Screens for electromagnetic separator

An electromagnetic separation and screen technology, which is applied in magnetic separation, filtration separation, solid separation, etc., can solve the problems of reduced number of screens, small area of magnetically adsorbed iron powder, and low recovery rate of iron powder, so as to improve the recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

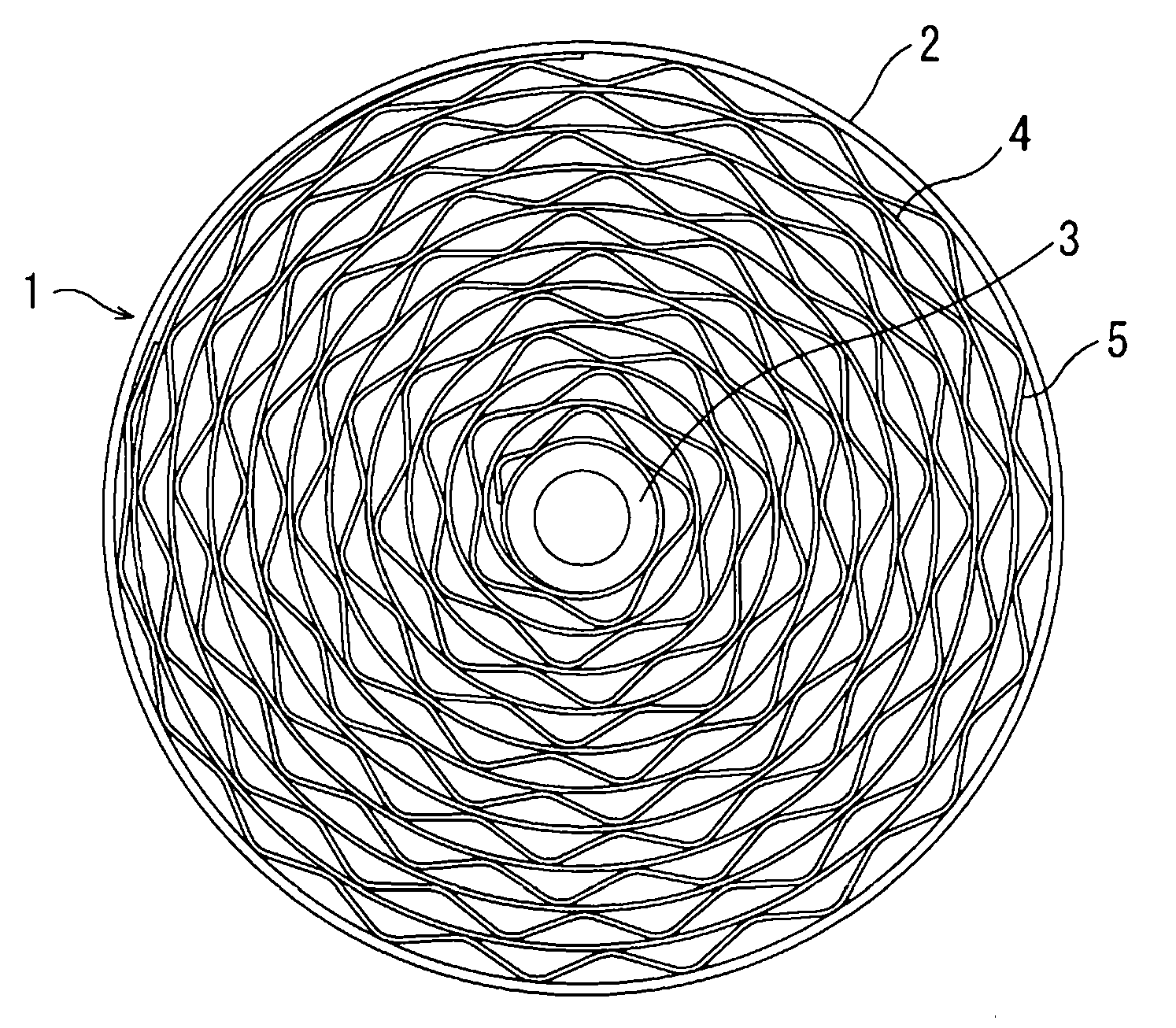

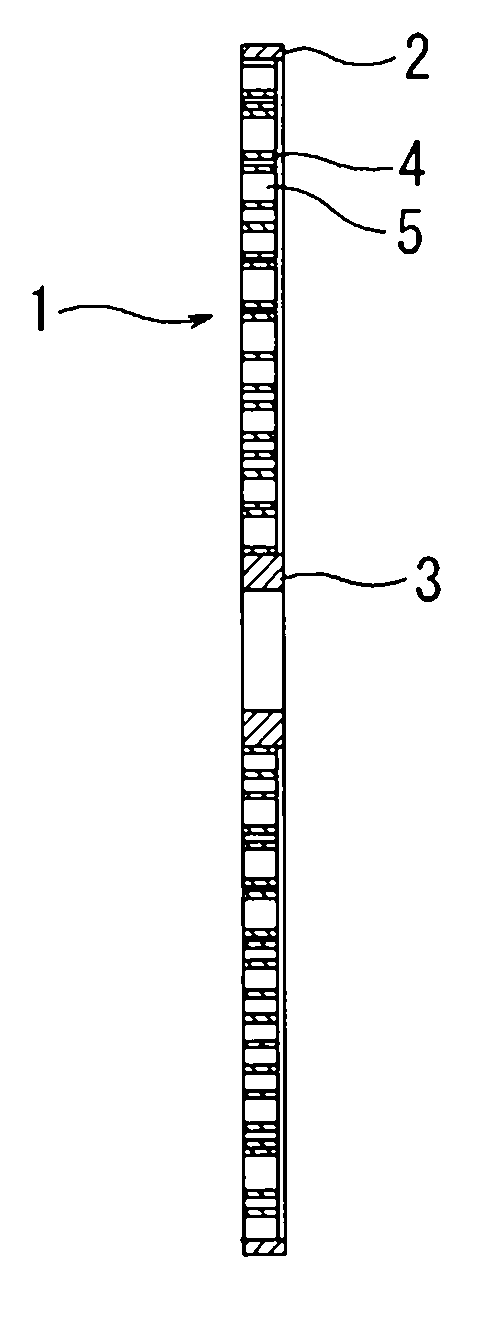

[0023] figure 1 Among them, the screen for electromagnetic separator (hereinafter referred to as "screen") 1 is made of magnetic material. The magnetic material may be any magnetized material, but ferritic stainless steel having corrosion resistance and strength is suitable.

