Patents

Literature

70results about How to "Improve tooling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick swap load port

ActiveUS7578650B2Improve tooling efficiencyImprove compatibilitySemiconductor/solid-state device manufacturingConveyor partsEngineeringMaterials processing

Owner:KLA TENCOR TECH CORP

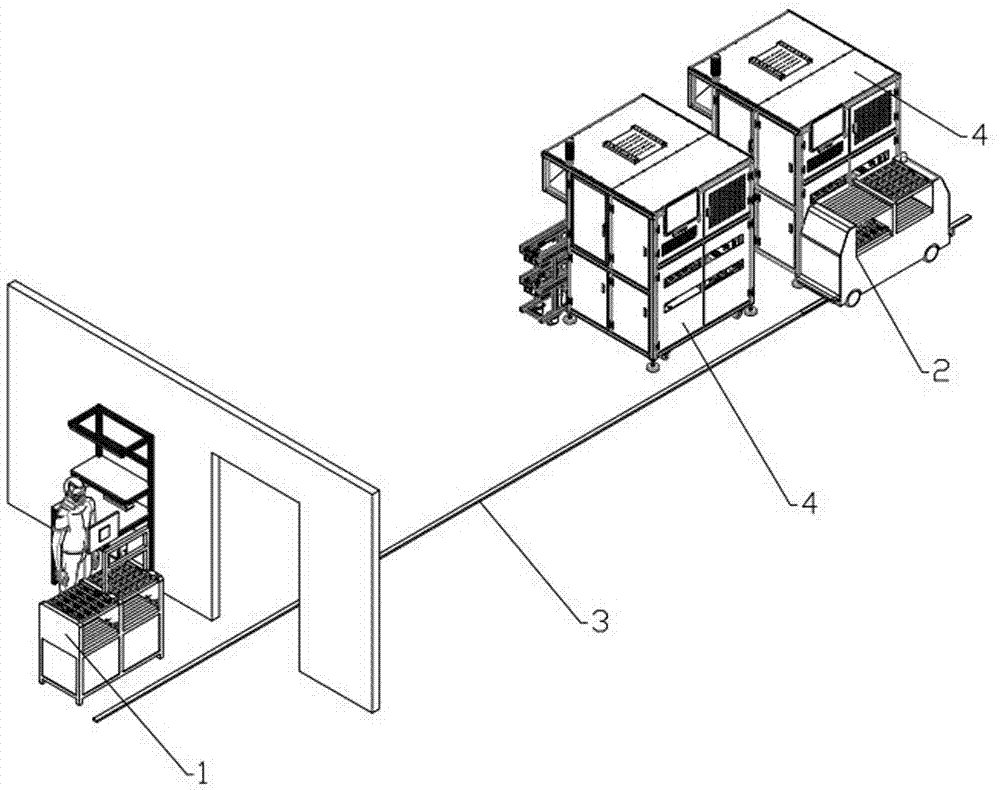

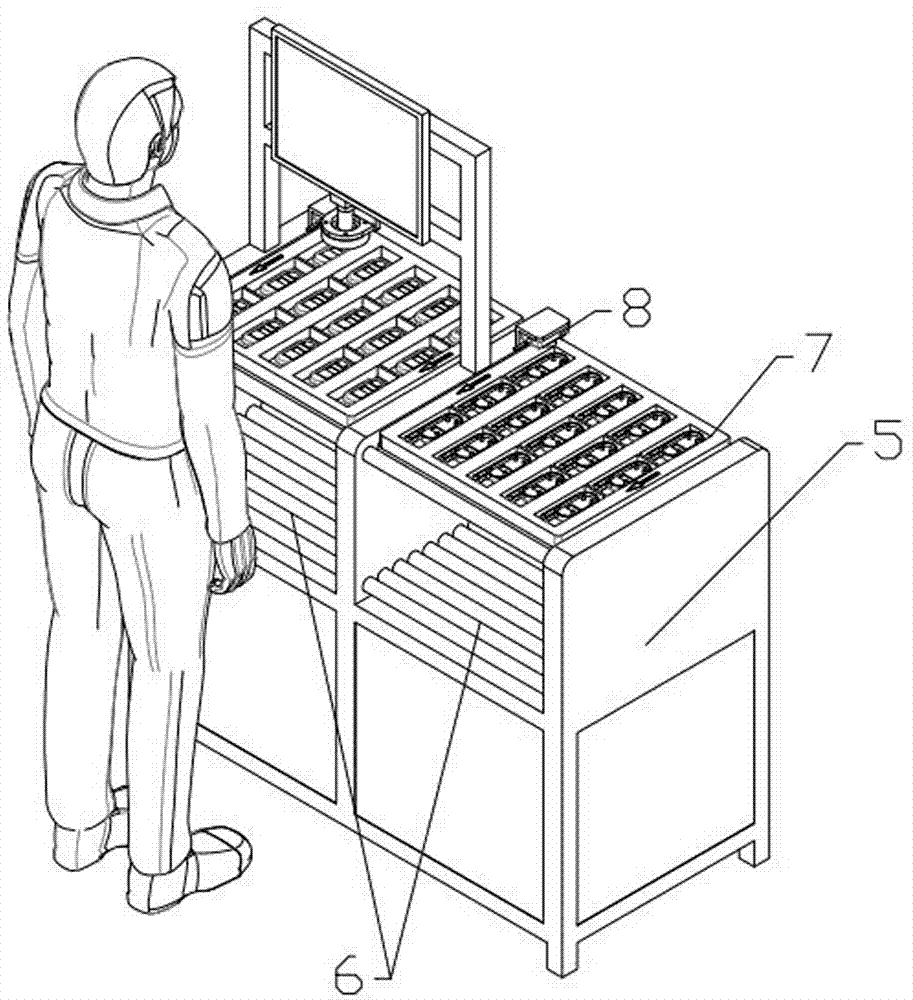

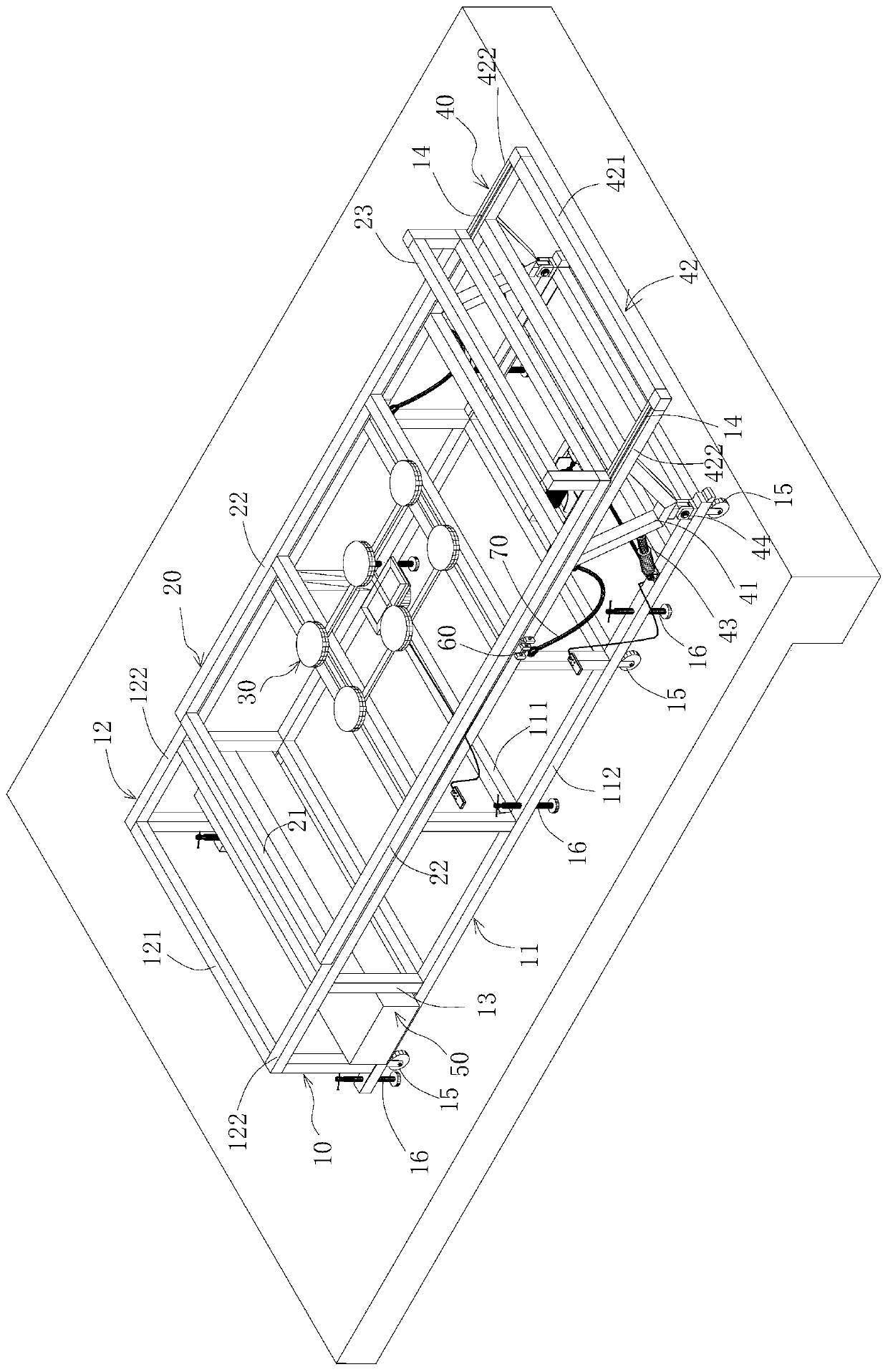

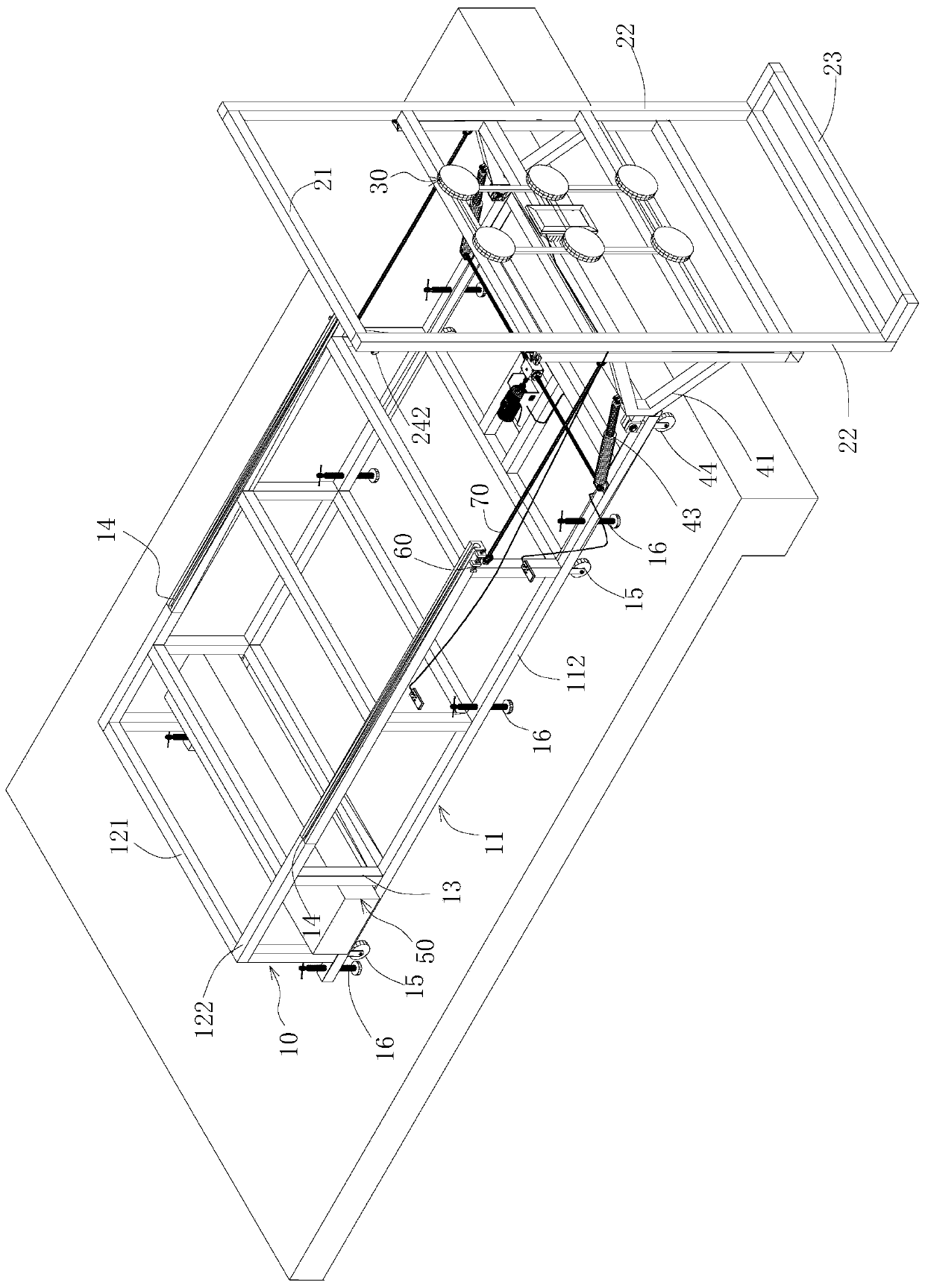

Automated material distributing system

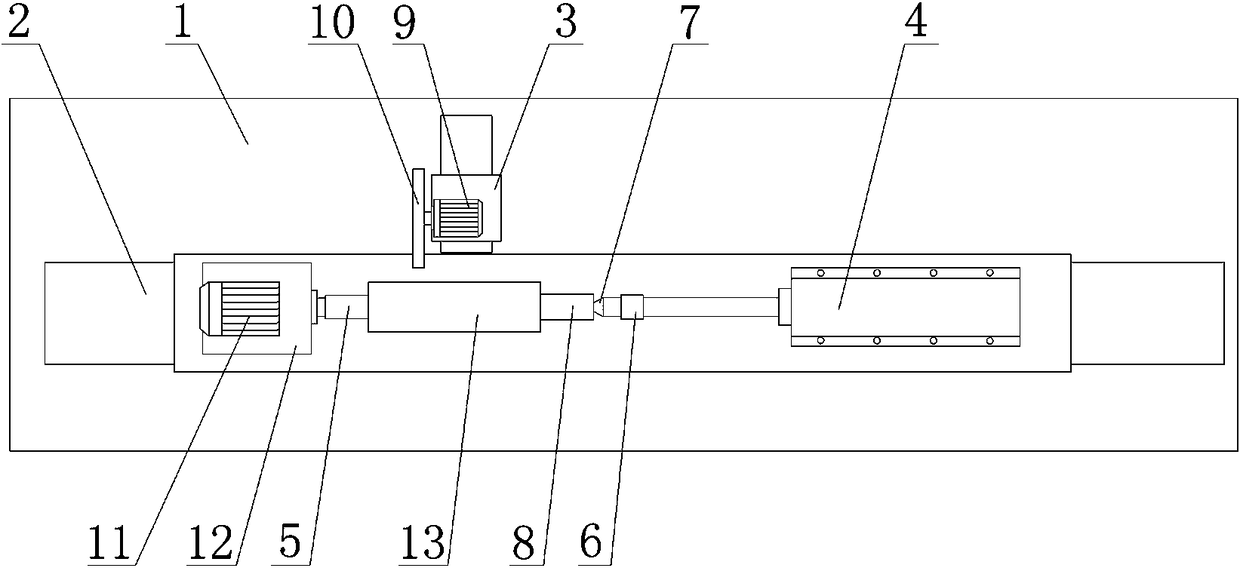

PendingCN107336962ARealize automatic feeding processRealize blankingControl devices for conveyorsStorage devicesEngineeringMechanical engineering

The invention provides an automated material distributing system. The automated material distributing system comprises an AGV inspection conveyor, an AGV trolley, an AGV trolley track, three-dimensional feeding mechanisms and a central controller, wherein the AGV inspection conveyor comprises multiple first horizontal conveying mechanisms, trays used for containing materials are arranged on the first horizontal conveying mechanisms, and the AGV trolley is provided with second horizontal conveying mechanisms which are connected with the first horizontal conveying mechanisms in a butted manner; and each three-dimensional feeding mechanism comprises a stock bin, a butting platform, a vertical lifting mechanism and a horizontal conveying mechanism, wherein the stock bin is used for enabling the trays to be stored in a stacked manner, the butting platform is fixed to the vertical lifting mechanism, the horizontal conveying mechanism is arranged at the bottom end of the butting platform, and the butting platform is driven by the vertical lifting mechanism and the horizontal conveying mechanism to enable the trays to move between the stock bin and the AGV trolley. According to the automated material distributing system, automatic feeding and discharging of materials can be achieved, and artificial burdening and material changing are reduced; and meanwhile, automatic conveying is achieved, artificial distribution is reduced, the tool efficiency can be effectively improved, and the labor cost is reduced.

