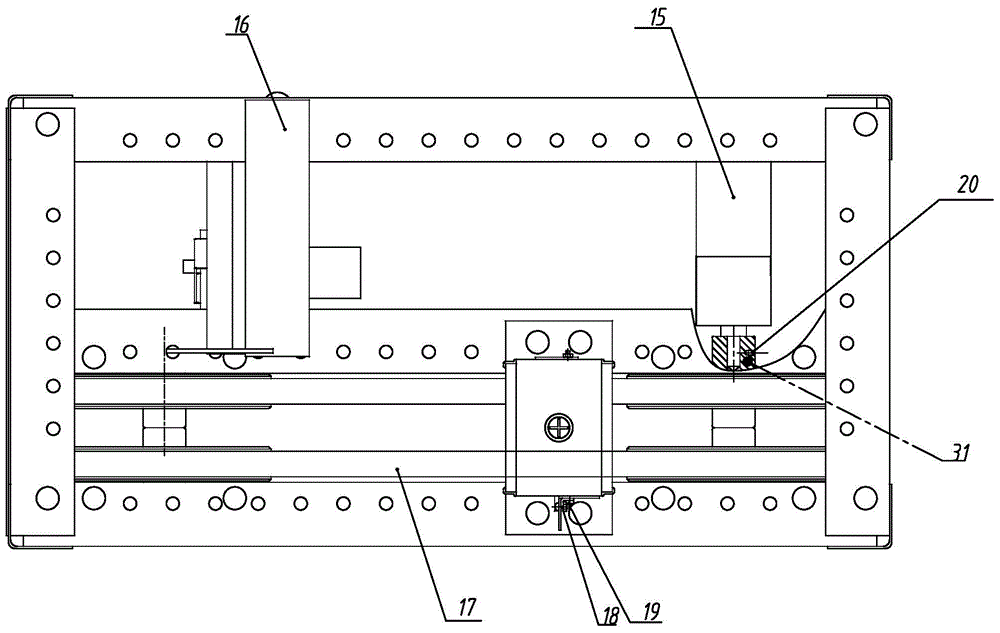

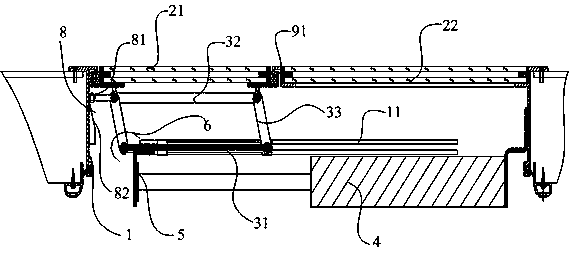

Automatic conveying device for compact wafer

A compact wafer automatic transmitting device overcomes shortages that the prior art can not do complicated actions in a narrow space in a processing procedure and the like, which comprises a framework, a material loading platform, a wind chest body and an arm mechanism. The technical key includes that a lifting motor and an extending motor are not arranged on an identical plane, a lower arm is connected with a catching mechanism through a translating mechanism and a turnover mechanism, the catching mechanism is driven by a geared linkage driving mechanism to rotate around a shaft line, a catching motor of the catching mechanism drives a holding jaw to reciprocate, and a locating mechanism on the catching mechanism can be equipped with an adjustable locating block. The compact wafer automatic transmitting device is reasonable in design, stable in operation when transmitting during the processing procedure, and flexible and reliable in action, completes automatic transmitting of wafers in horizontal or perpendicular state in a limited travel space, simultaneously realizes left and right translating and turnover of a wafer cassette to be suitable for totally realizing automatic transmitting in a narrow space in which center distances of process equipment which are in parallel arrangement are smaller than the center distance of the transmitting device, and can flexibly stop when encountering interference of outsides, thereby achieving transmitting effect of accurate control.

Owner:SHANGHAI FORTREND TECH CO LTD

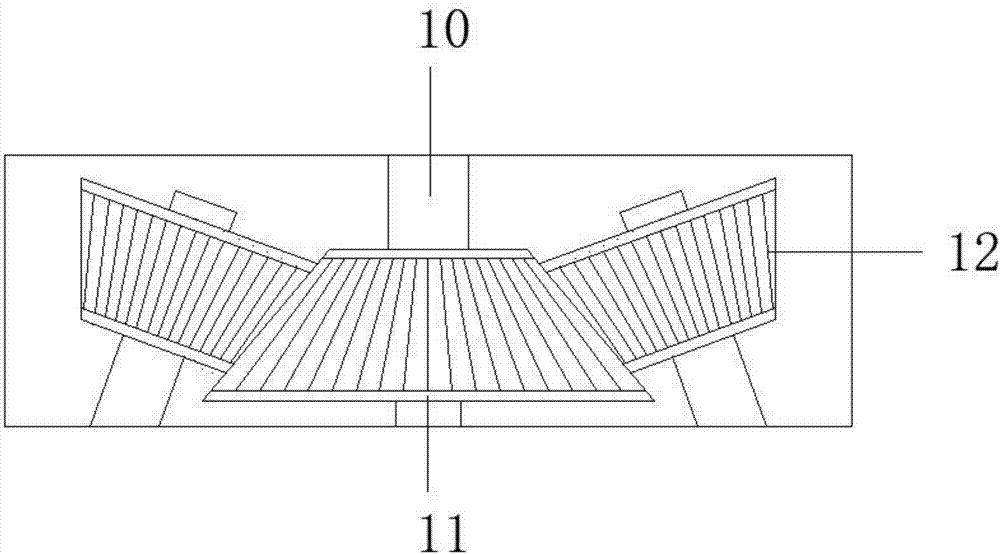

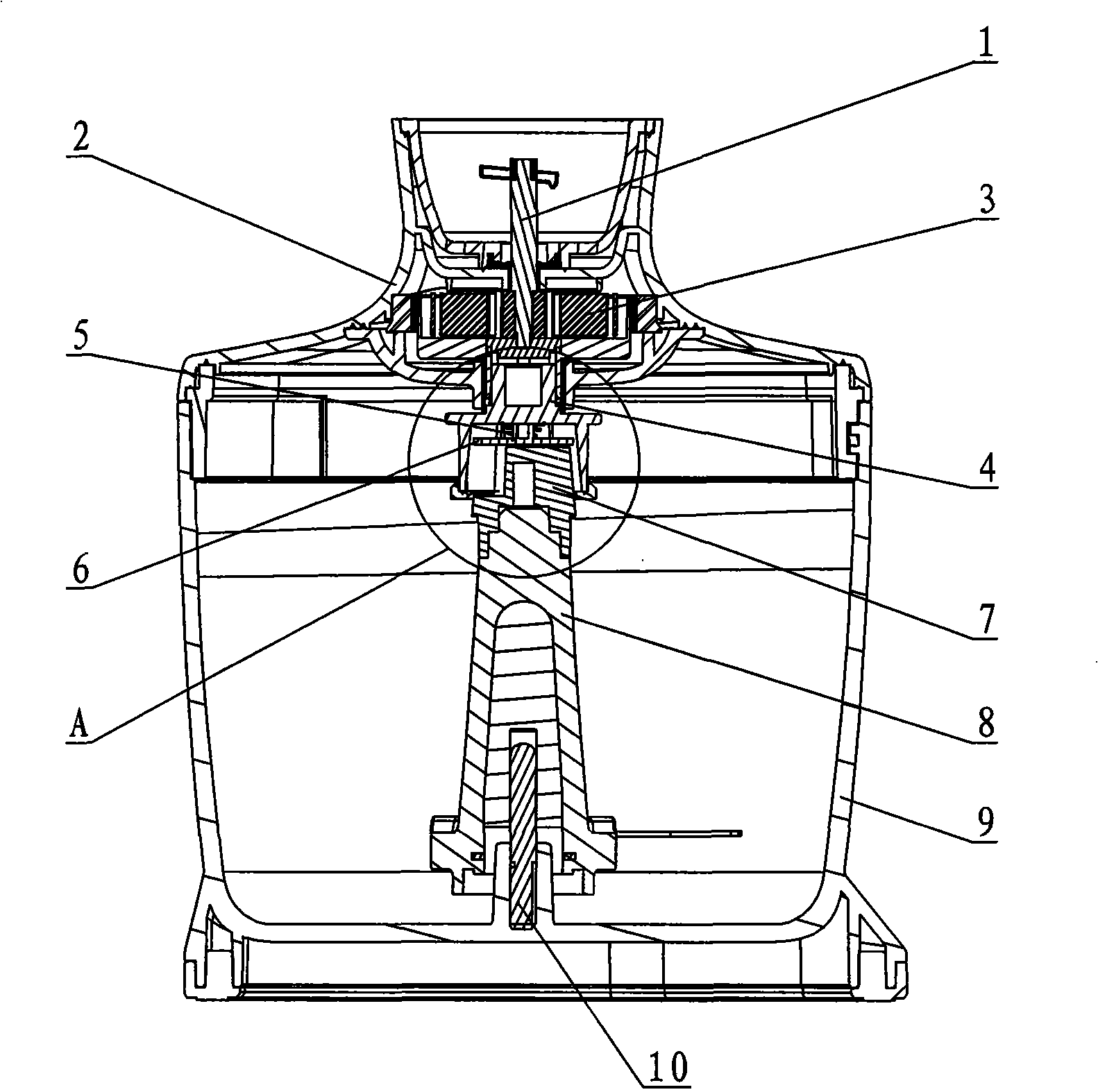

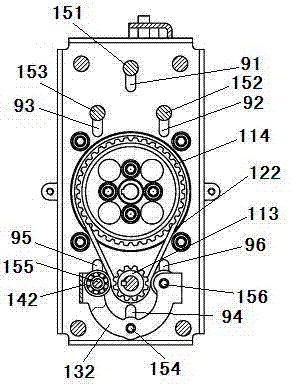

A cutter linkage structure of a mixing cup

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Compact wafer automatic transfer unit

ActiveCN101459100BIncrease operating spaceWon't fall offConveyor partsState of artAutomatic transmission

Owner:SHANGHAI FORTREND TECH CO LTD

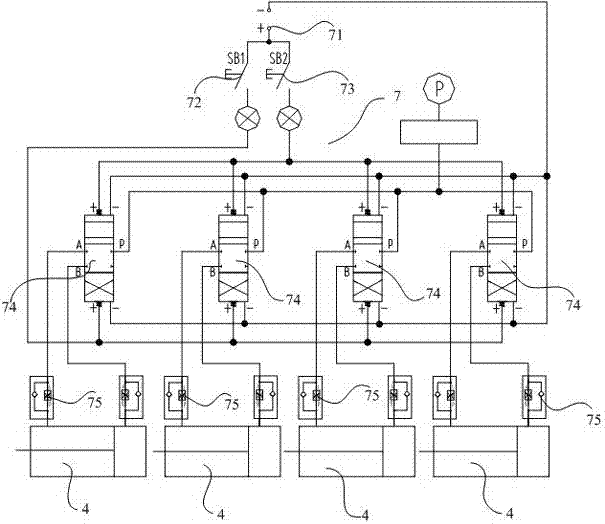

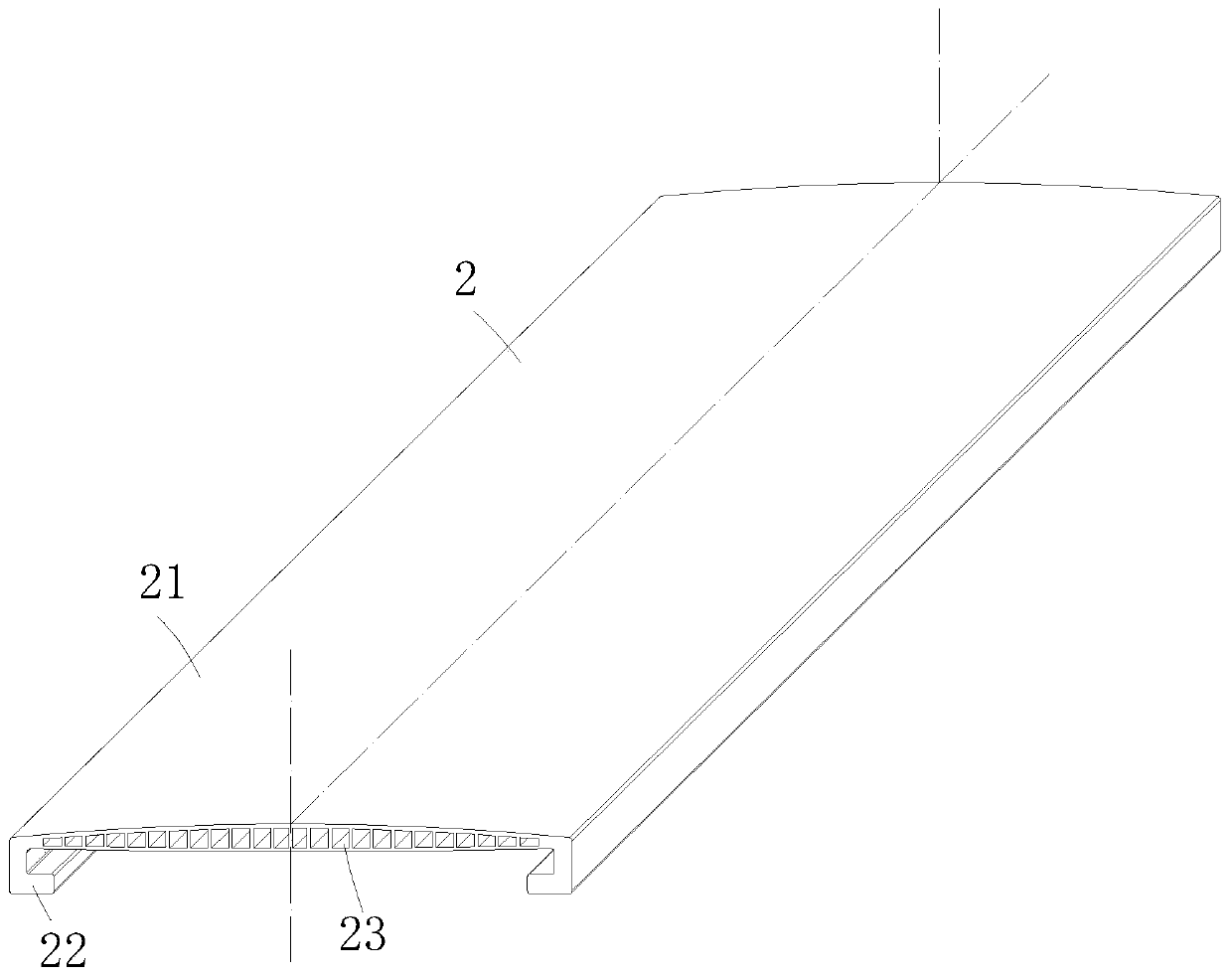

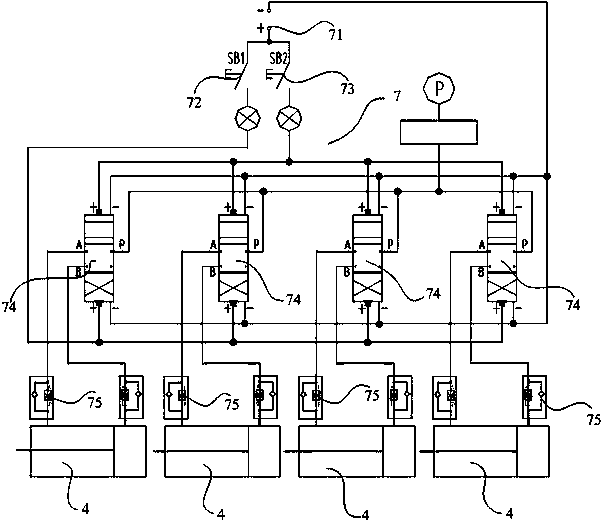

Automatic train window and railway carriage with same

ActiveCN106968548AAchieve openAchieve closurePower-operated mechanismWindow arrangementsSash windowRailway passenger car

The invention provides an automatic train window. The automatic train window comprises a window frame, a fixed window sash, a movable window sash, a transmission mechanism and a telescopic driving part; the transmission mechanism comprises an inner side rod, an outer side rod and connecting rods connected between the inner side rod and the outer side rod, the inner side rod is slidably arranged on the window frame, the movable window sash is fixedly connected with the outer side rod, the driving part is fixedly connected with the inner side rod, and an elastic twisting part is arranged between the inner side rod and each connecting rod. Accordingly, the problems that in the prior art, a train window of a railway carriage needs to be manually opened and is high in labor intensity and low in automation level are solved.

