Hollow floor system filled with an air-filling bag and construction method thereof

A hollow floor and air-filled technology, which is applied to floors, building components, buildings, etc., can solve the problems of waste of materials and the inability to ensure the compactness of concrete pouring, and achieve the quality of pouring, good economy and applicability, and crack resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is realized in the following manner:

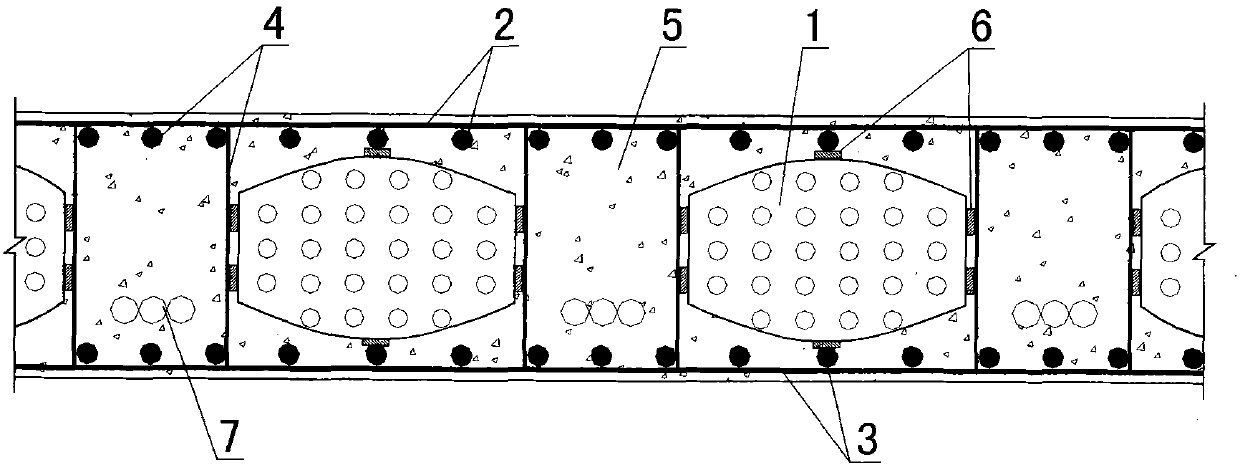

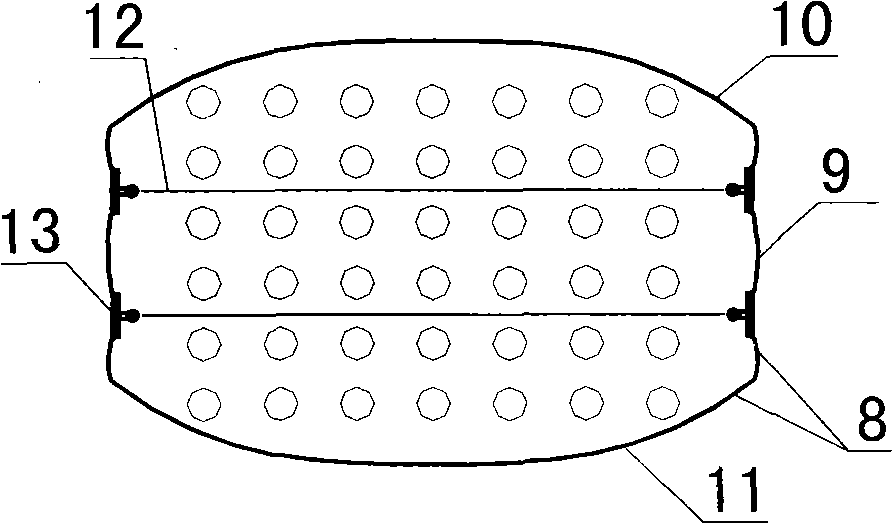

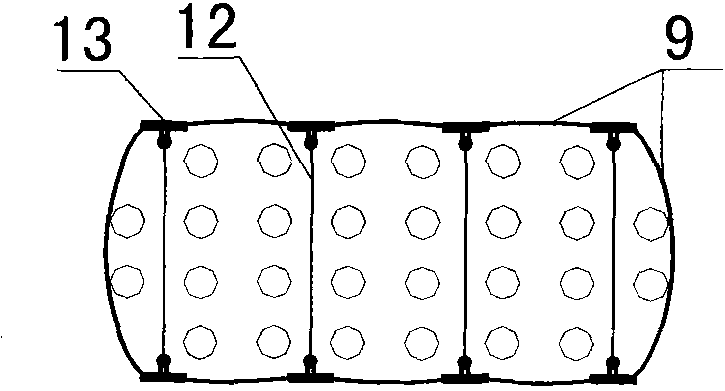

[0032] exist figure 1 , figure 2 , image 3 In the shown embodiment, a hollow floor filled with an air bag is composed of an air bag (1), upper reinforcement (2), lower reinforcement (3), concealed beam reinforcement (4) and concrete (5). (1) Located between the upper steel bar (2) and the lower steel bar (3) and the concealed beam steel bar (4), the bag wall (8) of the air bag (1) consists of four side walls (9) and one upper wall (10 ) and a piece of lower wall (11), after injecting compressed gas, the shape of the air bag (1) is hexahedron, and at least two side walls (9) adjacent to the hidden beam steel bar (4) in the air bag (1) have the shape Approximate to a plane, the shape of the upper wall (10) and the lower wall (11) is similar to an outwardly bulging arc surface, and the spacers (12) are set between the inner sides of the side walls (9) to ensure that the two pieces The side walls (9) are par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com