Patents

Literature

59 results about "Increased iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for separating oolitic hematite

InactiveCN101693222AReduce lossesEconomic beneficiation costHigh gradient magnetic separatorsFlotationSulfateReverse flotation

The invention discloses a method for separating oolitic hematite, and the process of the method comprises discarding tailings of ores by intense magnetic separation through stage grinding and stage separation, and de-phosphorizing and increasing iron to the intense magnetic concentrated by reverse flotation. The intense magnetic separation is functioned of concentrating iron minerals and desliming, thereby preventing smile from influencing flotation. The highly-effective regulator is made from sodium carbonate, sodium silicate and sodium hydroxide, the collecting agent is a composite medicine made from hydroximic acid and alkyl sulfate, and the method for separating oolitic hematite is a key technology for the reverse flotation to further upgrade the concentrate of iron ore. The invention has the advantages of simple technological process, low energy consumption, low cost and good product index, and solves the defects in prior art.

Owner:GUIZHOU UNIV

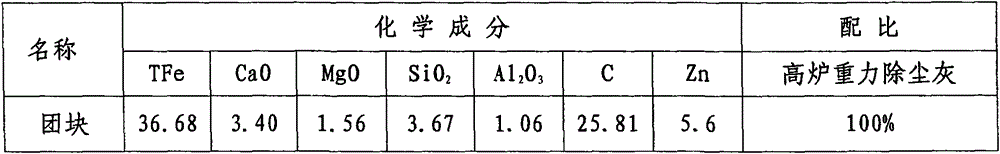

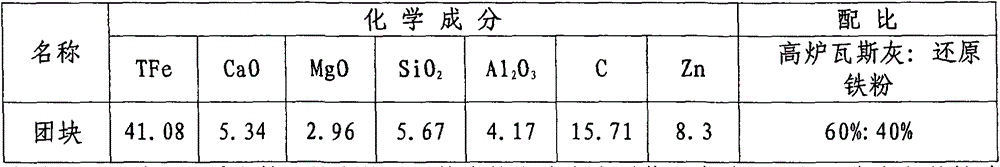

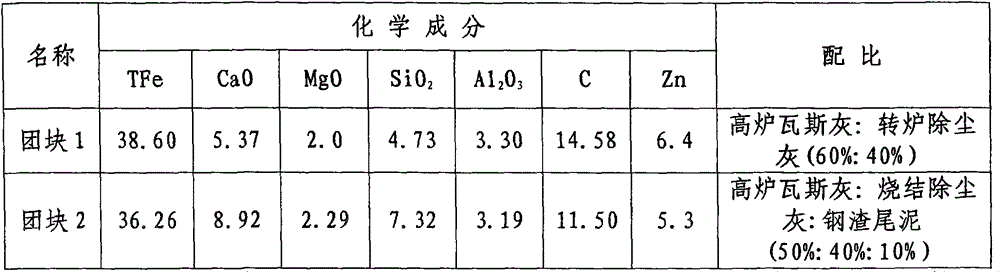

Technological method for reducing block masses containing carbon, iron, zinc, etc. into molten iron, zinc, etc. in blast furnace molten iron trough

ActiveCN105296694AReduce consumption costIncrease productionBlast furnace detailsSteelmakingSocial benefits

Te invention discloses a production technological method for reducing oxide block masses (pellets) containing carbon, iron and / or zinc, etc. into molten iron and / or zinc, etc. in a blast furnace molten iron trough (containing a swing flow spout in front of a furnace) and belongs to the field of steel metallurgy. The production technological method is characterized in that the oxide block masses containing the carbon, iron and / or zinc, etc. are added into the blast furnace molten iron trough before blast-furnace tapping and / or during tapping, so that the iron and / or zinc, etc. in the block masses are obtained in a reduction mode through the carbon. The production technological method has the advantages that one kind or several kinds of industrial powder material of cheap blast furnace gas dust (or gas mud), gravitational dust collection dust, sintering machine dust collection dust, converter dust collection dust (or mud), steelmaking steel slag powder, oxidized iron scales, reduced iron powder, etc. and reductants of carbon-containing coal powder, coke powder, etc. are mixed and made into the block masses, the block masses are added into the blast furnace molten iron trough, and the zinc is recovered through increased iron and / or dezincification; the industrial powder material difficult to treat is treated well, so that good economic and social benefits are achieved. Meanwhile, the effect of molten iron desilicication is further achieved.

Owner:廖辉明

Application method of slag conglomeration agent for desulphurization pre-treatment of molten iron

The invention relates to an application method of a slag conglomeration agent for desulphurization pre-treatment of molten iron. The invention is characterized in that the slag conglomeration agent comprises the following components in percentage by weight: 50-70% of SiO2, 15-20% of Al2O3, 8-17% of CaF2, 1-3% of CaO and the balance of impurities; the slag conglomeration agent is added 1-3min before desulphurization is finished; temperature of molten iron is 1280-1350 DEG C; and addition of the slag conglomeration agent is 1.0-2.0kg per ton of iron. The application method provided by the invention has the advantages that components of the slag conglomeration agent are optimized and adding time and addition amount of the slag conglomeration agent are improved on the basis of the original components of the slag conglomeration agent, and molten iron desulphurization effect is improved without increasing iron loss, so that the average desulphurization degree of molten iron is increased to 88.1% from the original 81.3% (test data for 100 furnaces).

Owner:INNER MONGOLIA BAOTOU STEEL UNION

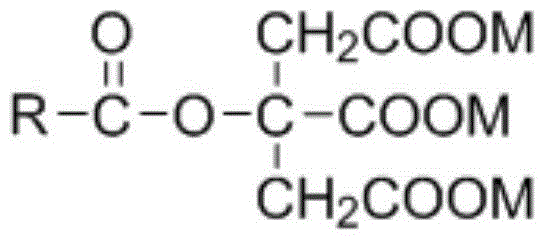

Combined collector capable of increasing iron grade and decreasing silicon content and preparation method and application thereof

InactiveCN104588216AExcellent iron-enhancing and silicon-reducing characteristicsMake up for performance deficienciesFlotationSide effectNitrogen

Owner:SHANDONG JIANZHU UNIV +1

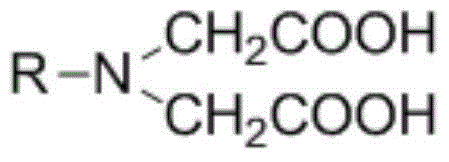

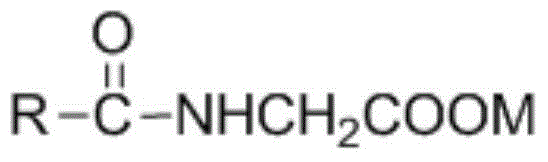

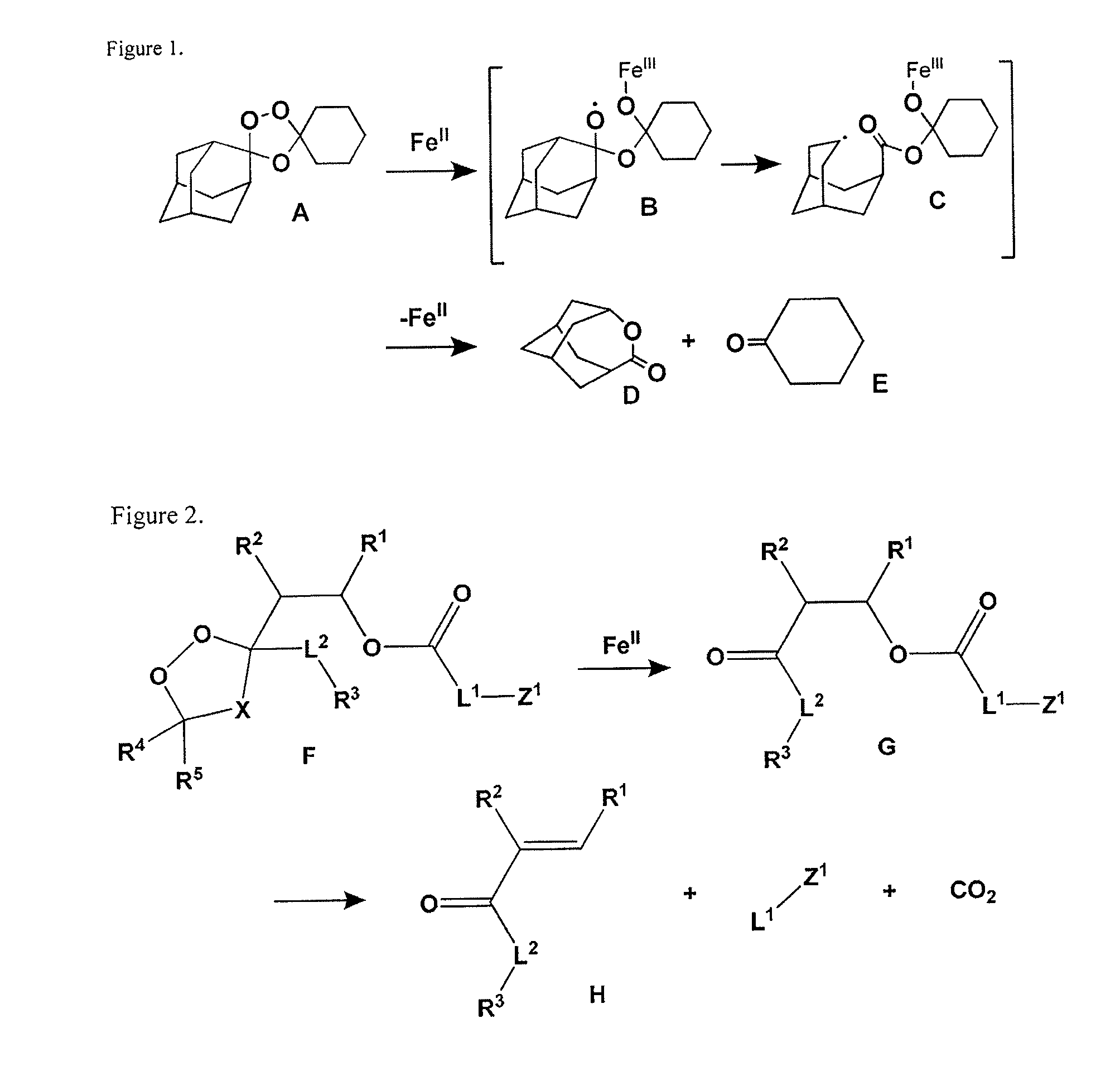

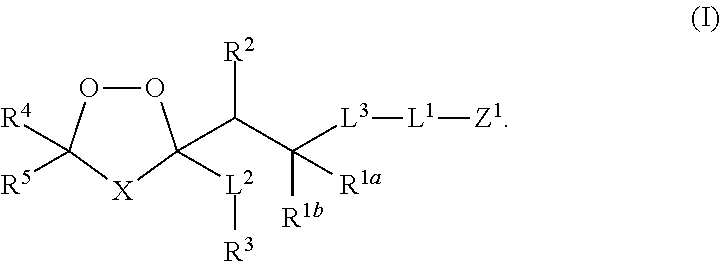

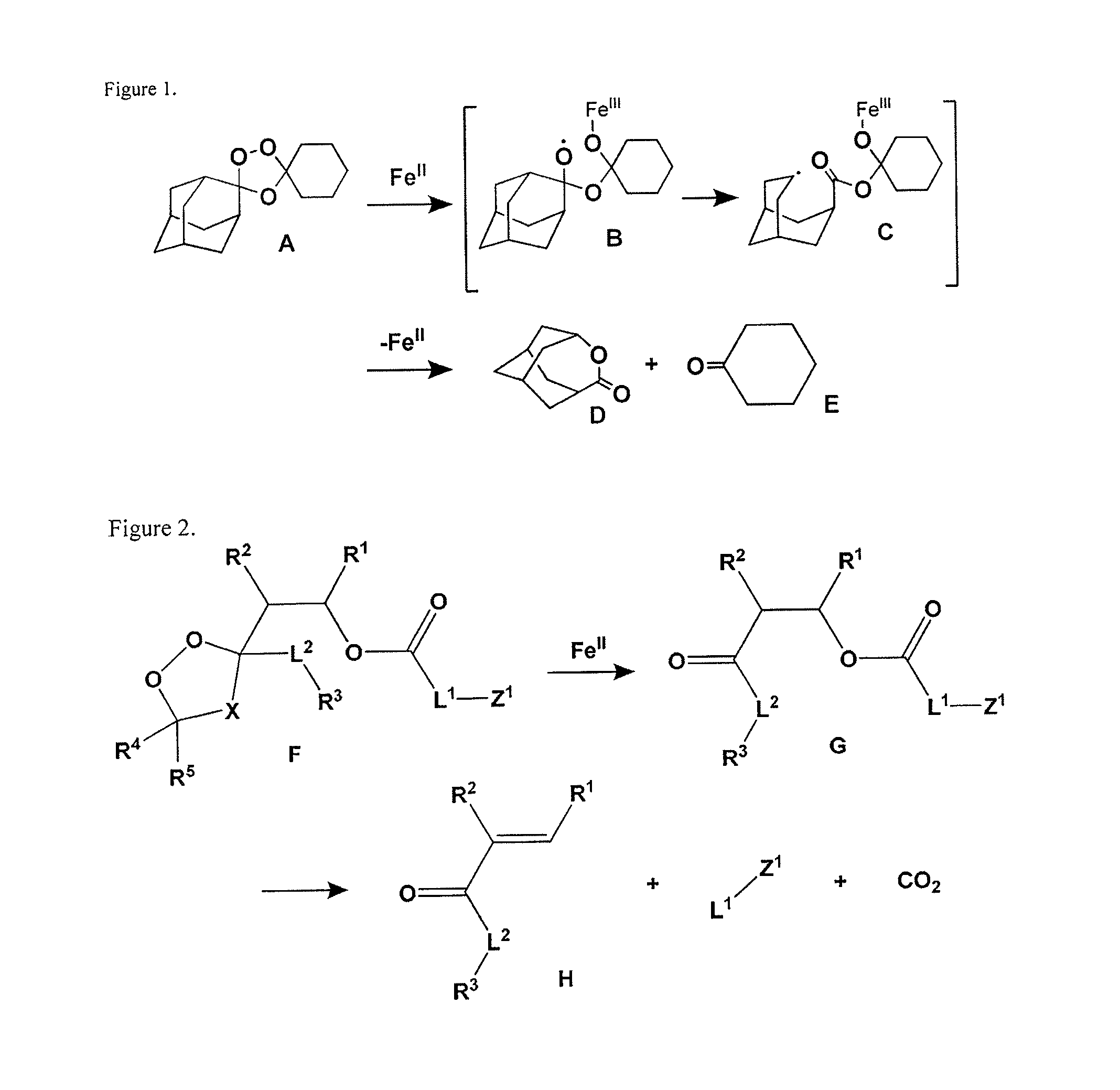

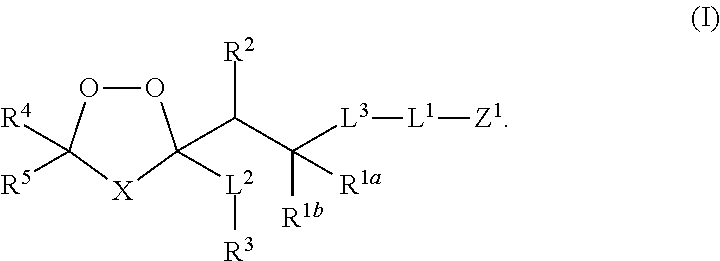

Prodrug and Fluoregenic Compositions and Methods for Using the Same

Methods and compositions for treating disease caused by increased iron levels are disclosed Fluoregenic compounds and methods of using the same are also described.

Owner:RGT UNIV OF CALIFORNIA

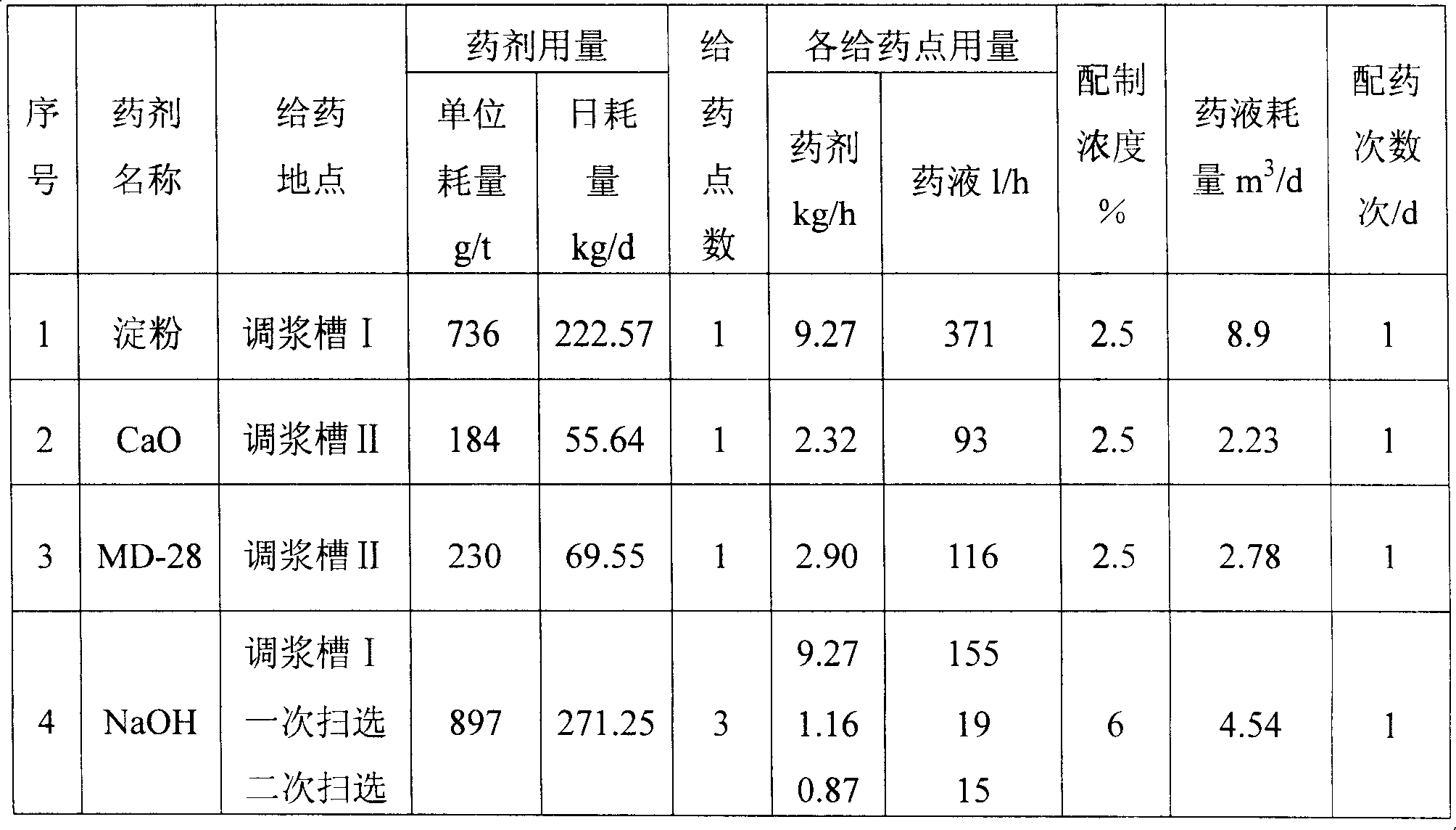

Anti-flotation Fe-refining and Si-reducing technology medicine

The invention relates to a technology reagent of reverse flotation for increasing iron and reducing silicon, which is characterized in that the technology reagent consists of the materials with the weight ratio: amylum: sodium hydroxide: collecting agent: calcium oxide is 1: 0.15-0.30: 0.20-0.35: 1.0-1.3. The reagent of the invention has the advantages of simple preparation process, convenient storage and rational adding method, etc. The invention is used in the reverse flotation milling. The iron grade of the iron concentrate can reach more than 66.5 percent and has a substantial economic benefit.

