Energy-saving aluminum electrolysis bath

An aluminum electrolytic cell and energy-saving technology, applied in the field of aluminum electrolysis, can solve the problems of restricting the development of the aluminum industry and the improvement of economic benefits, the production capacity of electrolytic aluminum cannot be fully utilized, and the energy consumption of aluminum electrolysis is high, so as to achieve the distribution of cathode current Uniformity, reduce investment cost, and alleviate the effect of magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

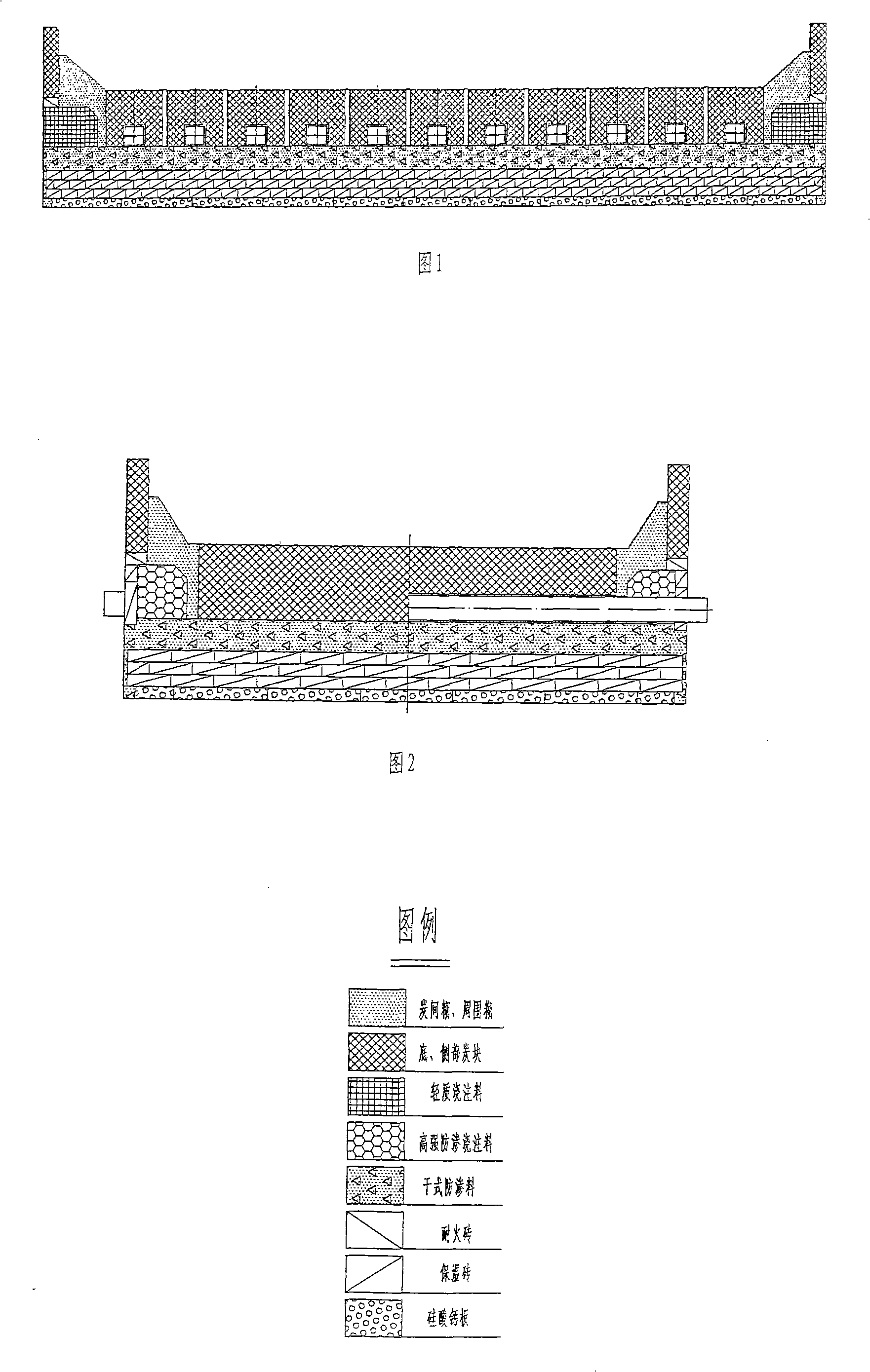