Owner:青岛中车四方轨道车辆有限公司

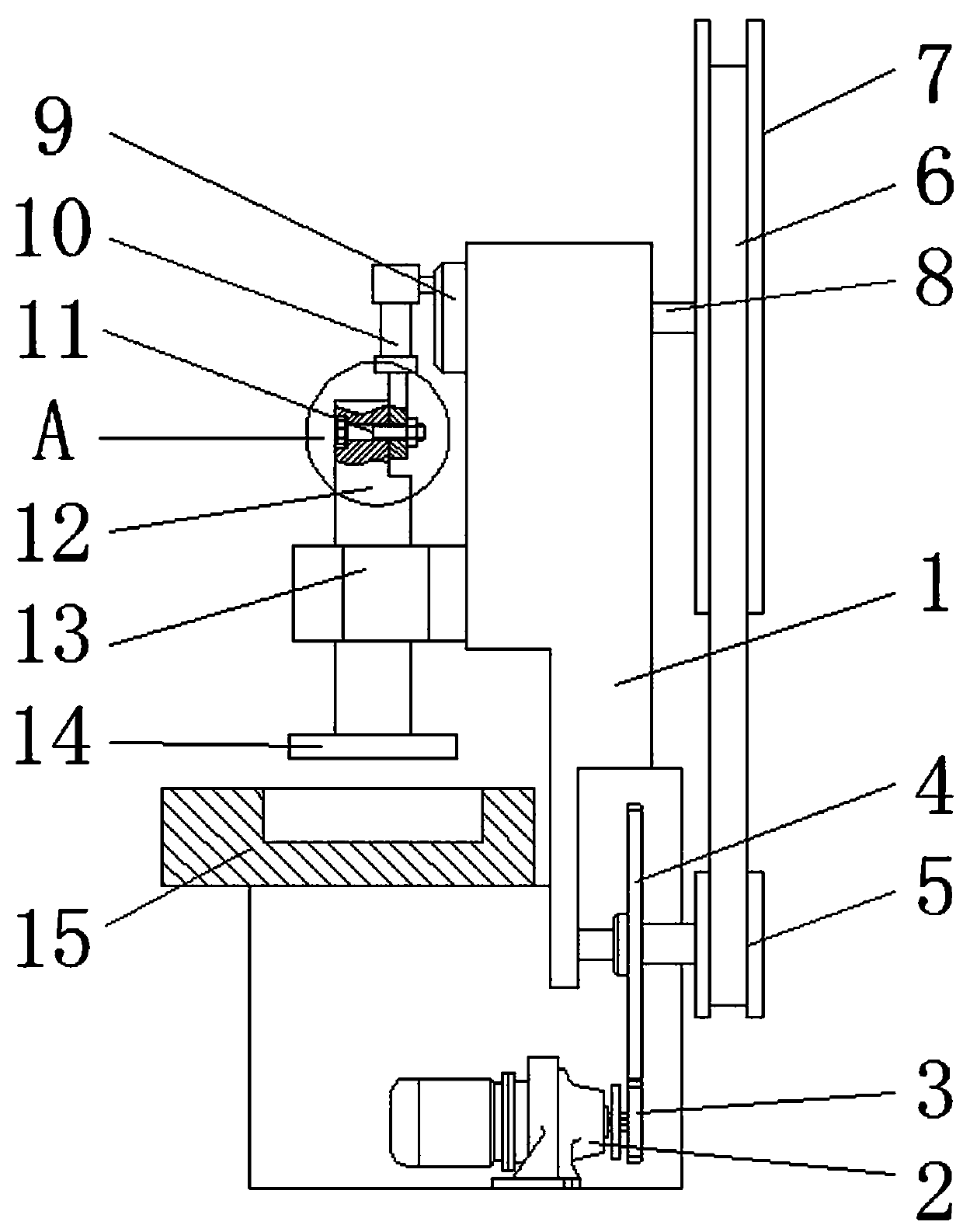

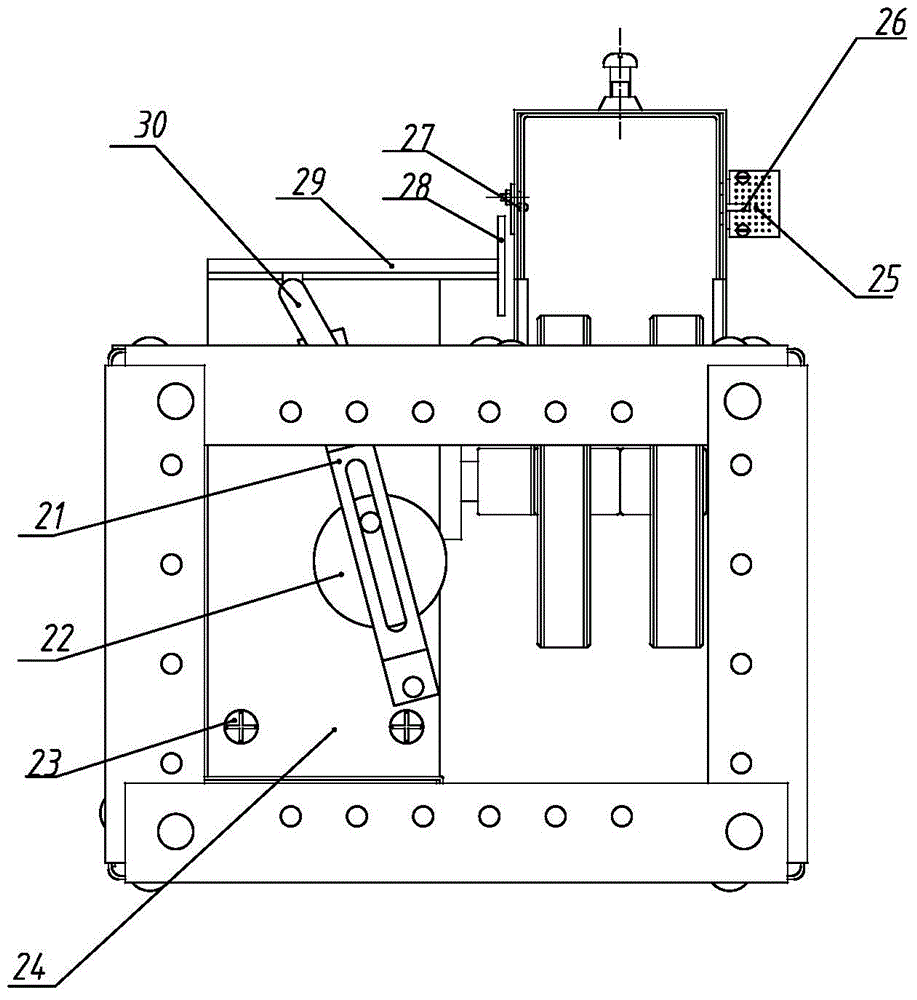

Protective stamping device for metal processing

InactiveCN107617663AEasy to replaceGuaranteed instantaneous speedShaping safety devicesPunchingSoftware engineering

The invention discloses a protective stamping device for metal processing. The device comprises a box body, a belt, a rotary shaft and a stamping die, a motor is installed below the inside of the boxbody, a driving gear is installed at the right end of the motor, a reducing gear is arranged above the driving gear, a first belt pulley is connected to the right side of the reducing gear, a second belt pulley is connected to the upper portion of the belt pulley, the belt is located above the first belt pulley, an eccentric turntable is installed at the left end of the rotary shaft, a movable connection rod is installed at the left side of the eccentric turntable, a stamping rod is installed below a bolt, and a stamping protection groove is formed below the stamping die. Compared with an existing common punching machine, the structure is added, and the operation is more convenient and simpler; meanwhile, the protective stamping device has a protection effect in the operating process, thedrive capability of the whole device is more excellent, and the work efficiency and safety when the protective stamping device is in use are effectively improved.

