Patents

Literature

38results about How to "Guaranteed pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

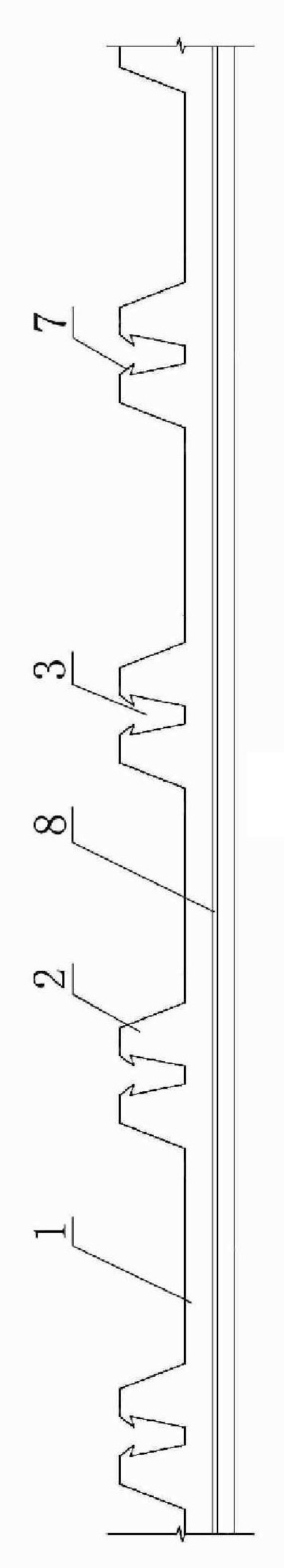

Fastening strip and fastening network framework

ActiveCN101457572AGuaranteed pouringSolve the problem of convenient and quick fixWallsForms/shuttering/falseworksFloor slabStructural element

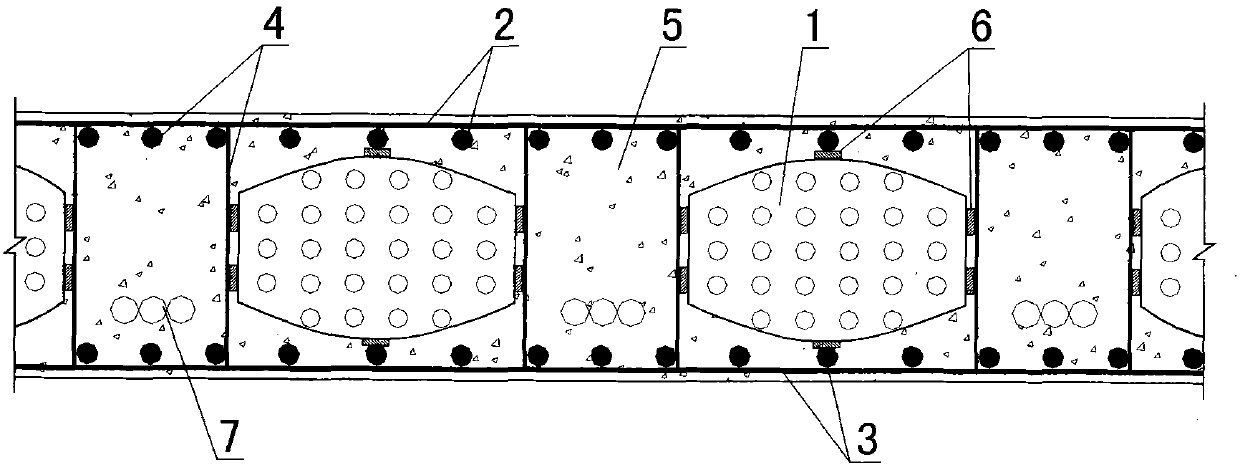

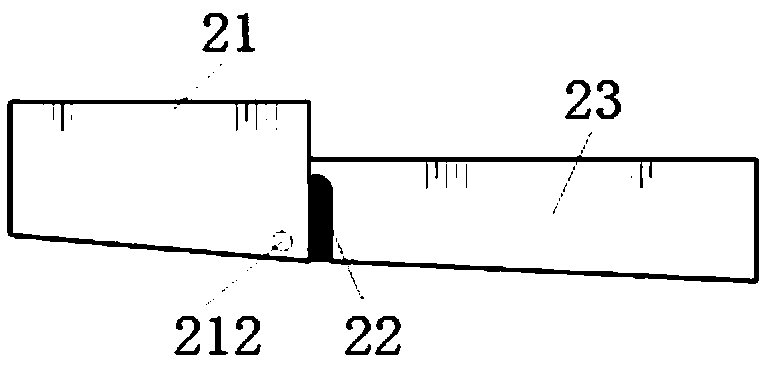

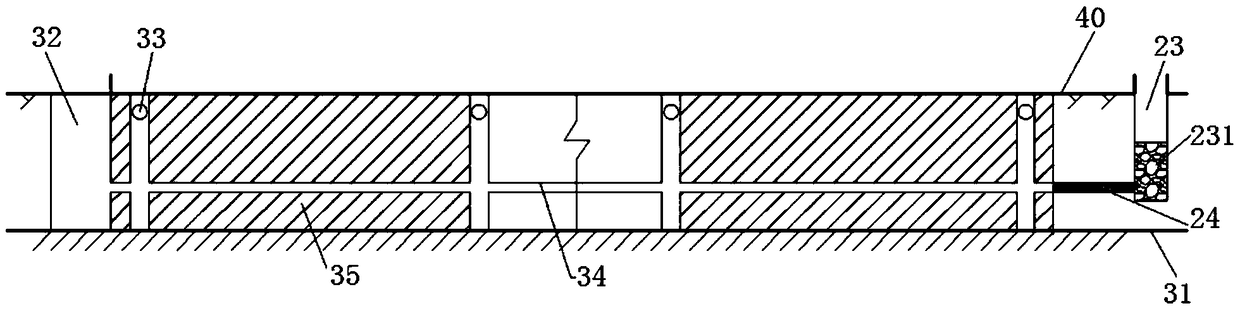

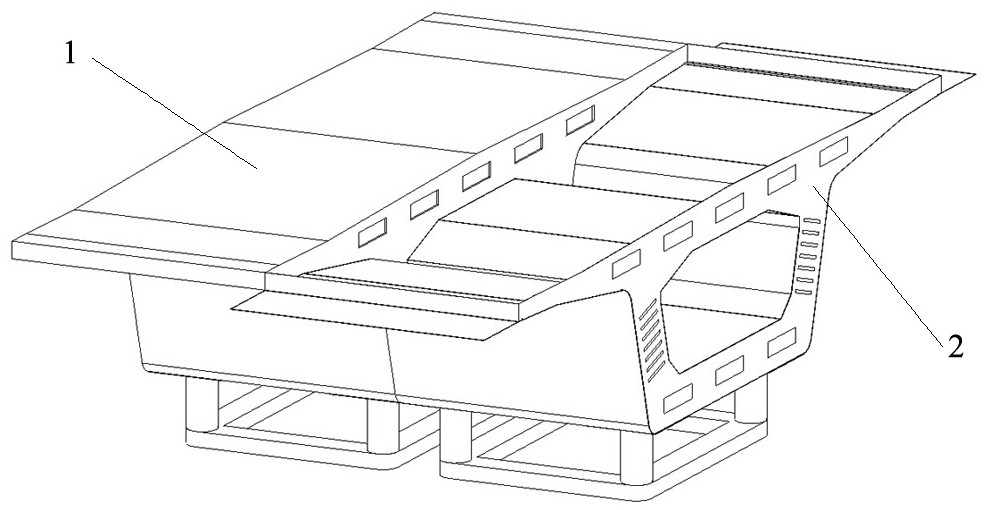

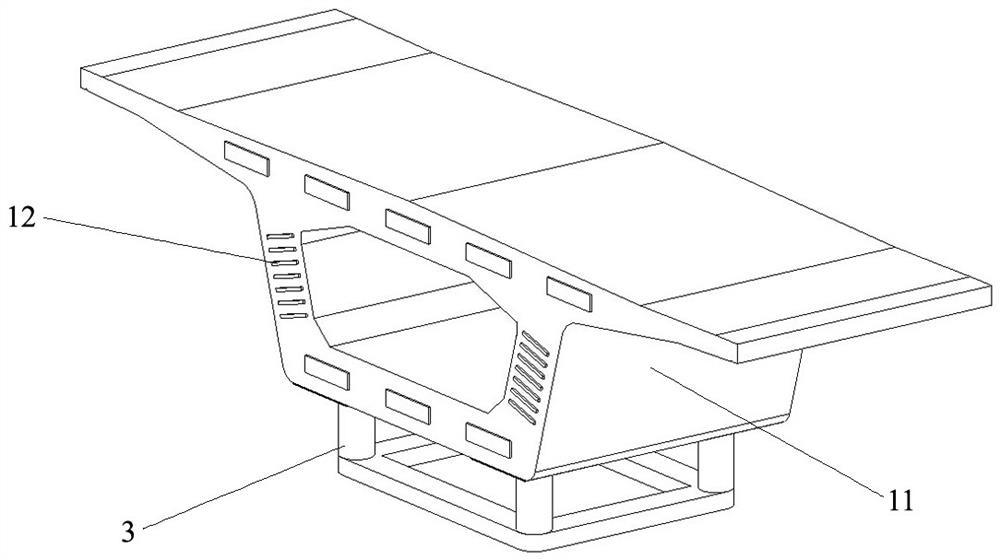

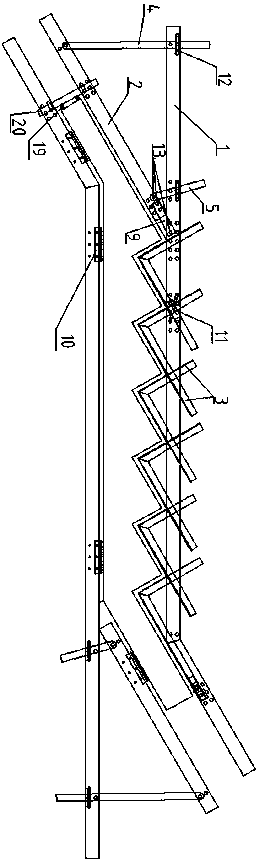

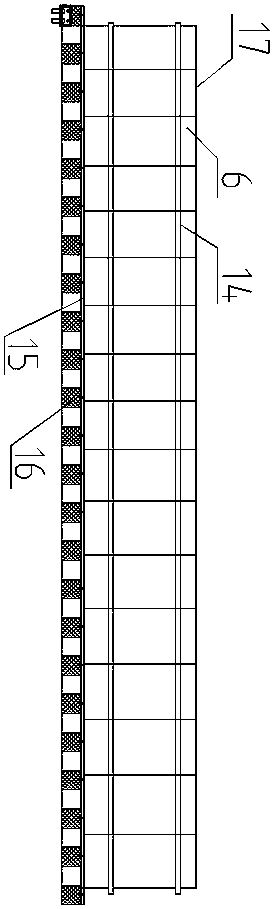

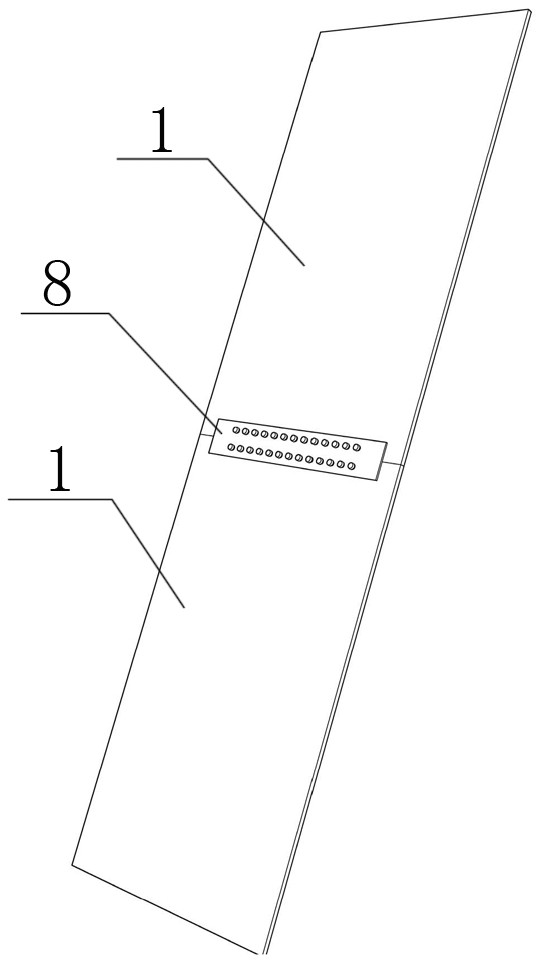

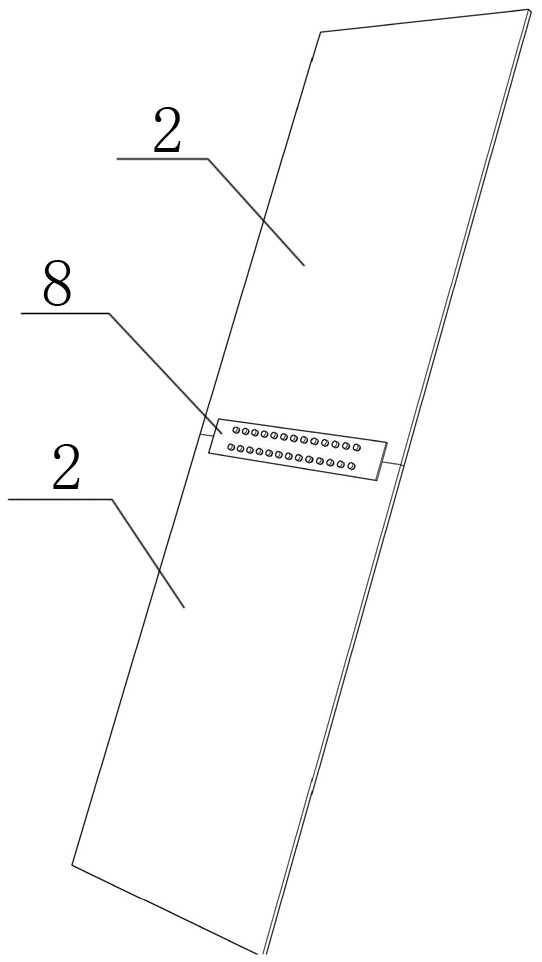

The invention relates to a blocking strip and a blocking net framework. The blocking strip comprises at least two strip sides, at least one of which is provided with convex teeth that are provided with breaches, the breaches are internally provided with agnails or barbs. The blocking net framework can be made by applying the blocking strip, and is formed by connecting keels, the blocking strip and a steel screen in a combining way. The keels are section steel parts and are arranged in parallel according to certain spacing; the blocking strips are vertical to the keels, arranged in parallel according to certain spacing and are fixed at one side or two sides of the keels to form a steel frame; the steel screen is distributed with a longitudinal convex rib as well as fish scales holes or meshes on the surface; the steel screen is attached to the outer surface of the steel frame, and is firmly and conveniently blocked and connected with the blocking strip. The invention solves the problems of composition and construction of a steel screen concrete member as well as the reinforcement of a steel screen concrete wall body. Meanwhile, the invention realizes large-scale and mechanized production, and is suitable for various building structural elements, especially for the structures of multilayer and high residential building wall bodies and floor slabs.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

