Fabricated building shaping protective stair and construction method thereof

A prefabricated and stereotyped technology, applied in stairs, buildings, building structures, etc., can solve the problems of inadequate edge protection, weak connection of outer frames, and high labor costs, saving turnover materials, man-hours, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

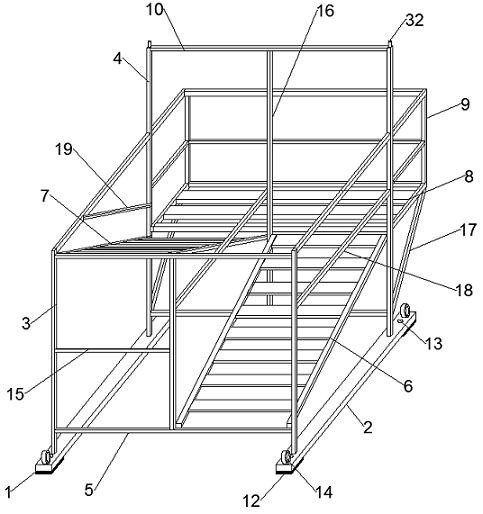

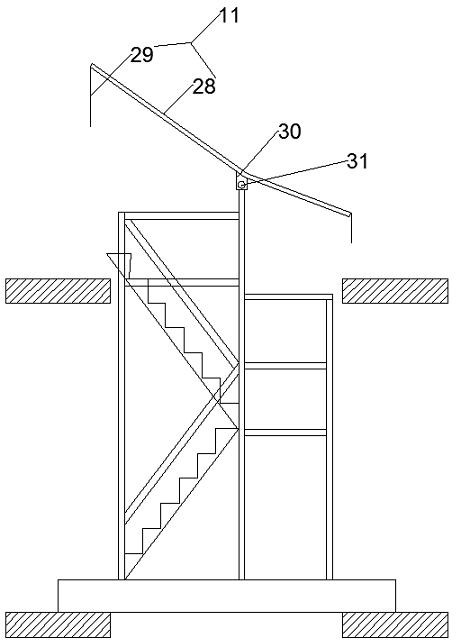

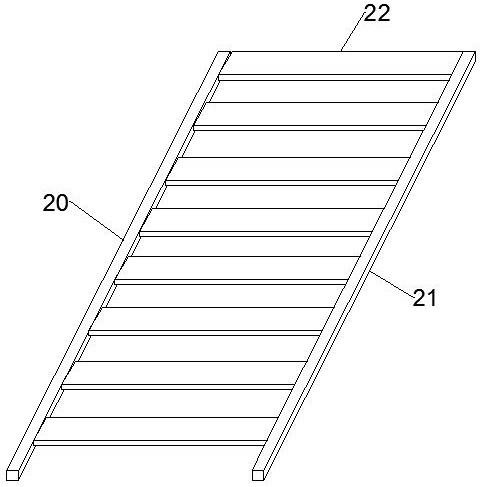

[0035] Such as Figure 1-5 As shown, the prefabricated building stereotyped protective staircase and its construction method according to the embodiment of the present invention include supporting bottom beam one 1 and supporting bottom beam two 2, and the top of the supporting bottom beam one 1 and the supporting bottom beam two 2 One end of each is provided with a support column one 3, and the other end of the support bottom beam one 1 and the support bottom beam two 2 tops are all provided with a support column two 4, between the support column one 3 and the support column A number of supporting beams 5 are arranged between the two 4, one side of the top of the supporting beam 5 is provided with a staircase unit assembly one 6, and the top of one side of the staircase unit assembly one 6 is provided with a staircase unit assembly two 7, the A corner platform 8 matching the staircase unit assembly 1 6 and the staircase unit assembly 2 7 is provided at the middle position of ...

Embodiment 2

[0038] Such as Figure 1-5As shown, one end of the top of the supporting bottom beam 1 and the supporting bottom beam 2 is provided with a supporting column 1 3, and the other end of the supporting bottom beam 1 and the top of the supporting bottom beam 2 are all provided with There are supporting columns two 4, and several supporting beams 5 are arranged between the supporting columns one 3 and between the supporting column two 4, and one side of the top of the supporting beams 5 is provided with a staircase unit assembly one 6, and the The top of one side of the stair unit assembly 6 is provided with a stair unit assembly two 7, and the middle position of the side of the support column two 4 away from the support column one 3 is provided with the stair unit assembly one 6 and the stair unit The corner platform 8 matched with the component two 7, the side of the top of the corner platform 8 is provided with a guardrail 9, and the side of the top of the corner platform 8 away ...

Embodiment 3

[0040] Such as Figure 1-5 As shown, one end of the top of the supporting bottom beam 1 and the supporting bottom beam 2 is provided with a supporting column 1 3, and the other end of the supporting bottom beam 1 and the top of the supporting bottom beam 2 are all provided with There are supporting columns two 4, and several supporting beams 5 are arranged between the supporting columns one 3 and between the supporting column two 4, and one side of the top of the supporting beams 5 is provided with a staircase unit assembly one 6, and the The top of one side of the stair unit assembly 6 is provided with a stair unit assembly two 7, and the middle position of the side of the support column two 4 away from the support column one 3 is provided with the stair unit assembly one 6 and the stair unit The corner platform 8 matched with the component two 7, the side of the top of the corner platform 8 is provided with a guardrail 9, and the side of the top of the corner platform 8 away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com