Owner:鲍建军

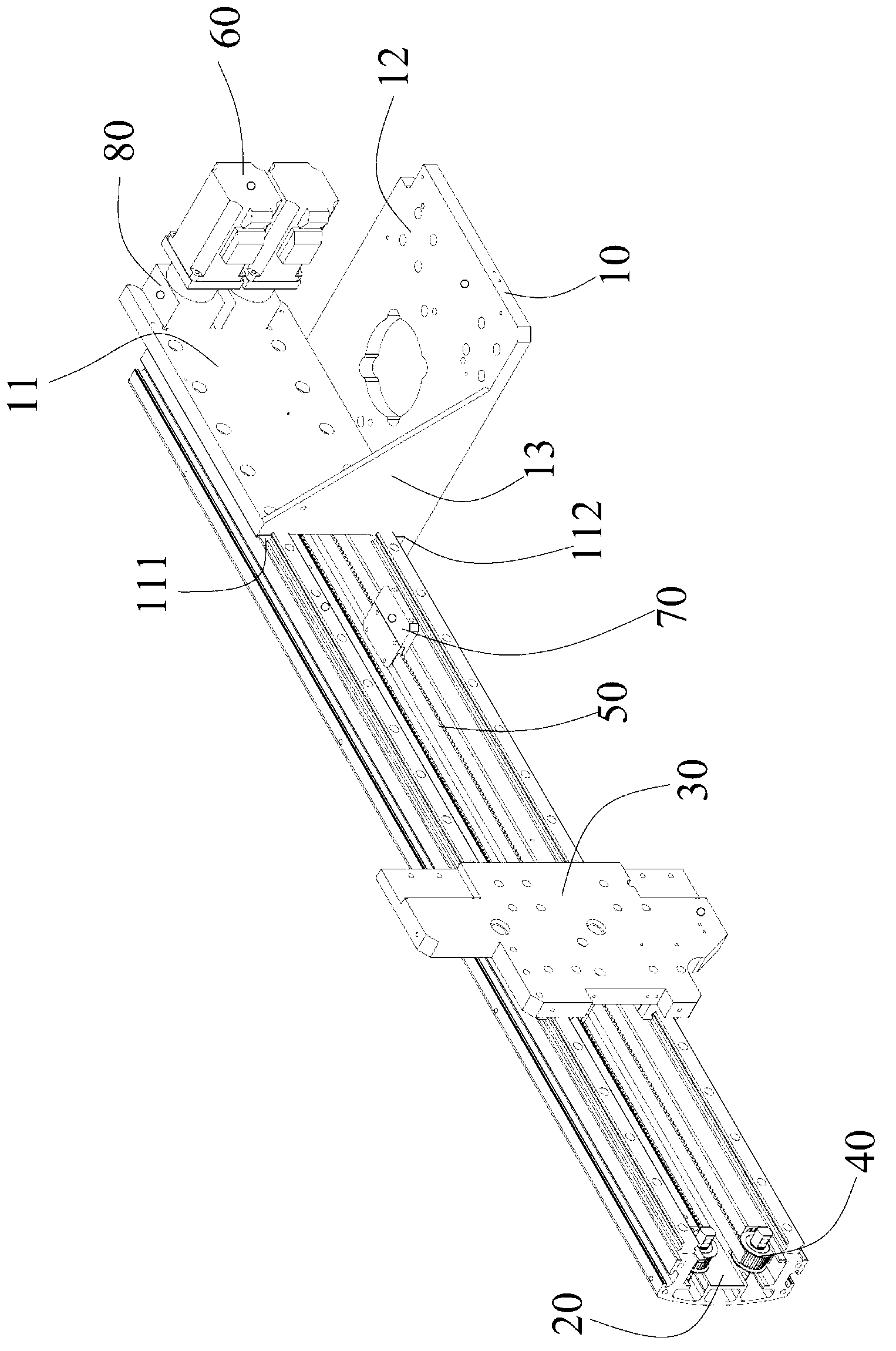

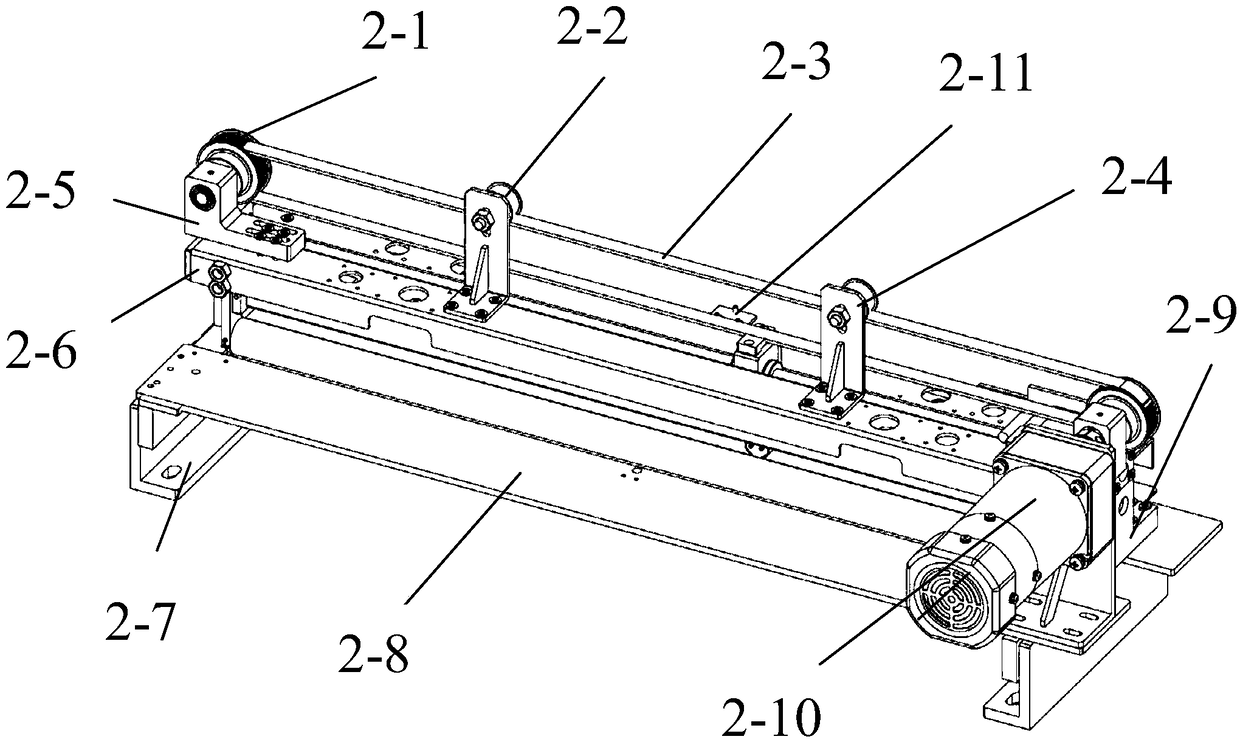

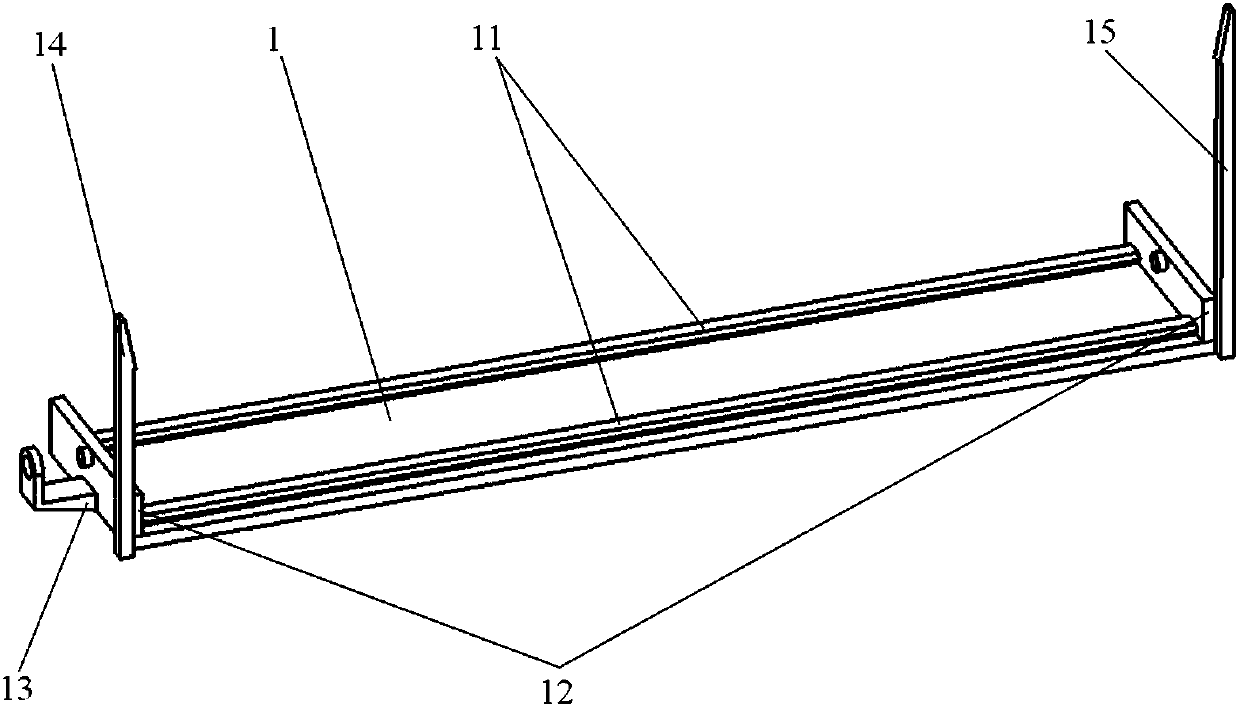

Belt transmission structure for mechanical arm

InactiveCN102699903ASimple structureEasy assembly and adjustmentProgramme-controlled manipulatorEngineeringSlide plate

The invention discloses a belt transmission structure for a mechanical arm, which comprises a transversal slide plate, a drawing arm mounted on the transversal slide plate, and a drawing slide plate mounted on the drawing arm, wherein at least two groups of belt pulleys are arranged on the drawing arm; a belt is mounted outside each group of belt pulley; at least two servomotors are mounted on the transversal slide plate; the belt pulleys are driven by the servomotors; and a belt clamp plate is arranged on each belt and is fixedly arranged with the drawing slide plate. The belt transmission structure provided by the invention has the advantages that the structure is simple; the assembly and the adjustment are very convenient; the transmission and the operation are stable; and the noise and the vibration are low.

Owner:ALFAR SUZHOU AUTOMATION TECH

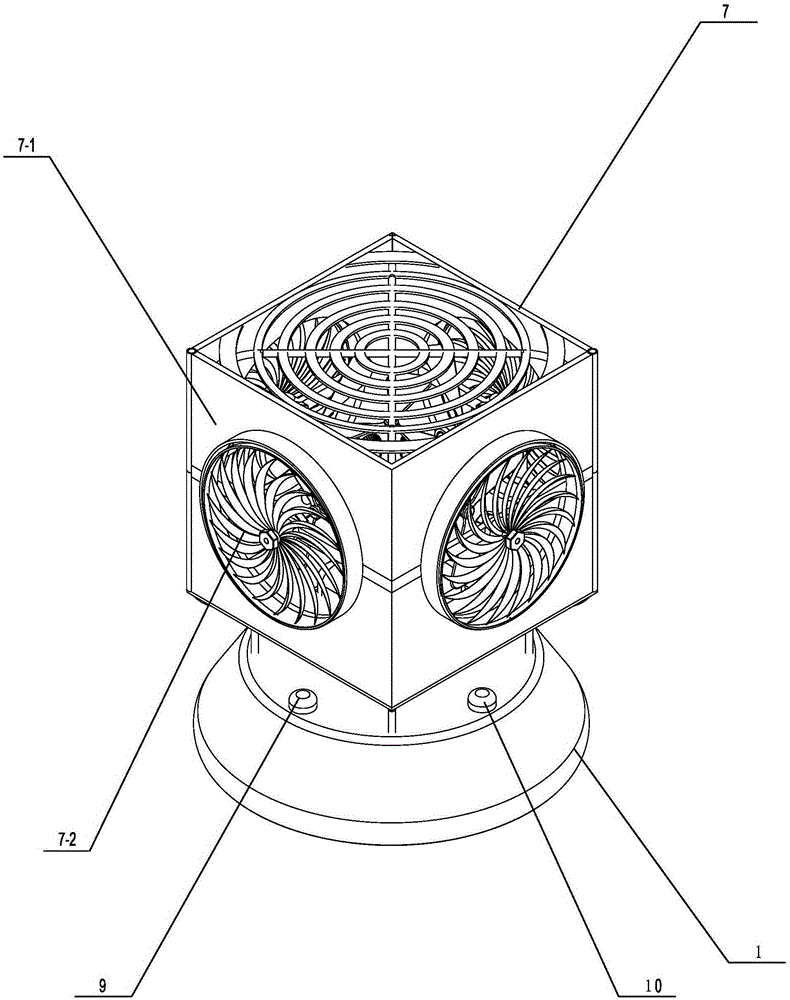

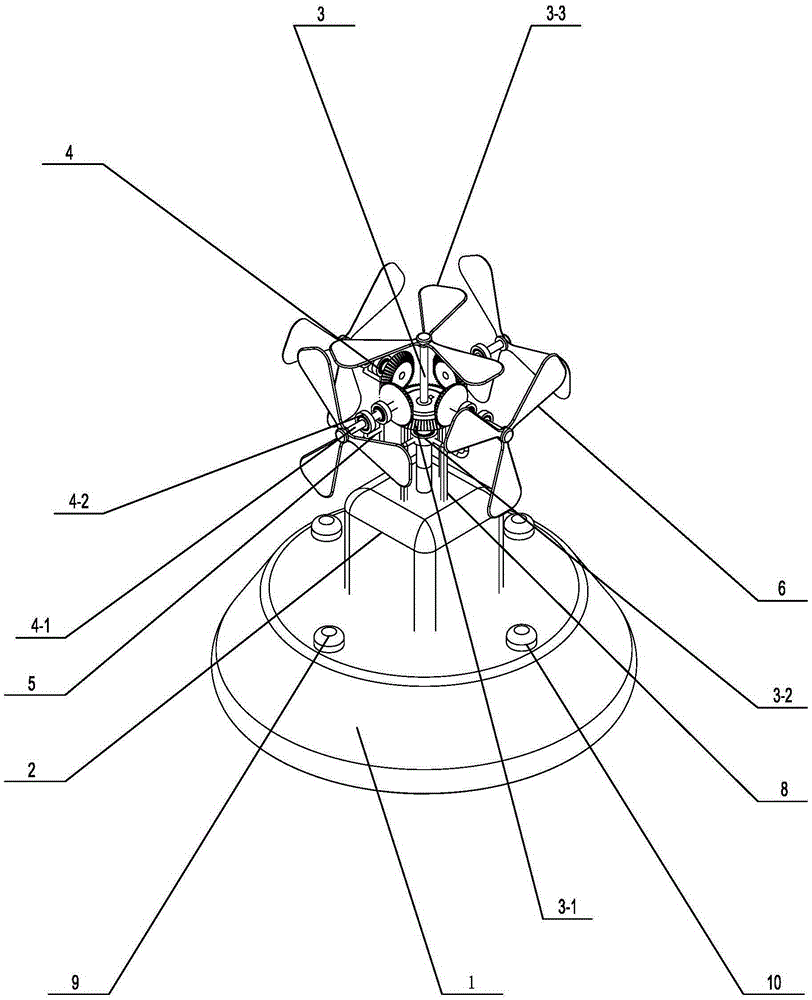

Electric fan capable of blowing air in large area

InactiveCN105298886AImprove cooling performanceThe transmission runs smoothlyPump componentsPump installationsFan bladeDrive shaft

The invention provides an electric fan capable of blowing air in a large area. The electric fan comprises a base and a motor arranged on the base. The output end of the motor is connected with a drive shaft. The drive shaft is sleeved with a drive gear and a drive bearing in sequence from top to bottom. The drive gear is further provided with at least two driven gears meshed with the drive gear. Fixed shafts are arranged in the centers of the driven gears. Fixed bearings connected with the drive bearing through connecting pieces are arranged on the fixed shafts. Fan blades are arranged at the ends of the fixed shafts and wrapped with a housing which is connected with the base and can disperse air. Power rotation in different directions is achieved through gear meshing, the defect that a traditional swinging electric fan or rotating electric fan can not be used by multiple people is overcome, and the electric fan has the advantages of being firm in connection, convenient to maintain and inspect, high in cooling performance and the like; meanwhile, by the arrangement of rotation speed buttons of different levels, the requirement for use under different conditions can be met, and the electric fan is convenient to use and practical.

Owner:QINZHOU UNIV

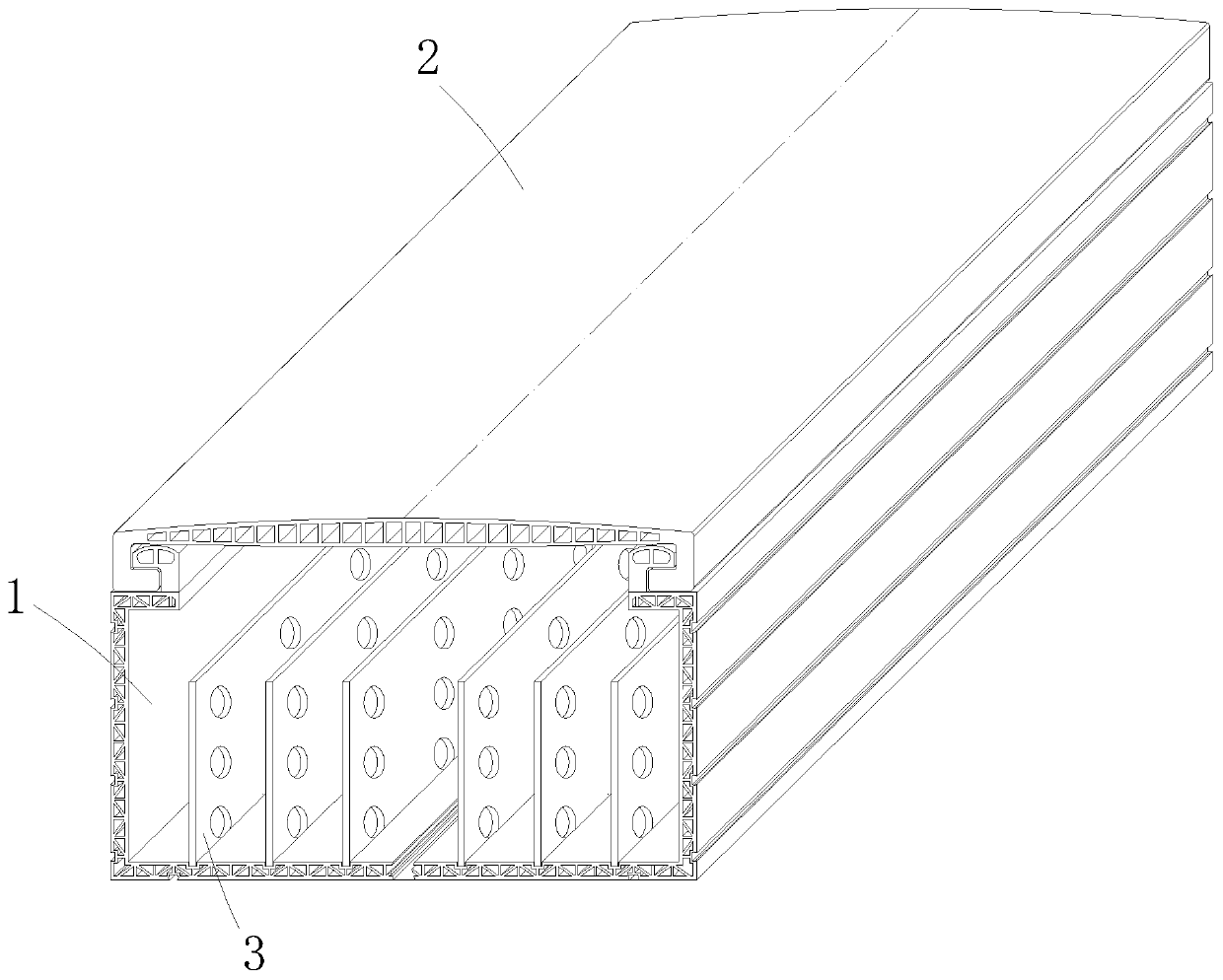

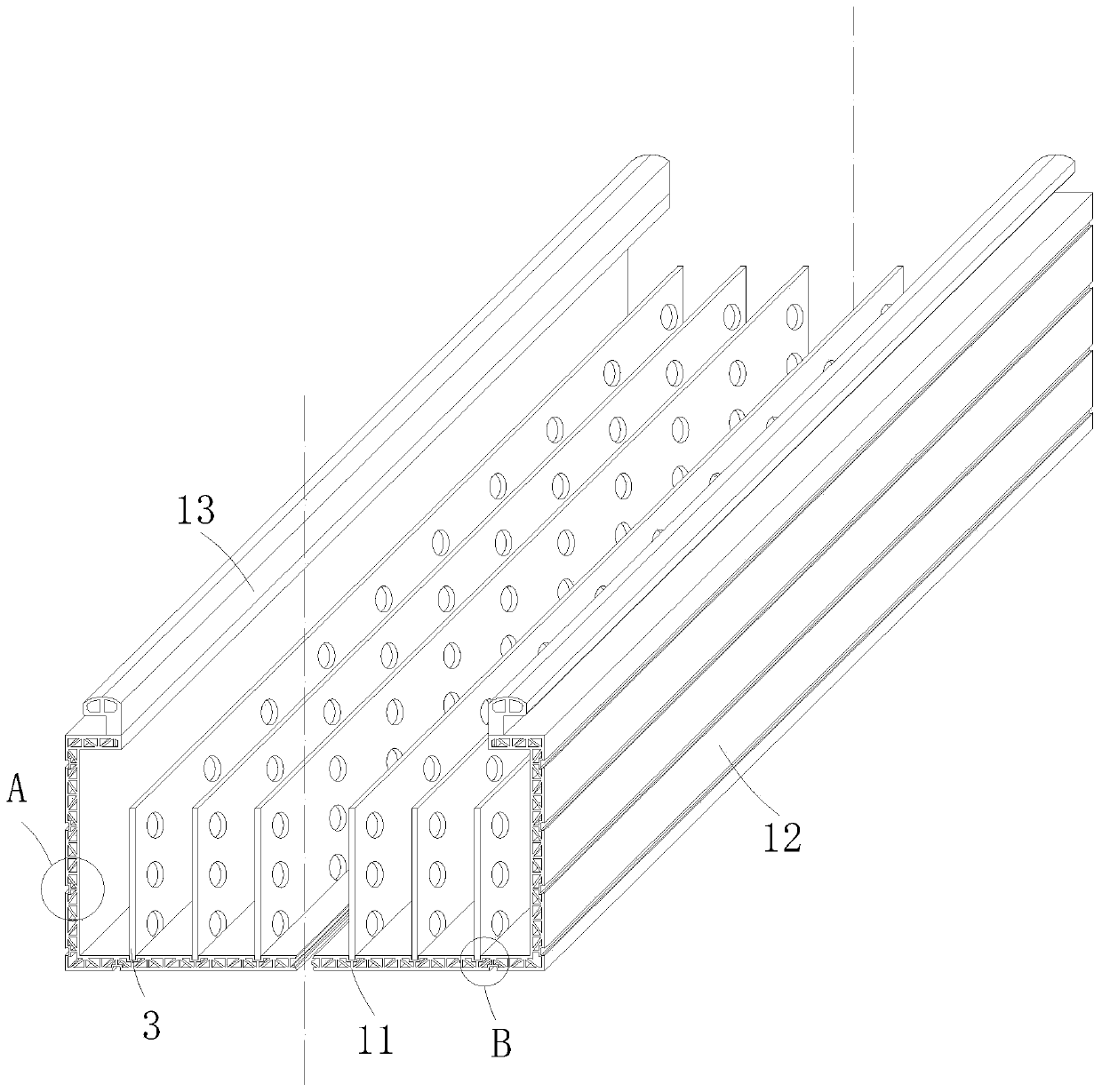

Novel high-molecular alloy plastic hollow cable bridge

InactiveCN110556762ARealize combined installationGuaranteed closureElectrical apparatusGlass fiberEngineering