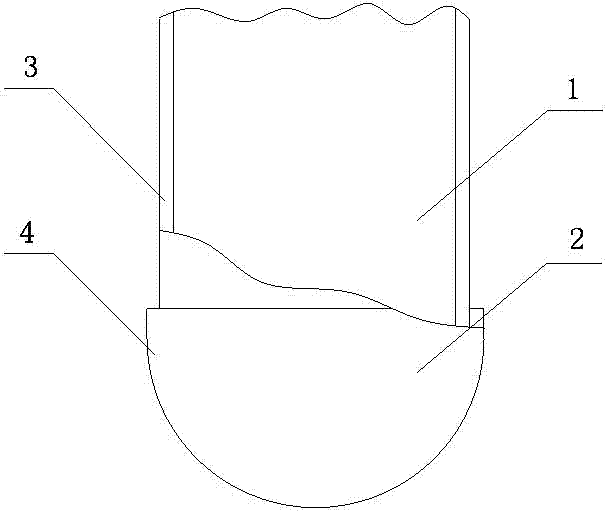

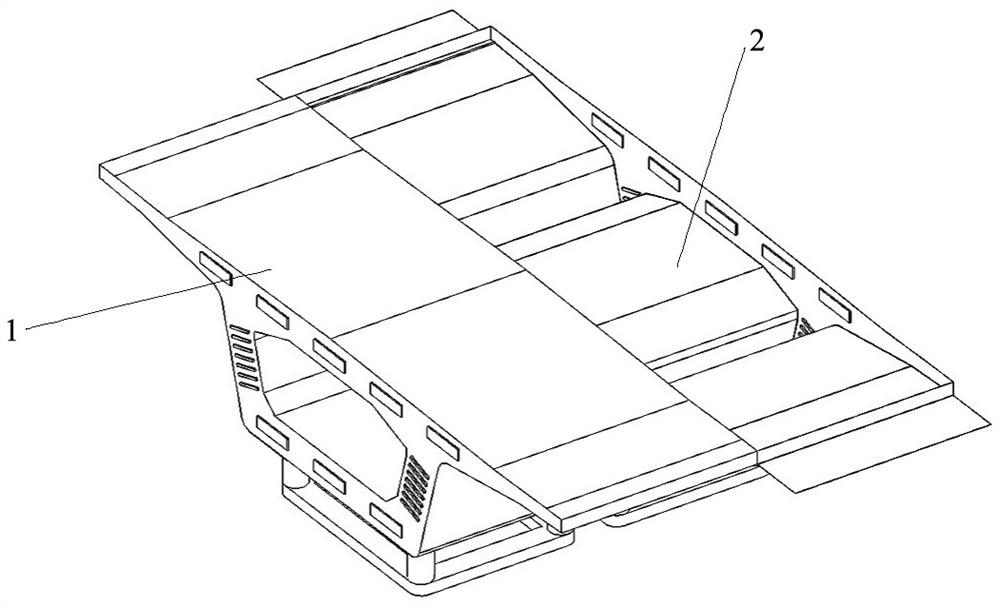

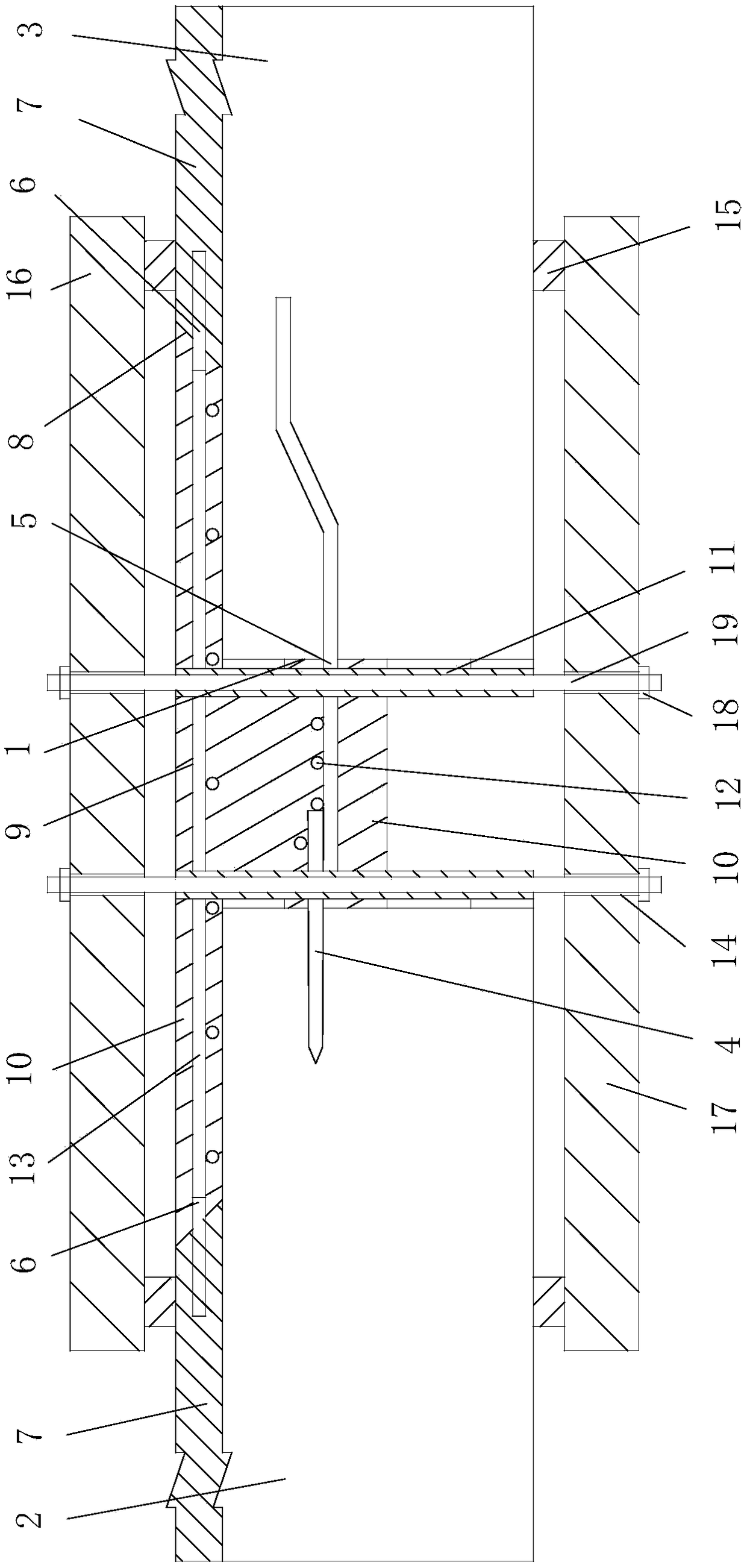

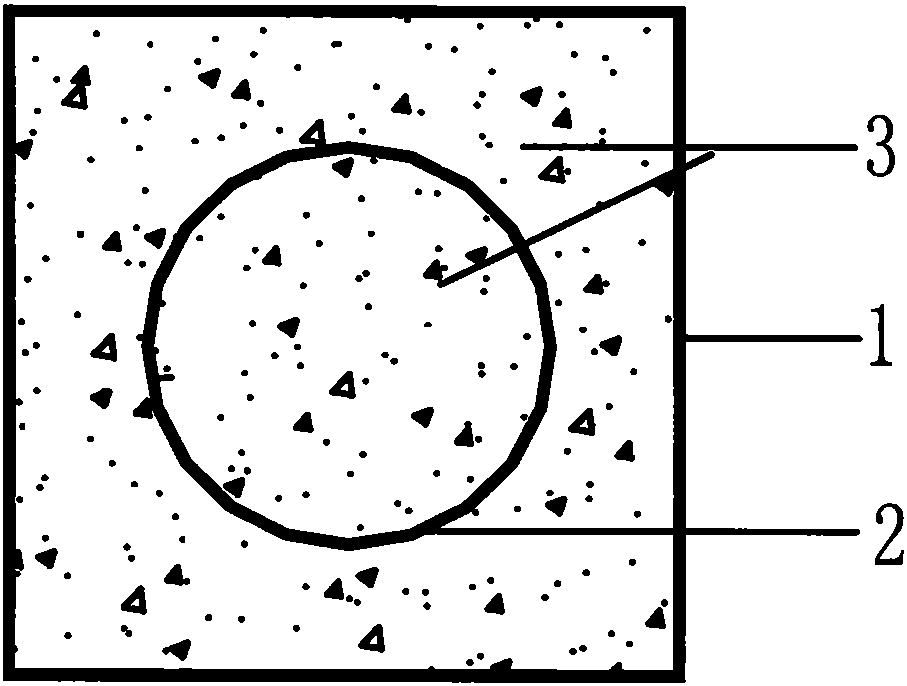

Hollow floor system filled with an air-filling bag and construction method thereof

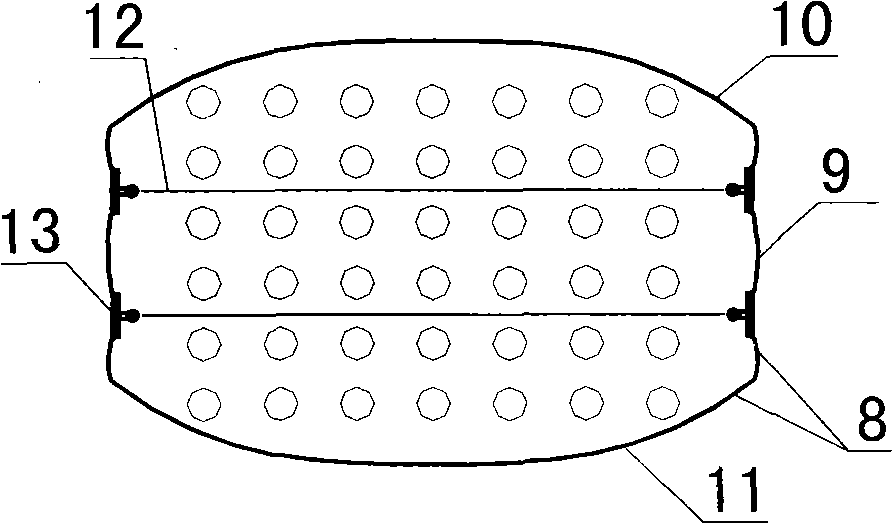

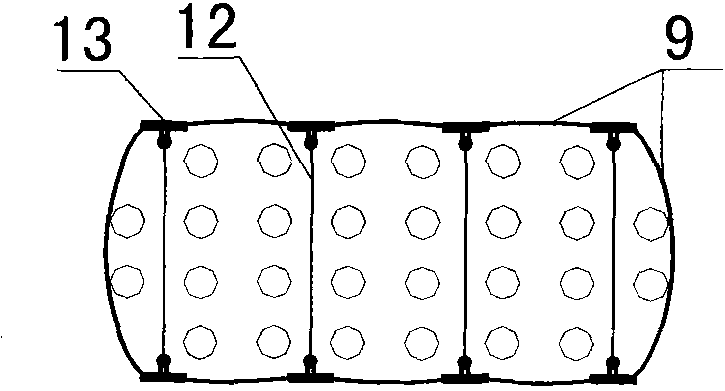

InactiveCN101793070AGood technical and economic indicatorsReasonable forceFloorsEngineeringSteel bar

The invention relates to a hollow floor system filled with an air-filling bag and a construction method thereof, belonging to the field of the structure of the common building. The hollow floor system consists of the air-filling bag (1), upper steel bars (2), lower steel bars (3), hidden girder steel bars (4) and concrete (5), wherein the air-filling bag (1) is positioned among the upper steel bars (2), the lower steel bars (3) and the hidden girder steel bars (4); a bag wall (8) of the air-filling bag (1) consists of four side walls (9), an upper wall (10) and a lower wall (11); the shapes of at least two side walls (9) adjacent to the hidden girder steel bars (4) in the air-filling bag (1) are planes; the shapes of the upper wall (10) and the lower wall (11) are heaved-outward arc surfaces; and positioning pieces (12) are arranged among the inner sides of the side walls (9) so as to ensure that the two side walls (9) are parallel mutually. The hollow floor system has large span, better reliability, earthquake resistance and crack resistance, and good economy and applicability.

