Longitudinal Splicing Structure and Splicing Method of Hollow Slab Beam in Expressway

A hollow slab beam and expressway technology, applied in bridges, bridge construction, bridge maintenance and other directions, can solve the problems of unstable quality of longitudinal joint splicing, affecting the anchoring force of planting glue, and difficult to control the amount of planting glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

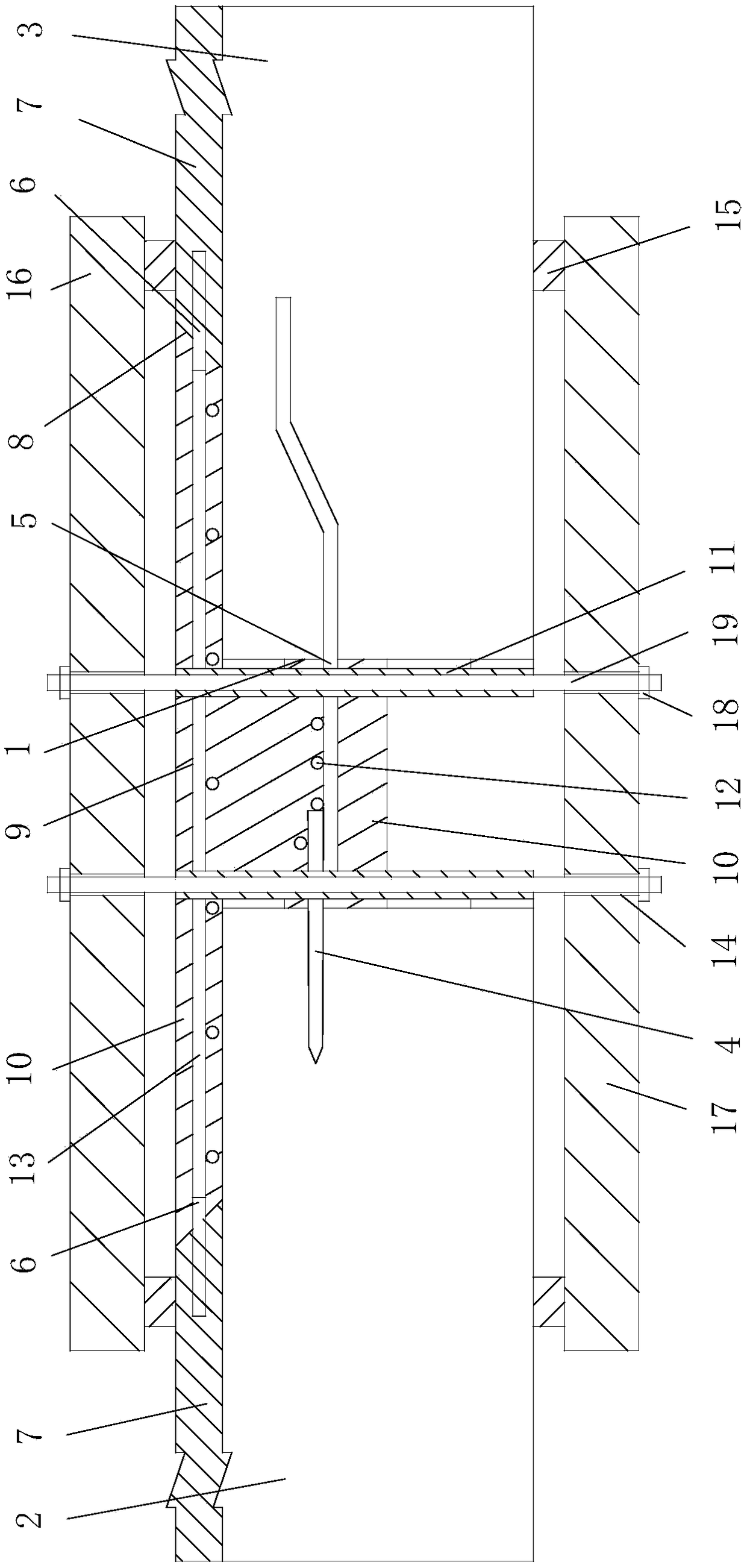

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] as attached figure 1 Shown: a longitudinal splicing structure of highway hollow slab girders, including: the old bridge hollow slab girder 2 and the new bridge hollow slab girder 3 arranged side by side with a filling gap 1 in the middle, and a plurality of hollow slab girders 2 along the old bridge The self-tapping bolts 4 arranged longitudinally on one side and connected with the self-tapping thread of the old bridge hollow slab girder 2 are arranged on one side of the new bridge hollow slab girder 3. The tails correspond to the pre-embedded connecting steel bars 5 welded one by one, and the outer sides of the upper end of the old bridge hollow slab girder 2 and the upper end outer sides of the new bridge hollow slab girder 3 are each equipped with a concrete pre-pavement layer 7 with a fixed steel bar group 6 embedded in it. In the pavement space 8 formed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com