A deep hole installation and recovery device for microseismic sensors in water-containing soft rock and soil

A technology of microseismic sensor and recovery device, applied in the direction of seismic signal receiver, etc., can solve the problems of waste, non-recovery, difficult installation and recovery of sensors, etc., and achieves the effect of high reuse rate and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

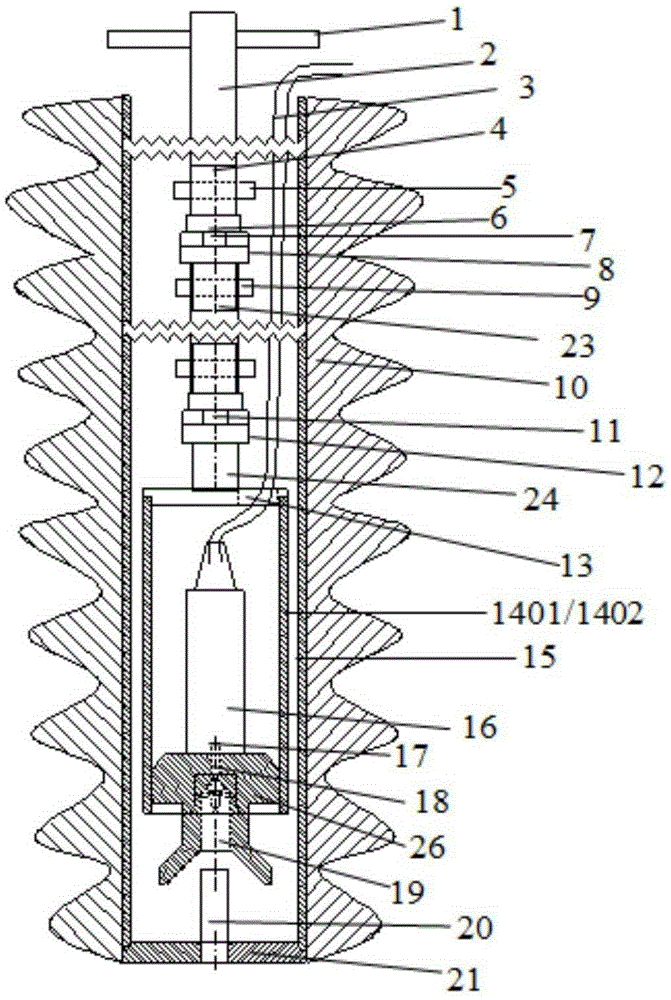

[0049] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

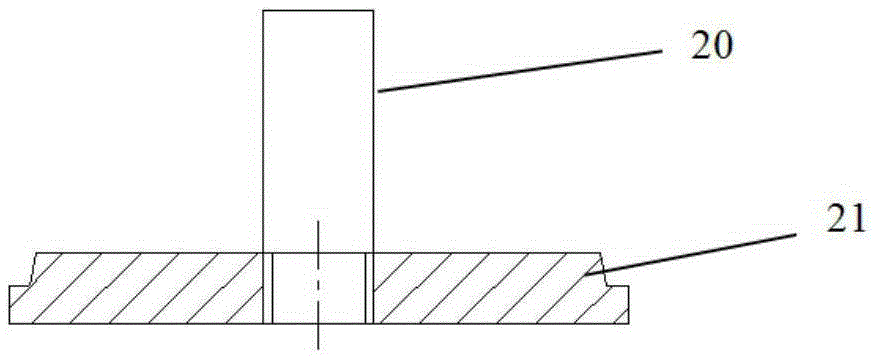

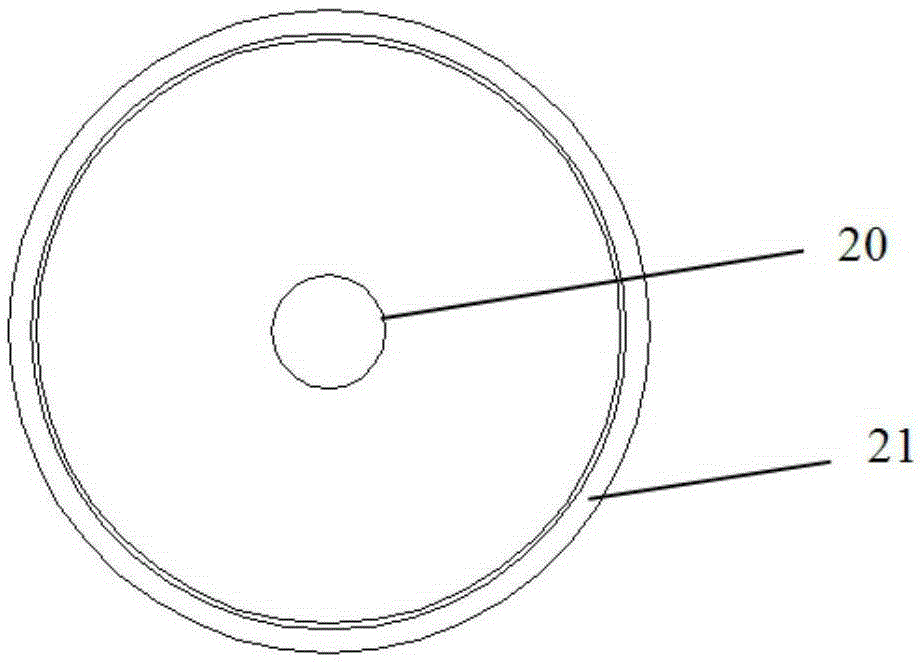

[0050] A device for installation and recovery of deep holes in watery and weak rock and soil for microseismic sensors, including a hot-dip galvanized pipe 15 arranged in a pre-drilled hole, a base 21 sealed and arranged at the bottom of the hot-dip galvanized pipe 15, and a detachable connection Several operating rods 2, the sensor base 26 connected with the sensor 16, the installation sleeve 1401 and the recovery sleeve 1402 that are all detachably connected with the operating rod 2, the base 21 is provided with a base outer stud 20, the sensor base The side of the sensor base 26 is provided with a sensor base convex body 27, the installation sleeve 1401 and the recovery sleeve 1402 are provided with a sleeve card slot 22, and the bottom of the sensor base 26 is provided with a sensor base that is adapted to the outer stud 20 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com