Patents

Literature

657results about How to "Guaranteed installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

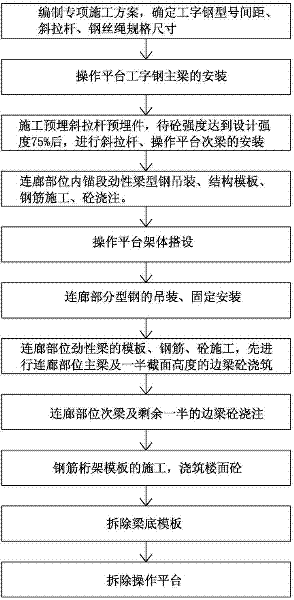

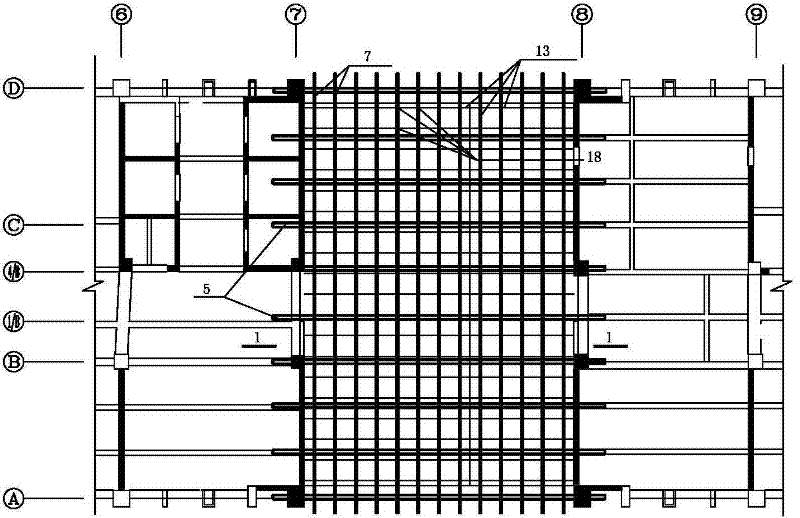

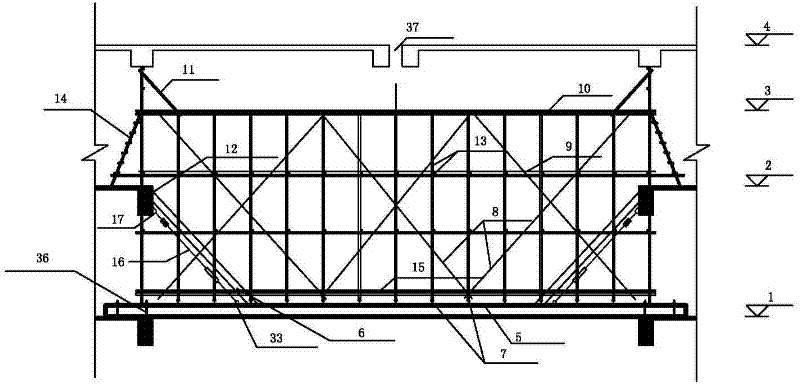

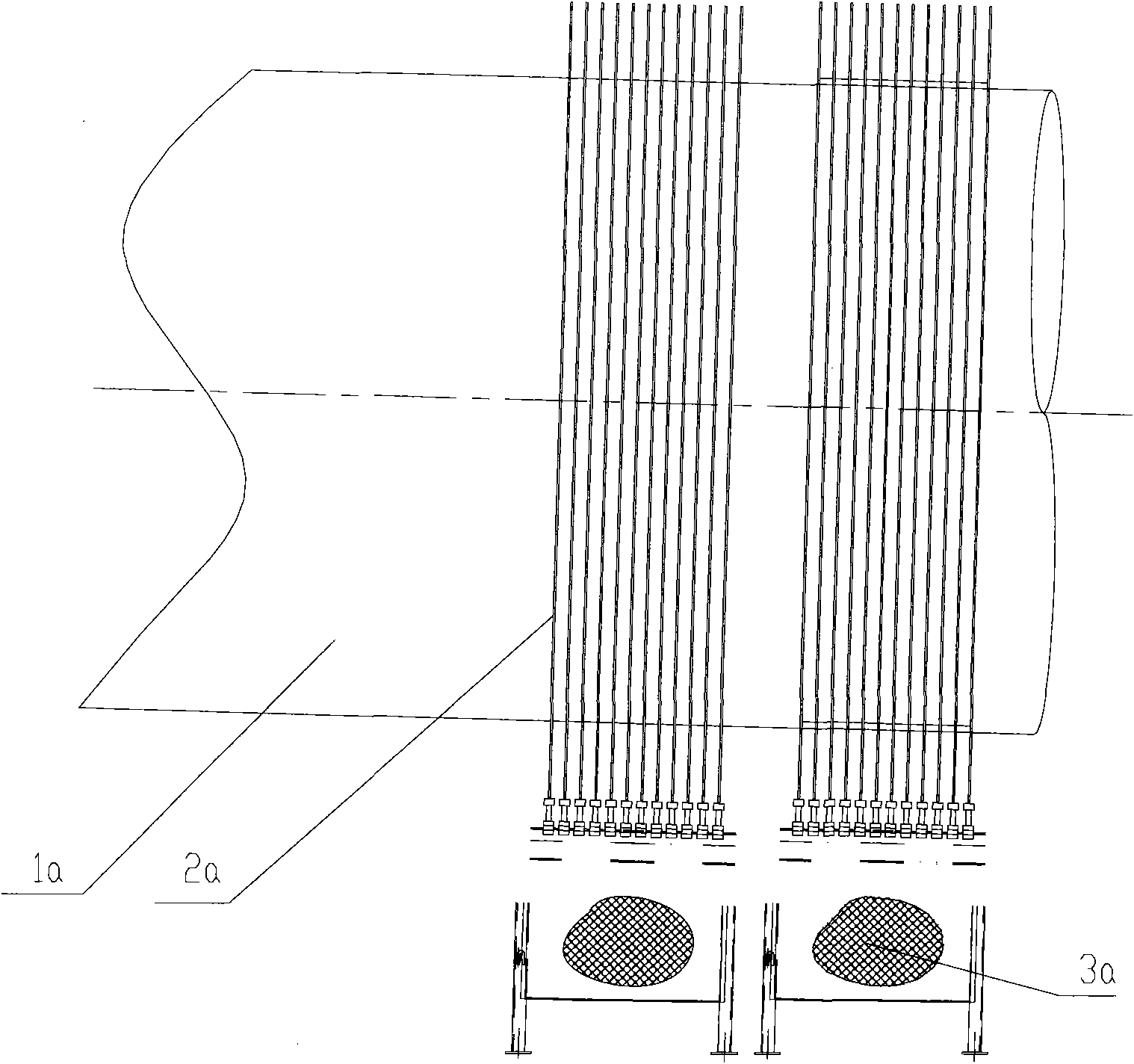

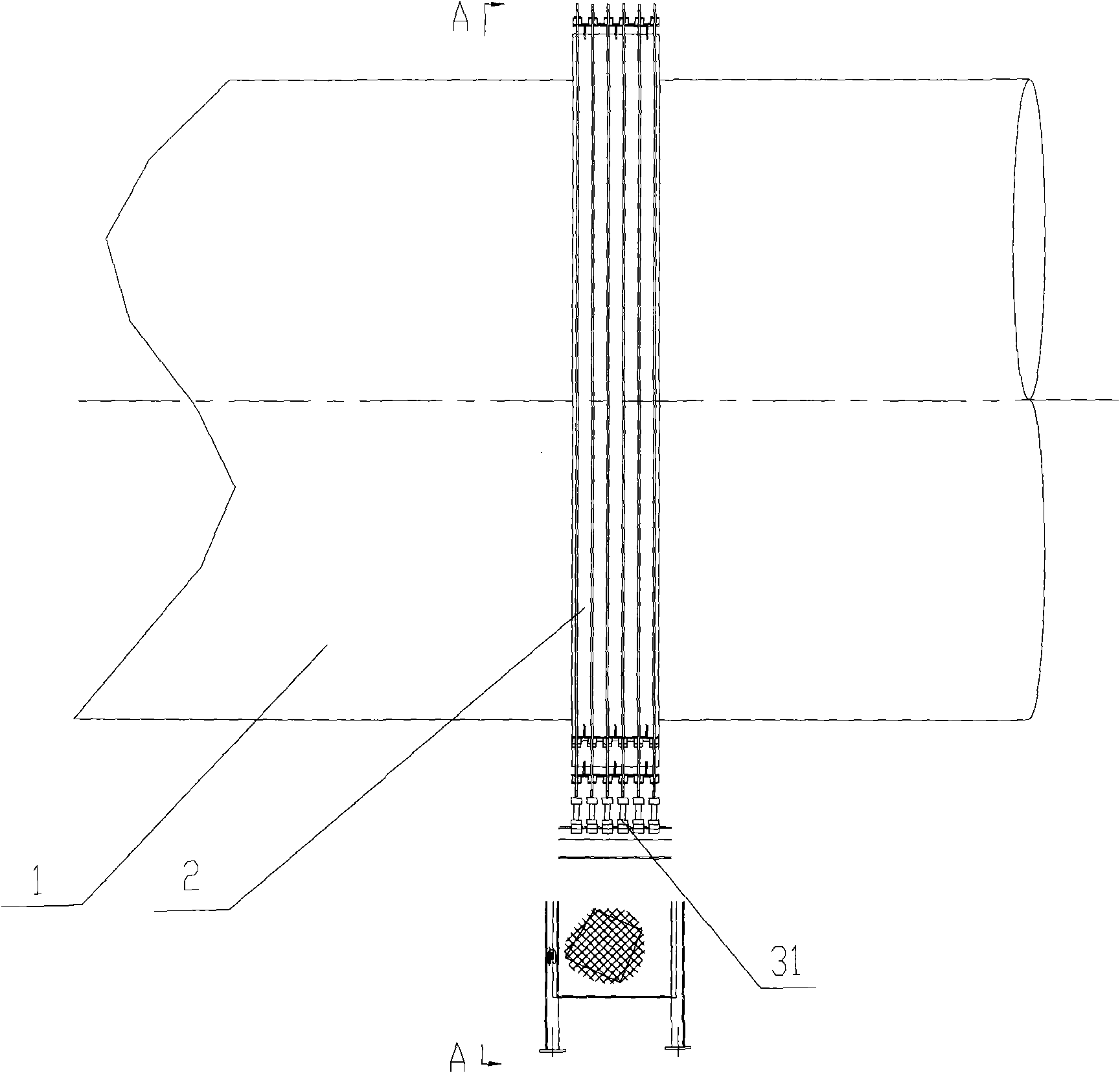

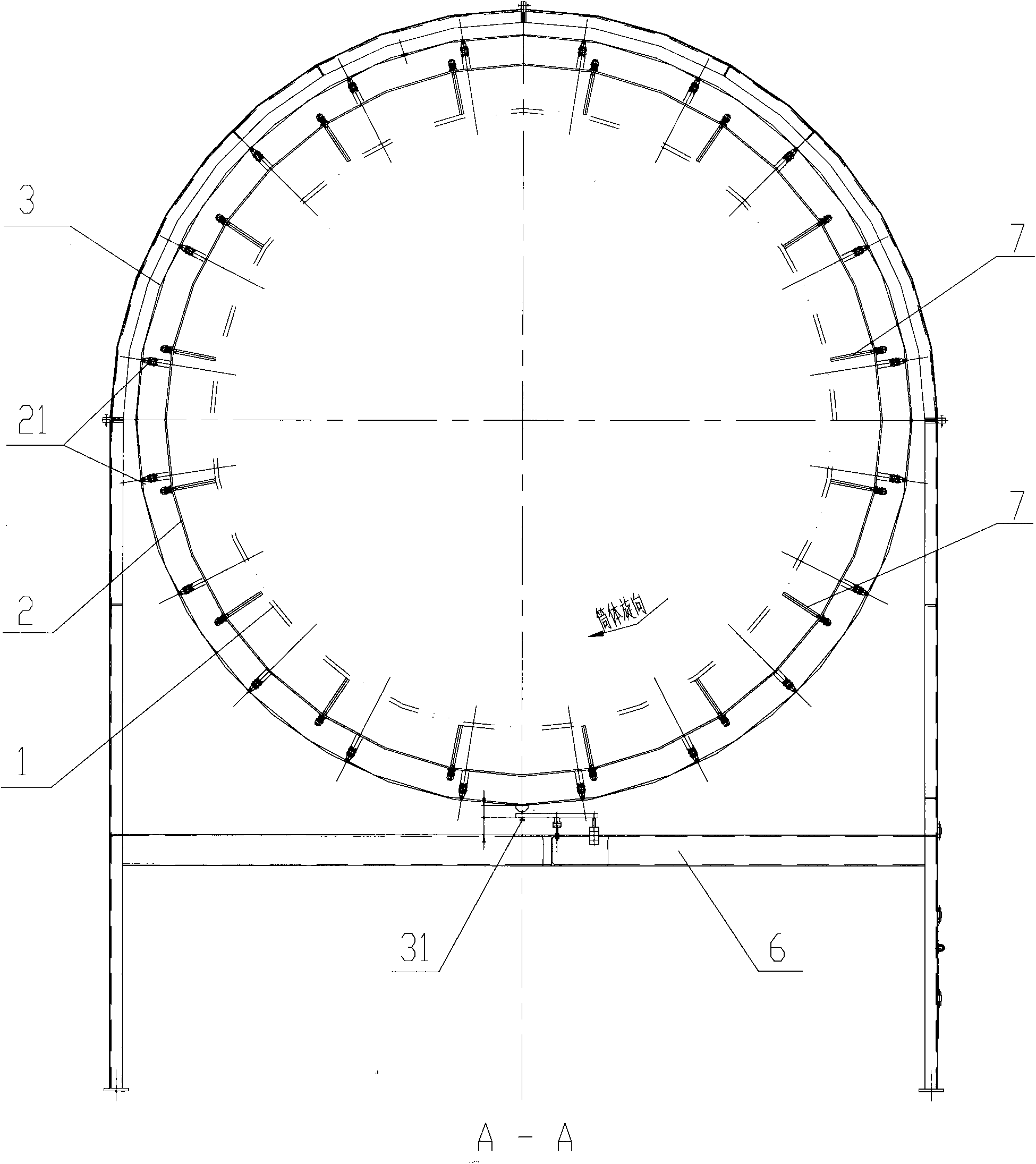

High-altitude long-span overhanging corridor type reinforced concrete structure and construction method

InactiveCN102444203ASave turnover materialsReduce construction costsBuilding material handlingSteel platesReinforced concrete

The invention relates to a high-altitude long-span overhanging corridor type reinforced concrete structure and a construction method, wherein the corridor part is a stiff beam structure; with own bearing capacity of a profile steel, a beam template supporting system is a hung template supporting system in such a manner of fixing a square steel by means of a U-shaped screw and a nut; a floorslab is a self-supporting steel bar truss template which is welded to a pre-embedded steel plate on the stiff beam by means of a pin; and a steel platform is arranged on a corresponding floor at the lower part of the corridor as an operating and safety protection platform for template support construction. The high-altitude long-span overhanging corridor type reinforced concrete structure and the construction method have the advantages that: the template supporting construction method, according to which the operating platform is built from H-steel or profile steel beams, the stiff beam is hung and is self-supported and the floorslab is self-supported, is employed, so that the problem of difficult template supporting of the high-altitude long-span overhanging corridor structure, the revolving materials are greatly saved, the construction cost is reduced, the construction progress is accelerated and the safety is ensured; and the steel plate is pre-embedded on the stiff beam, so that the floor bearing plate is effectively connected with the stiff beam and the floor bearing plate and the stiff beam are capable of acting together to ensure the safety of the structure.

Owner:浙江城建建设集团有限公司

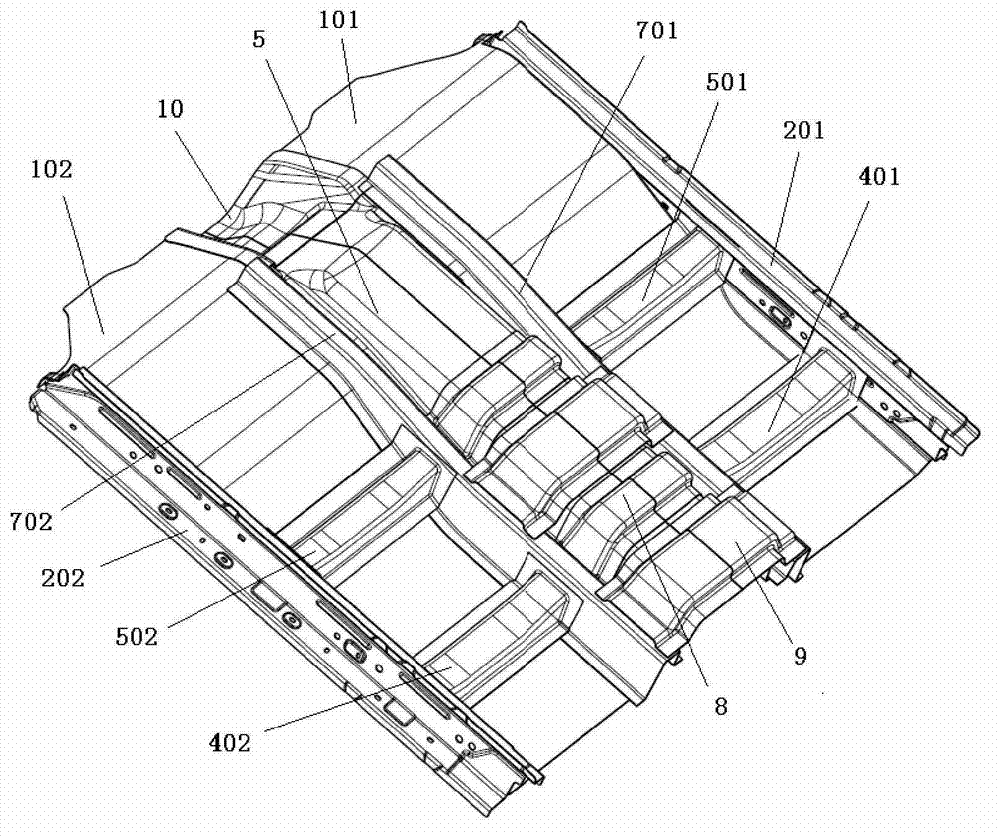

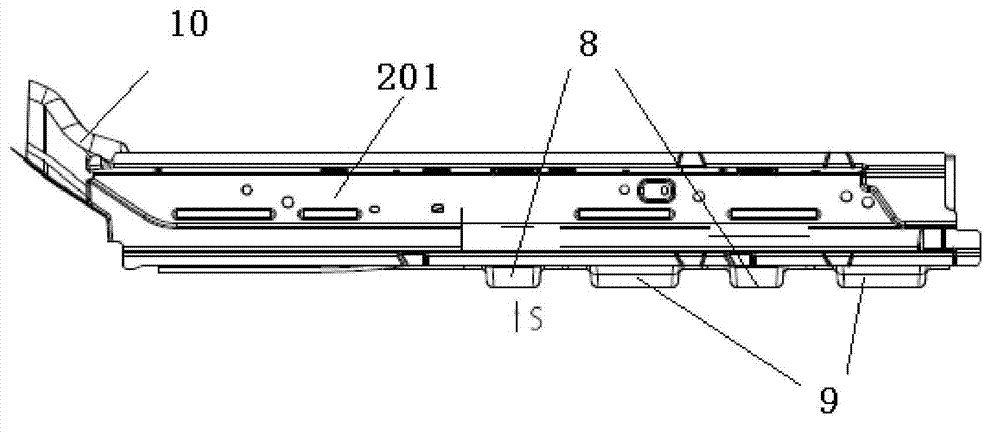

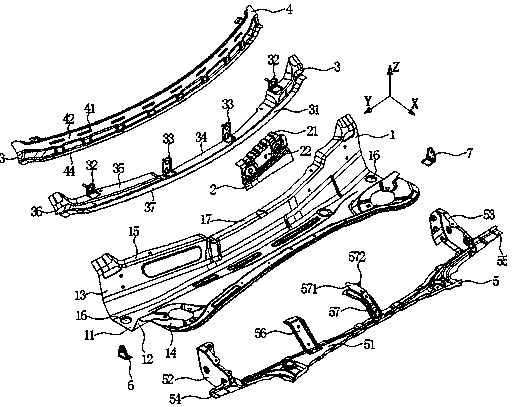

Automobile front floor assembly

ActiveCN102862612ASmall structural changesEasy to manufactureSuperstructure subunitsNacelleCost savings

The invention discloses an automobile front floor assembly which is arranged between a cabin assembly and a back floor assembly of an automobile and comprises a front floor body. The front floor body defines a center passage extending longitudinally along the automobile, and the center passage protrudes to the outside of the body of the automobile so that the cross section of the front floor body is in an inverted n-shaped approximately. The center passage of the automobile front floor assembly provides wider space for holding a motorcycle, so that the automobile front floor assembly is more suitable for a motorcycle and car combination mode. Besides, other structures on the automobile front floor assembly require small modification, the automobile front floor assembly is simple in manufacturing and cost-saving.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

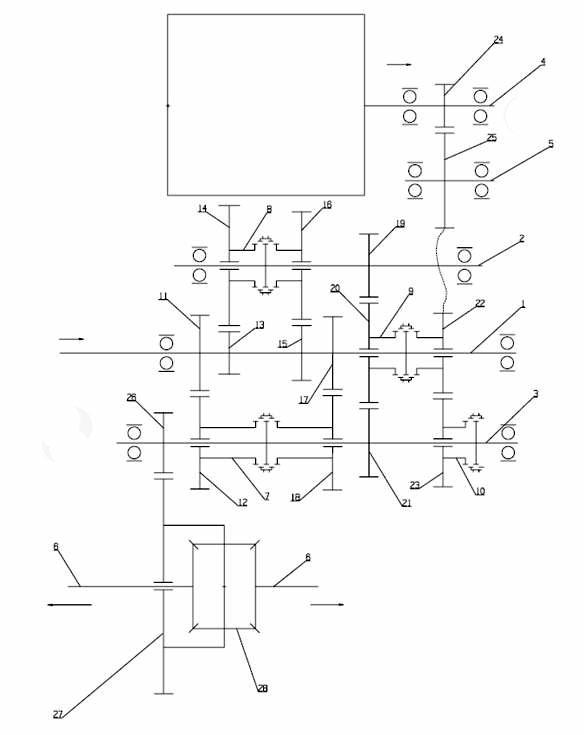

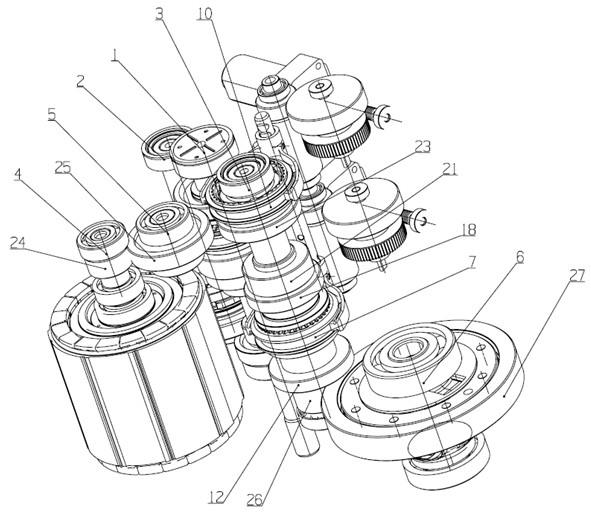

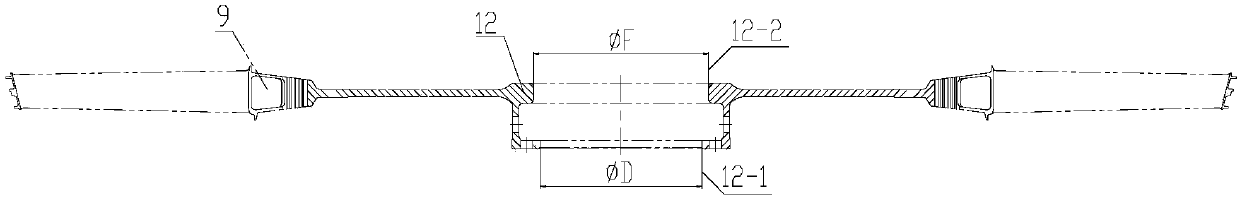

Automobile hybrid power assembly

InactiveCN102490585ASave radial spaceReduce weightGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringIdler-wheel

The invention relates to an automobile hybrid power assembly, which comprises a motor and an automated mechanical transmission (AMT). The AMT comprises an input shaft, a first middle shaft, a second middle shaft, a motor shaft, a motor idler shaft and an output shaft which are in location matching connection on a case body and parallelly arranged in space, wherein the input shaft is provided with driving gears from a first gear to a sixth gear and a five-gear motor synchronizer; the first middle shaft is provided with driven gears from a first gear to a second gear, one-two-gear synchronizer and a five-gear input gear; the second middle shaft is provided with driven gears from a third gear to a sixth gear, a driving speed reducing gear and a motor synchronizer; the motor shaft is provided with a motor output driving gear; the motor idler shaft is provided with an idler shaft; and the output shaft is provided with a driven speed reducing gear and a differential mechanism. The automobile hybrid assembly resolves the problem of power interruption during shifting of the AMT, greatly improves comfortableness, is compact in structure, saves axial space of the transmission and guarantees installation arrangement in the whole automobile.