Owner:SHENZHEN HYTERA COMM

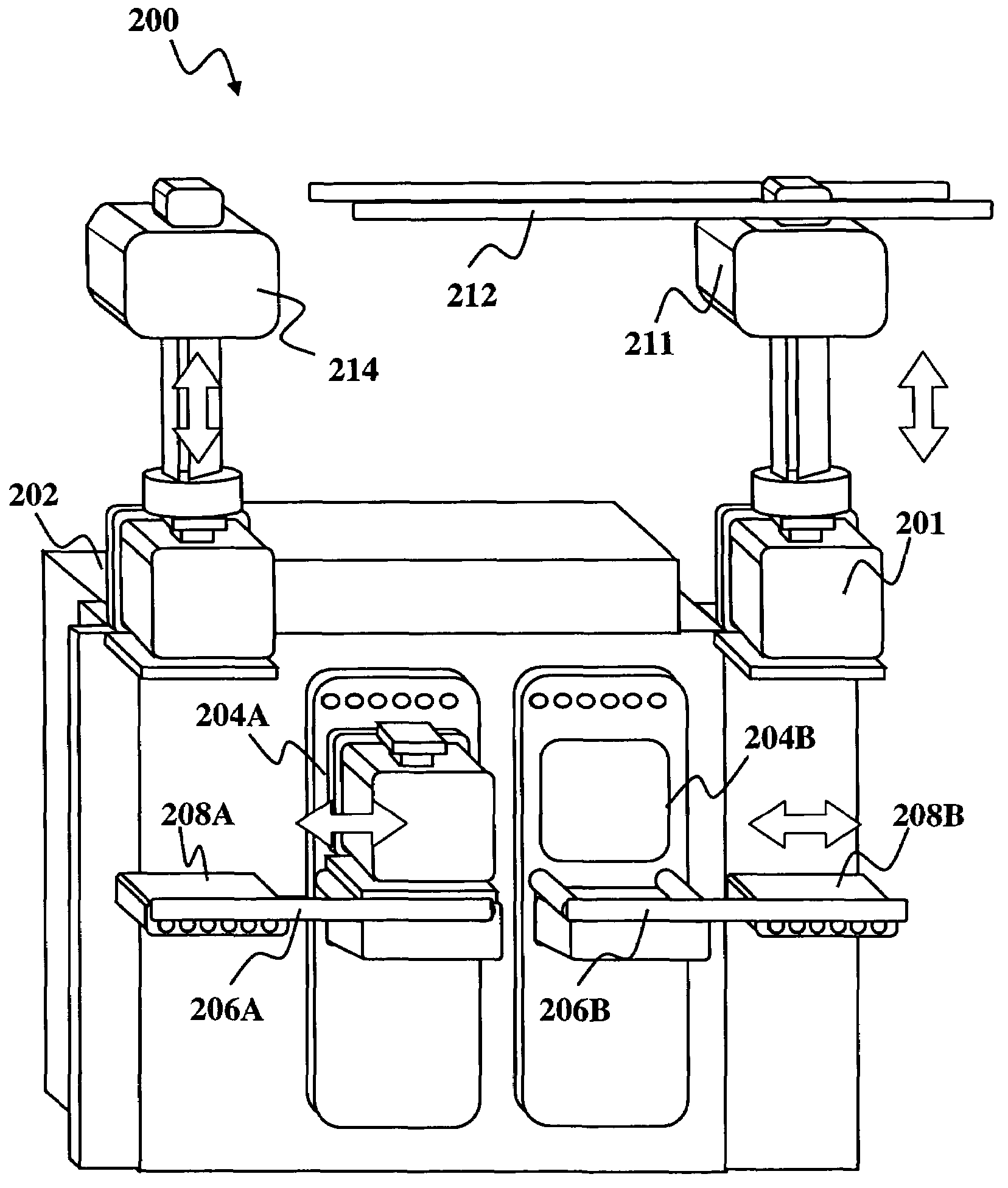

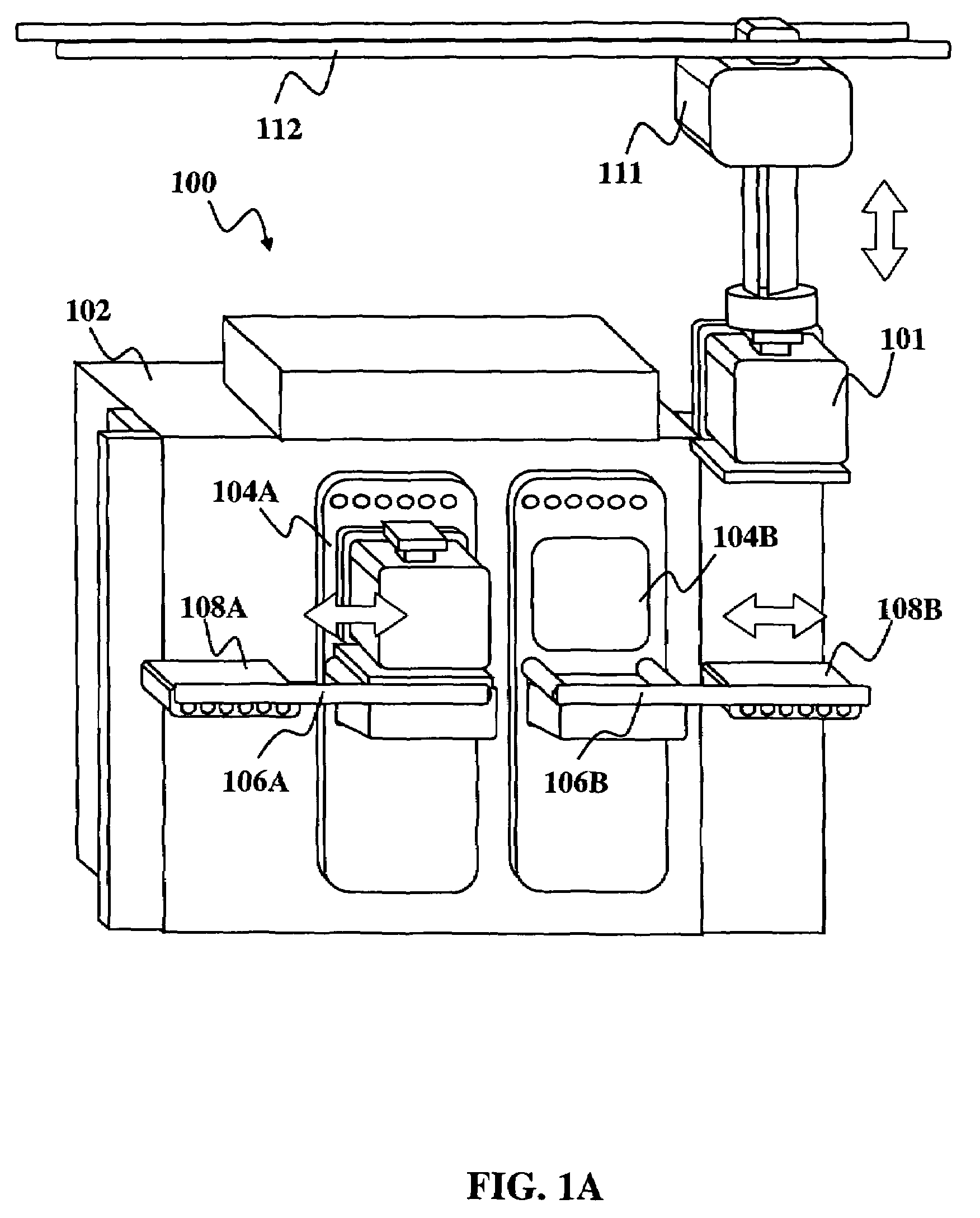

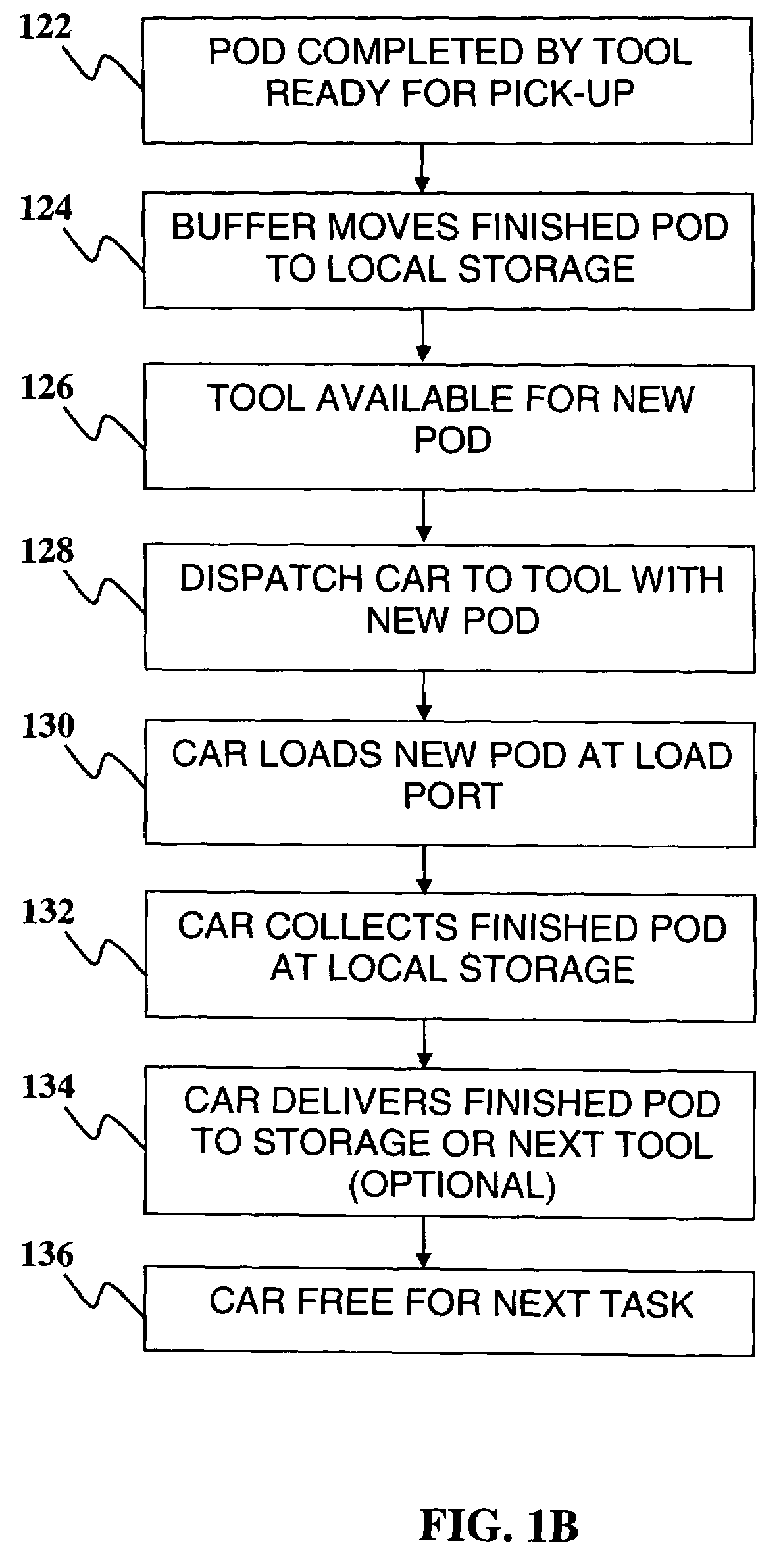

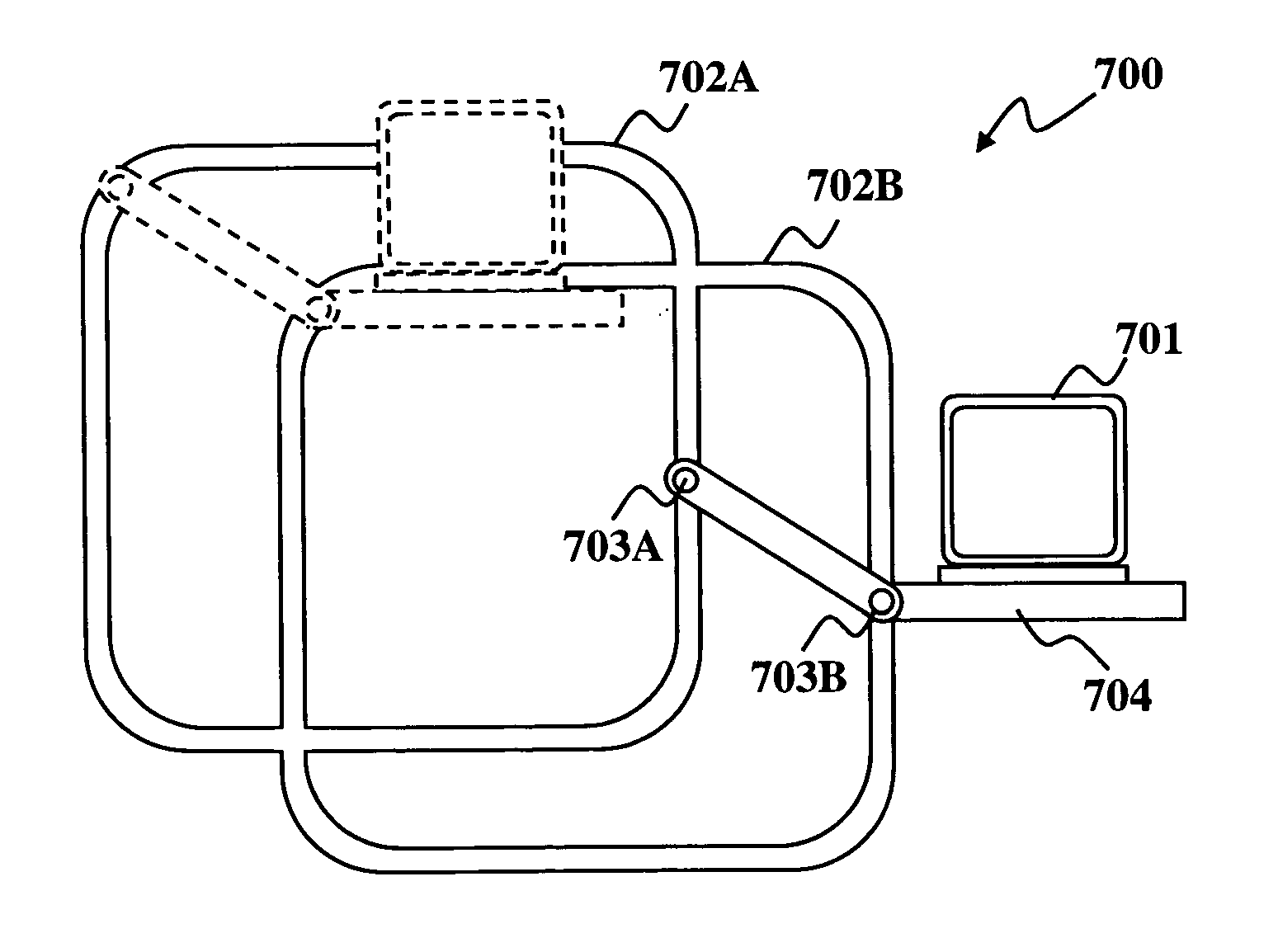

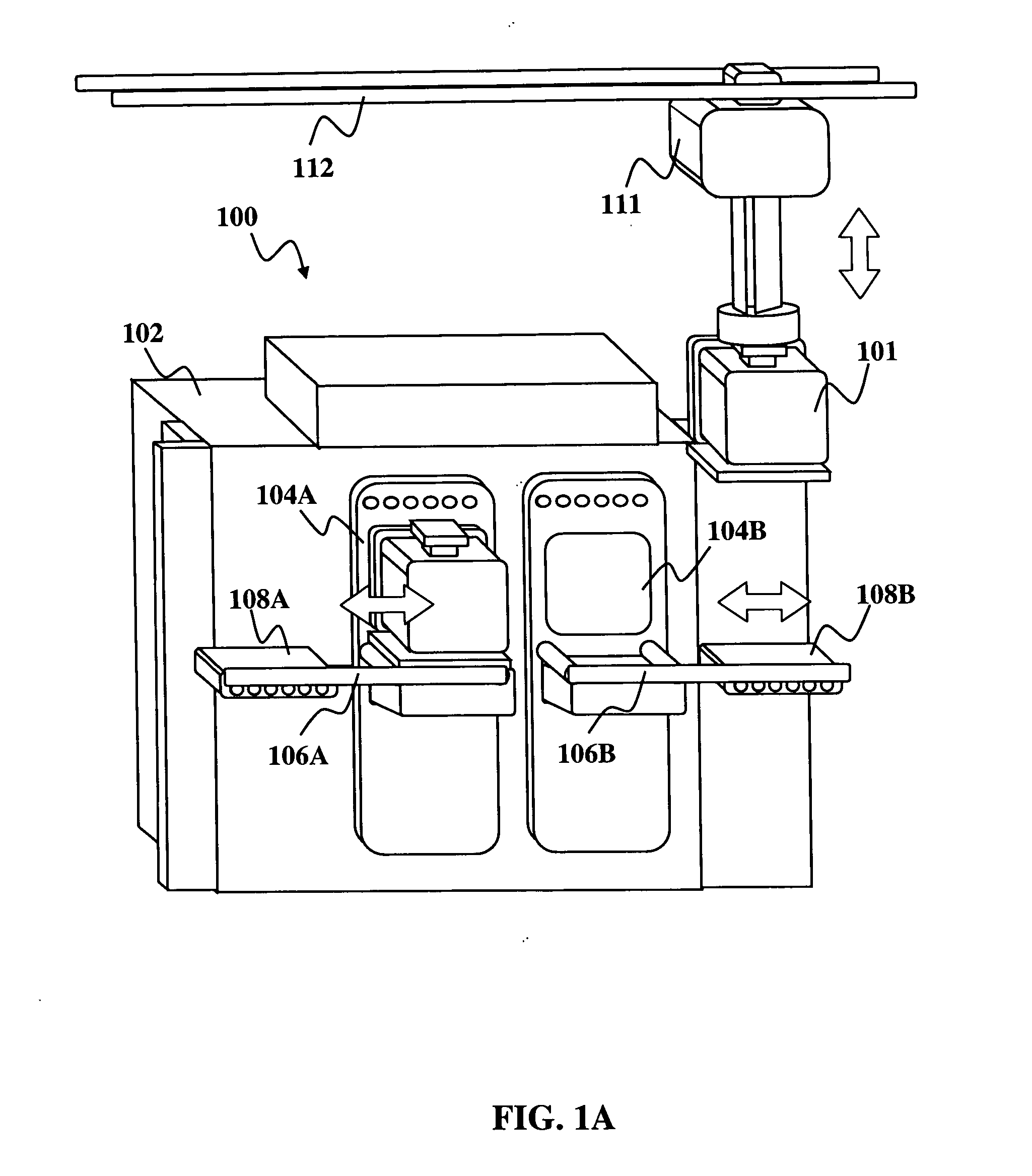

Quick swap load port

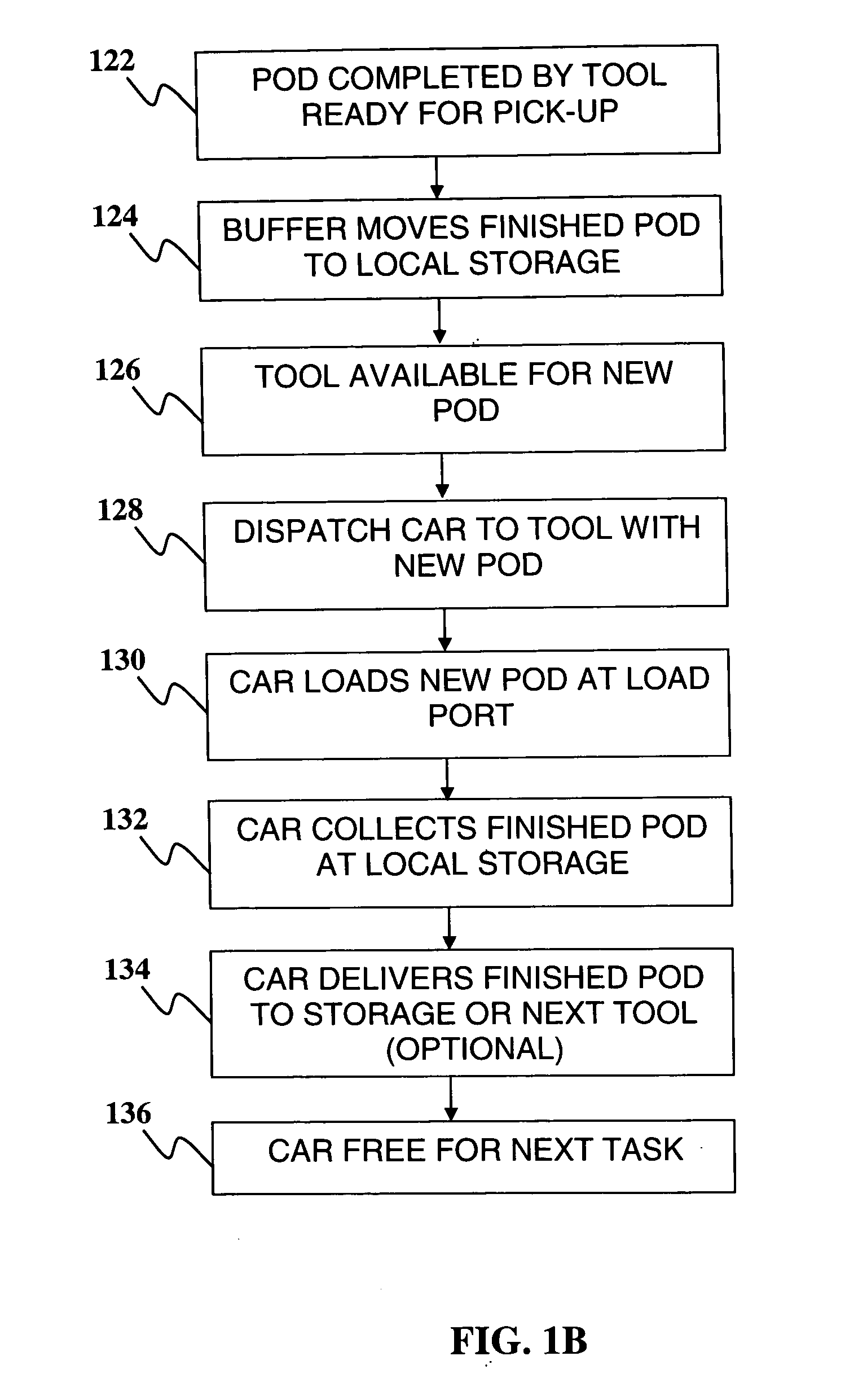

ActiveUS20060045662A1Reduce loadImprove tooling efficiencySemiconductor/solid-state device manufacturingConveyor partsEngineeringSnubber

Apparatus and method for reducing the load on an automated material handling system during processing of materials are disclosed. A materials processing tool with one or more load ports is equipped with at least one movable buffer attached to the tool front end. The buffer is configured to receive a materials pod from the automated material handling system at a storage location and move the pod to one or more of the one or more of the load ports and / or receive a pod from one or more of the one or more load ports and move the pod to the storage location. Any pod in the buffer is accessible either manually or by the material handling system.

Owner:KLA TENCOR TECH CORP

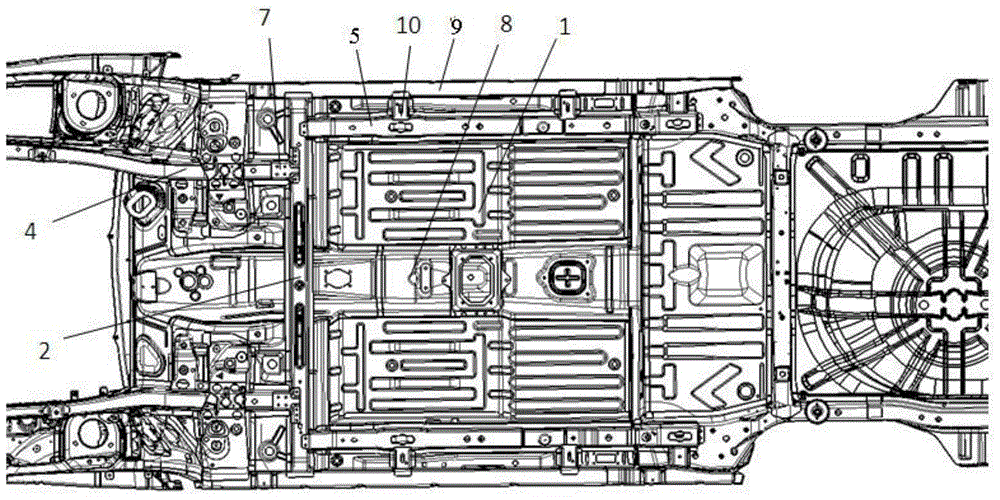

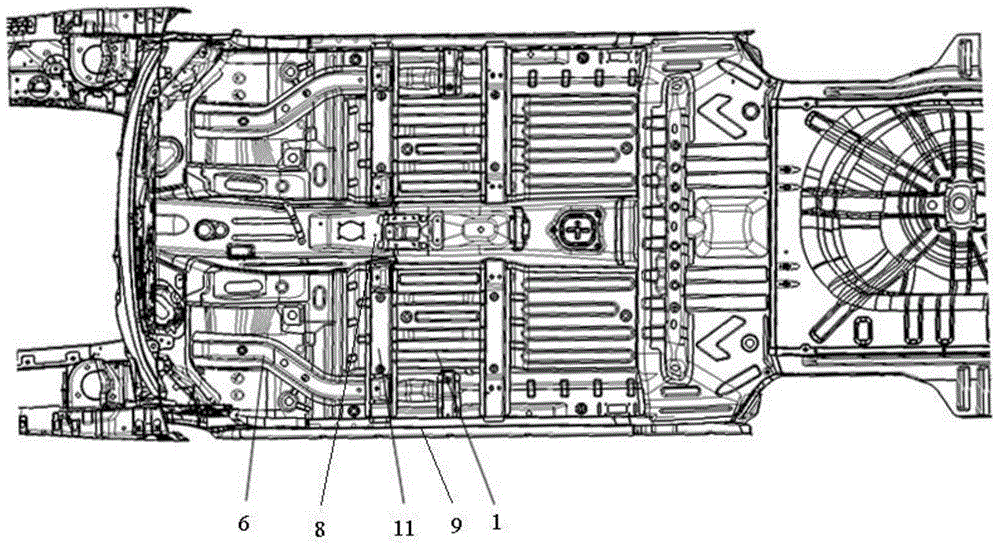

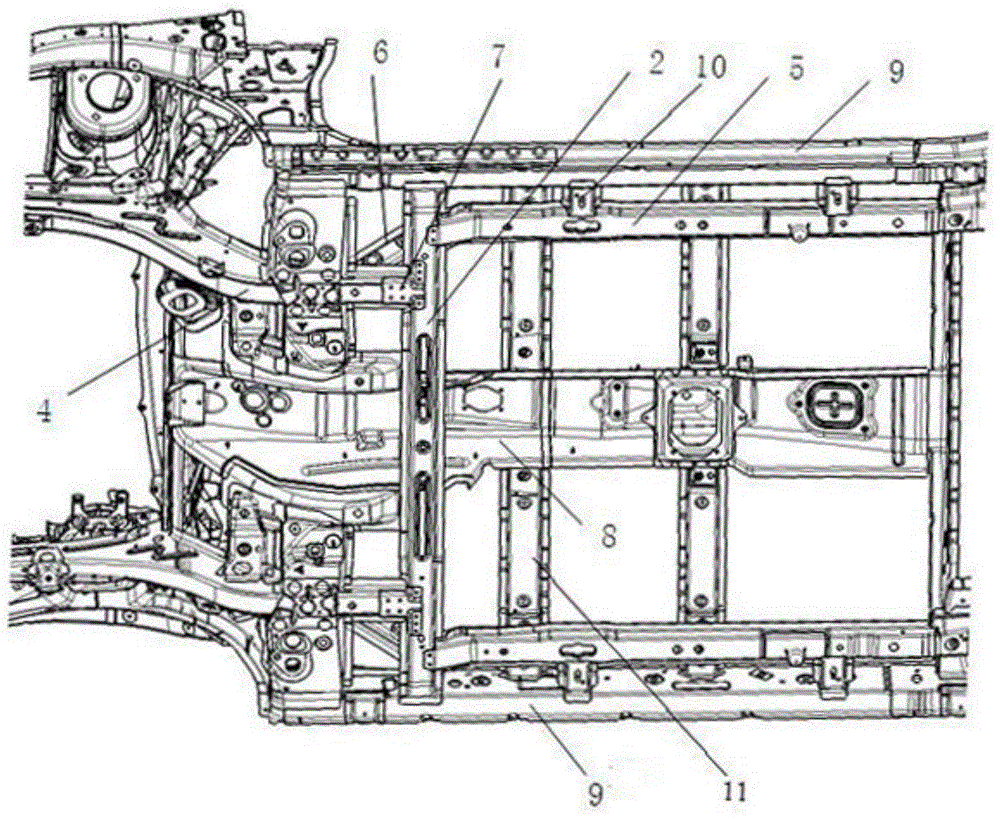

Front floor lower beam connecting structure of battery-changing type electric vehicle body

ActiveCN104787123AIncreased longitudinal stiffnessIncrease lateral stiffnessSuperstructure subunitsAutomotive batteryElectric vehicle

The invention discloses a front floor lower beam connecting structure of a battery-changing type electric vehicle body. The front floor lower beam connecting structure comprises a vehicle body front floor, a front floor lower beam is arranged in front below the vehicle body front floor, the two ends of the front floor lower beam are fixedly connected with front floor side longitudinal beams, the middle of the front floor lower beam is fixedly connected with a middle channel, the rear ends of vehicle body front longitudinal beams are fixedly connected with the front floor lower beam, and the front ends of front floor inner longitudinal beams are fixedly connected with the front floor lower beam. The front floor lower beam connecting structure is simple, convenient to assemble and reliable to use, and installs and fixes a vehicle battery pack without substantially changing a traditional vehicle body structure, meanwhile, longitudinal and transverse rigidity of the lower portion of an electric vehicle body floor is guaranteed, the performance of resisting front face and side face collision of the vehicle body is effectively improved, the safety and the stability of an electric vehicle are improved, the manufacturing cost of the electric vehicle is lowered, and the consumed tooling time for the electric vehicle is shortened.

