A pre-assembled leaching tank and assembly method

A leaching tank and pre-assembled technology, which is applied in the field of construction engineering, can solve the problems of long formwork processing time, complicated procedures, and large amount of turnover materials, and achieve the effect of fast construction period, less turnover materials and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

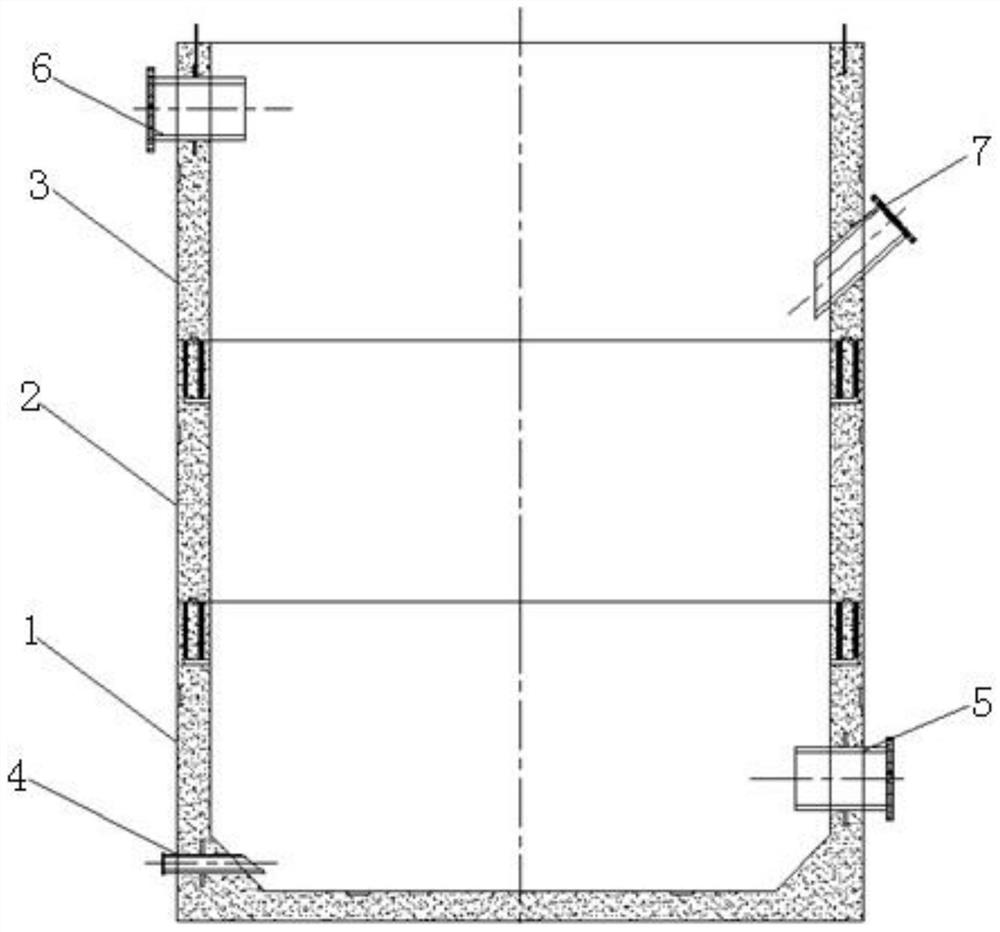

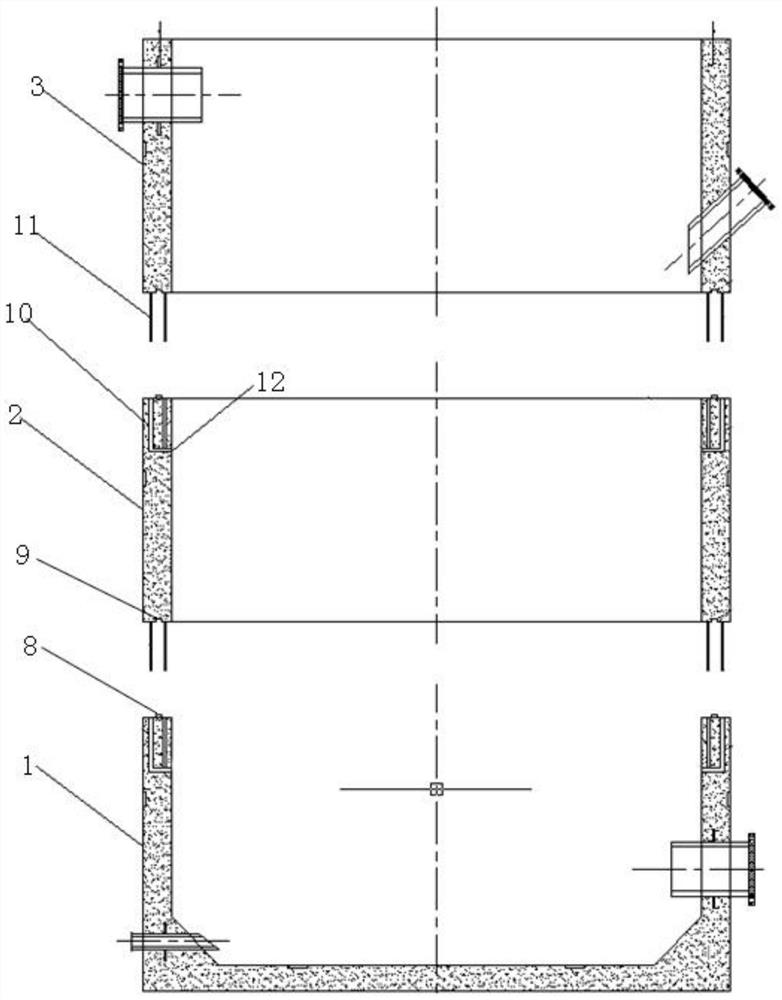

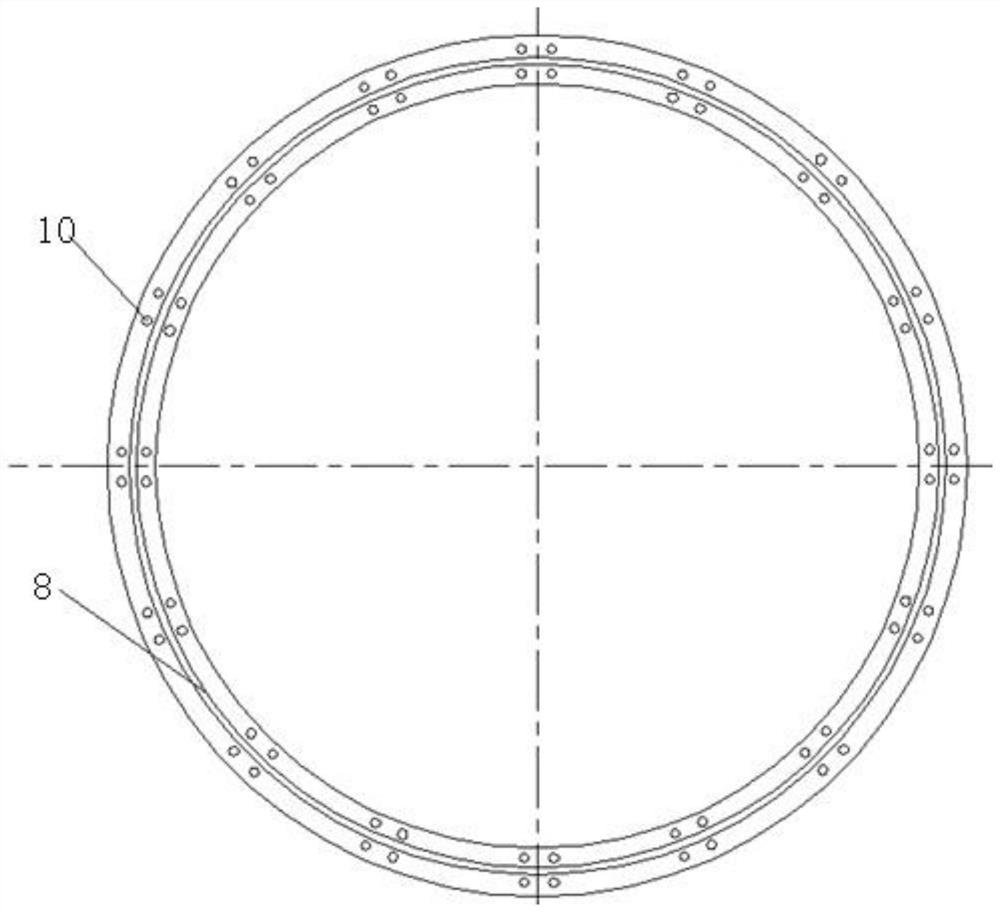

[0026] Such as Figure 1-Figure 2 As shown, a pre-assembled leaching tank includes a bottom plate section 1, a middle section 2 and an upper tank body 3 sequentially connected from bottom to top. The pre-embedded casing 4 at the entrance and the pre-embedded casing 5 for the maintenance manhole. The pre-embedded casing at the discharge port is lower than the installation position of the pre-embedded casing for the maintenance manhole. The middle section and the upper tank are both cylindrical cylinders with upper and lower openings. structure, the upper tank wall is provided with overflow hole embedded casing 6 and feed inlet embedded casing 7, and the overflow hole embedded casing is higher than the installation position of the feed inlet embedded casing.

[0027] The center of the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com