Owner:CHONGQING TSINGSHAN IND

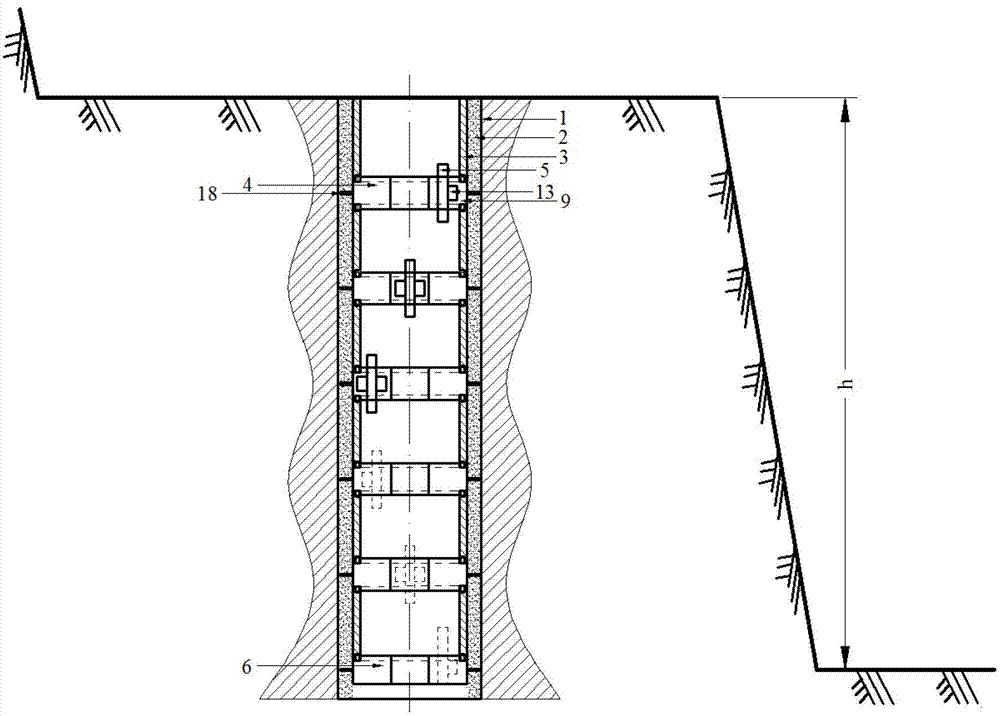

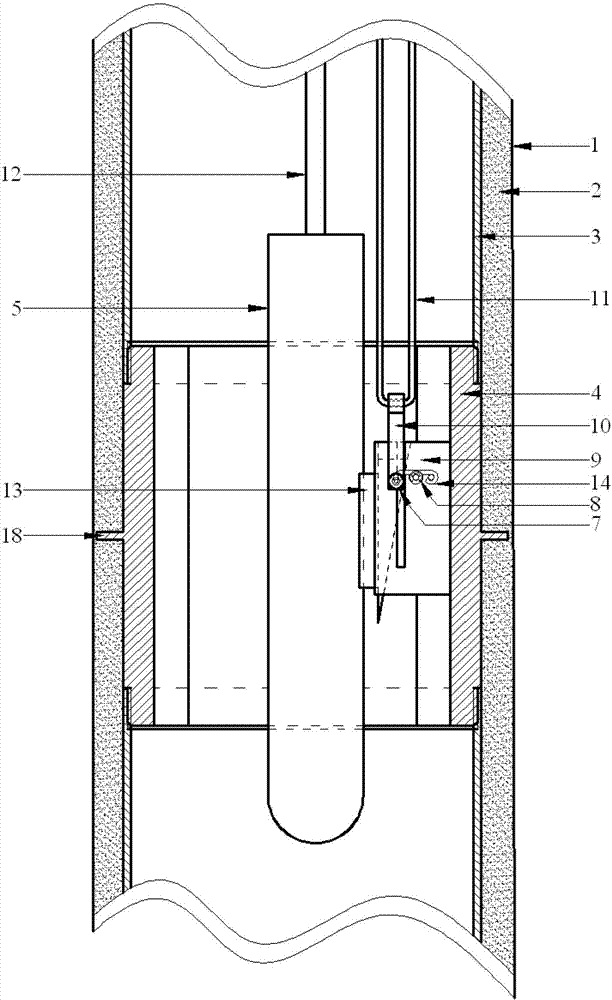

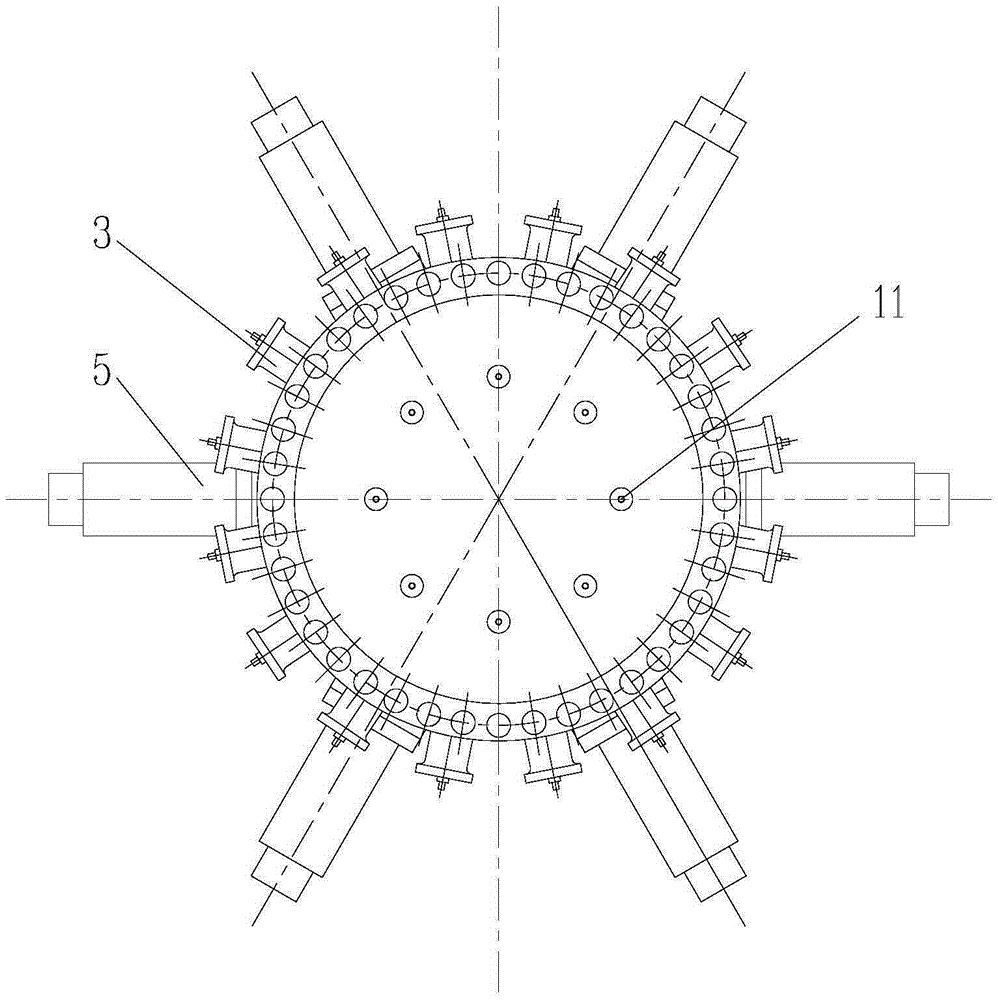

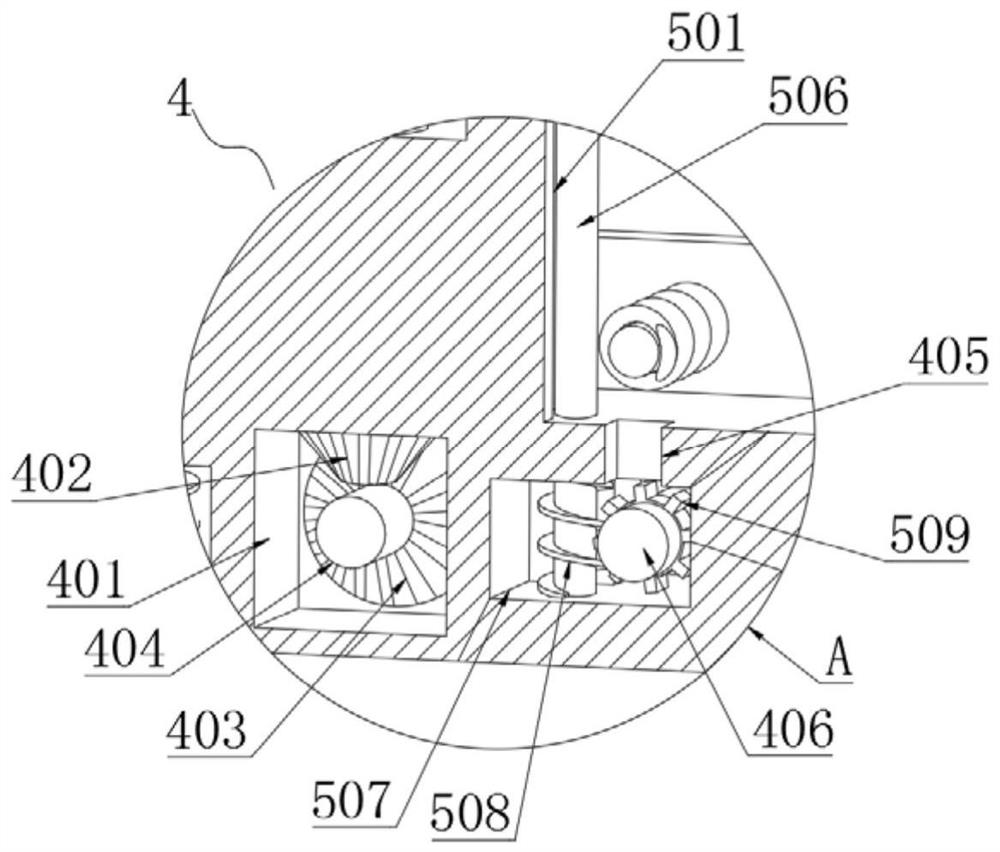

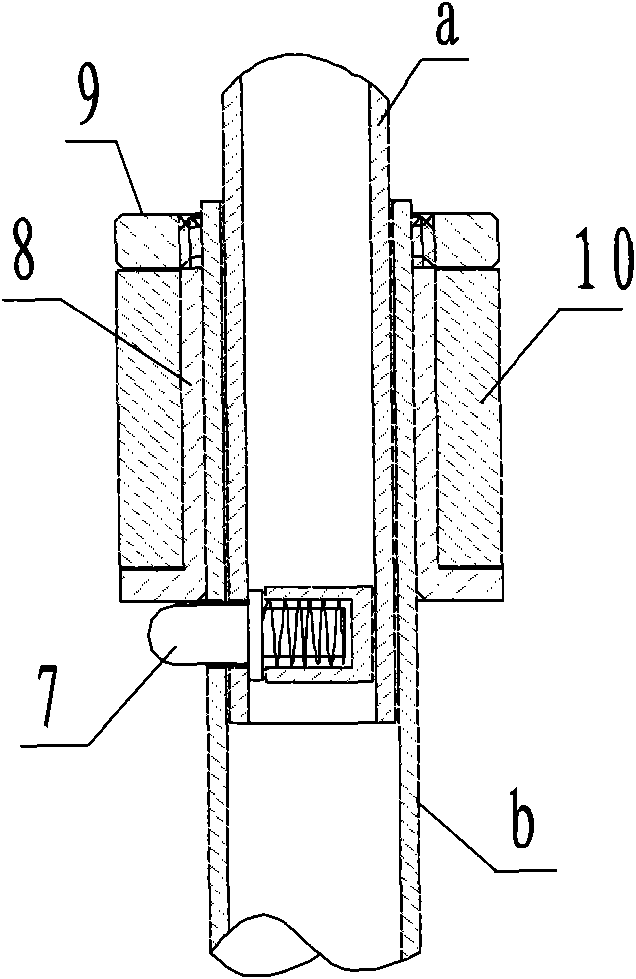

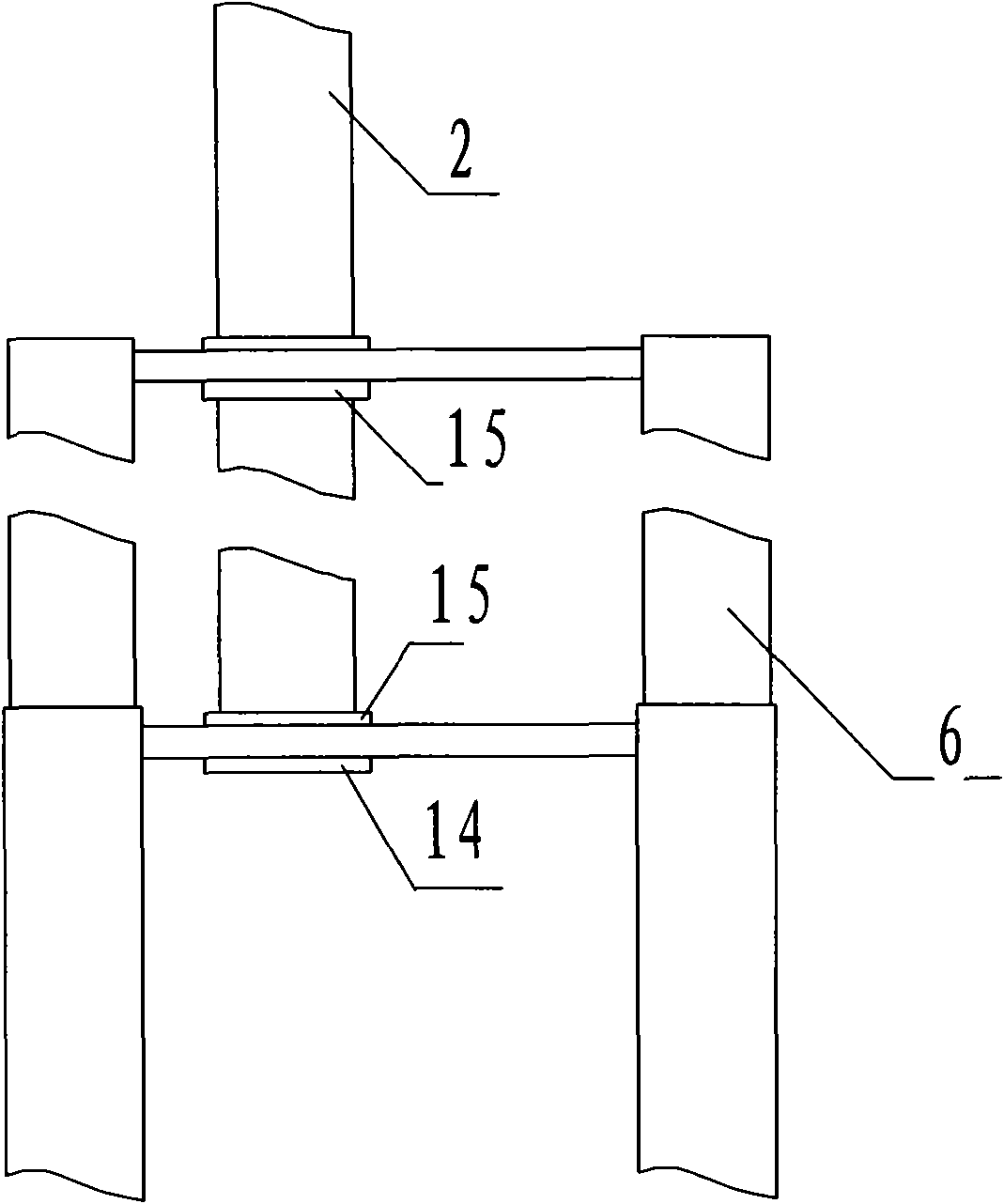

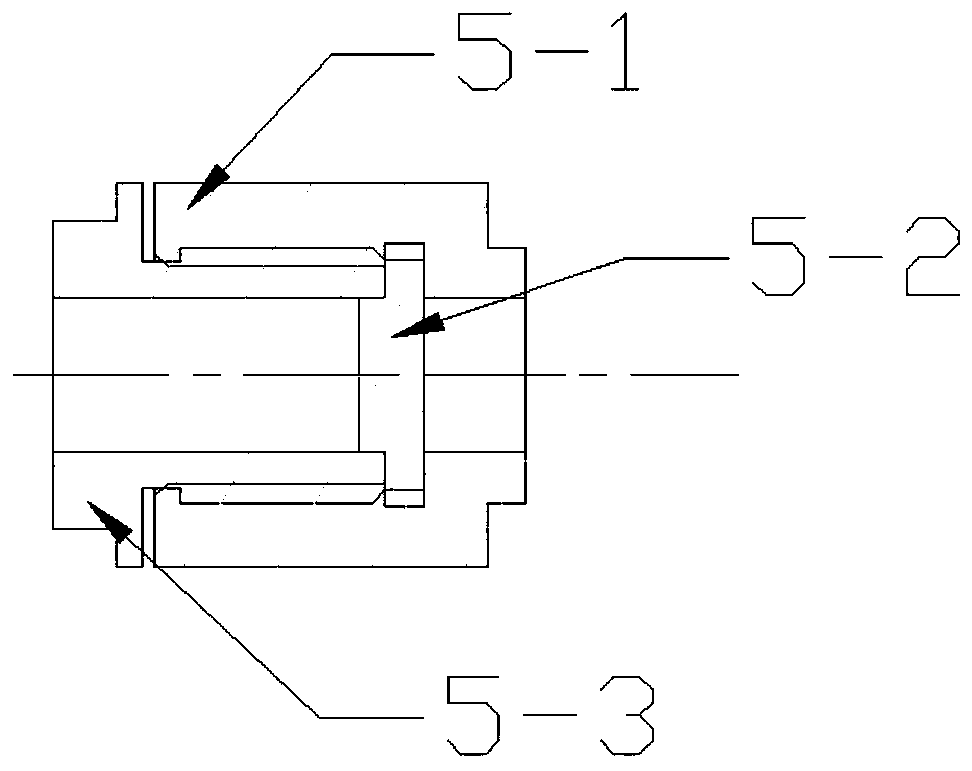

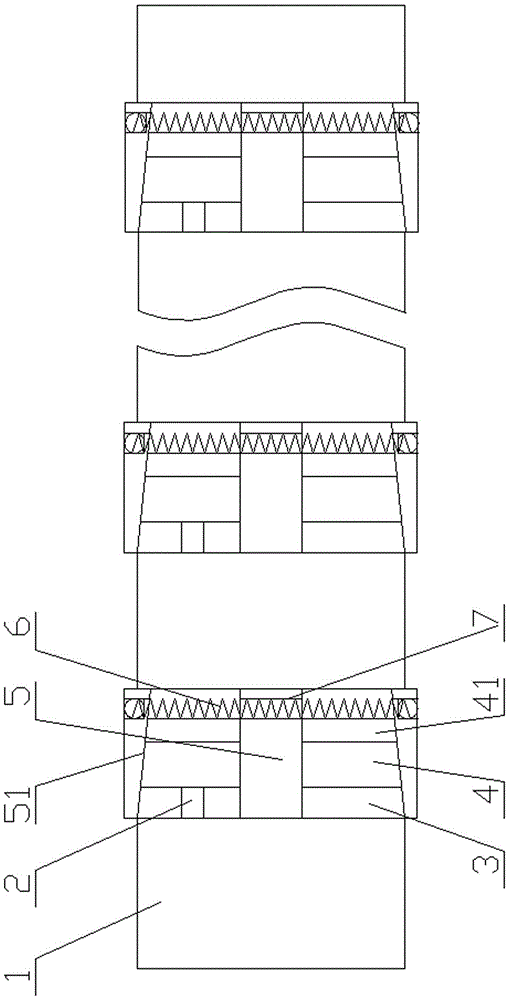

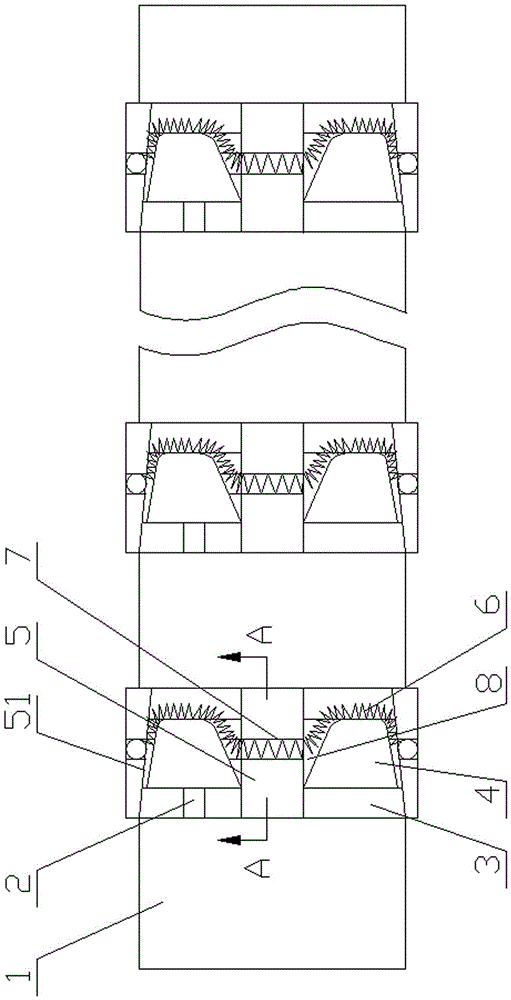

Omnidirectional cataclastic rock mass deep hole installation and recovery device of microseismic unidirectional sensor

InactiveCN102854525ASolve hard-to-couple problemsAvoid easy installationSeismic signal receiversBody femaleDeep hole

The invention discloses an omnidirectional cataclastic rock mass deep hole installation and recovery device of a microseismic unidirectional sensor. The omnidirectional cataclastic rock mass deep hole installation and recovery device comprises a sleeve which is embedded in a rock mass drilling hole, wherein a unidirectional sensor fixing device is installed at each part with a preset depth and direction in the sleeve and comprises an intermediate joint which is connected with the sleeve by inner threads, a wedge body combining body which is connected with the intermediate joint and is provided with a wedge body combining body female groove, a wedge body which is adapted to the wedge body combining body female groove, another unidirectional sensor which is connected with the wedge body, a tensile-resisting cable which is connected with the another unidirectional sensor, an elastic pressing device which is fixed on the wedge body combining body, and a pulling type lifting device which is connected with a second leading-out terminal of a cylindrical helical torsional spring of the elastic pressing device and is used for releasing the wedge body, wherein one end of the elastic pressing device tightly presses the wedge body in the wedge body combining body female groove. With the adoption of the omnidirectional cataclastic rock mass deep hole installation and recovery device, the installation is not limited by severe geological conditions and drilling inclined angles, the installation of a vertical hole and an inclined hole in a cataclastic rock mass can be realized, and the unidirectional sensors are easy to recover.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

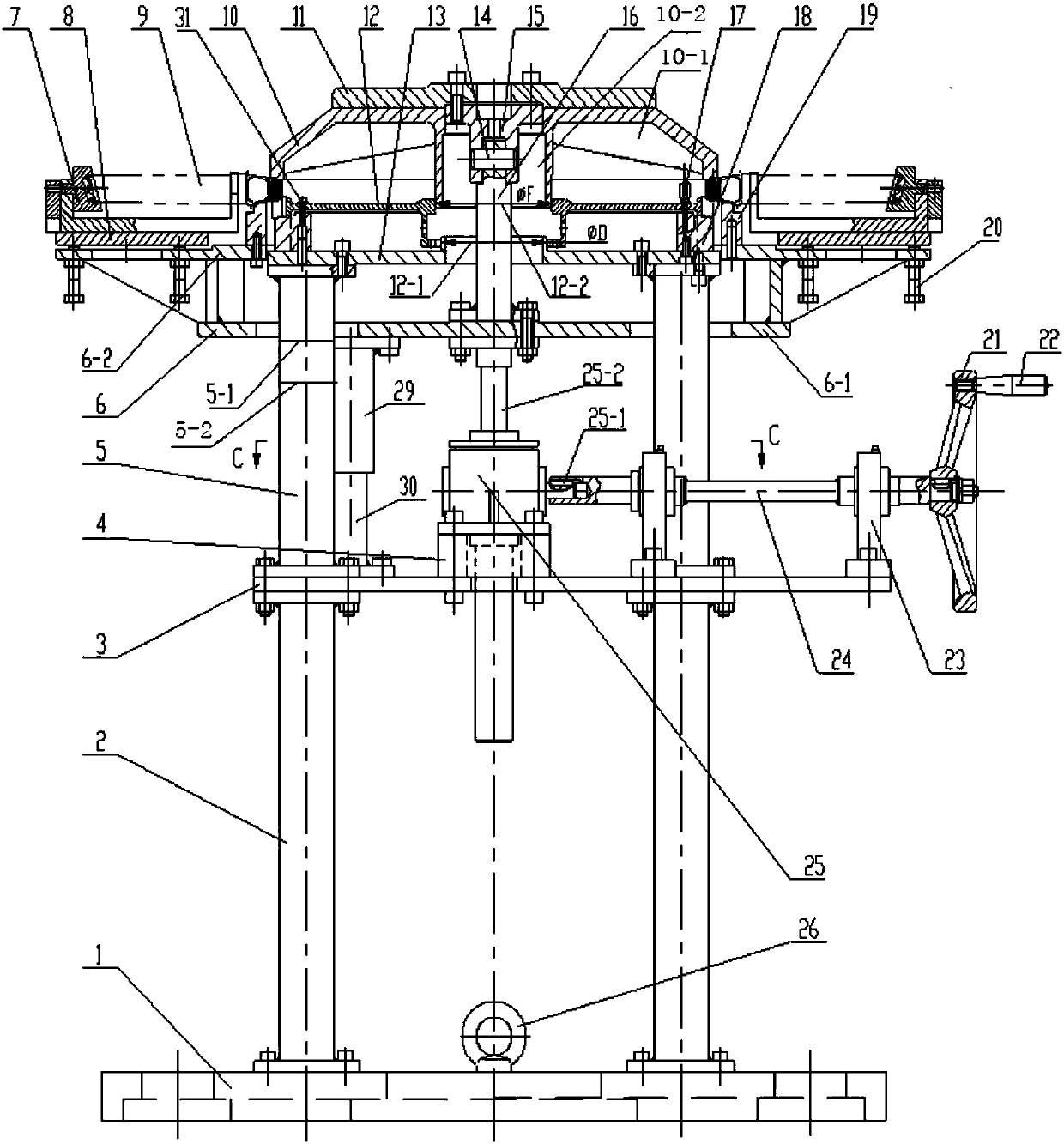

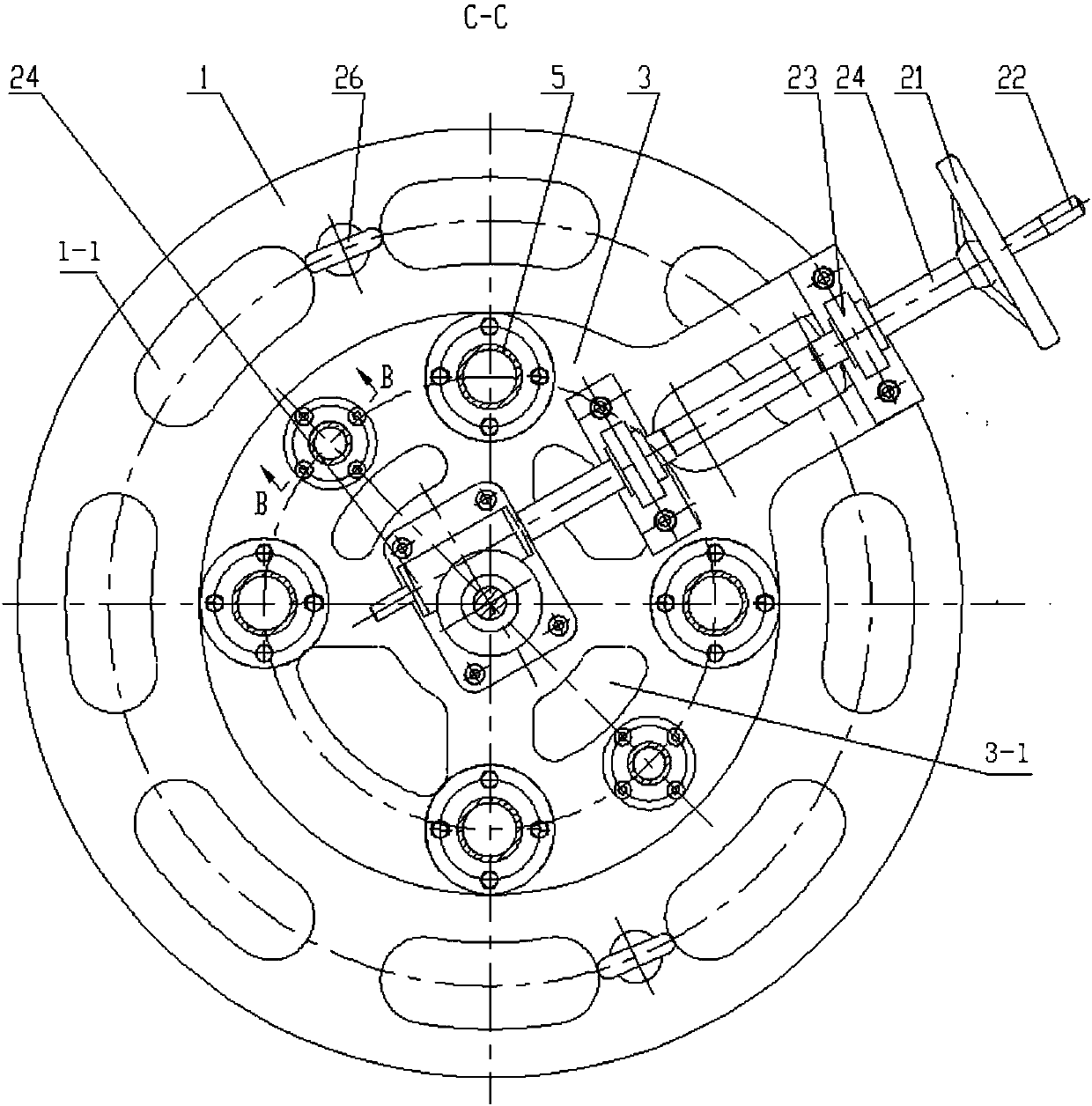

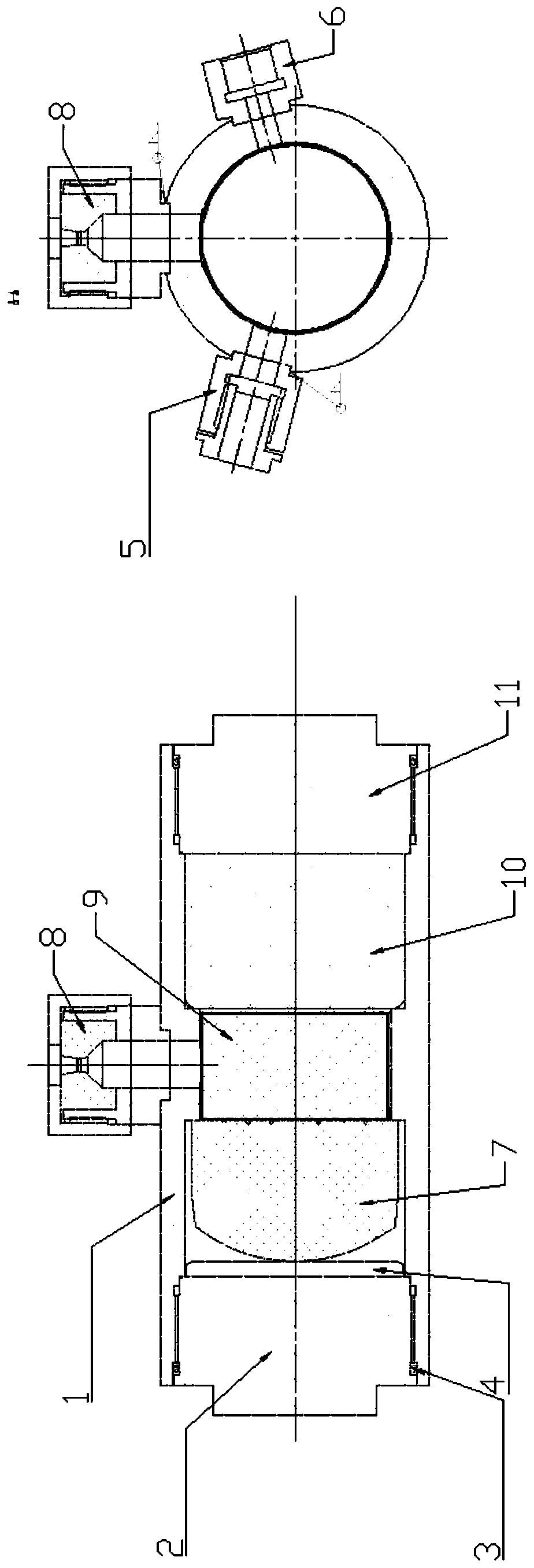

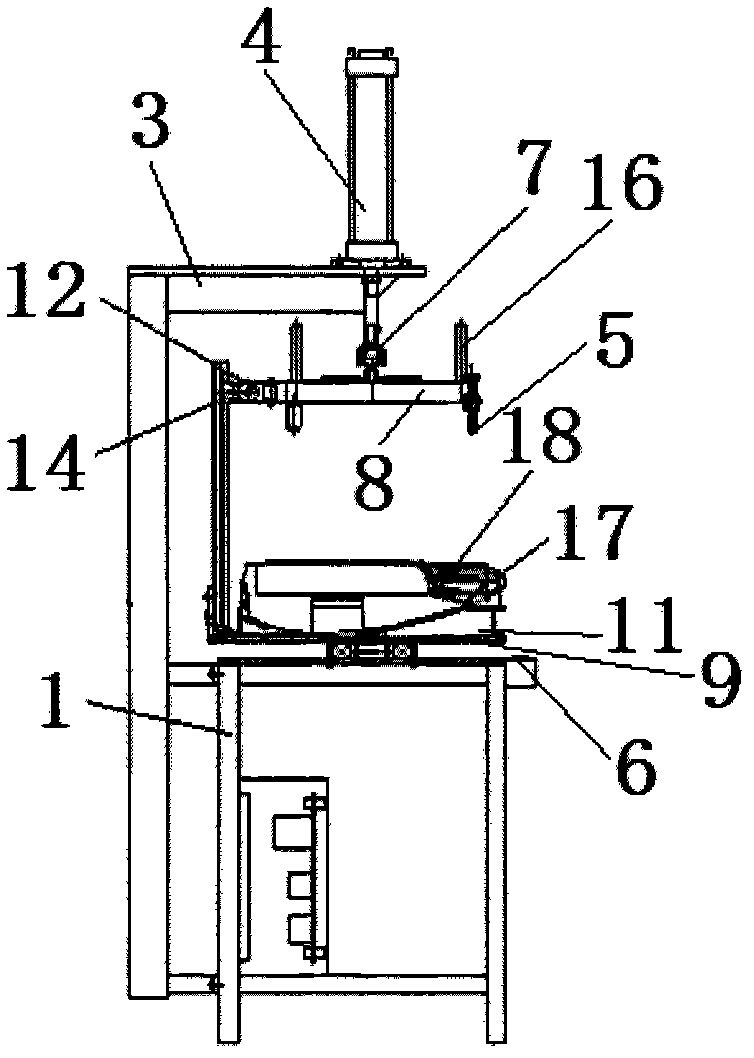

Integral engine turbine blade mounting and dismounting device and method

ActiveCN107584273AGuaranteed installationQuality assuranceWork holdersMetal working apparatusTurbine blade

An integral engine turbine blade mounting and dismounting device comprises a base, a lower column, an upper column, a lifter, a lifter driving assembly, a lifter installing plate, a lifting frame, a lifting frame guiding rod, a lifting frame guiding sleeve, a pull rod, a pull plate, an adapter part, a positioning disc, a turbine disc supporting ring, a blade supporting ring, an assembling compression cover and a detachable compression cover. An integral engine turbine blade mounting and dismounting method comprises the steps that when engine turbine blades are mounted and dismounted by using the device, a clamp for clamping the free ends of the blades and a base plate for the clamp to be placed, a turbine disc and the turbine disc supporting ring are fixedly connected, the turbine disc iskept stationary, the lifter is utilized as a power source, the turbine blades and the assembling compression cover or the detachable compression cover are driven to descend so as to achieve assembly and disassembly of the turbine blades. By using the device and the method, safe, quick and convenient mounting and dismounting of the engine turbine blades can be achieved, assembly and disassembly quality are ensured, and the effect is improved.