The invention relates to the technical field of cable bridges, provides a novel high-molecular alloy plastic hollow cable bridge, and aims to solve the problems that most cable bridges are made of metal and glass fiber reinforced plastic products in the prior art, there are various disadvantages, and a cable bridge which is convenient to install and has excellent comprehensive performance is urgently needed in the market. The cable bridge comprises a bridge body and a bridge cover which are detachable, wherein the bridge body comprises a bottom plate and vertical side edge parts vertically extending upwards from the two sides of the bottom plate, the upper ends of the vertical side edge parts vertically extend inwards to form installation parts, the upper ends of the installation parts areintegrally provided with lower buckling parts, and the bottom plate and the vertical side edge parts are both internally provided with a plurality of second cavities which are arranged at equal intervals. The cable bridge is particularly suitable for meeting the requirement of high-quality cable bridges in the current market, and has high social use value and application prospect.

Owner:ANHUI AUTOMATION INSTR

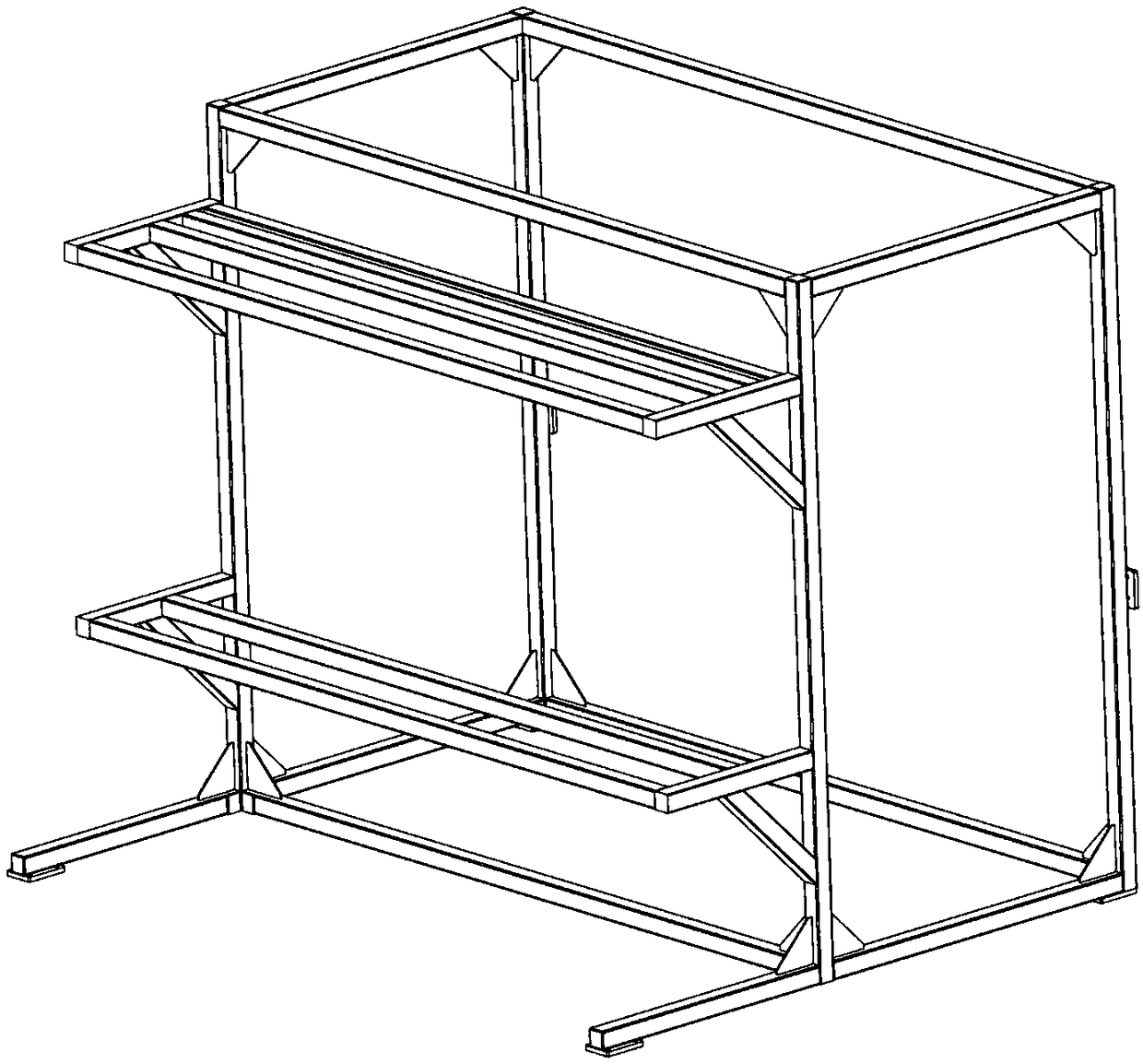

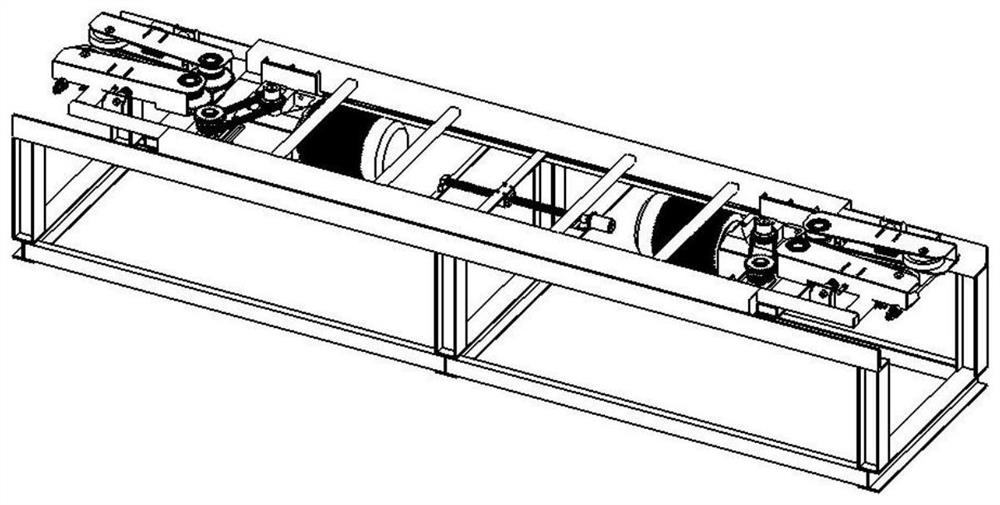

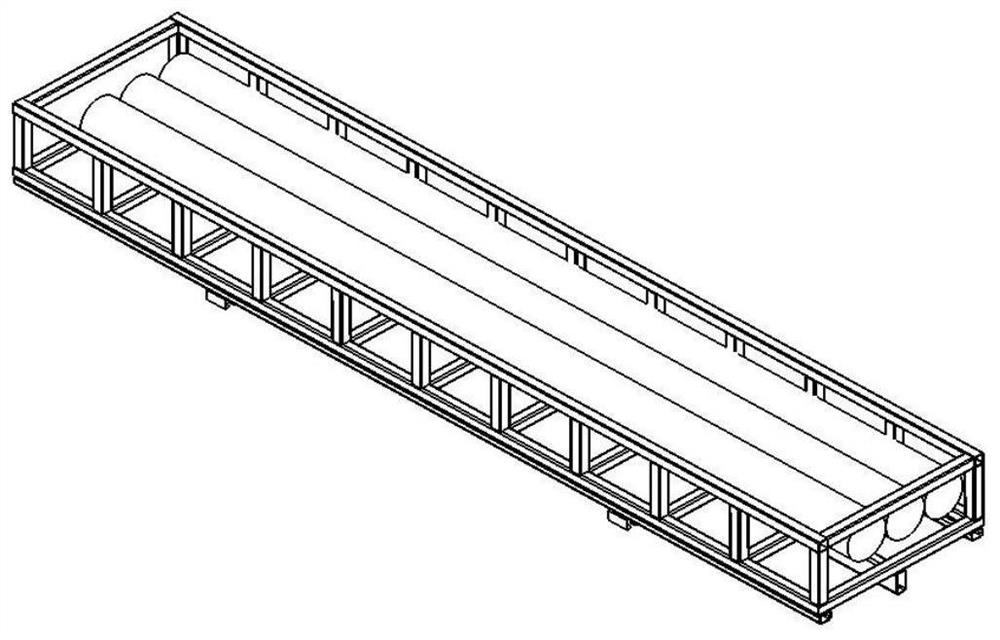

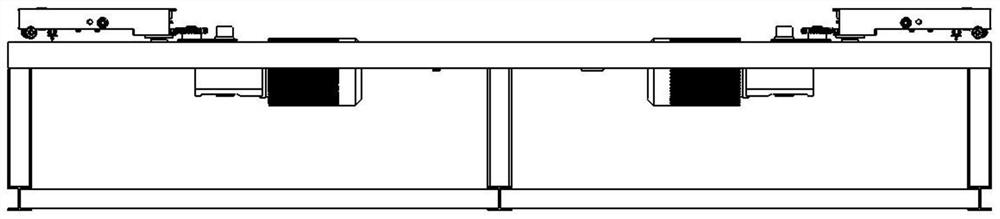

Industrial flow line model mechanism

ActiveCN104318848AThe transmission runs smoothlyReduce noiseEducational modelsIndustrial engineeringPulley

The invention relates to an industrial flow line model mechanism. The industrial flow line model mechanism comprises a rack, a product conveying system, a sensor module, a product redirection device and a control module; the product conveying system is arranged in the rack; the sensor module is used for detecting whether the product size specification exceeds the standard or not through a transmission tube and a receiving tube; the product redirection device is used for conveying out inferior-quality products; the control module is used for conducting centralized control. According to the industrial flow line model mechanism, belt pulley transmission is adopted; belt pulley transmission is sufficiently used, so that load impact can be buffered; the industrial flow line model mechanism is stable in transmission motion, low in noise, low in vibration, simple in structure and convenient to adjust; the industrial flow line model mechanism has the beneficial effect of having the overload protection function; the control module has the function of automatically detecting the product quality, so that the product quality detection efficiency is high, and the detection result is more accurate; a four-bar mechanism is adopted in a push rod mechanism, so that the mechanism quick-return characteristic is achieved through the structure design, and the work efficiency is improved; meanwhile, the industrial flow line model mechanism can serve as a training aid of a mechanical course and can help students to visually know the mechanism transmission principle.

Owner:SHAANXI UNIV OF SCI & TECH

High-power Z-shaped transmission device for marine

InactiveCN103287566AThe transmission runs smoothlyTransmission with mechanical gearingDrive shaftPropeller

The invention relates to a Z-shaped transmission device for marine, and particularly relates to an improvement to a bevel gear in a Z-shaped transmission device for marine. The high-power Z-shaped transmission device for marine comprises a driving shaft, a transmission shaft and an adjustable paddle propeller shaft, wherein the upper end of the transmission shaft and the driving shaft are meshed and transmitted with each other through an upper bevel gear, the lower end of the transmission shaft and the adjustable paddle propeller shaft are meshed and transmitted with each other through a lower bevel gear, and the upper bevel gear and the lower bevel gear are spiral bevel gears. The transmission power can reach more than 3000 Kw, the transmission and the operation are smooth, and the Z-shaped transmission device for marine can run with a large-scale ship in a matched manner.