Owner:淄博市华联矿业有限责任公司

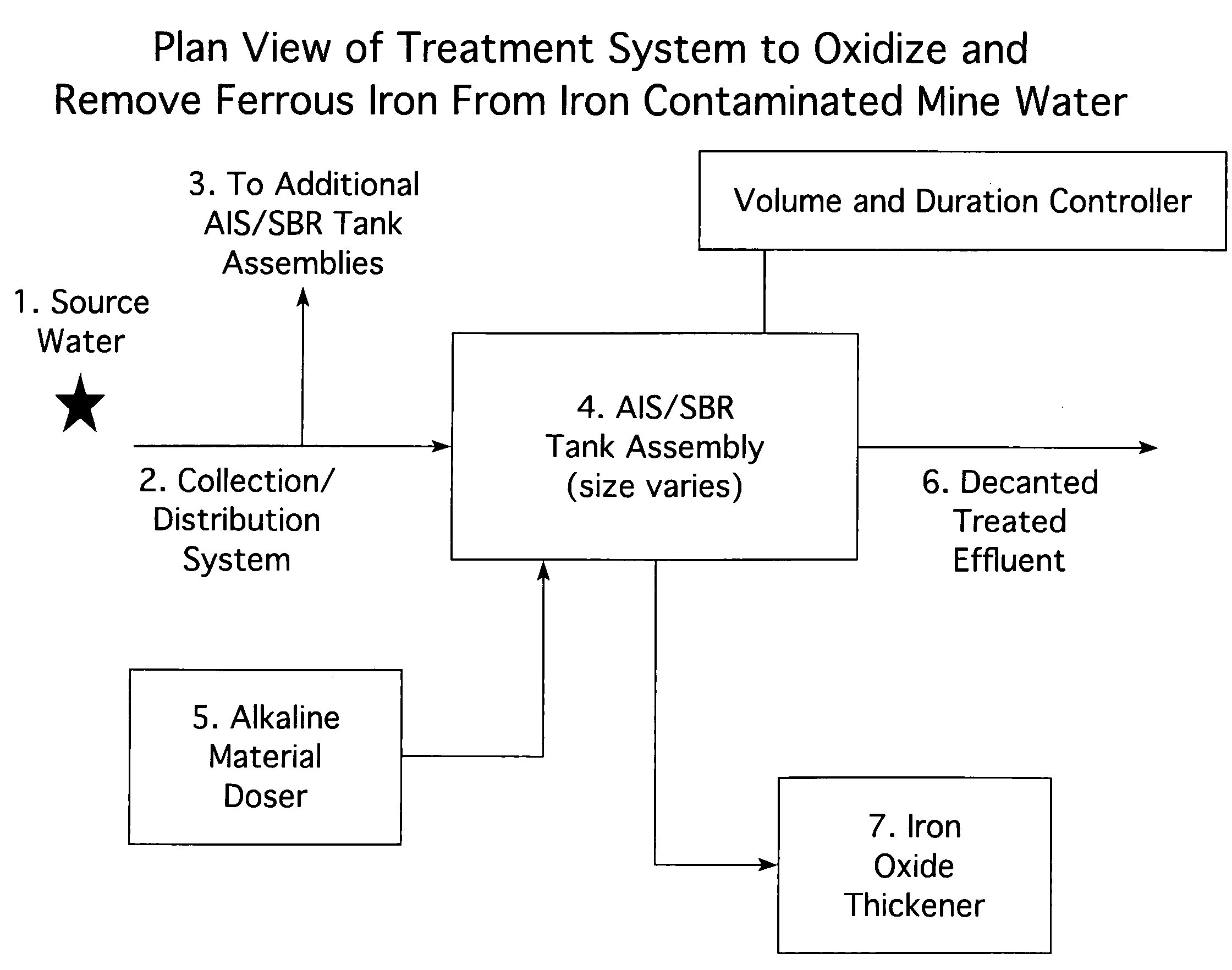

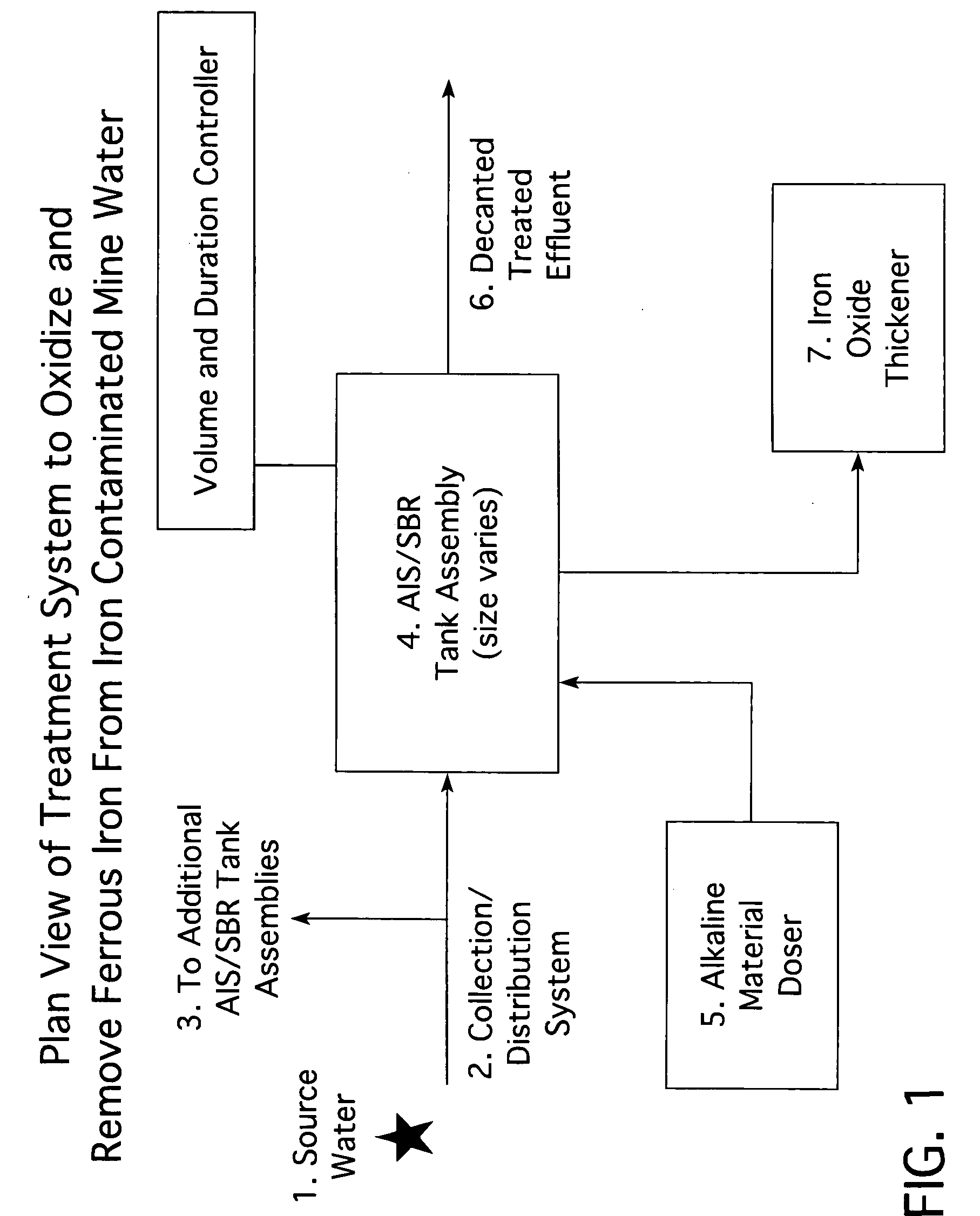

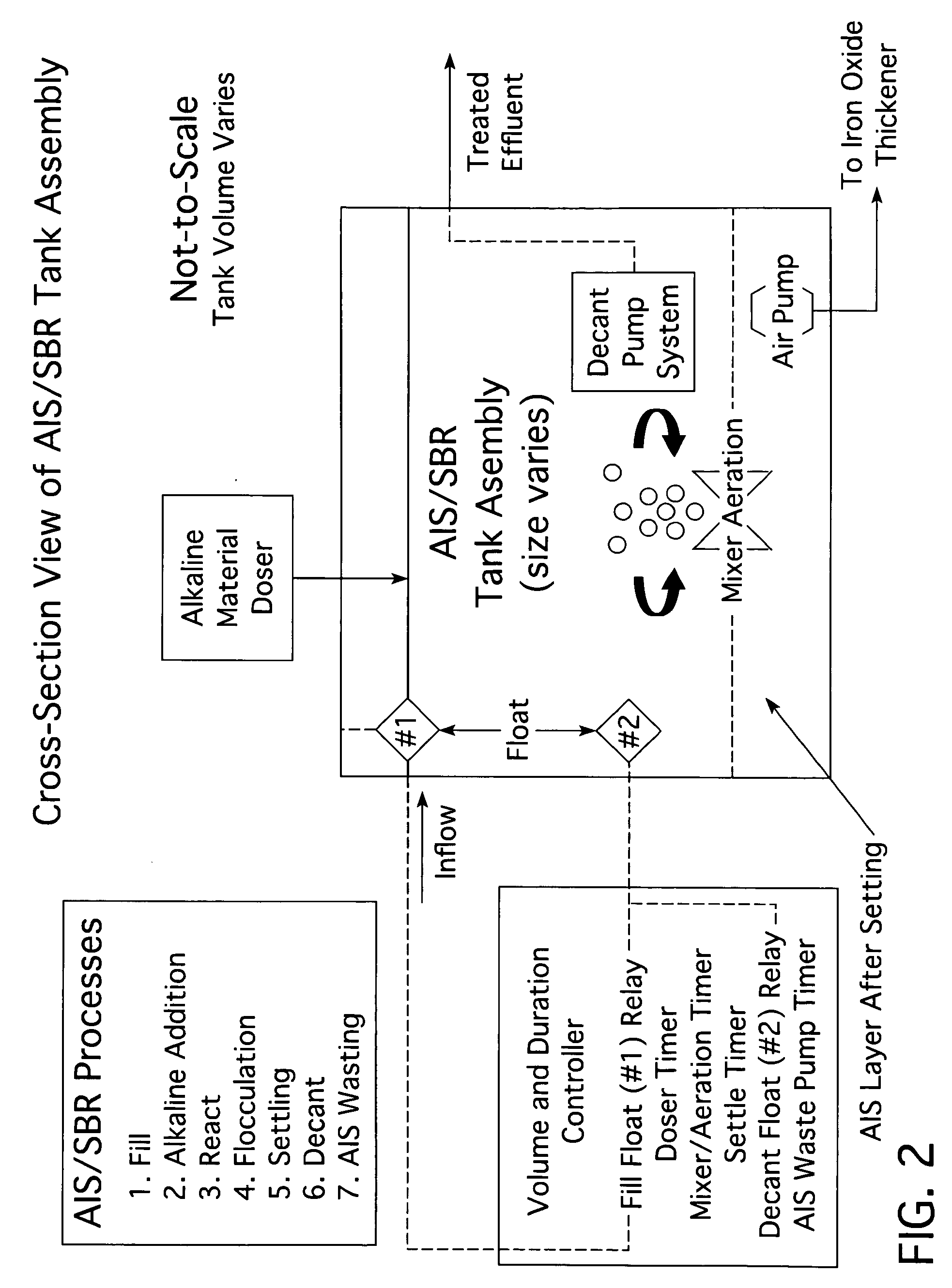

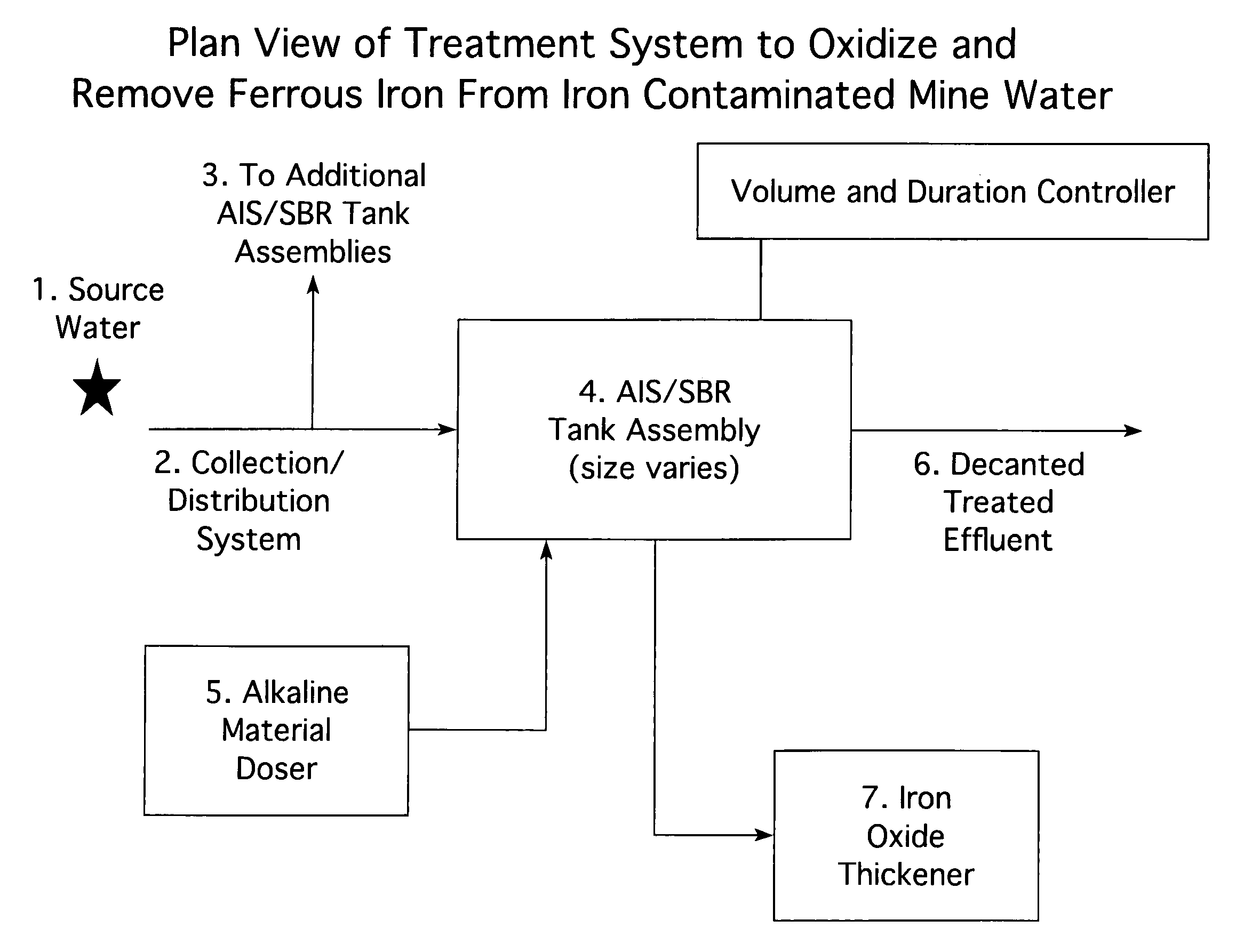

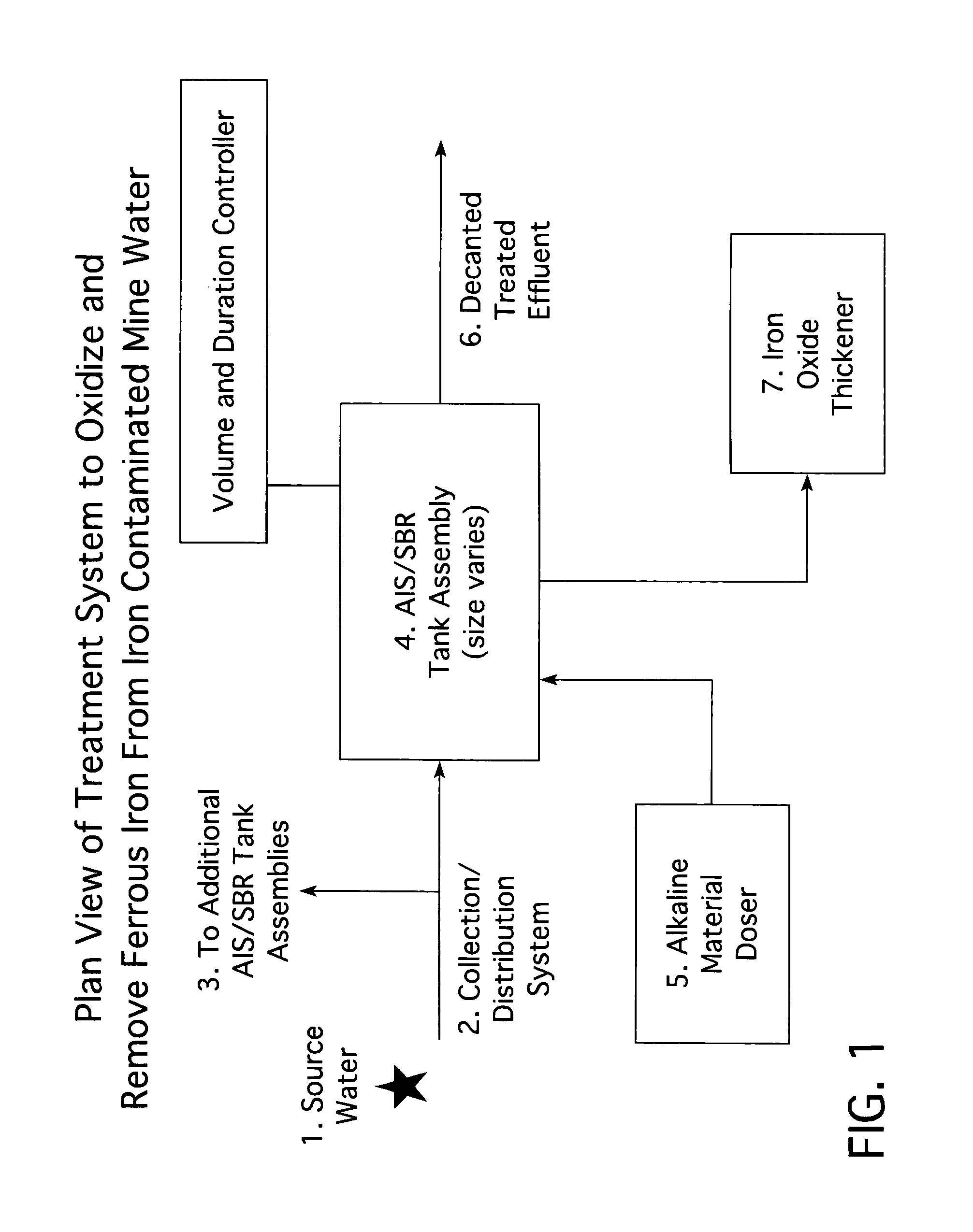

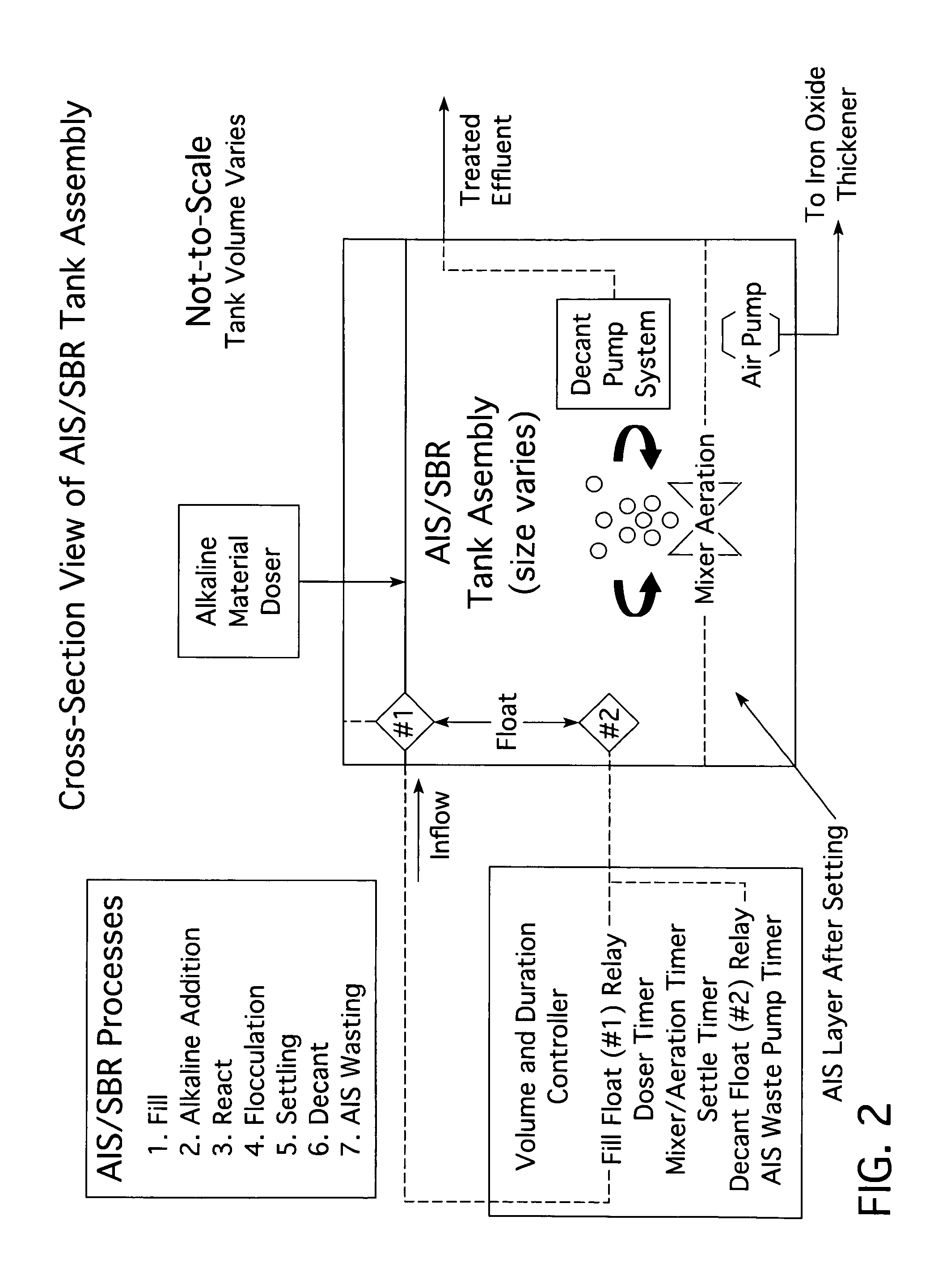

Treatment of iron contaminated liquids with an activated iron solids (AIS) process

ActiveUS20090084733A1Increase oxidation rateWaste water treatment from quariesWater treatment parameter controlHigh concentrationEarth surface

The present invention is a method and system for treating iron-contaminated water (e.g., mine drainage) using an innovative treatment approach identified herein as the Activated Iron Solids (AIS) Process. The AIS process is capable of oxidizing and removing iron as iron oxides from iron-contaminated waters (such as, mining-related discharge, groundwater, surface water and industrial waste streams) producing a clean effluent. The AIS process is performed in a single or multiple tank system in which high concentrations of AIS are suspended through mechanical mixing to maintain a catalytic surface chemistry environment that increases iron removal thousands times faster than would naturally occur and hundreds times faster than existing arts (e.g., aerobic pond passive treatment). The AIS process can utilize inexpensive alkaline material (such as, pulverized limestone) where initial mine drainage alkalinity (mg / L as CaCO3) to ferrous iron (mg / L) ratio is less than approximately 1.7. Excess accumulated activated iron solids are periodically removed from the system using a waste-activated iron solids (WAIS) system and directed to an iron oxide thickener for further concentration.

Owner:IRON OXIDE TECH

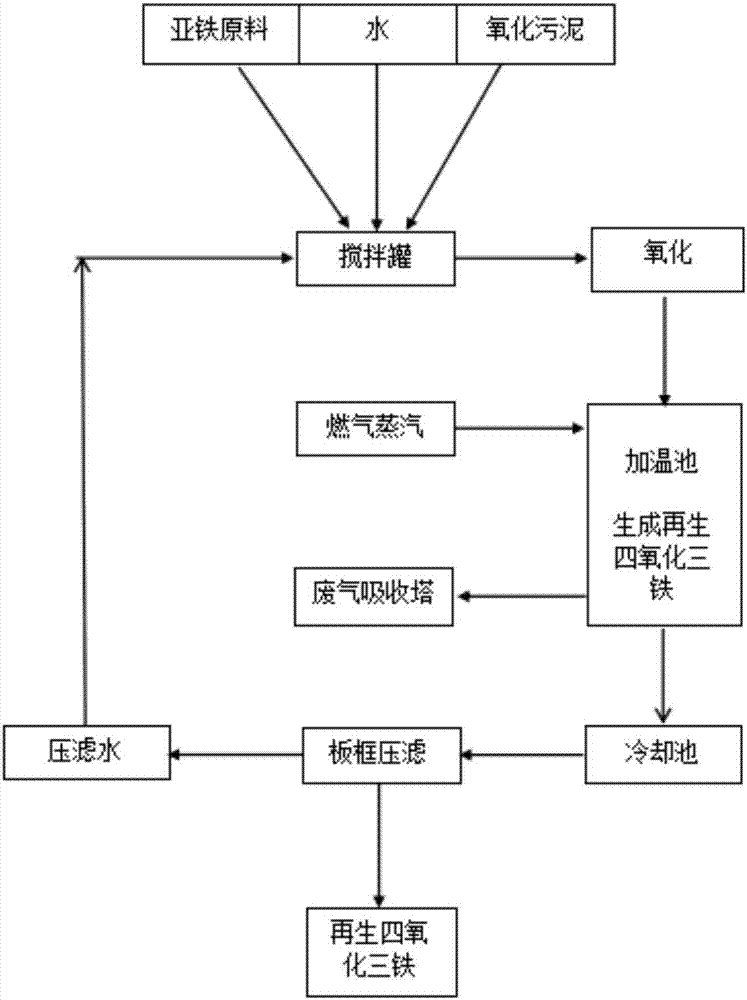

Resource utilization method after iron content of steel pickling sludge after quickly increasing iron contentis quickly improved

InactiveCN107200447AReduce the burden onSimple processSludge treatment by thermal conditioningSludge treatment by oxidationFerric hydroxideFiltration

The invention provides a resource utilization method after an iron content of steel pickling sludge after quickly increasing iron contentis quickly improved. The resource utilization method comprises the following steps: adding ferric hydroxide sludge and a ferrite solution which are generated by neutralizing and filter pressing pickling wastewater into a stirring tank and stirring; adjusting power of hydrogen of a mixture in the stirring tank until a the pH value reaches 6 to 9; transferring the evenly-stirred mixture into an oxidation pond and performing oxidation reaction; after reaction finishes, transferring the mixture into a warming tank and introducing steam to worm warm to generate recycled ferroferric oxide; transferring a generated recycled ferroferric oxide mixed material into a cooling tank to be cooled; performing filter pressing after cooling to obtain a black recycled ferroferric oxide magnetic mineral powder mud material; conveying filtration water generated in a filter pressing process into the stirring tank to be circulated and recycled. The resource utilization method disclosed by the invention has the advantages of simple technology, convenience in operation, safety, reliability, high treating efficiency, no secondary environmental pollution and the like; in addition, pollution sources are changed into recycled resources after the iron content is improved.