Owner:CHENGDU ENGINE GROUP

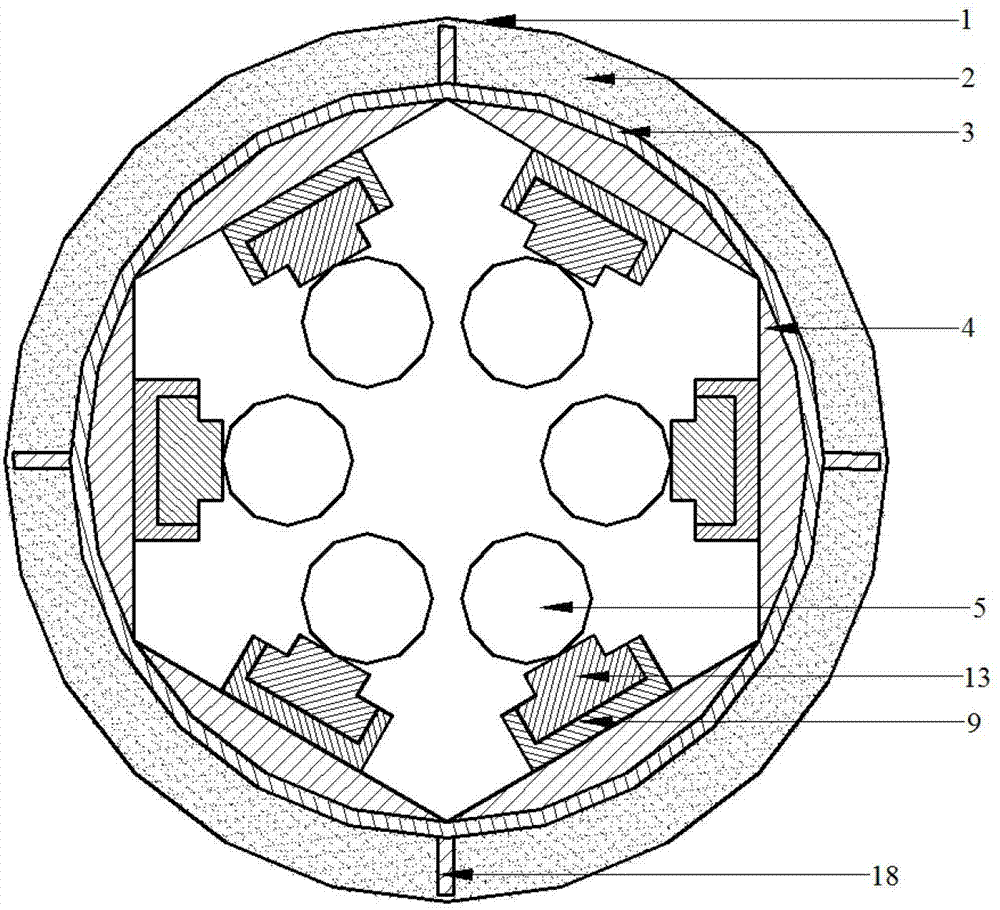

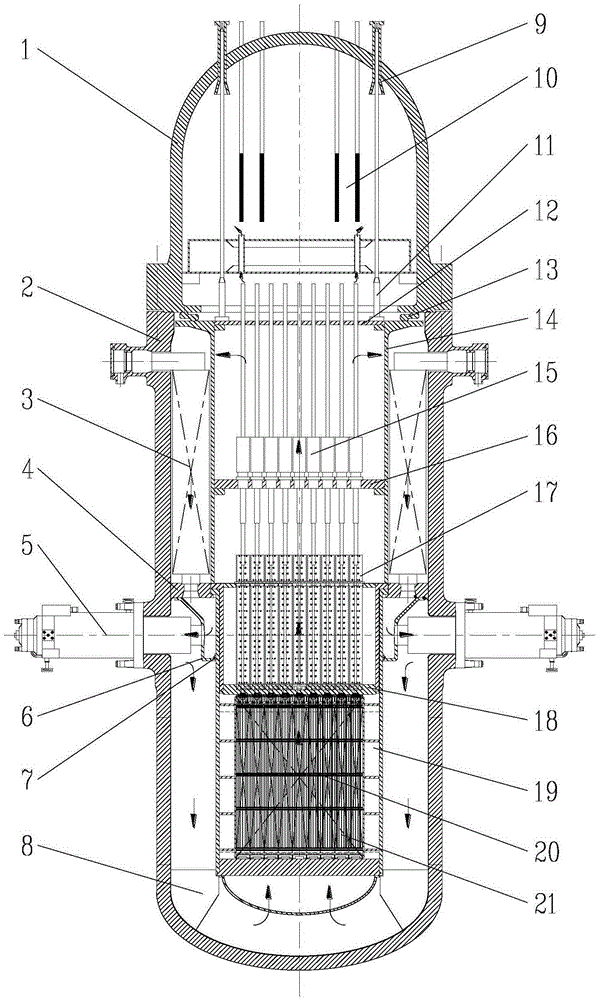

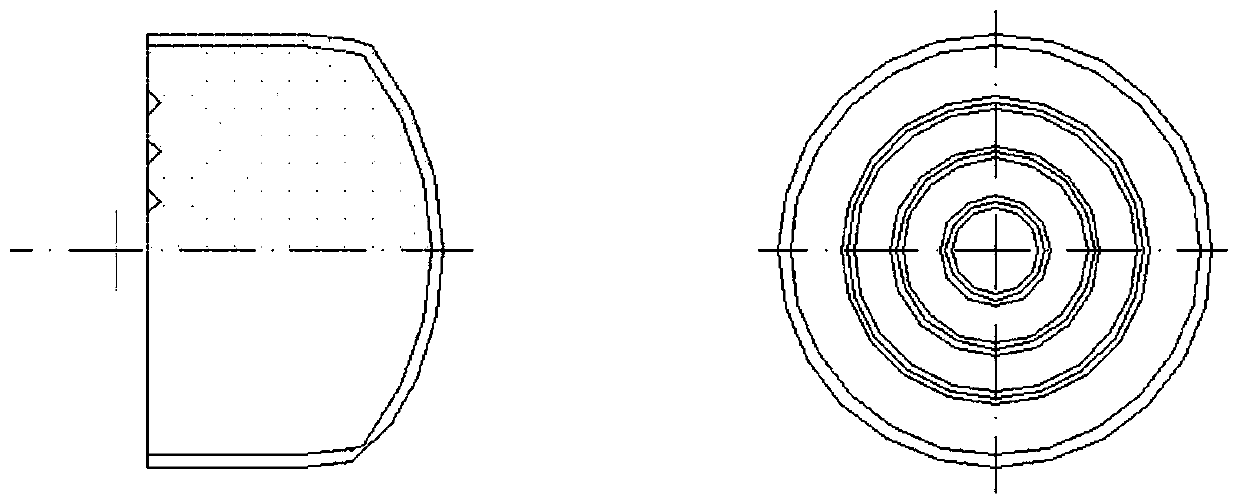

Integrated small reactor

ActiveCN105280257AEliminate large breach accidentsEliminate bouncing accidentsNuclear energy generationContainmentNuclear engineeringPressurized water reactor

The invention belongs to the pressurized water reactor overall structure design technology, and specifically discloses an integrated small reactor. The integrated small reactor comprises a pressure vessel, and a reactor core, a compressing assembly, a control rod assembly, a guide assembly, a control rod driving mechanism and a once-through steam generator which are arranged inside the pressure vessel, and further comprises a main pump directly connected with a cylindrical body of the pressure vessel, wherein the reactor core comprises a reactor core barrel and a fuel assembly; the compressing assembly and the control rod assembly are arranged inside the reactor core barrel; and the pressure vessel is directly connected with the main pump, the main pump is horizontally installed, and an inlet thereof is provided with a flow distribution device. Heating equipment is arranged on a top cover of the pressure vessel, a coolant inside the pressure vessel is subjected to pressure control directly through temperature adjustment, that is, main equipment such as the steam generator, voltage-stabilizing equipment and the control rod driving mechanism are arranged inside the pressure vessel of the reactor at the same time. According to the integrated small reactor, the external loop pipeline is omitted, large break accidents are eliminated, and the structure is compact; and the control rod driving mechanism is arranged internally, the rod ejection accident is eliminated, and the fixation safety is greatly improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Underwater installation method of ship rudder system

The invention discloses a method for the underwater installation of a ship rudder system, which comprises the following steps: 1. installing a rudder sleeve on the ship before launching, testing together with a rudder shaft, assembling a rudder stock and a rudder blade to a unit, installing the rudder system in mooring after launching; 2. regulating the ship trim by regulating ship ballast status; 3. horizontally moving the rudder blade and the rudder stock immediately below the rudder sleeve; 4. using the hand chain hoist of a tackle lifting mechanism at the ship stern to horizontally move the rudder stock / the rudder blade as a whole immediately below the rudder sleeve and meanwhile raising the hand chain hoist of a rudder cabin to lift the rudder blade to the top surface which has a certain distance with the bottom surface of the rudder sleeve; 5. sleeving lower rudder carrier parts on the rudder stock; 6. continuing to raise the rudder stock and the rudder blade, and installing a rudder carrier, a actuator and a jump stop block; 7. disassembling the tackle lifting mechanism at the ship stern, checking the whole rudder system, and finishing the whole work flow.

Owner:泰州口岸船舶有限公司

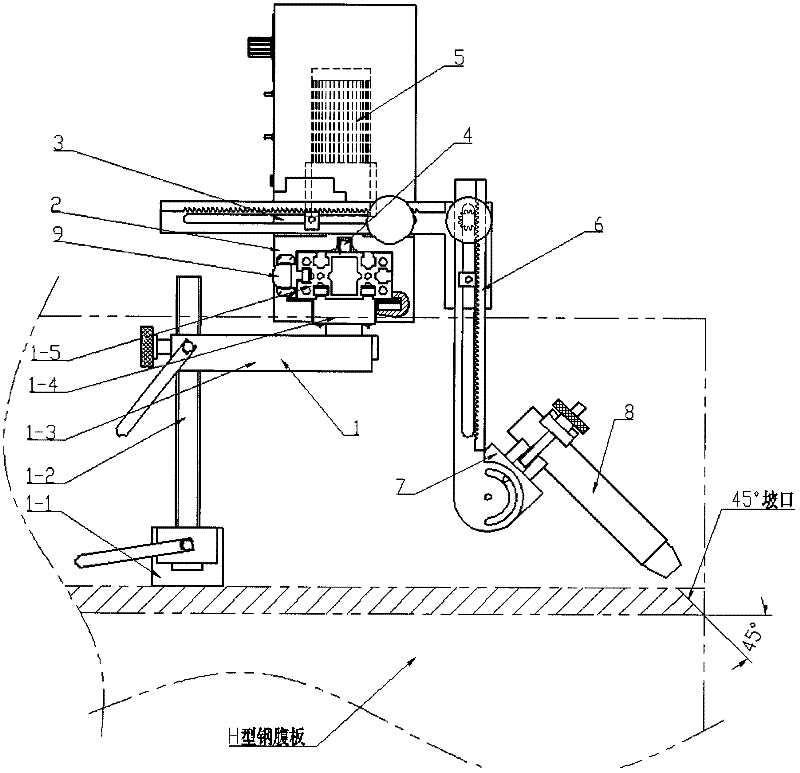

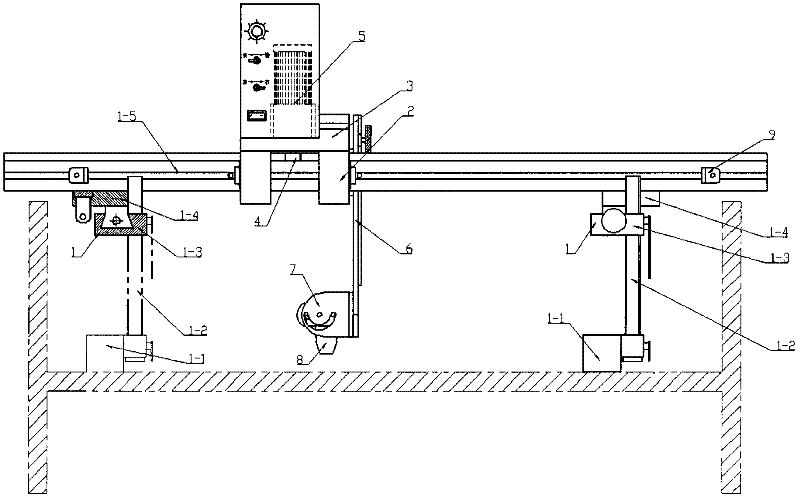

Semi-automatic short distance cutting machine and its cutting method

The invention provides a semi-automatic short-range cutting machine and a cutting method thereof and relates to a small-sized machine used for cutting a profile steel docking groove. The semi-automatic short-range cutting machine comprises a cutting torch (8), on which a manual micromatic setting device (6) is arranged; the manual micromatic setting device (6) is installed on a machine base (3); the machine base (3) is installed on a rail (1-5) in an adjustable quadrilateral mechanism (1) through a rail slider (2); an angle adjustment device (7) is installed at the bottom of the manual micromatic setting device (6); the machine base (3) is provided with a permanent magnet direct current deceleration motor (5); a gear rack (4) is used for realizing the transmission between the permanent magnet direct current deceleration motor (5) and the rail (1-5) so as to drive the cutting torch (8) to run to finish cutting task; a strong-force magnetic base (1-1) consists of two adjacent rotary fixing points and two rotary or clamped fixing points in the adjustable quadrilateral mechanism (1) so that the whole machine is firmly fixed on a processed workpiece. The invention fills the blank in the prior art; the semi-automatic short-range cutting machine has advantages of simple structure, portability and capability of site operation; and the provided cutting method can effectively guarantee cutting quality.

