Novel high-molecular alloy plastic hollow cable bridge

A polymer alloy and cable bridge technology, applied in the direction of electrical components, etc., can solve the problems of accelerating metal bridge decay, cable skin aging, reducing the service life of cables and bridges, etc., so as to ensure the effect of fixing and protection, and the effect of sealing and installation is better Excellent, guarantee the effect of stable transmission operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

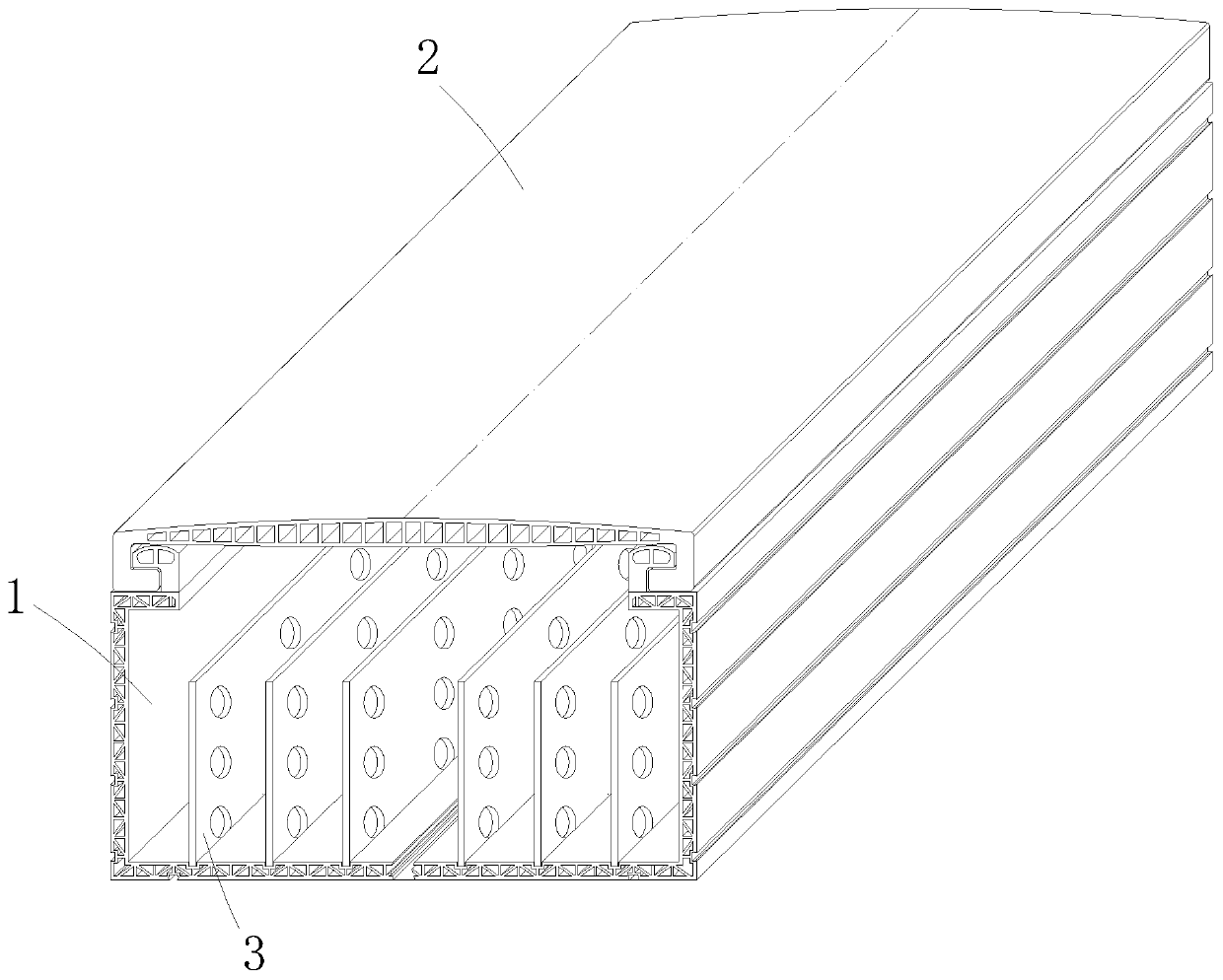

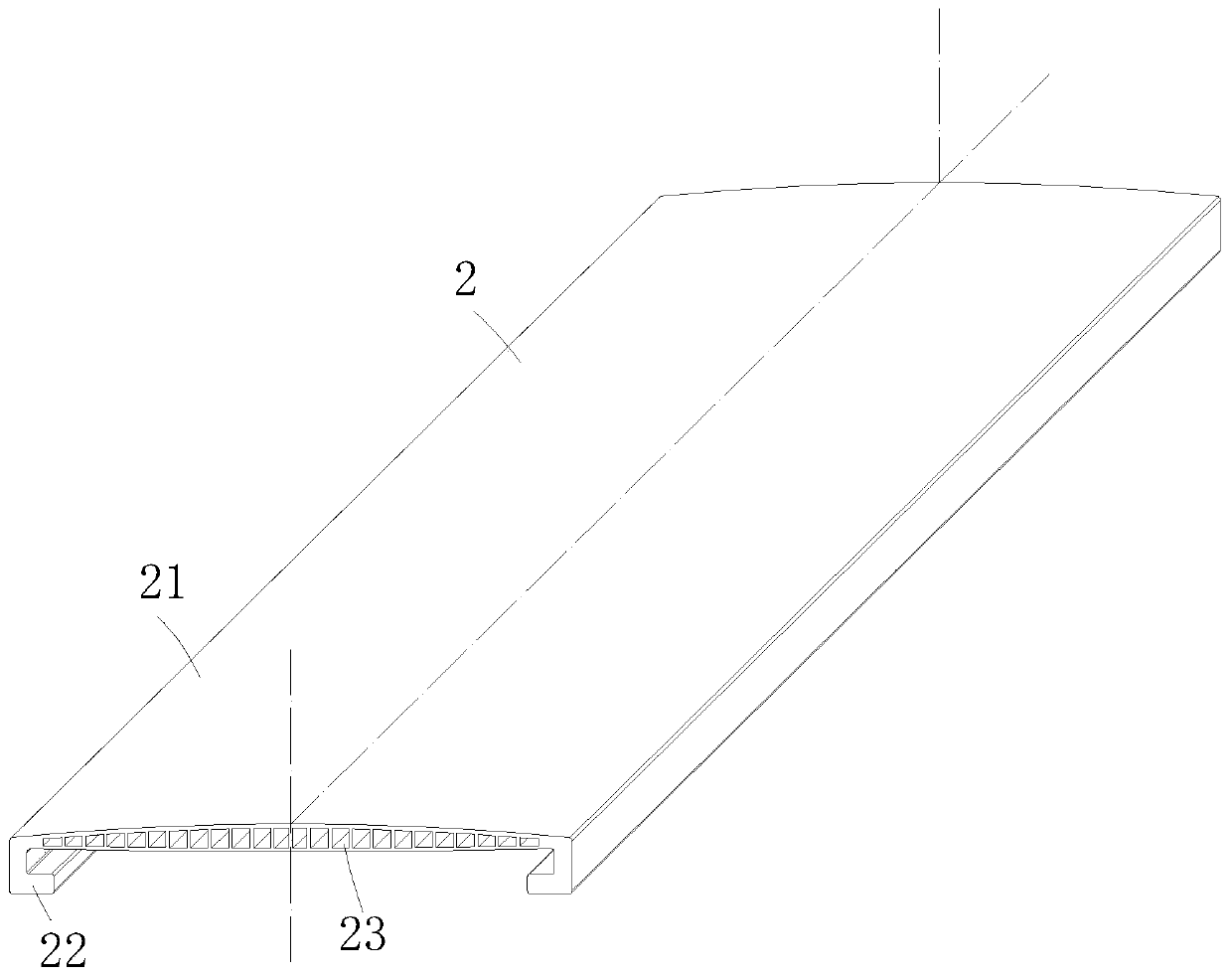

[0043] A new type of polymer alloy plastic hollow cable tray, including detachable bridge body 1 and bridge cover 2, both of which are made of high-tech polymer materials PVC and ABS polyphenylene oxide and other organic materials. It has excellent comprehensive performance, high impact strength, good dimensional stability, excellent corrosion resistance and high gloss.