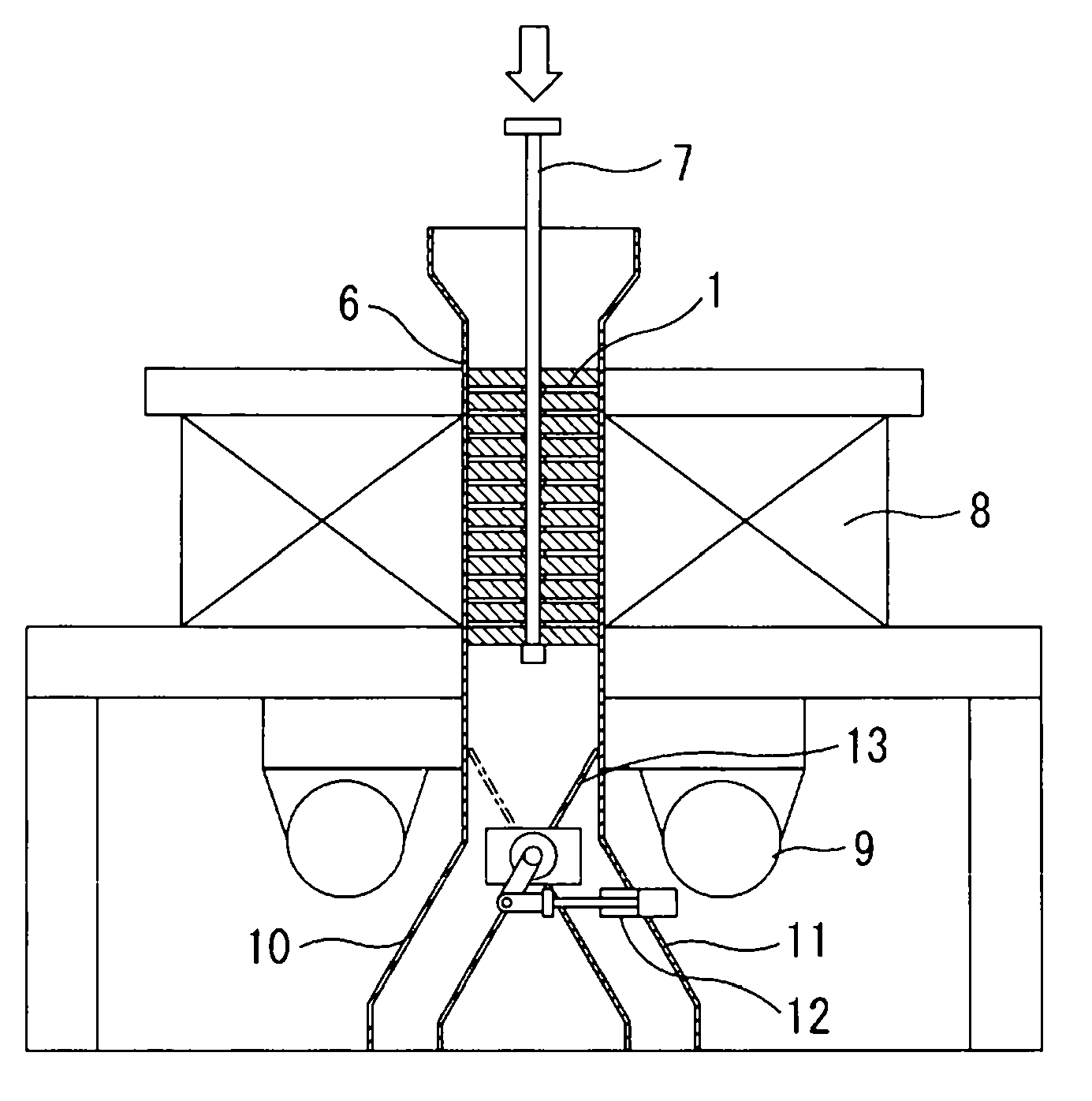

[0024] A stainless steel belt is wound around the outside of the screen 1 to form a ring frame 2 . The outer diameter of the ring frame 2 is, for example, about 30 cm. Formed in the center of the screen 1 is a holding rod ( image 3 ) through the annular penetrating portion 3 .

[0025] Starting from (or ending at) a certain point on the ring frame 2 , spiral plates 4 are formed that are spirally wound at intervals with the annular penetration portion 3 as the ending point (or starting point). Continuous corrugated corrugated plates 5 are arranged in gaps between the spiral plates 4 , and the grooves and tops of the corrugated plates 5 are fixed to the spiral plates 4 by spot welding. A plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com