Owner:天津丰源首创环保科技有限公司

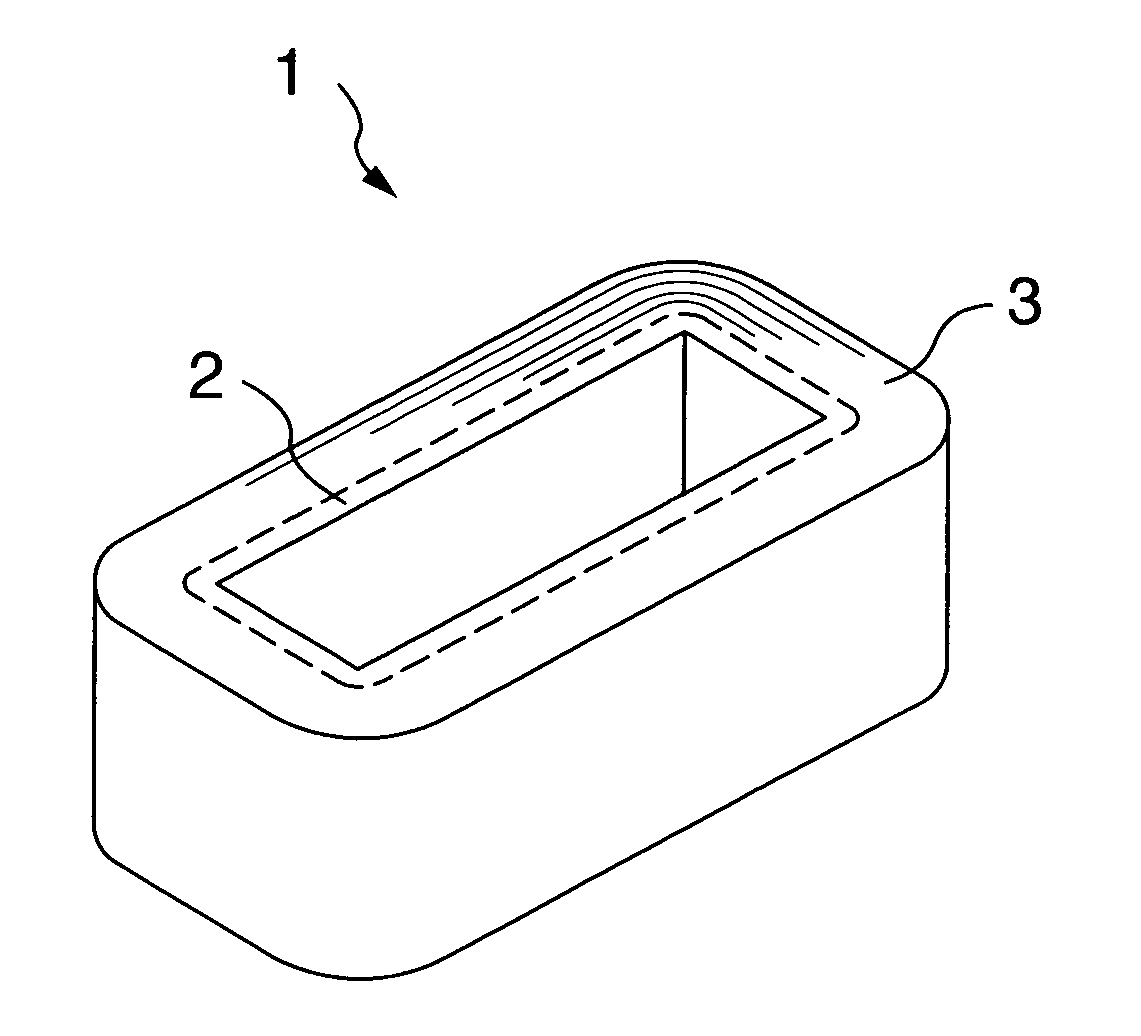

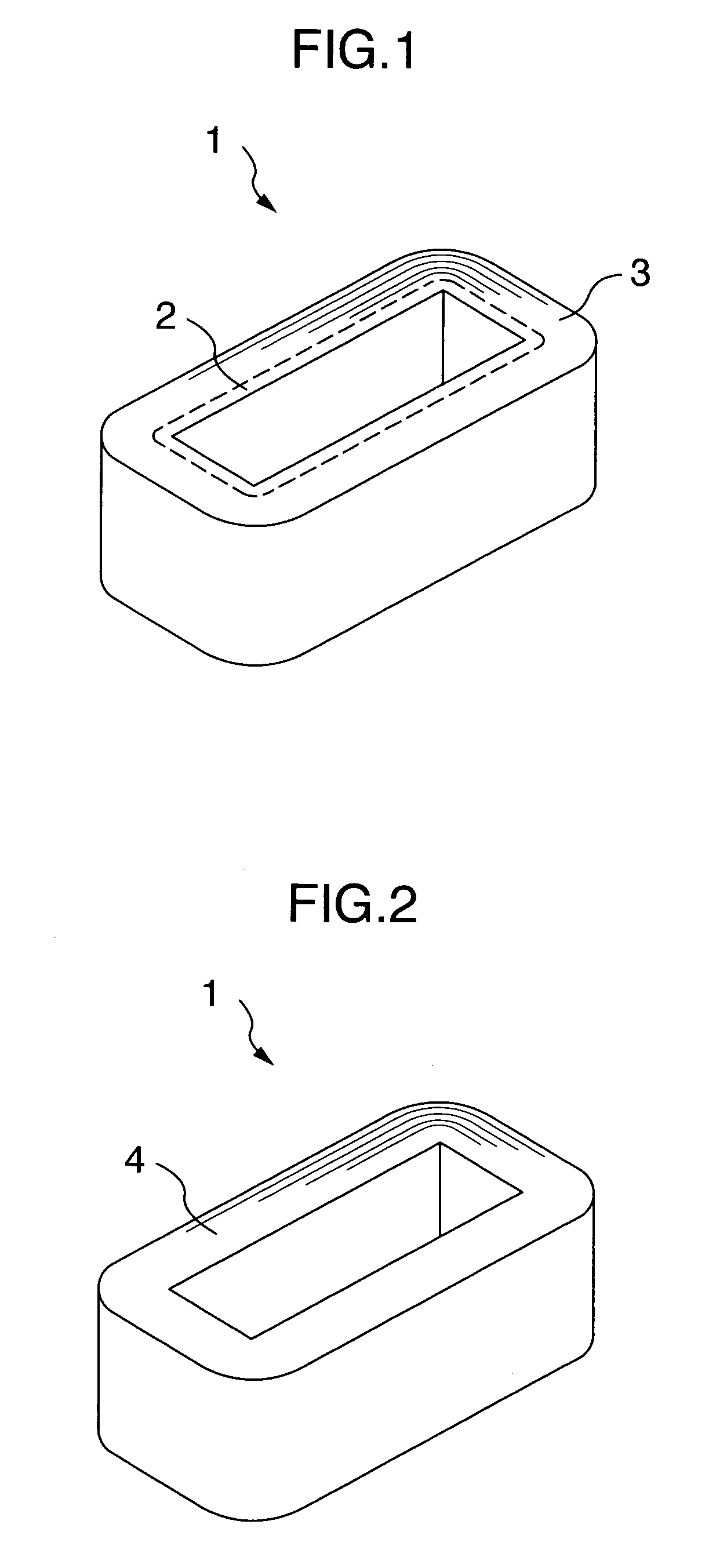

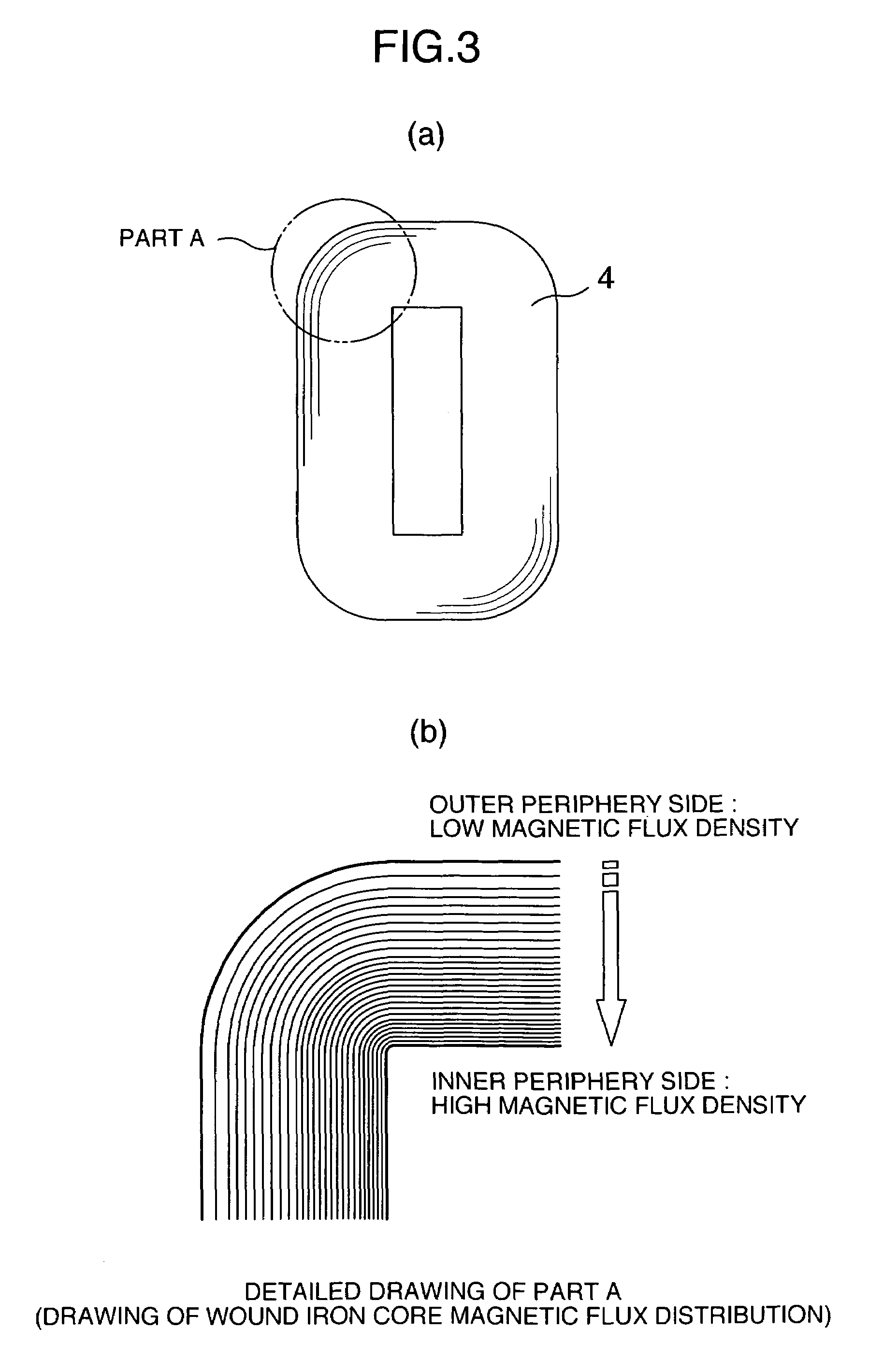

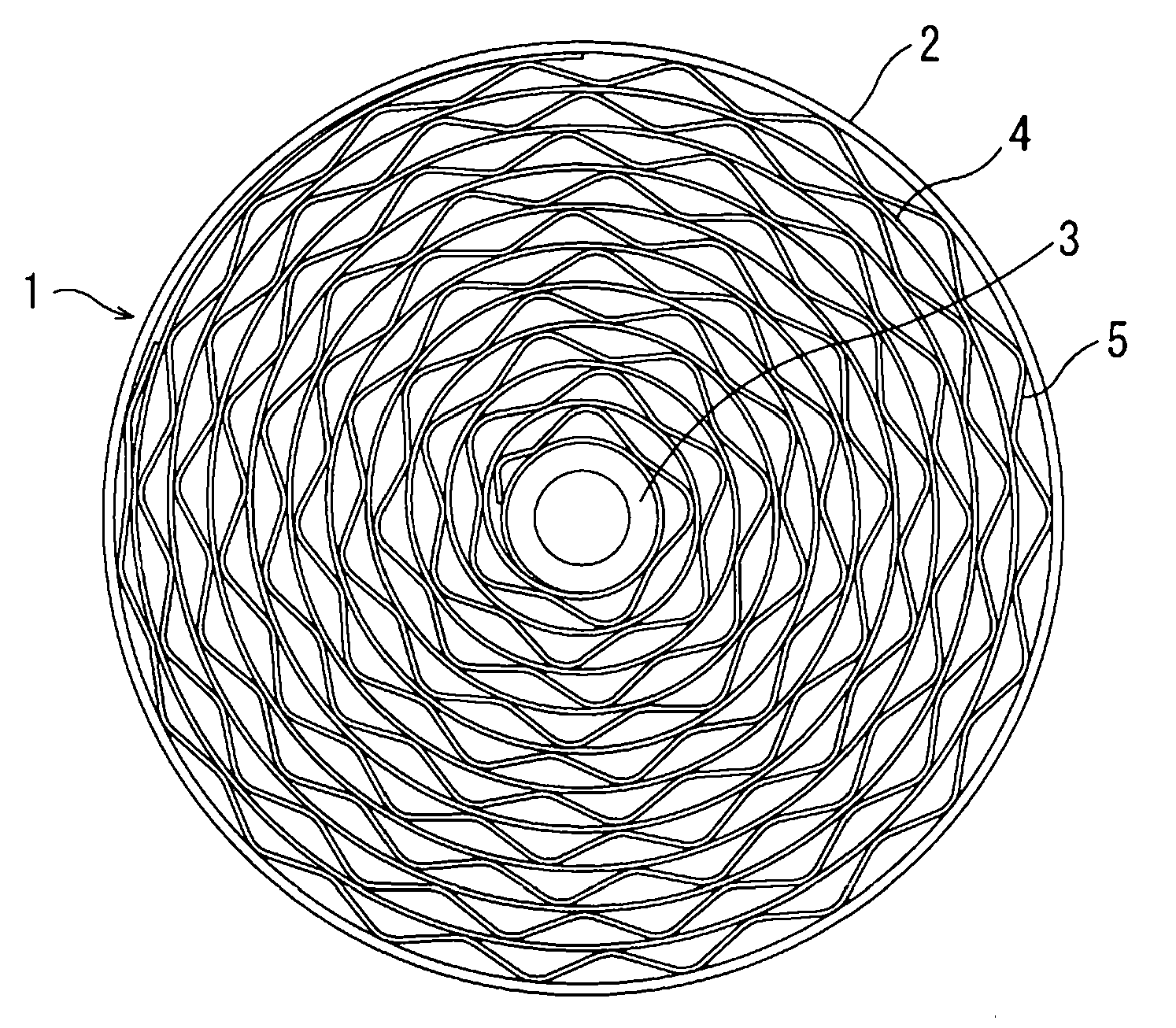

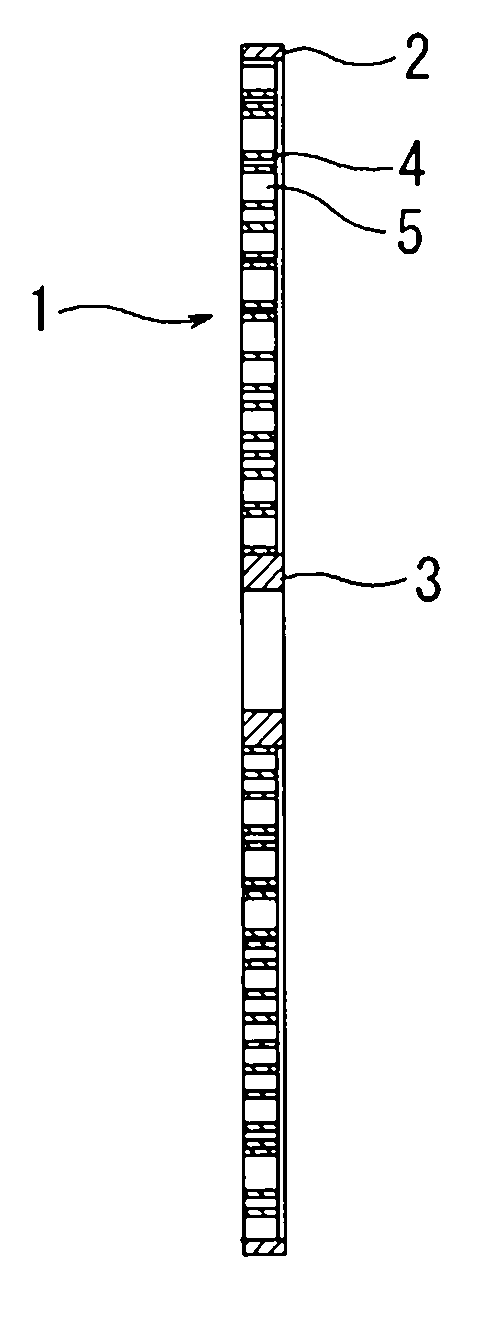

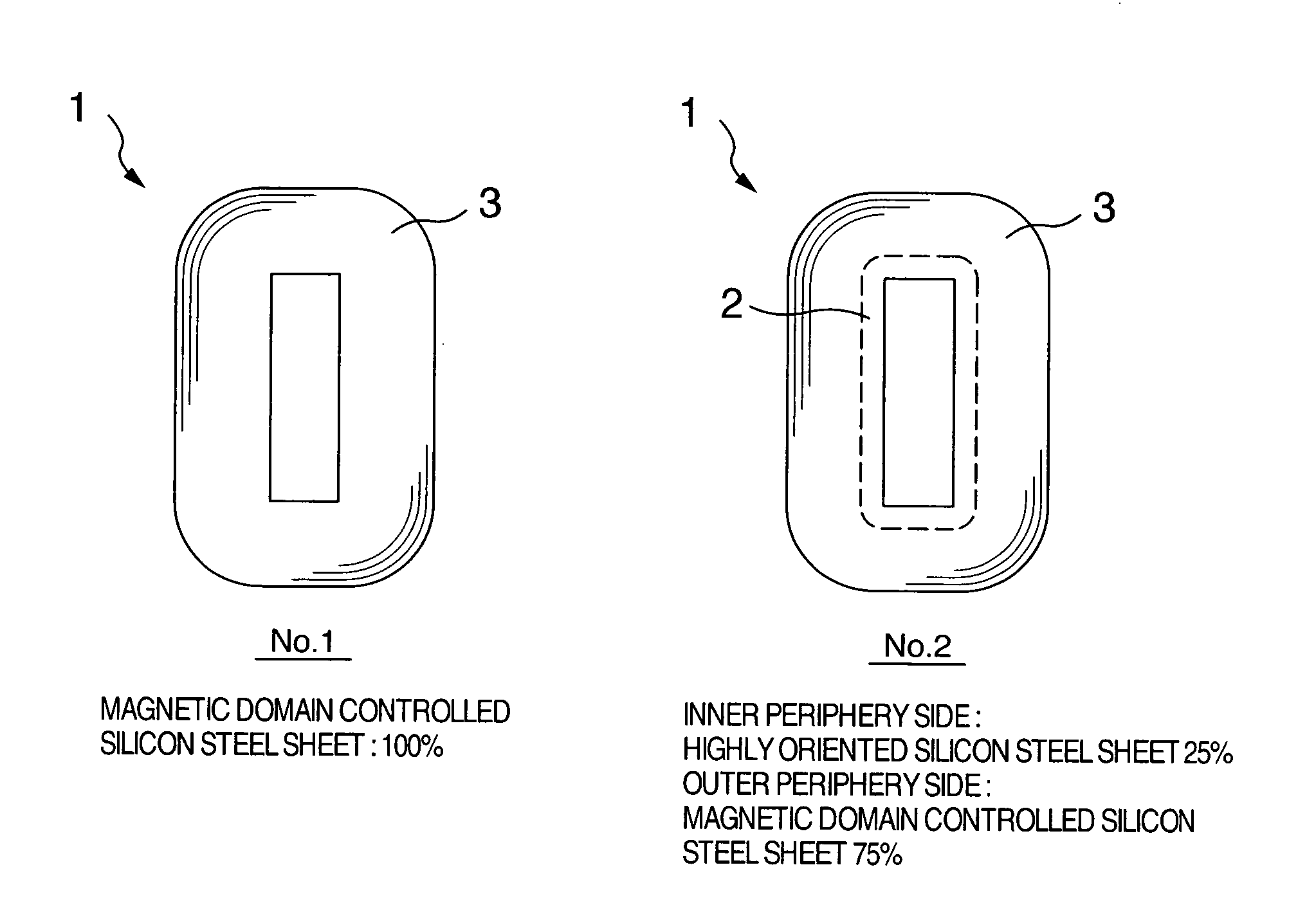

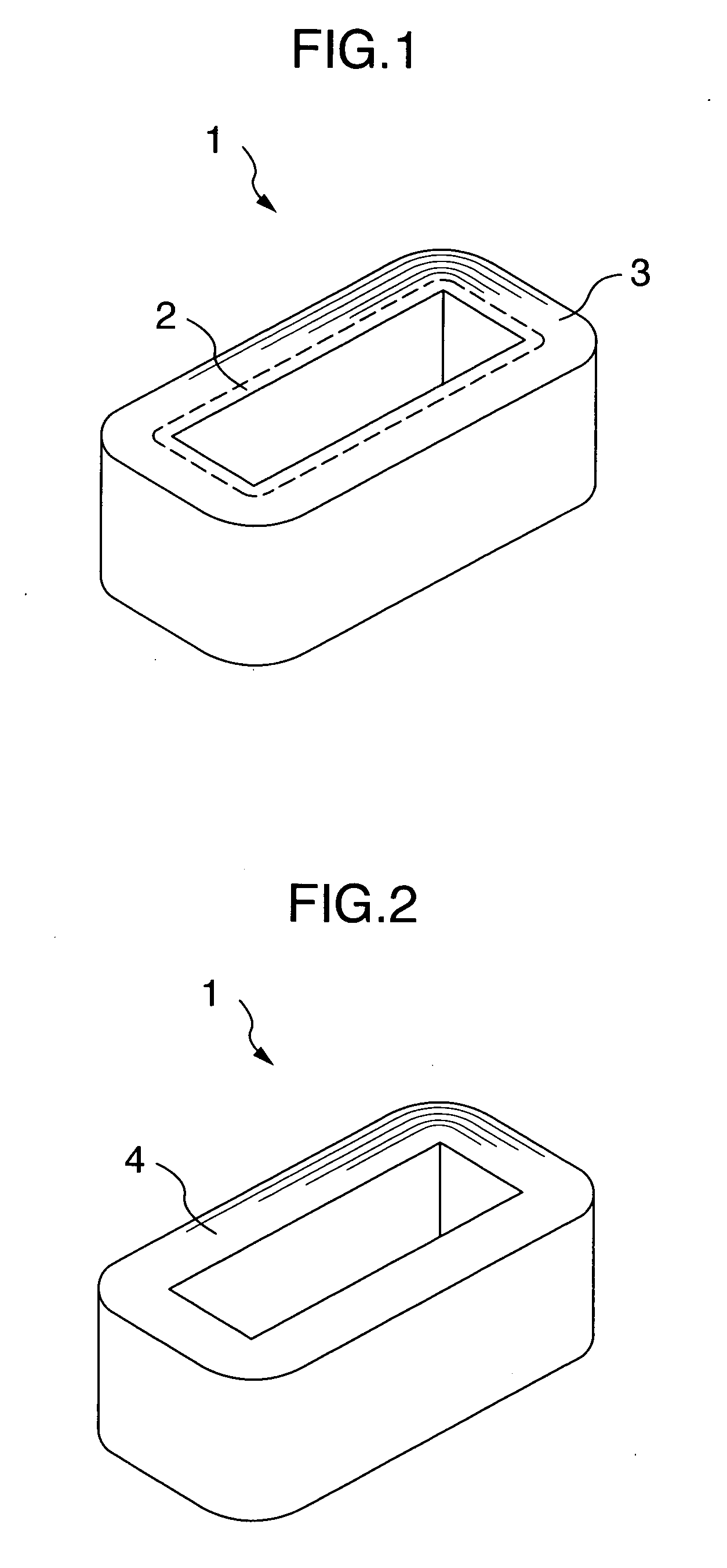

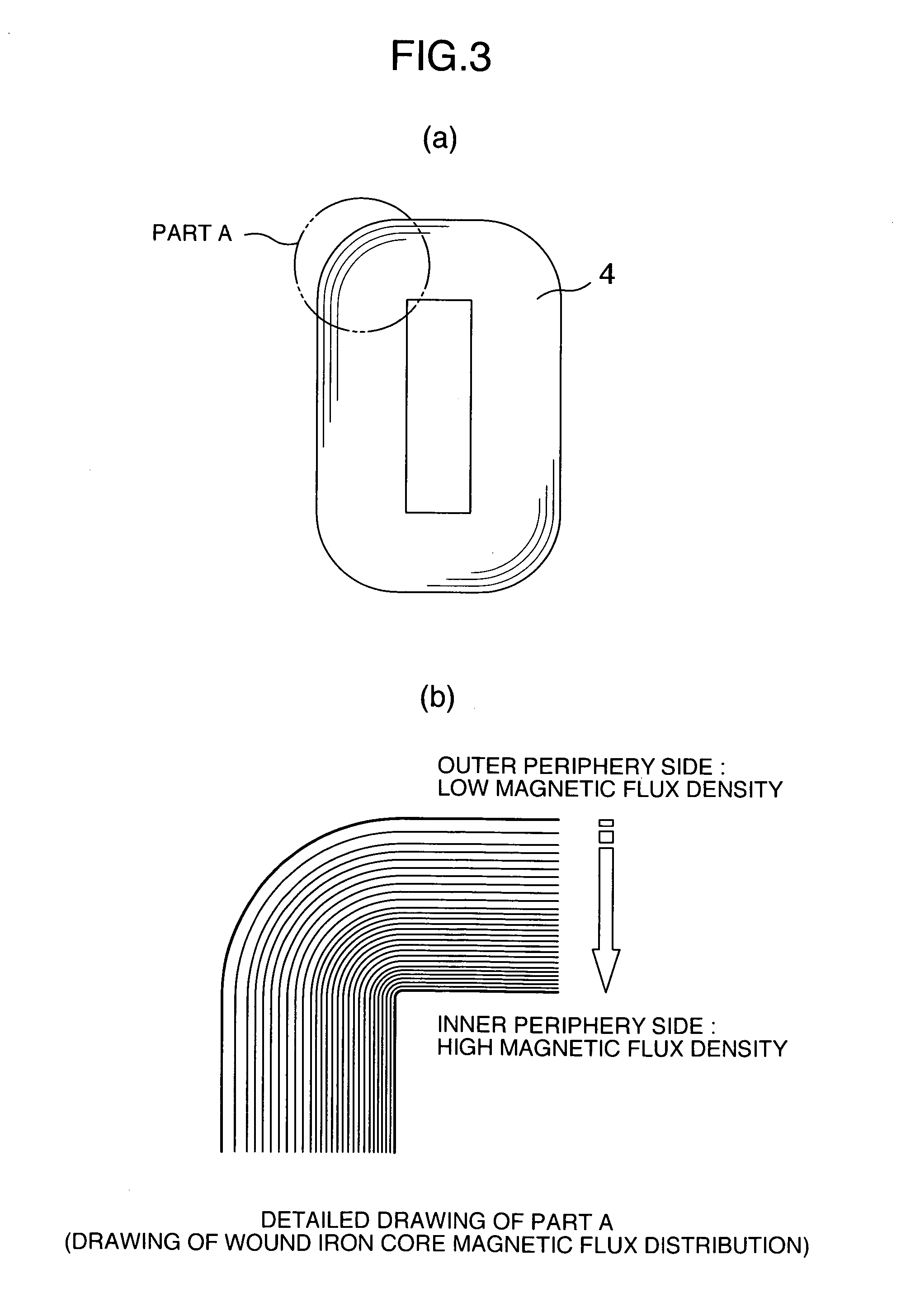

Iron core for stationary apparatus and stationary apparatus

InactiveUS7675398B2Small magnetic resistanceMagnetic flux densityTransformers/inductances magnetic coresCores/yokesMagnetic reluctanceMagnetic characteristic

Magnetic flux in a magnetic flux distribution inside a wound iron core for a stationary apparatus is mal-distributed toward the inner periphery side where the magnetic path of a laminated magnetic steel sheet is short with respect to the total lamination thickness and magnetic resistance is small and the inner periphery side on which magnetic flux is concentrated has a high magnetic flux density and increased iron loss, and therefore magnetic steel sheets of different magnetic characteristics are disposed at an arbitrary lamination ratio to make uniform the magnetic flux distribution inside the same wound iron core. In order to make uniform the magnetic flux distribution inside the wound iron core for a stationary apparatus, such a structure is adopted that a magnetic steel sheet having a magnetic characteristic inferior to that on the outer periphery side is disposed on the inner periphery side having a shorter magnetic path and smaller magnetic resistance and a magnetic steel sheet having a magnetic characteristic superior to that on the inner periphery side is disposed on the outer periphery side having a longer magnetic path and greater magnetic resistance to thereby make uniform the magnetic flux distribution in a sectional area of the iron core.

