Sublever caving mining model in large subsection without sill pillar

A technology of sub-caving and no bottom column, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of poor technical and economic indicators, low mine production efficiency, etc., and achieve the effects of high accuracy and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

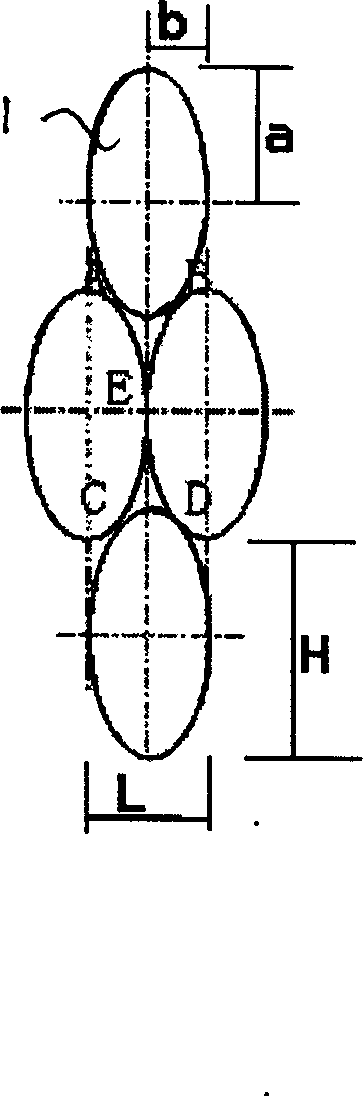

[0015] Referring to the accompanying drawings, a high-segmented bottom-pillar-free segmented caving mining model, with four spatially tangent discharge bodies 1 as a single body, the specific steps of the stope structure parameters are as follows: 1. According to the ore body storage conditions, mine Depending on factors such as production technology and economic level, select the appropriate section height H; 2. After the section height H is selected, press the ore drawing height H f Approximately equal to the determination method of the section height H, determine the ore drawing height H f ; 3. Drawing height H f After confirmation, according to the relation [2] C=0.000819H f 2 -0.025H f +2.578 Determination method, determine the ratio C of the semi-major axis a of the emanating body and the semi-minor axis b of the emanating body; 4. After C is determined, press the relational formula [1] H = ( 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com