Owner:ZHEJIANG XIZI HEAVY IND MACHINERY

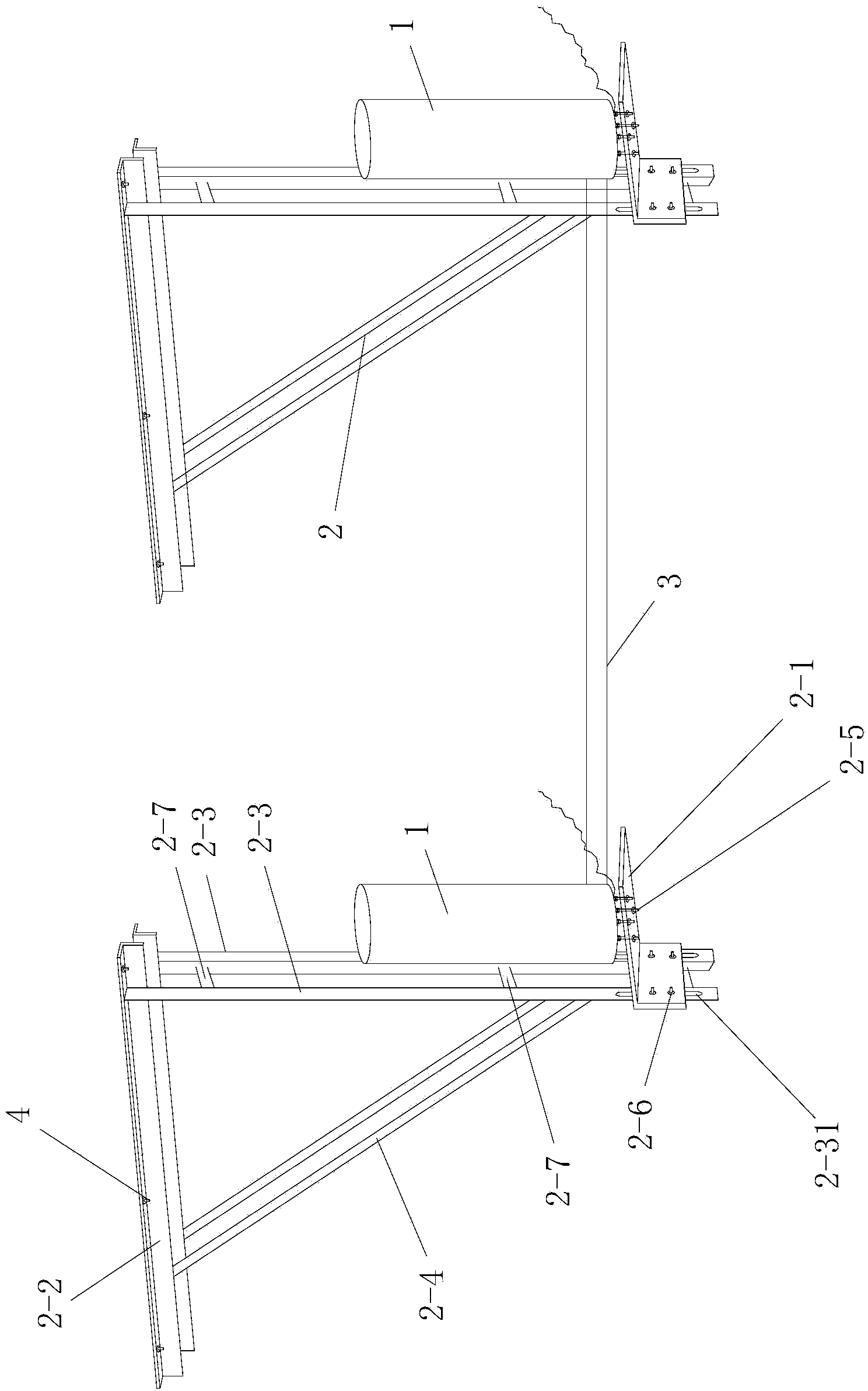

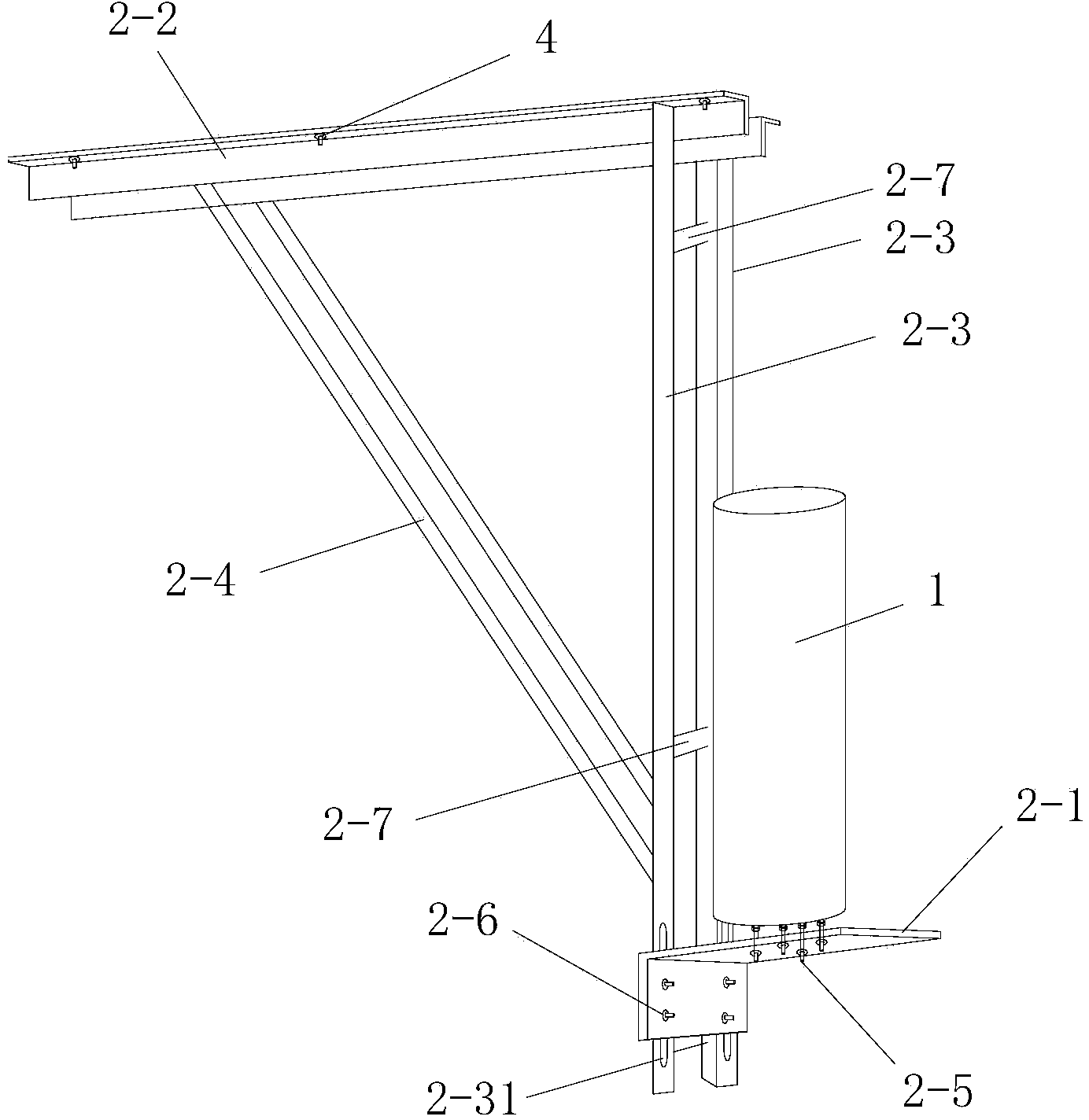

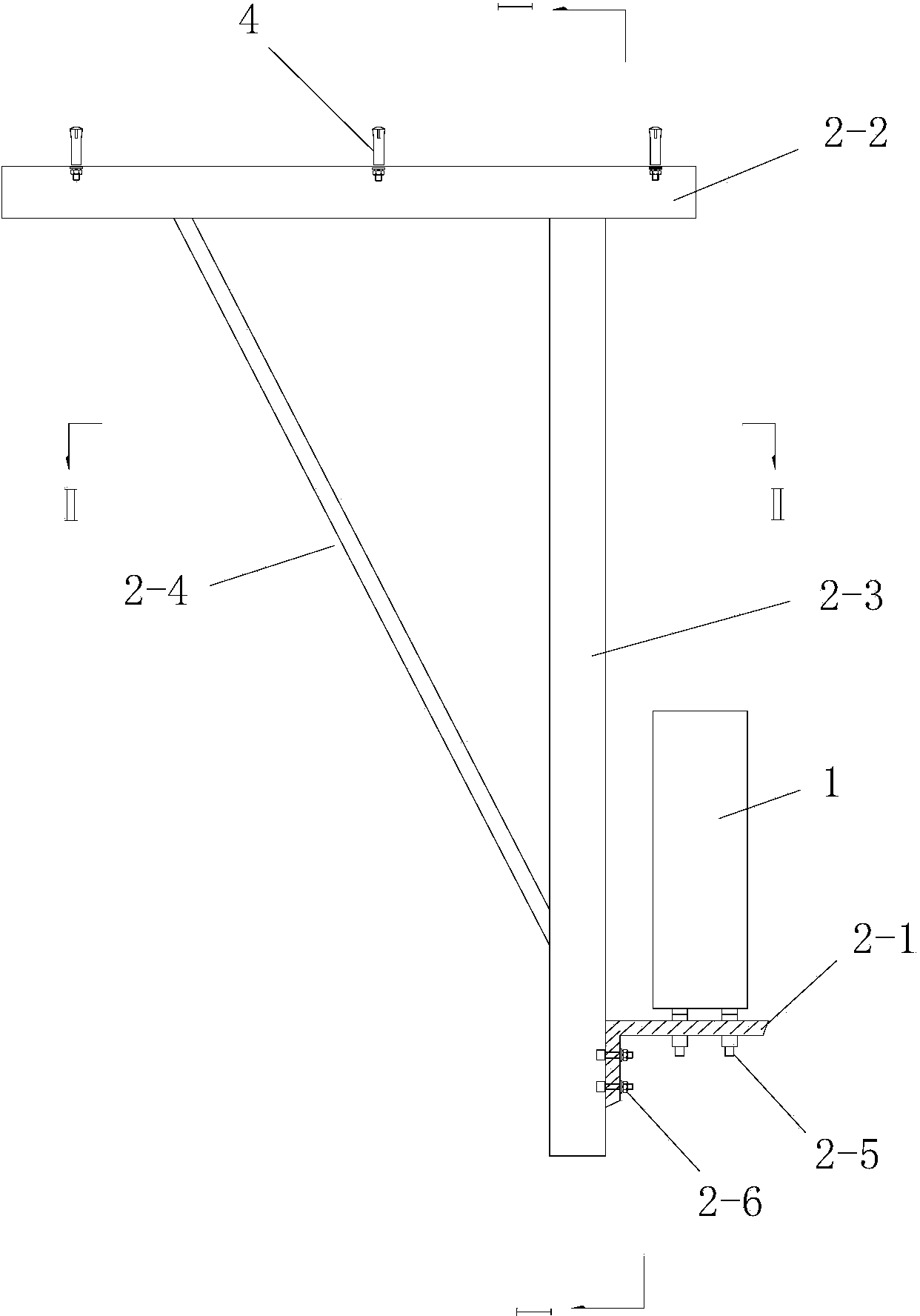

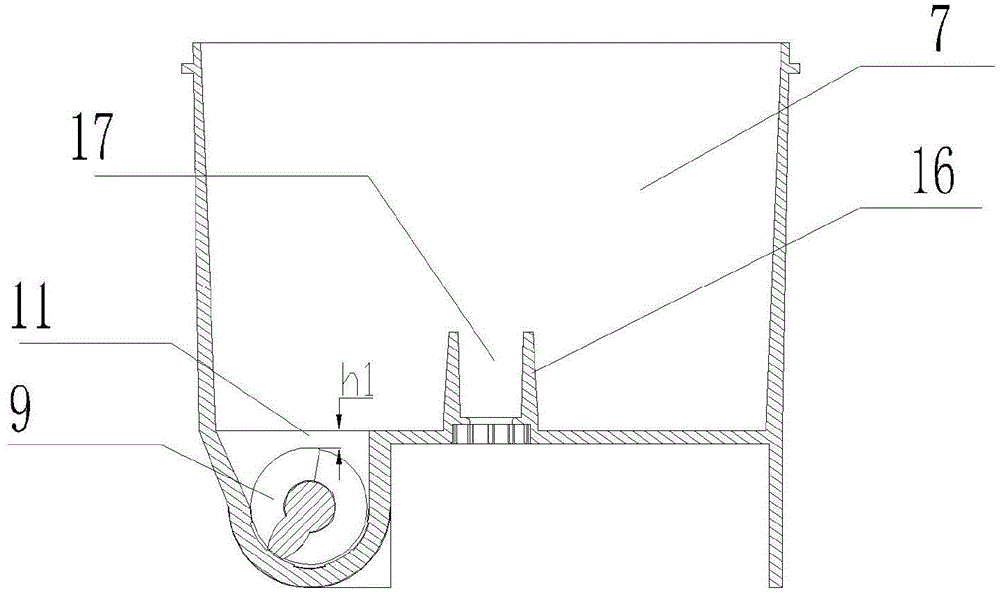

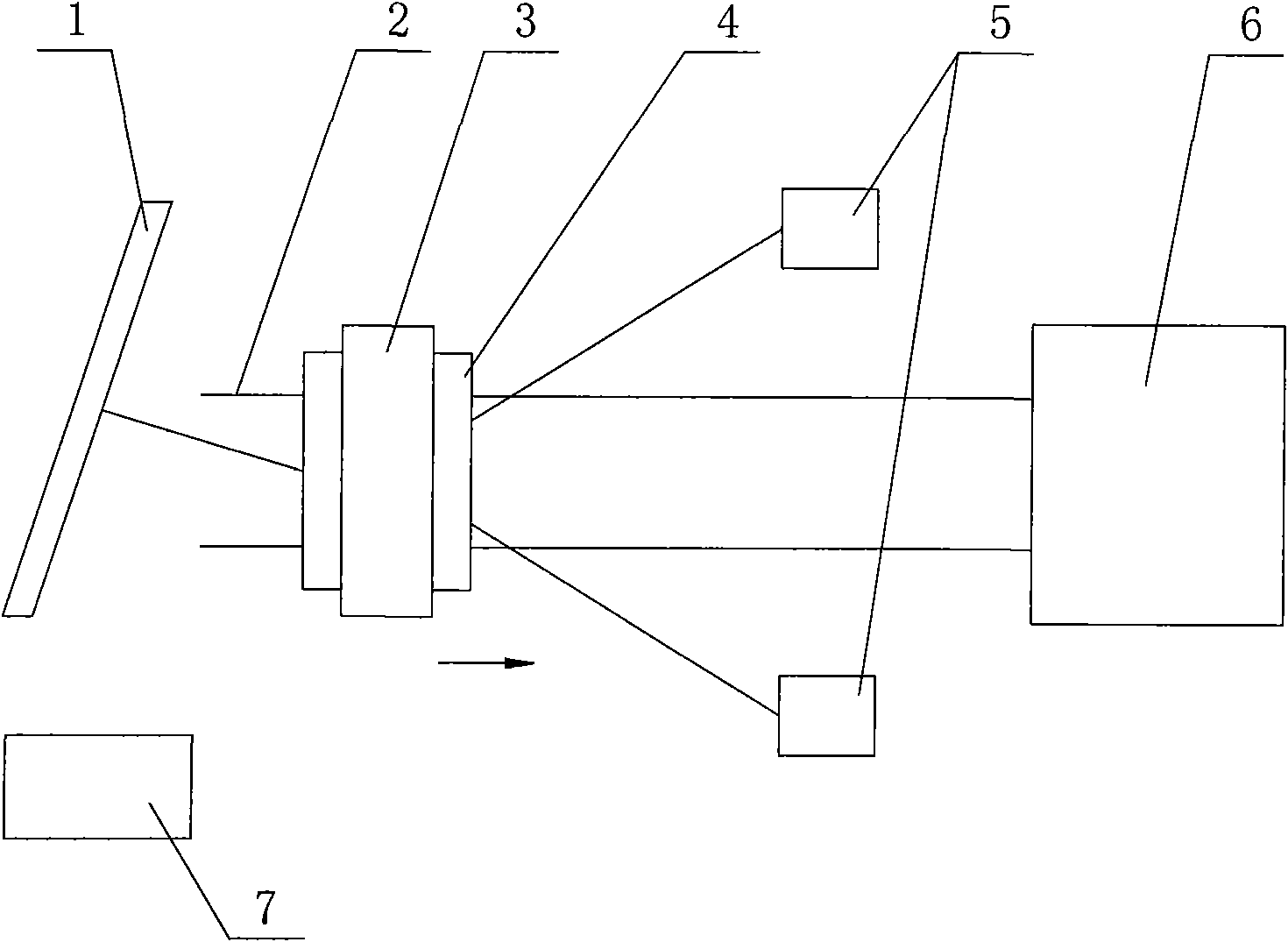

Long-term deflection monitoring system and method for long-span bridge

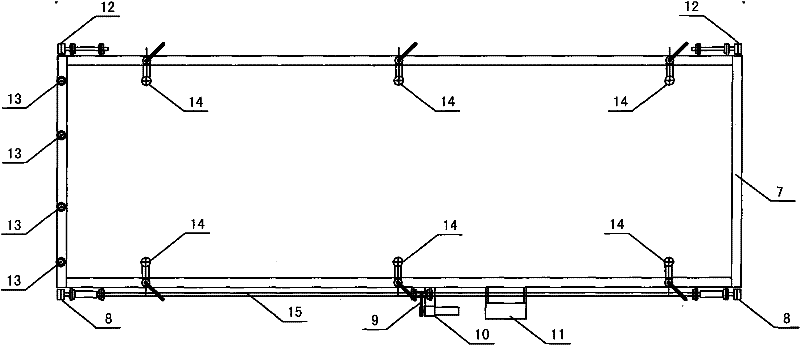

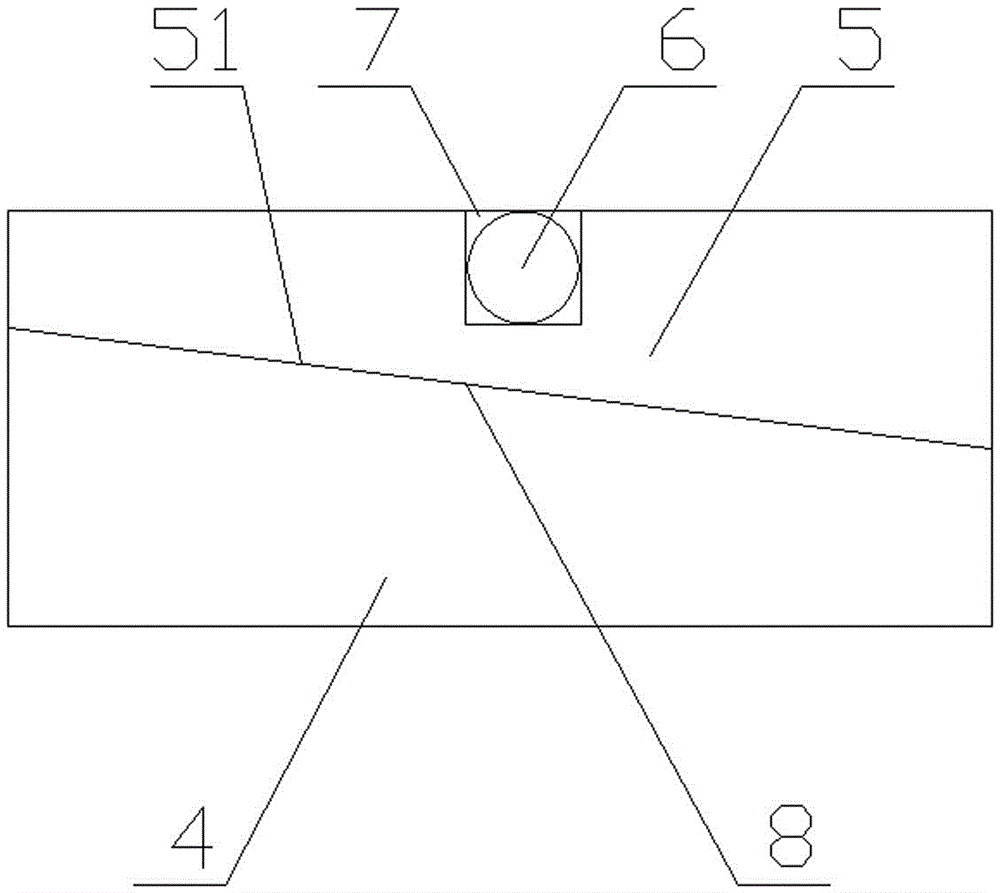

InactiveCN104132630ASimple structureReasonable designHydrostatic levellingUsing fluid meansMonitoring systemEngineering

The invention discloses a long-term deflection monitoring system and method for a long-span bridge. The monitoring system comprises a plurality of static level gages which are installed on a monitored bridge body through multiple installation frames, the monitored bridge body is a box girder, and the installation frames are installed at the bottom of a box girder top board; each installation frame comprises a triangular supporting frame and a supporting board which is installed on the triangular supporting frame and is adjustable in installation height, the triangular supporting frames are transversely arranged in the bridge direction, and the static level gages are installed on the corresponding supporting boards. The monitoring system is easy and convenient to install and arrange, influence from external environment is small, the monitoring precision is high, and the use effect is good. The monitoring method comprises the first step of determining measured points and selecting a datum point, the second step of installing the installation frames, the third step of installing the static level gages, and the fourth step of monitoring the deflection for a long term. The process of monitoring the deflection for a long term comprises the steps of obtaining the initial liquid level height, determining the monitoring time points of the deflection and monitoring the deflection. The monitoring method is simple in step, convenient to implement, good in use effect and capable of effectively monitoring the deflection of the bridge for a long term.

Owner:XIAN HIGHWAY INST

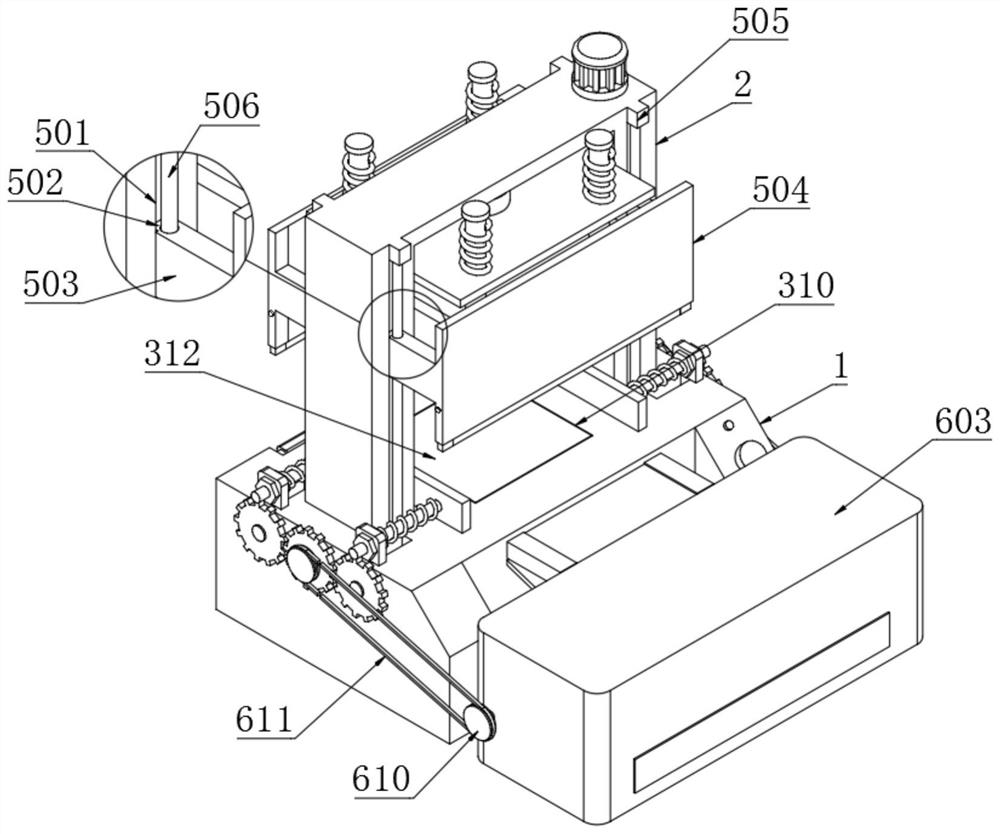

Pressure testing machine for building quality detection

InactiveCN112082864AScientific and reasonable structureEasy to useMaterial strength using tensile/compressive forcesArchitectural engineeringElectric machinery

The invention discloses a pressure testing machine for building quality detection. The pressure testing machine comprises a base, portal frames are symmetrically and fixedly connected to the top end of the base, pressure measuring and buffering mechanisms are movably connected to the interiors of the portal frames, and power transmission and clamping fixing mechanisms are installed at the positions, corresponding to the two sides of the portal frames, in the base, and one end of the base is fixedly connected with a material recovery and crushing mechanism. The pressure testing machine is scientific and reasonable in structure and safe and convenient to use, the pressure measuring and buffering mechanisms are arranged, lead screws are driven by a driving motor to rotate, and through cooperation of a first belt, the two lead screws rotate together to push a lifting block to move; therefore, the lifting block drives a movable plate and a pressing plate to move along a groove, the distancebetween the pressing plate and a building material is adjusted, the pressing plate is attached to the top end of the building material, the pressing plate is pushed to press downwards through cooperation of an air cylinder and a piston rod, and a pressure bearing test is conducted on the building material on a bearing plate.

Owner:张瑞麟

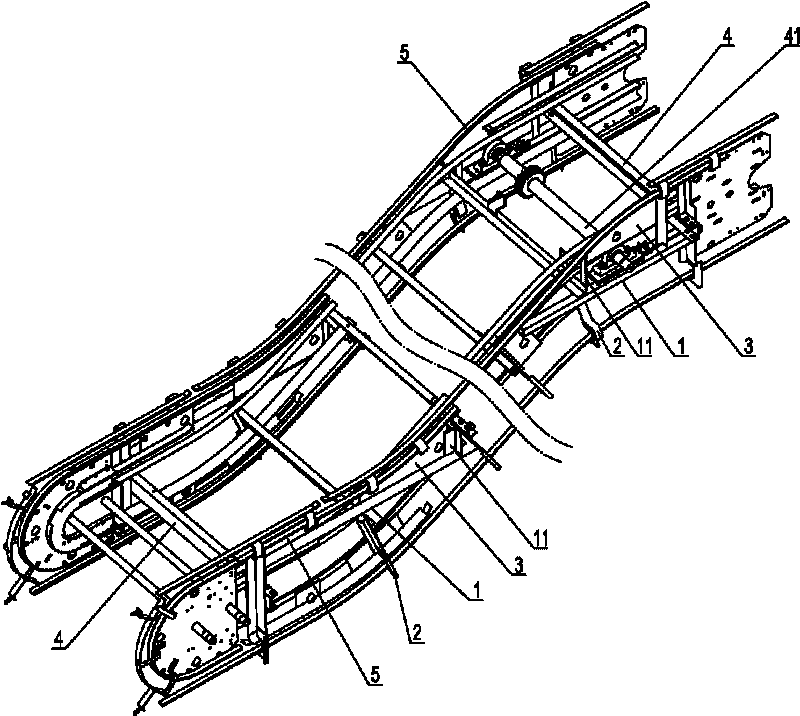

Head ladder way and escalator thereof

The invention discloses a head ladder way and an escalator thereof. The head staircase way comprises vertical frames which are parallel on the left and right sides, a plurality of connecting rods and a plurality of bearing plates; the vertical frames are formed by a plurality of stiffeners which are staggered mutually; the vertical frames on the left and right sides are connected integrally through at least two horizontal beams inbetween; the bearing plates are fixedly connected with the vertical frames and the connecting rods; and each guide rail of the head ladder way is fixedly connected with the bearing plates and the connecting rods. In the escalator adopting the head ladder way of framed structure, the vertical frames on the two sides of the head ladder way are provided with horizontal connecting plates for mounting the bearings of balustrade driving parts respectively and oblong assembly holes are formed on the connecting plates. The rigidity and stability of the head ladder way are obviously improved by adopting the head ladder way of framed structure; and the escalator changes the assembly mode of the bearing bases of the driving parts, so the arrangement is convenient and the head ladder way is prevented from deforming by force.

Owner:XIZI OTIS ELEVATOR

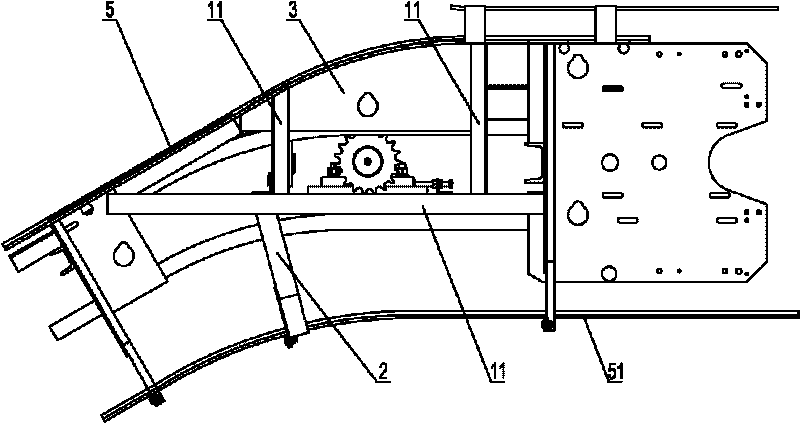

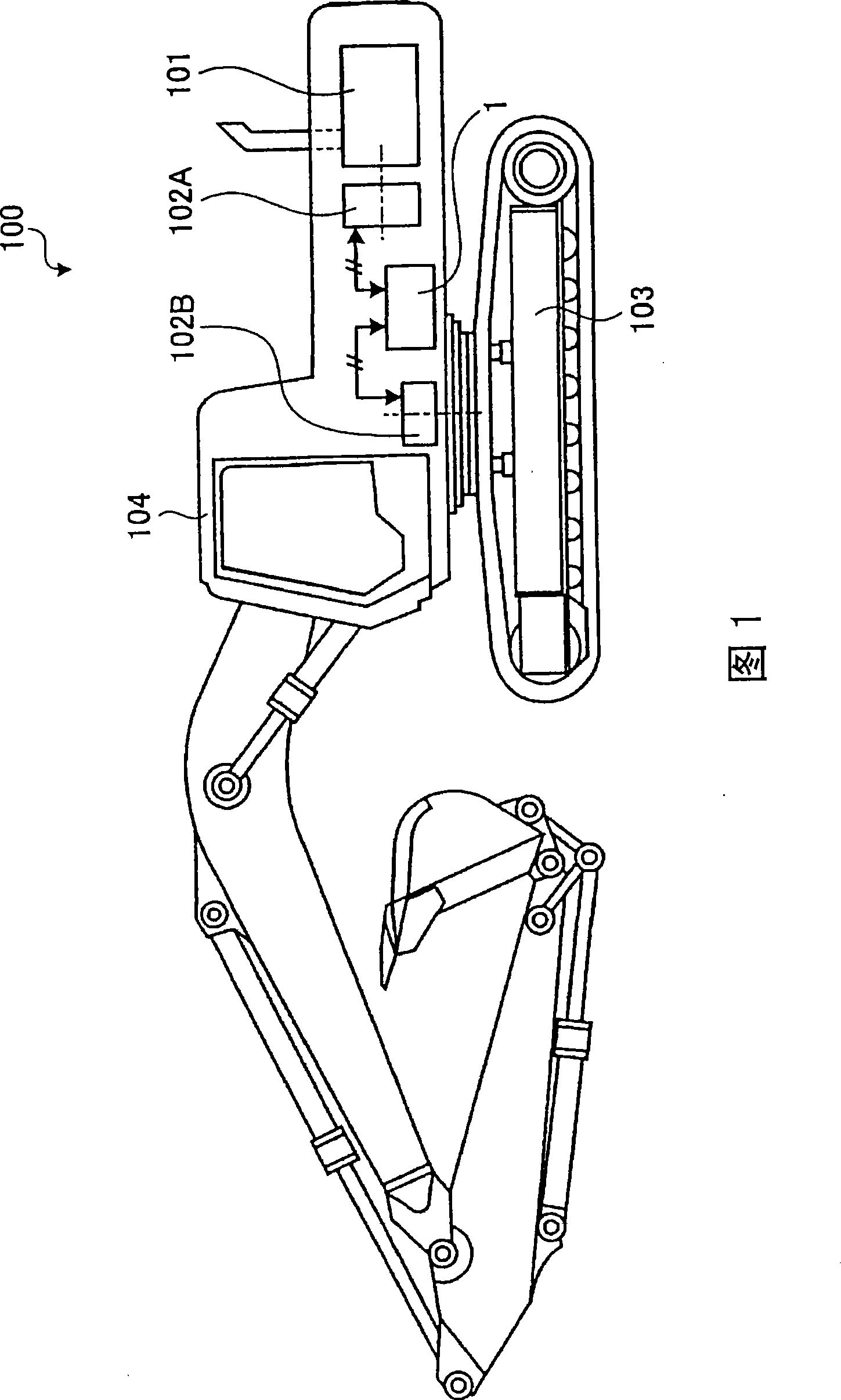

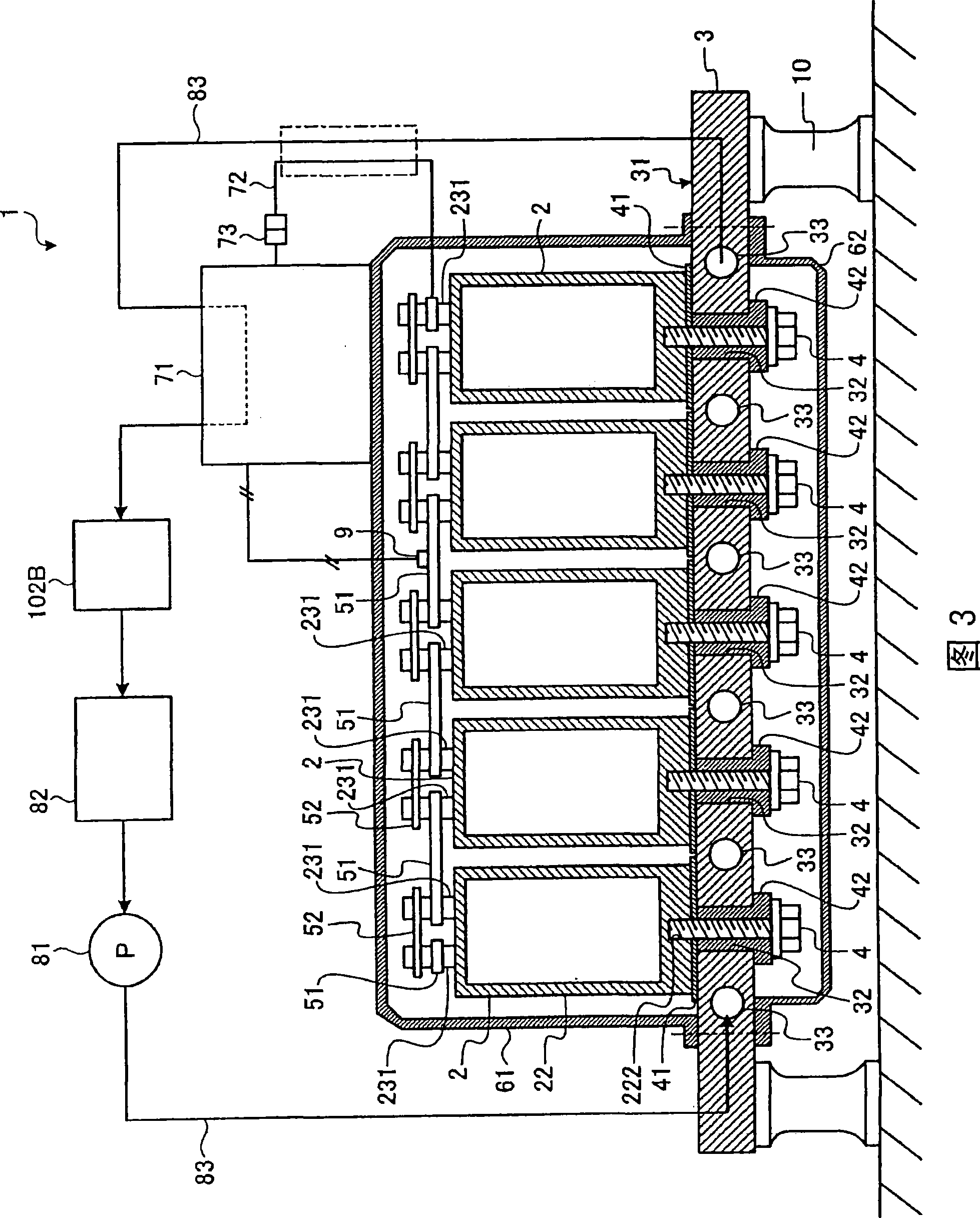

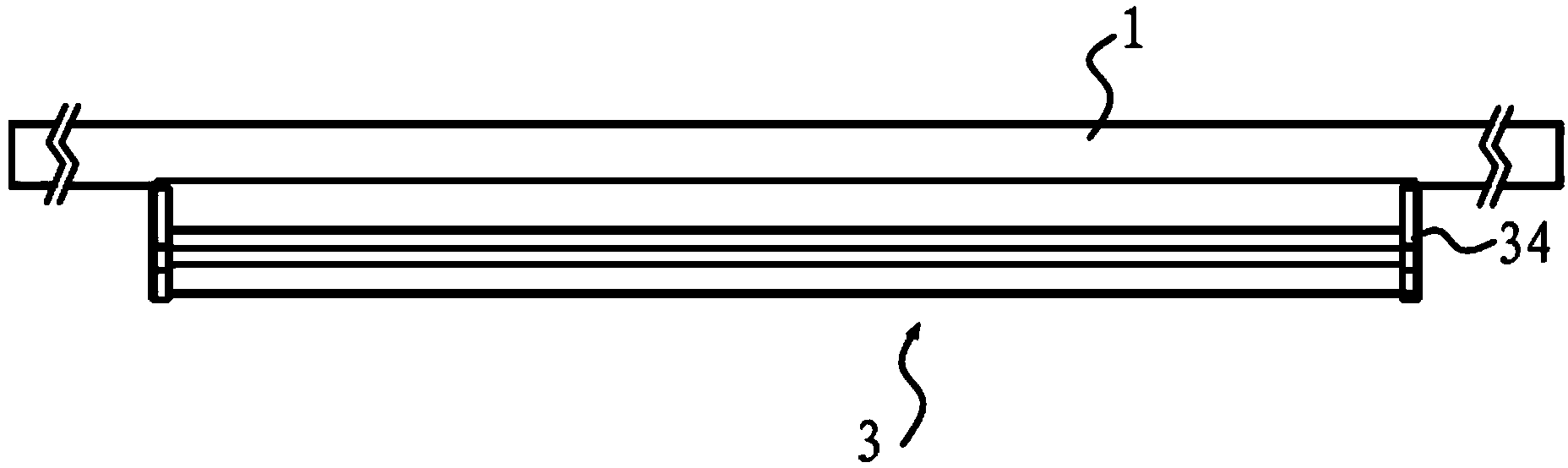

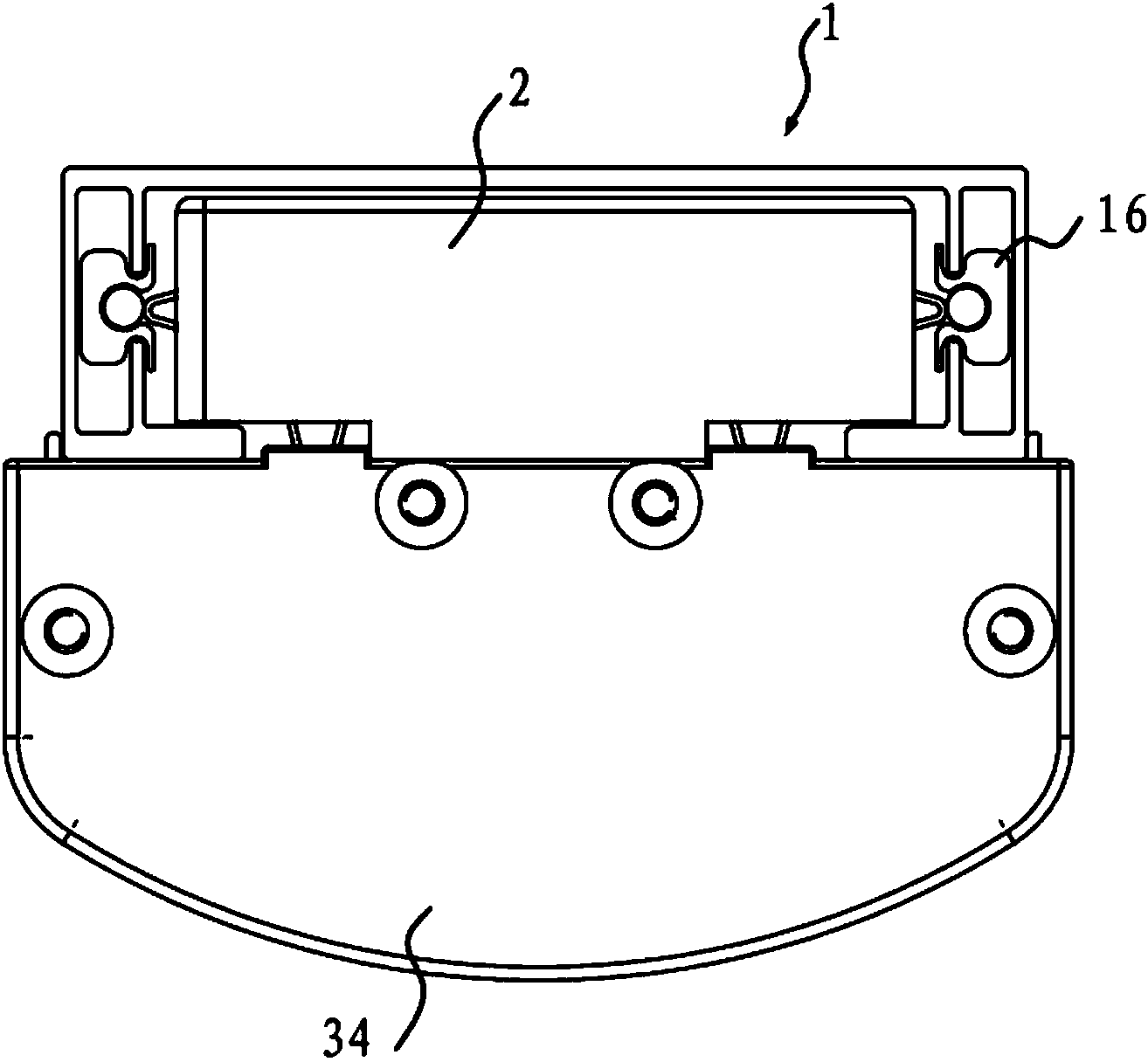

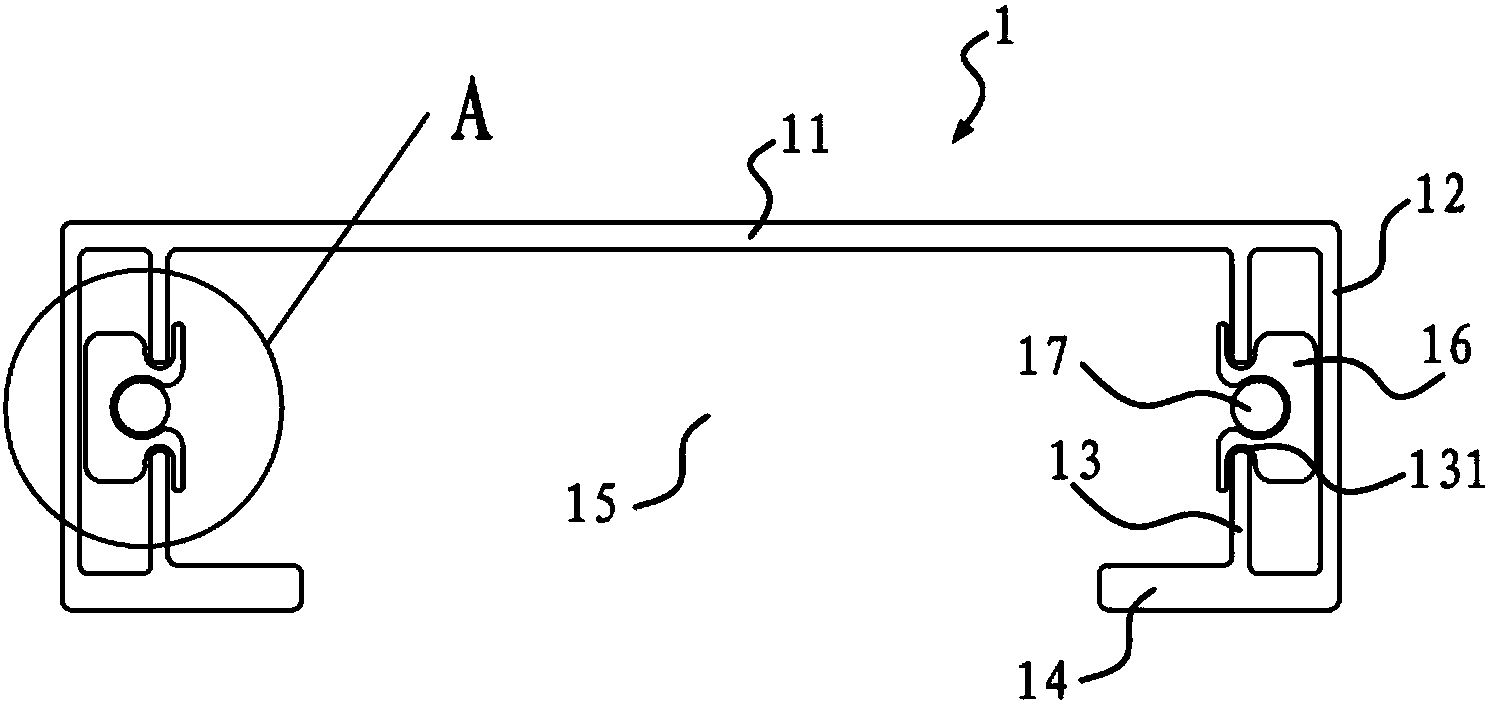

Capacitor module

InactiveCN101432829AEnsure reliabilityExcellent adhesionDouble layer capacitorsMultiple hybrid/EDL capacitorsFixed capacitorEngineering

Provided is a capacitor module capable of fixing a capacitor while assuring reliability and durability even under a condition where vibration is applied and having a heat dissipation structure appropriate for temperature increase inside the capacitor. The capacitor module includes a capacitor (2) having a screw hole (222) in the external bottom wall surface of a capacitor case (22) containing capacitor elements and a heat dissipater (3) for fixing a plurality of capacitor cases (22) by screwing a fixing screw (4) in the screw hole (222) of the capacitor (2). As a result, when the capacitor module (1) is mounted, for example, on a construction machine and a very strong vibration is repeatedly applied, it is possible to fix the capacitor (2) while assuring reliability and durability. Moreover, since the fixing screw (4) is screwed in the screw hole (222) and the external bottom wall surface of the capacitor case (22) is closely attached to a fixing surface (31) of the heat dissipater (3), heat generated in the capacitor (2) is appropriately conducted to the heat dissipater (3) so as to cool the capacitor (2).