Owner:JIANGSU HUAYANG HEAVY IND

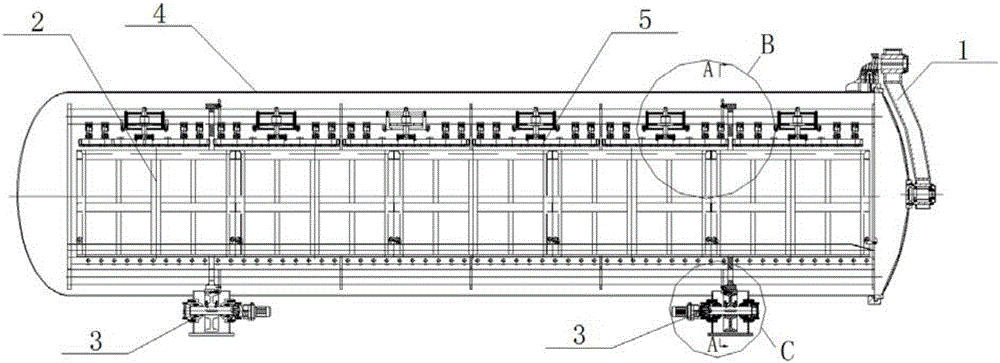

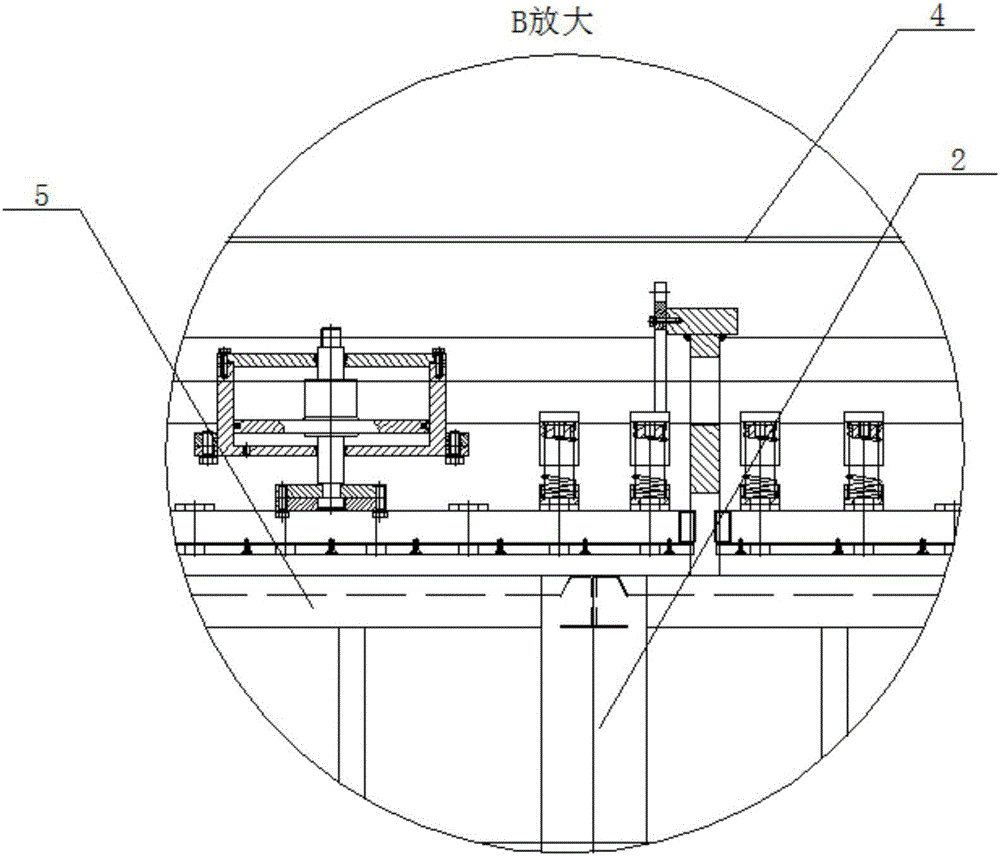

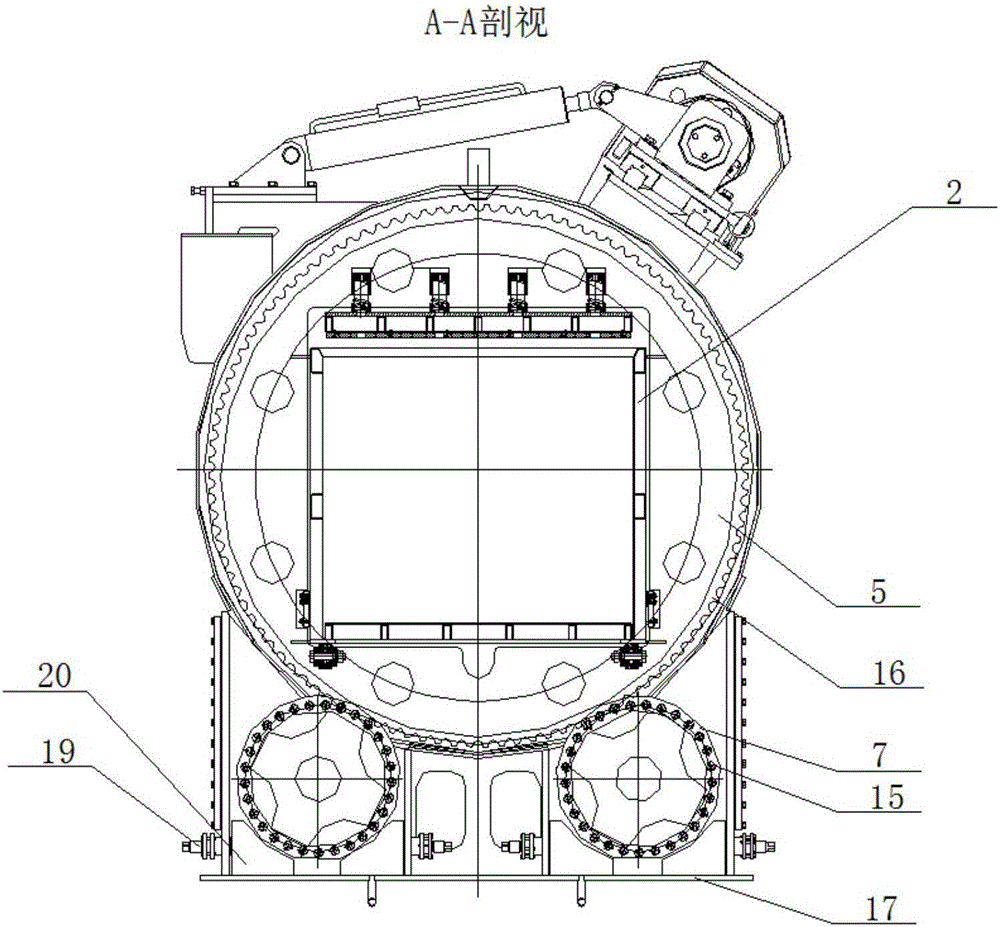

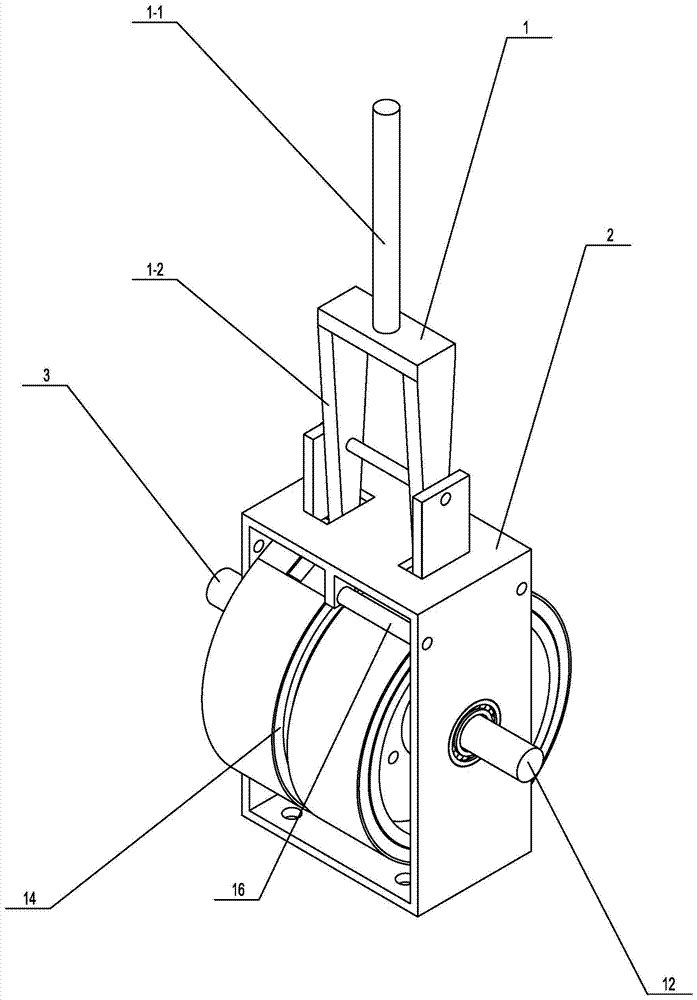

Supporting and driving device for rotating bodies in sterilization kettle

InactiveCN106616197AThe transmission runs smoothlyExtended service lifeFood preservationThrough transmissionFood sterilization

The invention discloses a supporting and driving device for rotating bodies in a sterilization kettle, and relates to an improvement of a food sterilization production device, in particular to a supporting and driving device for rotatable type sterilization kettle rotating bodies. The supporting and driving device comprises a quick door opening device, cage boxes, saddle devices, a barrel body and rotating bodies, wherein the quick door opening device is arranged on one side of the barrel body, and the other side of the barrel body is closed; the rotating bodies are arranged inside the barrel body, and the cage boxes are arranged inside the barrel body; the two saddle devices penetrate through the barrel body and are arranged below two sides of the barrel body. According to the supporting and driving device, an output torque of a motor of a speed reducer is transmitted to the rotating bodies through parts such as transmission shafts, driving wheels and pin teeth; the driving wheels are mounted and fixed in saddle bodies; the driving wheels transmit power to the rotating bodies through transmission modes such as the pin teeth, gears or chains, namely the driving wheels have multiple effects of gravity supporting, power transmission and axial locating of the rotating bodies; power sources are transmitted in the saddle bodies; pin wheels are of integrated or spliced structures, so that maintenance and replacement are facilitated. The whole structure of the supporting and driving device is balanced in stress, the transmission operation is steady, and the service life of equipment is long; the transmission structure is novel and simple, spare parts are convenient to repair and replace, the manufacturing cost is low, energy consumption is low, and the overall aesthetic property is high.

Owner:安徽沛愉包装科技有限公司

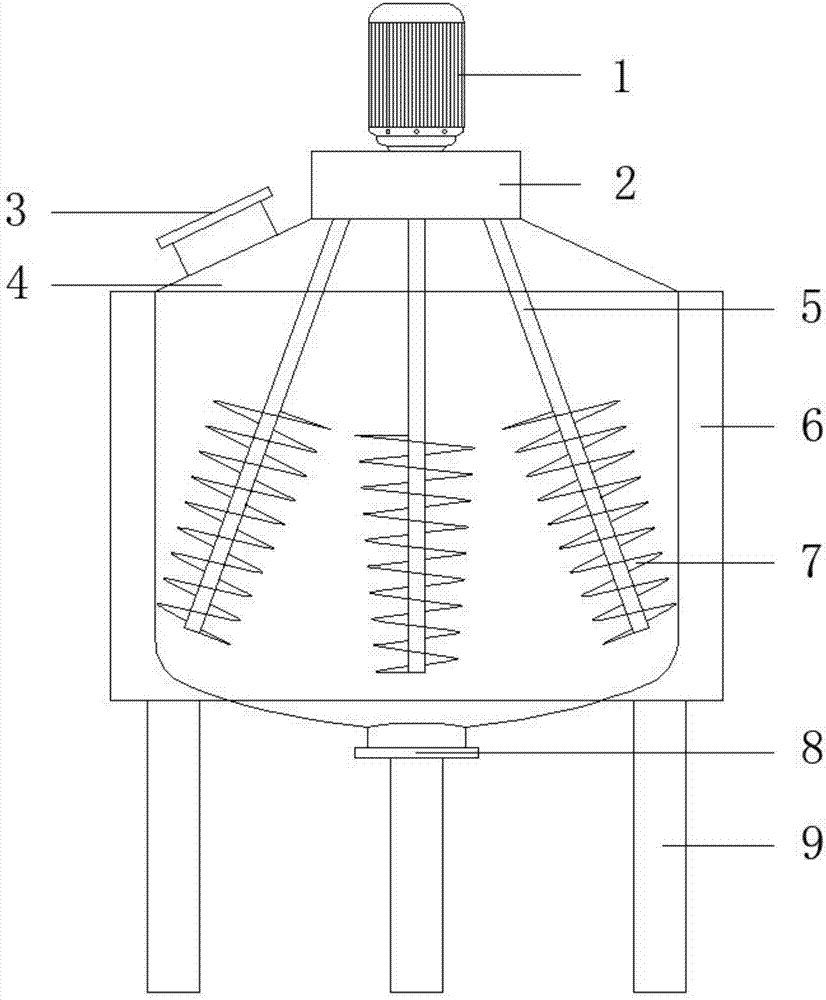

Mixing tank for production processing of metal powders

InactiveCN107970821AImprove mixing efficiencyWell mixedTransportation and packagingRotary stirring mixersEngineeringDrive motor

The invention relates to the technical field of coating production equipment, in particular to a mixing tank for production processing of metal powders. The mixing tank comprises a driving motor, a gear transmission group, and a feed inlet; the gear transmission group is arranged on the top of a tank body and is connected with the tank body via a connection flange; the driving motor is installed on the gear transmission group, and the driving motor and the gear transmission group are connected in a fixed manner; a driving gear is located inside the gear transmission group and driven gears aredisposed on both sides of the driving gear; the driven gears and the driving gear are connected in a meshing manner, and a main shaft is mounted on the driving gear. Through improvement of the structure, the mixing tank has the advantages that a mixture is stirred and mixed evenly, the heat preservation performance is good, solidification is not easy to occur, subsequent production is not affected, the product quality is good, the precision is high, and the production technology is advanced, and thus problems and disadvantages of existing devices are effectively solved.