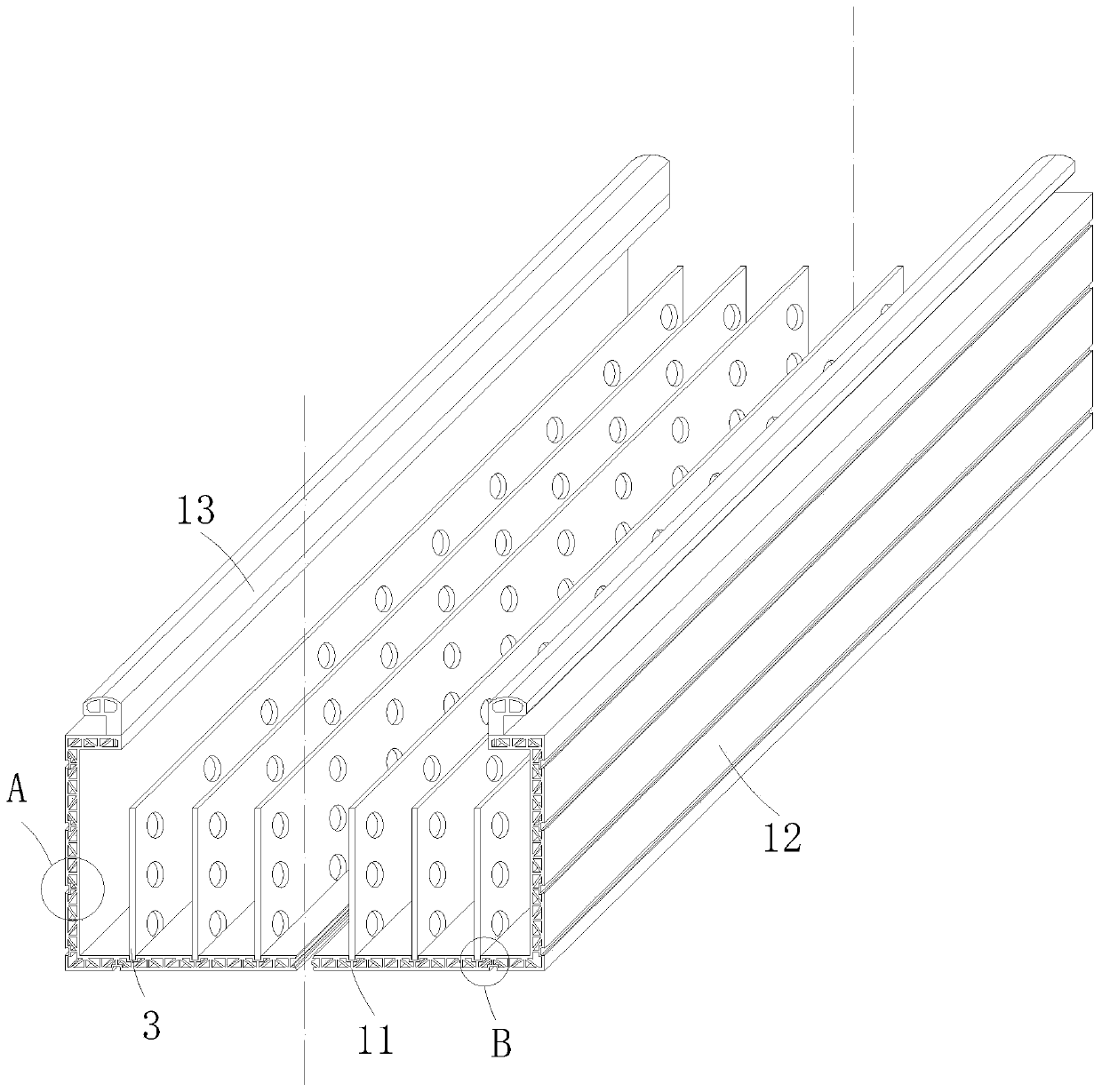

[0044] In this example, if figure 2 , 6 As shown in and 11, the bridge body 1 includes a bottom plate 11 and vertical side portions 12 extending vertically upward on both sides of the bottom plate 11 to form a groove-shaped bridge, and the upper end of the vertical side portion 12 extends vertically inward to form a mounting portion. And the upper end of the installation part is integrally formed with a lower buckle part 13, a plurality of equidistantly arranged second cavities 15 are arranged in the bottom plate 11 and the vertical side part 12, and the cross-section of the second cavities 15 is Rectangul...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is that, as Figure 4-6 As shown, further, the inner cavity of the bridge body 1 is provided with a plurality of partition plates 3 arranged in parallel vertically, and a plurality of cooling holes 31 are distributed in a matrix on the side wall of the partition plate 3, and a plurality of optional The assembled partition plate 3 can effectively ensure the arrangement of the cables, and is convenient for installation and maintenance. Combined with the design of multiple cooling holes 31, the heat dissipation effect is better, and the stable transmission and operation of the cables to the power is guaranteed.

[0052] In this example, if figure 1 , 2 As shown in and 11, the upper end surface of the bottom plate 11 is provided with a plurality of upper buckle grooves 19 matching the lower end surface of the partition plate 3, and the opposite side walls of the upper buckle grooves 19 are inwardly convex arcs. The s...

Embodiment 3

[0055] The difference between this embodiment and embodiment 2 is that, as Figure 5 , 8 Shown in and 9, also include the protective edge plate 4 that is symmetrically arranged on both sides of the bridge body 1, the protective edge plate 4 includes an L-shaped side protective edge 41, and the side protective edge 41 is close to the side of the bridge body 1 side A horizontal section and a vertical section are provided with a plurality of strip buckles 42 extending along the installation direction of the bridge body. The strip buckles 42 have a rectangular structure, and both sides of the strip buckles 42 are outwardly facing. The raised arc structure, the installation of the protective side plate 4 can effectively ensure its fixing and protective effect on the side of the bridge body 1, and cooperate with the L-shaped structure of the side protective side 41, which can also share the weight of the bottom plate 11. function, the protective effect is better.

[0056] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com