Owner:徐焱

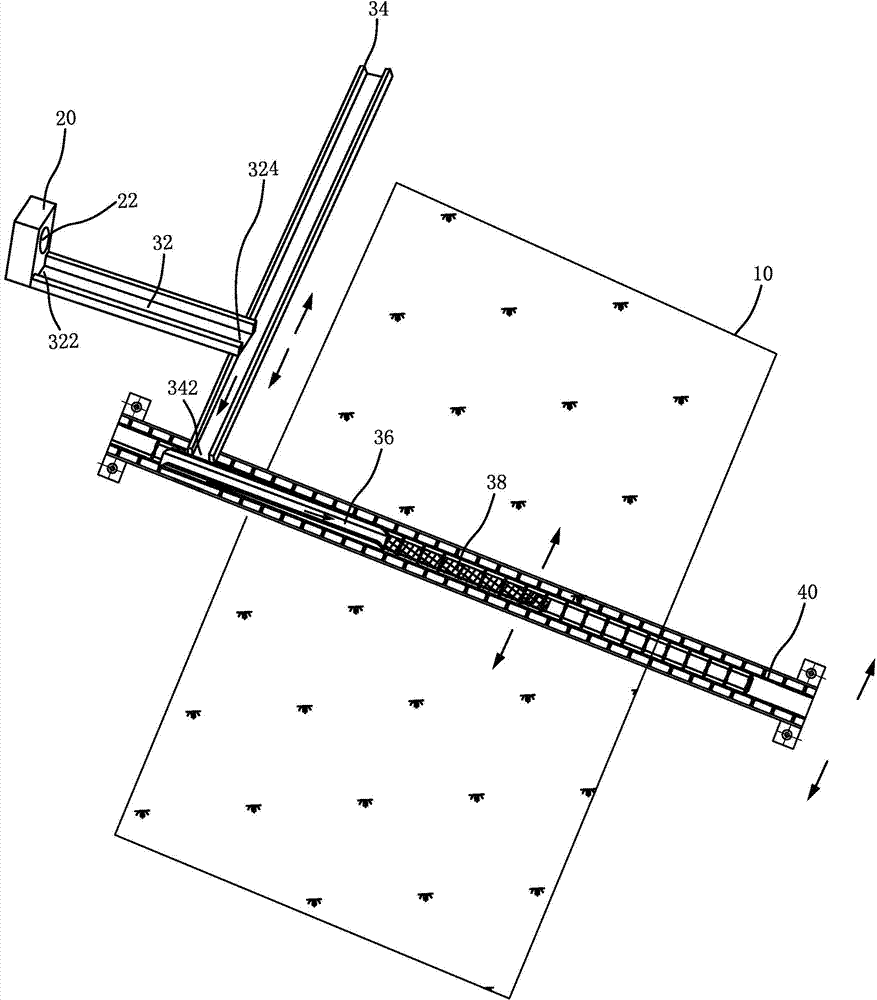

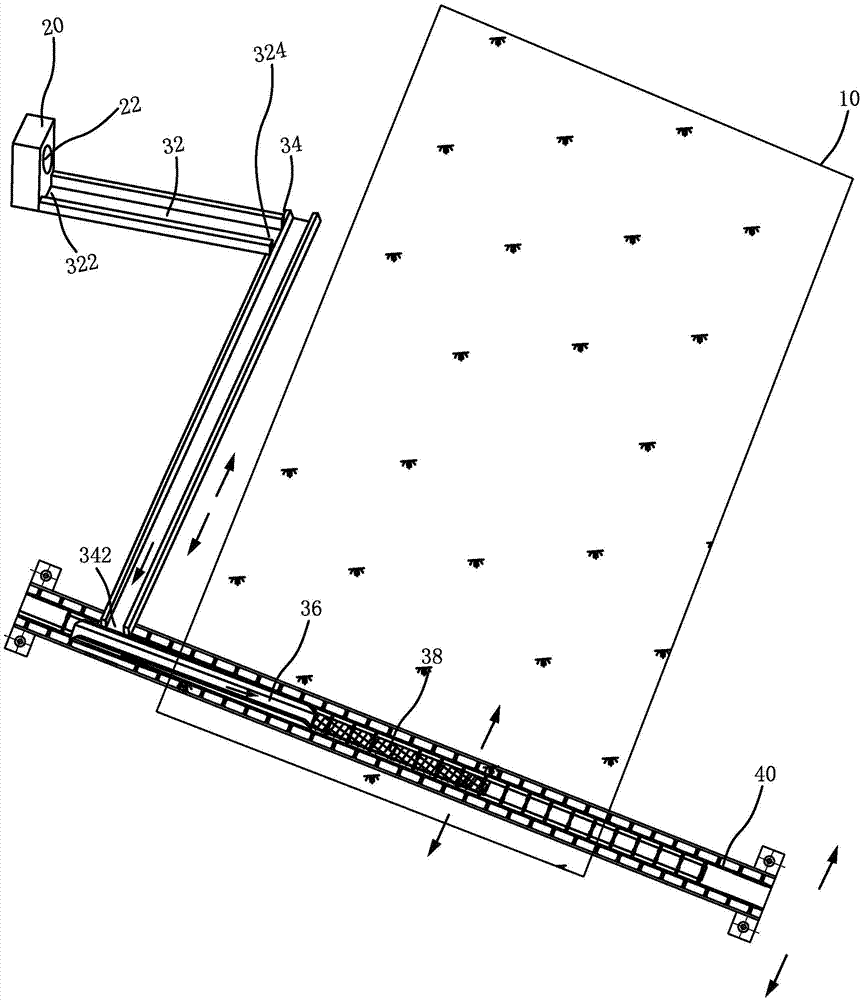

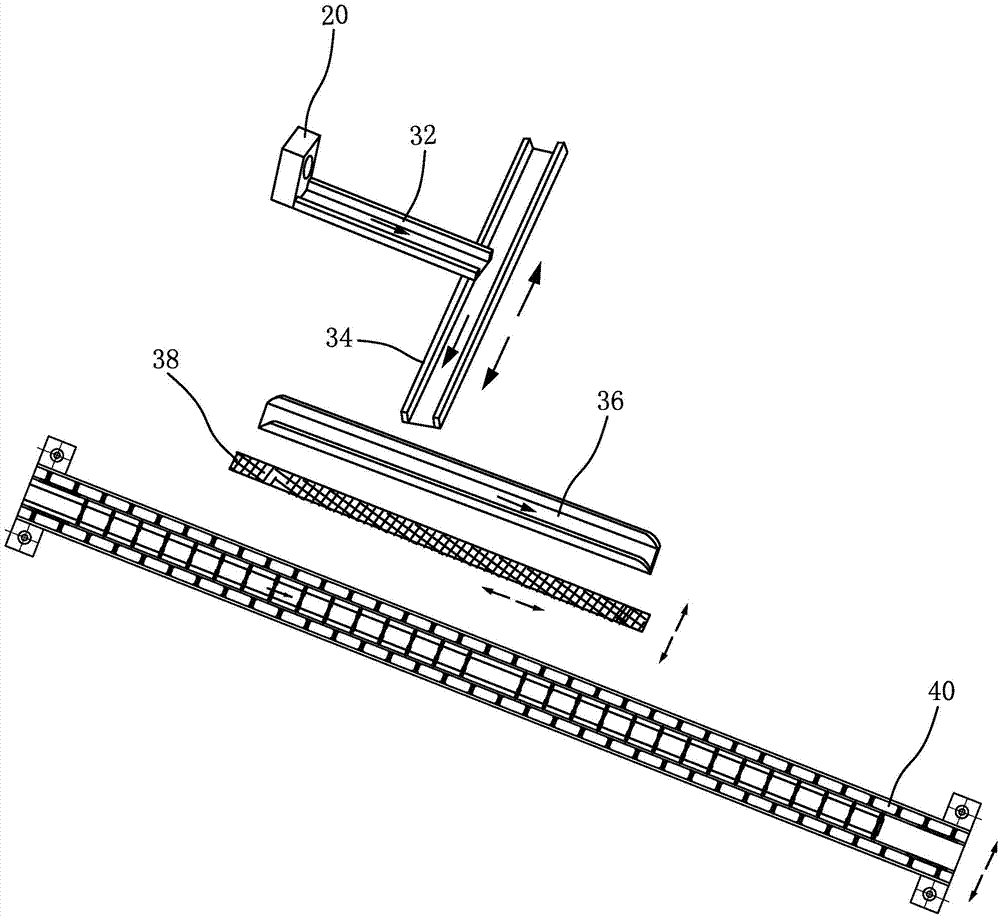

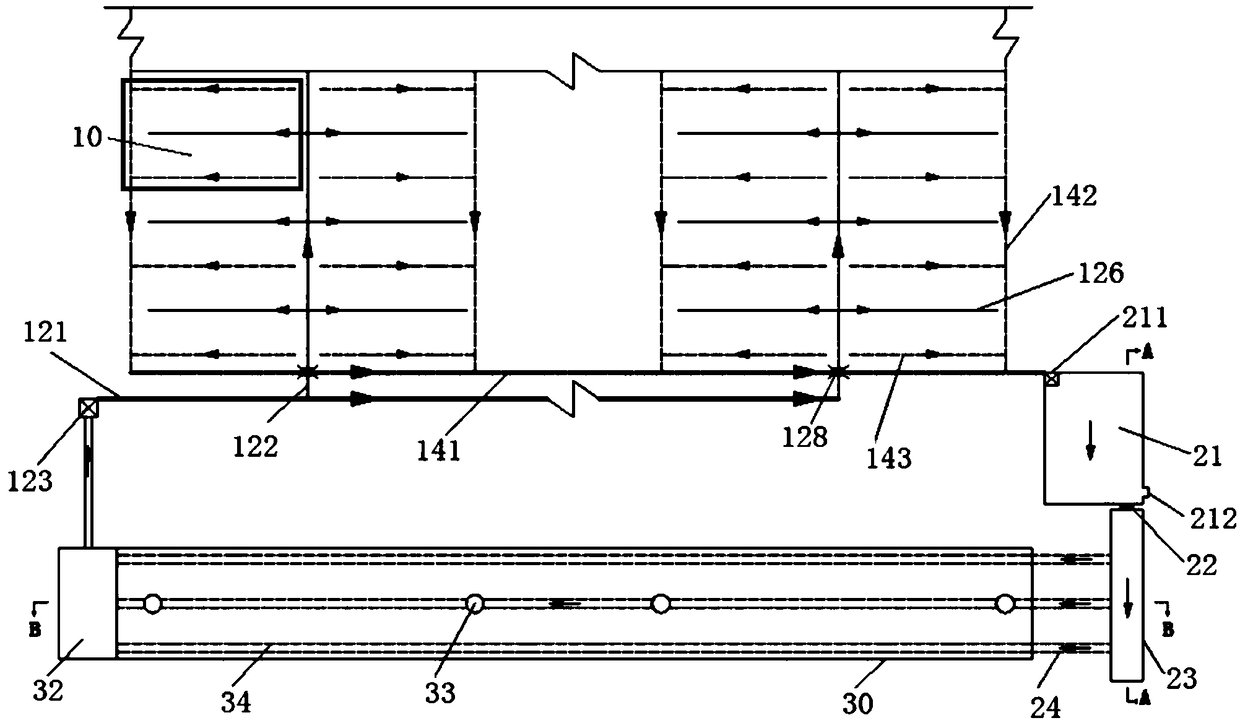

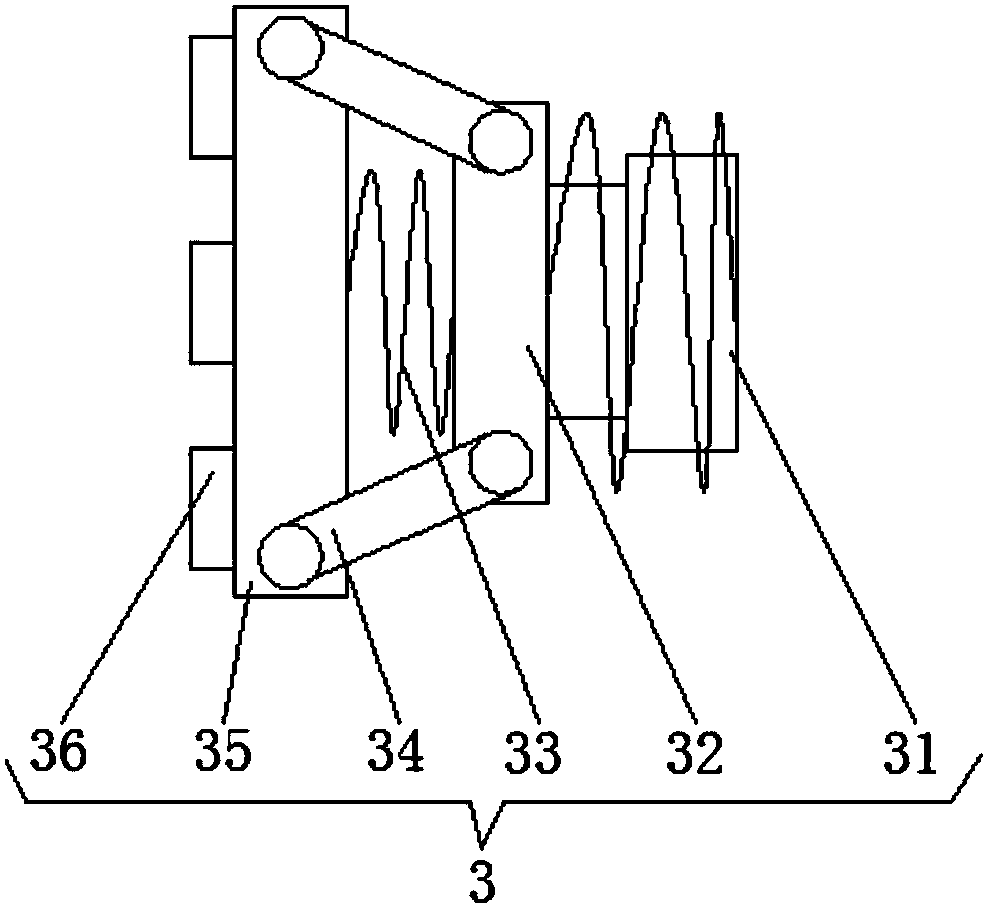

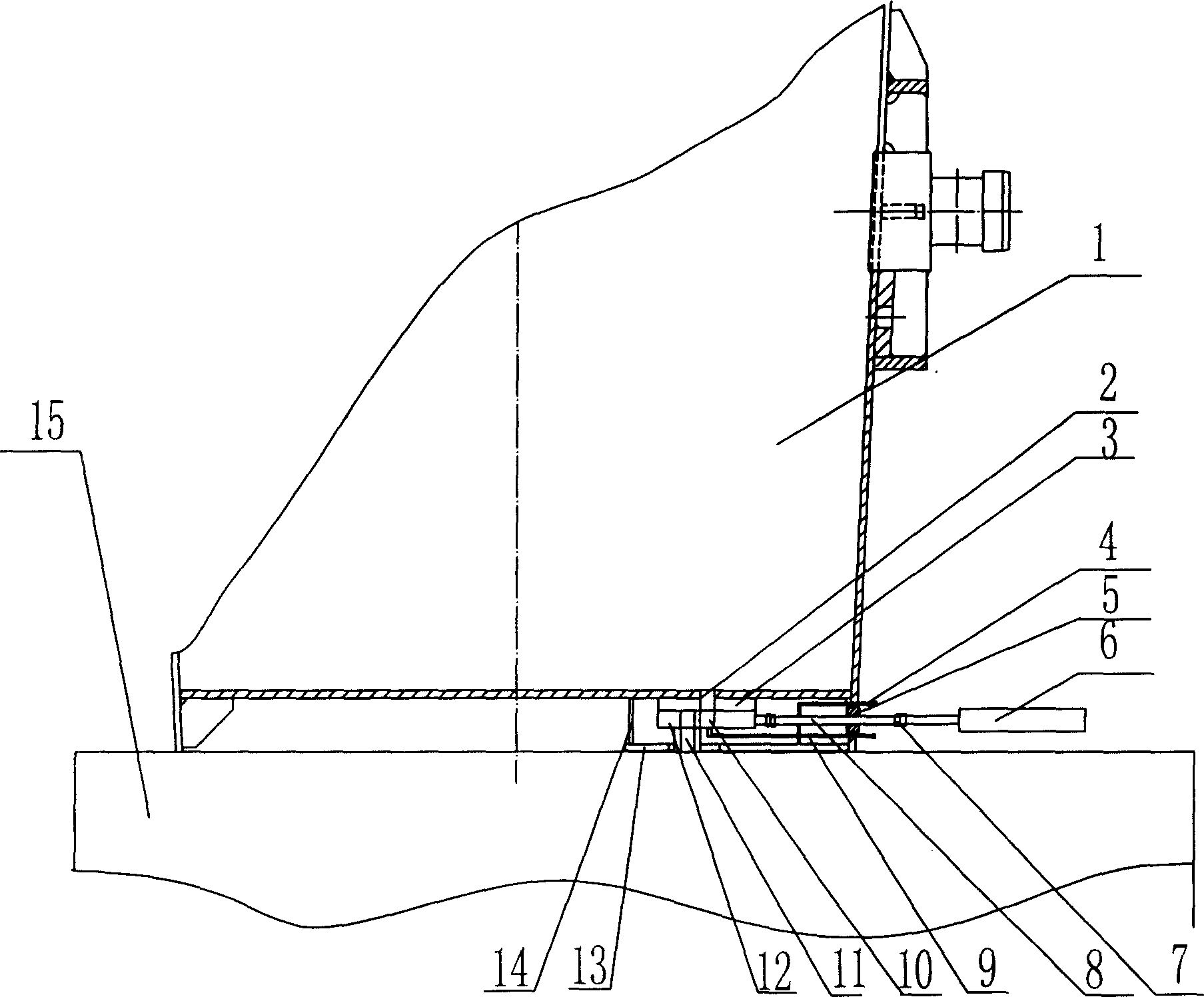

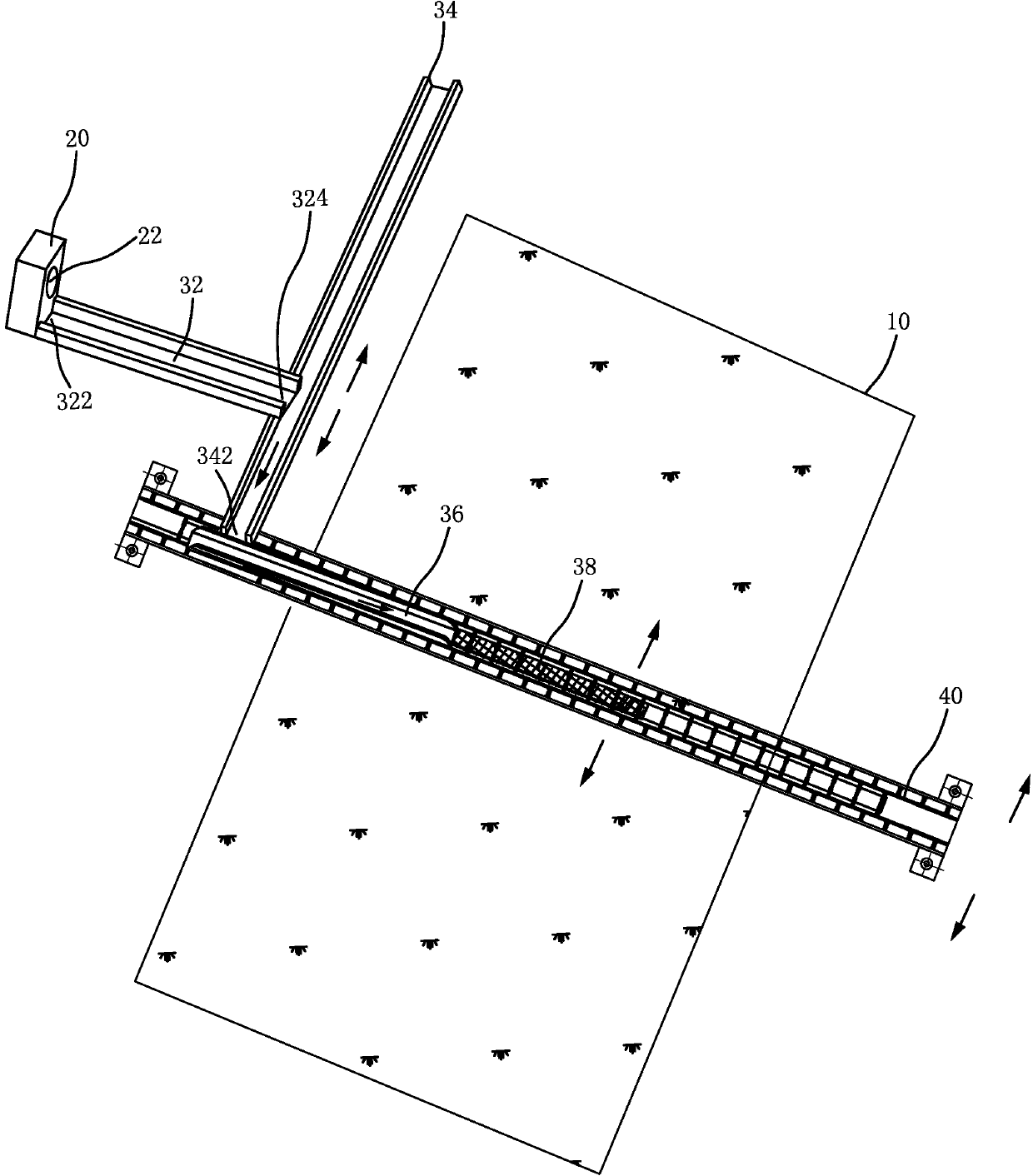

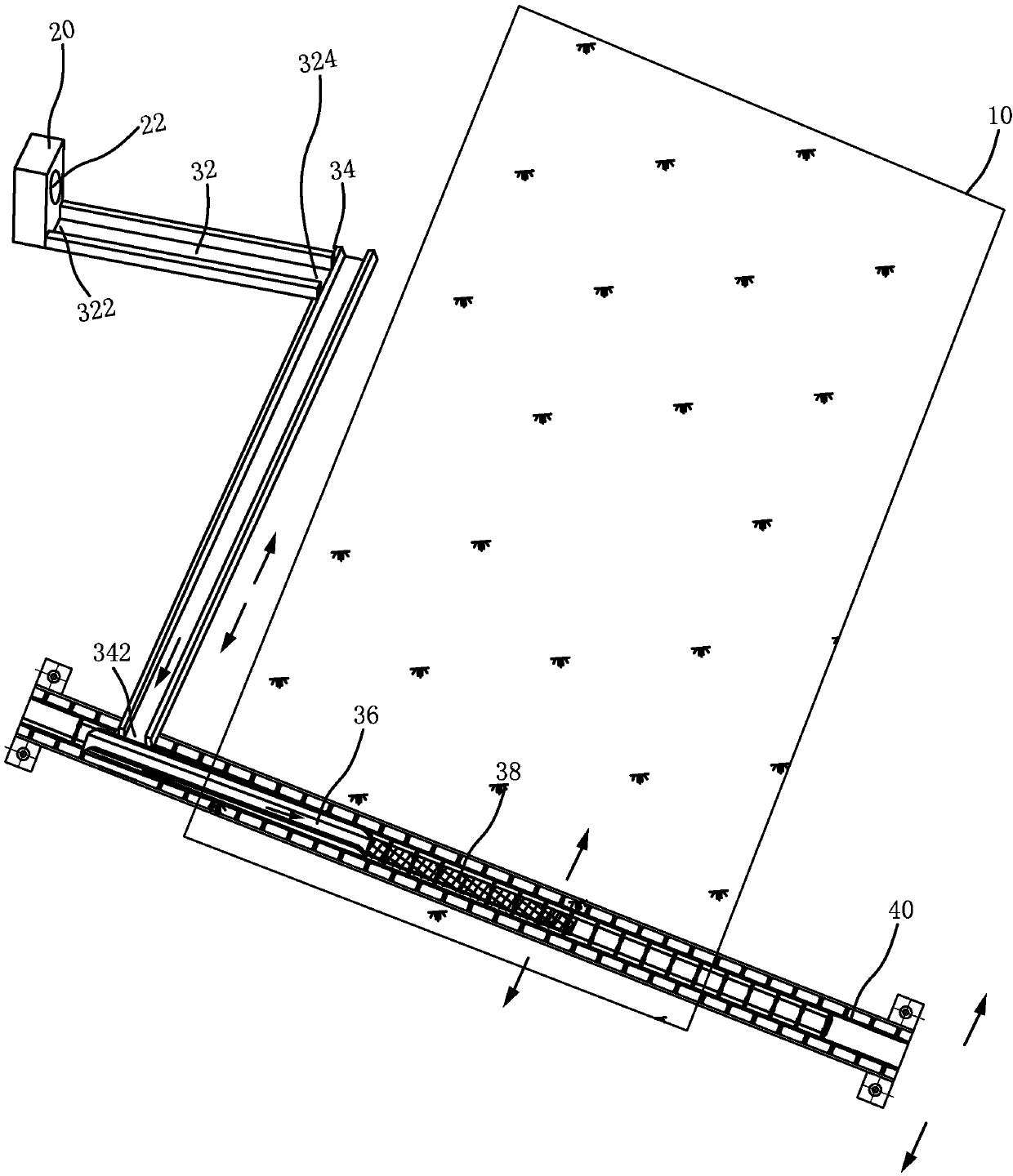

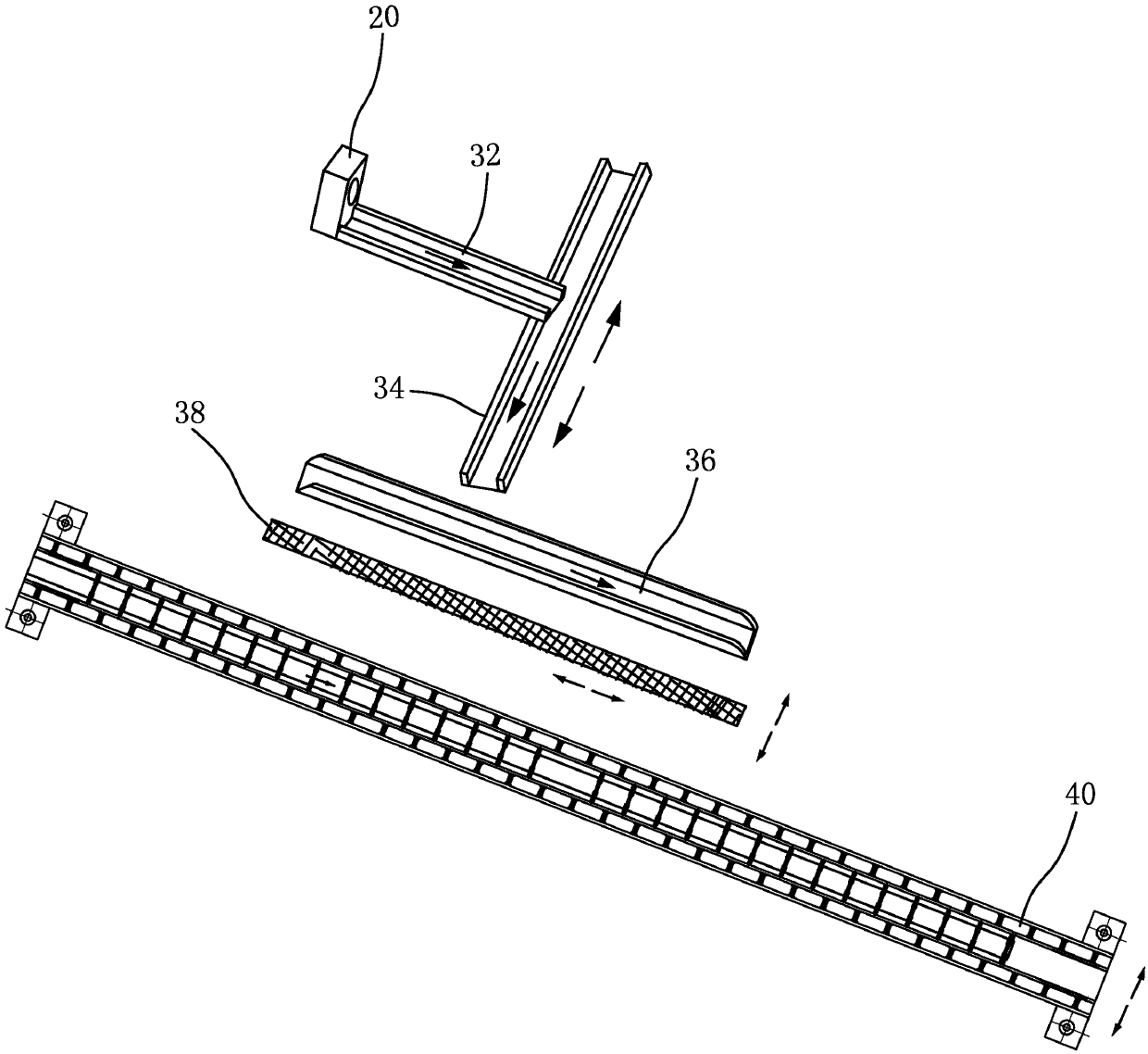

Concrete distributing and conveying system

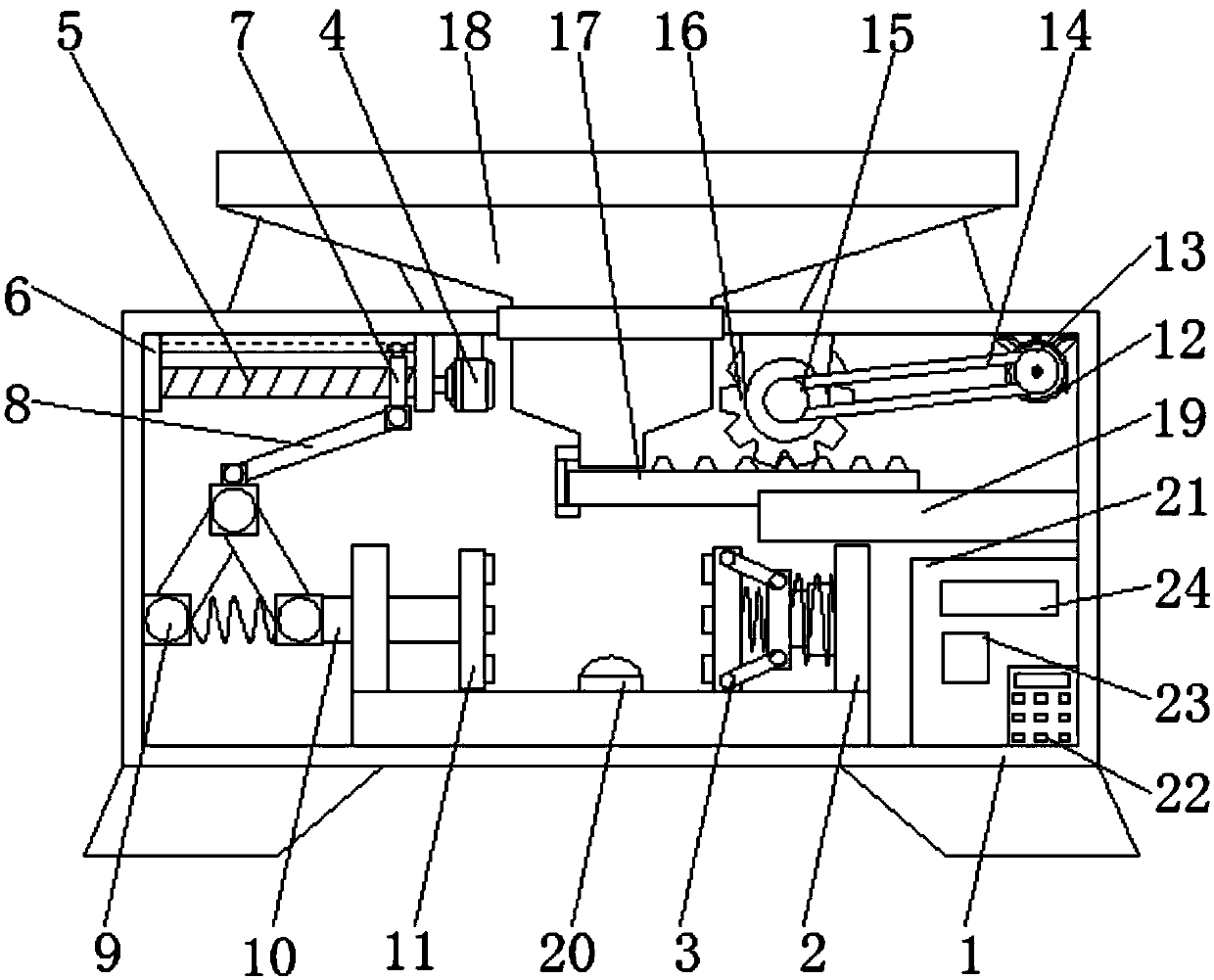

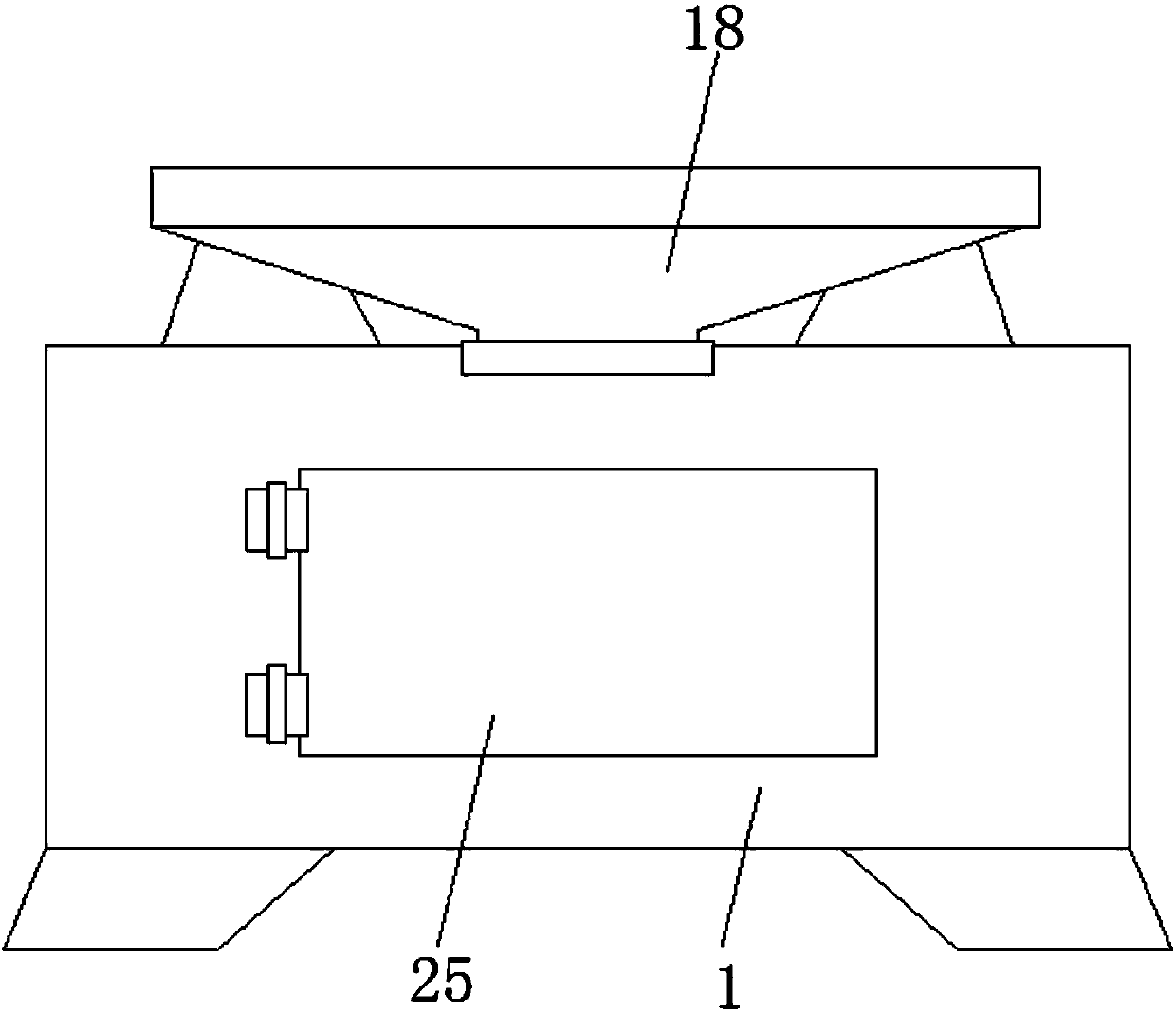

The invention relates to a concrete distributing and conveying system. The system comprises a hopper, a conveyer belt, a cross beam and a to-be-poured area, wherein the cross beam stretches across the upside of the to-be-poured area, the conveyer belt comprises a first conveyer belt, a second conveyer belt, a third conveyer belt and a fourth conveyer belt, which are sequentially arranged from top to bottom, a feeding hole of the first conveyer belt is connected with a discharge hole of the hopper, the second conveyer belt is arranged below the discharge hole of the first conveyer belt, the third conveyer belt is arranged below the discharge hole of the second conveyer belt, the third conveyer belt is fixedly arranged on the cross beam, the fourth conveyer belt is arranged right below the third conveyer belt, the third conveyer belt rotates for transmission in a direction far away from the direction of the second conveyer belt, and a forwardly and backwardly rotating motor is arranged between the fourth conveyer belt and the cross beam, so that the fourth conveyer belt can move longitudinally on the cross beam back and forth and can rotate backwardly and forwardly, and the material is ensured to be discharged from two ends of the fourth conveyer belt. The fourth conveyer belt is driven to longitudinally move forth and back and rotate forwardly and backwardly through the movement of the cross beam and the forwardly and backwardly rotating motor, so that the concentrate is poured and is ensured to be poured in all places of the to-be-poured area.

Owner:ZHEJIANG TIANSHENG BUILDING MATERIALS CO LTD

Anti-adhesive coating and monolithic stopper using anti-adhesive coating

ActiveCN104497650AHigh strengthImprove high temperature strengthMelt-holding vesselsCoatingsCold resistanceAluminium oxides

The invention discloses an anti-adhesive coating and a monolithic stopper using the anti-adhesive coating. The anti-adhesive coating is prepared from white corundum, clay, aluminum oxide and a binding agent, and the outer surface of the stopper head of the monolithic stopper is coated with the anti-adhesive coating layer. The anti-adhesive coating layer has the advantages of good scouring resistance, erosion resistance and sudden heat and cold resistance, adhesion between the stopper and an intermediate tundish nozzle can be effectively avoided, normal casting start of continuous casting production is guaranteed, and the service life of the stopper and the water gap is greatly prolonged.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

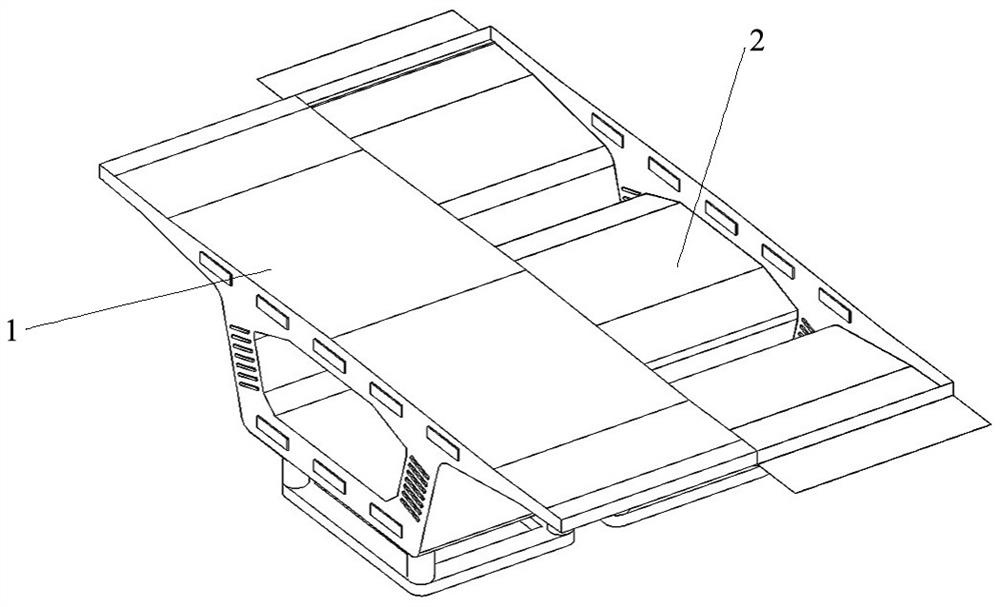

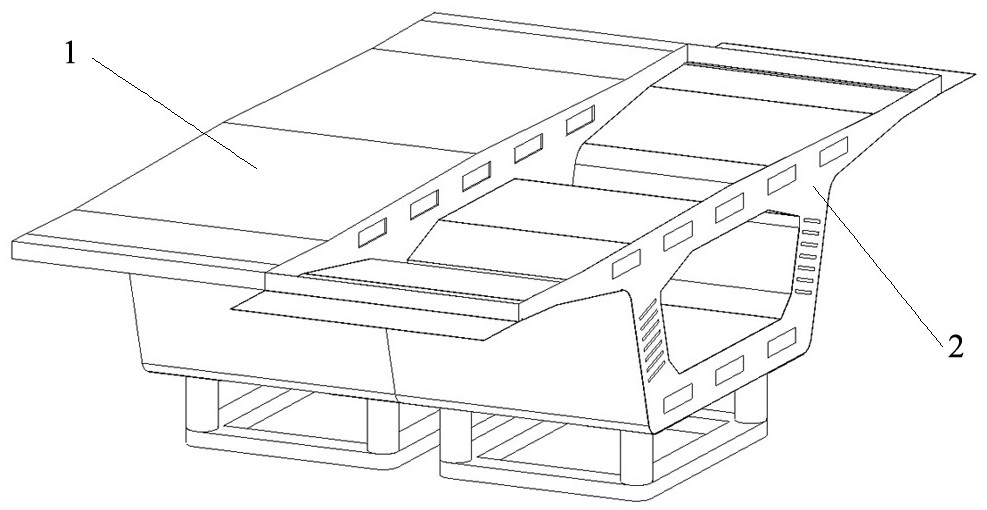

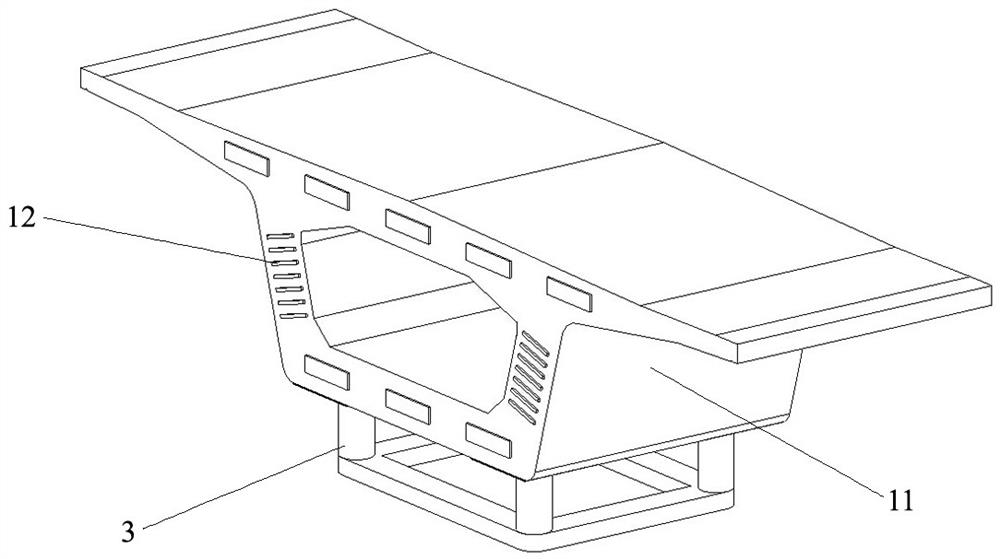

Segmental box beam short line matching control and prefabrication construction method

ActiveCN112060307AEffective organizationEnsure construction efficiencyMouldsCeramic shaping plantsControl systemConstruction engineering

The invention discloses a segmental box beam short line matching control and prefabrication construction method. The method comprises the following steps that firstly, a beam field is divided into functional areas; secondly, end beams are manufactured in a beam manufacturing area; thirdly, a cast-in-place beam formwork is installed; fourthly, a tied steel reinforcement framework is put in, and theposition is controlled and checked; fifthly, concrete is poured into the cast-in-place beam formwork; sixthly, cast-in-place beams serve as matching beams to be prefabricated circularly, until pouring of adopted beam bodies is completed; and seventhly, the completed beam bodies are placed in a beam storing area to be maintained. According to the method, the beam field is divided into the functional areas, site construction flows can be organized effectively, and construction efficiency is ensured. By means of joint arrangement of a table base beam manufacturing system, a measuring control system and a supporting and adjusting platform, installing can be achieved, the position can be adjusted precisely, and real-time control can also be achieved. By means of design of a shear force key, line type butt joint of the later period can be ensured. By arranging different spraying facilities, maintaining of the later period can be carried out effectively.