Owner:HITACHI IND EQUIP SYST CO LTD

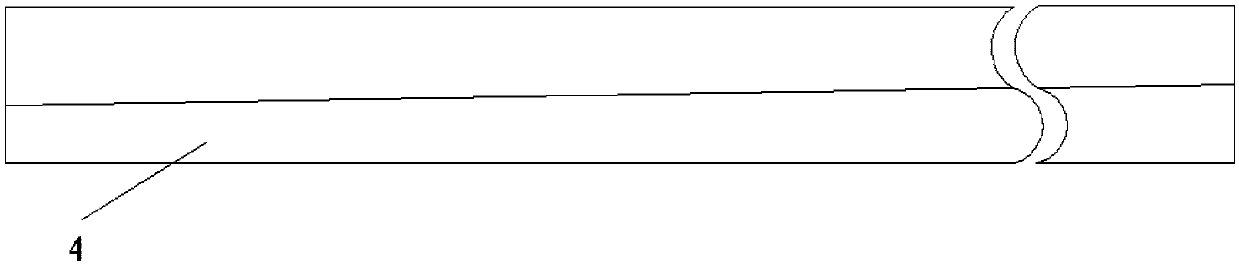

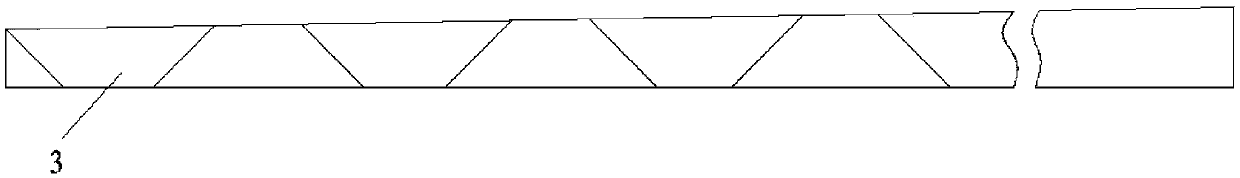

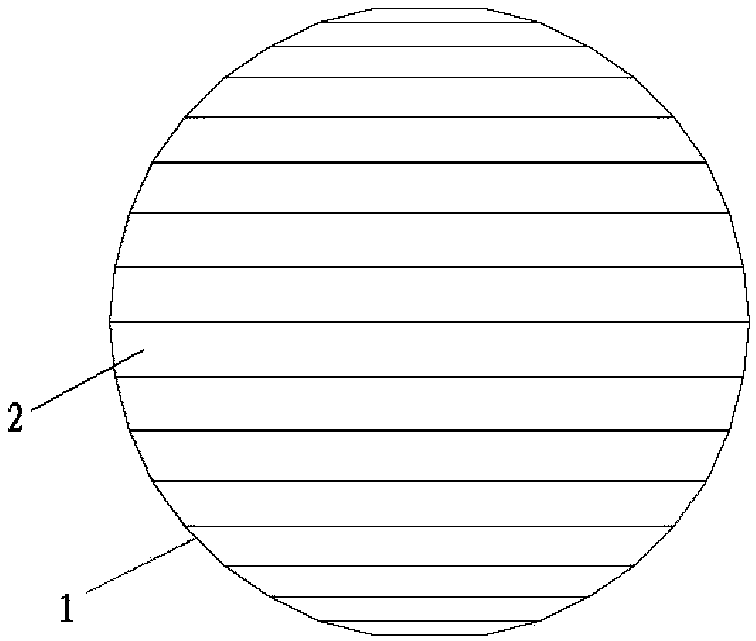

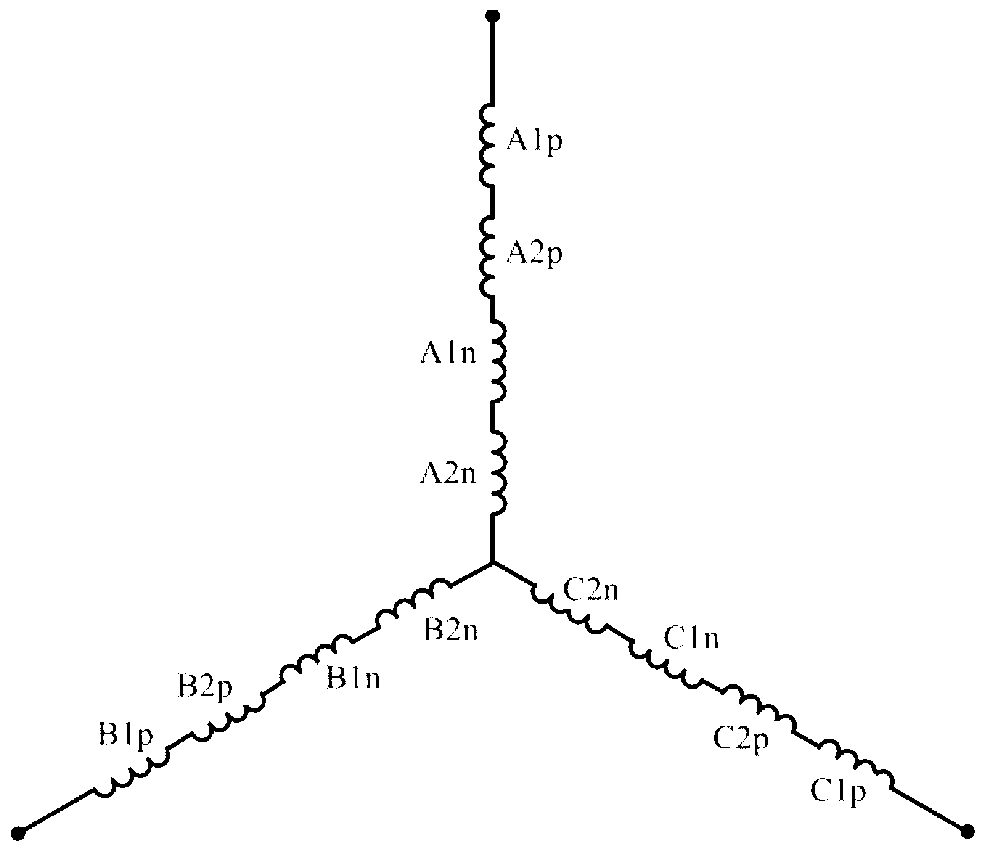

Iron core structure capable of increasing iron core filling rate and shearing and assembling method of iron core structure

PendingCN107658110AImprove fill rateImprove tooling efficiencyTransformers/inductances magnetic coresInductances/transformers/magnets manufactureSingle stageFilling rate

The invention relates to an iron core structure capable of increasing the iron core filling rate and a shearing and assembling method of the iron core structure. A core column and a yoke of an iron core are polygonal cross sections which are laminated by multi-grade trapezoidal cross-section structures, and the lengths of adjacent bottom sides of two adjacent grades of trapezoids in the cross section of the core column or the cross section of the yoke are equal. The method comprises the steps of conducting longitudinal shearing on a silicon steel sheet roll material according to a prescribed angle formed by the roll material and a rolling direction to form a trapezoidal material; conducting transverse shearing on the trapezoidal material according to the prescribed angle and the length ofa single silicon steel sheet to form multiple single silicon steel sheets; laminating the multiple single chip silicon steel sheets into one grade of the iron core, wherein the cross section is a trapezoid; laminating multiple grades of different specifications according to the method; laminating the multiple grades into one iron core. The single-grade iron core cross section of the trapezoidal structure is adopted, the iron core filling rate is effectively increased, the materials of the iron core can be saved by 20%, the cost is lowered, three-phase coils are independently wound and then sleeved with a core column part of a stereoscopic laminated iron core, lamination is convenient, the assembly time is shortened, and the tool efficiency is improved.

Owner:TEBIAN ELECTRIC APP CO LTD +1

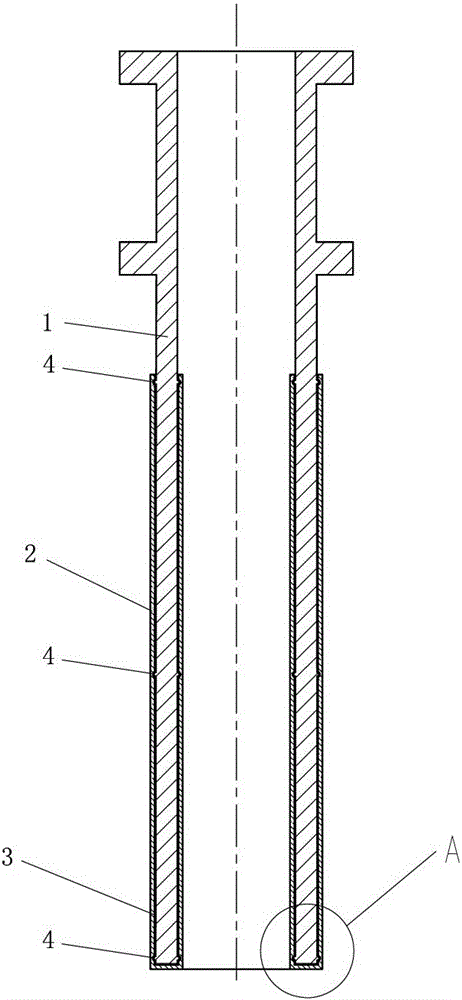

Riser tube and manufacturing method thereof

The invention discloses a riser tube for a low-pressure cast aluminum alloy gearbox and a manufacturing method of the riser tube. The riser tube comprises an iron riser tube body and further comprises a ceramic protection sleeve and refractory cotton transition layers. The iron riser tube body is wrapped with the refractory cotton transition layers. The refractory cotton transition layers are wrapped with the ceramic protection sleeve. The method comprises the steps that the iron riser tube body is made of an ordinary #45 steel material; the refractory cotton transition layers are made of an ordinary fiber refractory cotton material; fixing protruding bosses are manufactured in selected positions of the inner tube wall and the outer tube wall of the iron riser tube body in the axial height direction; the refractory cotton transition layers which are 2 mm+ / -0.5 mm thick are fixed to the inner tube wall and the outer tube wall of the iron riser tube body correspondingly, SiC particles with the purity being 99%+ / -0.2% are fixed to the refractory cotton transition layers, the thickness of the SiC particles is 5 mm+ / -0.5 mm, and the iron riser tube body is placed in a dry and ventilated position to be air-dried; and the air-dried riser tube body is placed into a sintering furnace and subjected to overall sintering, the sintering temperature is about 1390-1410 DEG C, and the riser tube is obtained after roasting. According to the riser tube and the manufacturing method thereof, in the using process, the situation that corrosion occurs and consequently increased iron is generated can be avoided, and manufacturing is easy.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

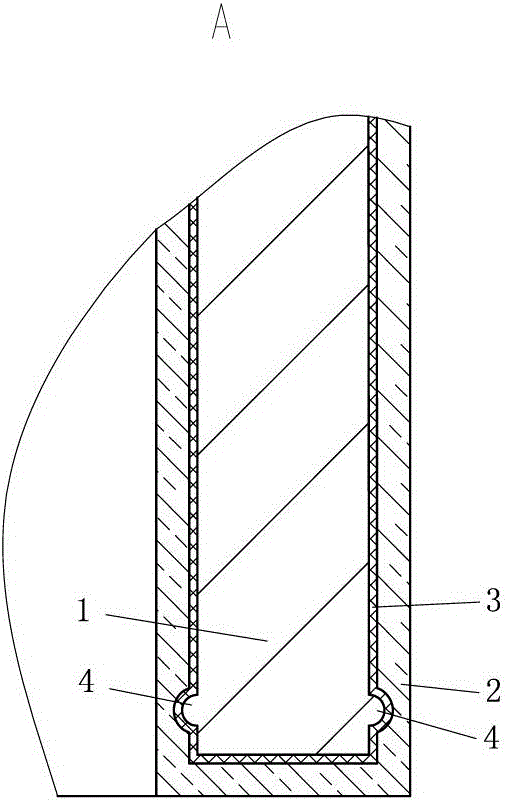

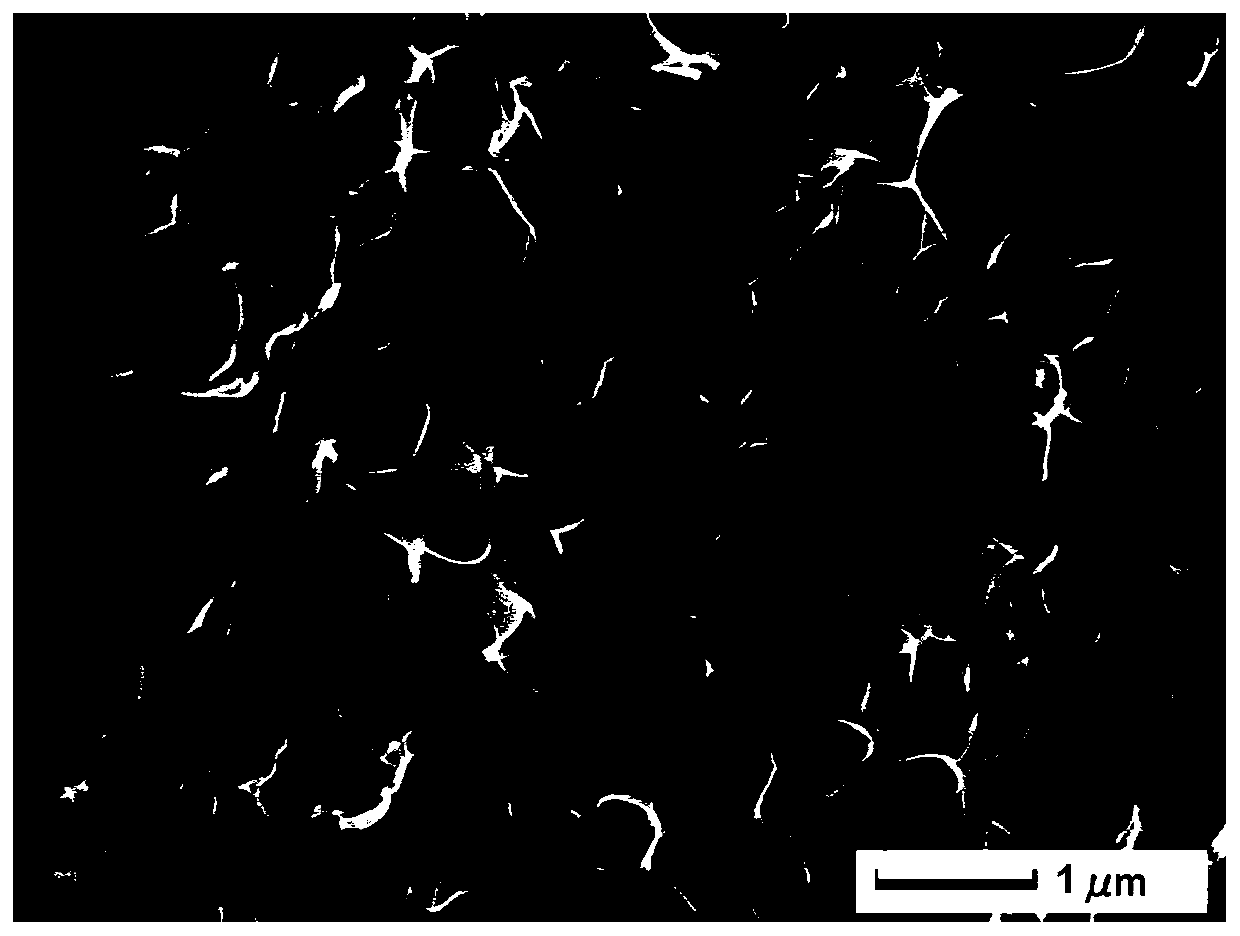

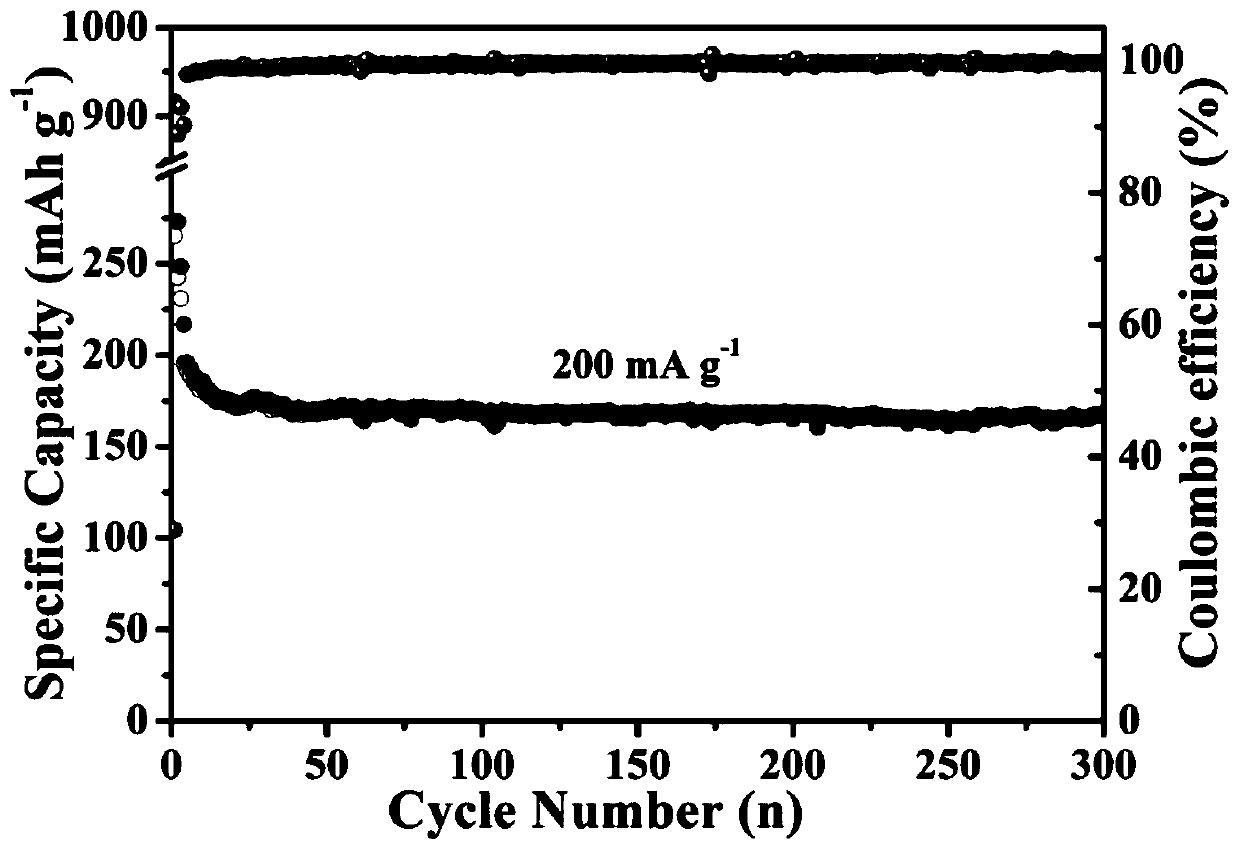

Preparation method of biomass derivative carbon material used for sodium-ion batteries

InactiveCN110467180AImprove cycle stabilityImprove stabilityCarbon compoundsCell electrodesCapacitanceSodium-ion battery

The invention belongs to the field of electrochemistry and energy material, and discloses a preparation method of a biomass derivative carbon material used for sodium-ion batteries. According to the preparation method, soybean is taken as a biomass source, KOH is taken as an activator, high temperature calcining is carried out so as to obtain the porous biomass derivative carbon material. Soybeanis a natural product, is abundant in sources, is high in protein content, contains a large amount of nitrogen element, and is capable of forming a natural nitrogen doped carbon material; the nitrogendoped carbon material can be used for providing Na<+> with sufficient sodium embedding vacancies, providing substantial fake capacitance in sodium-ion battery charging and discharging process, and increasing battery specific capacity; and in addition, nitrogen element doping is capable of improving material conductivity, and increasing iron transmission efficiency; KOH activation is capable of increasing porous structure specific surface area further, it is beneficial for electrolyte infiltration, and increasing of ion and electron transmission efficiency. The biomass derivative carbon material possesses the above advantages, so that when the biomass derivative carbon material is taken as a sodium ion anode material, relatively high reversible specific capacity and excellent circulation stability are achieved.