Owner:DONGFENG MOTOR CORP HUBEI

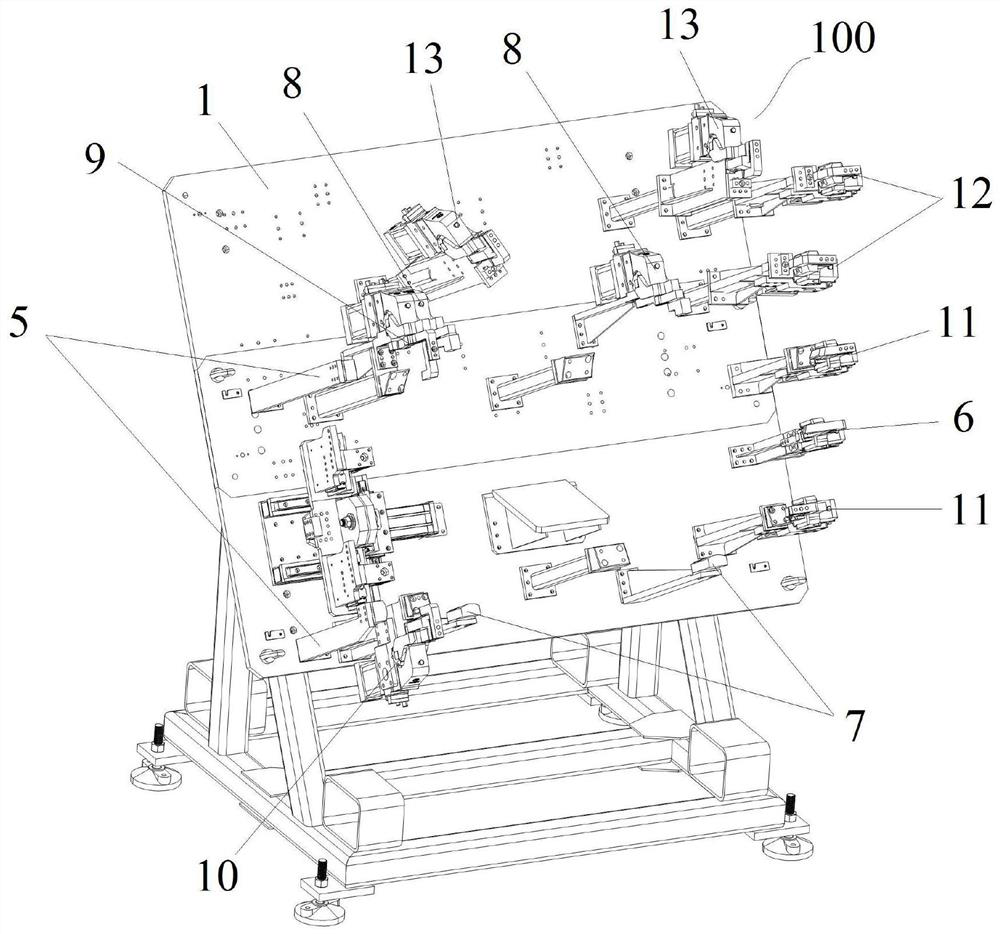

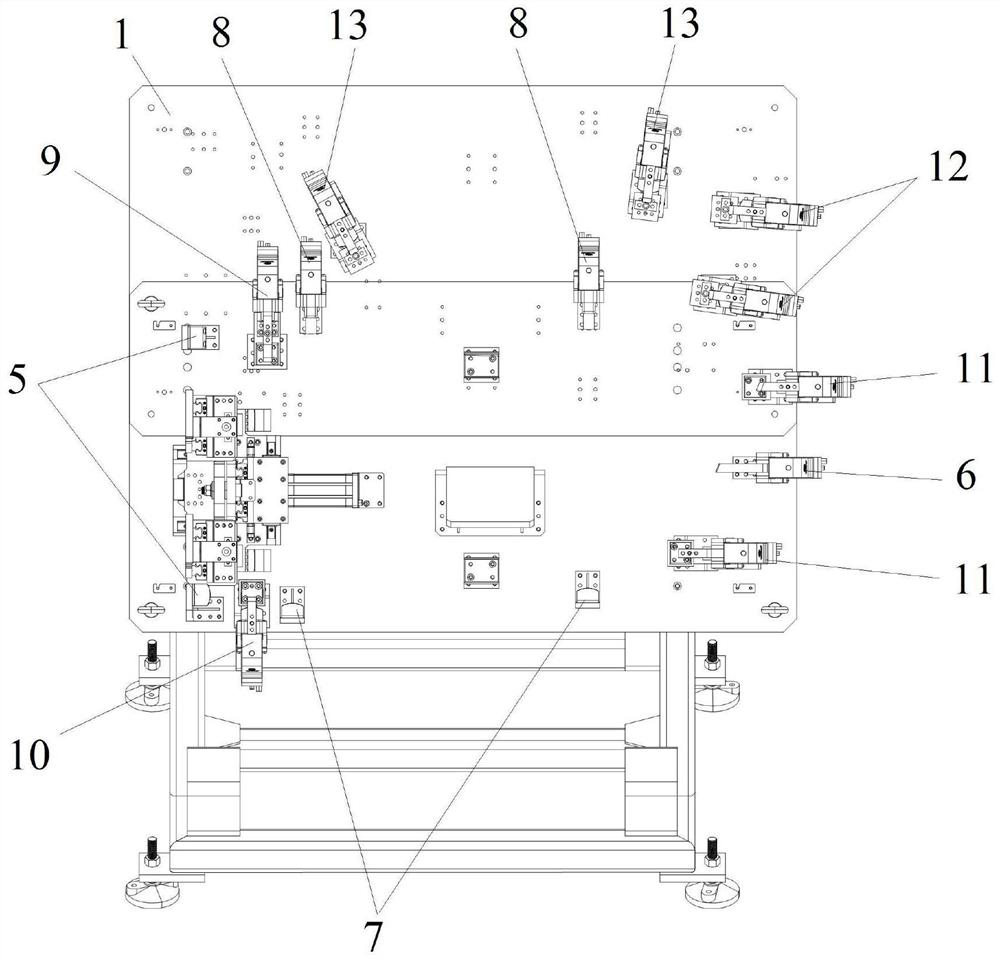

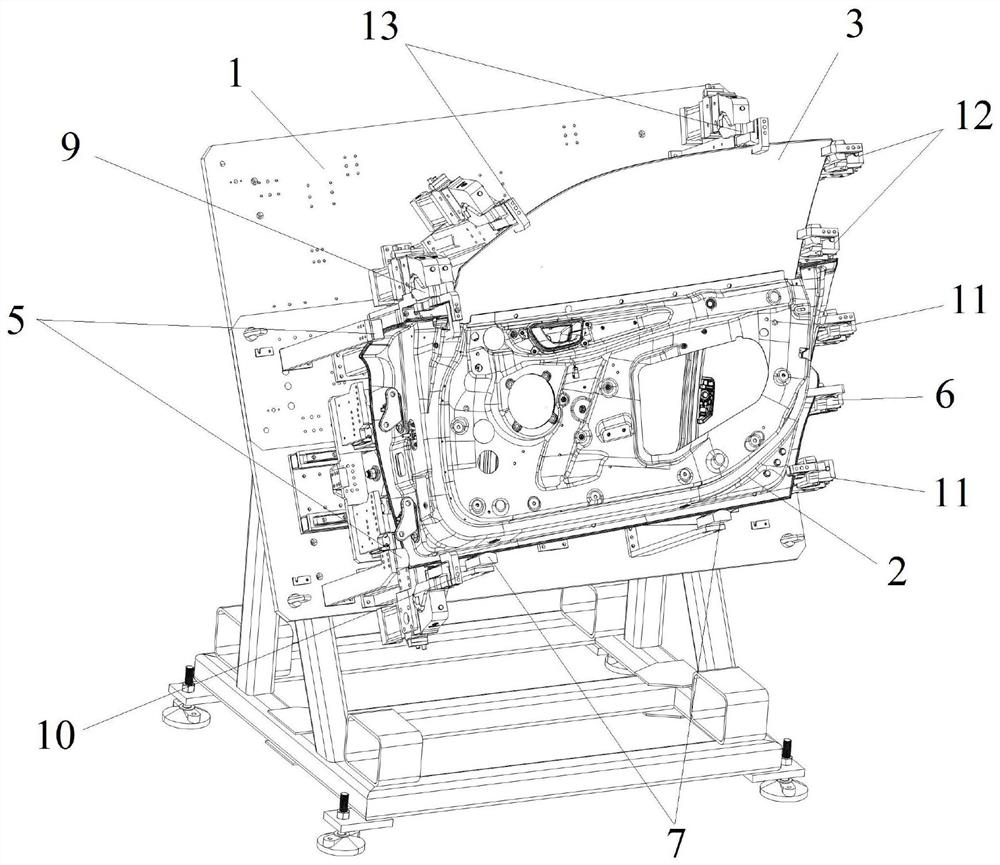

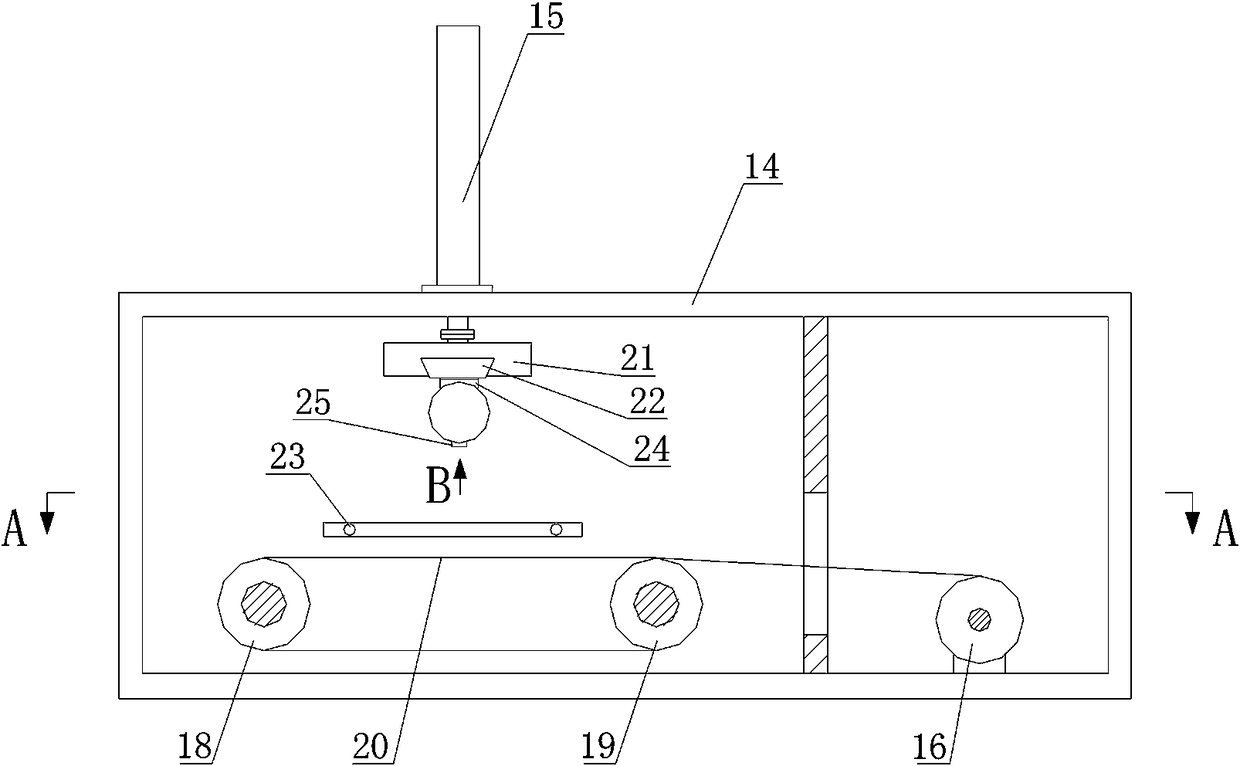

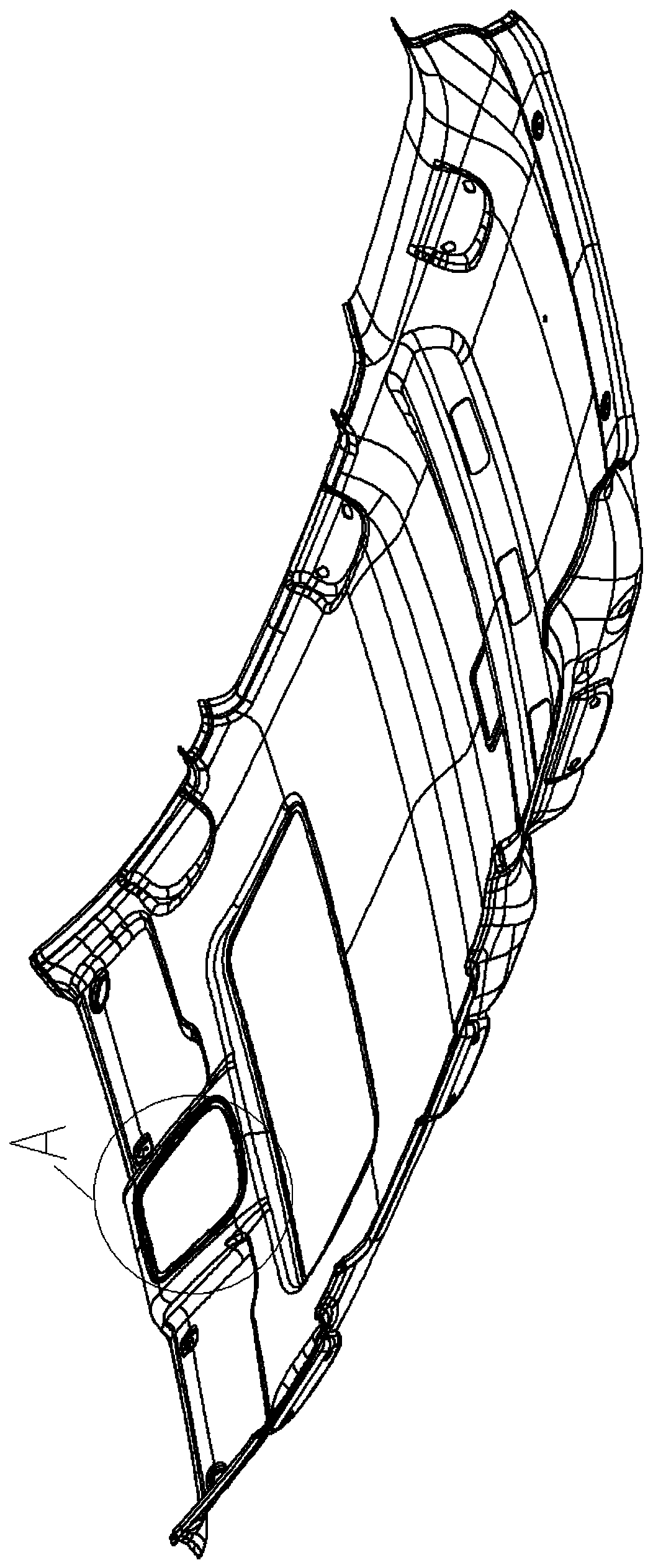

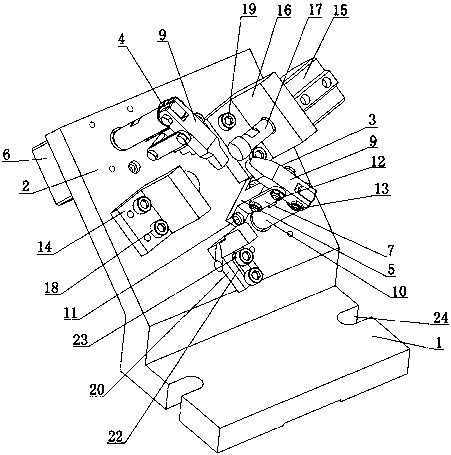

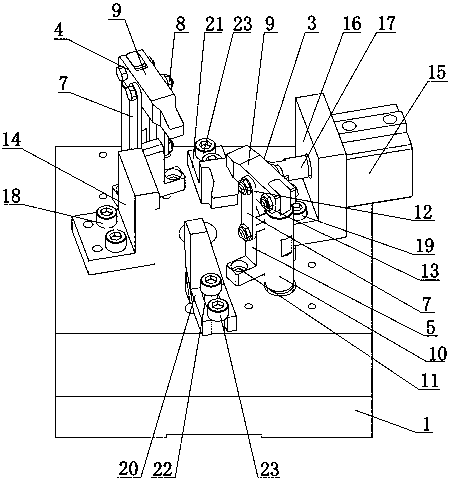

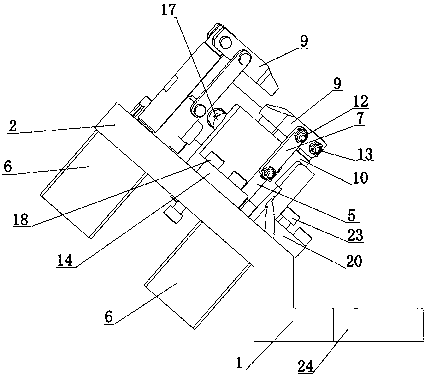

Window glass adjusting device of frameless vehicle door

The invention discloses a vehicle window glass adjusting device of a frameless vehicle door, and relates to the field of tools. The vehicle window glass adjusting device comprises a tool support, a vehicle door fixing mechanism and a vehicle window glass fixing mechanism, the vehicle door fixing mechanism comprises a vehicle door X-direction limiting assembly, a vehicle door Y-direction limiting assembly and a vehicle door Z-direction limiting assembly which are arranged on the tool support; the vehicle door X-direction limiting assembly is used for abutting against the left side and the rightside of the vehicle door outer plate, the vehicle door Y-direction limiting assembly is used for clamping the inner side face and the outer side face of the vehicle door outer plate, and the vehicledoor Z-direction limiting assembly is used for abutting against the upper side and the lower side of the vehicle door outer plate. The vehicle window glass fixing mechanism comprises a vehicle windowglass X-direction limiting assembly and a vehicle window glass Z-direction limiting assembly which are arranged on the tool support, the vehicle window glass X-direction limiting assembly is used forabutting against the right side of vehicle window glass, and the vehicle window glass Z-direction limiting assembly is used for abutting against the upper side of the vehicle window glass. According to the device, the length of the dimension chain is shortened, so that the matching precision between the vehicle window glass and the vehicle door outer plate is higher.