Owner:中国建筑土木建设有限公司

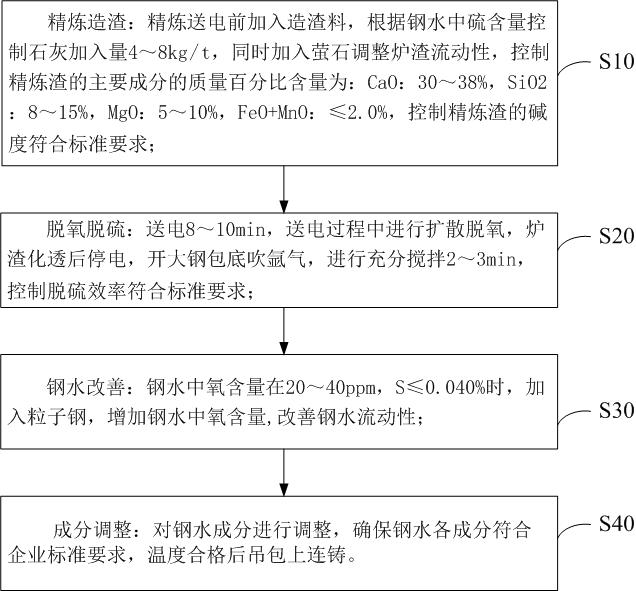

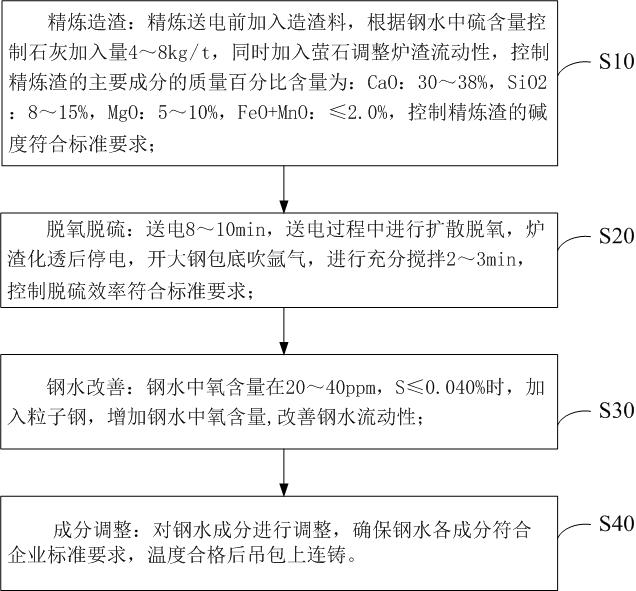

Smelting method capable of improving fluidity of molten steel after refining and desulfurizing of deformed steel bar

ActiveCN113234990AImprove the fluidity of molten steelGuaranteed normal pouringManufacturing convertersSlagSulfur content

The invention discloses a smelting method capable of improving fluidity of molten steel after refining and desulfurizing of a deformed steel bar. A deformed steel bar refining and desulfurizing process comprises the steps of converter smelting, post-furnace and argon station treatment, LF refining and continuous casting; and an LF refining process comprises the steps of: adding slag making material lime before refining and power transmission, and adding fluorite at the same time to adjust slag fluidity; controlling the alkalinity of refining slag to meet the standard requirement; carrying out diffusion deoxidation in the power transmission process, cutting off power after the slag is completely molten, expanding a steel ladle for bottom blowing argon, and controlling the desulfurization efficiency to meet the standard requirement; adding particle steel to increase the oxygen content in the molten steel and improve the fluidity of the molten steel; and adjusting the components of the molten steel to ensure that the components of the molten steel meet the standard requirement, and continuously casting on a crane ladle after the temperature is qualified. According to the technical scheme provided by the invention, after the sulfur content in the molten steel in the refining process reaches the standard requirement, a proper amount of oxidizing material high-quality particle steel is added, so that the fluidity of the molten steel is improved, a pouring nozzle is prevented from being blocked, and pouring in the continuous casting process is smooth.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Mudflat desalination method in combination with water circulation

ActiveCN108781576AReduce wasteImprove utilization efficiencySoil-working methodsWater circulationRainwater harvesting

The invention discloses a mudflat desalination method in combination with water circulation. The method comprises the steps of 1, arrangement of desalination units; 2, drilling of an in-situ water pumping well; 3, arrangement of a fixed water head well; 4, arrangement of salt-discharging underground pipes; 5, flatting of field plots; 6, salt leaching with brackish water; 7, salt leaching with brackish water and drainage; 8, rainwater collection; 9, salt leaching with fresh water; 10, salt leaching with fresh water and drainage; 11, circulation of salt leaching water. By means of the method, onone hand, underground water of saline-alkali land is changed and gradually desalinated through multiple times of circulation; on the other hand, by adopting a brackish water and rainwater rotation irrigation mode, the precious fresh water resources in a coastal area are saved, the collected rainwater is also fully added into the circulation of an underground phreatic layer, and therefore the purpose of the desalination of the coastal saline-alkali land is fundamentally achieved.

Owner:HOHAI UNIV

Metal casting pouring device convenient to use

InactiveCN108031828AEasy to usePrevent pouring effectsMolten metal pouring equipmentsMolten metal conveying equipmentsFixed frameEngineering

The invention discloses a metal casting pouring device convenient to use, and relates to the technical field of metal casting. The device comprises an outer frame. A fixing frame is fixedly connectedto the bottom of the inner wall of the outer frame. A fixing device is fixedly connected to the right side of the inner wall of the fixing frame, a first motor is fixedly connected to the top of the inner wall of the outer frame, a lead screw is fixedly connected to one end of an output shaft of the first motor, and rotating bases are rotationally connected to the two ends of the lead screw. According to the metal casting pouring device convenient to use, the purpose of clamping and fixing a mold is achieved, the phenomenon that the mold shakes in the pouring process, it is ensured that pouring is performed, the pouring quality is improved, the mold is damped and buffered, the phenomenon that the influence caused by shaking on pouring is avoided, the device stability is improved, pouring can be conveniently controlled, the phenomenon that waste of molten metal is caused due to excessive pouring is avoided, energy is saved, no artificial monitoring is needed, and burdens of workers arerelieved.

