Segmental box beam short line matching control and prefabrication construction method

A short-line matching and construction method technology, applied in the direction of manufacturing tools, mold fixtures, molds, etc., to reduce the optimal movement of transportation, reduce transportation costs, and ensure construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

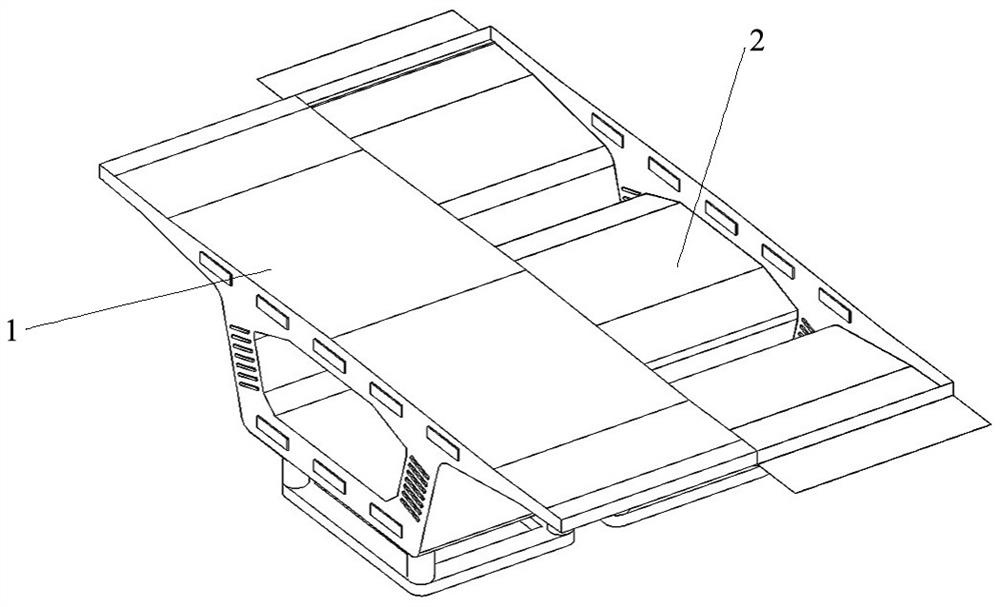

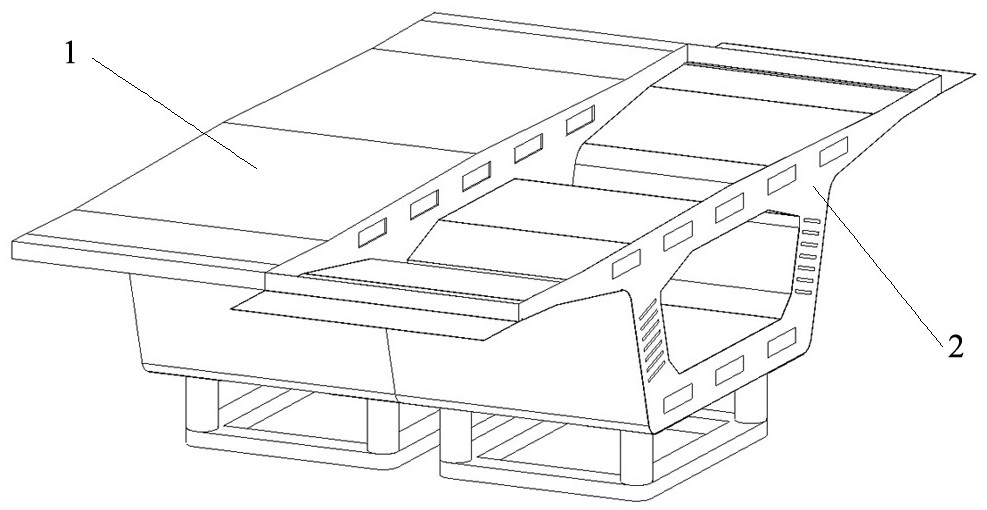

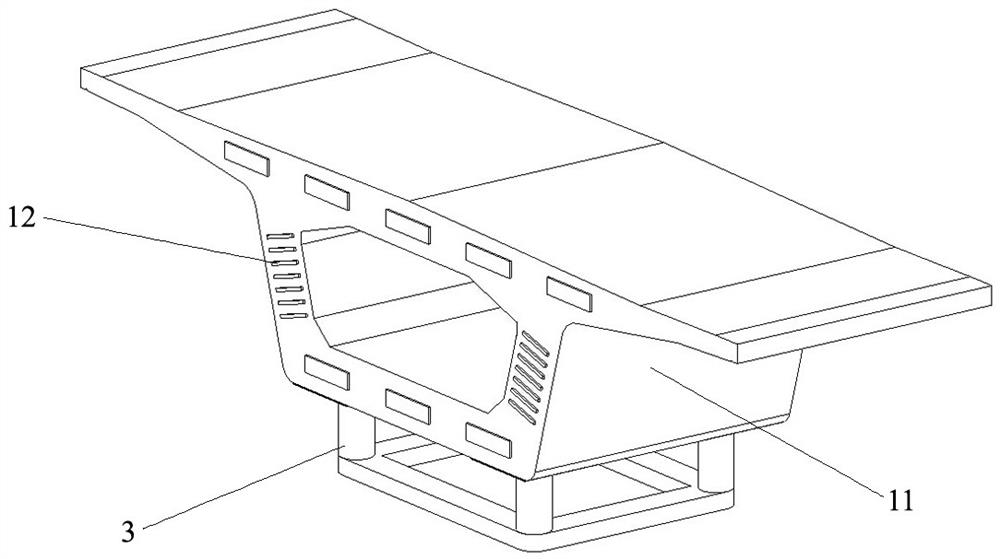

[0044] Taking the construction of a prefabricated section of a railway box girder as an example, according to the structural type of the box girder and the linear characteristics of the bridge, the box girder section is prefabricated using the short-line matching method, that is, multiple pedestals are set in the prefabricated beam yard, and each pedestal is operated simultaneously. All beam sections are poured on prefabricated pedestals. When pouring, except that the prefabricated initial beam section of each span beam section is poured with a fixed end formwork 24 at one end and a movable end formwork 24 at one end, the remaining beam sections use a fixed end formwork 24 at one end and the poured previous beam section at the other end. Section 1 of the matching beam is poured to ensure the splicing accuracy of the matching joints of adjacent beam sections. After the initial health maintenance and form removal of the newly poured beam section, the first section of the matching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com