Owner:欧恩科(北京)自动门科技有限公司

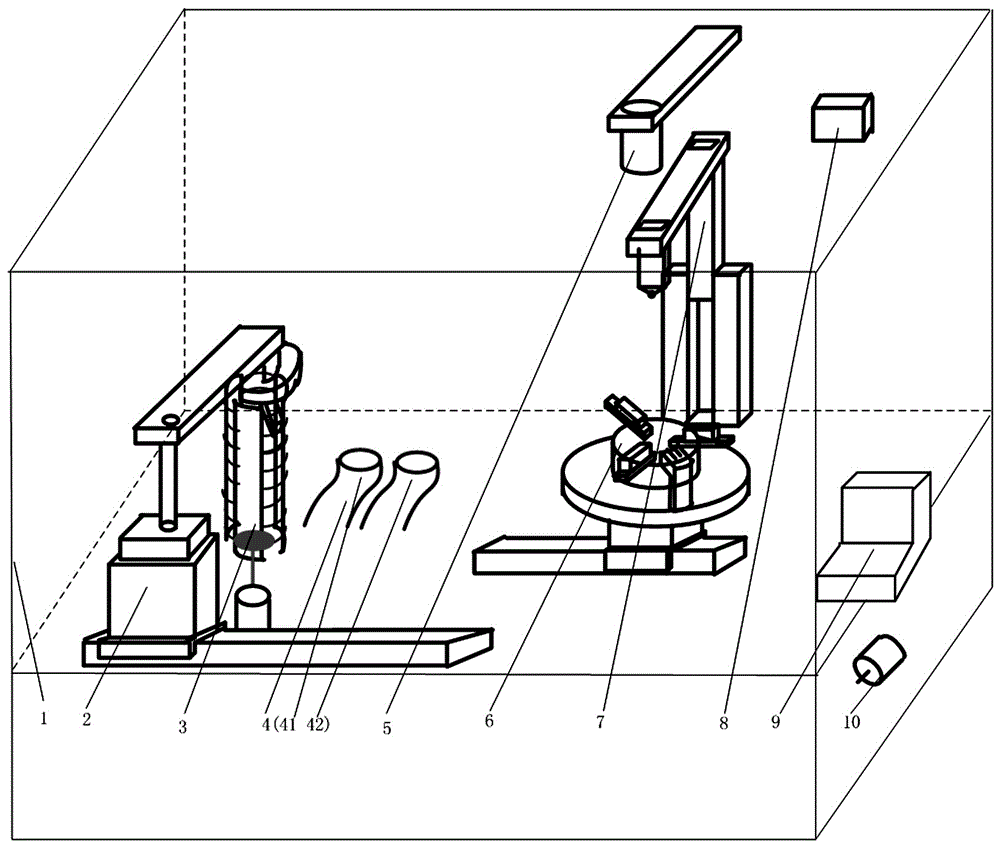

Monocrystalline wafer production system and production process thereof

ActiveCN108406458AImprove tooling efficiencyHigh grinding precisionEdge grinding machinesRevolution surface grinding machinesMonocrystalline siliconEngineering

The invention discloses a monocrystalline wafer production system which comprises a roller mill, a slicing device, a chamfering device, a grinding miller and a cleaning tank. The invention further discloses a monocrystalline wafer production process. The monocrystalline wafer production system and the monocrystalline wafer production process provided by the invention have the beneficial effects that the roll-milling accuracy is high, the clamping of monocrystalline silicon rods can be quickly realized, the monocrystalline silicon rods with different lengths can be roll-milled and can be slicedinto multiple monocrystalline wafers at one time, the automatic centering is realized, the chamfering efficiency is improved, an automation degree is high, the multiple monocrystalline wafers can beground at one time, the grinding efficiency is high, and the cleaning efficiency is high.

Owner:四川雅吉芯电子科技有限公司

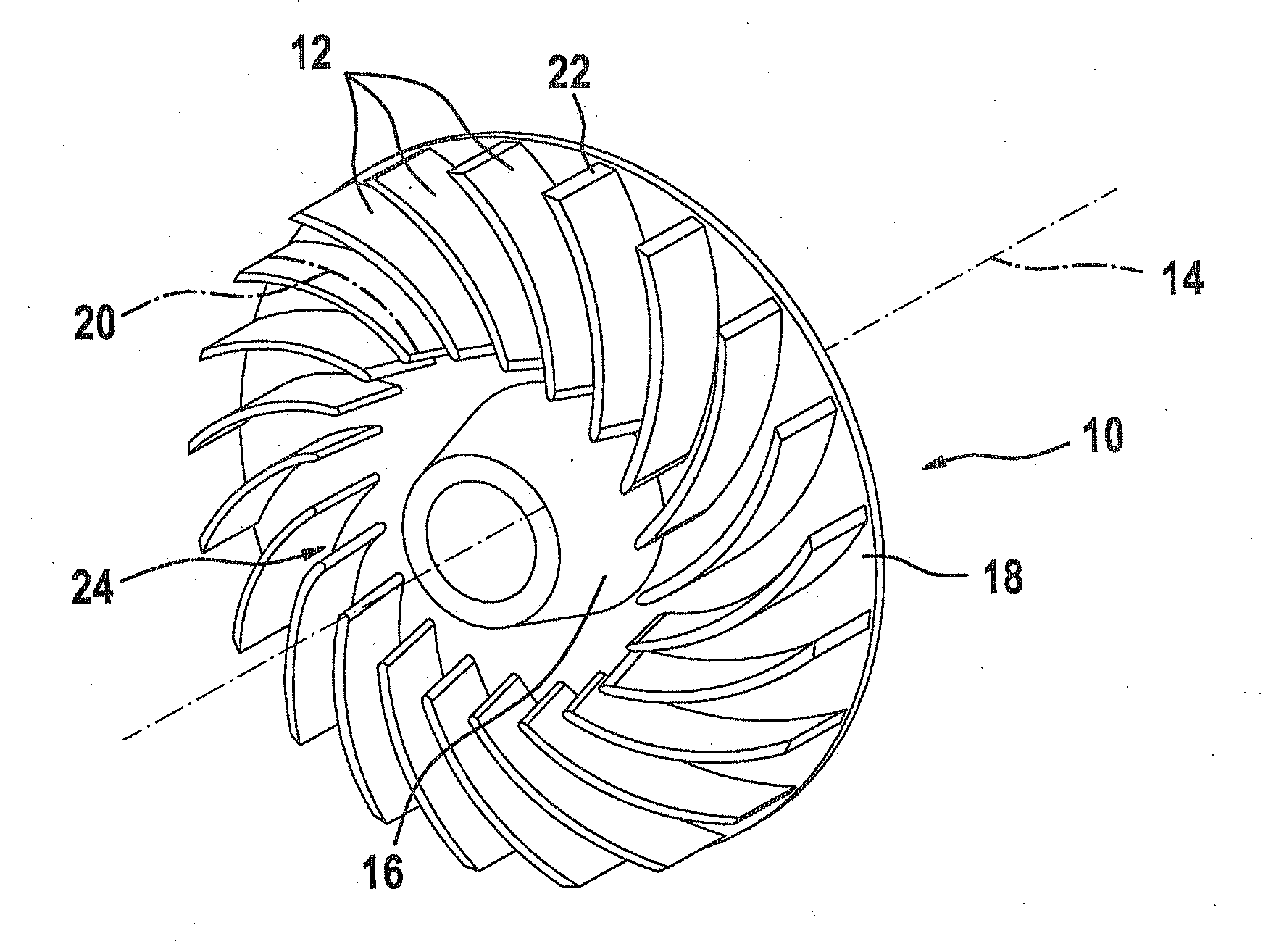

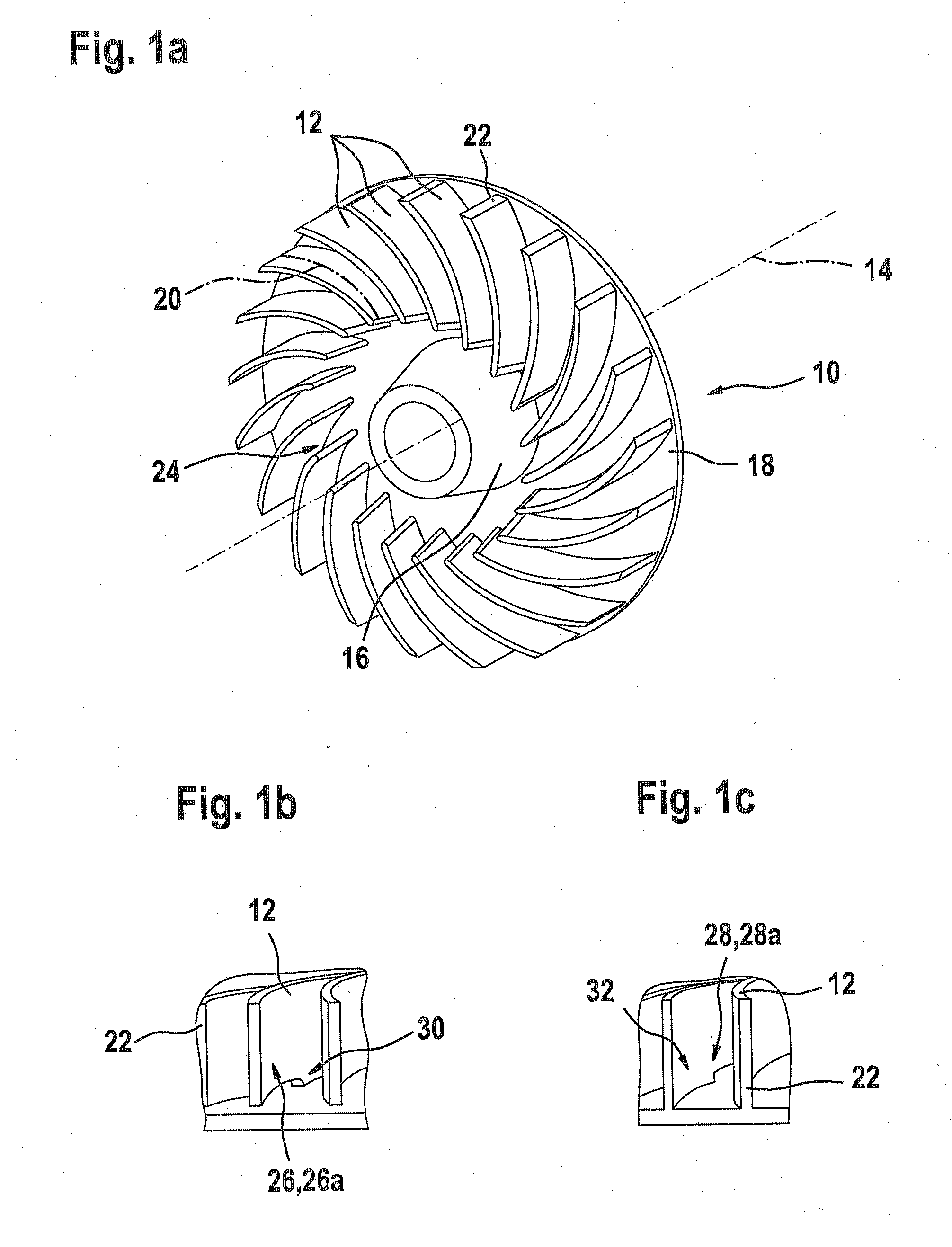

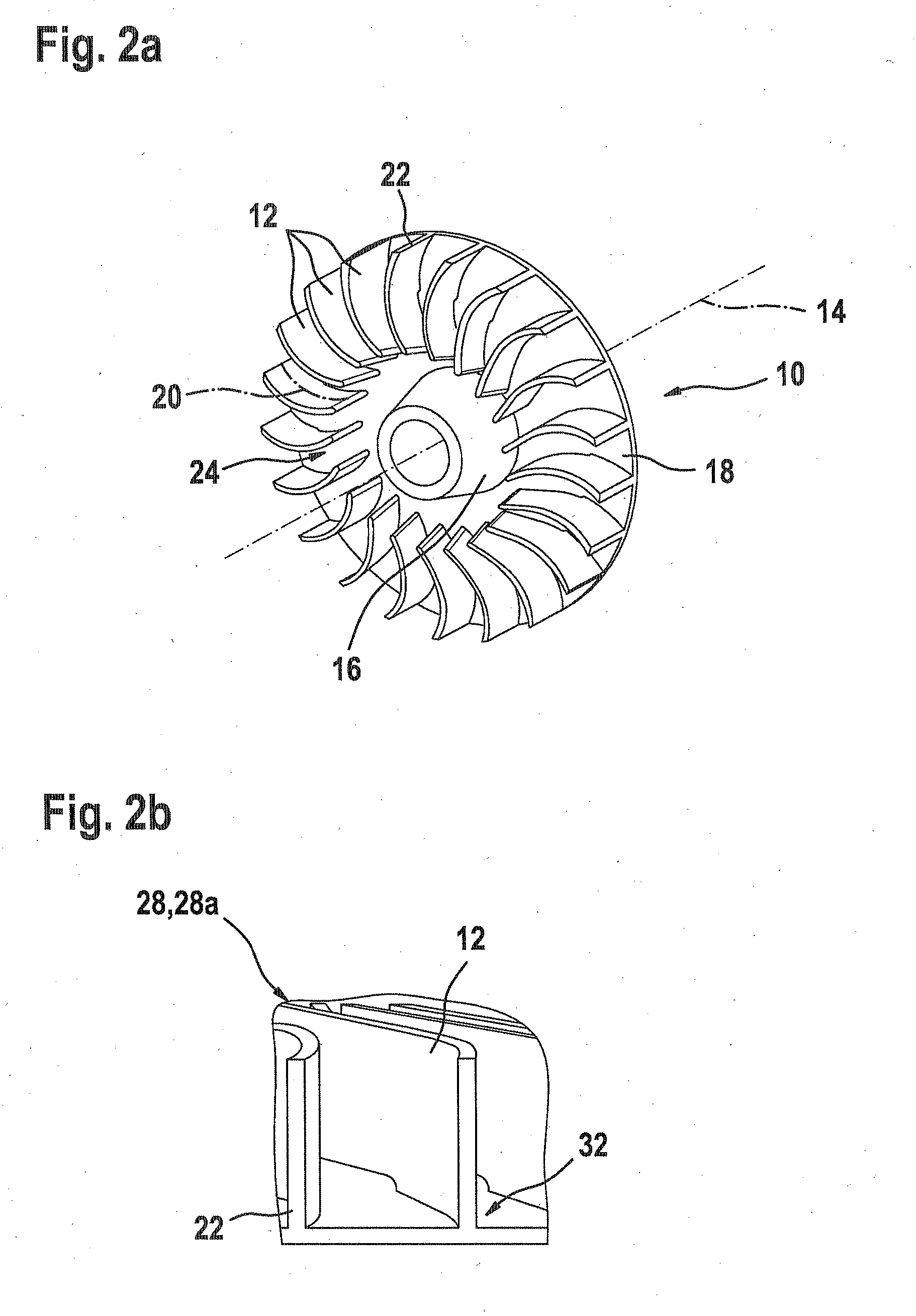

Fan and method for operating a fan

The invention relates to a fan, particularly a radial fan, having a fan hub with a rotational axis. A plurality of fan blades is disposed about the rotational axis for deflecting an air flow. The invention provides that an adjustment device is provided at the fan blades for the rotational speed-dependant adjustment of an air flow.