Owner:惠州市广源钢结构工程有限公司

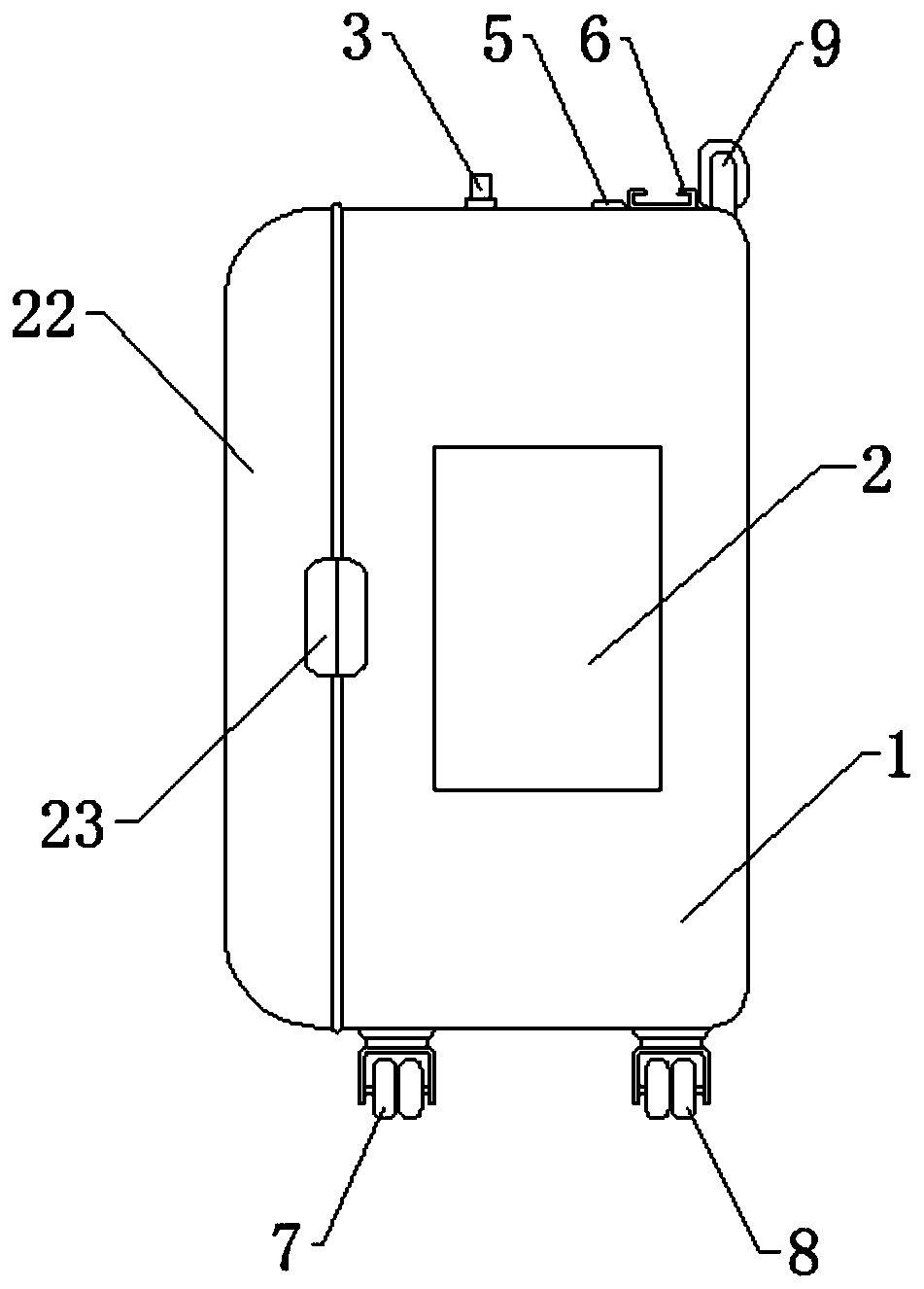

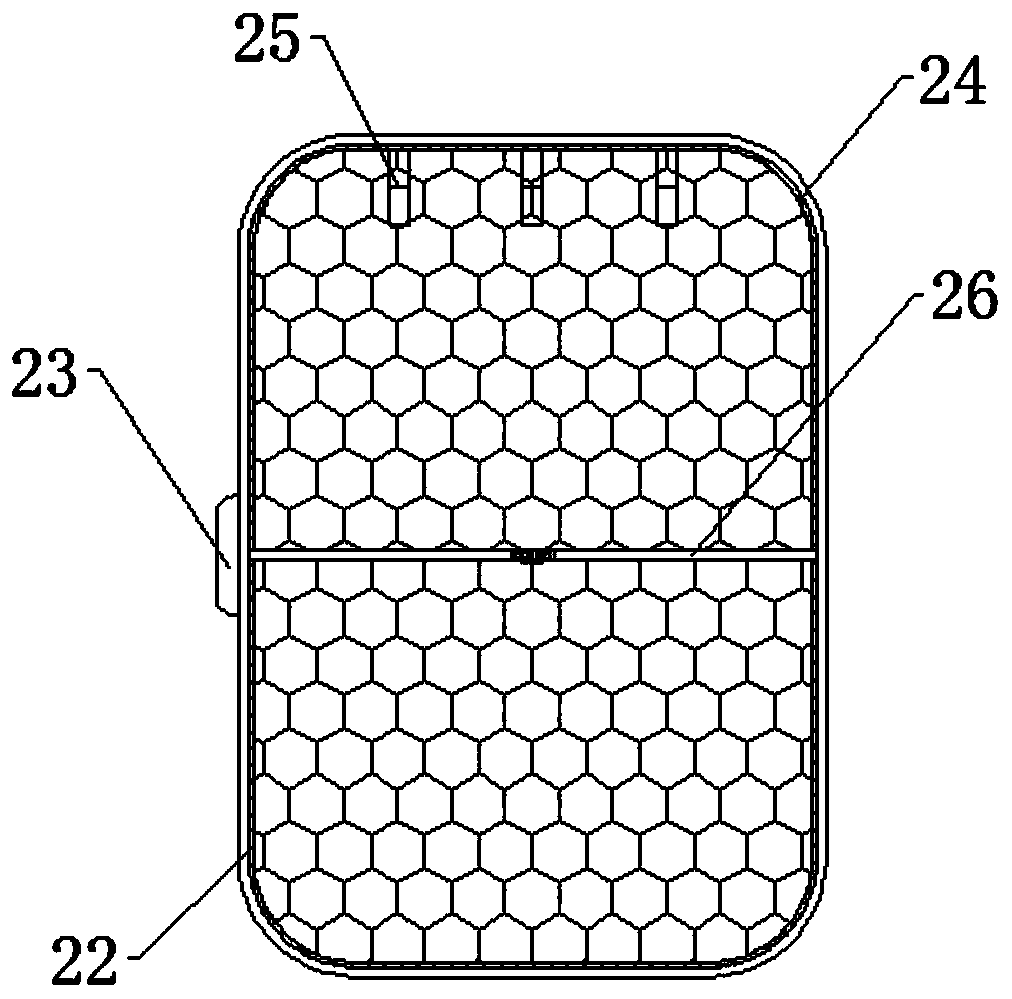

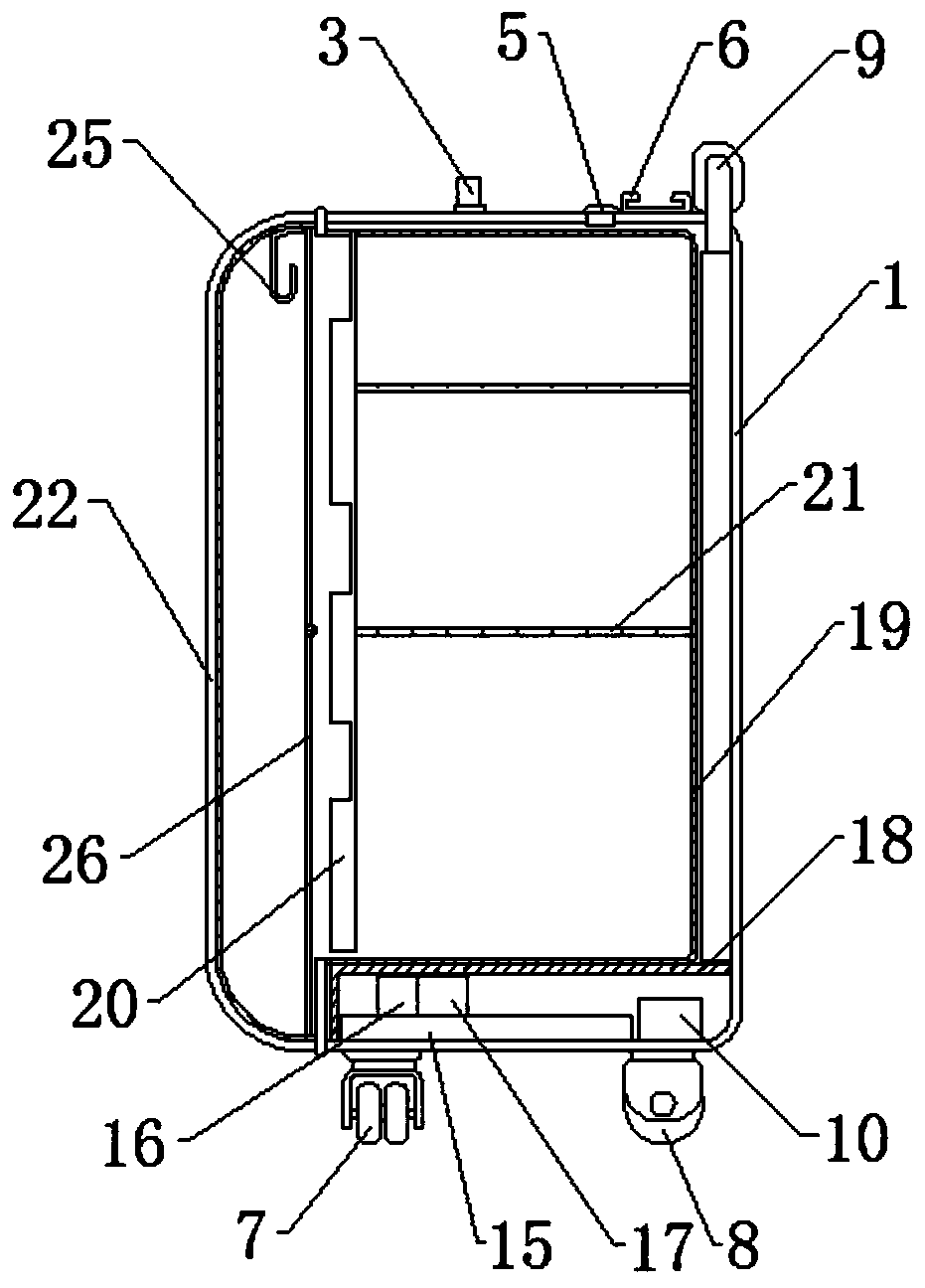

Multifunctional remote control box

The invention relates to the technical field of multifunctional boxes, especially to a multifunctional remote control box, which comprises a multifunctional box body. A solar panel is fixedly connected to the middle of the front face of the multifunctional box body; the upper side of the multifunctional box body is fixedly connected with a lifting handle; the lower side of the lifting handle is fixedly connected with a gravity sensor; a USB charging port is formed in the right side of the lifting handle and located in the multifunctional box body; the right side of the USB charging port is fixedly connected with a mobile phone holder; universal wheels are fixedly connected to the left lower side of the multifunctional box body; a driving wheel is fixedly connected to the right lower side of the multifunctional box body; a pull rod is fixedly connected to the right side of the inner wall of the multifunctional box body; a micro motor is fixedly connected to the right lower side of the interior of the multifunctional box body; and a motor spindle is fixedly connected to the right side of the micro motor. The whole equipment is simple in structure, convenient to operate, rich in function and high in stability and practicability, and has certain popularization value.

Owner:嘉兴聚力检测技术服务有限公司

A cutter linkage structure of a mixing cup

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Sewing device and sewing method for solving fluffing and scattering problems during jean seam splicing

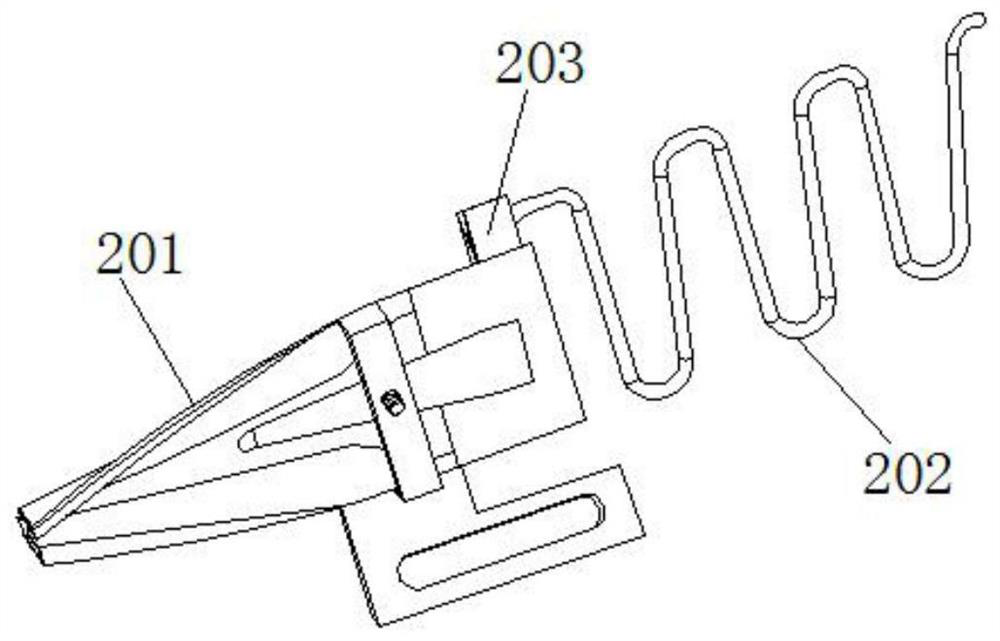

PendingCN113089195AEasy to operateTransmission runs smoothlyWorkpiece carriersWork-feeding meansStructural engineeringKnife holder

The invention discloses a sewing device for solving fluffing and scattering problems during jean seam splicing. The sewing device comprises an overlock machine, the overlock machine comprises a machine body, a machine head and a sewing table top, a machine needle and a cutter frame are mounted on the machine head, a cutter is fixed to the cutter frame, and a needle plate is mounted on the sewing table top. The sewing device is characterized by further comprising an edge covering device, the edge covering device is located on the side face of the needle plate, and the edge covering device is located behind the cutter; and the edge covering device comprises an edge covering plate and a snakelike frame, the edge covering plate is of a three-dimensional structure with one end in a flat opening shape formed by gradually shrinking along the width center line, and the snakelike frame is located on the inlet side of the edge covering plate and connected with the edge covering plate through a height adjusting structure. According to the sewing device for solving the fluffing and scattering problems during jean seam splicing, the operation is simple, the conveying operation of the edge covering cloth is stable, and the problem that the splicing part of the washing seam of the jean garment product is fluffed and scattered is effectively solved.

Owner:佛山市顺德区智域服装设计有限公司

An Executing Device for Diesel Engine Digital Electronic Governor

ActiveCN110397506BReduce noiseThe transmission runs smoothlyFuel-injection pumpsMachines/enginesElectric machineDieseling

The invention discloses an executive device for a digital electronic governor of a diesel engine, which comprises a casing, a shock absorbing pad, a stepping motor, a tooth box connection end, a fuel injection pump plunger connection end, a recovery mechanism, and a rectangular hole. A rectangular hole is opened on one side of the top, a shock absorber is installed on one side of the bottom of the housing, a stepper motor is installed on one side of the shock absorber, and a stepper motor is installed on one side of the stepper motor through the shock absorber and the shell. The first pulley, the outer side of the first pulley is sleeved with a belt, the bottom of the first pulley is provided with a second pulley, and the first pulley and the second pulley are connected by a belt; the present invention can be used at low cost through the shock absorber Reduce the impact of vibration and noise, and use the buffering effect of the rubber between the two mounting plates to improve the vibration and noise effects; when the diesel engine fails, it can quickly make an emergency response to quickly stop the oil supply and stop the equipment quickly.

Owner:广东宇豪新材料科技有限公司

LED online assembly line

InactiveCN102528445BThe transmission runs smoothlyGuaranteed uptimeAssembly machinesAssembly lineUltimate tensile strength

The invention discloses an LED online assembly line, which comprises a conveying line with an aging function, an assembly area, an aging area, a boxing area, a packing area, an automatic stacking area and a product supervision system. The LED online assembly line using a speed chain for transmission is stable in operation, safe, reliable, high in practicability and capable of controlling cost budgeting and production procedures, production efficiency is improved, product turnover transportation is decreased, and labor intensity is reduced.

Owner:DALIAN JIALIN EQUIP MFG

Speed reduction mechanism of self-balancing two-wheeled vehicle

InactiveCN103615508BEasy to processThe transmission runs smoothlyChain/belt transmissionGearingEngineeringGear transmission

The invention discloses a speed reducing mechanism of a self-balancing two-wheel vehicle. The speed reducing mechanism is connected between a wheel driving motor and a wheel shaft of the self-balancing two-wheel vehicle. The wheel driving motor and the wheel shaft are fixed on a support. The speed reducing mechanism is characterized in that the speed reducing mechanism is composed of a belt transmission mechanism. The belt transmission mechanism replaces an existing gear transmission mechanism to be used as the speed reducing mechanism of the self-balancing two-wheel vehicle, manufacturing and processing are simpler and more convenient, transmission operation is more stable, and the speed reducing mechanism has the advantages of being low in noise, low in weight, high in reliability and the like.

Owner:SHANGHAI NEW CENTURY ROBOT

Transverse cutting device of laminating machine

InactiveCN109366545AHigh feasibilityThe transmission runs smoothlyMetal working apparatusHands freeFront and back ends

The invention provides a transverse cutting device of a laminating machine. The transverse cutting device is composed of three sub-cutting devices, and can be divided into two parts, namely a utilityknife assembly device and paper clamping devices. The utility knife assembly comprises a stepping motor, a transverse cutter assembly is driven to move through a synchronous pulley and a synchronous belt, a belt clamping block on the transverse cutter assembly is connected with the synchronous belt, and the synchronous belt drives a transverse cutter to move by the friction force; the clamping devices are divided into a front side clamping device and a rear side clamping device, wherein the front side clamping device and the rear side clamping device are used for fixing the front end and the rear end of paper to be transversely cut, the front side clamping device is installed on a machine frame, and the rear side clamping device is installed below the stepping motor. The transverse cuttingdevice has the positive and progressing effects that belt transmission is used for driving a cutter to perform cutting, the belt transmission has the advantages that the belt transmission is stable in operation, no noise is generated, the structure is simple, the maintenance is convenient, and the feasibility of the transverse cutting device is improved; and hands-free operation is completely realized in the whole cutting process, the transverse cutting can be simultaneously conducted on three pieces of paper after longitudinal cutting to the largest extent, and therefore the transverse cutting efficiency and the paper utilization rate are greatly improved.