Owner:JIANGSU UNIV

Method for producing fine powder of magnetite from active iron ore

InactiveCN1916196AHigh fine powder contentShorten the timeMagnetic separationHazardous substanceMagnetite

This invention discloses a method for manufacturing magnetite concentrate from active iron ore. The method comprised: (1) pulverizing active iron ore, mixing with separation-deoxygenation promoter at a weight ratio of 1: (0.001-0.005), and placing the mixture in an earth kiln or suspended kiln; (2) uniformly heating to 550-850 deg.C to calcine the active iron ore, taking out milling in a ball mill to obtain iron ore slurry; (3) performing magnetic separation by a magnetic separator, precipitating, filtering and drying to obtain magnetite separator, precipitating, filtering and drying to obtain magnetite concentrate. The method has such advantages as low cost and simple process, and can obviously reduce the contents of harmful substances such as S, P, Zn, Na, Cu, Si, crystalline water, Hg and Mg, and increase iron content to higher than 62%. The obtained magnetite concentrate can satisfy corresponding state standards, and can be used to manufacture high-quality steel.

Owner:石启洁

Prodrug compositions and methods for using the same in treating cancer and malaria

Methods and compositions for treating disease caused by increased iron levels are disclosed Fluoregenic compounds and methods of using the same are also described.

Owner:RGT UNIV OF CALIFORNIA

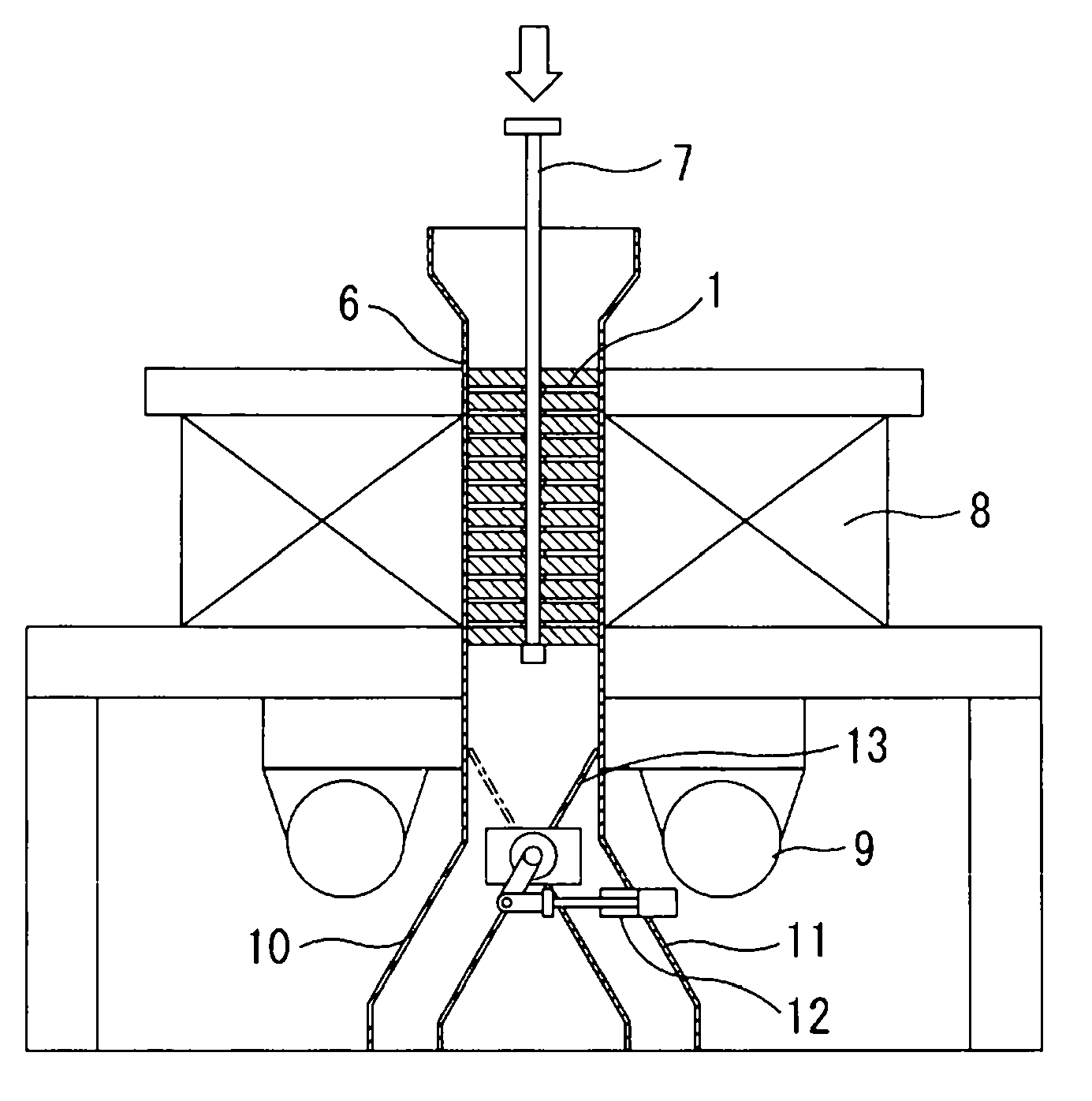

Screens for electromagnetic separator

ActiveCN102939164AHigh recovery rateReduce throughputFiltration separationMagnetic separationIron powderMagnetic separator

Screens for an electromagnetic separator for separating iron powder contained in powder, the screens having increased iron powder collection efficiency which is obtained by increasing the area to which the iron powder is magnetically attracted and also by increasing the number of the screens to reduce the amount of iron powder which passes through the screens without being magnetically attracted to the outer peripheries of the screens. Screens for an electromagnetic separator are supported in multiple layers in the vertical direction within a tube which is disposed at the center of the electromagnet of the electromagnetic separator, and the screens consist of a magnetic material which magnetically attracts iron powder contained in powder supplied from the opening in the upper part of the tube. The screens (1) for an electromagnetic separator have formed at the center thereof circular through sections (3) through which a holding bar for holding the screens (1) pass, and the screens (1) also have ring frames (2) formed on the outer sides thereof. Each of the ring frames (2) has disposed therein a spiral plate (4) and a wave-like wave plate (5), the spiral plate (4) being spirally wound toward the through section with a gap between the turns, the wave-like wave plate (5) being disposed between the turns of the spiral plate (4). The crests and troughs of the wave plate (5) are affixed to the spiral plate (4).

Owner:日本磁学株式会社

Method for increasing iron clad bonding strength of leading edge of blade

InactiveCN105667832AAvoid deformationIncrease roughnessAircraft assemblyRotocraftLeading edgeUltimate tensile strength

The invention relates to a method for increasing the iron clad bonding strength of the leading edge of a blade, which belongs to the technical field of composite materials. According to the method, before iron clad is formed, blasting treatment is performed on the bonding surface of the iron clad in advance, so that the roughness of the bonding surface of the iron clad is increased, then the iron clad is formed, thus, the roughness of the surface of the iron clad can be increased, the iron clad of the leading edge is difficult to debond from the composite blade, and the deformation of the iron clad due to the blasting treatment can be avoided. By adopting the method, the bonding quality of the stainless steel iron clad and the composite material can be effectively increased, and the reliability and safety of an airplane are increased.

Owner:HARBIN

Fermented nutrition with non-digestible oligosaccharides with increased iron bioavailability

InactiveUS20160050960A1Increases bioavailability of ironImprove iron uptakeMilk preparationHeavy metal active ingredientsPhysiologyBioavailability

The present invention relates to fermented nutritional compositions comprising non-digestible oligosaccharides for improving the bioavailability of iron and preventing or treating of iron deficiency, in particular for infants and young children or pregnant women.

Owner:NUTRICIA

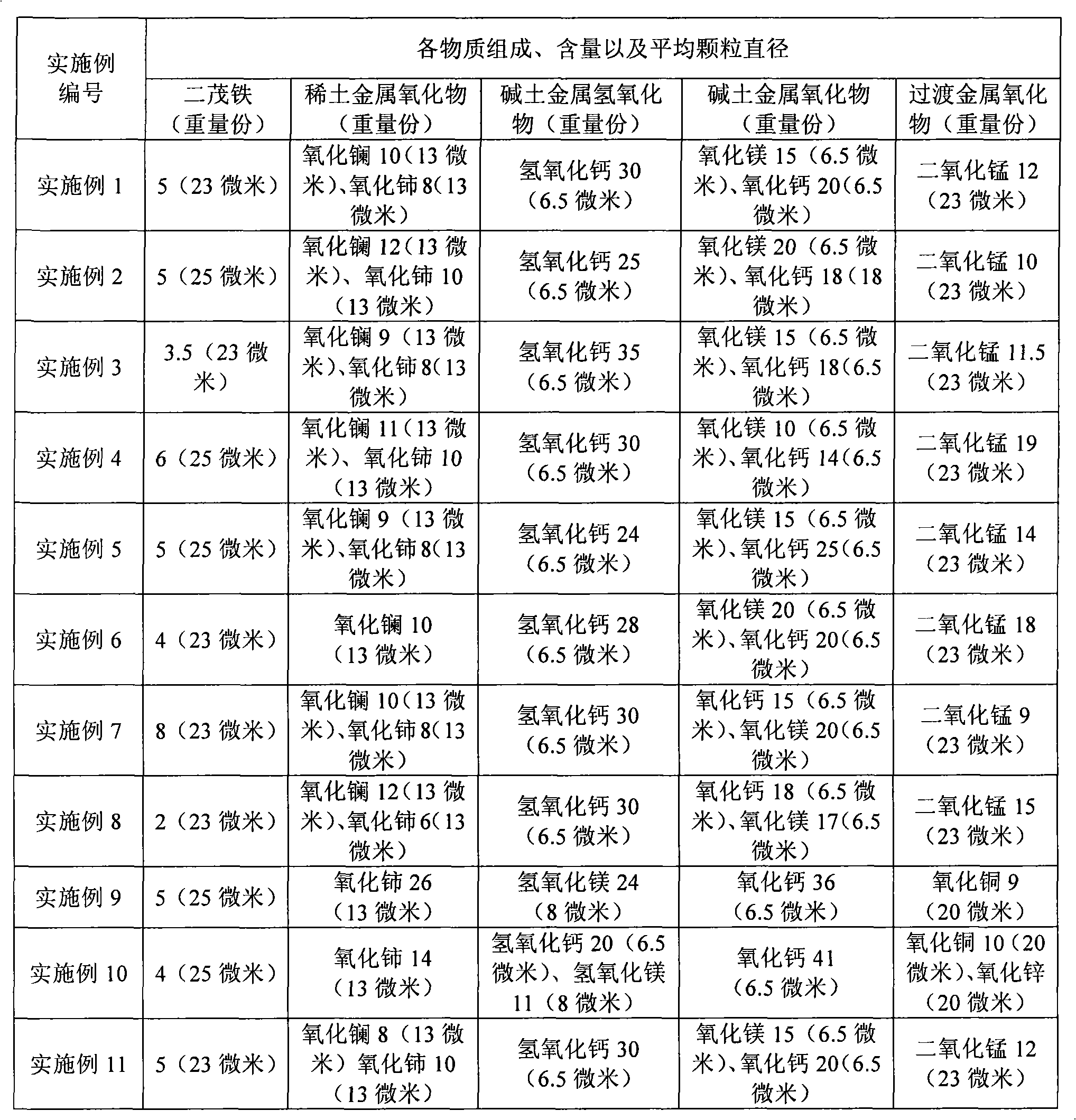

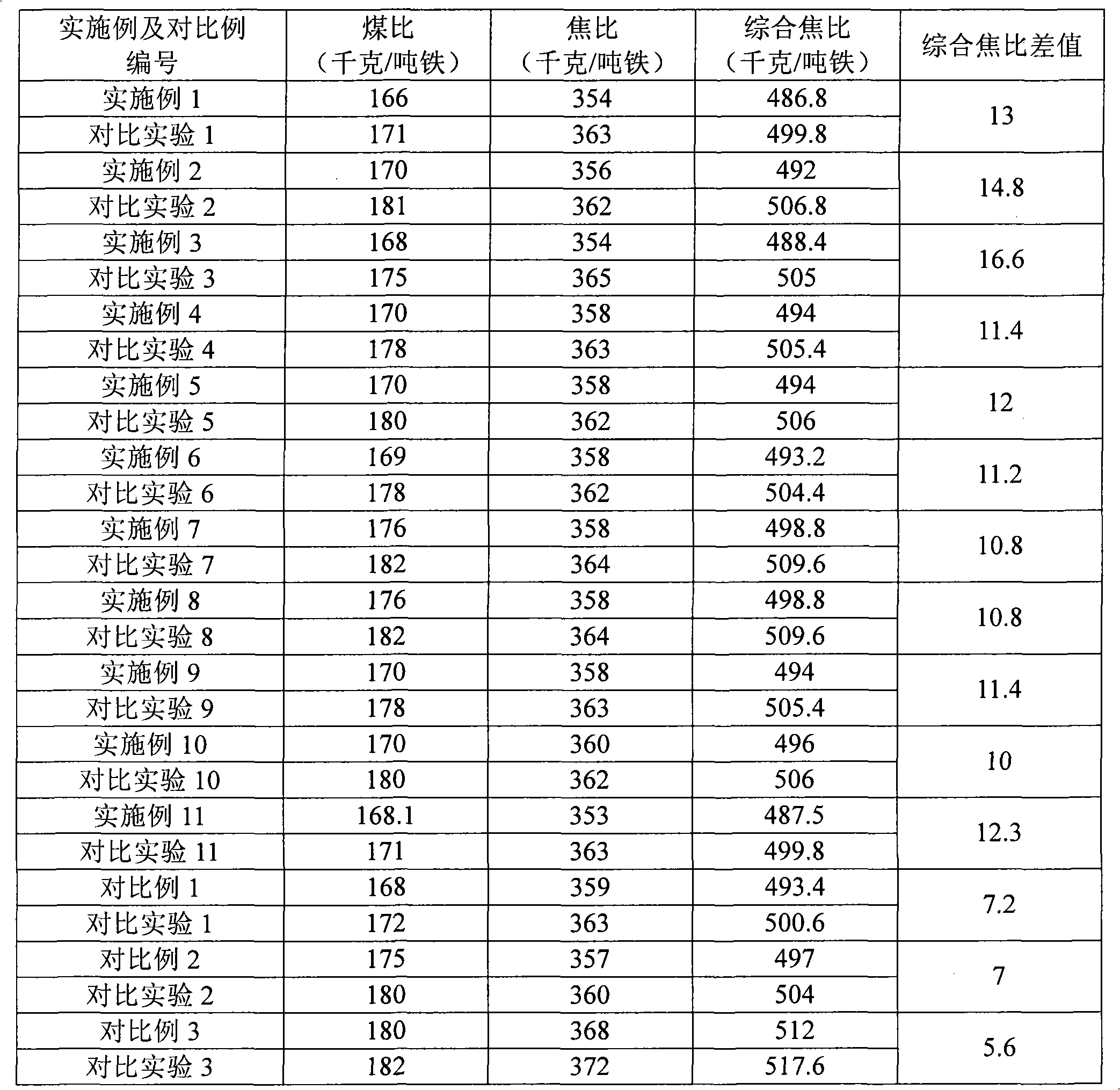

Composition for blast furnace coal powder injection and preparation method thereof

InactiveCN101768496APromote combustionQuality improvementSolid fuelsBlast furnace detailsCombustionRare earth

The invention relates to a composition for blast furnace coal powder injection, comprising ferrocene, rare-earth metal oxides, alkali-earth oxides, alkali-earth hydroxides and transition metal oxides except rare earth metals. The average grain diameter of each component of the composition is 5-25mm. The invention also provides a preparation method of the composition for blast furnace coal powder injection. By using the composition for blast furnace coal powder injection of the invention, coal powder combustion can be effectively improved, and comprehensive coke ratio is enhanced; when being used in iron industry, the composition has the advantages of having a little of additive amount, being environment-friendly, effectively improving molten iron quality, increasing iron yield and greatly lowering ironmaking cost.

