A comprehensive recovery and beneficiation method of low-grade uranium-containing polymetallic ore

A beneficiation method and polymetallic ore technology, applied in the field of uranium ore beneficiation, can solve the problems of low concentrate grade, low recovery rate, high recovery cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

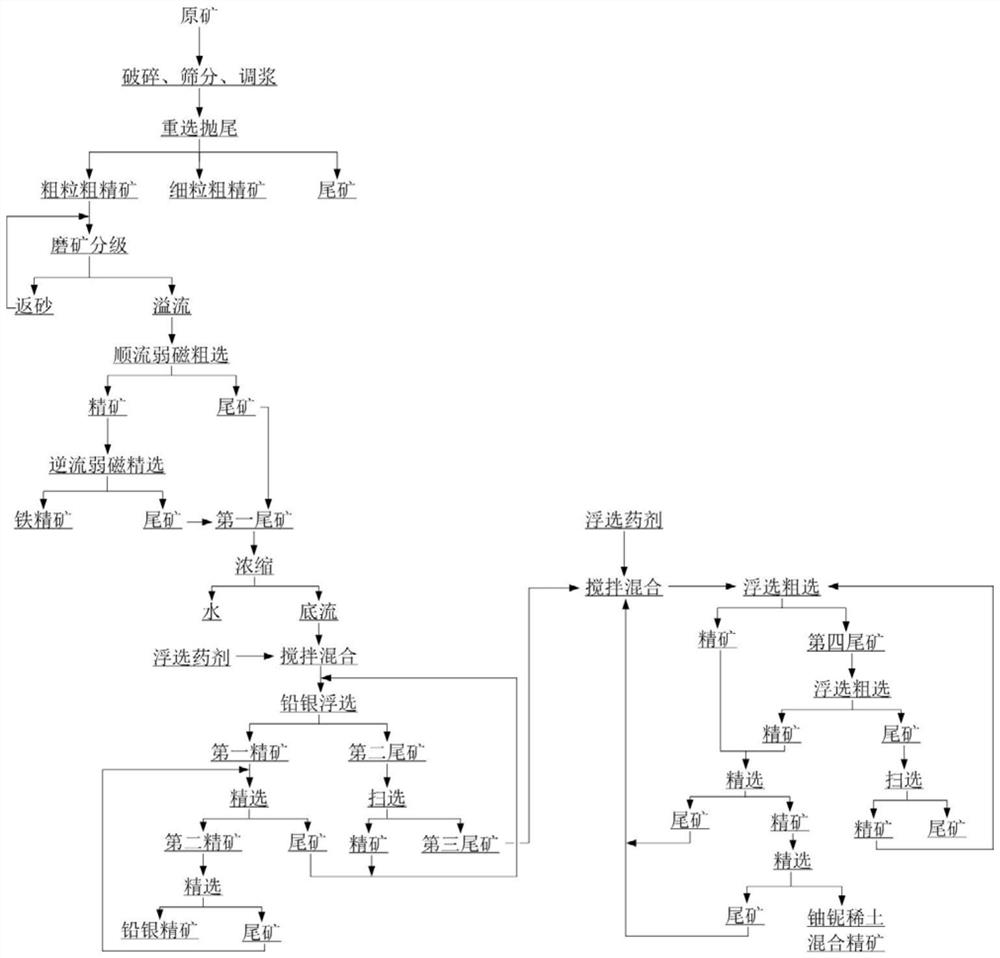

Image

Examples

Embodiment 1

[0153] This embodiment provides a comprehensive recovery ore dressing method for uranium-containing polymetallic ore. The uranium-containing polymetallic ore is a certain uranium-niobium-lead deposit, which is mainly composed of uranium, niobium and lead, and co-(associated) with gold and silver. , bismuth, cadmium, barium strontium and rare earth and other minerals are super-large hard rock uranium deposits, which have the characteristics of large scale, many kinds of minerals, low grade, shallow buried depth and easy mining. Most of the niobium and uranium in the ore are symbiotic in niobium-titanium-uranium ore, and most of the uranium-containing minerals are closely combined. Lead is mainly produced as galena, and a small part is produced as white lead ore. The rare earth mineral is mainly allanite.

[0154] Such as figure 1 As shown, the method includes the following steps:

[0155] (1) After the raw ore is crushed by jaw crusher and cone crusher in turn, it enters high-...

Embodiment 2

[0161]This embodiment provides a comprehensive recovery ore dressing method for uranium-containing polymetallic ores. The uranium-containing polymetallic ores are polymetallic ores containing uranium, rare earth and iron in a certain area, and the ore-containing vein rocks are mainly granite veins. The uranium-containing minerals are mainly niobium-titanium-uranium ore, followed by crystalline uranium ore and brown yttrium-niobium ore. The uranium-containing minerals are distributed unevenly, disseminated, and the particle size is very fine. Most of the uranium-containing minerals are closely symbiotic and form aggregates. Rare earth minerals mainly exist in monazite, iron mainly exists in the form of magnetite, lead mainly exists in the form of galena, followed by white lead ore, and silver and white lead ore are closely related.

[0162] The method comprises the steps of:

[0163] (1) After the raw ore is crushed by jaw crusher and cone crusher in turn, it enters high-pressu...

Embodiment 3

[0169] This embodiment provides a method for comprehensive recovery and beneficiation of uranium-containing polymetallic ores. The uranium-containing polymetallic ores are polymetallic ores containing uranium, thorium, niobium, and rare earths in a certain place, and the ore-containing vein rocks are mainly mixed pegmatites. veins, the uranium content in the ore body varies greatly, and the particle size distribution is uneven, showing a disseminated distribution. 60% of the uranium-containing minerals are concentrated in the +0.074mm particle size. Uranium ore, niobium-containing minerals are mainly distributed in niobium-titanium-uranium ore, followed by brown yttrium-niobium ore and niobium rutile. The rare earth minerals are mainly allanite, and a small part is monazite. The lead minerals are mainly galena, and the iron-bearing minerals are mainly magnetite, followed by pyrite and limonite. Finer, rare earth minerals are the finest.

[0170] The method comprises the steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com