Owner:毕淑珍

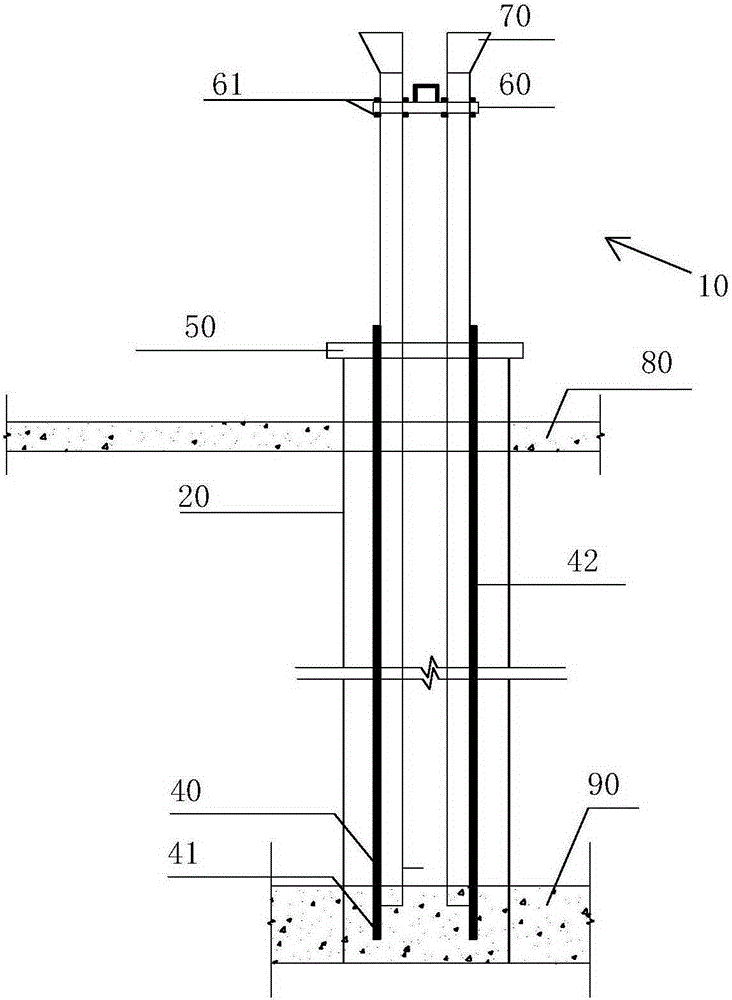

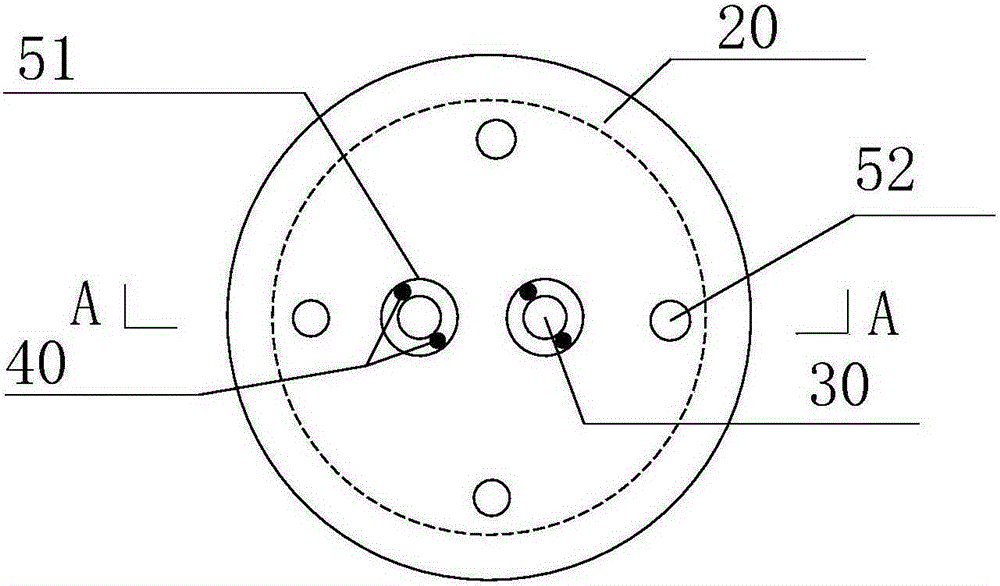

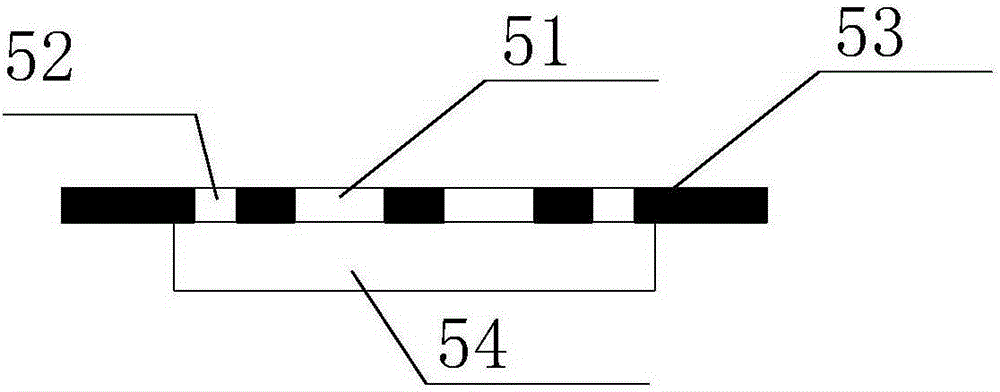

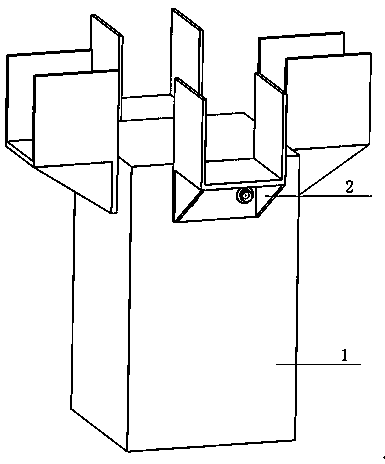

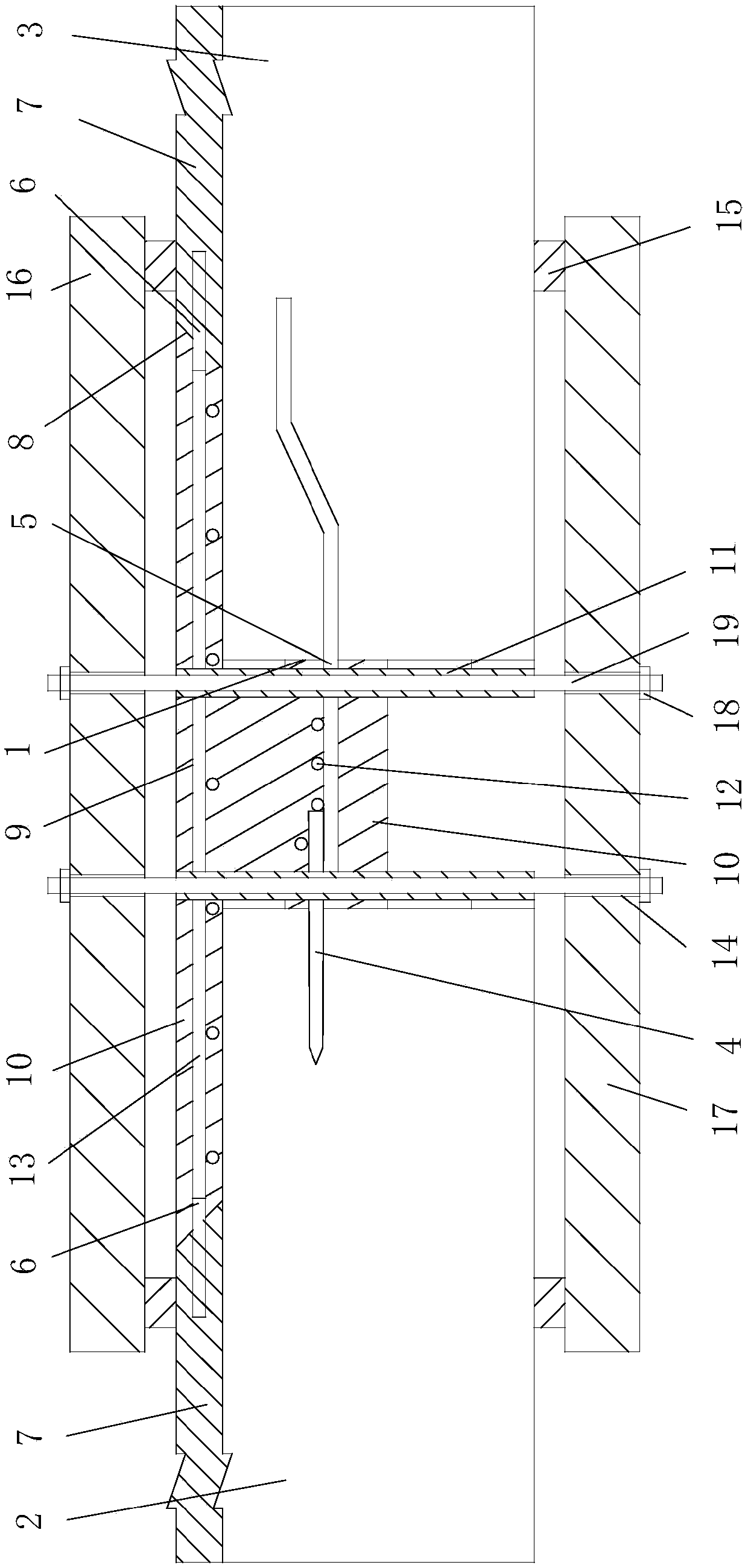

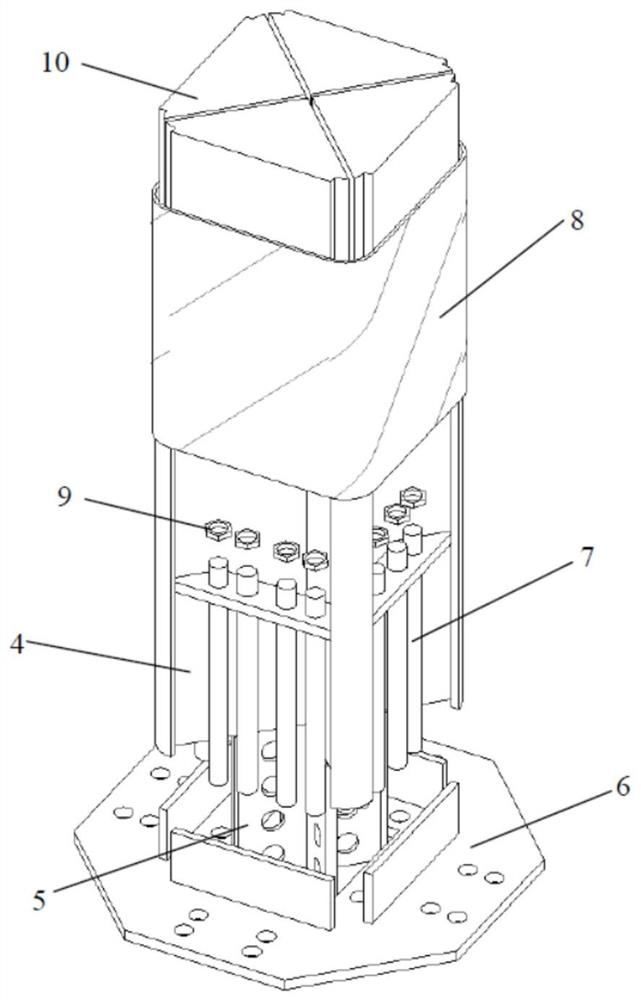

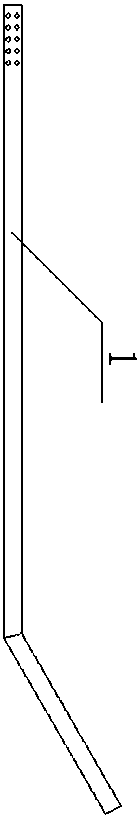

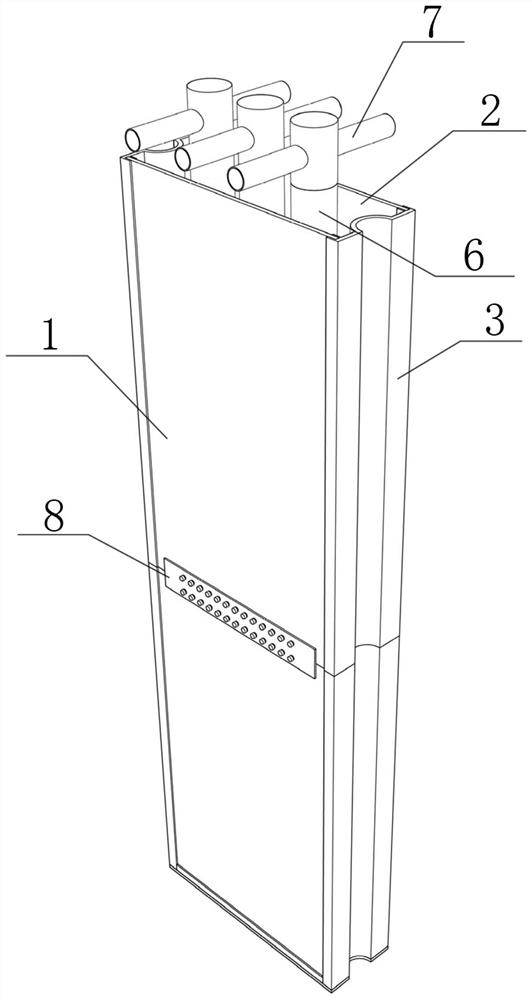

Huge concrete filled steel tubular column core grouting pouring and tamping device and method

ActiveCN105332511AFirmly connectedStable horizontal connectionBuilding material handlingGuide tubeSteel tube

The invention relates to a huge concrete filled steel tubular column core grouting pouring and tamping device and method, and belongs to the technical field of building construction. Problems that in construction of pouring and tamping a huge concrete filled steel tubular column core by using a multi-guiding-tube method, positions of a plurality of guiding tubes are not fixed in the horizontal direction, vertical lifting is not uniform, and heights are not determined are solved. The pouring and tamping device comprises a limiting plate and fastener clamps, wherein the limiting plate is inlaid in an upper port of a huge steel tubular column and is provided with a plurality of limiting holes; pouring and tamping guiding tubes can penetrate in the limiting holes; and the fastener clamps fixedly sleeve the outer walls of the pouring and tamping guiding tubes. The pouring and tamping method comprises the following steps: firstly, fixedly positioning the huge steel tubular column; secondly, mounting the limiting plate on the huge steel tubular column, arranging the fastener clamps and fixing seats on the outer walls of the pouring and tamping guiding tubes, and placing the pouring and tamping guiding tubes in the huge steel tubular column through the limiting plate; thirdly, pumping concrete in the huge steel tubular column through the pouring and tamping guiding tubes, and slowly and synchronously raising the pouring and tamping guiding tubes and vibration bar guiding tubes while pumping; and finally, detaching the pouring and tamping device after concrete pouring of the huge concrete filled steel tubular column is finished.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Novel prefabricated structure precast column unit and beam-column joint construction method

PendingCN109577553ASimple and fast constructionLess site loadingStrutsPillarsBeam columnComposite beams

The invention discloses a novel prefabricated structure precast column unit which comprises an embedded nut arranged in a precast column. The distance between the embedded nut and the top of the precast column is 120mm, the spacing of two sides of a center line of a beam is D / 4 (D refers to the width of a supporting bracket), the supporting bracket mainly comprises angle steel, a positioning steelplate, a reinforcing steel plate, a high-strength bolt and a nut, during industrial production, circular holes are formed in the side face of the angle steel, the depth of each circular hole is 5mm,the diameter of each circular hole is 100mm, the positioning steel plate is arranged at the top of the angle steel, the reinforcing steel plate is arranged on the side face of the angle steel, and a composite beam is fixed. The novel prefabricated structure precast column unit has the advantages that erection of a vertical support at the end of the junction of the precast column and the compositebeam is omitted, on-site construction is simple and convenient, a site is less in loading, the precast column, the composite beam and the supporting bracket can be produced in a standardized manner ina factory, economic feasibility is strong, the supporting bracket can be recycled, a green building conforms to national advocacy, the supporting bracket is arranged at the junction of the precast column and the composite beam, mortar leakage in casting can be avoided, and construction quality is ensured.

Owner:郑鹏

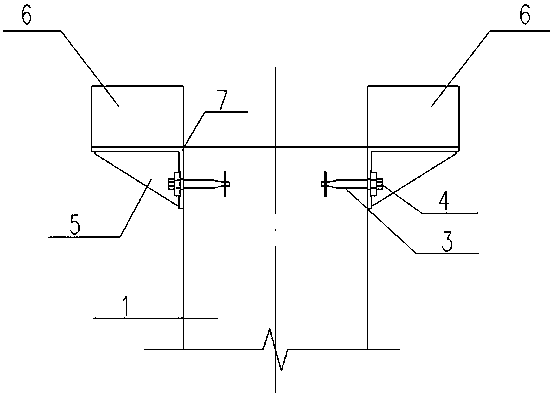

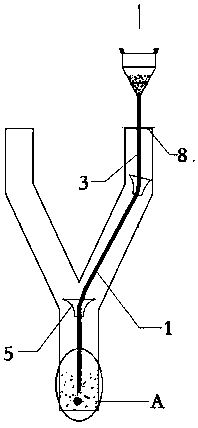

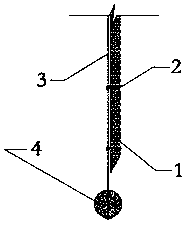

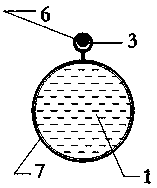

Rolling ball type concrete pouring structure and method for overground large special-shaped stiff column

ActiveCN105804403AQuality assuranceGuaranteed performanceStrutsBuilding material handlingField conditionsTower crane

The invention relates to the technical field of concrete pouring of the construction industry, in particular to a rolling ball type concrete pouring structure and method for an overground large special-shaped stiff column. According to the method, a flexible pouring guide pipe is connected in series with a steel wire through small steel rings in a full-length mode, through the dead weight of a concrete ball, the flexible pouring guide pipe is released to the bottom of the special-shaped column in a rolling mode along string pipes located on the inner wall and inflection point portions of a column body by means of the steel wire, and then a top connecting opening of the guide pipe is connected with a discharge outlet of a hopper or a pump pipe; and in the pouring process, the burying depth of the discharge outlet of the guide pipe is kept until pouring is completed. According to the structure and method, the guide pipe is adopted for pouring construction, the concrete pouring conveying path is independent and is prevented from being separated due to space blocking of steel bars, steel ribs and the like in the column body, and the blending quality and performance of concrete in the pouring position are guaranteed. Tower crane hopper feeding, or mechanical pumping or other ways can be flexibly selected for column body concrete pouring according to field conditions, so that the efficiency of column body concrete pouring is improved.

Owner:DALIAN BRANCH OF CHINA CONSTR EIGHTH ENG DIV CORP

Support method of top plate template in electric ditch whole pouring process

The invention relates to the field of electric construction, in particular to a support method of a top plate template in an electric ditch whole pouring process. The support method comprises the following steps: a soil beam is embedded in a concrete baseplate of a cable ditch; the total height of the soil beam is lower than the upper plane of the concrete baseplate by 2-3 cm; a transverse rib of the soil beam is higher than the bottom surface of the concrete baseplate by 15 cm; then, the upper end of the soil beam is coated with a PVC pipe; the bottom end of the PVC pipe is joined on the transverse rib; a support steel pipe is inserted in the PVC pipe, and coats the soil beam; after the concrete baseplate is poured, the support steel pipe and the PVC pipe are pulled away; and a hole left by the PVC pipe is floated by expansion waterproof mortar. The support method has the following beneficial effects: the support method can save the reinforcement cutting process, saves the cost, is safe and beautiful, guarantees whole pouring of the baseplate with a thickness of 15 cm on the soil beam, and can guarantee water resistance.