Owner:KOMATSU LTD

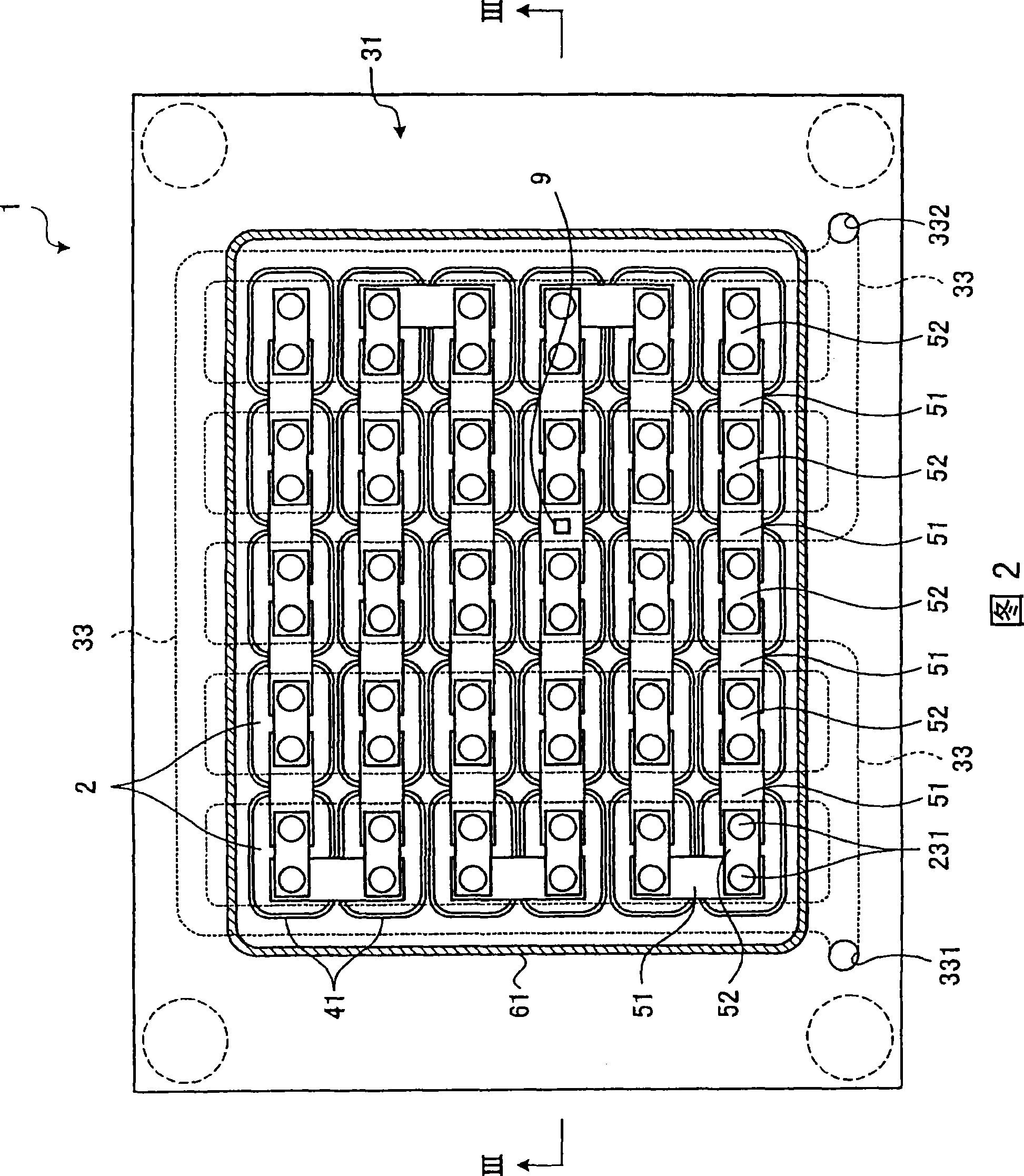

LED (light-emitting diode) lamp

ActiveCN104235686AAchieve linear straightnessEasy to moveLighting support devicesPoint-like light sourceElectricityLED lamp

The invention discloses an LED (light-emitting diode) lamp, which comprises a power supply guide rail, a power unit and a lamp body, wherein the lamp body comprises a reflecting bracket, an LED light bar and a lampshade; the power unit is arranged in the power supply guide rail; power is transmitted to the LED light bar after being taken from the power supply guide rail by the power unit. According to the LED lamp, the rail is usually manufactured by a metal section, and the metal section is stretched and formed by virtue of a die when being manufactured, and can be machined to be straight within a certain length range, so that a linearly straight technical effect can be achieved after the whole lamp is mounted; meanwhile, the position of the lamp body can be conveniently shifted along the power supply guide rail without changing the position of the power supply guide rail, so that the LED lamp is more convenient.

Owner:苏州市琳珂照明科技有限公司

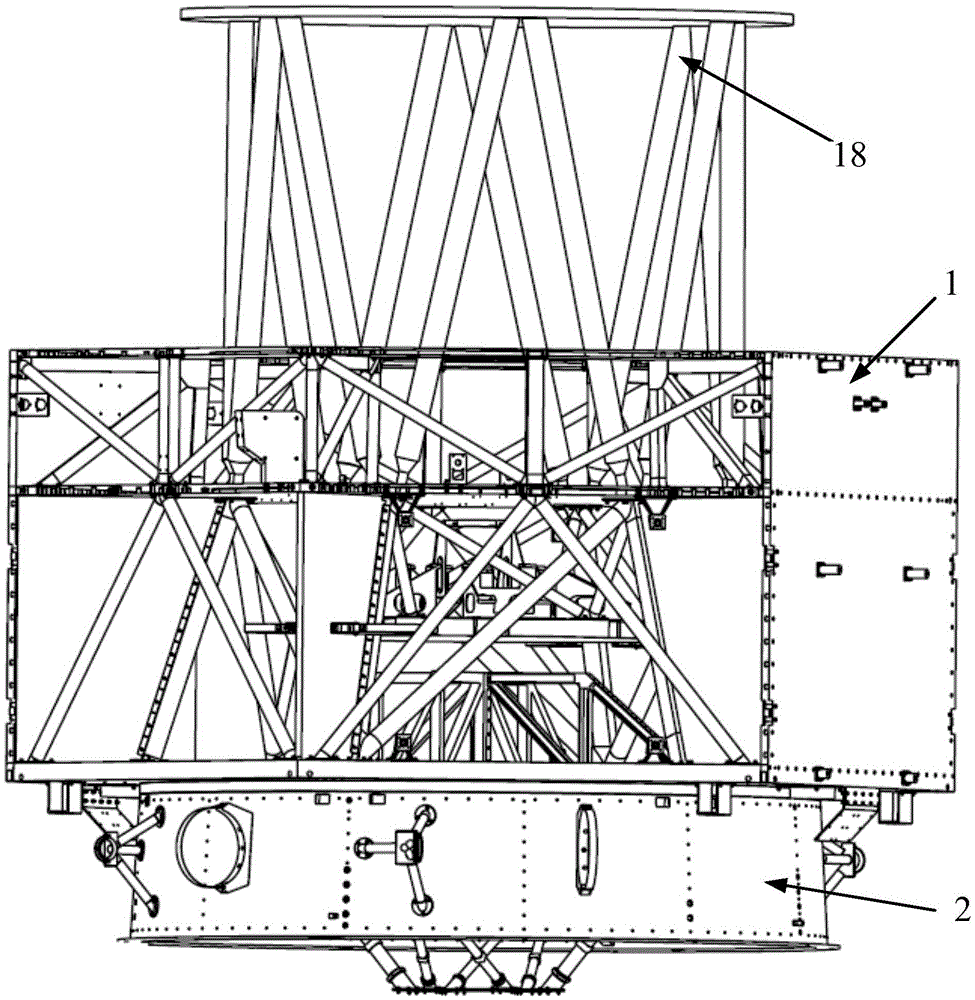

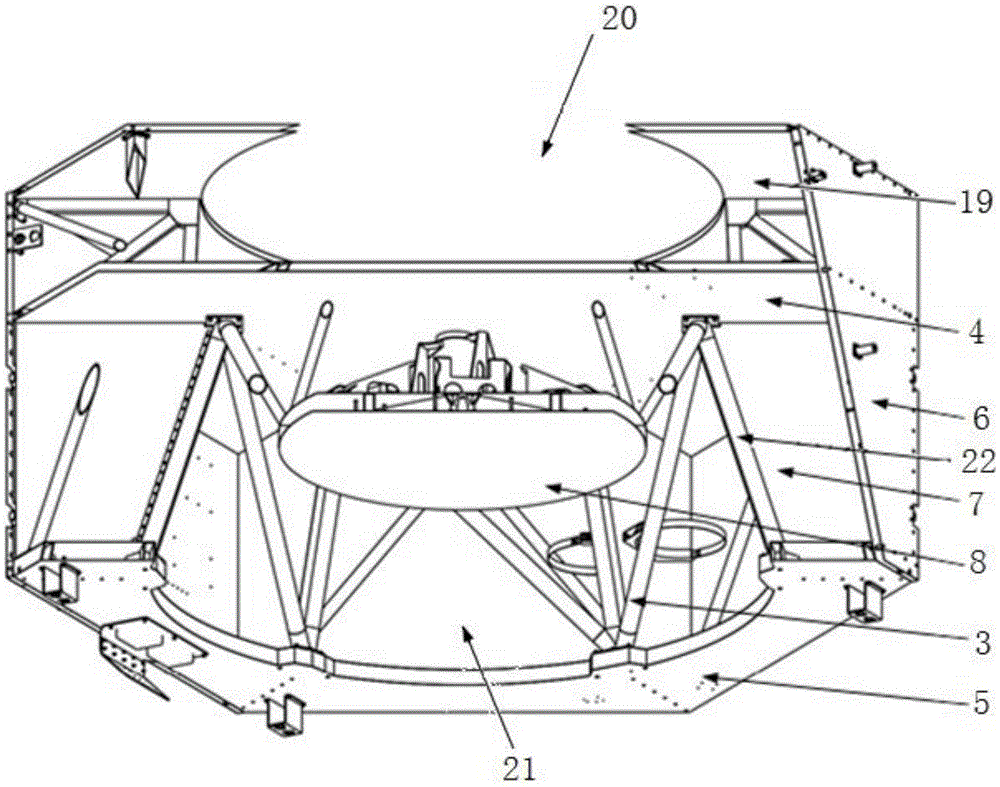

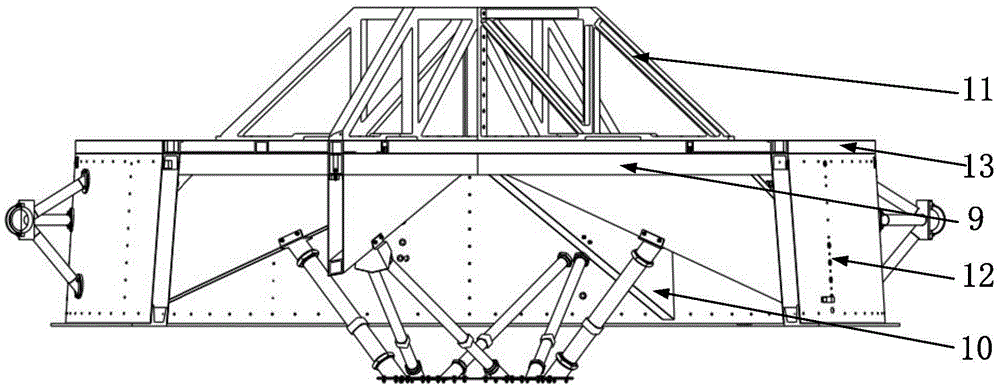

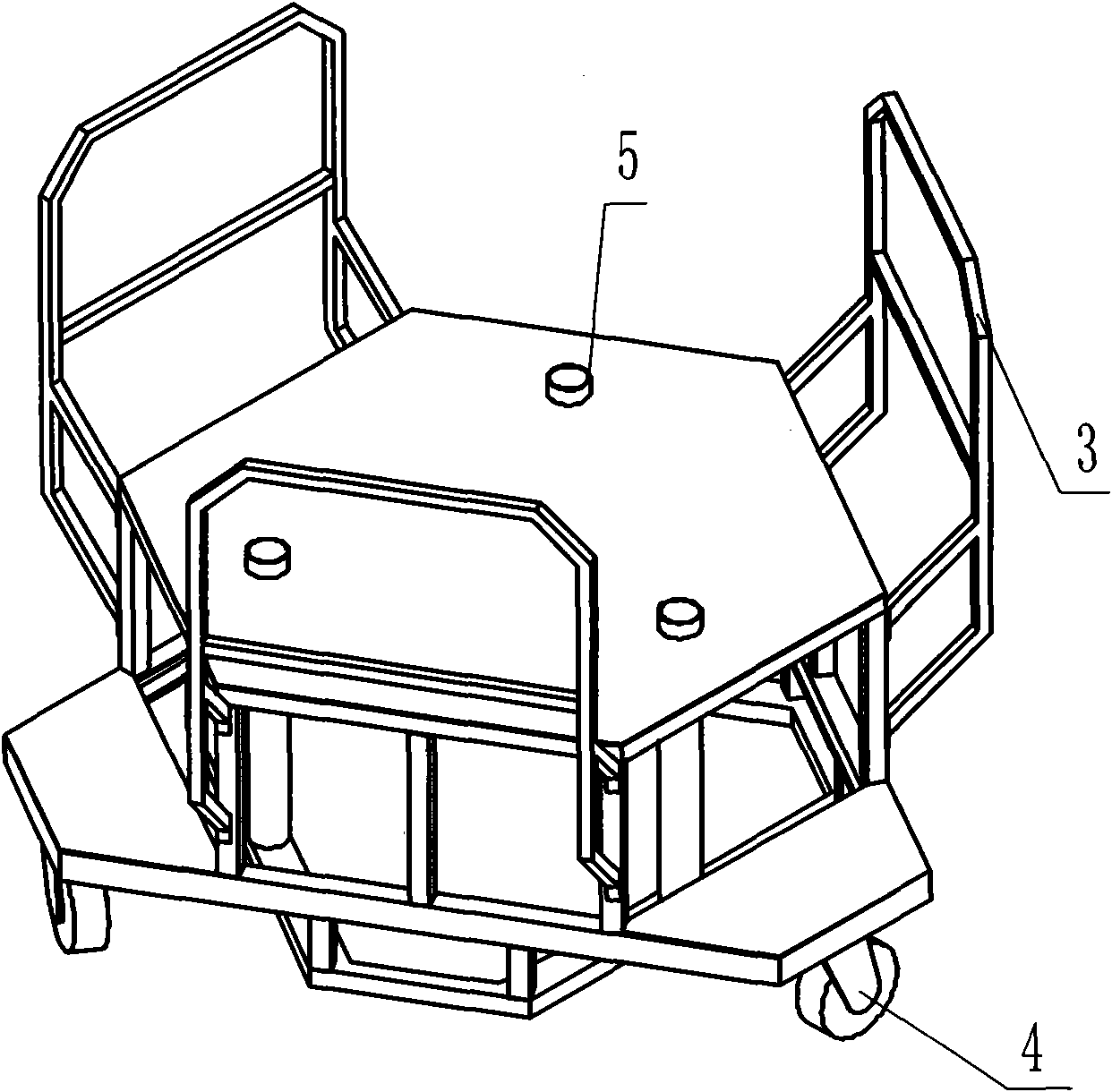

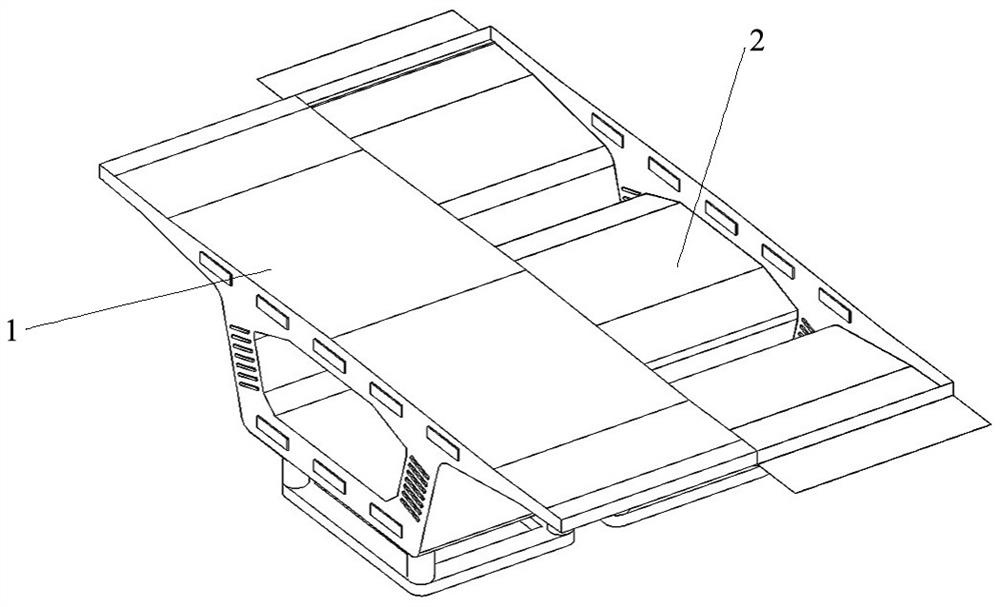

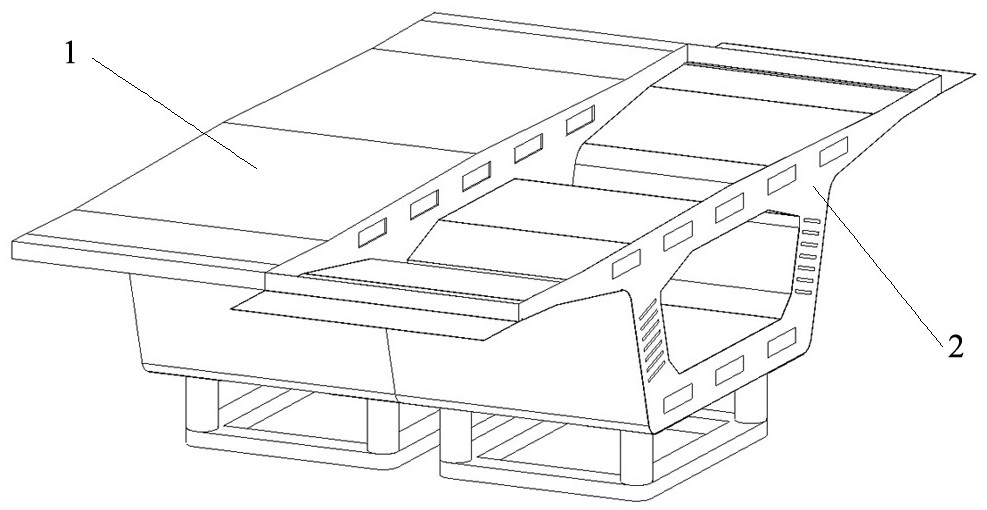

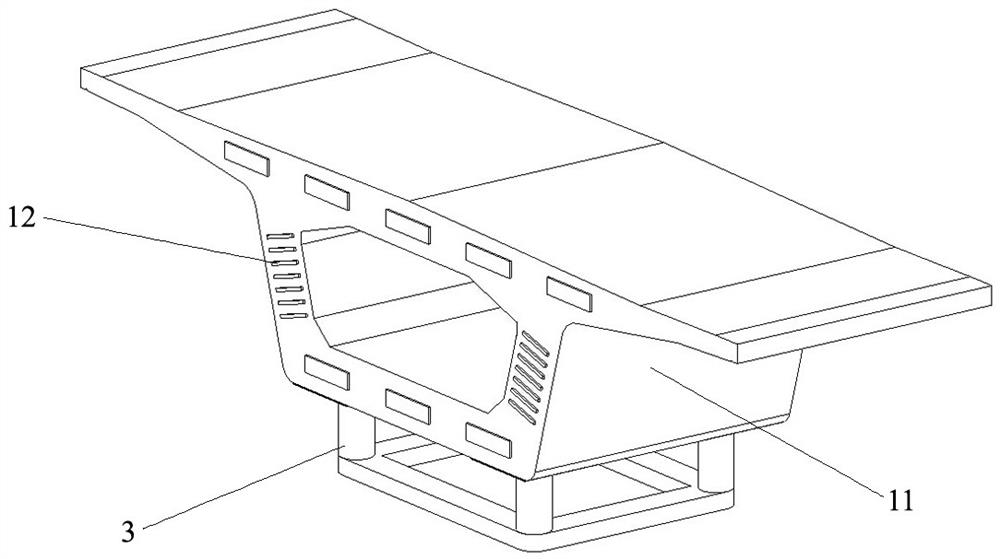

Large truss type vibration isolation platform structure facing various effective loads

The invention provides a large truss type vibration isolation platform structure facing various effective loads. The large truss type vibration isolation platform structure facing the various effective loads comprises a service module, a secondary vibration isolation mechanism and a propelling module, wherein the secondary vibration isolation is arranged at the top of the service module; a load simulation piece is arranged on the secondary vibration isolation; and the propelling module is arranged at the bottom of the service module. Compared with the prior art, the invention is advantaged in that a satellite realizes high adjusting capacity and strong space extendable assembling capacity due to adoption of the large truss structure with light weight, high bearing capacity and good technological property so that the mounting of a plurality of propelling systems and service platform system single machines and equipment is ensured; vibration isolation requirements of high accuracy loads on specific frequency are realized through adoption of primary and secondary vibration isolation mechanisms so that micro vibration responses of the loads are effectively reduced and the working performances of the effective loads at in-orbit sections are improved; and a clamped separating and unlocking device is arranged at a transmitting section so as to realize a supporting structure effect and an unlocking separation effect.

Owner:SHANGHAI SATELLITE ENG INST

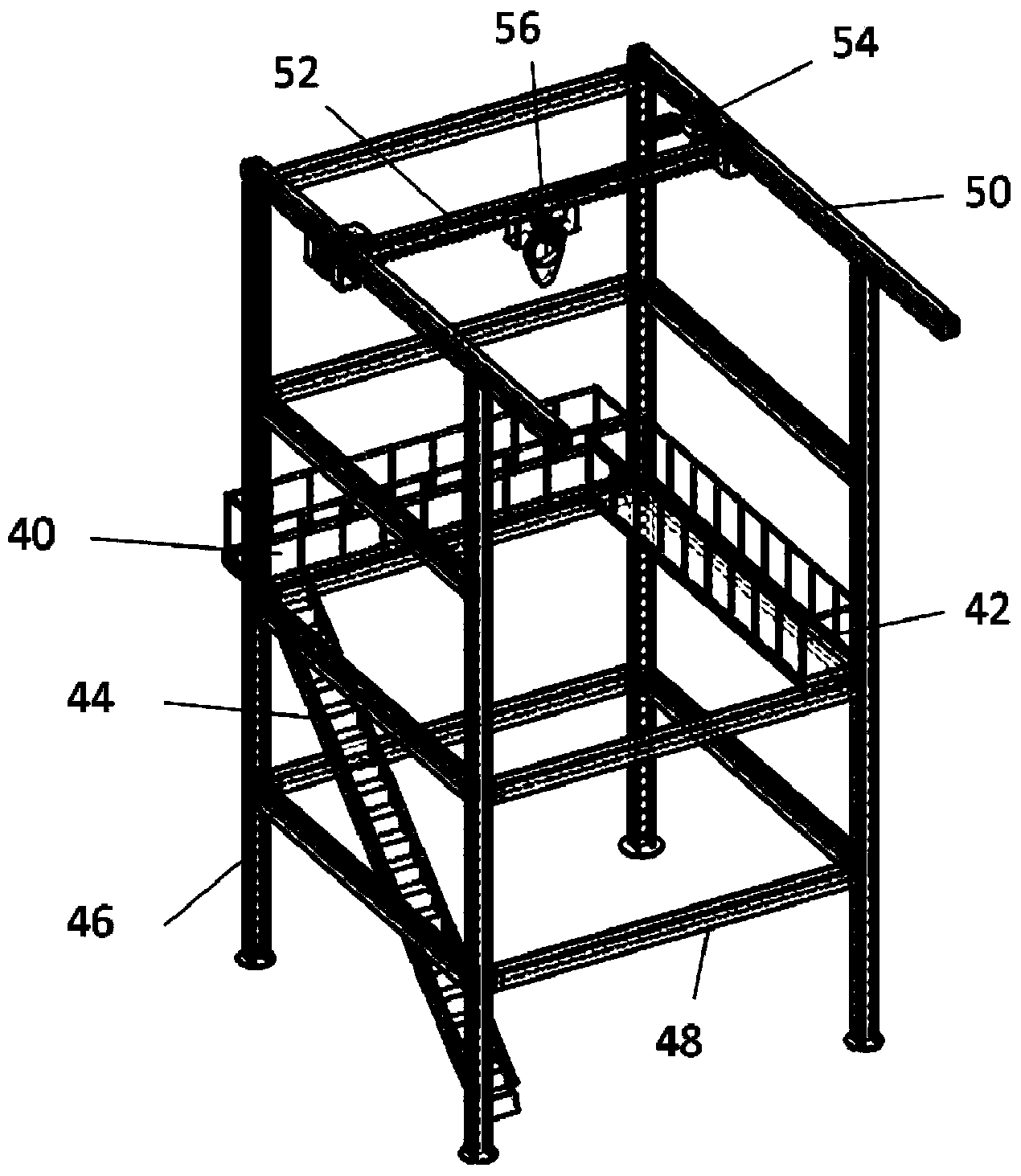

Insulating lifting device

InactiveCN102001606AGuaranteed collectionGuaranteed installationLifting devicesElectroscopeArchitectural engineering

The invention discloses an insulating lifting device which relates to an insulating lifting device applied to high-voltage (not larger than 750kV) electric checking detection. The insulating lifting device comprises a base, a truss structure and an insulation operating rod, wherein the periphery of the base is provided with a guardrail, and the bottom of the base is provided with a caster wheel; three base sleeves are welded on the surface of the base; three groups of telescopic rods of the truss structure are inserted into the base sleeves and fixed by utilizing locking screws; the insulation operating rod is fixed to the center of the truss structure by a shaft sleeve and a shaft sleeve nut; and the telescopic rods of the truss structure have a sleeve telescopic structure, and the upper sections and the lower sections of the telescopic rods are positioned and connected by spring pins. The invention is simple and convenient for construction and can move, stretch and contract, lighten the working intensity of an operator to a greater extent and prevent the accident of flashover of the insulating lifting device near high-voltage electric equipment due to unstable electroscope handholding and deflection of an insulating rod.

