High-altitude long-span overhanging corridor type reinforced concrete structure and construction method

A large-span cantilever, concrete structure technology, applied in building construction, construction, building materials processing and other directions, can solve the problems of national and enterprise losses, affecting the life safety of construction workers, affecting the reputation of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

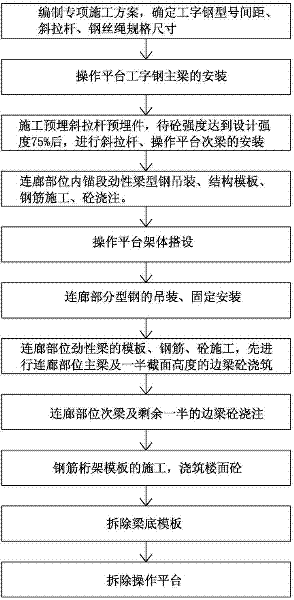

Method used

Image

Examples

example

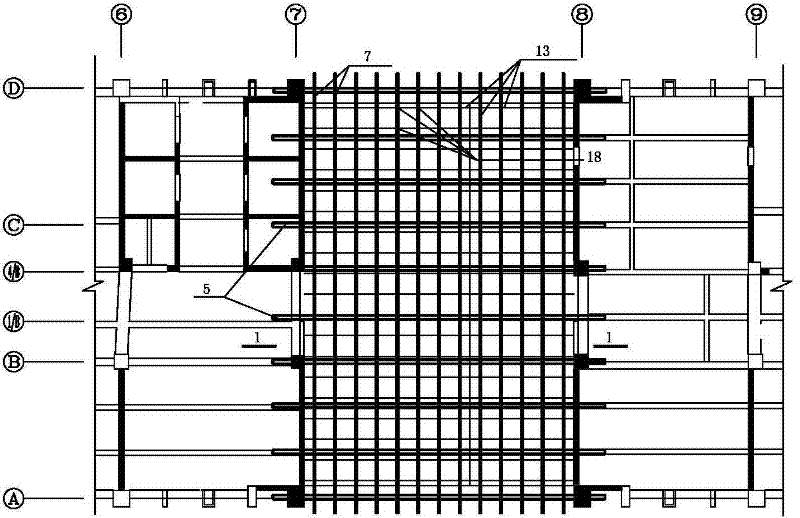

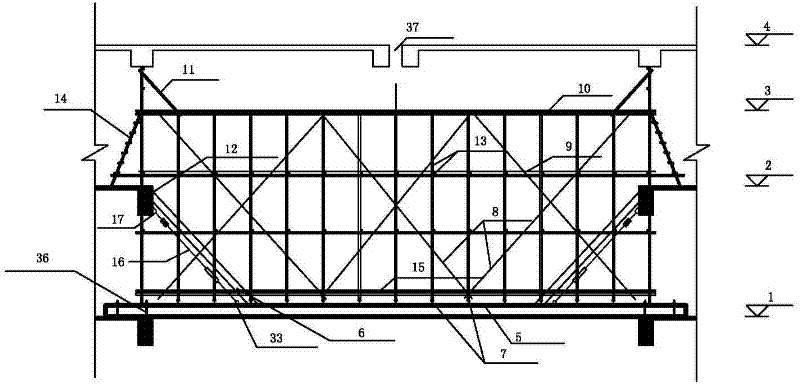

[0087] Example: With a frame-shear structure, the main building consists of two towers in the east and west, with one floor underground and 24 floors above ground, with a total building height of 108.700 meters; the podium has three floors, a frame structure, and a building height of 16.900 meters. The main building is divided into two independent towers in the east and west starting from 10.950m on the third floor. The towers in the west area are 1-7 axes, and the towers in the east area are 8-14 axes. The elevation of the roof layer is 91.85m). Form the 7-8 axis room of the high-altitude corridor. Take a building with a bottom elevation of 92.45m and a top elevation of 108.7m as an example.

[0088] The floor slabs of the corridor have a net height of 80.950m from the third floor +10.950m to the roof layer of 91.850m, and cantilever 6.725m outwards to form a high-altitude corridor. 150mm thick self-supporting reinforced truss concrete floor. The section size of the rigid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com