Iron core structure capable of increasing iron core filling rate and shearing and assembling method of iron core structure

A technology of iron core structure and assembly method, applied in transformer/inductor core, transformer/inductor components, inductor/transformer/magnet manufacturing, etc., to achieve the effect of enhancing short-circuit resistance, reducing cost, and improving tooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

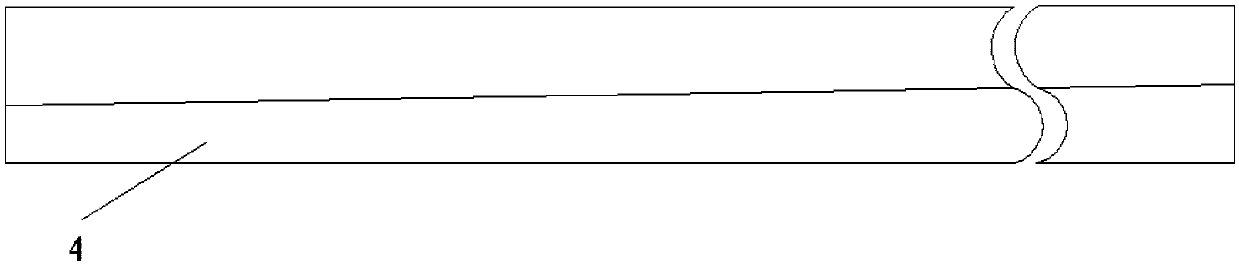

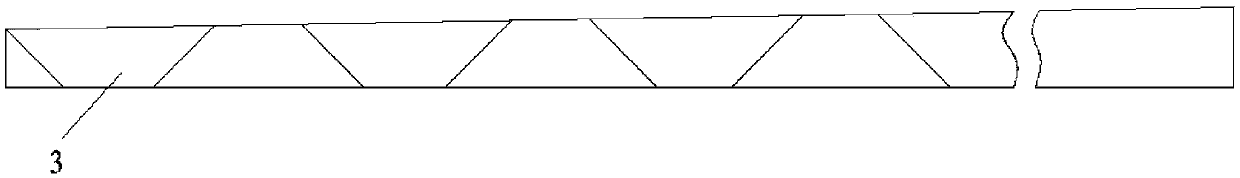

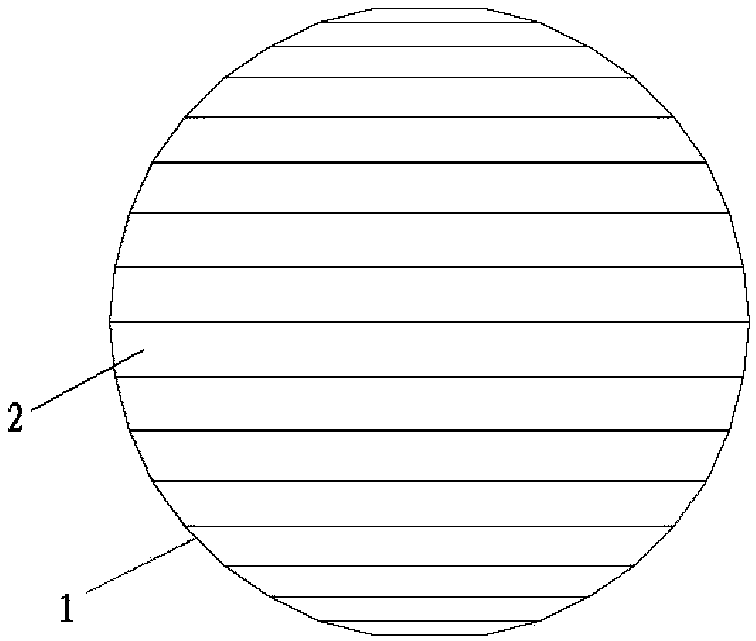

[0039] The invention provides an iron core structure for improving the filling rate of the iron core. The core column or yoke of the iron core is a polygonal cross-section formed by stacking multi-stage trapezoidal cross-section structures. The adjacent bases are of the same length.

[0040] This embodiment provides three structural forms, the first such as Figure 3A As shown, the multi-level trapezoidal cross-section structure is stacked in parallel. This structure is suitable for the main column of the plane laminated iron core.

[0041] The second such as Figure 3B As shown, the multi-level trapezoidal cross-section structure is divided into two parts, and each part is stacked in parallel and symmetrically spliced to form an overall iron core column cross-section 1 . This structure is suitable for the main column of the three-phase three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com