Owner:ROBERT BOSCH GMBH

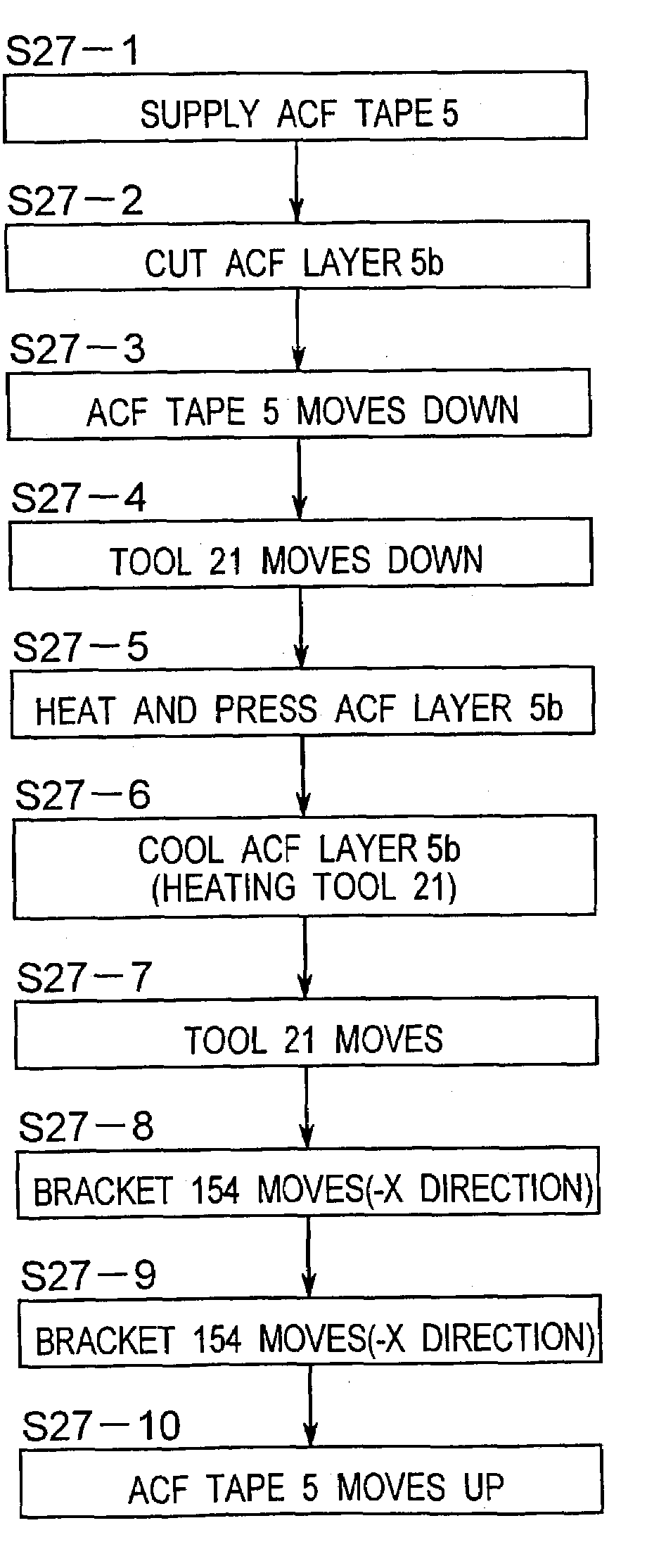

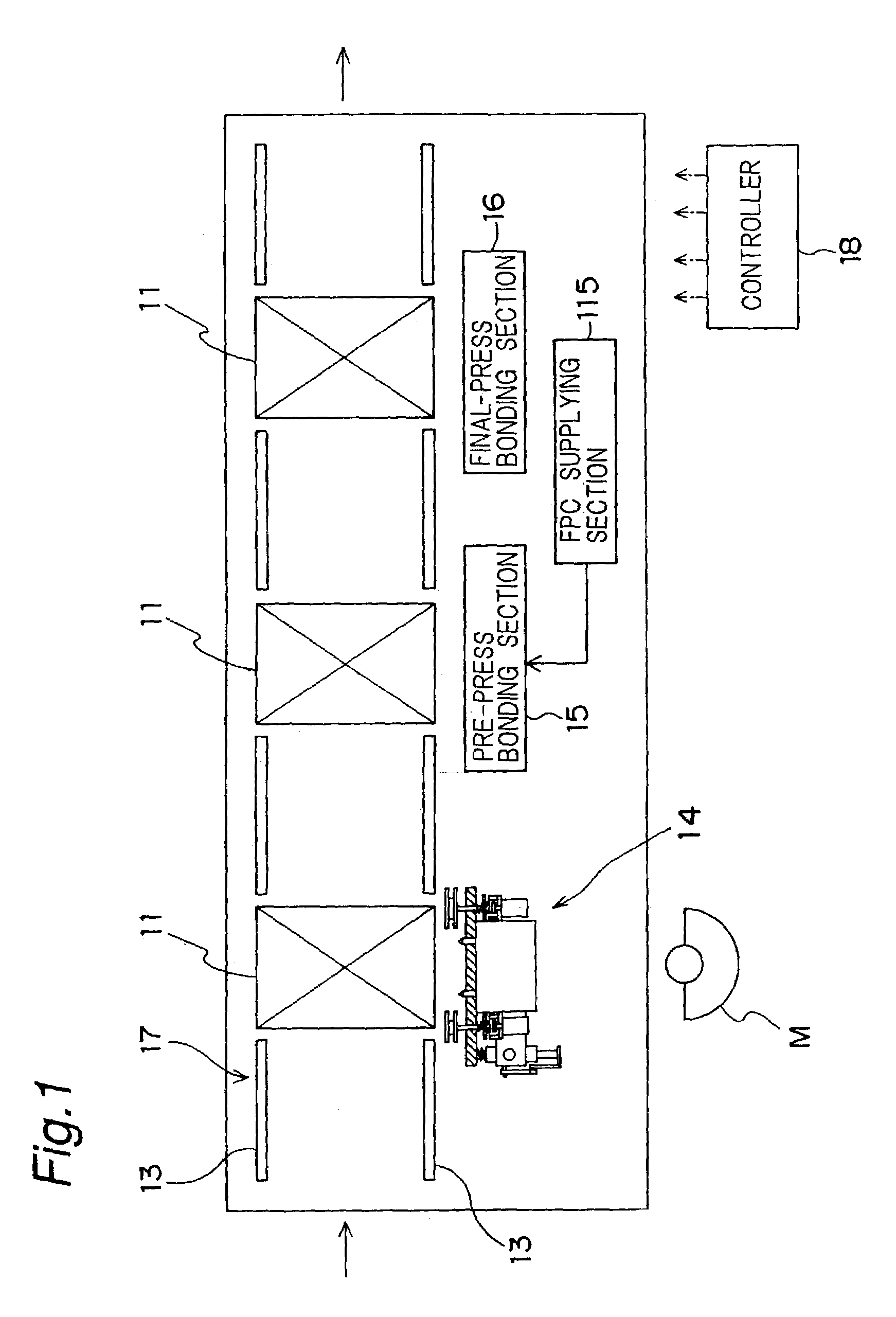

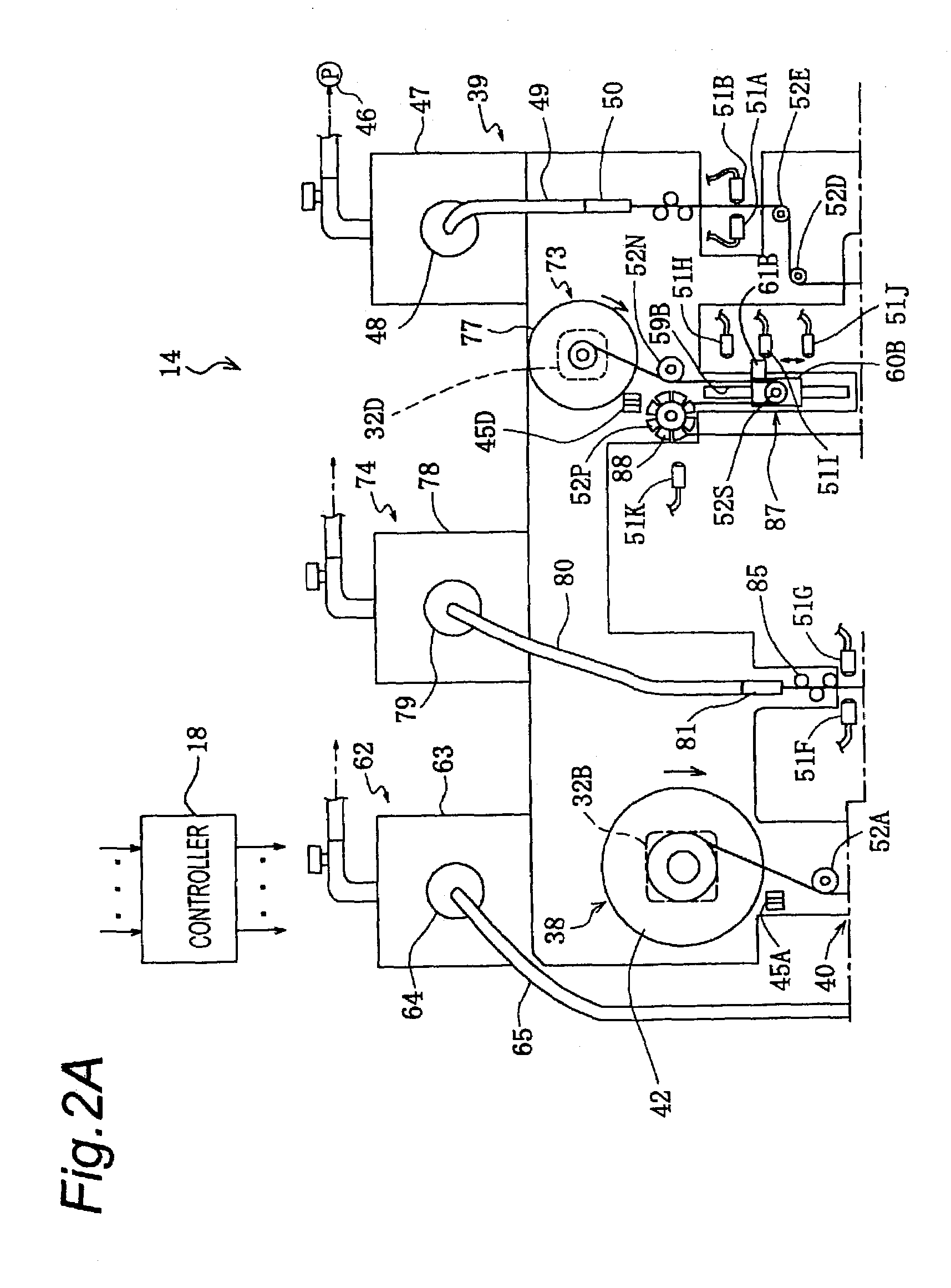

Pressurizing method

InactiveUS7076867B2Joining strengthImprove joint strengthPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

Owner:PANASONIC CORP

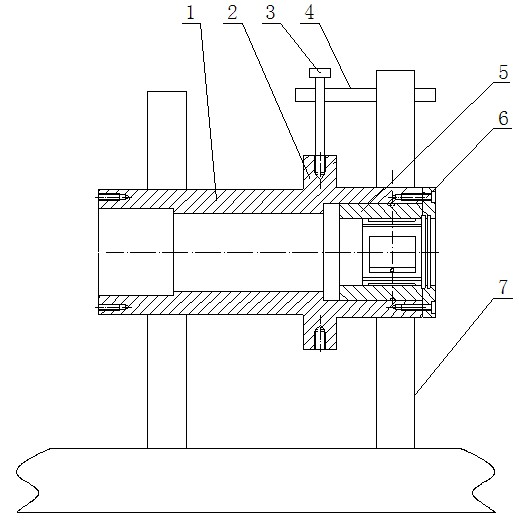

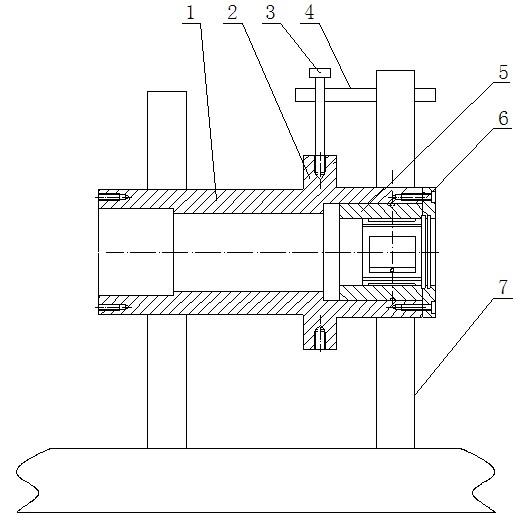

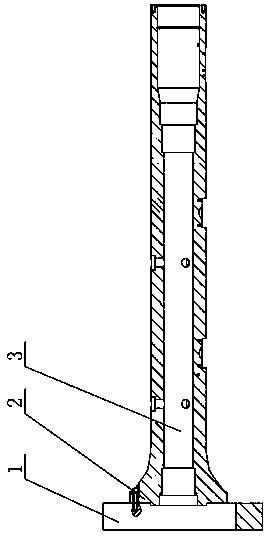

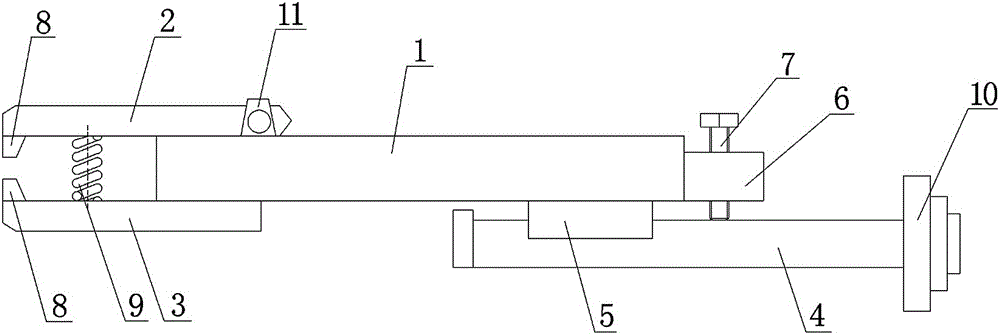

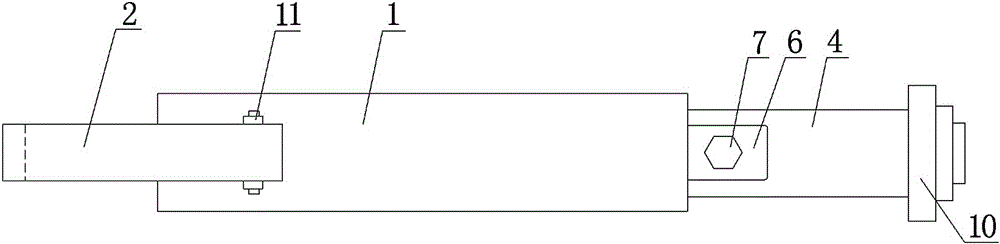

Fixture for machining depth cavity for dynamic and static pressure bearings by using inner-aperture grinder

InactiveCN102528585APrevent tamperingSimple structureRevolution surface grinding machinesMachiningEngineering

The invention provides a fixture for machining a depth cavity for dynamic and static pressure bearings by using an inner-aperture grinder. The fixture comprises a sleeve provided with an annular boss, angle control screw holes are radially and evenly distributed on the annular boss, angle control screws are arranged on the angle control screw holes, stop rods are fixed onto the inner-aperture grinder, each stop rod is positioned between the two corresponding angle control screws, and fixing screw holes and fixing screws for fixing the bearings are arranged on two end faces of the sleeve. The fixture has the advantages that the structure is simple, the machining angle travel of the depth cavity is determined by using the fixture for indexing, the cavity is conveniently machined, working efficiency is improved, cavity machining evenness is ensured, and qualification rate is increased.