Owner:JINAN URBAN CONSTR GRP

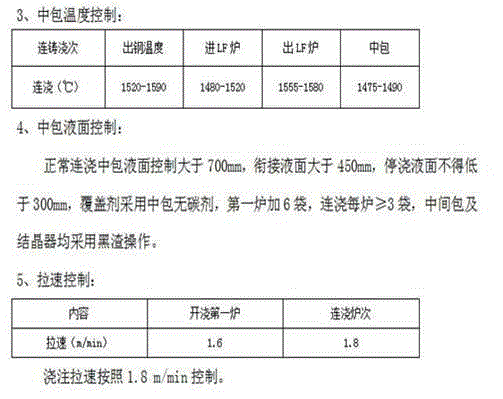

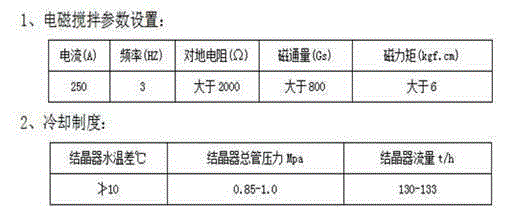

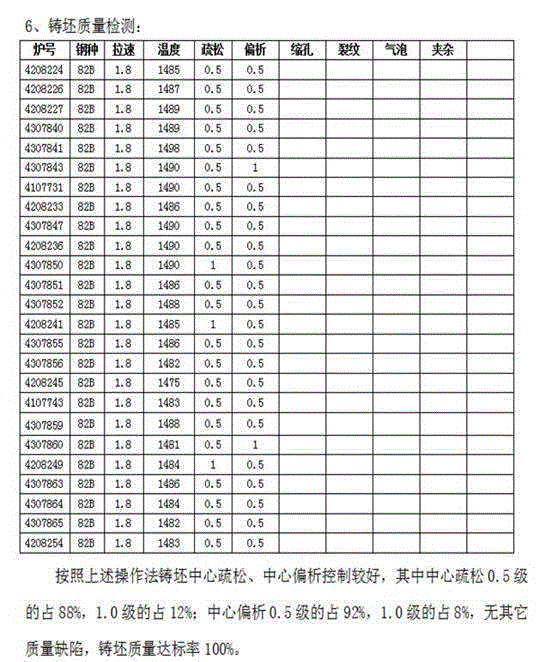

Method for improving quality of high-carbon steel in continuous casting process

The invention belongs to the technical field of improving the internal quality of high-carbon steel, and particularly relates to a method for improving the internal quality of high-carbon steel in the continuous casting process. The method comprises the following steps that 1, the parameter of an electromagnetic stirring crystallizer is set; 2, the coil parameter of the electromagnetic stirring crystallizer is set; 3, the water volume parameter of the crystallizer is set; 4, tundish black slag operation is carried out; 5, the temperature of tundish molten steel is controlled; and 6, a pouring mode is selected. The method has the beneficial effects that the set electromagnetic stirring parameter, a pull speed system, a cooling system and a temperature system are combined, and the internal quality of the high-carbon steel is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

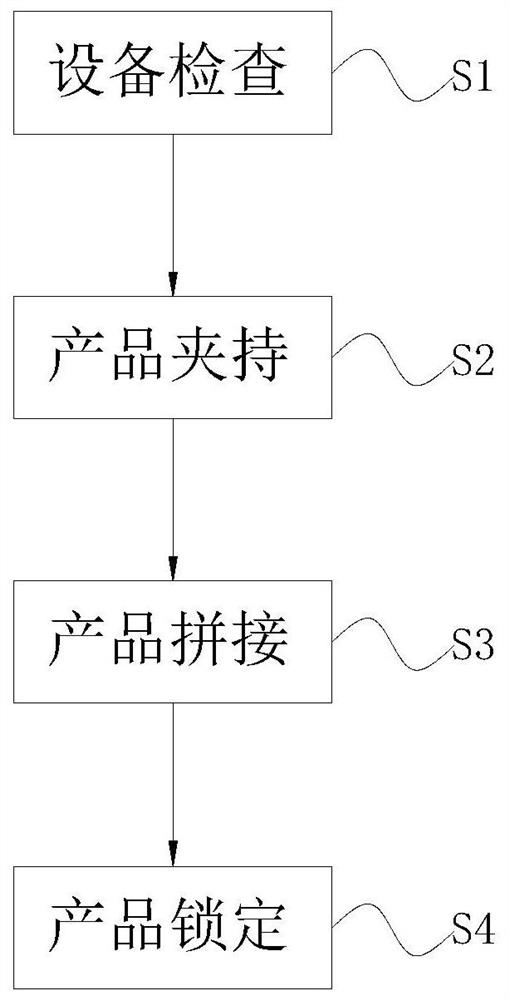

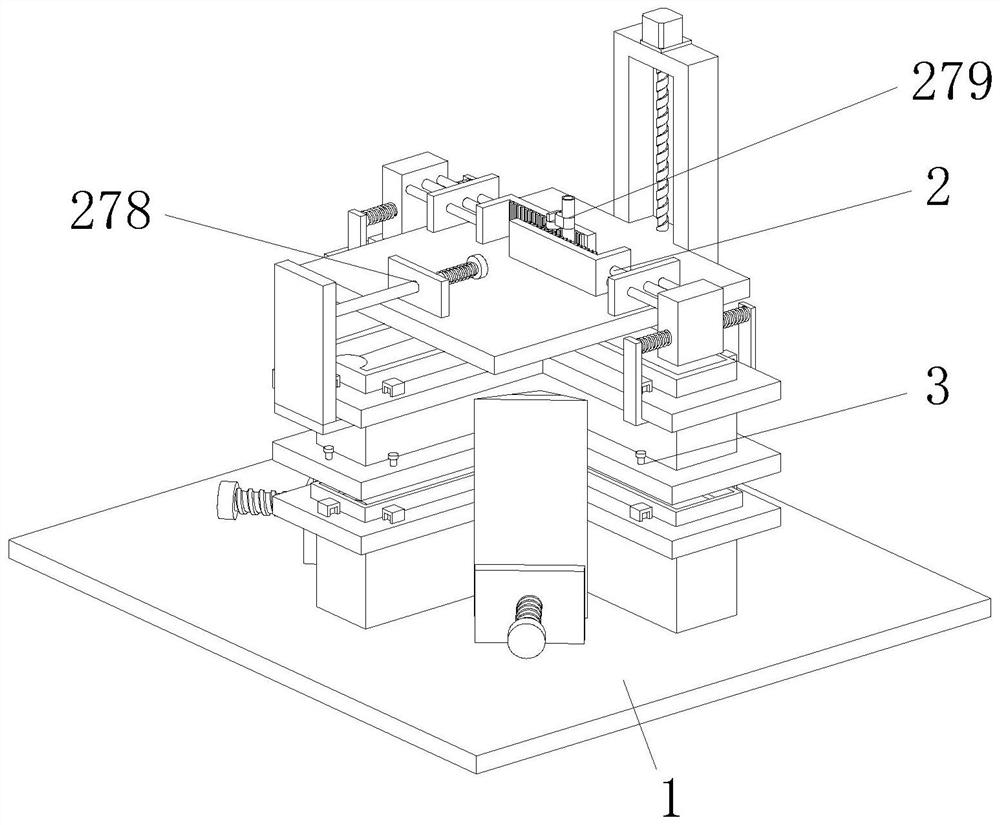

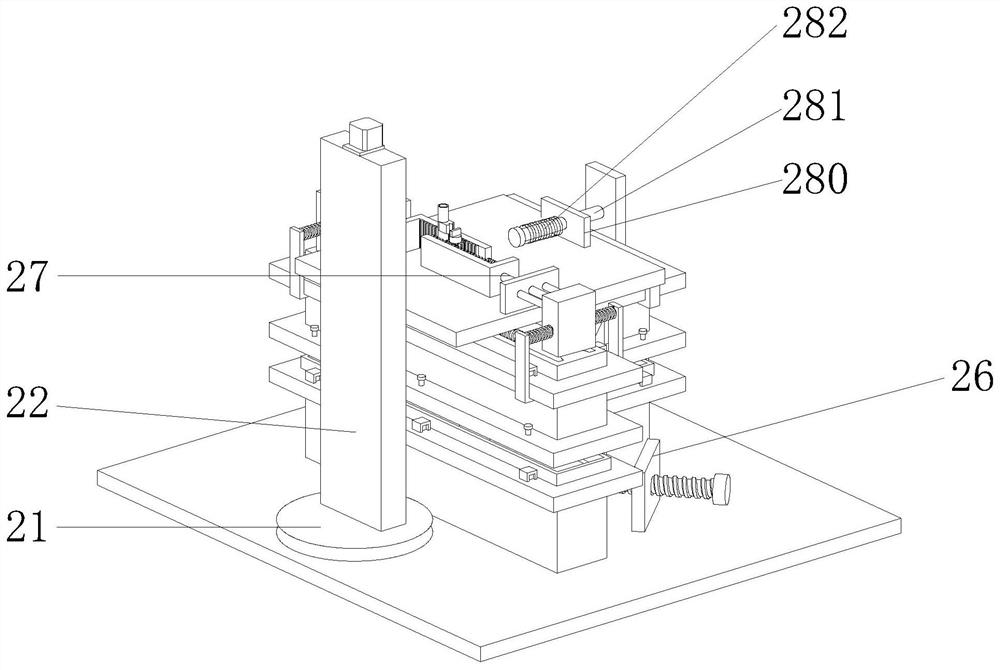

Manufacturing, pouring and forming method for reinforced concrete prefabricated wall

ActiveCN113183285AGuaranteed small deviation adjustmentImprove convenienceAuxillary shaping apparatusMould fastening meansReinforced concreteArchitectural engineering

The invention provides a manufacturing, pouring and forming method for a reinforced concrete prefabricated wall, and relates to the technical field of building prefabricated part machining. A bottom plate, a clamping device and a pouring device are included, the clamping device is fixedly installed on the bottom plate, and the pouring device is arranged on the bottom plate. The pouring device comprises a first pouring mold, a second pouring mold, a first placing frame, a second placing frame, a third placing frame, a locking assembly and a splicing assembly. The pouring device can solve the following problems that firstly, stability is very poor when concrete pouring is conducted through an existing pouring method, and construction hazards can occur in the pouring process, and in addition, the harm of material leakage can also occur in the pouring process. Secondly, a mold adopted in an existing pouring method is connected in a manner of splicing a plurality of plates, so that the mold is very troublesome to use, and the mold is more difficult to detach.

Owner:湖南万众筑工科技有限公司

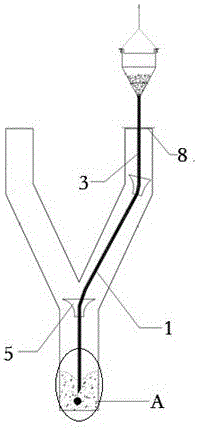

Vacuum pouring basket sliding mechanism and its operation method

InactiveCN1911566ASolidification of molten steelGuaranteed pouringMelt-holding vesselsHydraulic cylinderSlide plate

The present invention relates to vacuum molten steel casting technology, and is especially one kind of sliding mechanism for vacuum casting pouring basket and its operation process. The sliding mechanism includes sliding gate, hydraulic cylinder, link rod, lower sliding board with porous plug connected to the argon pipeline, protecting board connected to the pouring basket, sealing member set on the side wall of the pouring basket, and circular cooling pipe penetrating the side wall of the pouring basket. The operation process includes the steps of: blowing argon, pouring molten steel to the pouring basket, regulating argon pressure, pumping vacuum and opening the sliding gate for vacuum pouring. The present invention has the advantages of no plunger caused trouble, smooth running of the sliding member, long service life of the pouring basket and high internal quality of steel ingot.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

Expressway hollow slab girder longitudinal splicing structure and method

ActiveCN107740353ALongitudinal seam splicing quality is stableGuaranteed pouringBridge structural detailsBridge erection/assemblyRebarHollow core

The invention aims at providing an expressway hollow slab girder longitudinal splicing structure and method. The expressway hollow slab girder longitudinal splicing structure comprises an old bridge hollow slab girder, a new bridge hollow slab girder, multiple self-tapping bolts, multiple pieces of embedded connection rebar, concrete pre-pavement layers, reinforcing meshes, concrete wet connectionconnectors and hollow pipes; the middles of the old bridge hollow slab girder and the new bridge hollow slab girder are provided with filling gaps, the multiple self-tapping bolts are connected withone side end of the old bridge hollow slab girder, the multiple pieces of the embedded connection rebar are arranged at one side end of the new bridge hollow slab girder and are welded to tails of theself-tapping bolts in a one-to-one correspondence mode, the concrete pre-pavement layers are arranged on the outer side of the upper end of the old bridge hollow bridge and the outer side of the upper end of the new bridge hollow slab girder, the reinforcing meshes are arranged in a pavement space formed between the two concrete pre-pavement layers, the two side ends of the reinforcing meshes areconnected with fixed rebar groups of the two concrete pre-pavement layers in a one-to-one corresponding mode, the concrete wet connection connectors are poured into the pavement space and the fillinggaps, and multiple pairs of hollow pipes are arranged in the longitudinal direction and penetrate into the concrete wet connection connectors. The expressway hollow slab girder longitudinal splicingstructure is stable in longitudinal seam splicing quality.

