Method for installing acoustic emission sensor on mine

An acoustic emission sensor and installation method technology, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to prevent sensors, affect monitoring effects, and large monitoring errors, so as to ensure installation and monitoring effects, and avoid difficult judgments. Whether it is in place and the effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

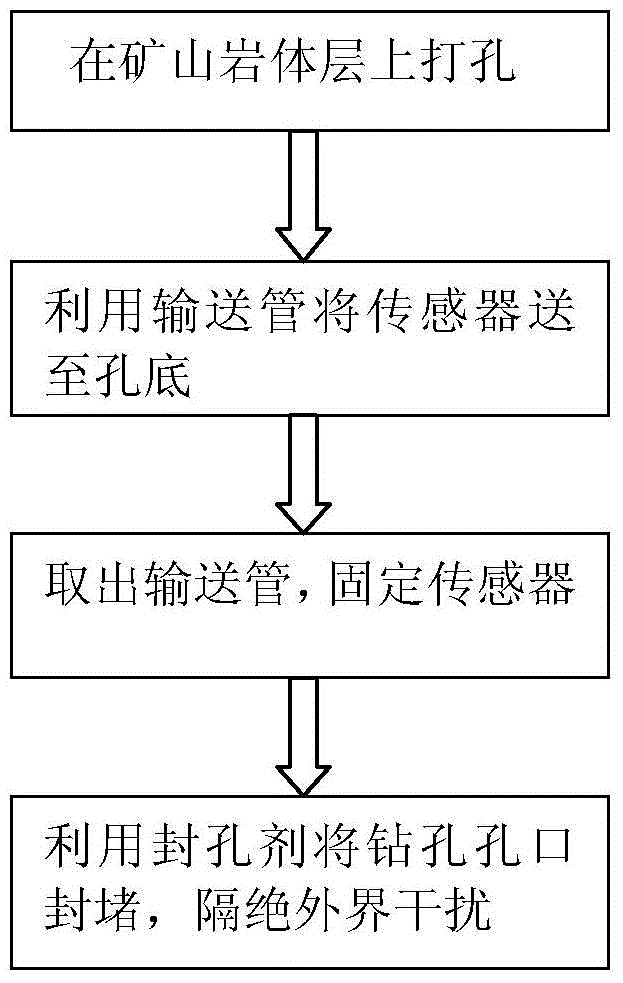

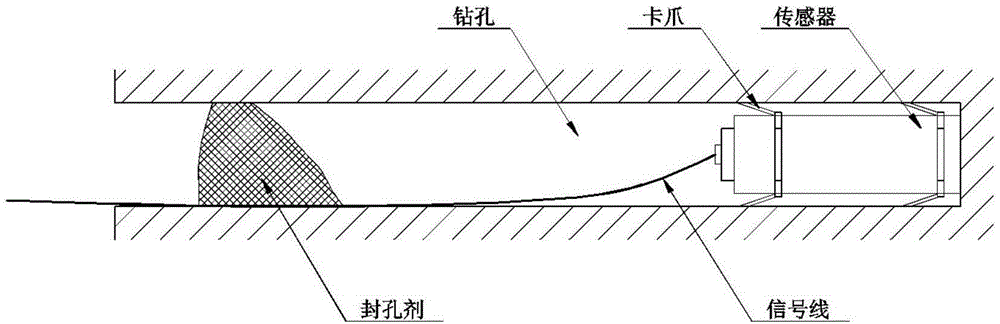

[0015] figure 1 It is a flow chart of the method of the present invention, as shown in the figure, the mine acoustic emission sensor installation method of the present invention specifically includes the following steps: Step 1: According to the design and construction requirements, punch holes in the mine coal formation; Step 2: Send the sensor to the bottom of the hole through the delivery pipe, so that the acoustic emission sensor is tightly coupled with the borehole wall; the acoustic emission sensor includes a signal line, a casing, an acoustic emission signal receiver, and claws; step 3: extract and transport Pipe, and make the claws of the acoustic emission sensor clamp the wall of the borehole without slipping, and discharge the signal line of the acoustic emission sensor; Step 4: Use mining sealing agent to seal the borehole openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com