Owner:SHANGHAI GENIE ROBOT AUTOMATIC

Speed reducing mechanism of self-balancing two-wheel vehicle

InactiveCN103615508AEasy to processThe transmission runs smoothlyChain/belt transmissionGearingEngineeringGear transmission

The invention discloses a speed reducing mechanism of a self-balancing two-wheel vehicle. The speed reducing mechanism is connected between a wheel driving motor and a wheel shaft of the self-balancing two-wheel vehicle. The wheel driving motor and the wheel shaft are fixed on a support. The speed reducing mechanism is characterized in that the speed reducing mechanism is composed of a belt transmission mechanism. The belt transmission mechanism replaces an existing gear transmission mechanism to be used as the speed reducing mechanism of the self-balancing two-wheel vehicle, manufacturing and processing are simpler and more convenient, transmission operation is more stable, and the speed reducing mechanism has the advantages of being low in noise, low in weight, high in reliability and the like.

Owner:SHANGHAI NEW CENTURY ROBOT

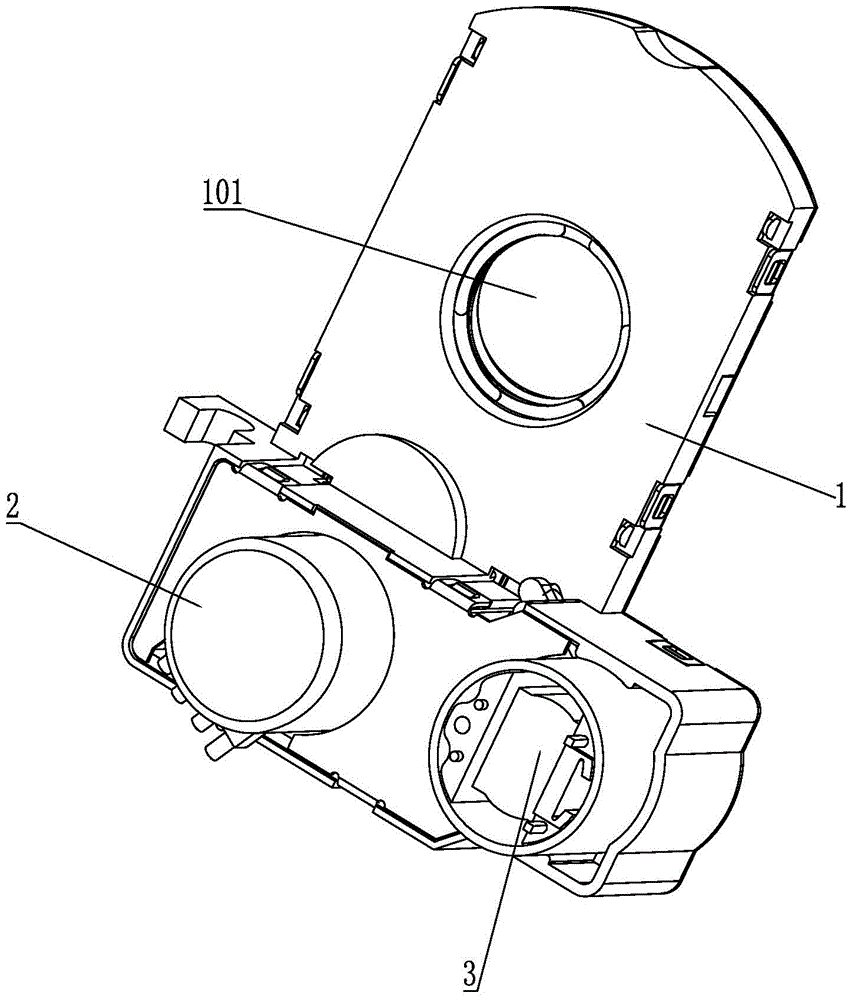

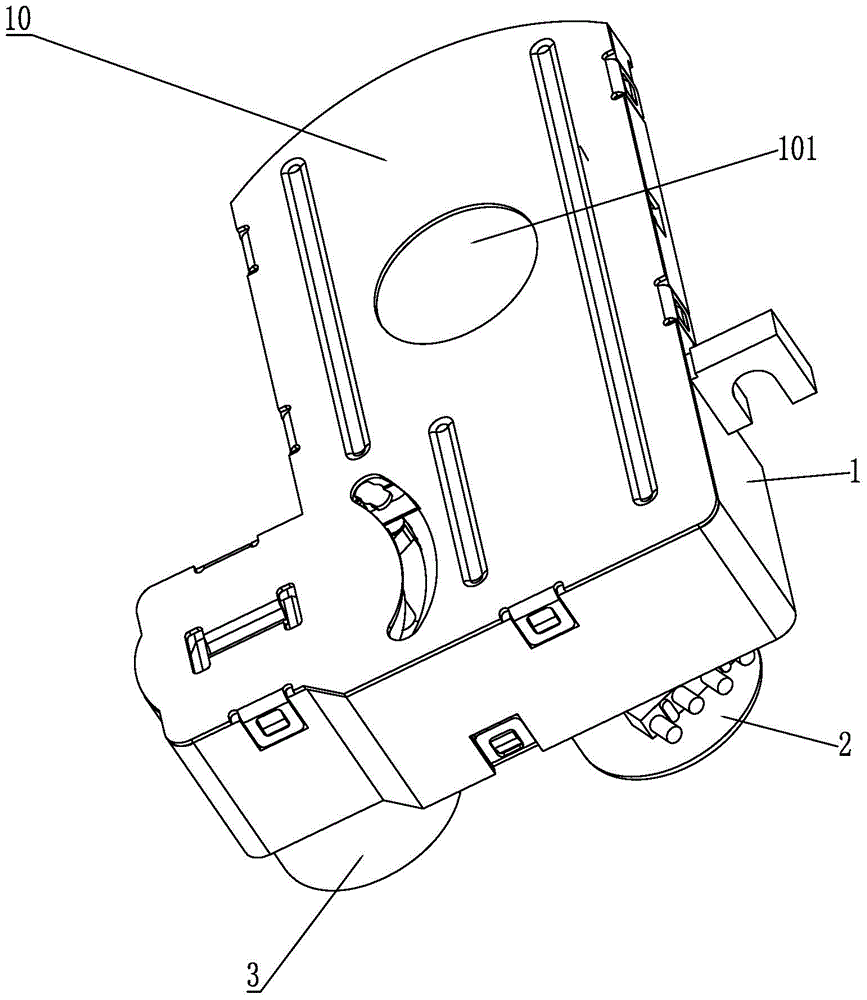

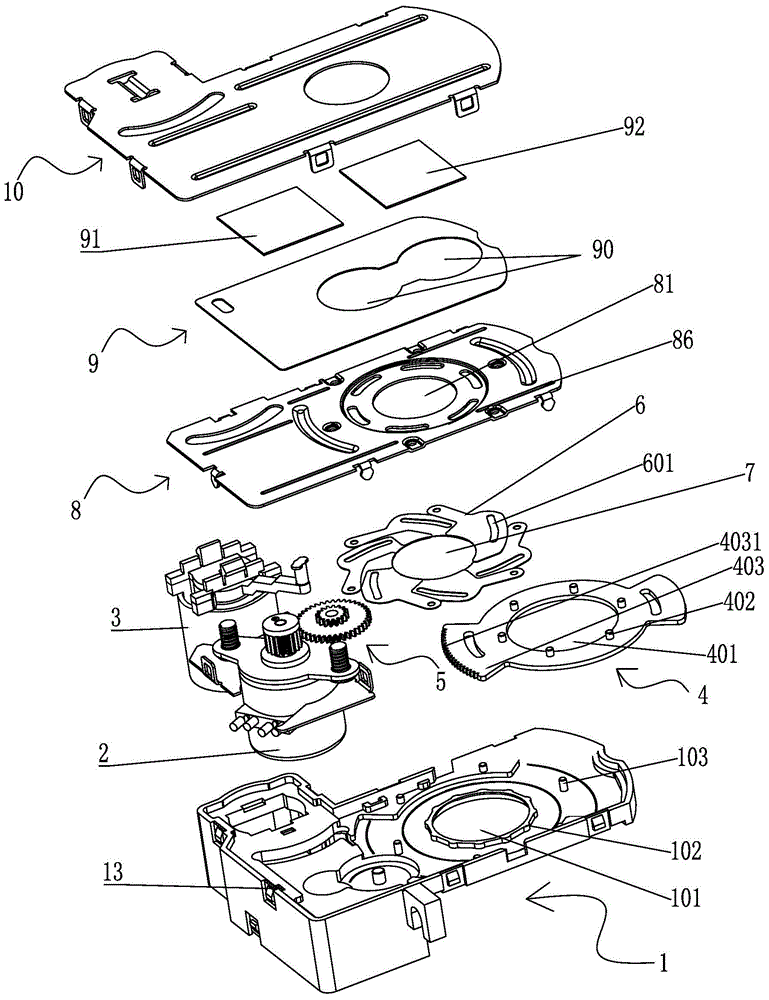

A multi-leaf aperture adjustment device with filter switching

ActiveCN103777433BQuality improvementPrecise and stable movementCamera filtersCamera diaphragmsExposureLight filter

The invention relates to a multi-leaf aperture adjustment device with filter switching, which has the function of automatic switching between an infrared cut-off filter and a full-transmission spectrum filter, and the aperture is close to a circle at any time, and the area of the aperture is between A controllable state, the size of the aperture area changes uniformly to adjust the size of the exposure, the automatic switching of the filter and the uniform change of the multi-leaf aperture area can obtain higher quality and clearer images than traditional cameras or cameras.

Owner:UNION OPTECH

Friction wheel-type heavy cargo carrying platform and storing and taking method

PendingCN113525983AInhibition rigidityAvoid precisionConveyorsStorage devicesMarine engineeringReciprocating motion

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

A double steering clutch

ActiveCN105546107BOvercome the disadvantage of only one-way rotationOvercome the disadvantage of one-way rotationToothed gearingsGearing controlEngineeringBrake pad

The invention discloses a double-steering clutch which comprises an operation piece, the operation piece comprises an operation rod and an inverted-U-shaped operation frame arranged below the operation rod, the lower end of the operation frame stretches into a hollow clutch box body, one side of the clutch box body is provided with an input shaft, and the clutch box body is internally provided with a drive gear arranged on the input shaft, an upper inner gear, a lower inner gear, an upper outer gear, a lower outer gear, an output shaft frame, an output shaft, brake gears, a brake drum and a brake pad, wherein the upper inner gear and the lower inner gear are meshed with the drive gear, the upper outer gear and the lower outer gear are mounted coaxial with the upper inner gear and the lower inner gear, the output shaft is located on the output shaft frame, the brake gears are located on the input shaft and the output shaft, and the brake drum and the brake pad are sequentially arranged outside the brake gears. The double-steering clutch is compact in structure, stable and firm in connection, capable of conducting bidirectional steering, flexible in braking, convenient to operate, large in torque transferred through gear meshing, capable of being applied to large vehicle equipment and worthy of wide popularization.

Owner:南通棉锦纺织品有限公司

Industrial assembly line model mechanism

ActiveCN104318848BThe transmission runs smoothlyReduce noiseEducational modelsAssembly lineProduct design specification

Owner:SHAANXI UNIV OF SCI & TECH

Automatic window and railway passenger car with the same structure

ActiveCN106968548BAchieve closureThe transmission runs smoothlyPower-operated mechanismWindow arrangementsSash windowRailway passenger car