Owner:蔺国庆

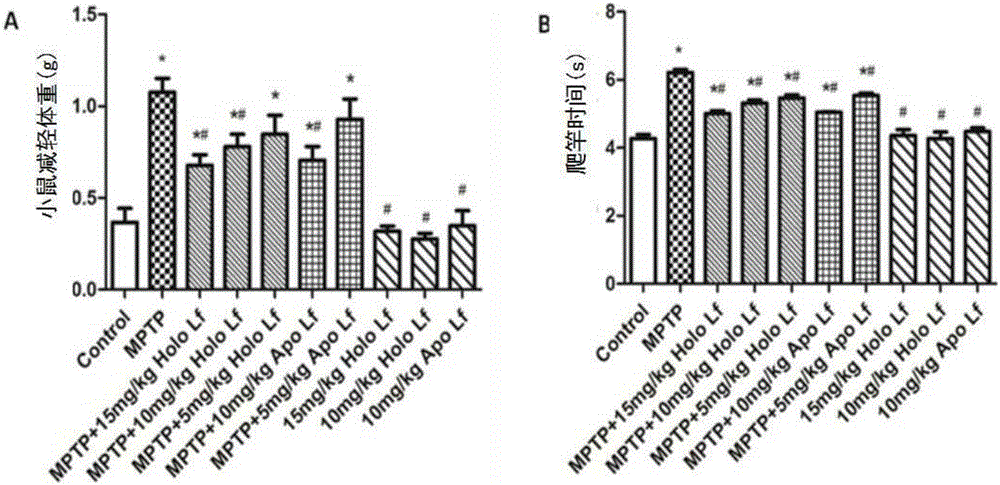

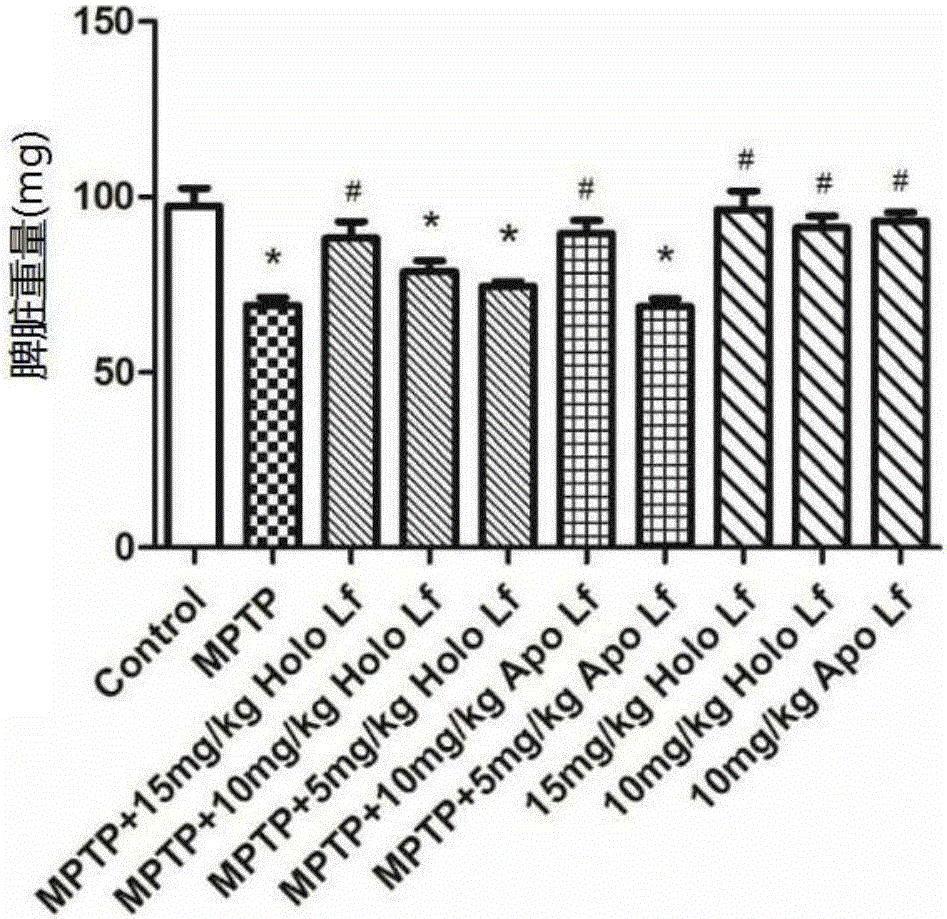

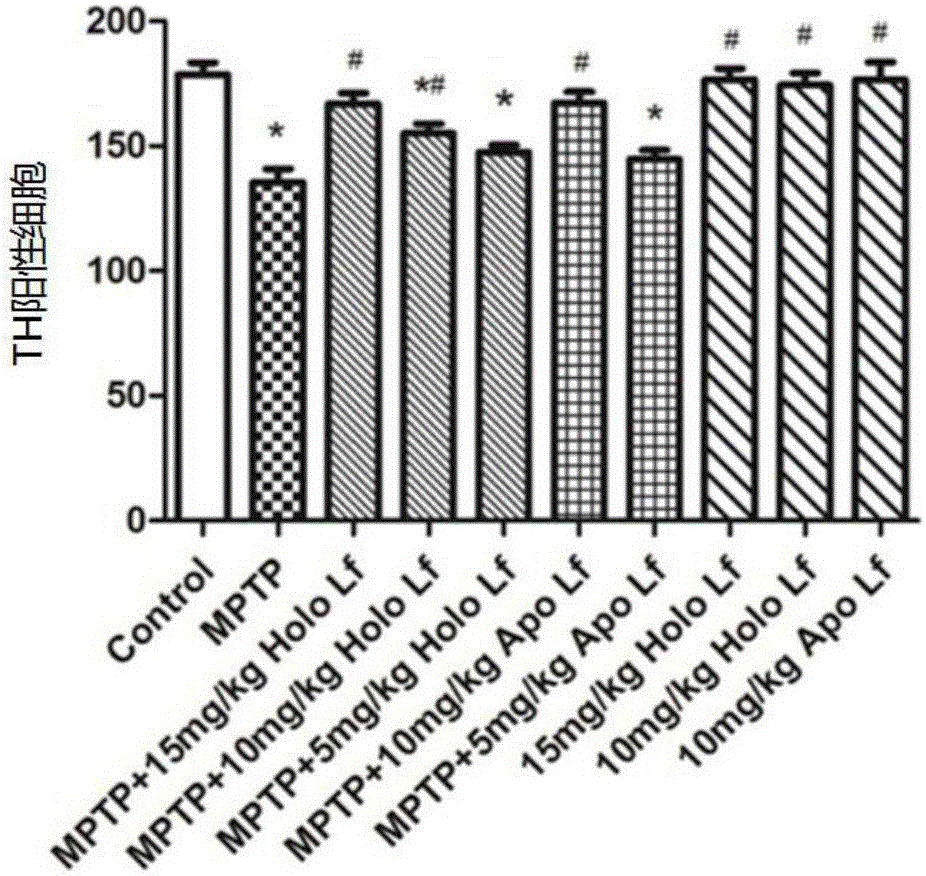

Application of Lf (lactoferrin) in preparation of PD (Parkinson's disease) treating drugs

InactiveCN106511979AImprove treatmentPrevention of Toxicological EffectsNervous disorderPeptide/protein ingredients1 methyl 4 phenyl 1Iron levels

The invention relates to an application of Lf (lactoferrin) in preparation of PD (Parkinson's disease) treating drugs. The drugs are used for treating or preventing a toxicological action of MPTP (1-methyl-4-phenyl-1,2 ,3 ,6-tetrahydropyridine), the Lf is APO-Lf or HOLO-Lf, the two drugs both can reduce the level of iron in substantia nigra in the brain and play a neuroprotective effect on a patient with PD, APO-Lf and HOLO-Lf have no influence on peripheral iron level, neither are chelated with iron to result in anemia, nor increase iron to cause iron loading. In one embodiment, the Lf is APO-Lf or HOLO-Lf.

Owner:QINGDAO UNIV

Treatment of iron contaminated liquids with an activated iron solids (AIS) process

ActiveUS8512571B2Waste water treatment from quariesWater treatment parameter controlHigh concentrationSurface water

The present invention is a method and system for treating iron-contaminated water (e.g., mine drainage) using an innovative treatment approach identified herein as the Activated Iron Solids (AIS) Process. The AIS process is capable of oxidizing and removing iron as iron oxides from iron-contaminated waters (such as, mining-related discharge, groundwater, surface water and industrial waste streams) producing a clean effluent. The AIS process is performed in a single or multiple tank system in which high concentrations of AIS are suspended through mechanical mixing to maintain a catalytic surface chemistry environment that increases iron removal thousands times faster than would naturally occur and hundreds times faster than existing arts (e.g., aerobic pond passive treatment). The AIS process can utilize inexpensive alkaline material (such as, pulverized limestone) where initial mine drainage alkalinity (mg / L as CaCO3) to ferrous iron (mg / L) ratio is less than approximately 1.7. Excess accumulated activated iron solids are periodically removed from the system using a waste-activated iron solids (WAIS) system and directed to an iron oxide thickener for further concentration.

Owner:IRON OXIDE TECH

Iron core for stationary apparatus and stationary apparatus

InactiveUS20080272876A1Small magnetic resistanceMagnetic flux densityTransformers/inductances magnetic coresCores/yokesMagnetic reluctanceMagnetic characteristic

Magnetic flux in a magnetic flux distribution inside a wound iron core for a stationary apparatus is mal-distributed toward the inner periphery side where the magnetic path of a laminated magnetic steel sheet is short with respect to the total lamination thickness and magnetic resistance is small and the inner periphery side on which magnetic flux is concentrated has a high magnetic flux density and increased iron loss, and therefore magnetic steel sheets of different magnetic characteristics are disposed at an arbitrary lamination ratio to make uniform the magnetic flux distribution inside the same wound iron core. In order to make uniform the magnetic flux distribution inside the wound iron core for a stationary apparatus, such a structure is adopted that a magnetic steel sheet having a magnetic characteristic inferior to that on the outer periphery side is disposed on the inner periphery side having a shorter magnetic path and smaller magnetic resistance and a magnetic steel sheet having a magnetic characteristic superior to that on the inner periphery side is disposed on the outer periphery side having a longer magnetic path and greater magnetic resistance to thereby make uniform the magnetic flux distribution in a sectional area of the iron core.

Owner:HITACHI IND EQUIP SYST CO LTD

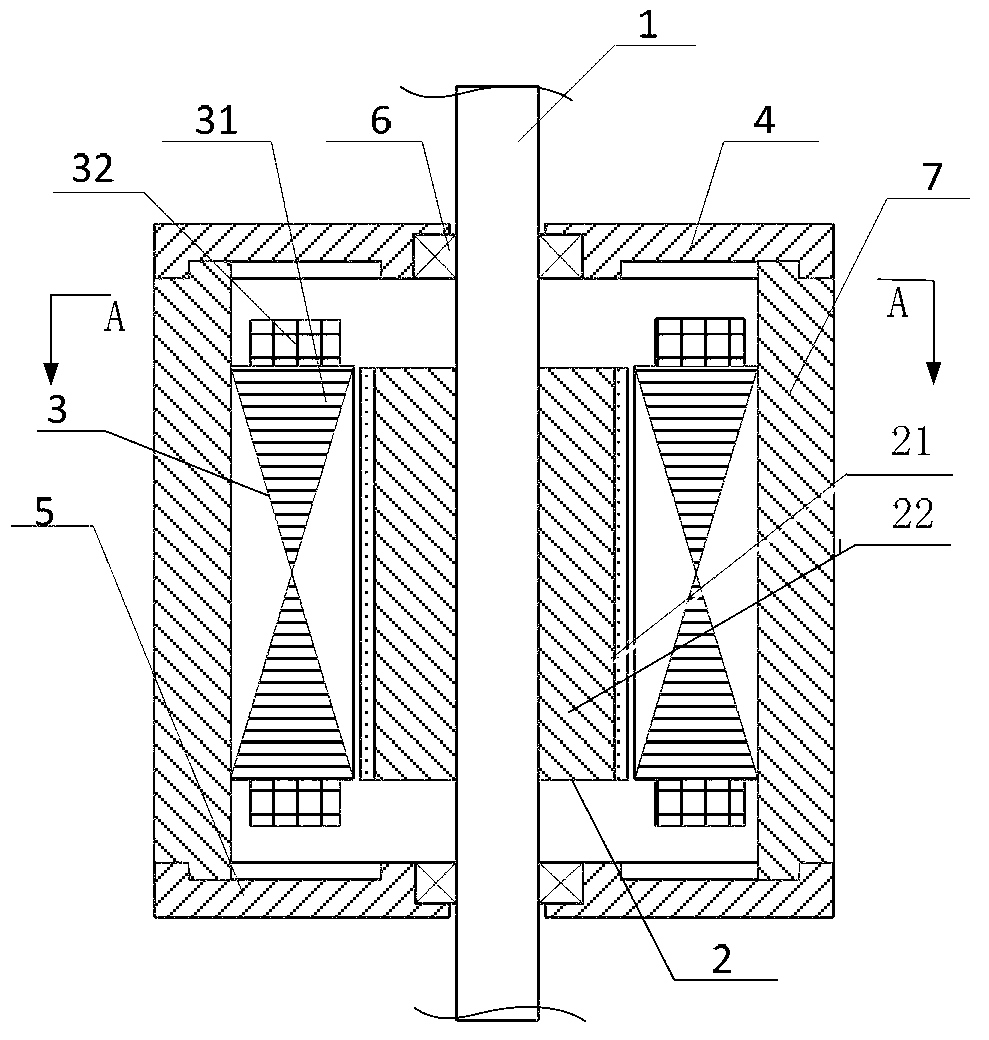

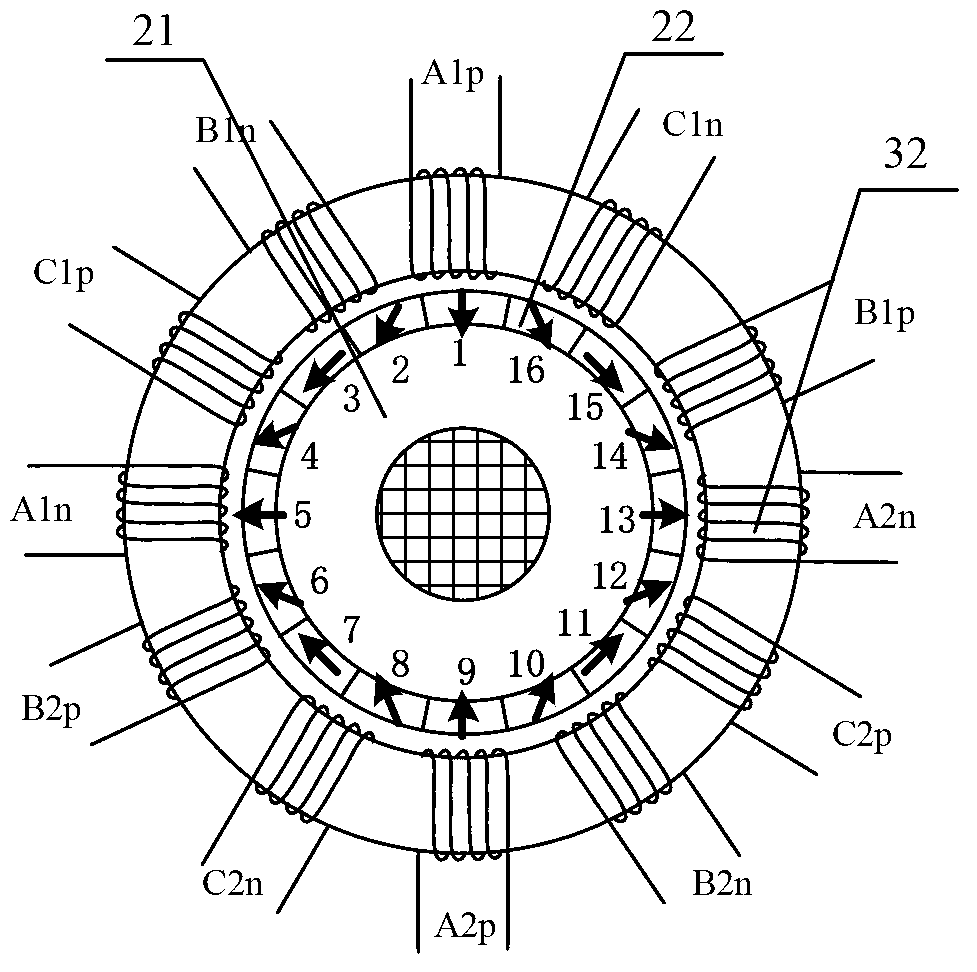

Low-inductance low loss PMSM

InactiveCN102801268AReduce inductanceLow inductance and low lossSynchronous machines with stationary armatures and rotating magnetsWindings conductor shape/form/constructionFlywheel energy storageLow inductance

The invention discloses a low-inductance low loss PMSM, and relates to the technical field of low-inductance low loss PMSM with a novel structure. Objective of the invention is to solve a problem that a motor in the prior art generates excessive inductance which is against high rotating speed operation of the motor, and hence generates iron core material magnetic saturation, thereby increasing iron core loss. The invention provides the low-inductance low loss PMSM, comprising a rotating shaft (1), a p-m rotor (2), a stator (3), an upper end cover (4), a lower end cover (5), a bearing (6), and a housing (7). The p-m rotor (2) comprises a rotor iron core (21) and a permanent magnet (22). The stator (3) comprises a stator iron core (31), and single-phase or polyphase stator windings (32) are radially winded on the stator iron core (31). The stator windings (32) are arranged toroidally, and each phase winding comprises a pair or a plurality of pairs of two adjacent coils. A distance between the two adjacent coils is a polar distance and the two adjacent coils are winded in opposite winding directions. The low-inductance low loss PMSM can be used in a plurality of different flywheel energy storage occasions.

Owner:HARBIN INST OF TECH

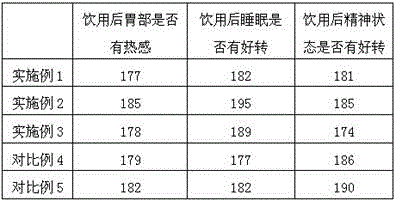

Goat milk product containing carrot juice, and preparation method thereof

The present invention provides a goat milk product containing a carrot juice, wherein the raw materials comprise a carrot juice, raw goat milk, oat powder, water, xylitol, inulin, loofah powder, a strawberry juice, white fungus, fructooligosaccharide, and a stabilizer. According to the present invention, by adding the carrot juice and the strawberry juice to the prepared goat milk product, such that the prepared goat milk product has fruit aroma, is rich in nutrition elements, and has the increased vitamin C content and the increased iron content; by adding the fructooligosaccharide and the inulin, the dietary fiber which is less in the goat milk is increased, and the prepared goat milk product is the high nutrition value milk product; and during the milk product preparation process, the special carrot juice preparation method is used, such that the carotene can be produced and retained at a maximum, and the prepared goat milk product has the good nutrition value.

Owner:山东坤泰生物科技有限公司

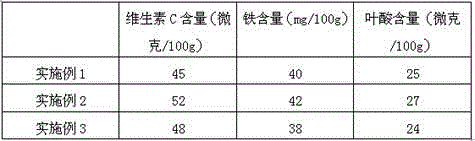

Restoring Physiology in Iron-Deficient Organisms Using Small Molecules

Provided are methods of treating a disease or condition characterized by a deficiency of or a defect in an iron transporter using a small molecule. For example, the method may increase transepithelial iron transport, or it may increase iron release. Additionally, the small molecule may be hinokitiol, or it may be selected from the group consisting of amphotericin B, calcimycin, nonactin, deferiprone, purpurogallin, and maltol. Also provided is a method of identifying a compound capable of treating a disease or condition characterized by a deficiency of or a defect in an iron transporter.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Energy-efficient annealing process for amorphous/ultra-microcrystalline alloy choke coil magnetic ring

InactiveCN110189910ASolve the performance fluctuation problemControl iron loss increaseFurnace typesMagnetic core manufactureAlloyInternal stress

An energy-efficient annealing process for an amorphous / ultra-microcrystalline alloy choke coil magnetic ring is provided. The choke coil magnetic ring is made of a Fe-B-Si-Nb-Cu-based amorphous / ultra-microcrystalline alloy strip. The energy-efficient annealing process mainly comprises four times of temperature-increasing annealing and two times of temperature-decreasing cooling. The amorphous / ultra-microcrystalline alloy choke coil magnetic ring subjected to the energy-efficient annealing process is completely free of internal stress and is nano-crystallized, so that a choke coil magnetic corehas high electromagnetic performance and does not increase iron loss, thereby ensuring the stability and the stress resistance of the choke coil magnetic ring, reducing the scrap phenomena caused byannealing, and thus improving the utilization rate of the amorphous / ultra-microcrystalline alloy choke coil magnetic ring. Compared with a conventional annealing process, the energy-efficient annealing process can save about 30% of electric energy per furnace, especially solves the performance fluctuation of the annealed Fe-B-Si-Nb-Cu-based amorphous / ultra-microcrystalline alloy choke coil magnetic ring, and controls the iron loss increase and stability of the choke coil magnetic ring.

