Fastening strip and fastening network framework

A strip and skeleton technology, applied in the field of steel components, can solve the problems of difficulty in ensuring reliability, inability to strengthen lateral strength, exposed keel steel, etc., achieve low maintenance and use requirements, and ensure smooth concrete construction and fixed reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

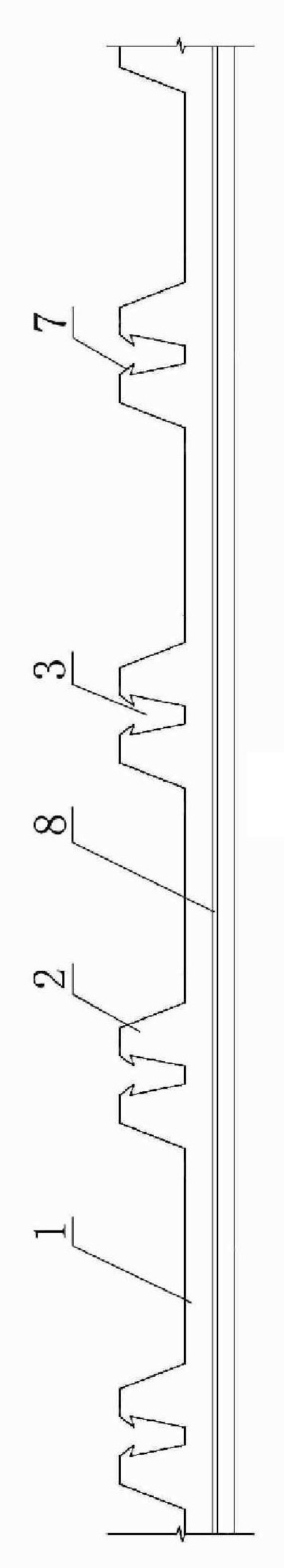

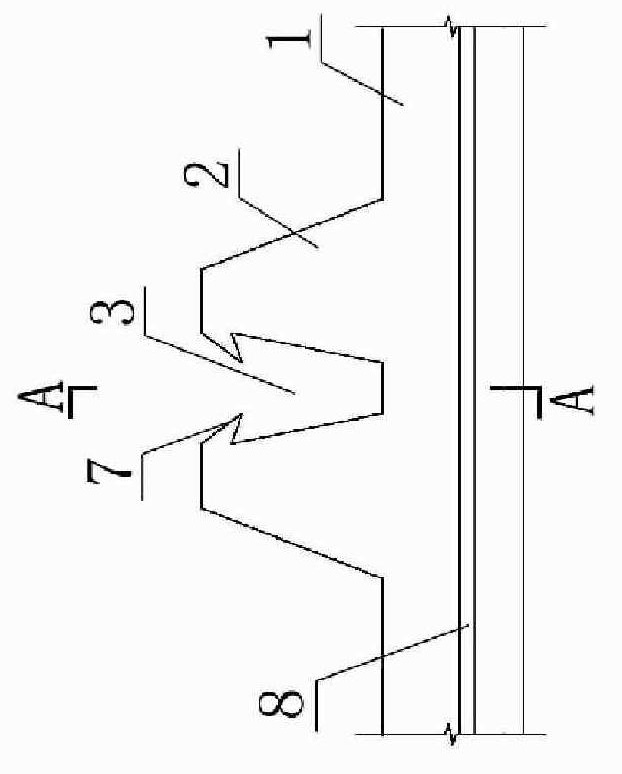

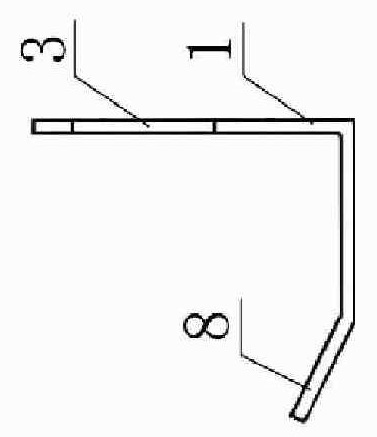

[0038] Examples see Figure 1-3 , this type of clip is a steel strip, the clip 1 has at least two sides, one of which is provided with protruding teeth 2, each protruding tooth 2 has a notch 3, and each notch has a V-shaped or pheasant-shaped barbs or barbs7. The barbs or barbs 7 go deep into the notch 3 obliquely and symmetrically. The inner contour of the gap 3 is open, narrowed, with a large abdomen and a small bottom. The end of the other side of the clamping strip is a straight side, a curved side or a folded side 8 . The outer contour of the protruding teeth is rectangular or trapezoidal.

[0039] see Figure 8-10 , this frame using the above-mentioned clamping strips is composed of keels 4, clamping strips 1, and steel mesh 5 combined and connected. The keels 3 are shaped steel parts and are arranged in parallel at intervals. The clamping strips are perpendicular to the keel, arranged in parallel at intervals, and fixed on one or both sides of the keel to form a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com