High-performance silicon-based wave absorbing material and preparation method thereof

A wave absorbing material and high-performance technology, applied in the field of high-performance silicon-based wave absorbing material and its preparation, can solve the problems of easy aging, high and low temperature resistance, etc., and achieve easy processing, good oxidation resistance, and excellent weather resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

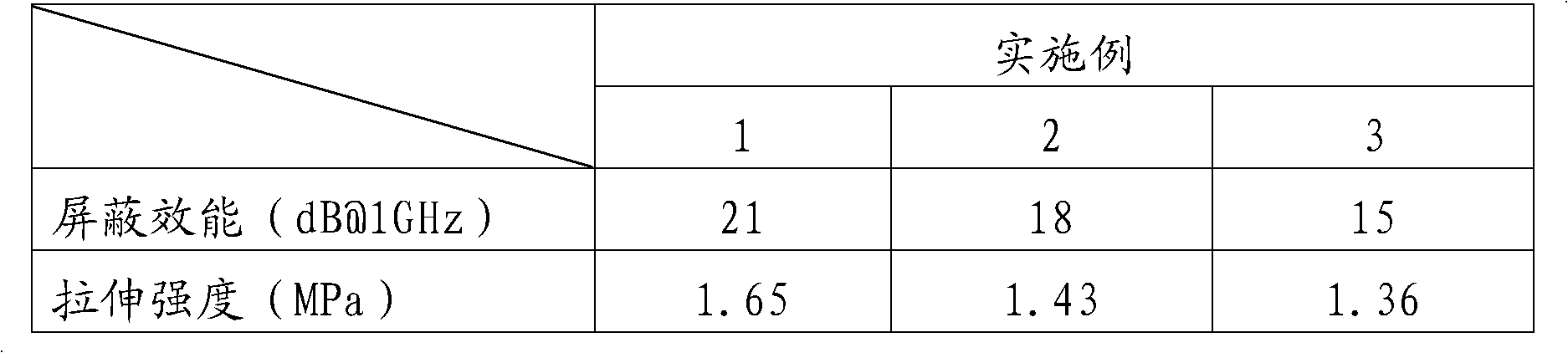

Examples

Embodiment 1~3

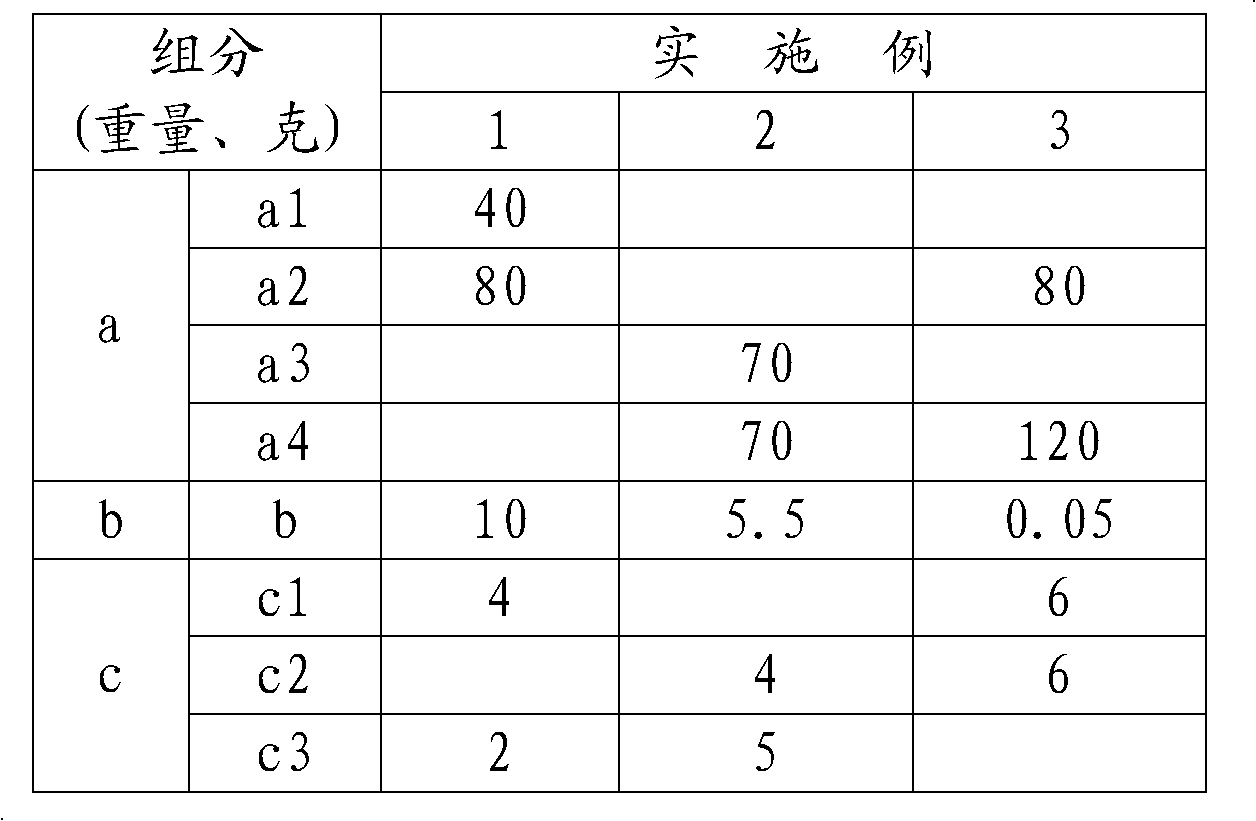

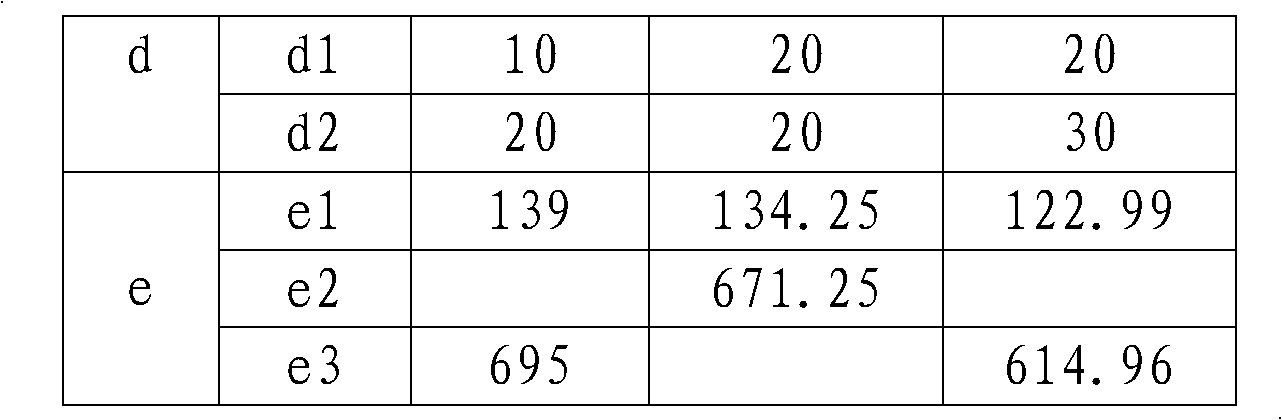

[0033] (1) Prepare raw materials

[0034] aSilicone rubber

[0035] Among them: a1 methyl silicone rubber

[0036] a2 methyl vinyl silicone rubber

[0037] a3. Methylphenyl vinyl silicone rubber

[0038] a4. Methyl vinyl trifluoropropyl silicone rubber

[0039] b Silane coupling agent A-172

[0040] c vulcanizing agent

[0041] Where: c1 DCBP c2 DCP c3 DBPMH

[0042] d flame retardant

[0043] Among them: d1 magnesium hydroxide d2 aluminum hydroxide

[0044] e absorbent

[0045] Among them: e1 hydroxyl iron powder (average particle size 25μm)

[0046] e2 iron alloy powder (average particle size 60μm)

[0047] e3 ferrite powder (average particle size 60μm)

[0048] The above-mentioned powders were prepared according to the proportions shown in Table 1, and then the absorbent after the preparation was surface-treated by a wet method to obtain an absorbent powder coated with a layer of silane coupling agent on the surface.

[0049] (2) Put the above-mentioned componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com