Owner:洛阳中赫非晶科技有限公司

Method for brewing black millet iron-rich nutritional soy

InactiveCN103564406BIncrease added valueEfficient use ofFood ingredient functionsFood preparationAdditive ingredientEnzyme system

The invention relates to a method for brewing black millet iron-rich nutritional soy, which mainly overcomes the shortage of low organic iron content in general soy taking soybeans and wheat as raw materials and the shortcoming of addition of an iron additive into finished soy, and can be used for increasing iron-containing microelements. The method comprises the following step: with black crops with high organic iron content as raw materials, carrying out biochemical reaction on various enzyme systems under specific environmental conditions through a combined constant-temperature fermentation process of a low-salt solid-state fermentation process and a high-salt diluted-state fermentation process of various strains to enable iron microelements and other nutritional ingredients such as proteins, amino acids and vitamins in the raw materials to be fully decomposed and effectively enriched in soy so as to generate soy with unique color, aroma, taste and shape and high content of various nutritional ingredients such as organic iron.

Owner:山西省农业科学院农业科技信息研究所

A method for increasing the carbon content of molten iron

The invention discloses a molten iron recarburization method. A carburant and molten iron are added in a molten iron container. When the excessive carburant cannot be directly dissolved in molten iron and floats on the surface of the molten iron, the molten iron and the carburant are poured into the other molten iron container at least one time from one molten iron container. The temperature of the molten iron is controlled to range from 1,450 DEG C to 1,700 DEG C, and each time used when the molten iron and the carburant are poured into the other molten iron container from one molten iron container is controlled to be within 20 s. According to the provided method, the problem that according to a stirring method in the prior art, when the content of carbon in the molten iron reaches a certain proportion in the recarburization process, increasing is very difficult to achieve is solved; a specially-made stirring machine is not needed, the carbon absorbing rate is high, cost is low, efficiency is high, and safety and production stability are high. Most importantly, the carbon content of the molten iron reaches 4.5 % through a stirring method; and by means of the method, the carbon content can reach 6% or above, the method is simple and easy to operate, and the method is very suitable for industrial production and application.

Owner:河北瑞欧消失模科技有限公司

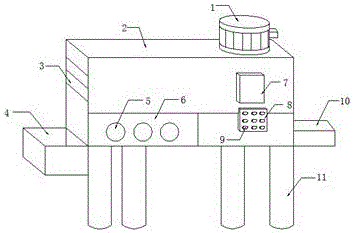

Soft magnet iron core production equipment

InactiveCN106098352AEasy to disinfectEasy to useInorganic material magnetismMagnetic core manufactureSoft magnetOperations management

The invention provides soft magnet iron core production equipment comprising a motor, a housing, a feed inlet, a material box, a heating motor, a heating box, an electric cabinet, an operation panel, buttons, a discharge port and legs; one end of the housing is provided with the feed inlet, and the other end of the housing is provided with the discharge port; one end of the housing is provided with the material box arranged below the feed inlet; the bottom of the housing is provided with the legs; the heating box is arranged in the housing; the side wall of the housing is provided with the electric cabinet; the operation panel is arranged below the electric cabinet, and the surface of the operation panel is provided with buttons; the top of the housing is provided with the motor. The soft magnet iron core production equipment can directly process the soft magnet iron core, can conveniently disinfect the soft magnet iron core, and increase iron core usage performance, and the heated iron core is long in service life; the electric cabinet can provide power for running the motor and operation panel.

Owner:CHANGSHU ZHONGYING ELECTRONICS

Compositions and methods for increasing iron intake in a mammal

ActiveUS20190054115A1Improve bioavailabilityDose lessHeavy metal active ingredientsDispersion deliveryBioavailabilityBuffering agent

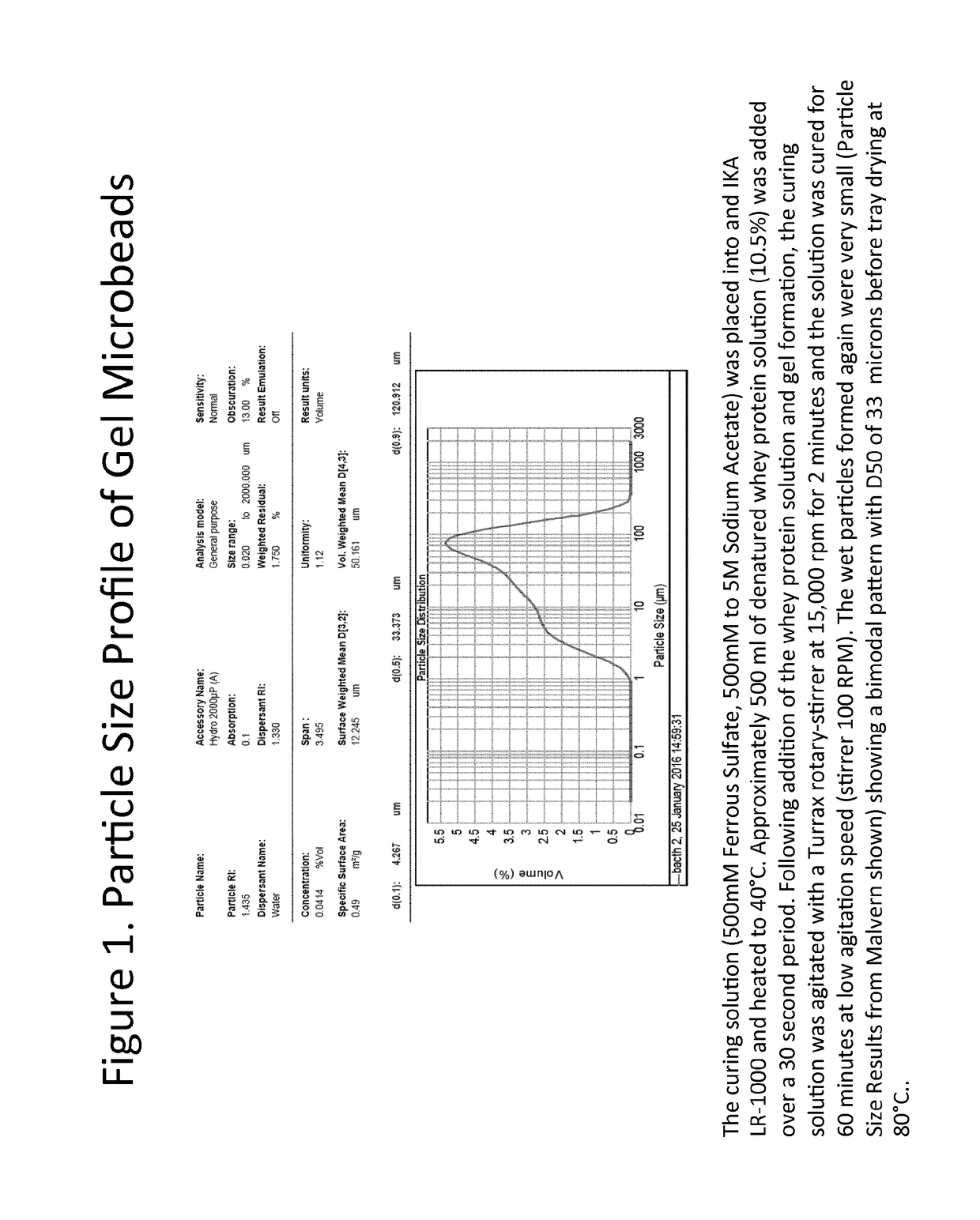

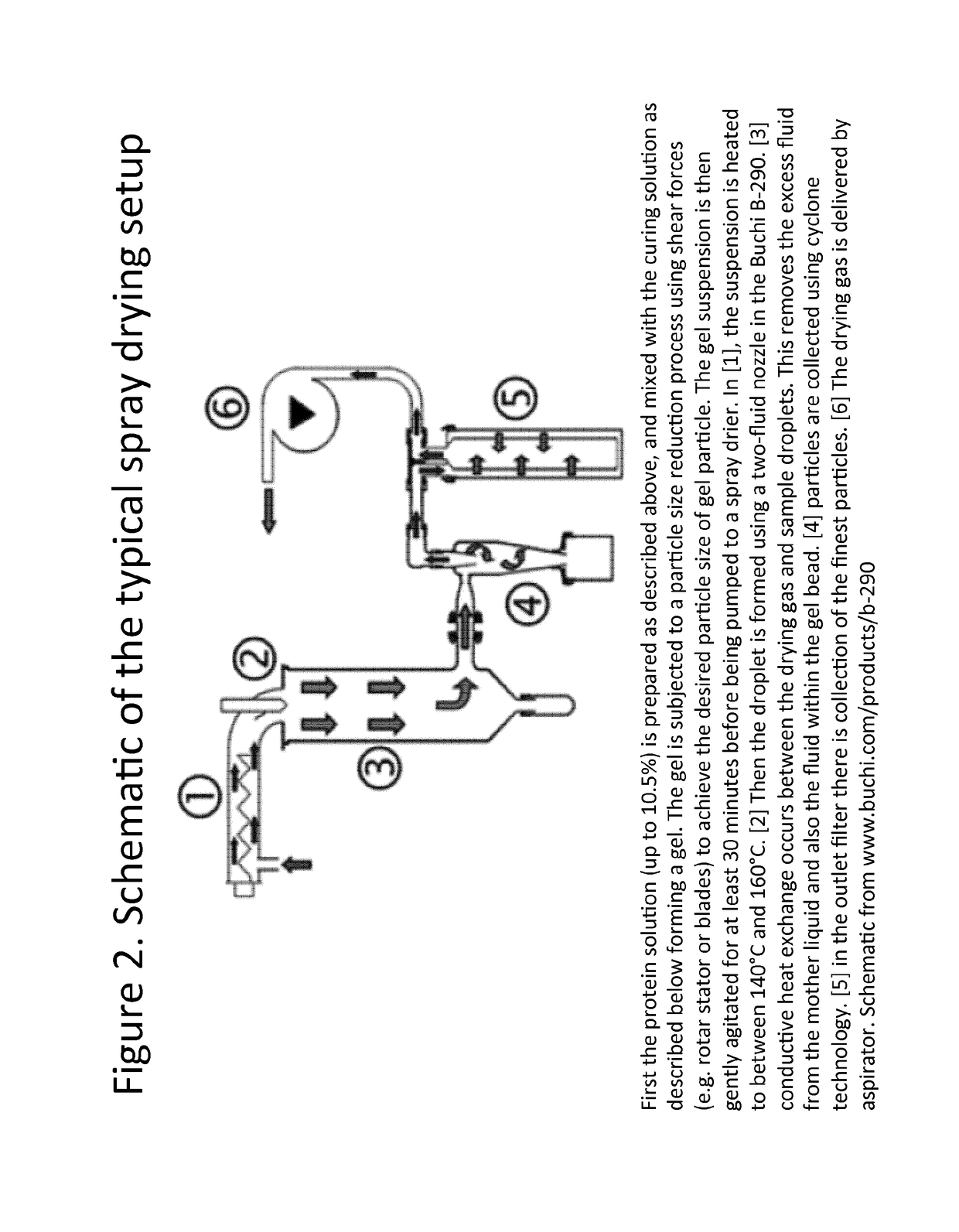

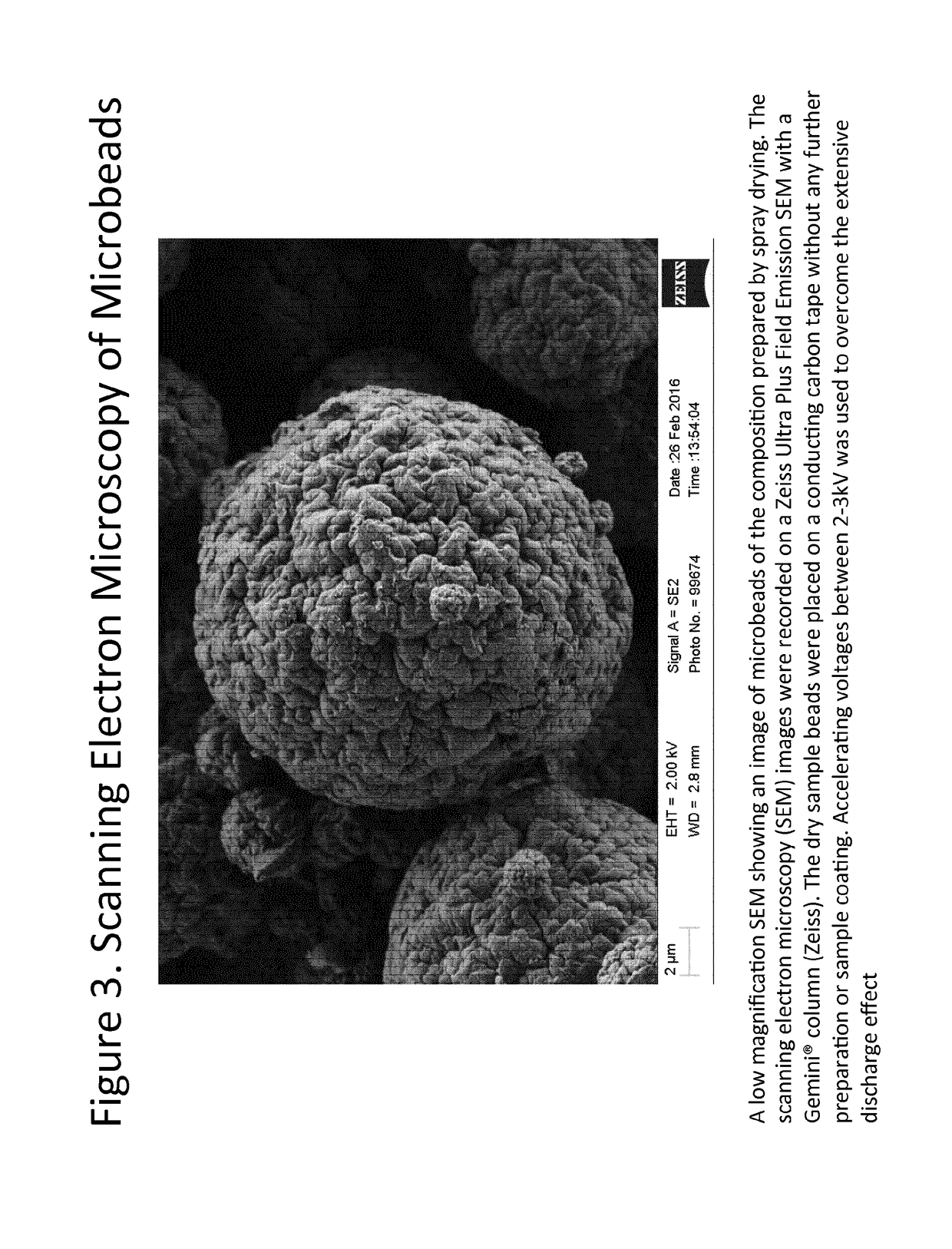

Compositions containing iron, buffering agent and denatured protein have been prepared that are capable of increasing serum iron in a subject. For example, spray dried microbeads have been prepared containing iron entrapped within a protein matrix and unbound iron in a buffered composition that provides a gastroprotective effect, preserves iron in the more available Fe2+ form and improves iron bioavailability in humans relative to previously known vehicles for delivering iron to a subject.

Owner:SOLVOTRIN THERAPEUTICS LTD

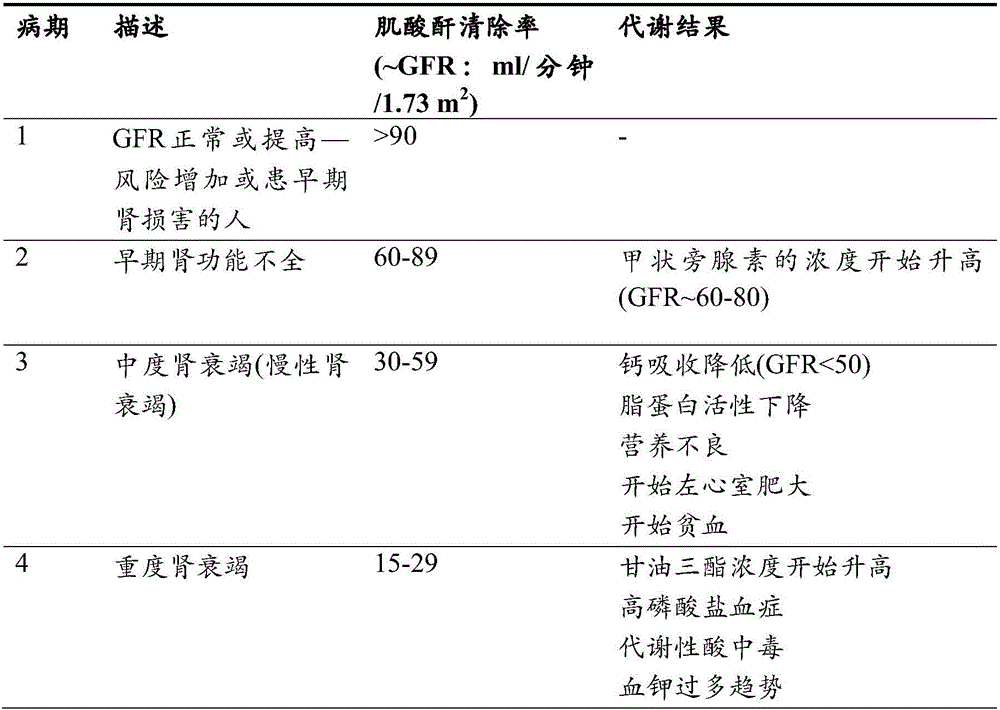

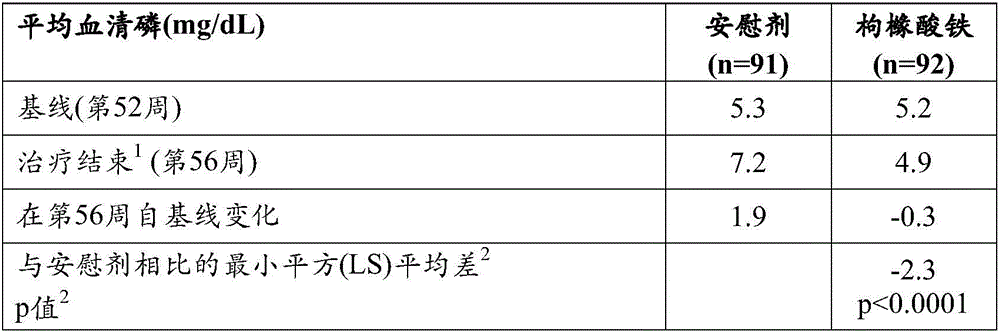

Ferric citrate for reducing cardiac failure in chronic kidney disease patients

InactiveCN105873583AFull explanationHeavy metal active ingredientsOrganic active ingredientsErythropoiesis-stimulating agentIncreased iron

Methods of administering ferric citrate to reduce and / or control serum phosphorus levels, increase serum bicarbonate levels, improve one or more iron storage parameters (e.g., increase serum ferritin levels, increase transferrin saturation (TSAT), increase hemoglobin concentration), increase iron absorption, maintain iron stores, treat iron deficiency, treat anemia, reduce the need for IV iron, reduce the need for erythropoiesis-stimulating agents (ESAs), and / or reduce mortality and morbidity related to adverse cardiac events in chronic kidney disease patients, are disclosed.

Owner:KERYX BIOPHARMLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com