Owner:STATE GRID CORP OF CHINA +2

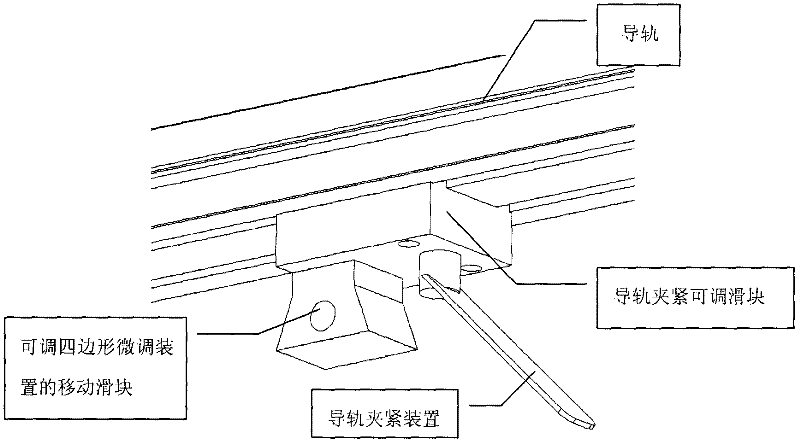

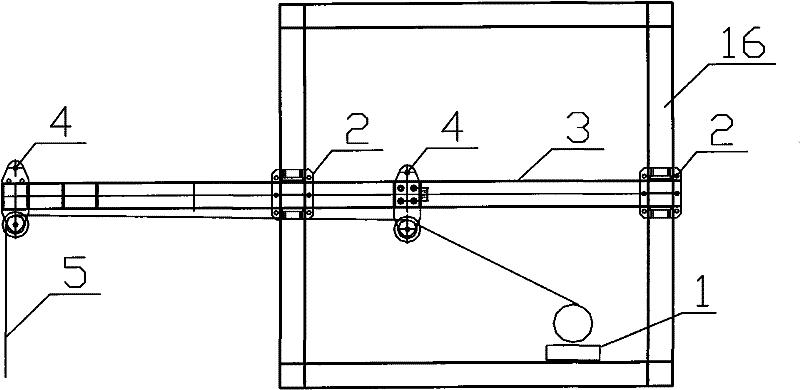

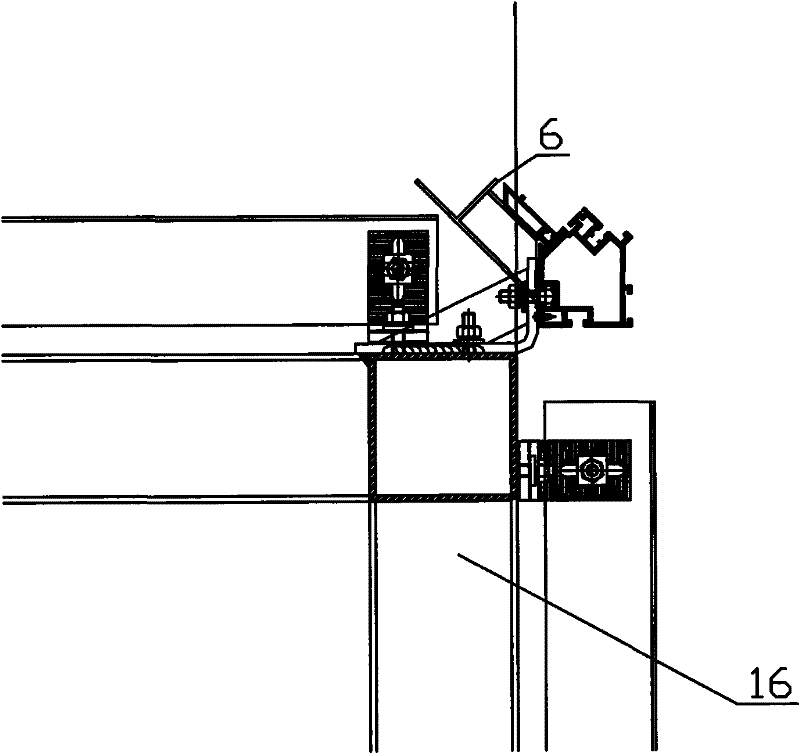

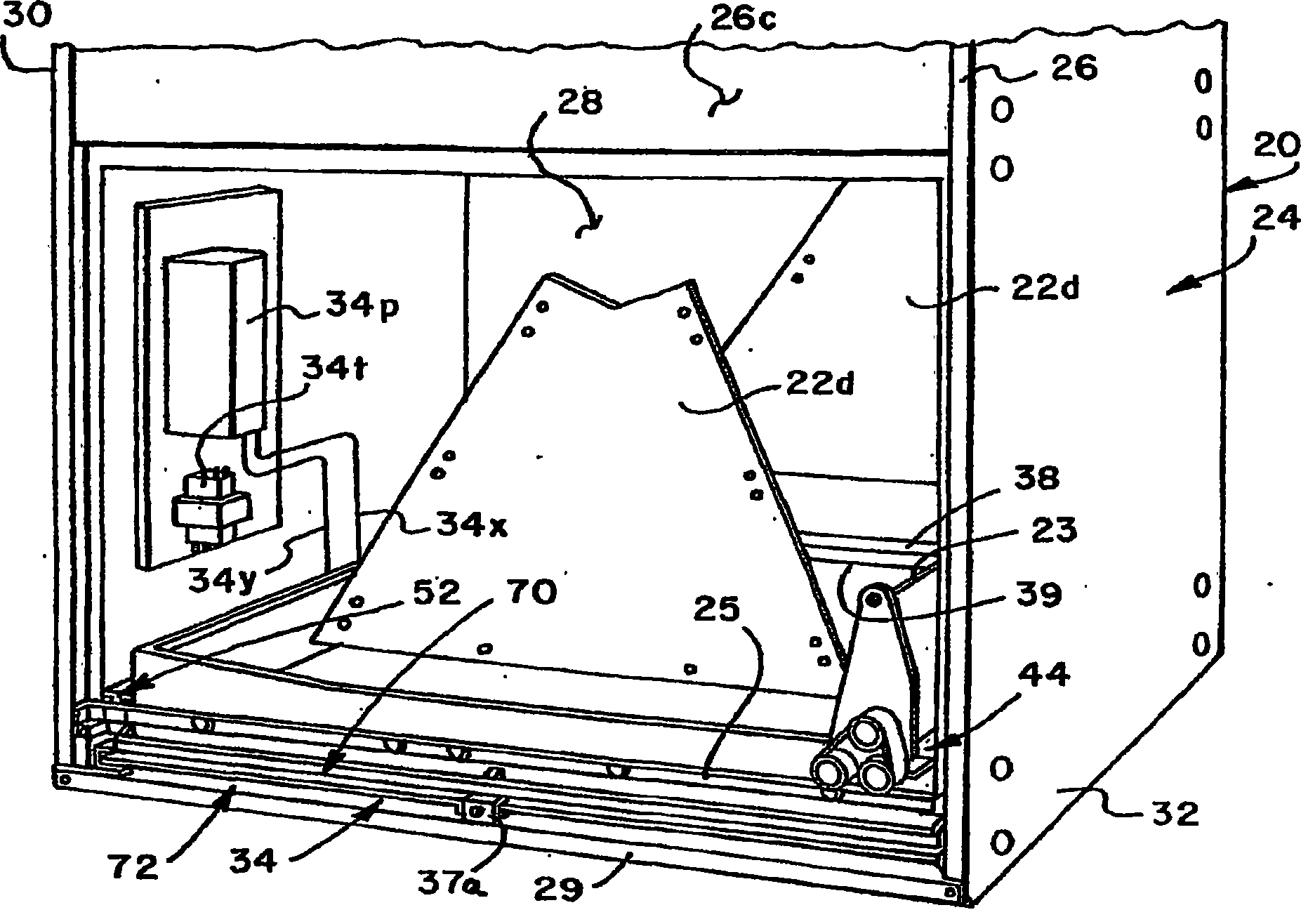

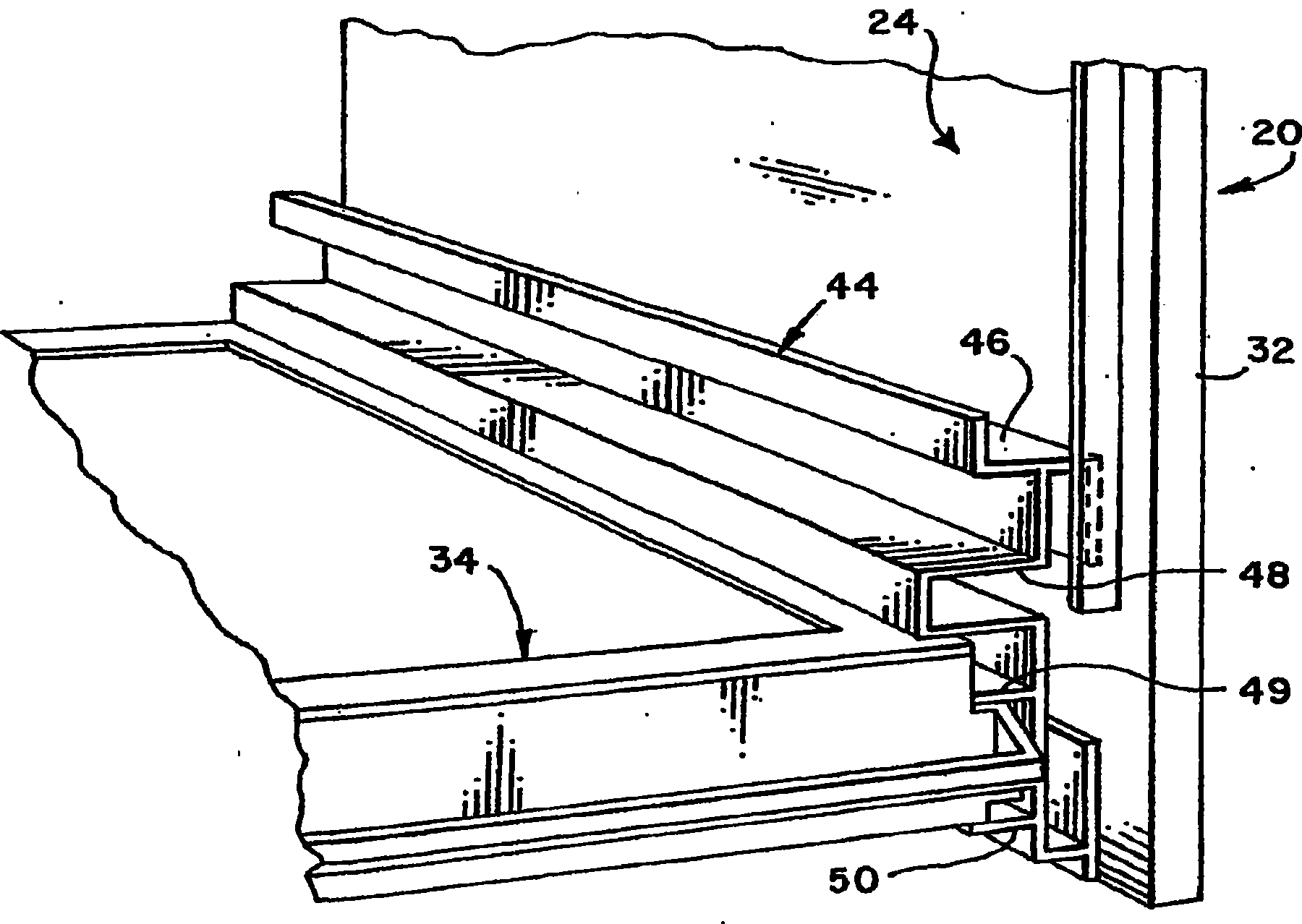

Self-propelled track installation system for profiled frame glass curtain walls

InactiveCN102296830AReduce transferSimplified installation procedureWallsBuilding material handlingDrive wheelVehicle frame

A self-propelled track installation system for a special-shaped frame glass curtain wall, including a special-shaped frame pipe truss, characterized in that it consists of a lifting device, a track device, and a self-propelled glass installation vehicle, and the track device includes two parallel tracks (6) , the two ends of the track (6) are respectively connected on the truss, the lifting device is installed on the special-shaped frame tube truss, and the self-propelled glass installation vehicle slides into contact with the two parallel rails through the driven wheel and the driving wheel on the frame. The application of the present invention reduces the transfer of lifting poles, simplifies the installation procedure, saves installation time, and provides a strong guarantee for ensuring installation and shortening the construction period.

Owner:武汉凌云建筑装饰工程有限公司

Test engine and test method for combustion of double-base system propellant in different overload directions

ActiveCN110596301AImprove safety and reliabilityChange overload directionChemical analysis using combustionRocket engine plantsInternal ballisticsThroat

The invention discloses a test engine and a test method for combustion of a double-base system propellant in different overload directions, which successfully eliminate the influence of the overload directions on combustion of the propellant. The test engine comprises a combustion chamber shell body, wherein the combustion chamber shell body is provided with a blasting device, and a large-small dual-circular-step-shaped blasting sealing plug is installed on the blasting device and screwed up by means of a blasting cover; a spray pipe is arranged in the middle of the combustion chamber shell body, and high-strength graphite is installed in a spray pipe base and screwed up by means of a gland so as to prevent the graphite from being sprayed out of a graphite spray throat in a test; and the combustion chamber shell body takes the center of the spray pipe as a symmetry axis, an end surface combustion propellant charge and a fake grain are placed on the two sides, and the purpose of changing the overload directions is achieved through exchanging the positions of the propellant charge and the fake grain. In order to prevent the spray pipe from being blocked and the ignition powder from being thrown out due to combustion of the charge under overload, the celluloid box without residues after combustion is used for fixing the ignition powder, thereby guaranteeing safety and reliabilityof the engine test under overload. The test engine and the test method is suitable for measuring and evaluating propellant charge combustion properties and internal ballistic trajectory performance indifferent overload directions.

Owner:XIAN MODERN CHEM RES INST

Segmental box beam short line matching control and prefabrication construction method

ActiveCN112060307AEffective organizationEnsure construction efficiencyMouldsCeramic shaping plantsControl systemConstruction engineering

The invention discloses a segmental box beam short line matching control and prefabrication construction method. The method comprises the following steps that firstly, a beam field is divided into functional areas; secondly, end beams are manufactured in a beam manufacturing area; thirdly, a cast-in-place beam formwork is installed; fourthly, a tied steel reinforcement framework is put in, and theposition is controlled and checked; fifthly, concrete is poured into the cast-in-place beam formwork; sixthly, cast-in-place beams serve as matching beams to be prefabricated circularly, until pouring of adopted beam bodies is completed; and seventhly, the completed beam bodies are placed in a beam storing area to be maintained. According to the method, the beam field is divided into the functional areas, site construction flows can be organized effectively, and construction efficiency is ensured. By means of joint arrangement of a table base beam manufacturing system, a measuring control system and a supporting and adjusting platform, installing can be achieved, the position can be adjusted precisely, and real-time control can also be achieved. By means of design of a shear force key, line type butt joint of the later period can be ensured. By arranging different spraying facilities, maintaining of the later period can be carried out effectively.

Owner:中国建筑土木建设有限公司

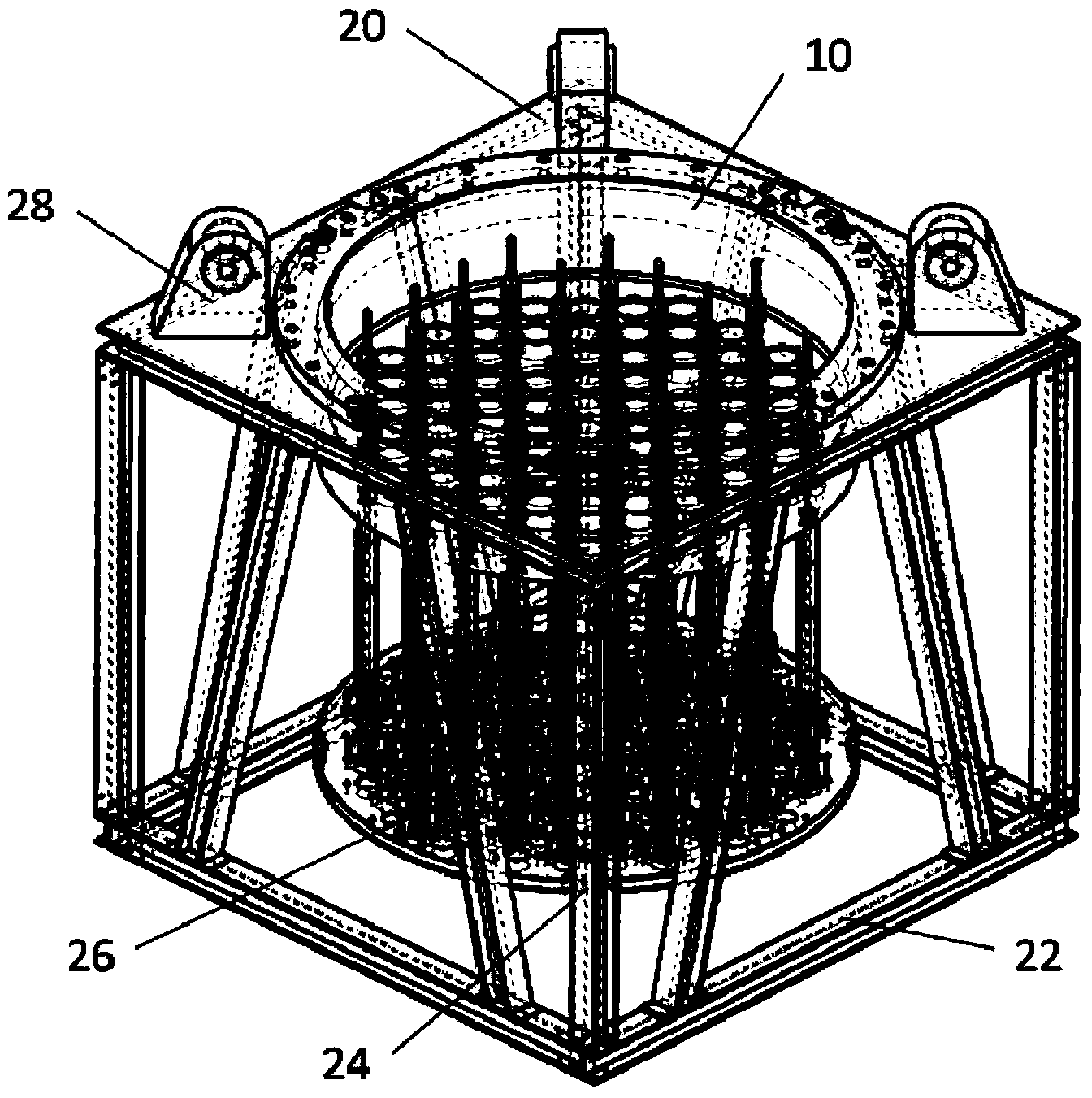

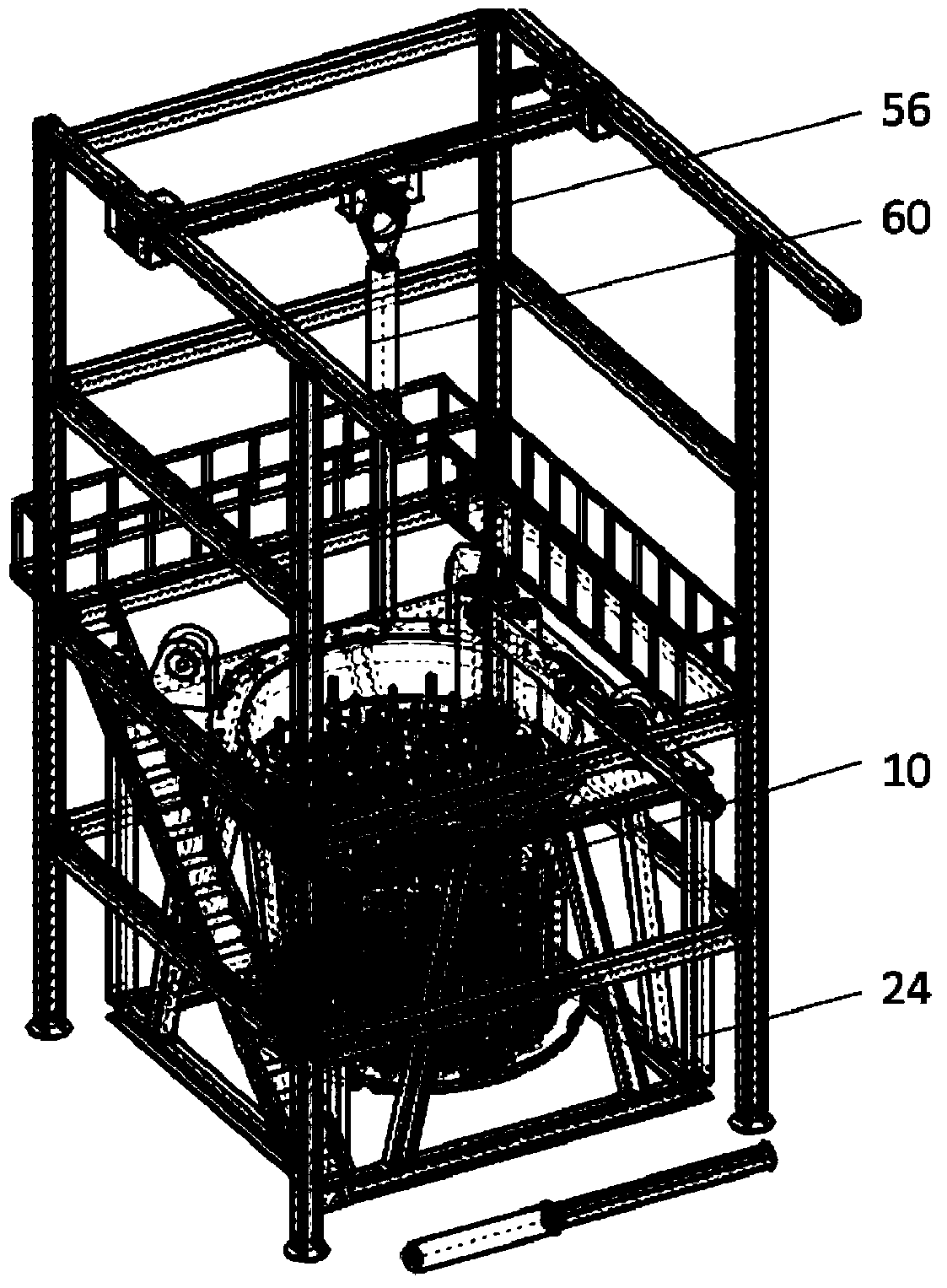

Nuclear power station upper-part in-reactor component mounting method

ActiveCN103366844AGuaranteed installationAvoid multiple flipsNuclear energy generationReactor fuel elementsNuclear powerTransport engineering

The invention discloses a nuclear power station upper-part in-reactor component mounting method comprising the steps that: (1) a produced upper-part in-reactor component is lifted and positioned with a forward direction into a vertical transportation support, wherein the vertical transportation support is provided with lugs; (2) the upper-part in-reactor component and the vertical transportation support are transported to a construction side with the lugs of the transportation support, and the entire lifting assembly are positioned into a mounting frame in a nuclear island plant designated mounting area; (3) the mounting of the upper-part in-reactor component is finished by using the mounting frame. Compared with prior art, according to the nuclear power station upper-part in-reactor component mounting method, with the vertical transportation support, upper-part in-reactor component vertical transportation is realized, such that frequent turning of the upper-part in-reactor component in a manufacturing plant and during a site construction process of an existing horizontal transportation scheme is avoided. Also, with the mounting frame, upper-part in-reactor component related part off-line mounting is realized, such that upper-part in-reactor component mounting can be carried out under the lack of condition at +7.5m water tank storage rack and peripheral areas.