Owner:青岛中车四方轨道车辆有限公司

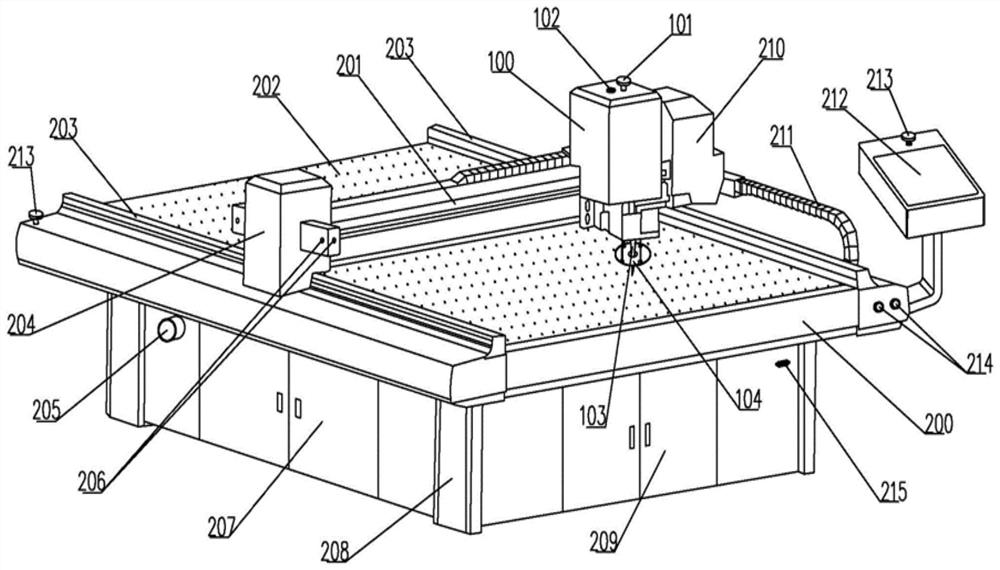

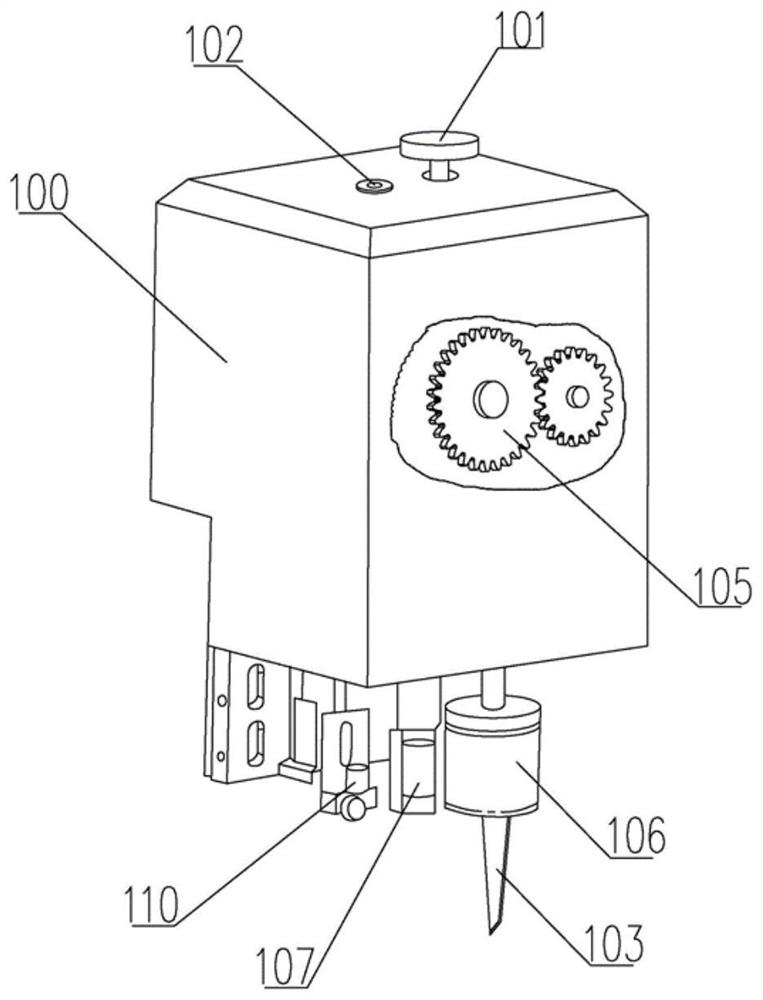

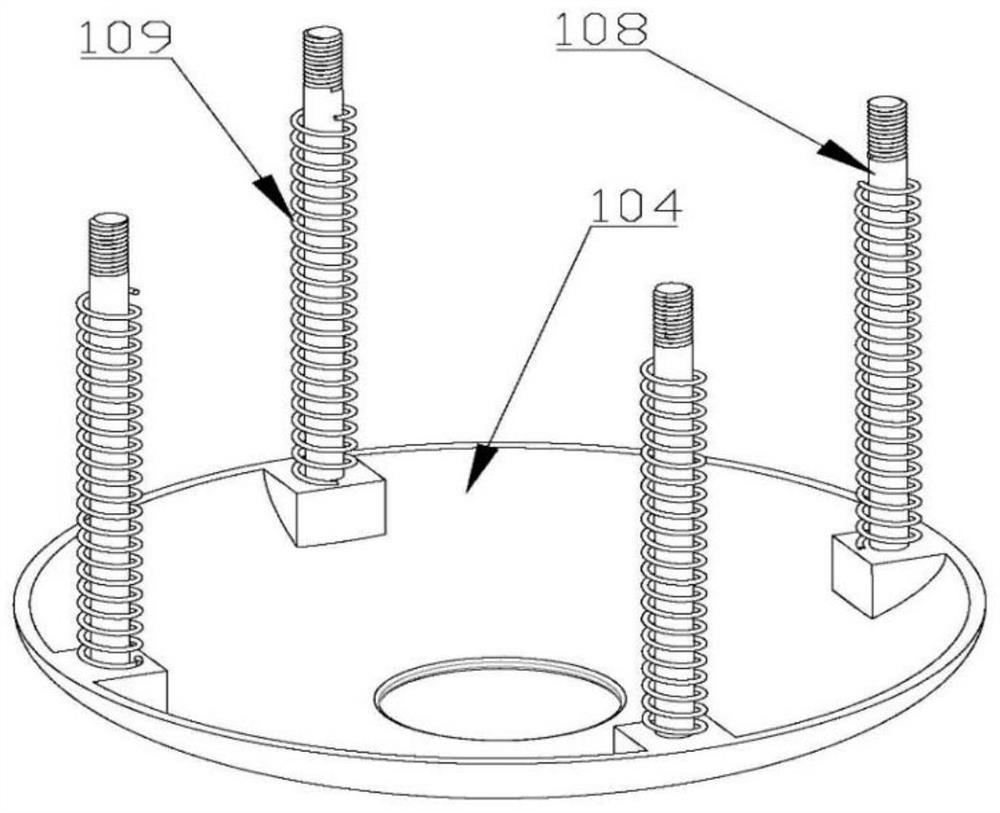

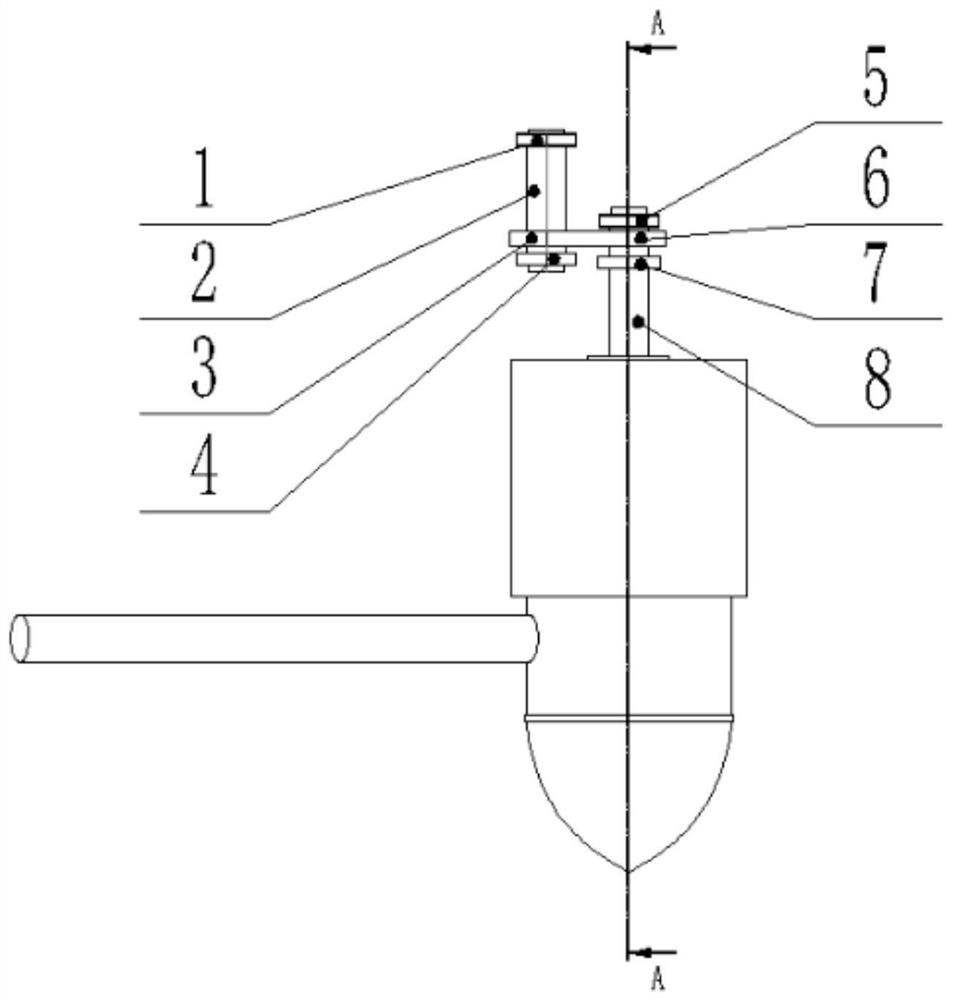

Cutting machine for ceramic fiber composite material

PendingCN114193533AIncrease profitIncrease intensityMetal working apparatusManufactured materialMachine

The cutting machine for the ceramic fiber composite material comprises a machine frame and a machine head, and the top of the machine frame is provided with a supporting platform capable of containing a to-be-cut material; the machine head is located over the supporting platform, the machine head has the stroke of moving along the X axis and / or the Y axis, the bottom end of the machine head is provided with a cutting blade facing the supporting platform, and the cutting blade has the stroke of linearly shaking in the Z-axis direction; a pressing structure is arranged at the bottom of the machine head and used for pressing a part of to-be-cut materials under the machine head when the machine head moves and / or the cutting blade shakes. And the production efficiency, the utilization rate of raw materials and the size control strength can be effectively improved, and the method has important significance on optimization of a production structure. The cutting device is applied to the technical field of aerogel composite material cutting.

Owner:CHANGSHA RONGLAN MACHINERY

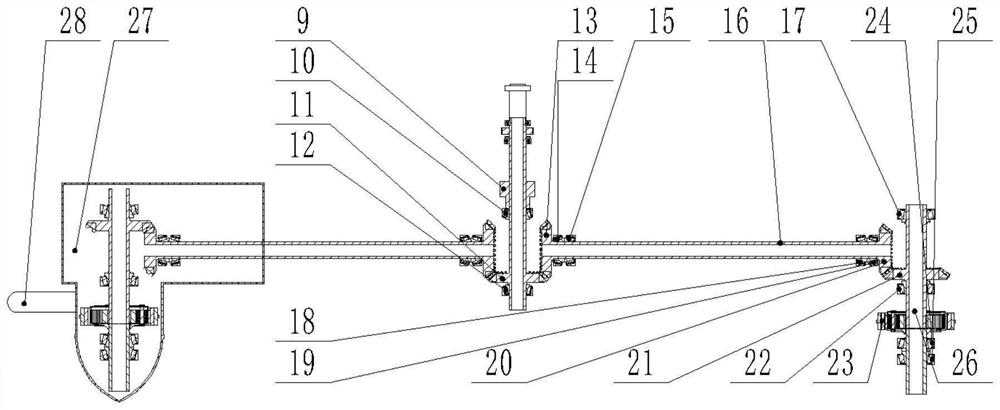

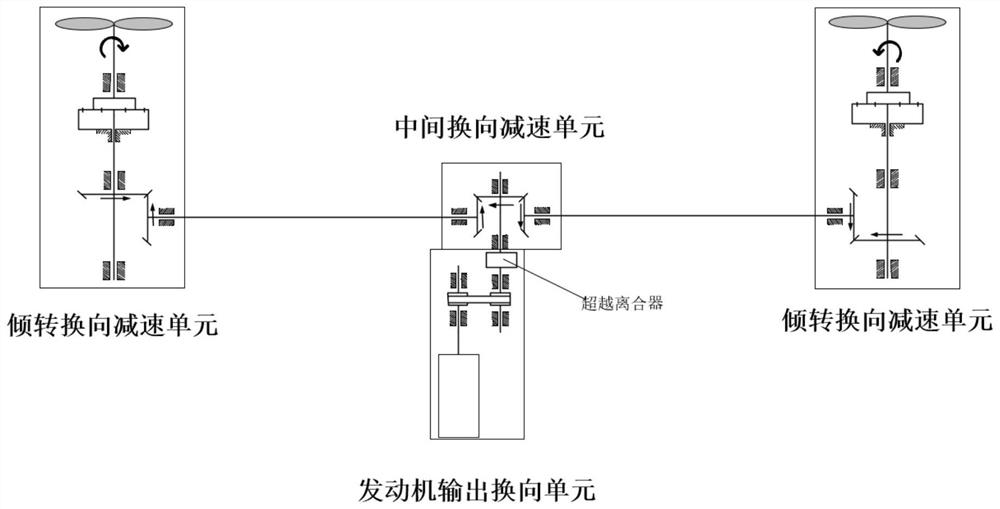

Belt transmission type tilt rotorcraft transmission system

PendingCN114435607AReduce weightSave construction spaceAircraft power transmissionRotocraftControl theoryBevel gear

The invention relates to a belt transmission type tilt rotorcraft transmission system which comprises an engine output reversing unit, a middle reversing speed reduction unit connected to the engine output reversing unit and a pair of tilt reversing speed reduction units symmetrically connected to the two sides of the middle reversing speed reduction unit. The tilting actuation units are symmetrically arranged on the two sides of the engine output reversing unit and connected with the tilting reversing speed reduction units in a one-to-one correspondence mode. According to the transmission system, one engine is adopted for output, diversion is conducted through bevel gears, power is transmitted to the rotors on the two sides, concentrated transmission of power input in one direction and power output in two directions is achieved, the weight is greatly reduced, and the structural space is reduced; in addition, the tilting actuation unit and the tilting reversing speed reduction unit are placed in the same casing, the weight can be reduced, and the structural size can be reduced as well.

Owner:CHONGQING UNIV

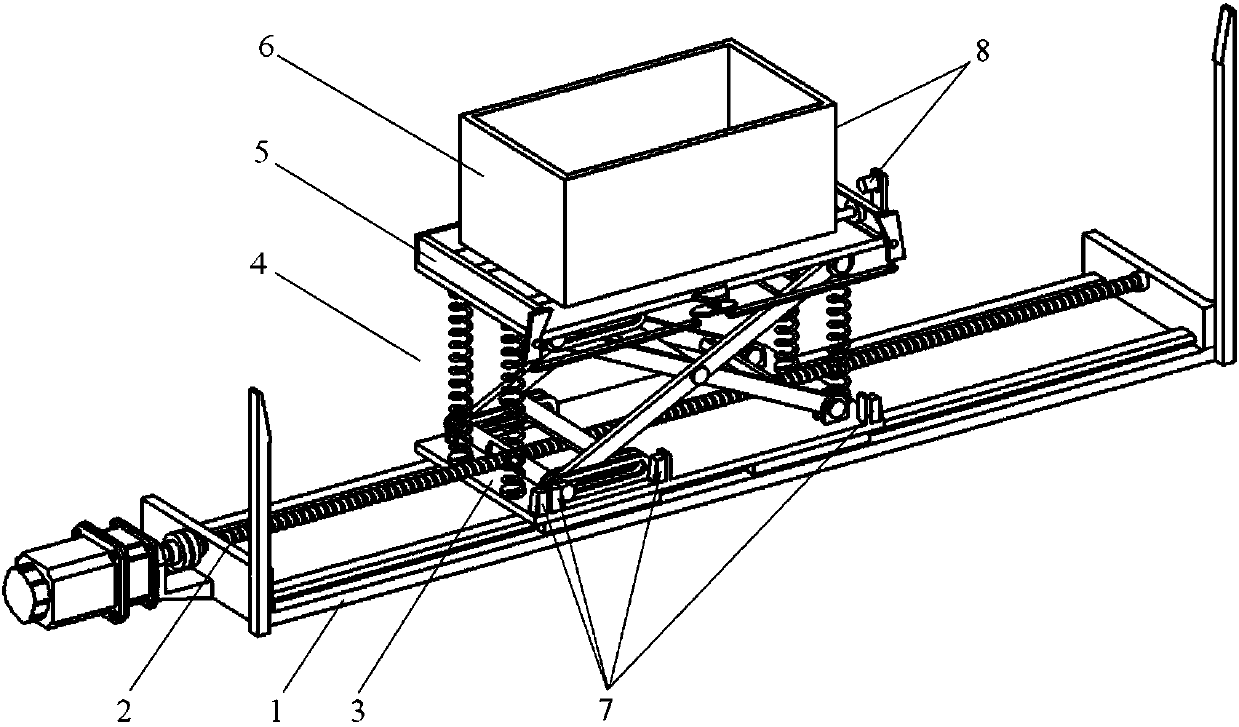

Two-degree-of-freedom automatic control scissor-type material conveying device

ActiveCN105110238BHigh degree of automationImprove exercise efficiencyLifting framesAutomatic controlEngineering

The present invention proposes a dual-degree-of-freedom automatic control scissors-type material delivery device, which is used to solve the problem of single movement direction and low degree of automation of the existing scissors-type work platform, including a base assembly, a driving mechanism, a scissors mechanism, a moving Material mechanism and control assembly; the scissor mechanism includes a lower platform, an upper platform and a telescopic mechanism connecting the two platforms above the base assembly; the drive mechanism is installed on the base assembly to realize the scissor mechanism in the horizontal and vertical directions The movement of the upper two degrees of freedom; the control component includes a scissor mechanism detection sensor and a box detection sensor, which are respectively installed on the lower platform and the upper platform; the material transport mechanism includes a material transport box, which is placed on the upper platform. The invention has the advantages of motion precision, degree of automation, high work efficiency and stable operation, and can be widely used in occasions such as material transportation between workbenches of different heights and workshop assembly.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com