Owner:浙江交工宏途交通建设有限公司

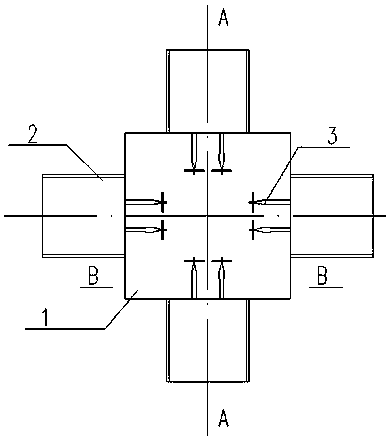

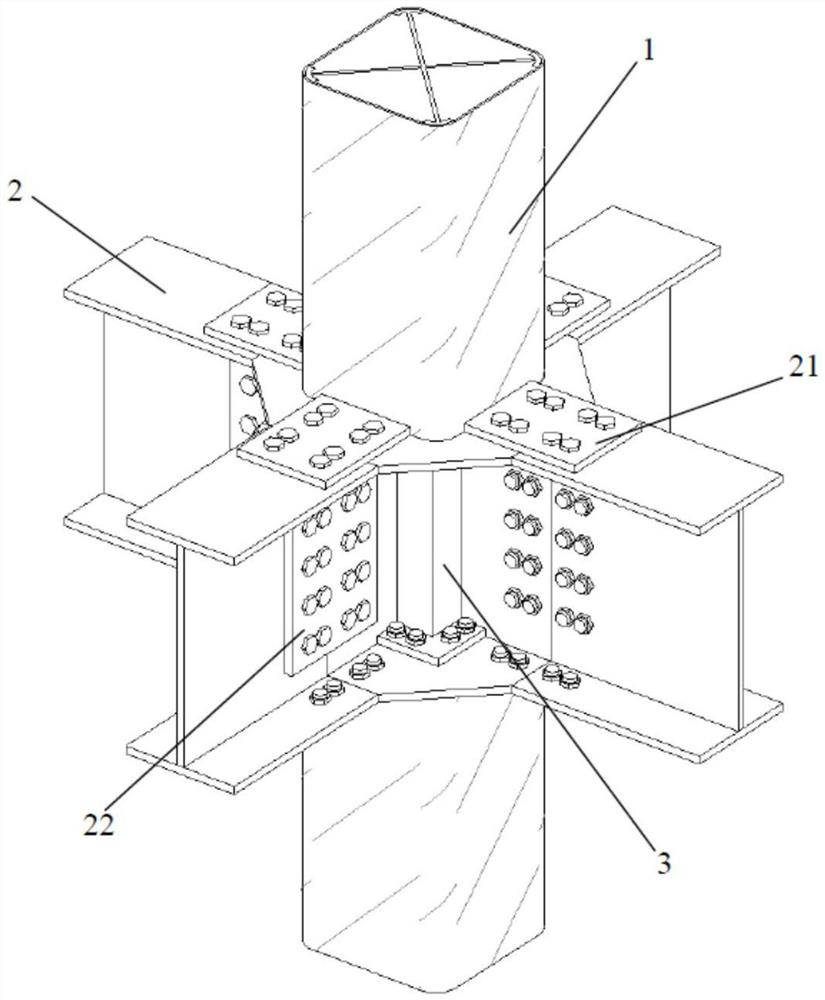

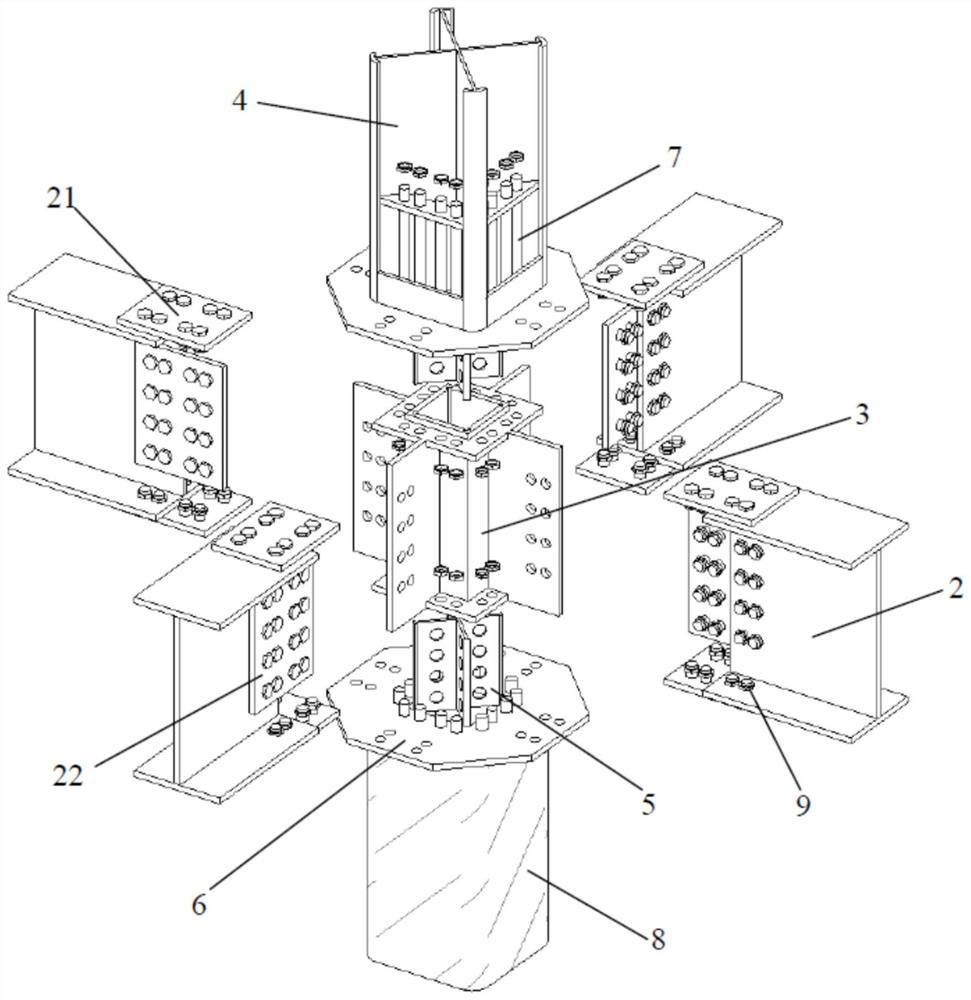

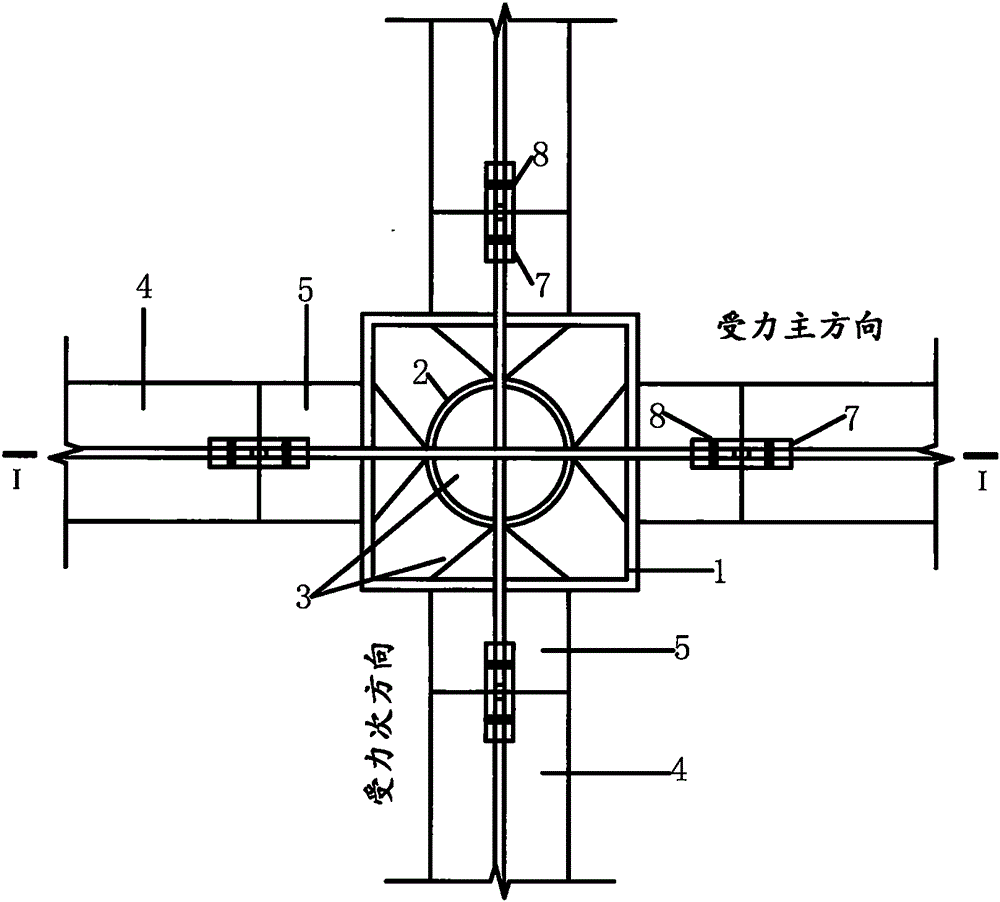

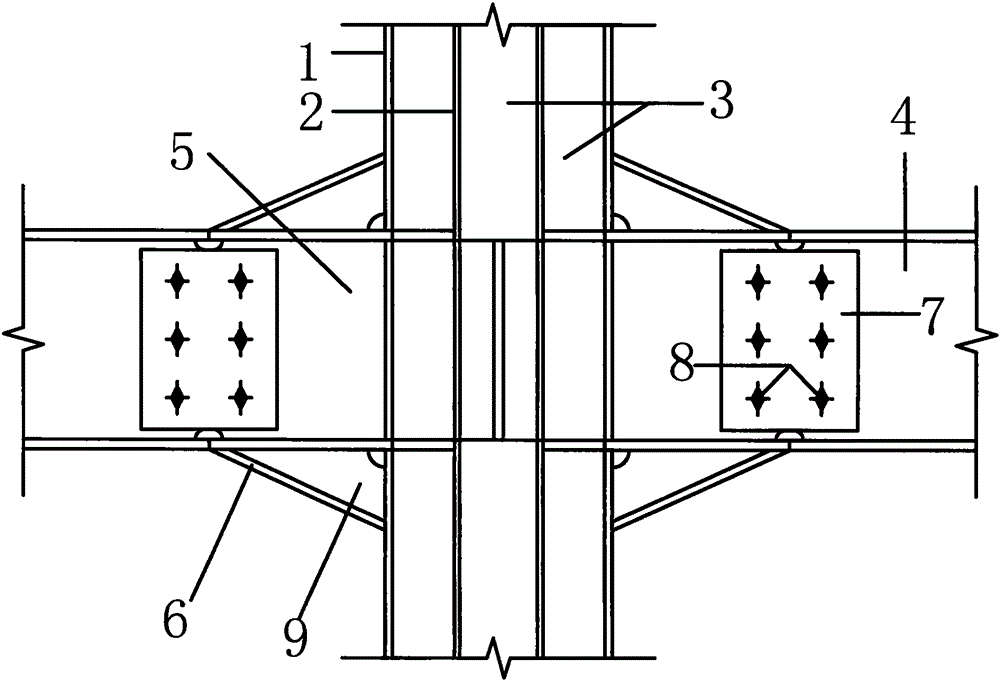

FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint and mounting method

ActiveCN113513089AImprove quality and efficiencyImprove construction efficiencyStrutsClimate change adaptationReinforced concrete columnEngineering

The invention relates to an FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint and a mounting method, and belongs to the field of design of a building structure beam-column joint. The FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint comprises an FRP externally-wrapped cross-shaped steel reinforced concrete column, an H-shaped steel beam and a square joint connecting sleeve, the FRP externally-wrapped cross-shaped steel reinforced concrete column comprises an upper column and a lower column, the square joint connecting sleeve is located between the upper column and the lower column, and the upper column and the lower column are connected with the square joint connecting sleeve through column end opening connecting plates correspondingly; and the H-shaped steel beam is fixedly connected with the column end opening connecting plates and the square joint connecting sleeve. By adopting the design of vertical force transfer of steel bars, the vertical connection of the joint is greatly enhanced, and the overall structural performance of the joint is enhanced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

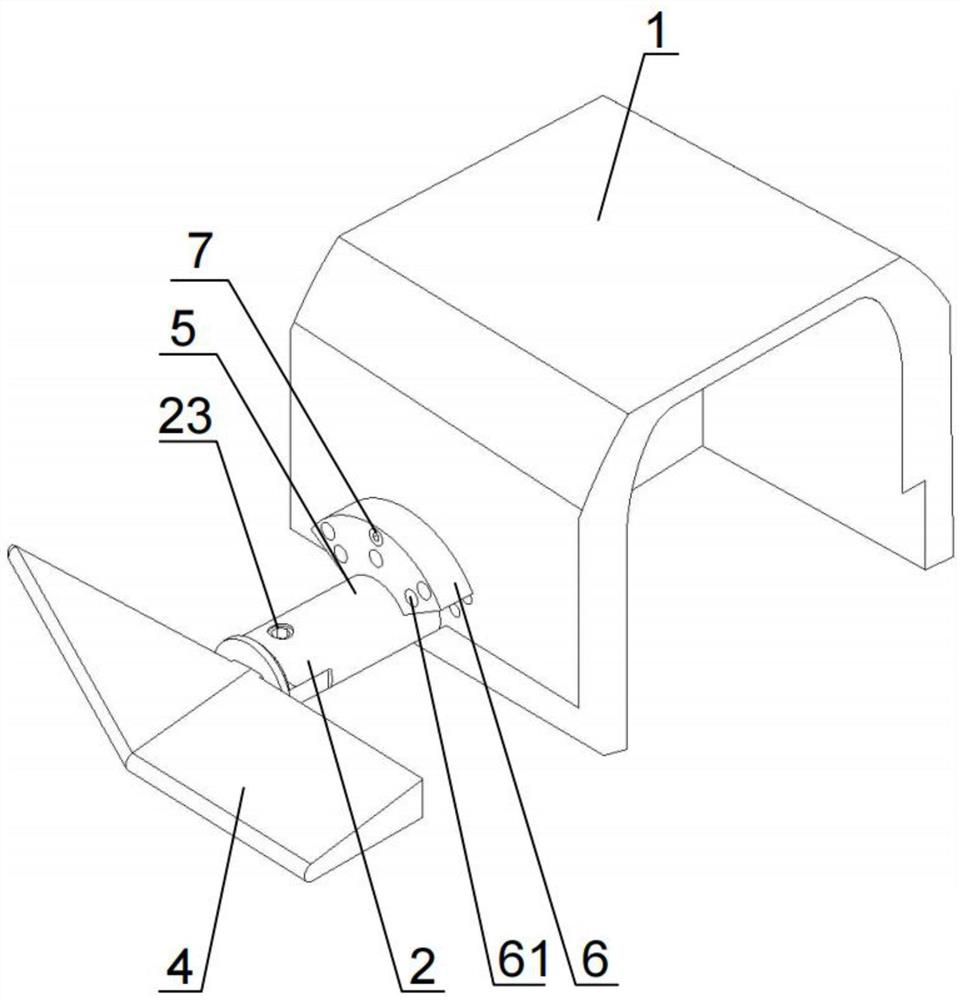

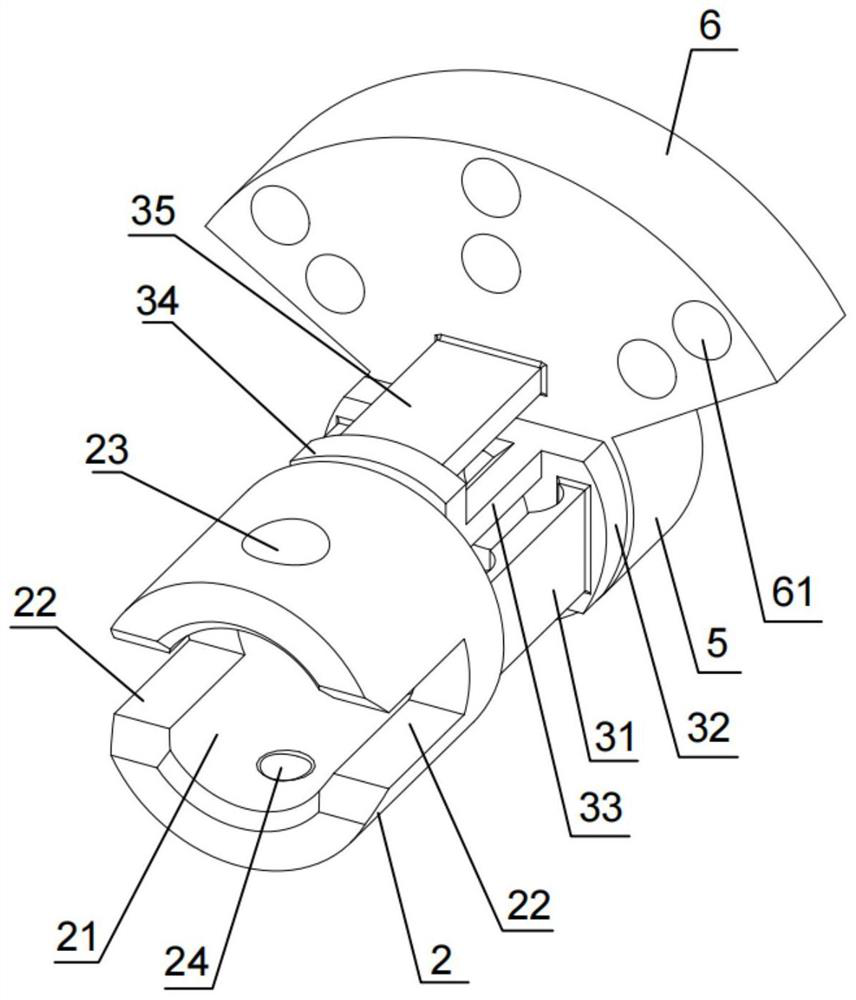

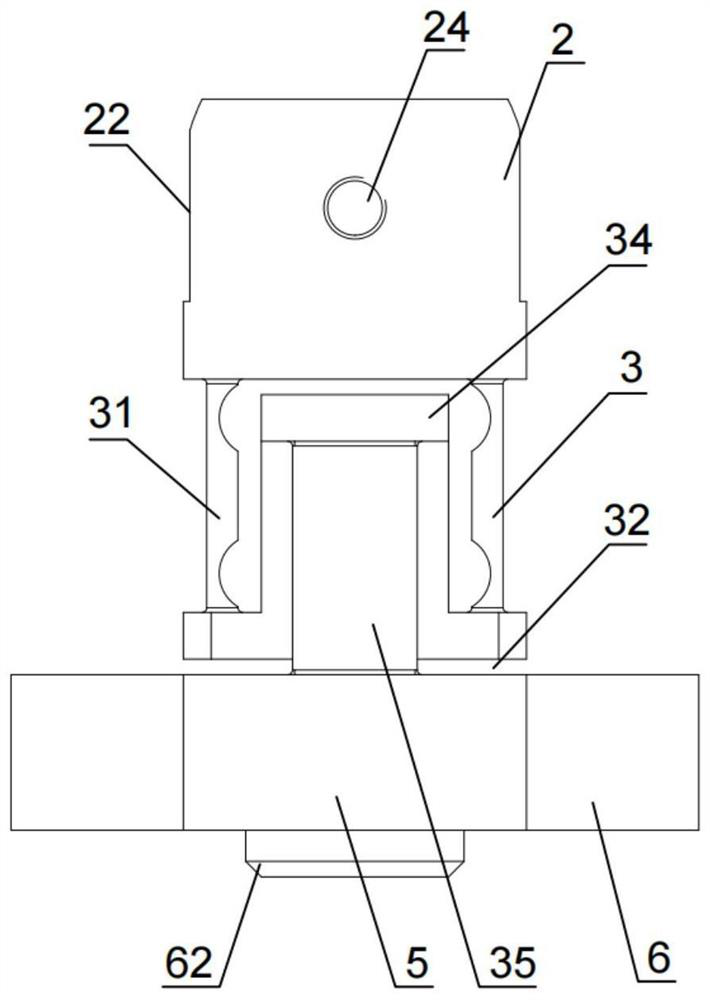

Design and use method of device for testing simultaneous deflection angle of balance and control surface

ActiveCN114001907AReduce the effect of temperatureAvoid conversionSustainable transportationAerodynamic testingEngineeringMechanical engineering

The invention discloses a design and use method of a device for testing the simultaneous deflection angle of a balance and a control surface. The device comprises: a model body which is provided with a cylindrical hole, wherein two reference circles which take the central point of the cylindrical hole as the center of a circle are respectively provided with a circle of taper pin holes I; and a hinge moment balance comprising a model end, wherein the lower end of the model end is integrally provided with a measuring element, and the upper end of the model end is connected with a measuring rudder; a fixed end is integrally processed at the lower end of the measuring element; and the fixed end is provided with a fan-shaped flange face coaxial with the measuring element, the fan-shaped flange face is provided with two circles of taper pin holes II, the diameter of a reference circle where the two circles of taper pin holes II are located is correspondingly equal to the diameter of a reference circle where the two circles of taper pin holes I are located, and the bottom of the fan-shaped flange face is provided with a cylindrical section. According to the invention, the conversion of the rudder deflection angle can be realized by aligning the taper pin hole II with the taper pin hole I of the model body in a model space with a smaller axial size and a larger radial size, so that the conversion of a coordinate system is avoided, and the conversion efficiency of the rudder deflection angle is improved.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

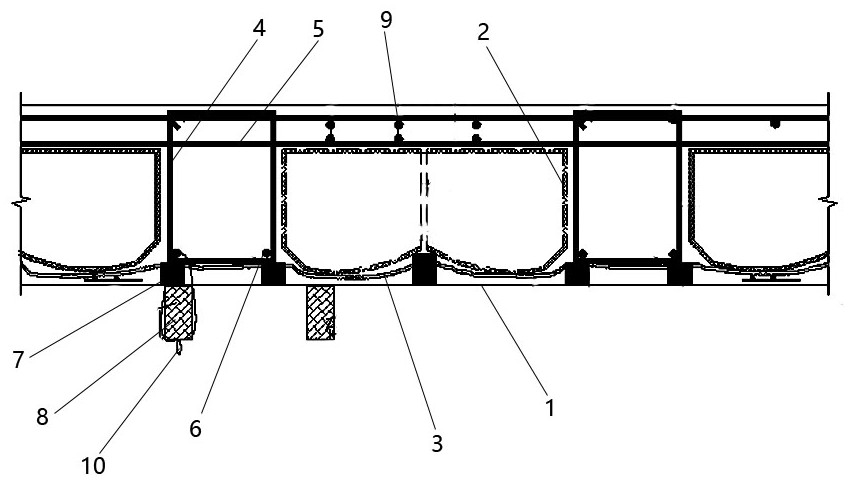

Construction method for large cavity hollow floor slab

InactiveCN111622407APrevent floating and displacementGuarantee the vibration qualityFloorsHollow coreRebar

The invention relates to a construction method for a large cavity hollow floor slab. The invention transfers the buoyancy generated by a box mold during pouring and vibrating to a formwork system through floor steel bars, box mold side rib beams, iron wires and formwork keels to form an anti-floating point. By setting the box mold as an inner mold that can replace a template to be erected, the filling and vibrating can be seen during concrete pouring, which can ensure the quality of pouring and vibrating. Through the anti-floating design, the box mold is fixed to prevent the box mold from floating and displacement during pouring and vibrating, thereby ensuring the quality of concrete pouring and vibrating. The construction method provided by the invention is especially suitable for the construction of large-cavity hollow floor slabs, and can solve the problems of inconvenience of large-cavity formwork and easy vibration leakage during concrete pouring to be unable to guarantee the quality.

