Anshan-type hematite silicon-control benefication method

A mineral processing method, Anshan-style technology, applied in the field of Anshan-style hematite silicon-controlled mineral processing, can solve the problems of poor economic efficiency and sintering difficulties of the mineral processing plant, and achieve good economic benefits, good technical and economic indicators, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

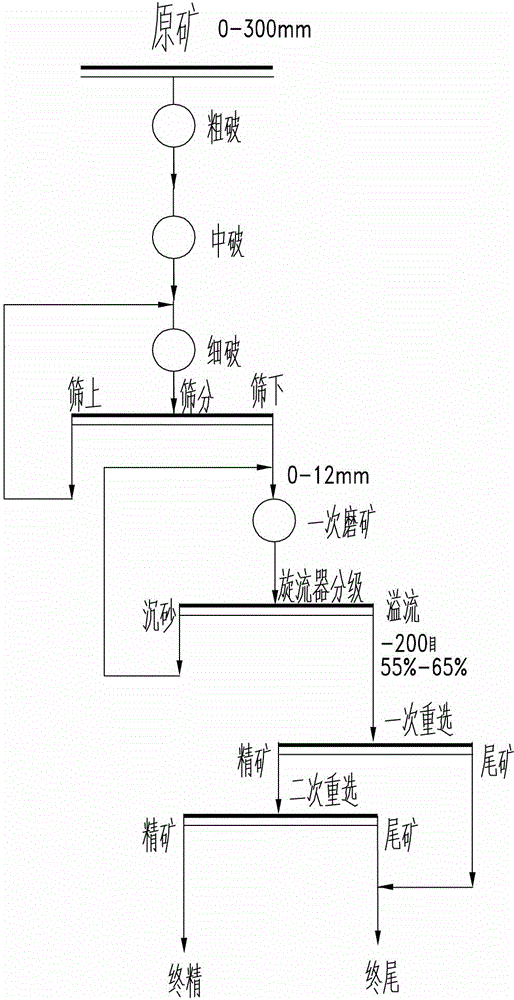

Image

Examples

Embodiment 1

[0021] The raw ore composition of Anshan type hematite used in embodiment 1 is:

[0022] Table 1 Composition of Anshan-type hematite in Example 1 %

[0023] TF SiO 2 CaO MgO Al 2 o 3 28.4 57.5 0.5 0.6 0.4

[0024] 1) Broken

[0025] Carry out medium crushing, fine crushing and screening operations on Anshan-style hematite mined from the stope,

[0026] Among them, the ore of coarse crushing is 0-300mm, the ore of medium crushing is 0-100mm, and the particle size of fine crushing and screening is 0-12mm, which accounts for more than 92%, and is sent to the cylindrical ore bin by belt conveyor;

[0027] 2) Ball mill classification

[0028] The crushed and sieved products with a particle size of 0-12mm accounting for more than 92% are fed into the overflow ball mill of model Ф5.49×8.83m by the feeding belt conveyor, and the overflow ball mill is combined with FX660×5-GT-HW The involute cyclone group forms a closed-circuit grinding for coarse ...

Embodiment 2

[0036] The raw ore composition of Anshan-type hematite used is the same as that in Example 1.

[0037] 1) Broken

[0038] Carry out medium crushing, fine crushing and screening operations on Anshan-style hematite mined from the stope,

[0039] Among them, the ore of coarse crushing is 0-300mm, the ore of medium crushing is 0-100mm, and the particle size of fine crushing and screening is 0-12mm, which accounts for more than 95%, and is sent to the cylindrical ore bin by belt conveyor;

[0040] 2) Ball mill classification

[0041] The crushed and sieved products with a particle size of 0-12mm accounting for more than 95% are fed into the overflow ball mill of model Ф5.49×8.83m by the feeding belt conveyor, and the overflow ball mill is combined with FX660×5-GT-HW The involute cyclone group forms a closed-circuit grinding for coarse and fine classification, and the proportion of -200 mesh ore powder is controlled at 62%;

[0042] 3) One re-election separation

[0043] Feed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com