Owner:中广核工程有限公司 +1

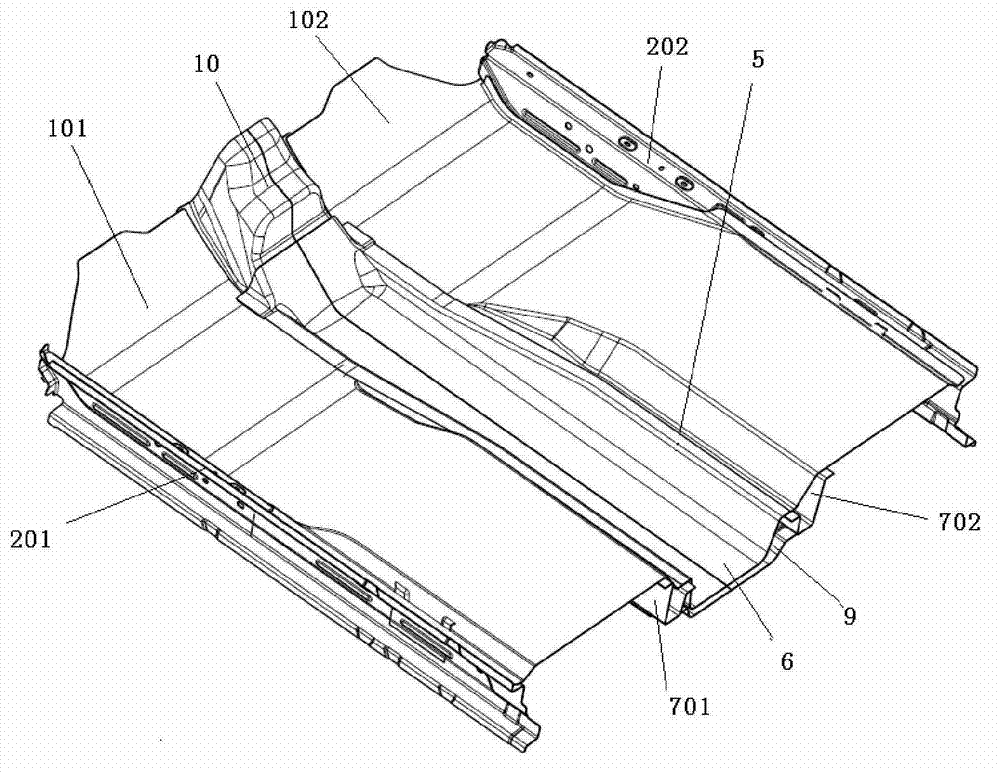

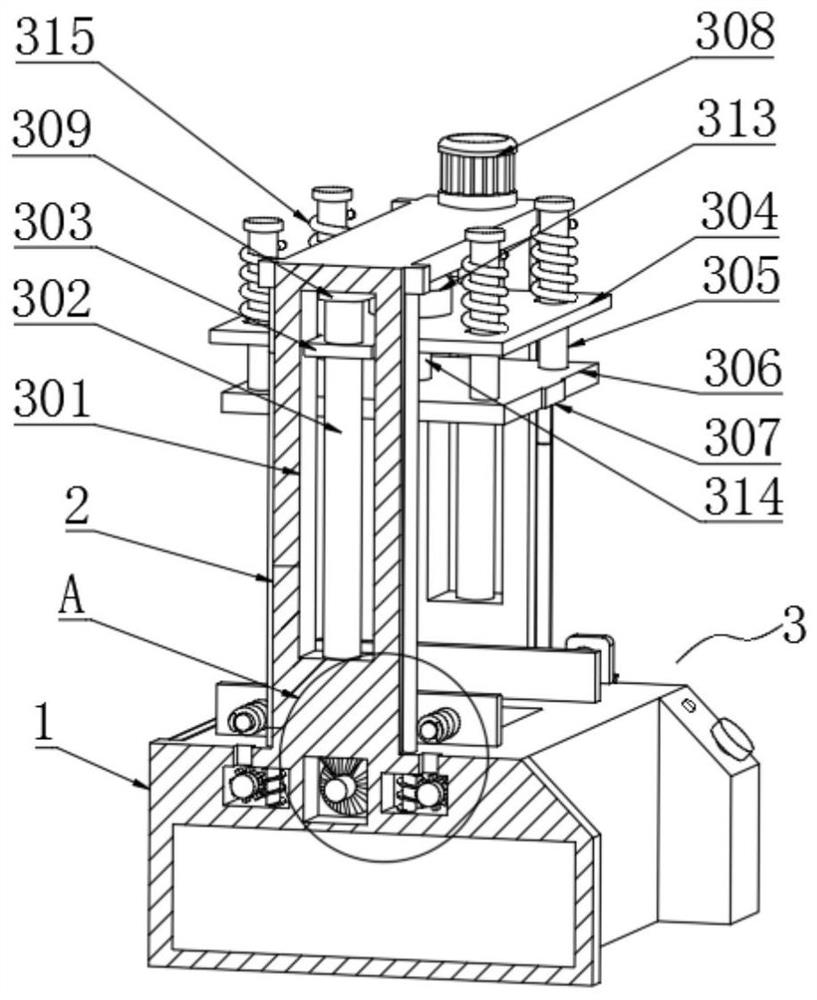

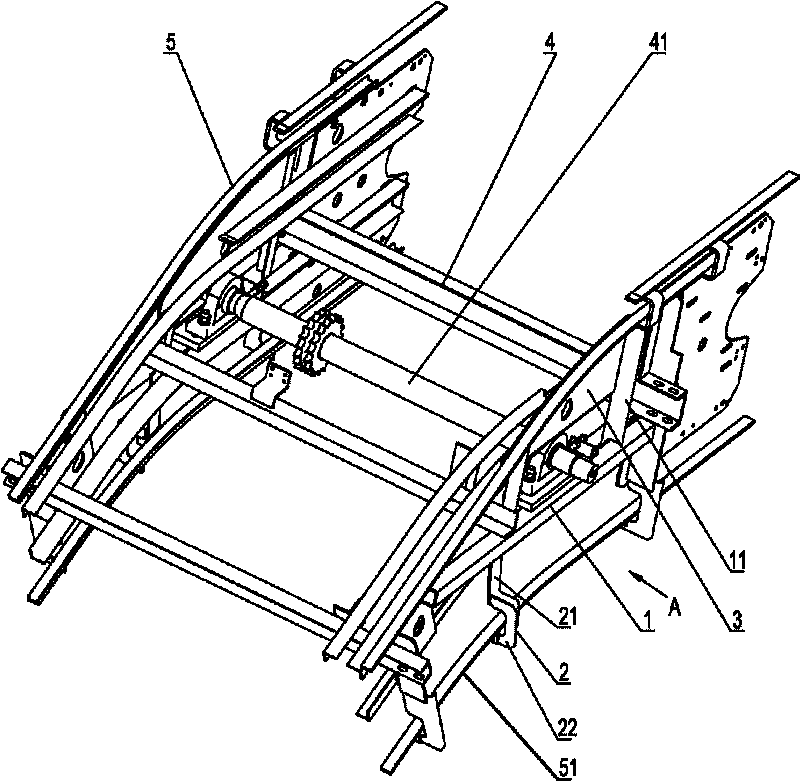

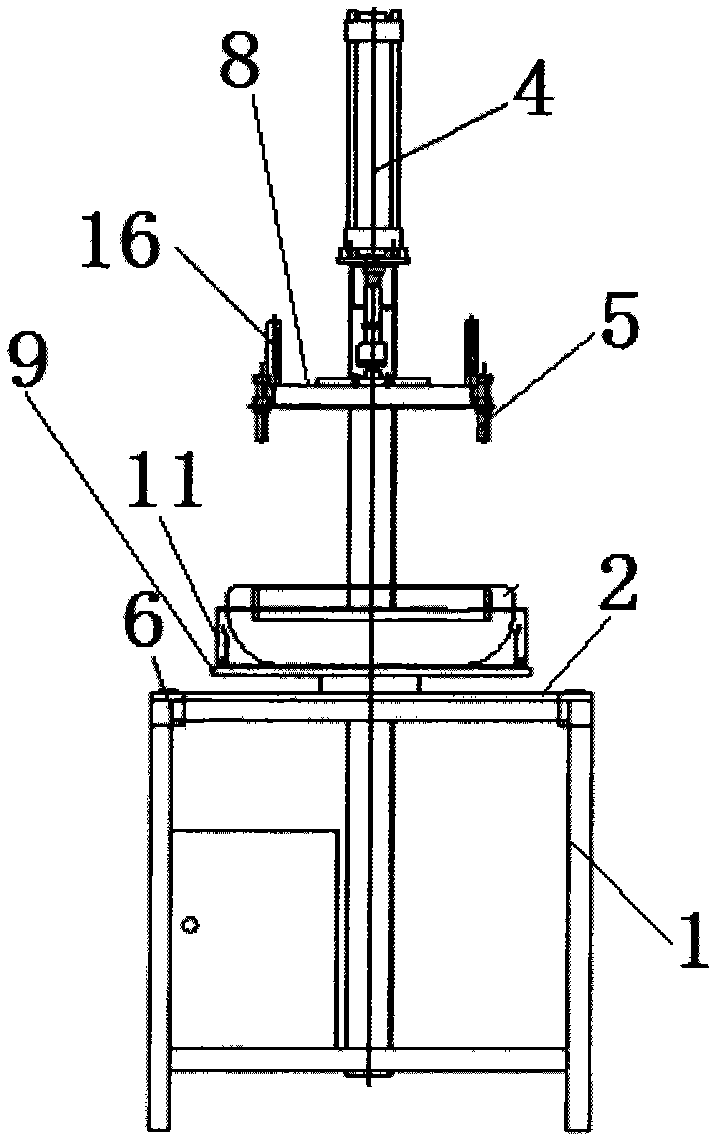

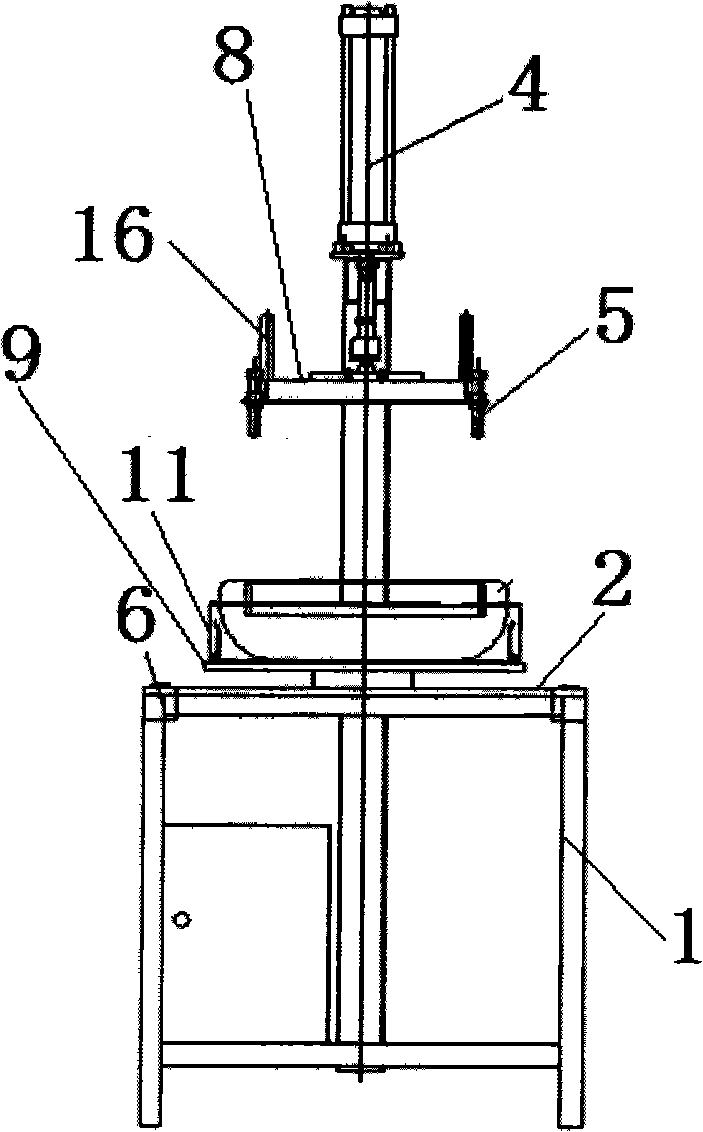

Car cushion skeleton assembling device and assembling method thereof

ActiveCN101973015AGuaranteed installationGuaranteed assembly qualityMetal-working hand toolsUltimate tensile strengthPressure controlled ventilation

The invention provides a car cushion skeleton assembling device which is applied to the technical field of car seats. The invention also relates to an assembling method of a car cushion skeleton. A device platform (2) of the car cushion skeleton assembling device is arranged on a device base (1), a device bracket (3) is connected with the device base (1), a pressure control device (4) is arranged on the device bracket (3) and is in a structure which is positioned above the device platform and can move up and down, a press head (5) is arranged on the pressure control device (4), and the pressure control device (4) is connected with a switch (6). The structure and the assembling method only need one operator, increase assembling efficiency, save manpower at the same time and obviously reduce the labor intensity of the operator.

Owner:NANTONG MEELAIN ELECTRIC APPLIANCE CO LTD

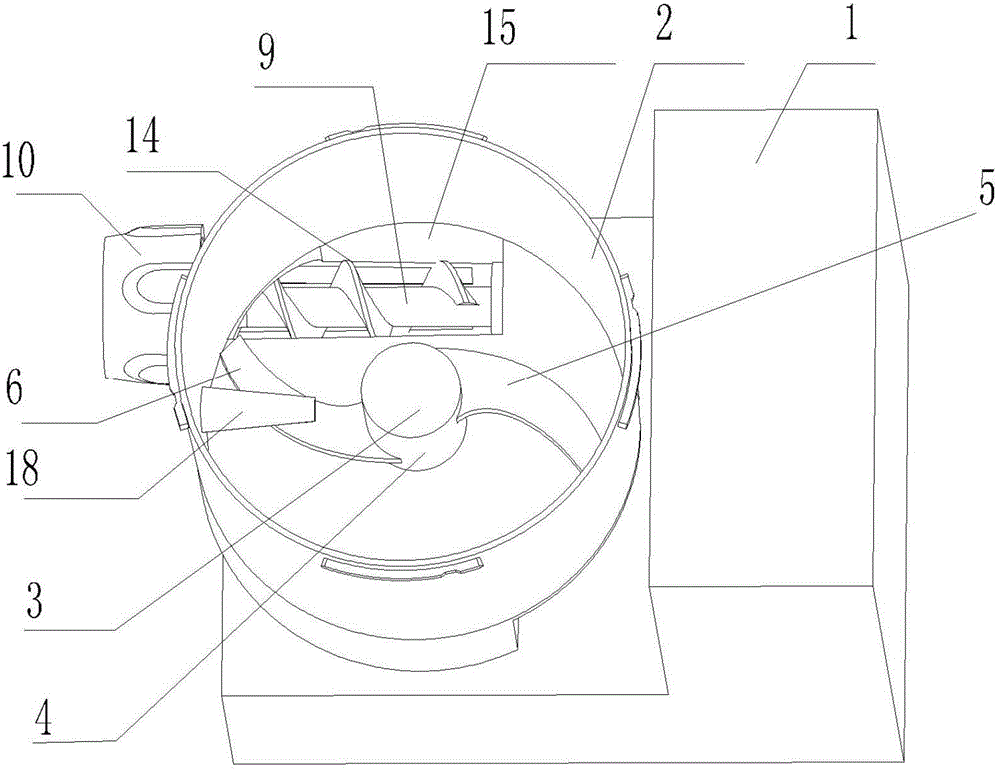

No-residual vertical type household noodle maker

ActiveCN104542787AImprove efficiencySmooth entryMixing/kneading with vertically-mounted toolsDough extruding machinesExtrusionPulp and paper industry

The invention discloses a no-residual vertical type household noodle maker which comprises a motor base, a motor arranged in the motor base, a stirring cup arranged above the motor base, a stirring rod and a dough extruding cylinder arranged in the stirring cup, a screw rod arranged in the dough extruding cylinder and a die head arranged on the end part of the dough extruding cylinder, wherein the dough extruding cylinder is horizontally arranged on one side below the stirring cup and consists of a material advancing cavity and an extrusion cavity, the motor drives the screw rod and the stirring rod to move, wherein a dough inlet communicated with the dough extruding cylinder is formed in the position of the bottom of the stirring cup, far away from the center, the material advancing cavity extends upwards and is intersected with the bottom of the stirring cup to form the dough inlet, and the dough inlet horizontally extends to the direction of the dough extruding cylinder along the bottom of the stirring cup, and extends to the side wall of the stirring cup. By adopting the technical scheme, the area of the dough inlet is largest, so that dough feeding is facilitated, residuals of dough in the stirring cavity can be avoided, and the stirring cavity and the stirring rod are conveniently cleaned.

Owner:JOYOUNG CO LTD

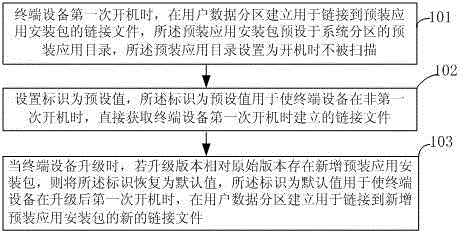

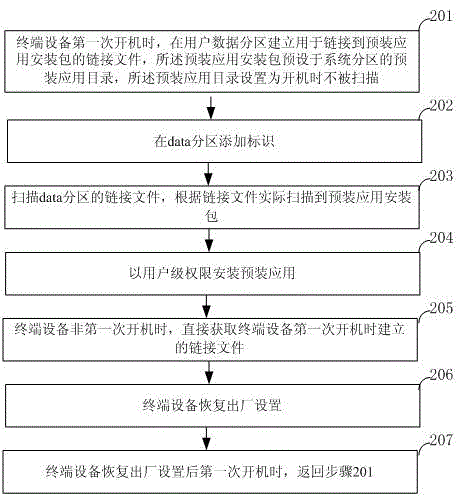

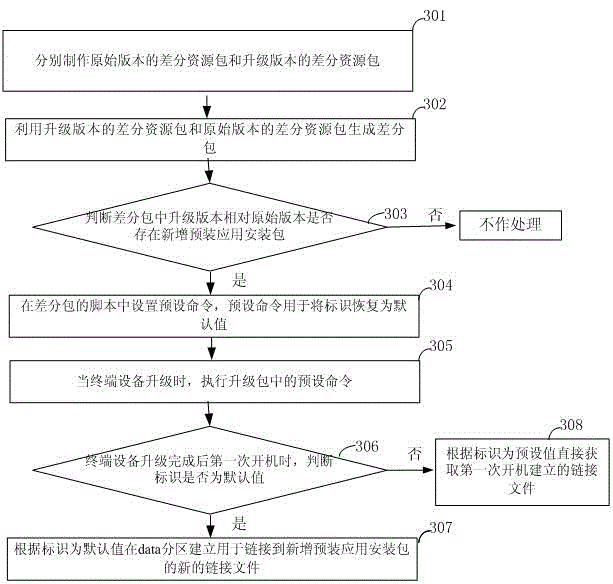

Terminal device pre-loaded application management method and terminal device

InactiveCN106406919AGuaranteed installationEasy to useProgram loading/initiatingTerminal equipmentComputer terminal

The invention provides a terminal device pre-loaded application management method. When a terminal device is powered on for the first time, a link file is established in a user data partition, the link file is used for linking to a pre-loaded application installation package of a pre-loaded application list and preset in a system partition, and the pre-loaded application list is set in a way that the pre-loaded application list is not scanned when the terminal device is powered on. The identification is set to be a preset value, and therefore when the terminal device is powered on not for the first time, the link file established when the terminal device is powered on for the first time can be directly obtained. When the terminal device is upgraded, a newly increased pre-loaded application installation package exists in the upgrade version relative to the original version, the identification is reverted to be a default value, and therefore when the terminal device is powered on for the first time after being upgraded, a new link file used for linking to the newly increased pre-loaded application installation package is established in the user data partition. According to the invention, the case that the link needs to be established repeatedly when the terminal device is powered on each time can be avoided, at the same time, the fact that when a newly increased pre-loaded application exists in the upgrade version, the newly increased pre-loaded application can be used normally can be guaranteed.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

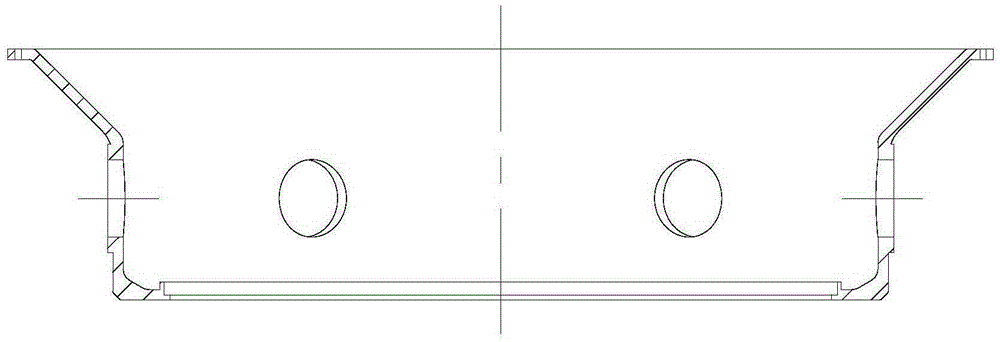

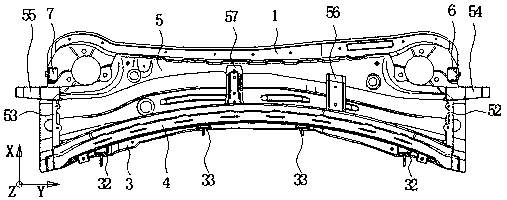

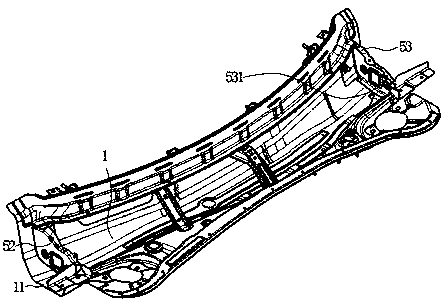

Automobile gutter channel assembly

The invention relates to an automobile gutter channel assembly which comprises a gutter channel. The gutter channel comprises a first bent part, a bottom board and a second bent part, all of which aresequentially connected and are each in a U shape. The upper end of the first bent part is connected with a first flanging part extending to the outer side of the gutter channel, and the upper end ofthe second bent part is connected with a second flanging part extending to the outer side of the gutter channel. The bottom board is in a shape with the middle portion higher than the two ends, drainholes are formed in the two ends of the bottom board, a downward-recessed section is arranged on the middle portion of the first flanging part, the two ends of the second flanging part are connected with a right gas supporting rod support component and a left gas supporting rod support component, the second flanging part is further connected with a gutter channel crossbeam assembly, the upper sideof the first flanging part is sequentially connected with a front windshield lower crossbeam connecting board assembly and a front windshield lower crossbeam upwards, and the face, facing the outer side of the gutter channel, of the first bent part is connected with a pedal tubular beam installation support component. By the adoption of the automobile gutter channel assembly, the problem of partrusting caused by bad accumulated water flow guidance is solved effectively, the rigidity and the rigidity of a whole automobile after the whole automobile is connected can be effectively guaranteed,and the automobile gutter channel assembly can be conveniently connected with other parts of the whole automobile.

Owner:力帆科技(集团)股份有限公司

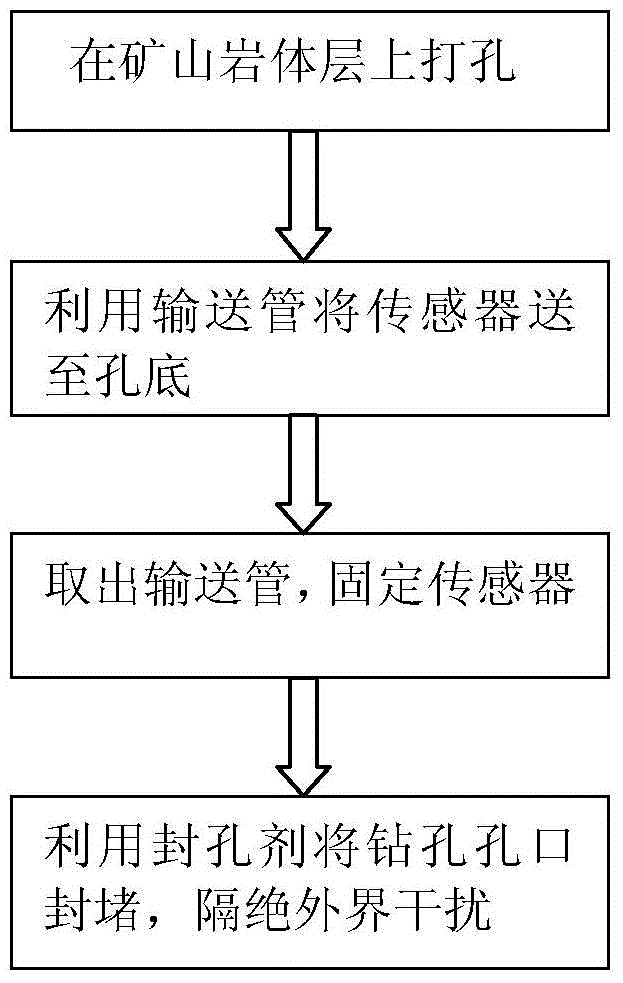

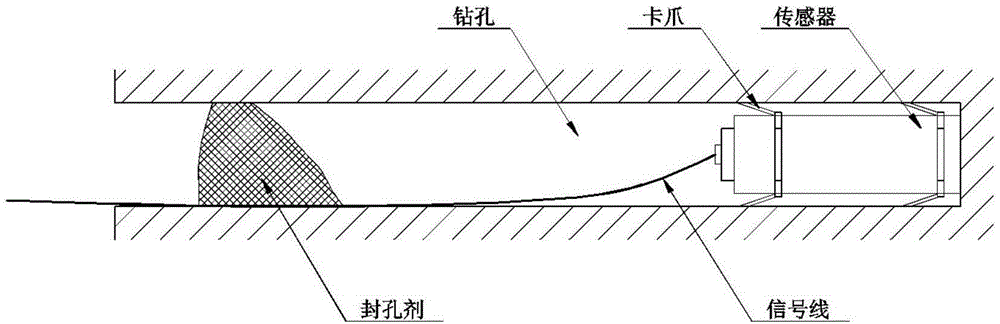

Method for installing acoustic emission sensor on mine

The invention discloses a method for installing an acoustic emission sensor on a mine, and belongs to the technical field of acoustic emission monitoring of a mine coal-rock mass. The method for installing the acoustic emission sensor on the mine comprises the following steps of (1) carrying out drilling on a mine coal-rock stratum according to the requirement of the design and construction; (2) conveying the sensor to the bottom of a hole through a conveying pipe to enable the acoustic emission sensor and the hole wall of the drilled hole to be in tight coupling contact, wherein the acoustic emission sensor comprises a signal line, an outer shell, an acoustic emission signal receiver and clamping jaws; (3) pulling the conveying pipe out, enabling the clamping jaws of the acoustic emission sensor to clamp the hole wall of the drilled hole so that the acoustic emission sensor cannot slide off, and arranging a signal circuit of the acoustic emission sensor; (4) using mining hole sealing agents to block the hole opening of the drilled hole to isolate interference noise of the outside world. According to the method for installing the acoustic emission sensor on the mine, due to the fact that the acoustic emission sensor is embedded into the rock mass in a drilling mode, interference caused by the noise of the outside world on real-time monitoring is avoided, and monitoring precision is improved; due to the fact that the clamping jaws are fixedly arranged in the drilled hole, the acoustic emission sensor and the rock mass of the mine are tightly coupled, and the problems that grouting is tedious and whether grouting is in place or not cannot be easily judged are effectively solved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Slip ring device

ActiveCN101662118AGuaranteed installationReduce gapRotary current collectorThermometers using electric/magnetic elementsRing deviceThermal expansion

A slip ring device comprises a heat insulation ring sheathed outside the barrel of a rotary kiln and at least one group of slip rings sheathed outside the heat insulation ring; each group of slip rings comprises two slip ring main bodies, wherein one slip ring main body is connected with a positive pole and the other slip ring main body is connected with a negative pole. The slip ring device provided by the invention can effectively avoid the problem of overheated slip rings and larger seam or deformation of the joints of slip rings caused by thermal expansion of the barrel of the rotary kiln.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

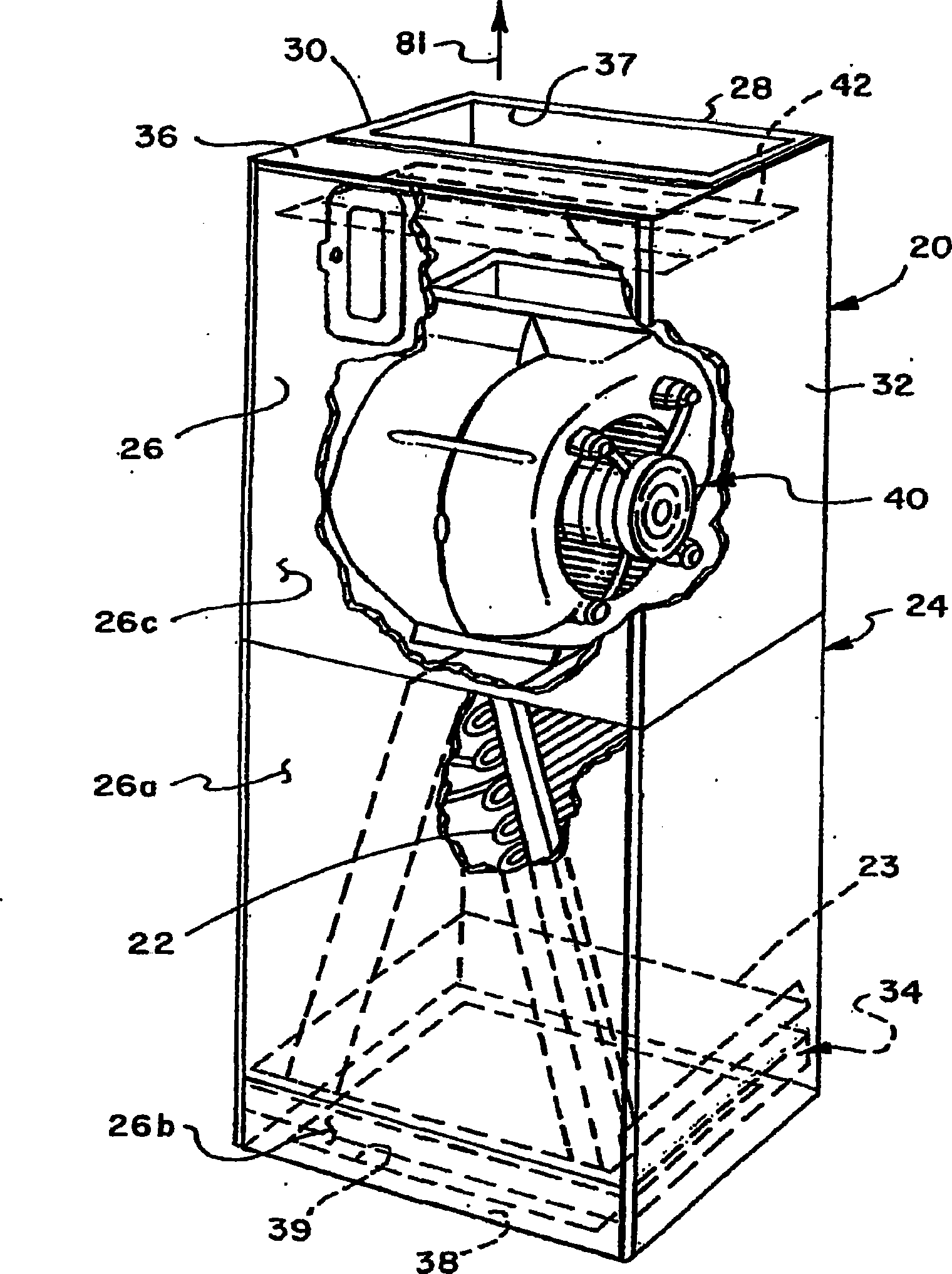

Air conditioning apparatus with integrated air filtration system

InactiveCN101523120AGuaranteed installationEasy to take outMechanical apparatusElectrostatic separation housingAir filtrationDielectric

An air conditioning apparatus includes a cabinet having air inlet and outlet openings and an intense field dielectric air filtration system disposed in the cabinet between the inlet and outlet openings. The filtration system includes a field charging unit and a filter unit. The filter unit may be mounted for removal from the cabinet on spaced apart support brackets connected to the cabinet or to a frame of the field charging unit. Electrical contact elements may be supported by the support brackets for engagement with corresponding contact elements on the filter unit and charging unit for establishing electrical communication between a power supply and the charging unit and filter unit, respectively. A shorting bar is aligned with the contact members on the filter unit for discharging high voltage potential upon removal of the filter unit from the cabinet.

Owner:TRANE INT INC

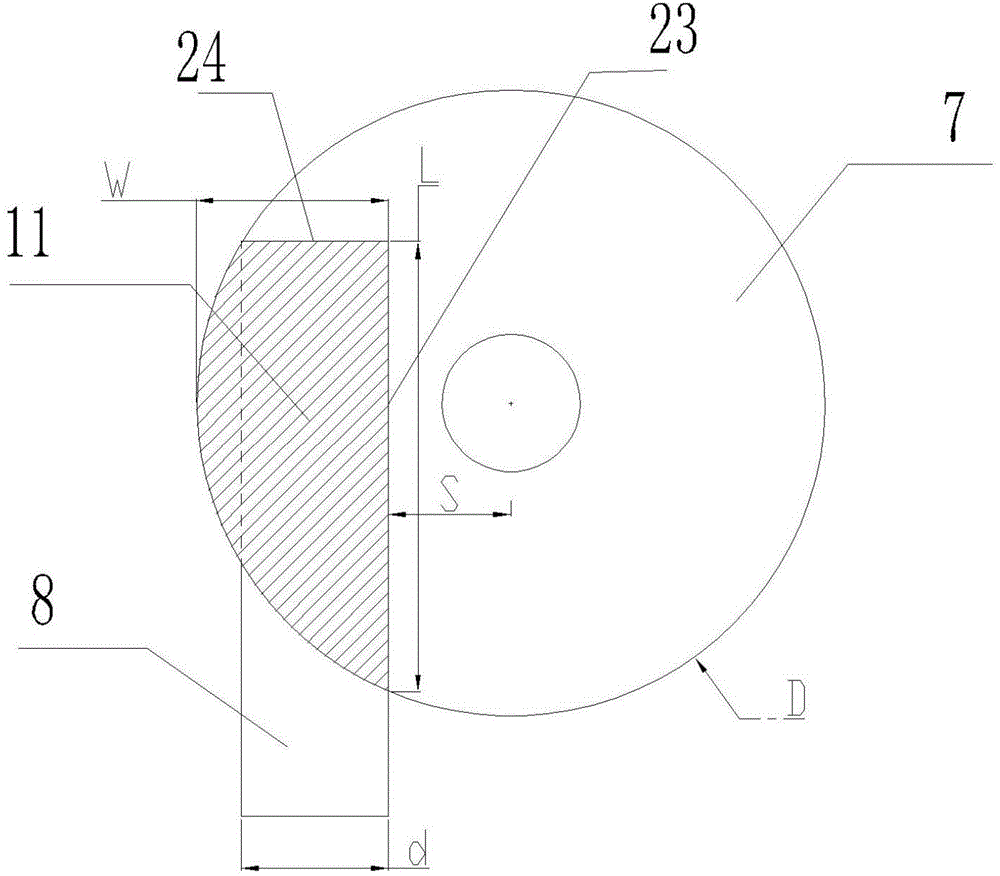

Pneumatic winding shaft

The invention relates to a pneumatic winding shaft. The pneumatic winding shaft comprises a shaft body and is characterized in that a plurality of pneumatic ring slots are evenly formed in the external circumferential wall of the shaft wall at intervals, a pneumatic device is arranged in each pneumatic ring slot and comprises a pneumatic push ring, a reset spring and a plurality of push-out blocks, the pneumatic push rings and the shaft body penetrate through the pneumatic ring slots coaxially and are communicated with an air pipe penetrating through the shaft body to be able to move axially in the pneumatic ring slots under air supply stress, the external circumferential wall of one end of each pneumatic push ring is of an external conical structure, the push-out blocks are evenly arranged on each pneumatic push ring trough the corresponding reset spring in a hooping mode, and the inner wall of each push-out block is of an internal conical structure matched with the external conical structure.