Owner:CHINA MCC20 GRP CORP +1

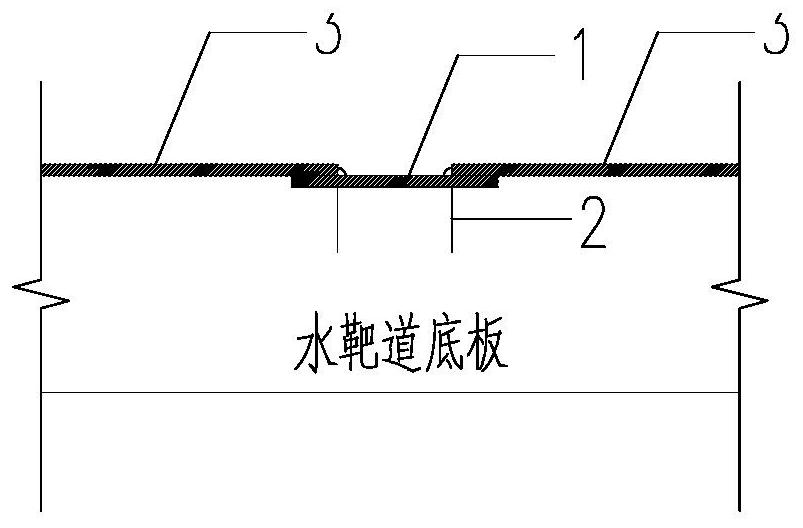

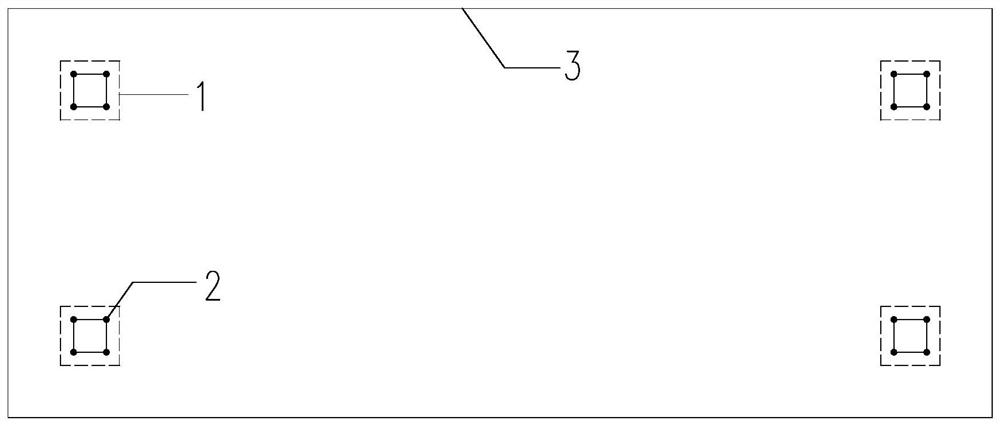

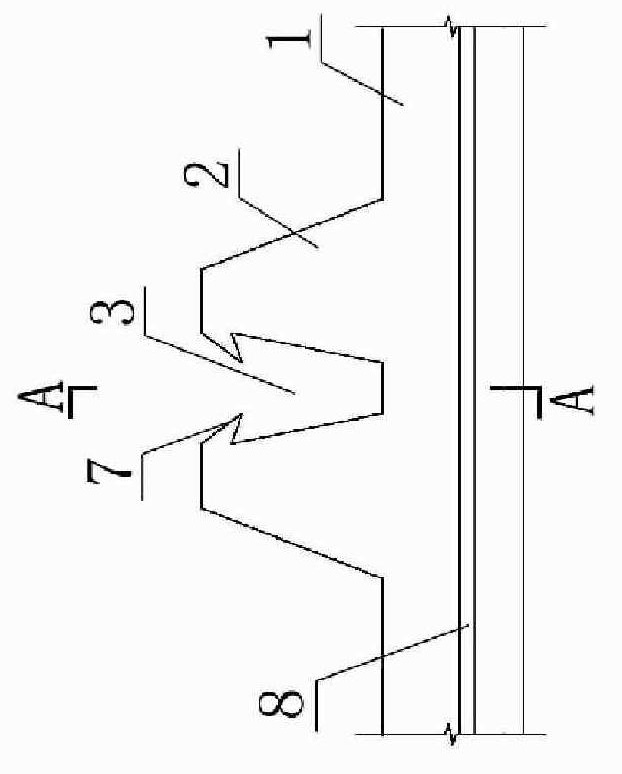

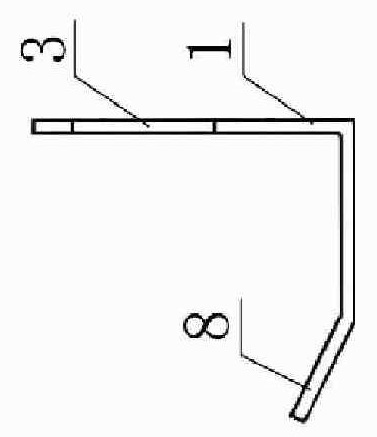

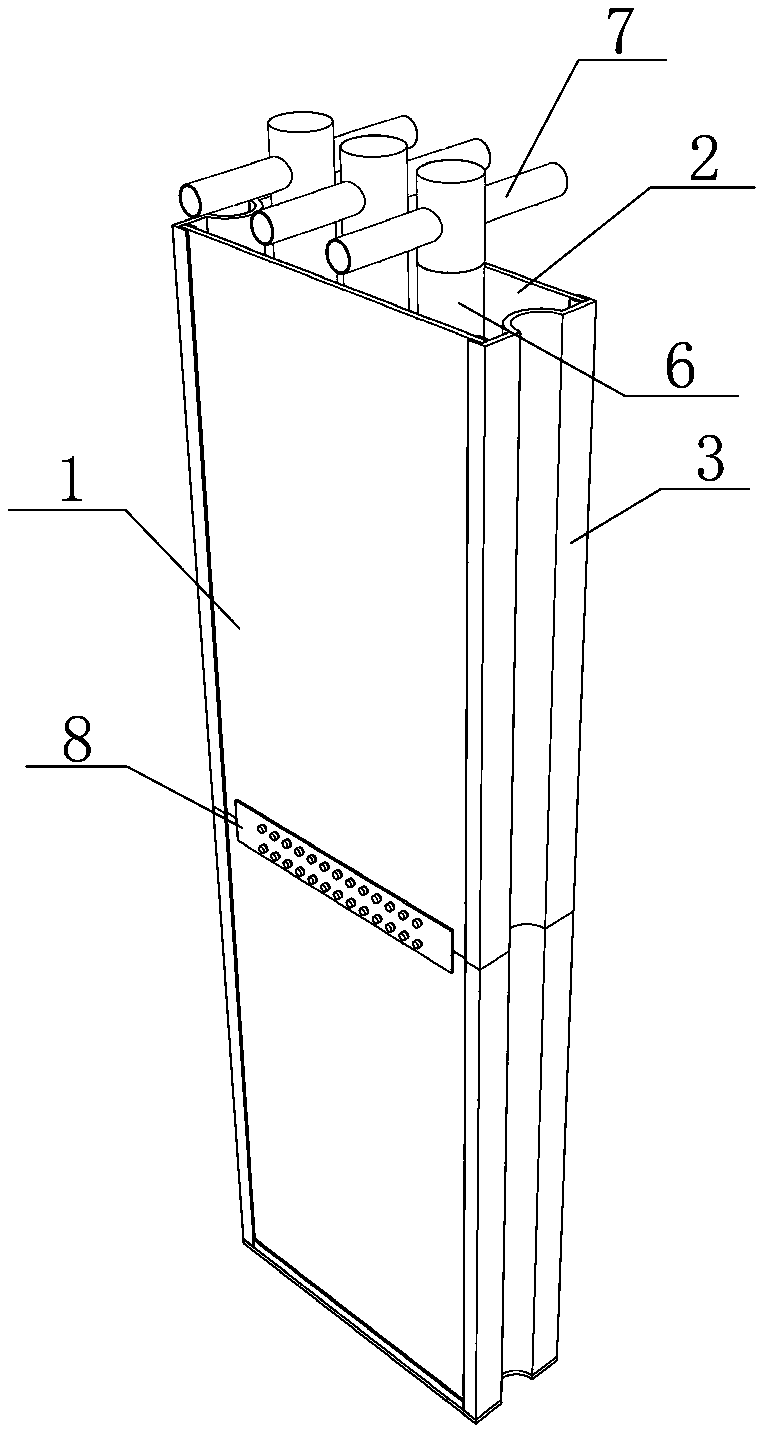

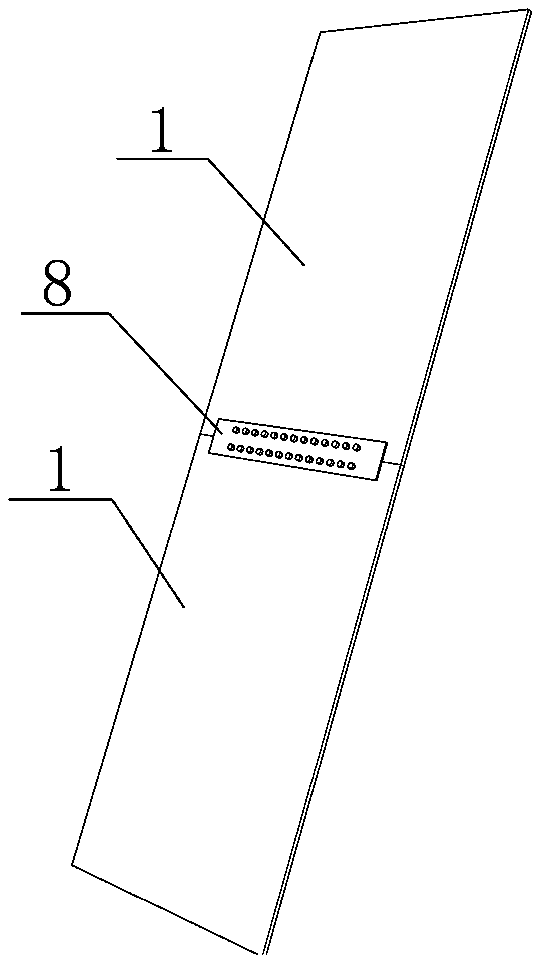

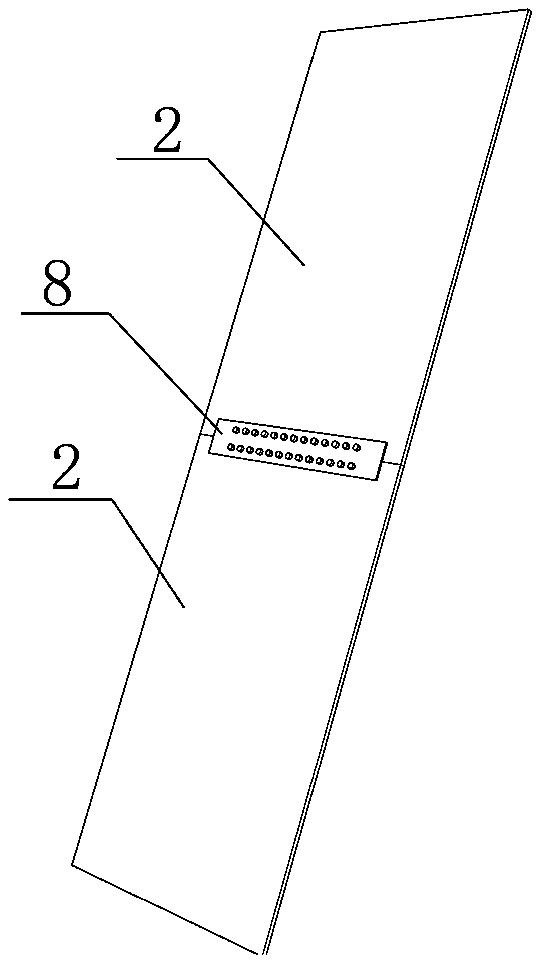

Lining steel plate assembly for water target channel bottom plate

PendingCN112161514AGuaranteed pouringGuaranteed normal vibrationWeapon testingStructural engineeringMechanical engineering

The invention discloses a lining steel plate assembly for a water target channel bottom plate. The lining steel plate assembly comprises bottom plate embedded steel plate connecting parts 1, anchor bars 2 and bottom plate lining steel plates 3; and the top ends of the anchor bars 2 are connected with the steel plate connecting parts 1, the steel plate connecting parts 1 and the anchor bars 2 are vertically embedded in the water target channel bottom plate, the bottom plate lining steel plates 3 are installed on the surface of the water target channel bottom plate, preformed holes are formed inthe bottom plate lining steel plates 3 corresponding to the anchor bars 2, and the bottom plate lining steel plates 3 are welded to the steel plate connecting parts 1 through the preformed holes. According to the lining steel plate assembly, quick mounting and dismounting of the lining steel plates can be achieved, the lining steel plate assembly is convenient to replace, and operation and maintenance are easy.

Owner:NANJING UNIV OF SCI & TECH

Fastening strip and fastening network framework

ActiveCN101457572BGuaranteed pouringSolve the problem of convenient and quick fixWallsForms/shuttering/falseworksFloor slabKeel

The invention relates to a blocking strip and a blocking net framework. The blocking strip comprises at least two strip sides, at least one of which is provided with convex teeth that are provided with breaches, the breaches are internally provided with agnails or barbs. The blocking net framework can be made by applying the blocking strip, and is formed by connecting keels, the blocking strip and a steel screen in a combining way. The keels are section steel parts and are arranged in parallel according to certain spacing; the blocking strips are vertical to the keels, arranged in parallel according to certain spacing and are fixed at one side or two sides of the keels to form a steel frame; the steel screen is distributed with a longitudinal convex rib as well as fish scales holes or meshes on the surface; the steel screen is attached to the outer surface of the steel frame, and is firmly and conveniently blocked and connected with the blocking strip. The invention solves the problems of composition and construction of a steel screen concrete member as well as the reinforcement of a steel screen concrete wall body. Meanwhile, the invention realizes large-scale and mechanized production, and is suitable for various building structural elements, especially for the structures of multilayer and high residential building wall bodies and floor slabs.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

A smelting method for improving the fluidity of molten steel after refining and desulfurization of rebar

ActiveCN113234990BGuarantee smooth productionImprove liquidityManufacturing convertersSlagMolten steel

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

A kind of segmental box girder short-line matching control and prefab construction method

ActiveCN112060307BEffective organizationEnsure construction efficiencyMouldsCeramic shaping plantsArchitectural engineeringRebar

The invention discloses a segmental box girder short-line matching control and prefabrication construction method, the steps are as follows: step 1, divide the beam field into functional areas; step 2, make end beams in the beam manufacturing area; step 3, install cast-in-place beams Formwork; step 4, put in the bundled steel skeleton and control the checking position; step 5, pour concrete into the cast-in-place beam formwork; step 6, use the cast-in-place beam as a matching beam for cyclic prefabrication; from this until the pouring is completed, the beams used body; Step 7, put the completed beam body into the beam storage area for maintenance; the present invention divides the beam field into functional areas, which can effectively organize the on-site construction flow and ensure construction efficiency; through the pedestal beam system, measurement control system and The joint setting of the support adjustment platform can not only install and adjust the precise position, but also can control in real time; through the design of the shear key, it can ensure the linear connection in the later stage; the setting of different spraying facilities can be effective and the later maintenance can be carried out.

Owner:中国建筑土木建设有限公司

A non-stereotyped, revolvable formwork system prefabricated stair steps and construction method

ActiveCN105804396BGuaranteed pouringQuality assuranceForms/shuttering/falseworksSingle stepConstruction waste

The invention discloses a precast stair flight manufactured by a non-established and circularly-used template system and a construction method. Each precast stair flight comprises a pedestal, a bottom die fixed on the pedestal, an overall stairboard spliced by a single step plate and a combination of fixing racks. The stairboard is installed on the bottom die in the mode of vertically matching. The combination of fixing racks is fixed on the stairboard along a horizontal direction. The distance between every combination of fixing racks and the vertical direction of the stairboard is the same. The precast stair flight manufactured by the non-established and circularly-used template system and the construction method have following beneficial effects: based on technological summary and innovation, the non-established and circularly-used template system is adopted to precast stair flights on the construction site; while ensuring the concrete forming quality of each stair flight in the first place, a working period is effectively shortened, construction cost is lowered and refuse discharge of construction waste on the site is reduced at the same time.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Continuous wall anti-collapse pouring formwork suitable for soft soil area and construction method

The invention relates to a continuous wall anti-collapse pouring formwork suitable for a soft soil area and a construction method, and belongs to the technical field of underground continuous wall construction. The continuous wall anti-collapse pouring formwork comprises a soil facing side supporting plate, a soil backing side supporting plate, an end plate, a bottom supporting plate and a mud discharging pipe, the soil facing side supporting plate, the soil backing side supporting plate, the end plates and the bottom supporting plate define a box-shaped structure with an open top, a mud discharging hole is formed in the bottom supporting plate, the bottom of the mud discharging pipe is inserted into the mud discharging hole, and the top of the mud discharging pipe exceeds the tops of thesoil facing side supporting plate and the soil backing side supporting plate and extends towards the outside of the underground continuous wall groove section. The formwork can effectively prevent wall protection mud from entering the formwork, it is guaranteed that an underground continuous wall is poured in a waterless environment, and mud inclusion during concrete pouring is prevented; a reinforcement cage cannot float upwards due to being lifted by mud when being lowered, so that the concrete pouring quality is ensured; and when underground continuous wall concrete is poured, a guide pipedoes not need to be inserted in advance, the concrete cannot disturb the groove wall, and the groove wall of a soft soil area is effectively prevented from collapsing.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Large-volume special-shaped rigid column yo-ball concrete pouring structure and method on the ground

ActiveCN105804403BQuality assuranceGuaranteed performanceStrutsBuilding material handlingField conditionsBall type

The invention relates to the technical field of concrete pouring of the construction industry, in particular to a rolling ball type concrete pouring structure and method for an overground large special-shaped stiff column. According to the method, a flexible pouring guide pipe is connected in series with a steel wire through small steel rings in a full-length mode, through the dead weight of a concrete ball, the flexible pouring guide pipe is released to the bottom of the special-shaped column in a rolling mode along string pipes located on the inner wall and inflection point portions of a column body by means of the steel wire, and then a top connecting opening of the guide pipe is connected with a discharge outlet of a hopper or a pump pipe; and in the pouring process, the burying depth of the discharge outlet of the guide pipe is kept until pouring is completed. According to the structure and method, the guide pipe is adopted for pouring construction, the concrete pouring conveying path is independent and is prevented from being separated due to space blocking of steel bars, steel ribs and the like in the column body, and the blending quality and performance of concrete in the pouring position are guaranteed. Tower crane hopper feeding, or mechanical pumping or other ways can be flexibly selected for column body concrete pouring according to field conditions, so that the efficiency of column body concrete pouring is improved.

Owner:DALIAN BRANCH OF CHINA CONSTR EIGHTH ENG DIV CORP

A construction method of anti-collapse pouring formwork for diaphragm walls suitable for soft soil areas

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Longitudinal Splicing Structure and Splicing Method of Hollow Slab Beam in Expressway

ActiveCN107740353BLongitudinal seam splicing quality is stableGuaranteed pouringBridge structural detailsBridge erection/assemblyEngineeringRebar

The invention aims at providing an expressway hollow slab girder longitudinal splicing structure and method. The expressway hollow slab girder longitudinal splicing structure comprises an old bridge hollow slab girder, a new bridge hollow slab girder, multiple self-tapping bolts, multiple pieces of embedded connection rebar, concrete pre-pavement layers, reinforcing meshes, concrete wet connectionconnectors and hollow pipes; the middles of the old bridge hollow slab girder and the new bridge hollow slab girder are provided with filling gaps, the multiple self-tapping bolts are connected withone side end of the old bridge hollow slab girder, the multiple pieces of the embedded connection rebar are arranged at one side end of the new bridge hollow slab girder and are welded to tails of theself-tapping bolts in a one-to-one correspondence mode, the concrete pre-pavement layers are arranged on the outer side of the upper end of the old bridge hollow bridge and the outer side of the upper end of the new bridge hollow slab girder, the reinforcing meshes are arranged in a pavement space formed between the two concrete pre-pavement layers, the two side ends of the reinforcing meshes areconnected with fixed rebar groups of the two concrete pre-pavement layers in a one-to-one corresponding mode, the concrete wet connection connectors are poured into the pavement space and the fillinggaps, and multiple pairs of hollow pipes are arranged in the longitudinal direction and penetrate into the concrete wet connection connectors. The expressway hollow slab girder longitudinal splicingstructure is stable in longitudinal seam splicing quality.

Owner:浙江交工宏途交通建设有限公司

A concrete distribution and conveying system

The invention relates to a concrete distributing and conveying system. The system comprises a hopper, a conveyer belt, a cross beam and a to-be-poured area, wherein the cross beam stretches across the upside of the to-be-poured area, the conveyer belt comprises a first conveyer belt, a second conveyer belt, a third conveyer belt and a fourth conveyer belt, which are sequentially arranged from top to bottom, a feeding hole of the first conveyer belt is connected with a discharge hole of the hopper, the second conveyer belt is arranged below the discharge hole of the first conveyer belt, the third conveyer belt is arranged below the discharge hole of the second conveyer belt, the third conveyer belt is fixedly arranged on the cross beam, the fourth conveyer belt is arranged right below the third conveyer belt, the third conveyer belt rotates for transmission in a direction far away from the direction of the second conveyer belt, and a forwardly and backwardly rotating motor is arranged between the fourth conveyer belt and the cross beam, so that the fourth conveyer belt can move longitudinally on the cross beam back and forth and can rotate backwardly and forwardly, and the material is ensured to be discharged from two ends of the fourth conveyer belt. The fourth conveyer belt is driven to longitudinally move forth and back and rotate forwardly and backwardly through the movement of the cross beam and the forwardly and backwardly rotating motor, so that the concentrate is poured and is ensured to be poured in all places of the to-be-poured area.

Owner:ZHEJIANG TIANSHENG BUILDING MATERIALS CO LTD

Cored bracket haunched type compound concrete-filled steel tube column-steel beam node

InactiveCN105297896ADelays the tendency to buckleStrong bending and shear resistanceBridge structural detailsBuilding constructionsBridge engineeringHigh integrity

The invention discloses a cored bracket haunched type compound concrete-filled steel tube column-steel beam node and relates to a joint connection form of compound concrete-filled steel tube columns and steel beams, belonging to the technical field of constructional engineering and bridge engineering. The joint is composed of a compound concrete-filled steel tube column, a steel beam and a force transfer member, wherein the compound concrete-filled steel tube column consists of an inner steel tube, an outer steel tube and filled concrete; the steel beam consists of upper and lower flanges and webs; the force transfer member consists of a steel bracket and an inclined haunch plate; and the steel bracket is composed of upper and lower flanges and webs. The steel bracket webs are continuously penetrated at the joint core, and the upper and lower flanges of the steel bracket are discontinuous inside the inner steel tube; the joint of the steel bracket and the inner and outer steel tubes is subjected to weld reinforcement, and one part, which extends out of the outer steel tube, of the steel bracket is in stud welded connection with the steel beam; and meanwhile, the inclined haunch plate is welded between the steel beam and the compound concrete-filled steel tube column. The joint disclosed by the invention is simple in structure and convenient in construction, combines the form of cored bracket and haunched type joints and has the advantages of high rigidity and strength, high integrity, clear force transfer path and the like, and rigid connection between the compound concrete-filled steel tube column and the steel beam can be realized.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com