Omnidirectional cataclastic rock mass deep hole installation and recovery device of microseismic unidirectional sensor

A recovery device and sensor technology, applied to seismic signal receivers, etc., can solve problems such as increased prediction costs, failure to recover, damage to sensor cables, etc., and achieve good coupling and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

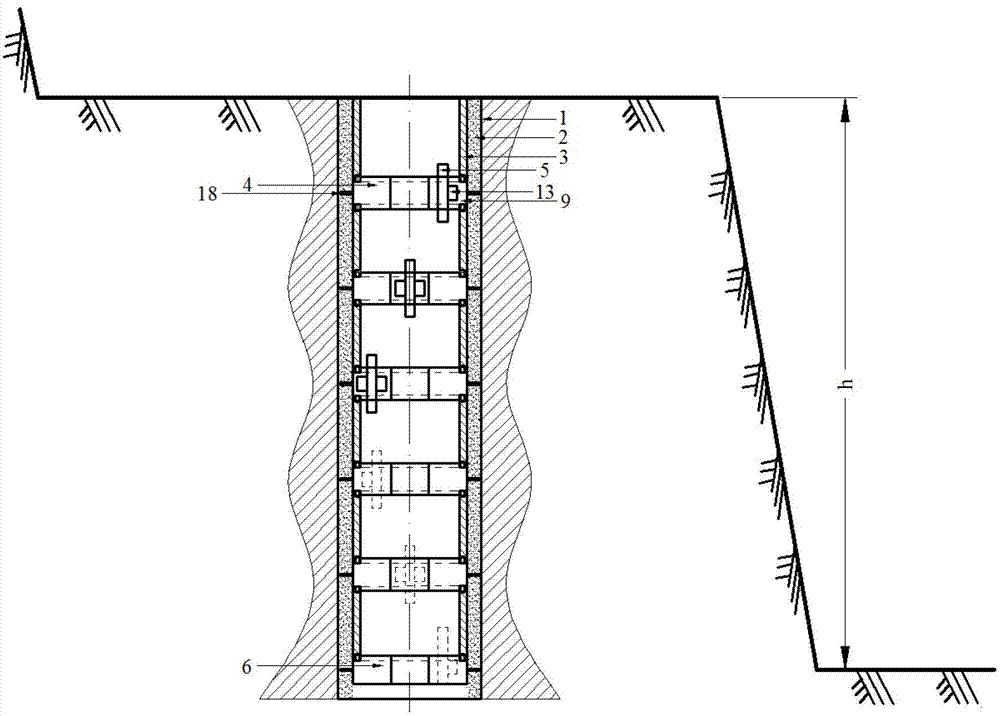

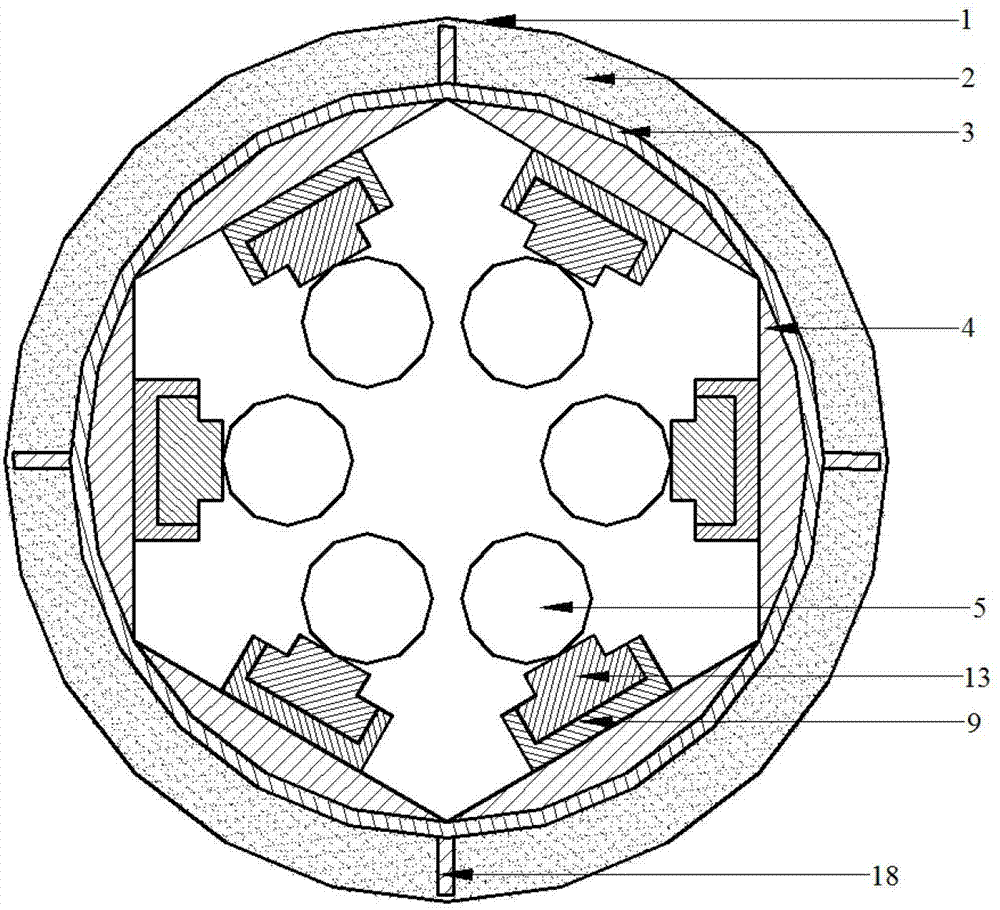

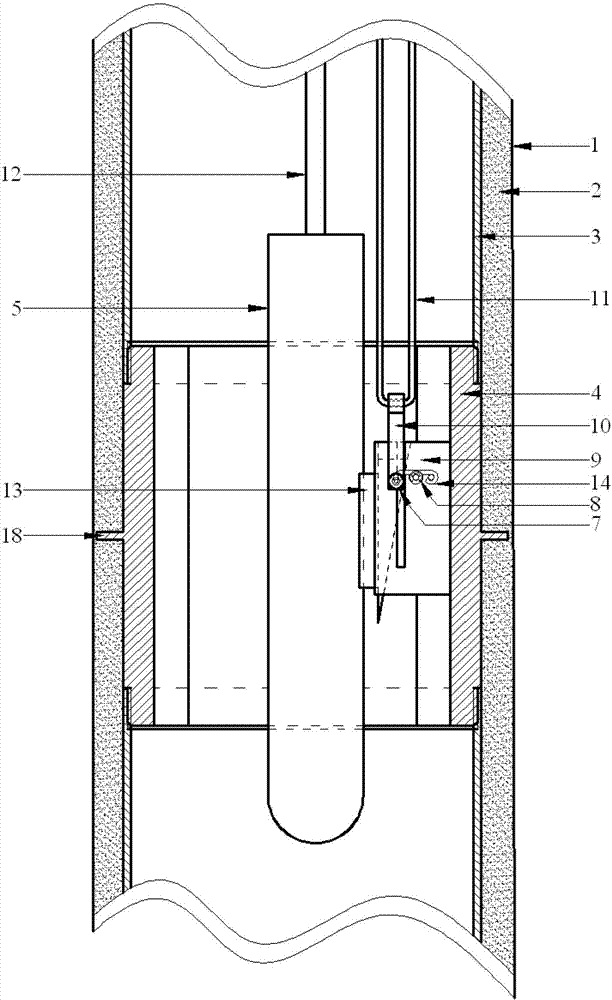

[0046] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047]A microseismic one-way sensor fractured rock mass omnidirectional deep hole installation and recovery device, including a sleeve 3 buried in the rock mass borehole 1, and a one-way sensor fixing device is installed in each predetermined depth and direction in the sleeve 3 , the one-way sensor fixing device includes an intermediate joint 4, a wedge fitting body 9, a wedge body 13, a one-way sensor 5, a tensile cable 12, an elastic pressing device and a pulling lifting device,

[0048] The intermediate joint 4 is arranged on the inner wall of the sleeve 3. The wedge fitting body 9 is connected to the intermediate joint 4 and is provided with a wedge fitting body female groove 23. The wedge body 13 is adapted to the wedge fitting body female groove 23 and is connected to the one-way sensor 5 Connection, tension cable 12 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com