Owner:JIANGSU SUNPOWER

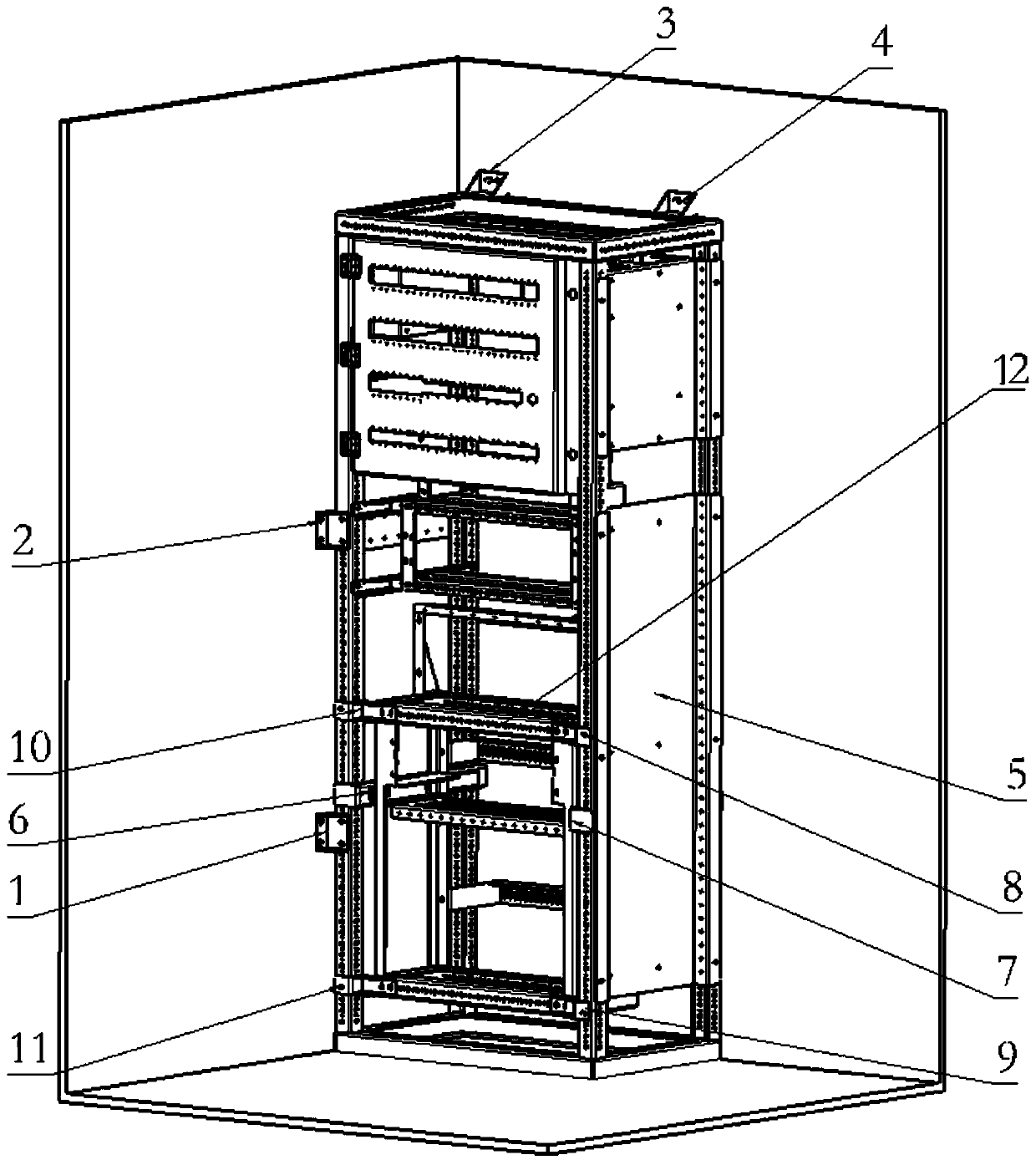

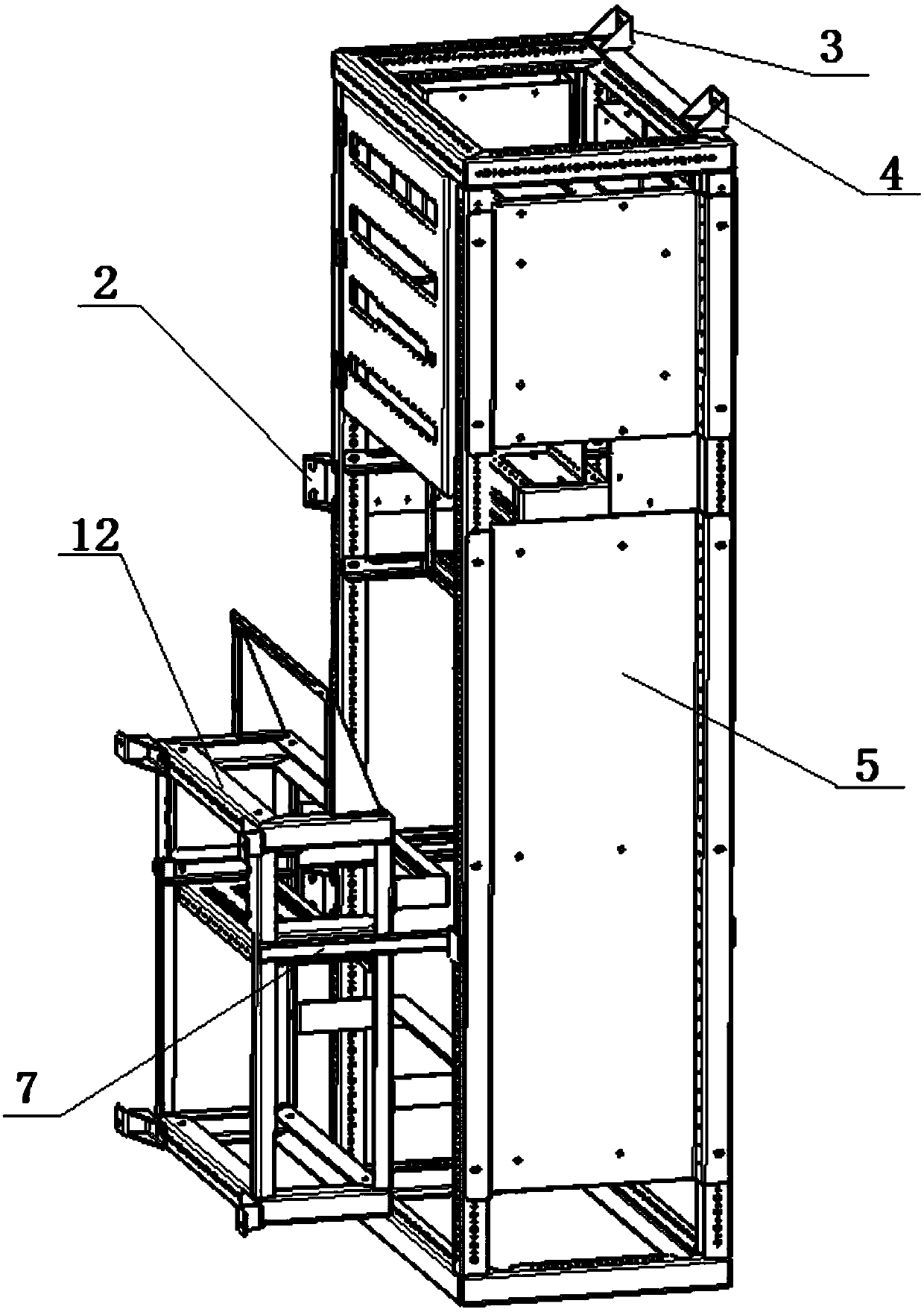

Installing structure of railway vehicle signal cabinet

ActiveCN109625005ASolve the installationIncrease productivityLocomotivesSoftware engineeringMaintenance Problem

The invention relates to an installing structure of a railway vehicle signal cabinet. The signal cabinet is installed at the second-site end of a vehicle, the bottom of the signal cabinet is fixed toa vehicle body chassis, the back side of the signal cabinet is fixed to an end wall, the left side or right side of the signal cabinet is fixed to a side wall of a vehicle body, a signal device integrated cabinet is arranged in the signal cabinet, the signal device integrated cabinet is drawably connected with the signal cabinet through a slide rail, and the front side of the signal cabinet is provided with a fixing support for fixing the signal device integrated cabinet into the signal cabinet. According to the signal cabinet, the problem that a signal device integrated cabinet of an unmannedvehicle cannot be installed in a cab electrical cabinet is effectively solved, and meanwhile the installation and maintenance problems of the signal device integrated cabinet are solved through the design of the slide rail.

Owner:CRRC NANJING PUZHEN CO LTD

Method for mounting head sprocket wheel of belt sintering machine

The invention relates to a method for mounting a head sprocket wheel of a belt sintering machine. The method comprises the following steps of: carrying the head sprocket wheel by temporarily constructing a track, a hoisting beam, an upright post and other equipment indoors; and mounting the head sprocket wheel of the sintering machine by utilizing an indoor gantry crane, a winch, a crane and other hoisting equipment. In the method, first-phase preparation work is a little, the main body equipment is quickly mounted, the construction of previous and subsequent processes and the civil engineering are not influenced, conditions are provided for ensuring whole equipment installation of the sintering machine, and the mounting cost is greatly reduced.

Owner:ANGANG CONSTR CONSORTIUM

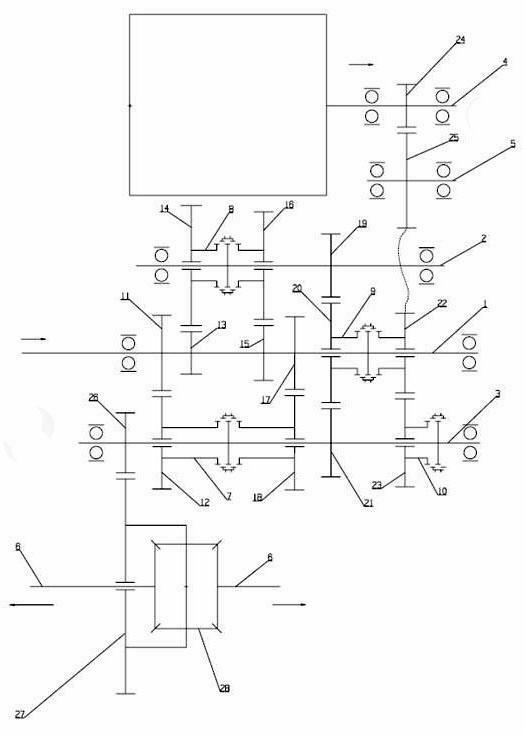

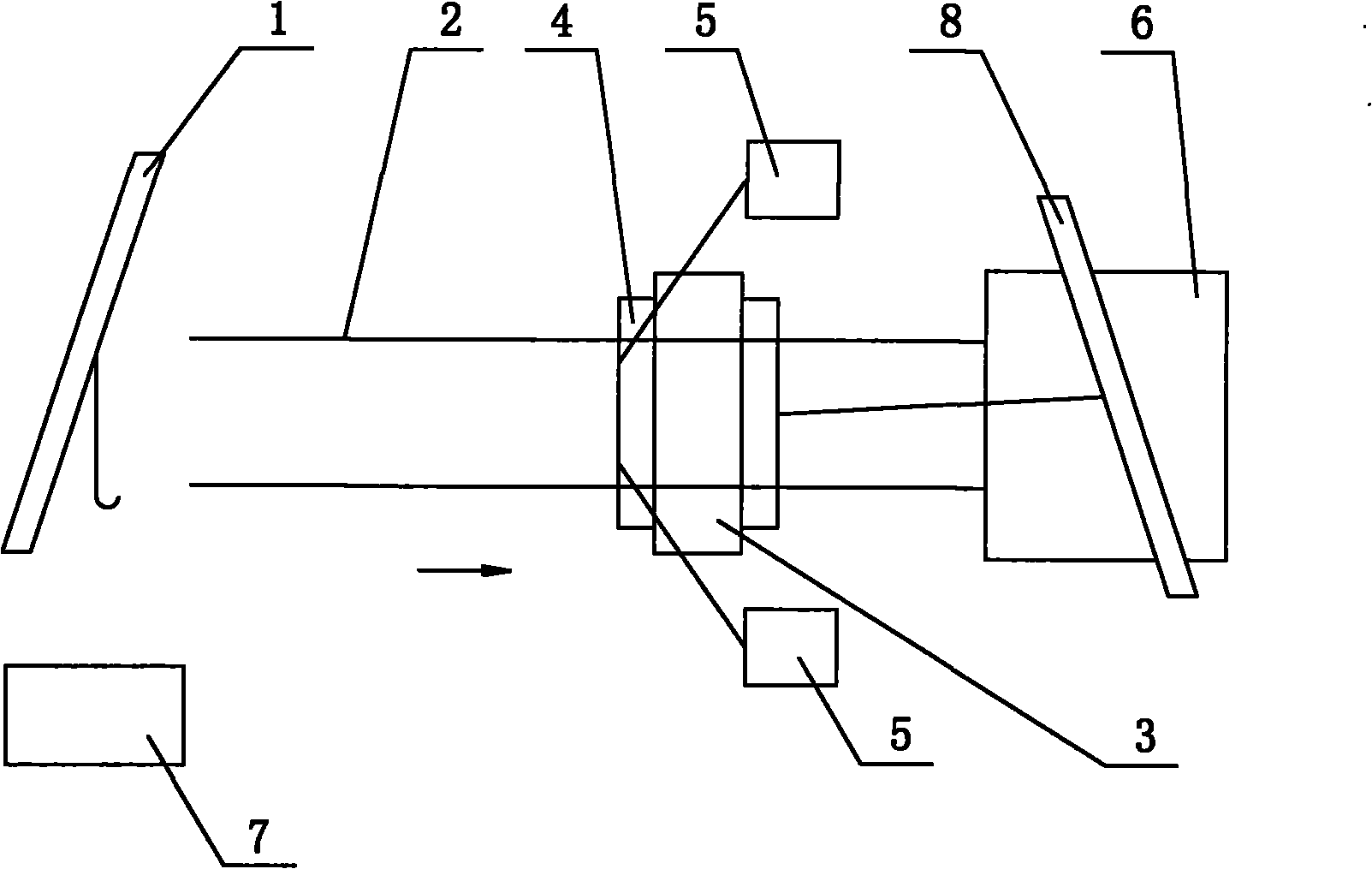

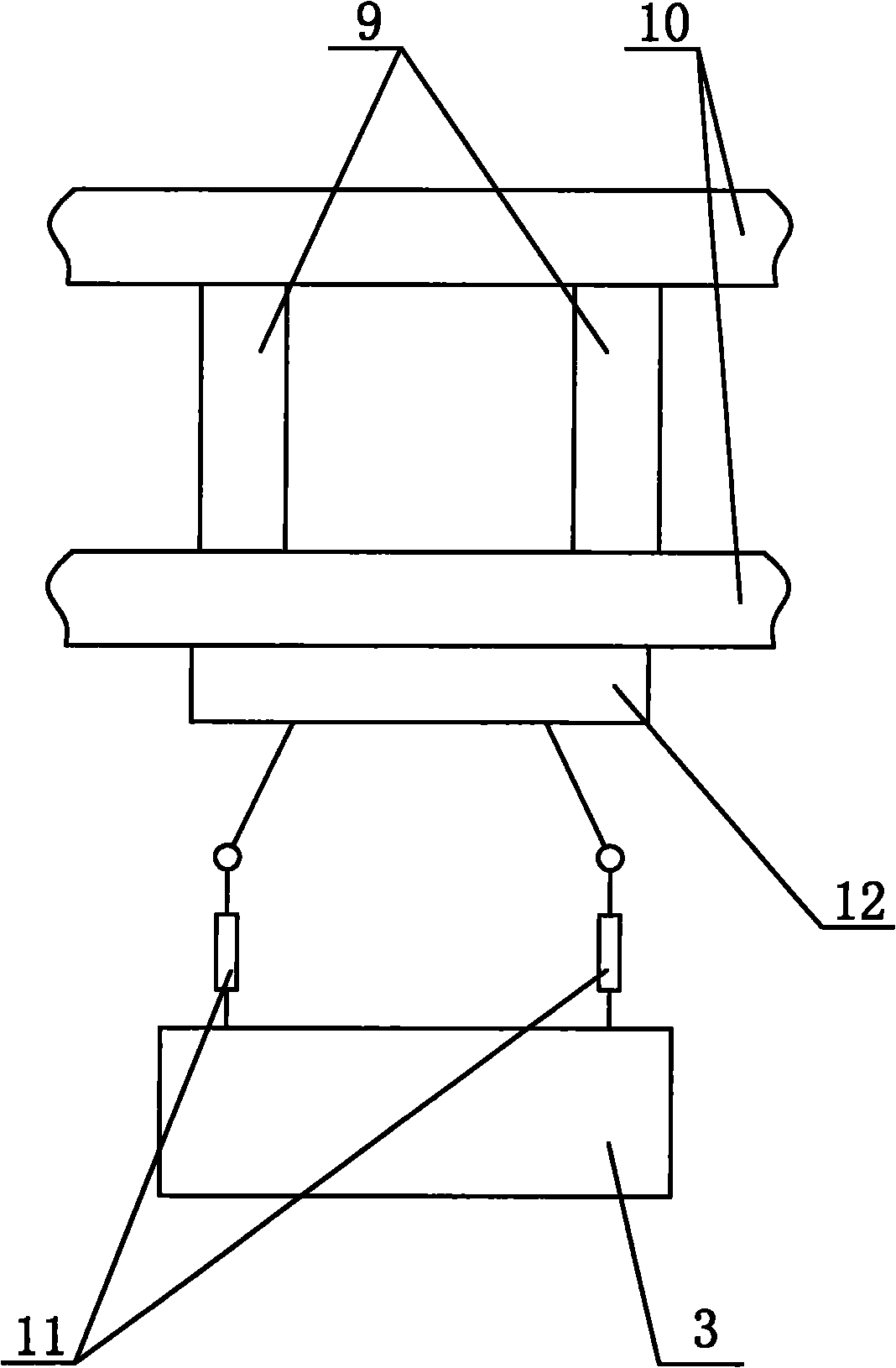

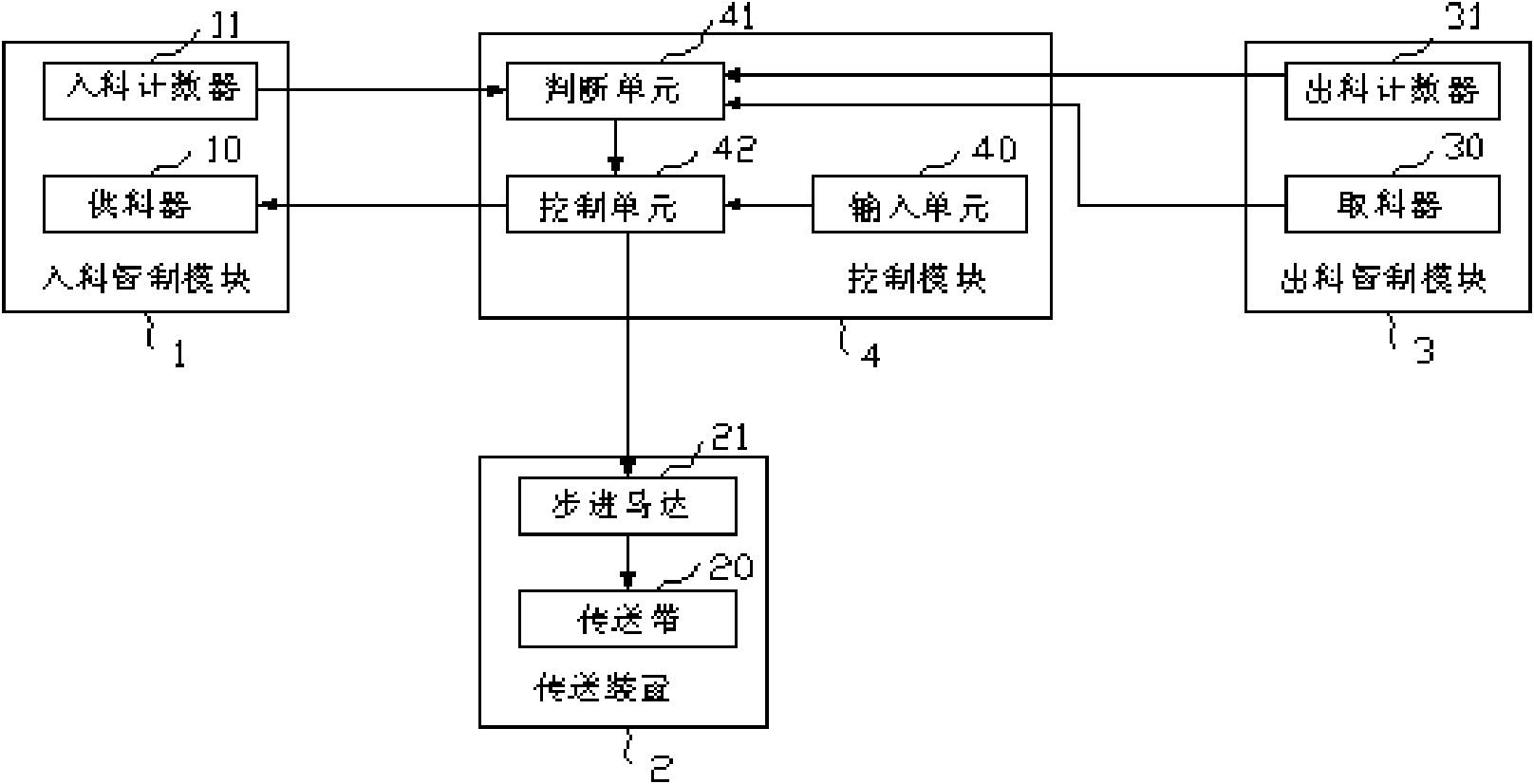

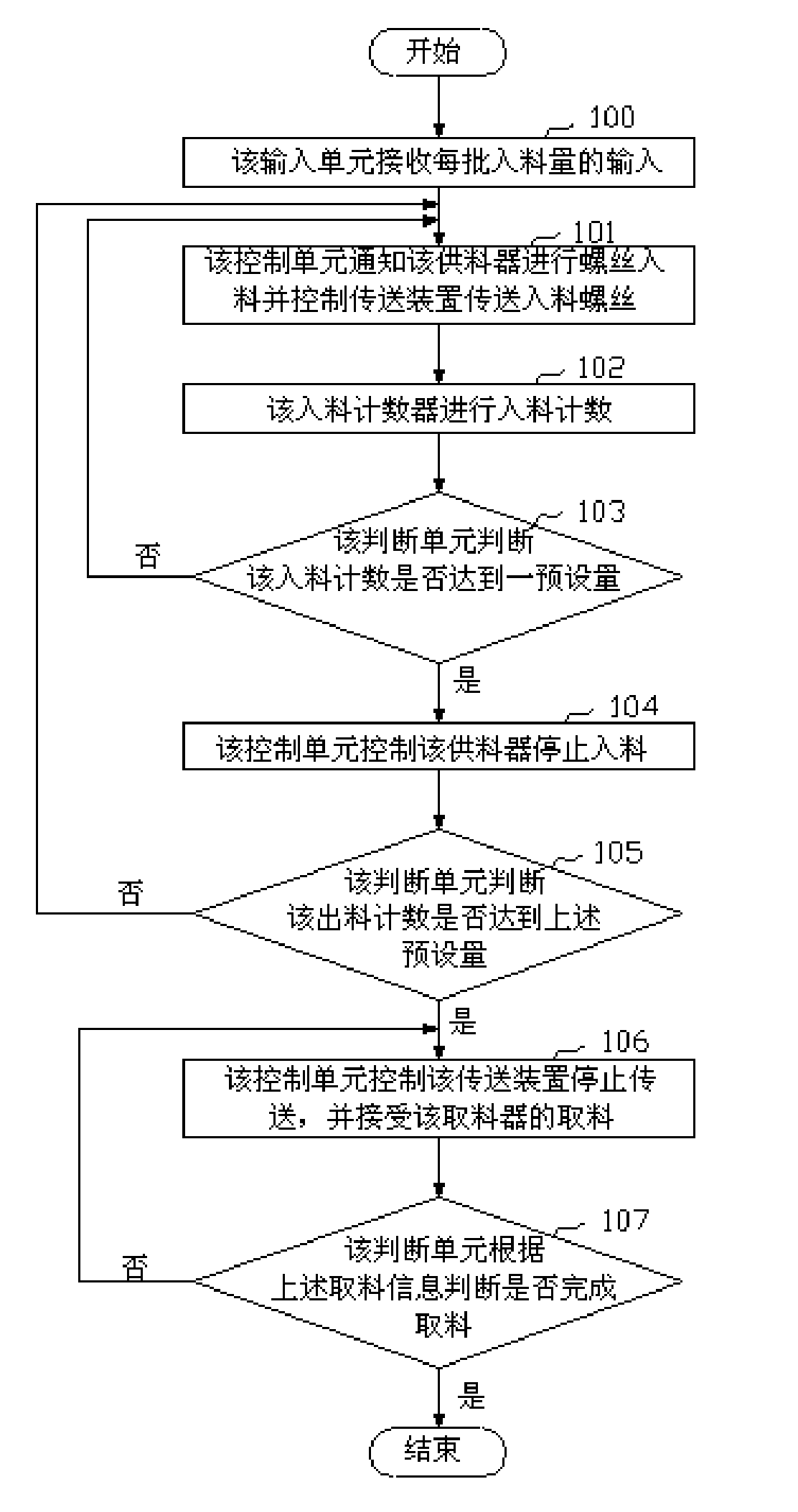

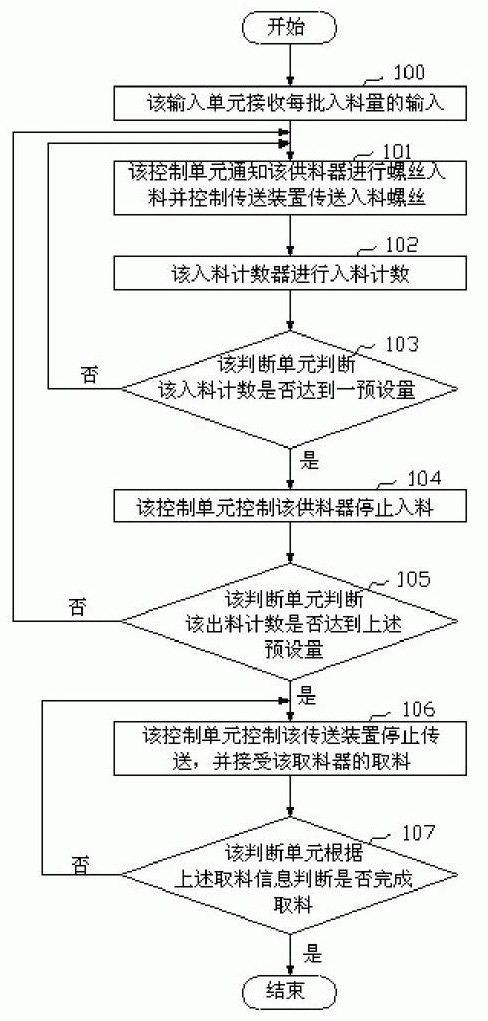

Screw inlet/outlet supply system and method

InactiveCN101850885AEnsure controlGuaranteed installationConveyorsControl devices for conveyorsManufacturing lineControl unit

The invention discloses a screw inlet / outlet supply system and a method, which are used for automatic screw feeding on a production line. The supply system comprises an inlet regulation module, a conveying device, an outlet regulation module and a control module, wherein the inlet regulation module consists of a feeder and an inlet counter; the conveying device comprises a conveyor belt and a stepped motor; the outlet regulation module comprises an extractor and an outlet counter; and the control module is connected with the inlet regulation module, the outlet regulation module and the conveying device thereon and is composed of an input unit, a judgment unit and a control unit connected with the input unit and the judgment unit. The method can realize automatic screw feeding on the production line based on the above supply system. By adopting the screw inlet / outlet supply system and method, continuous feeding can be realized after the screw inlet and outlet, thus ensuring regulation on the quantity of the screws and installation of the screws on products, and having the capability of automated feeding.

Owner:KUNDA COMP TECHKUSN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com