Owner:SHANDONG BEST PRECISION

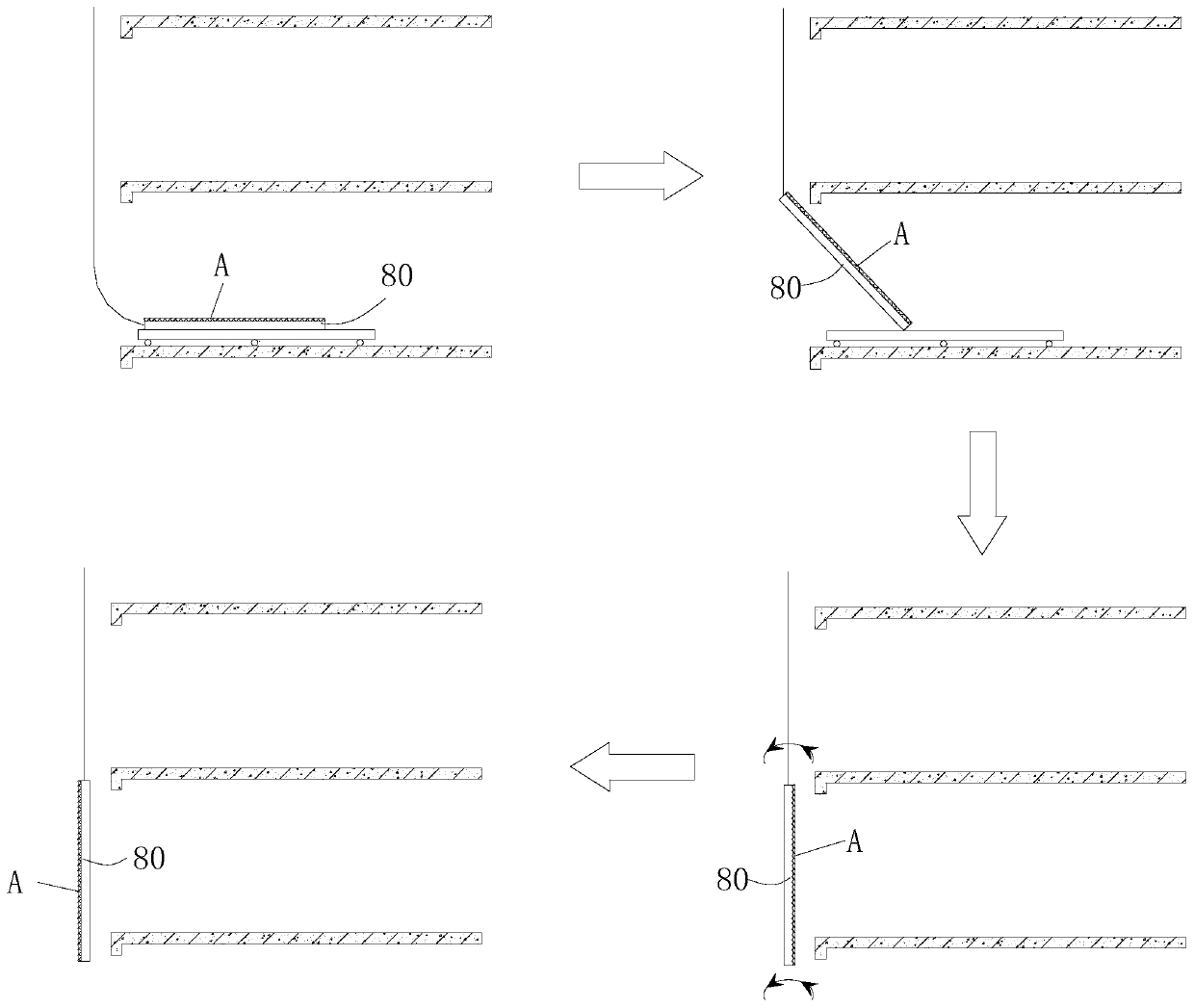

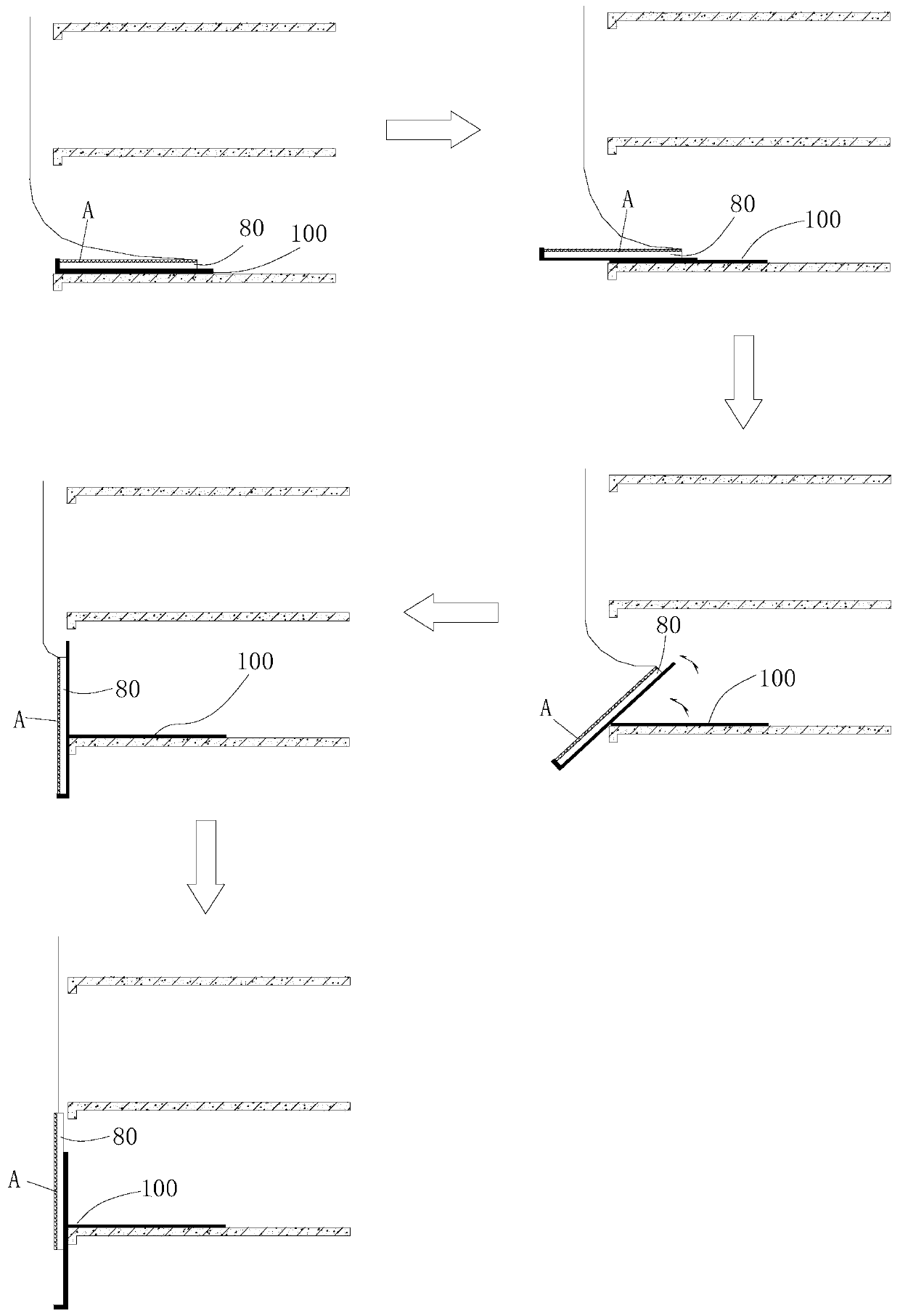

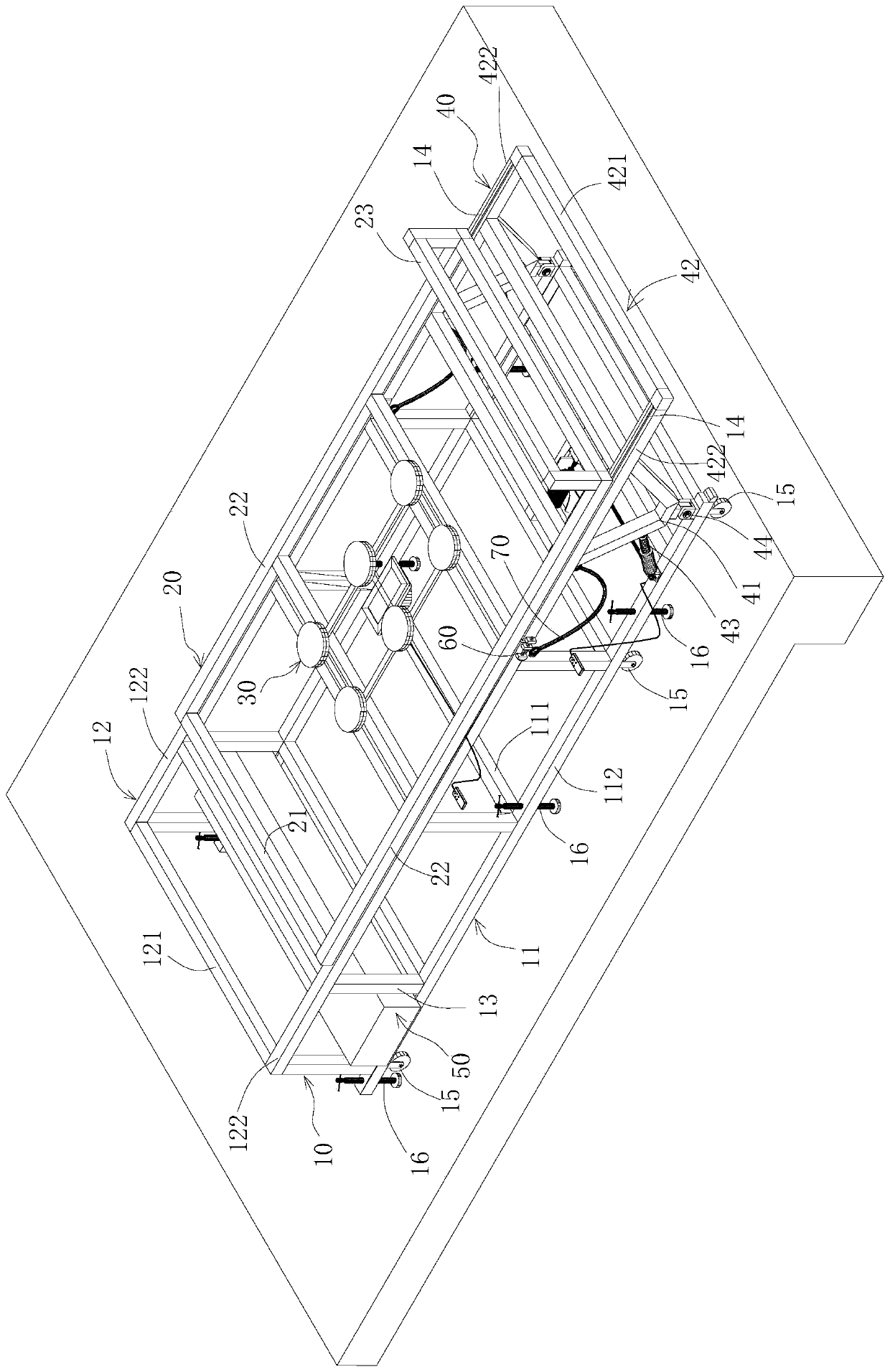

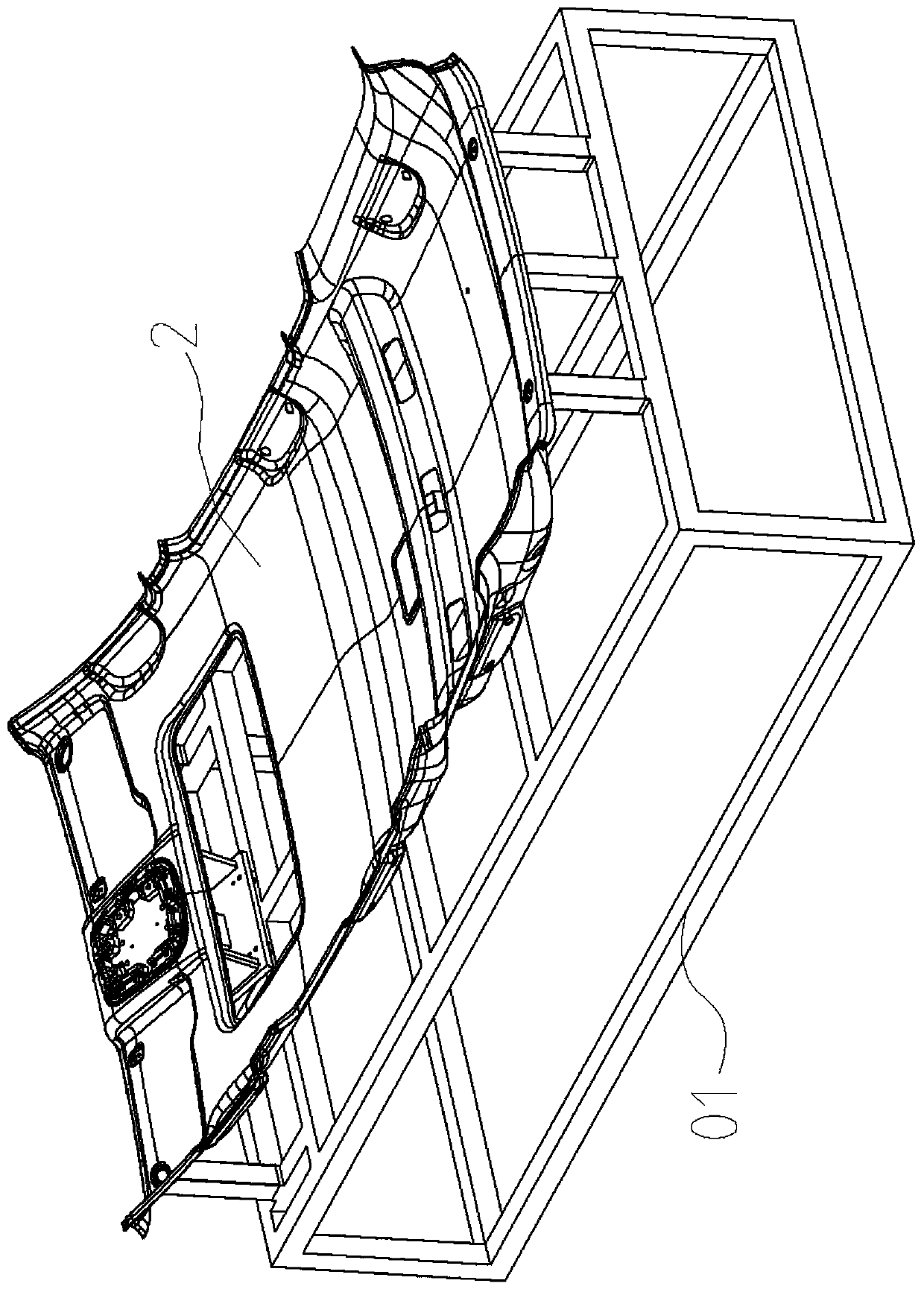

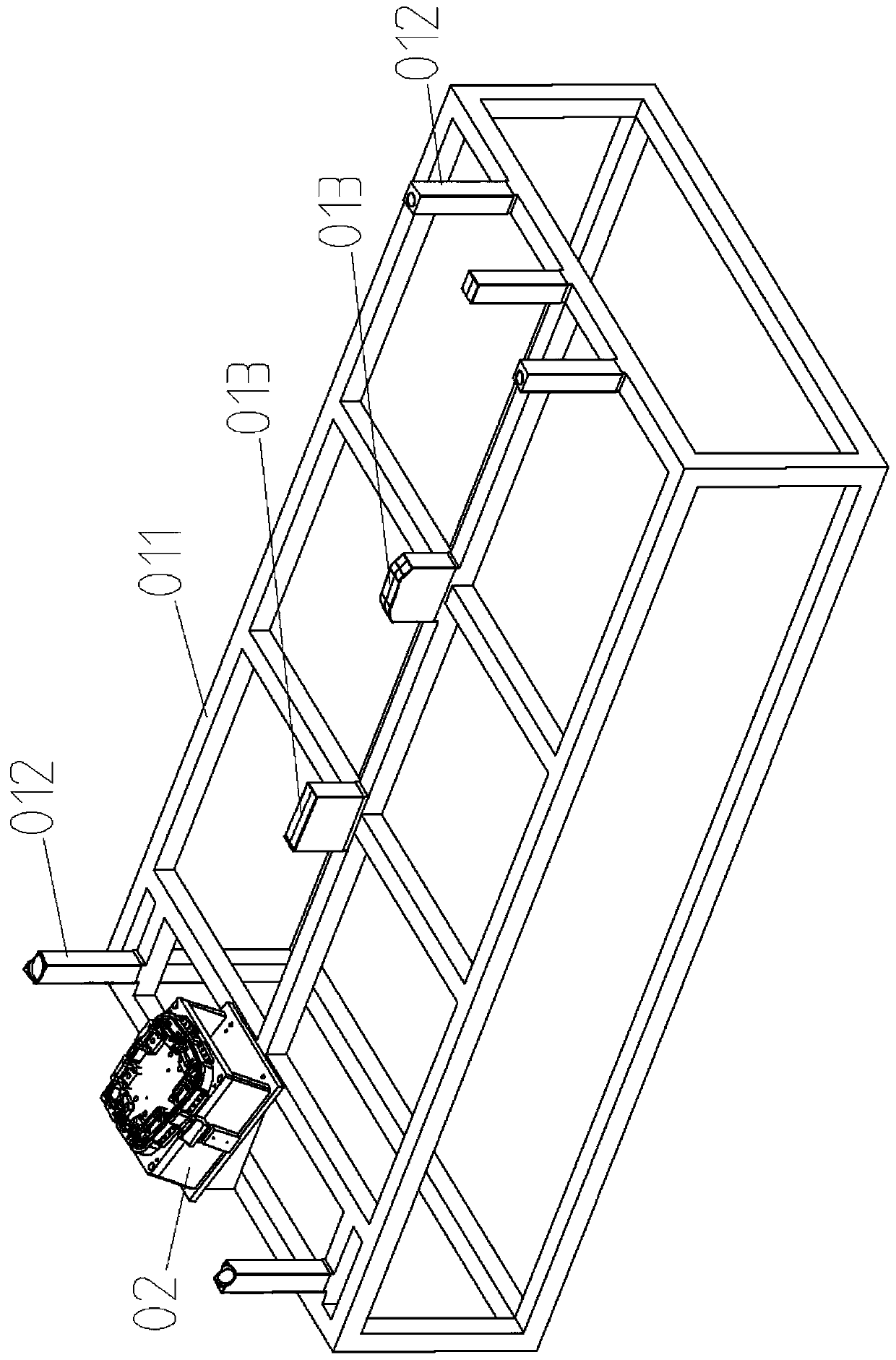

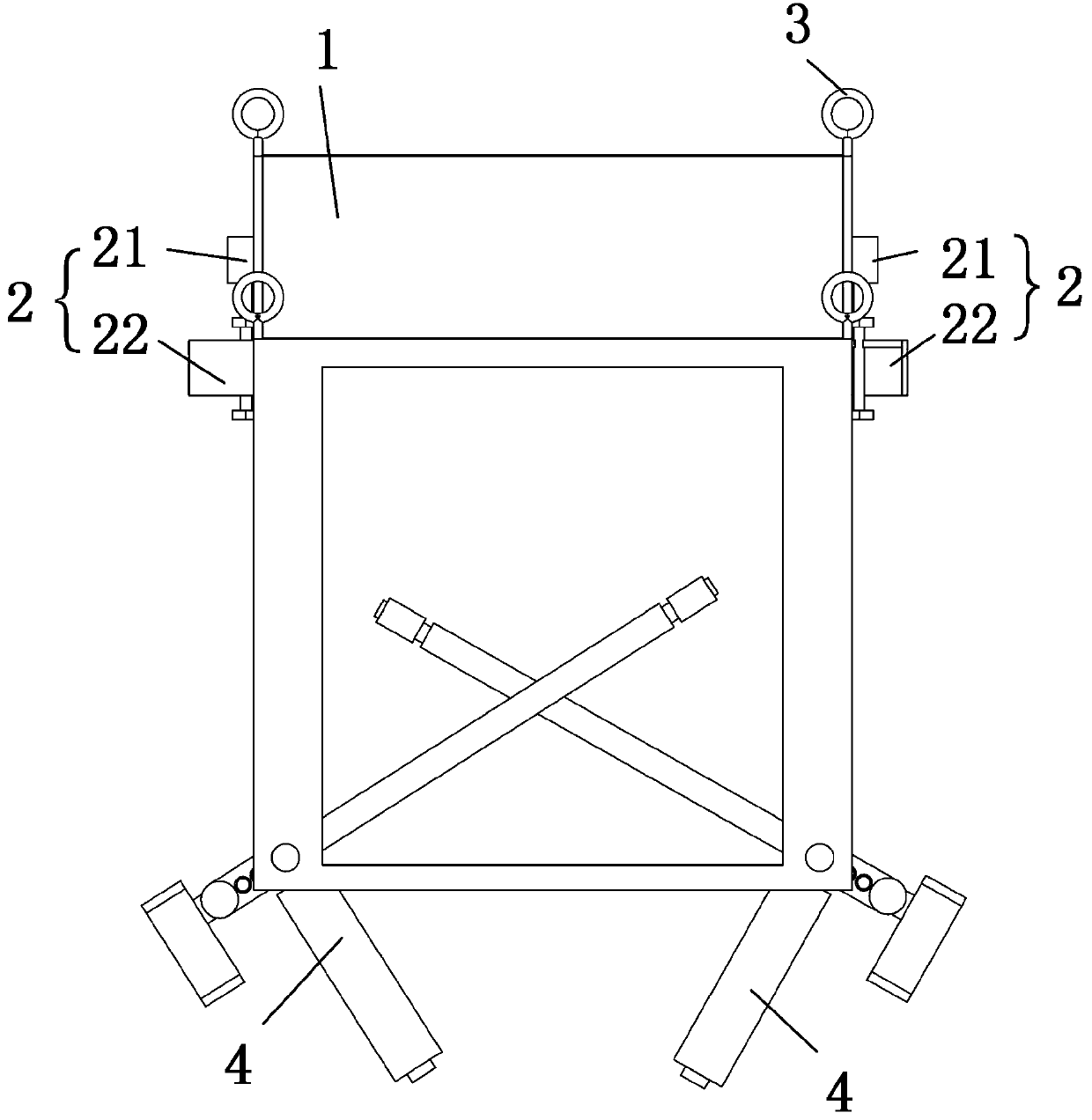

Large curtain wall large panel material and unit plate overturning device

PendingCN110593580AShorten hang timeAvoid bumps and scratchesWallsBuilding material handlingButt jointHorizontal axis

According to the adopted technical scheme, the invention provides a large curtain wall large panel material and unit plate overturning device. The device comprises a lower fixed steel frame, an uppersliding steel frame, an electric sucker mechanism and an overturning mechanism. The electric sucker mechanism is installed on the top face of the upper sliding steel frame. The upper sliding steel frame can be arranged on the top face of the lower fixed steel frame in a sliding and disengaging manner. The overturning mechanism is hinged to the front end of the bottom of the lower fixed steel framealong the horizontal axis, and in the non-overturning state, the rear end of the top of the overturning mechanism is in butt joint with the front end of the top of the lower fixed steel frame. The upper sliding steel frame can slide front and back on the top faces of the lower fixed steel frame and the overturning mechanism and overturns back and forth between a horizontal position and a verticalposition at the front end of the fixed steel frame under the drive of the overturning mechanism. By means of the large curtain wall large panel material and unit plate overturning device, fast overturning of unit plates is achieved, safety and reliability are achieved, the unit plates do not need to be horizontally rotated and overturned in outdoor air, finished product protection is facilitated,the unit plates are not likely to be collided by one another, and safety of personnel is ensured.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Telescopic arm

InactiveCN103511415AImprove the lack of adjustment difficultiesImprove precision controlRod connectionsEngineeringManipulator

The invention relates to a main structure part on a manipulator. The telescopic arm comprises an outer arm and an inner arm, wherein an upper sliding block and a lower sliding block are arranged between the outer arm and the inner arm; the upper sliding block comprises an mounting seat, a columnar sliding block, a screw and a locknut; the bottom of the mounting seat is arranged on the outer surface of the inner arm; the columnar sliding block is sleeved with the mounting seat; the mounting seat is further fixed onto the