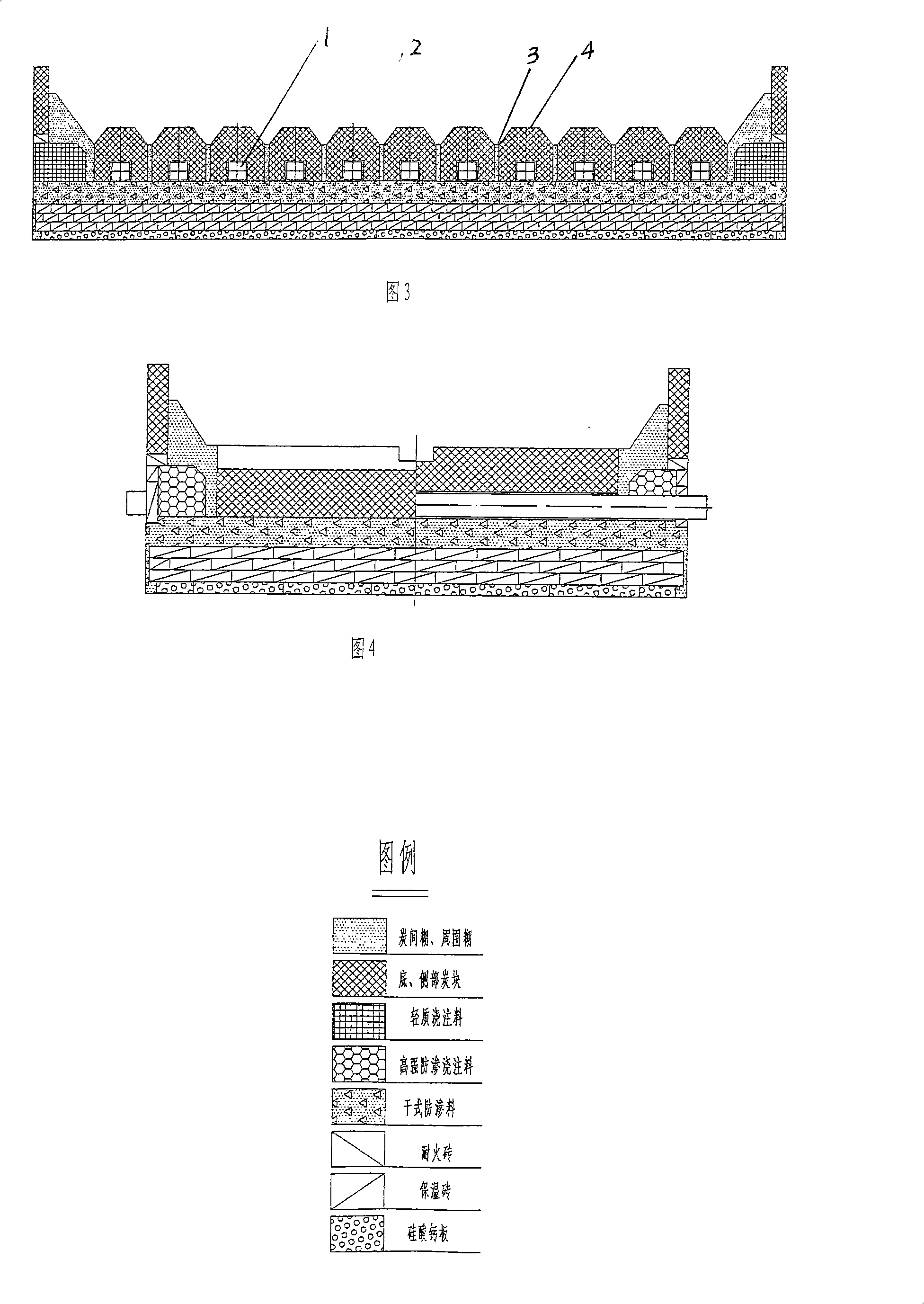

[0013] As shown in Figure 3 and Figure 4, the energy-saving aluminum electrolytic cell of the present invention is to design trapezoidal groove on the upper surface of the cathode carbon block, that is, a trapezoidal groove structure perpendicular to the longitudinal direction of the carbon block, and the cross-sectional size of the trapezoidal groove is: The surface is 200-250mm, the lower surface is 50-100mm, and the height is 100-200mm, which is a better size range. The cathode carbon block is made of graphitized or semi-graphitized carbonaceous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com