inner surface of the outer arm through the screw. By virtue of the improvement on the design of the sliding blocks, the telescopic arm conquers inconvenience in operation of the original structure when being added with an adjustable pad, improves defect of difficulty in adjusting clearance, simplifies the clearance adjusting procedure, easily controls the clearance fit precision, saves assembly time, and improves the fixture efficiency.

Owner:SHAANXI SHENGMAI PETROLEUM

Double handle shovel

A double handle shovel that increases the efficiency of the tool in a manner that reduces the risk of injury to the user and increases the ease of use. The first handle is strait and the second handle is turned so that the user's body avoids unnecessary torque. The second handle is perpendicular to the head to allow for more leverage and better side to side manipulation. And the head is offset 40 degrees form the first handle to help maintain proper body alignment.

Owner:WENSMAN ALAN

Positioning mechanism of air sensor press-fitting equipment

PendingCN113547491AEasy to moveMeet the needs of useWork holdersWork benchesControl engineeringControl theory

The invention belongs to the technical field of workpiece positioning, particularly relates to a positioning mechanism of air sensor press-fitting equipment, and provides the following scheme to solve the problems that existing positioning mechanisms mostly perform positioning and clamping manually, the tool efficiency is low, the application range of the positioning mechanisms is small, adjustment is inconvenient, and the positioning mechanisms cannot be conveniently used for different crowds. The positioning mechanism comprises a working plate, four supporting legs are fixedly installed at the bottom of the working plate, sliding blocks are installed on the four supporting legs in a sliding mode, universal wheels are fixedly connected to the sides of the four sliding blocks, two lifting plates are vertically installed at the top of the working plate in a sliding mode, the two lifting plates and the tops of the two corresponding sliding blocks are fixedly installed, and a lifting driving mechanism is arranged at the bottom of the working plate. The positioning mechanism is simple in structure and convenient to operate, workpieces can be automatically clamped and positioned, the tool efficiency is improved, the position of the positioning mechanism can be adjusted, the positioning device can be used for different crowds, and the application range is widened.

Owner:广东顺德正综科技服务有限公司

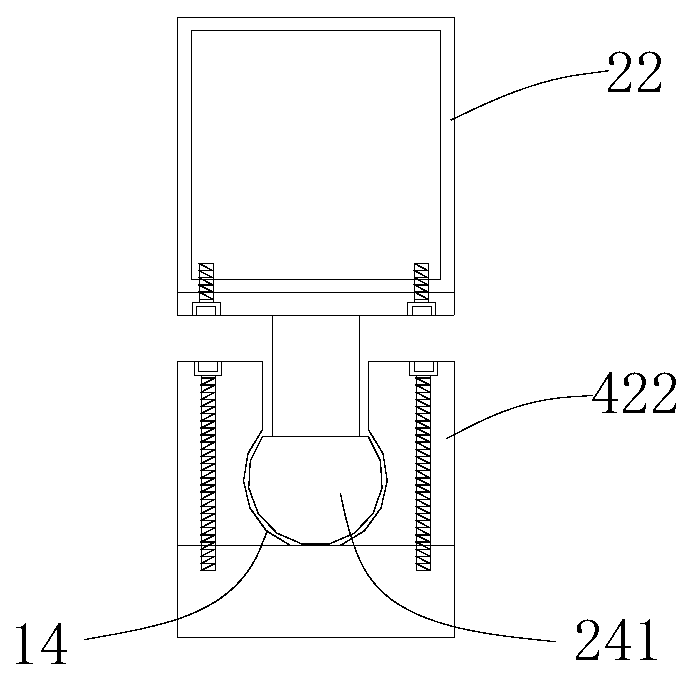

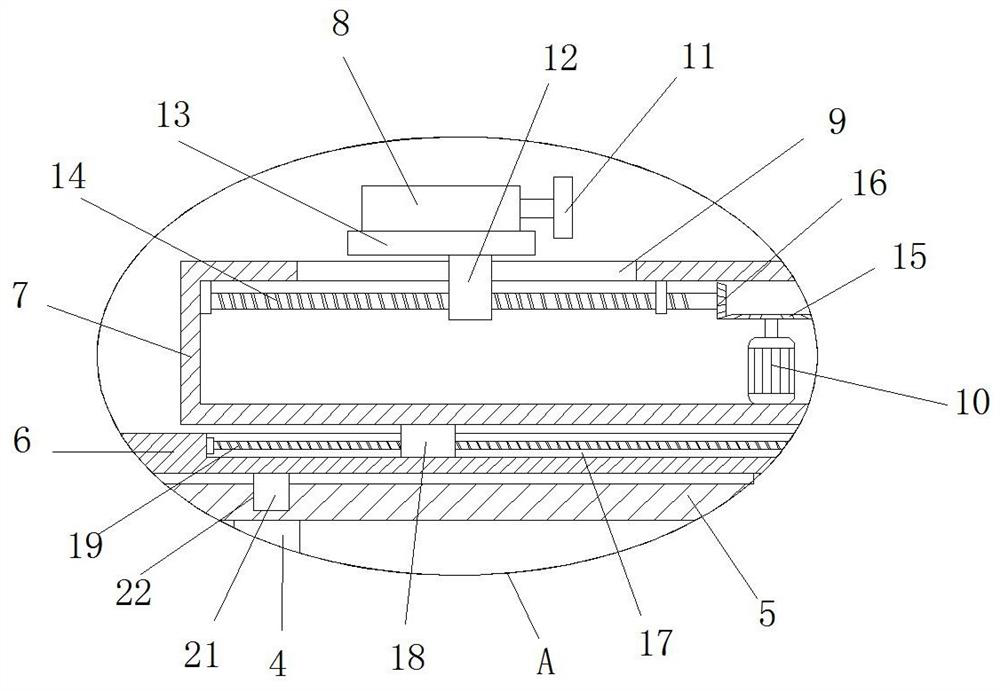

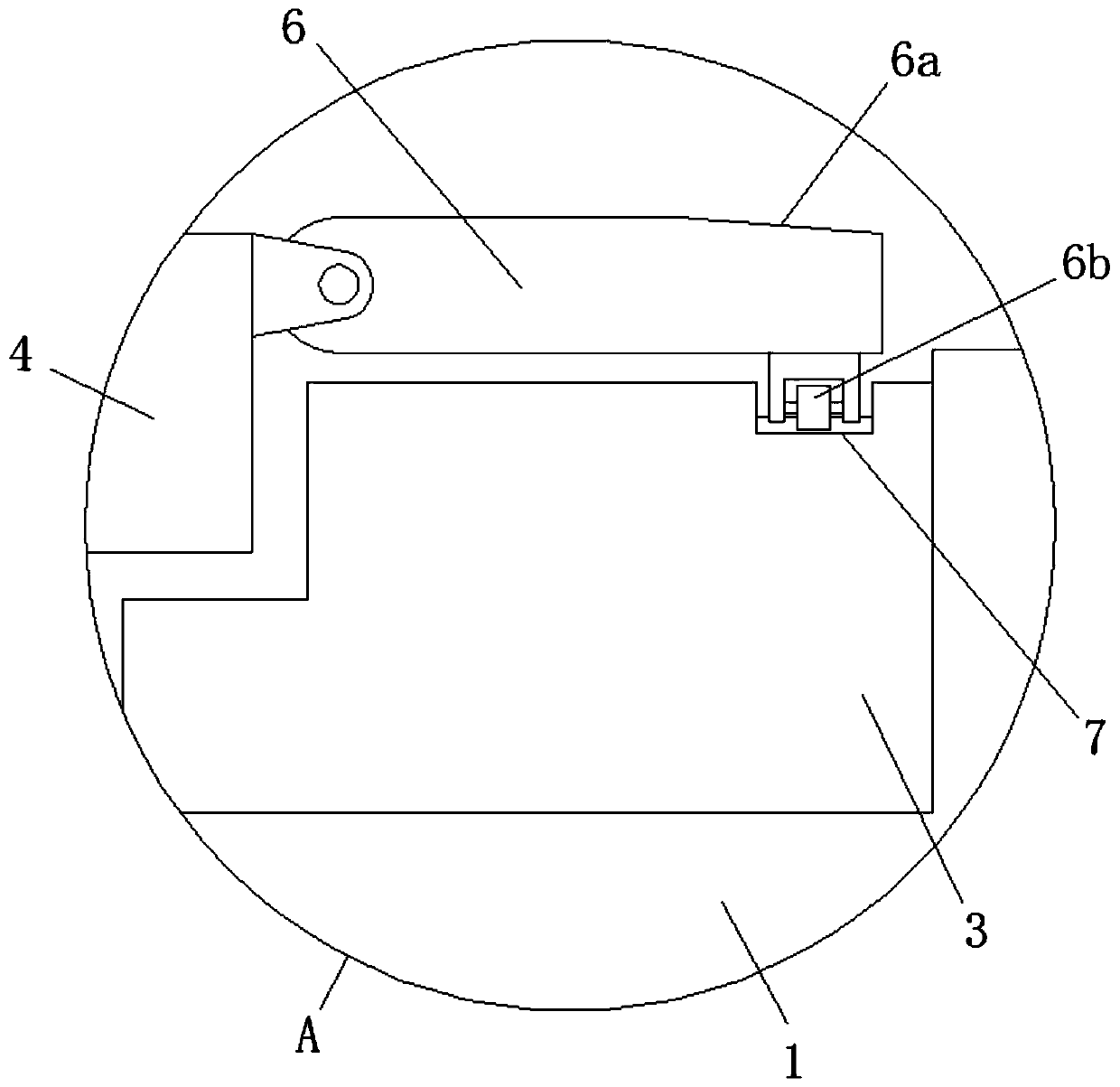

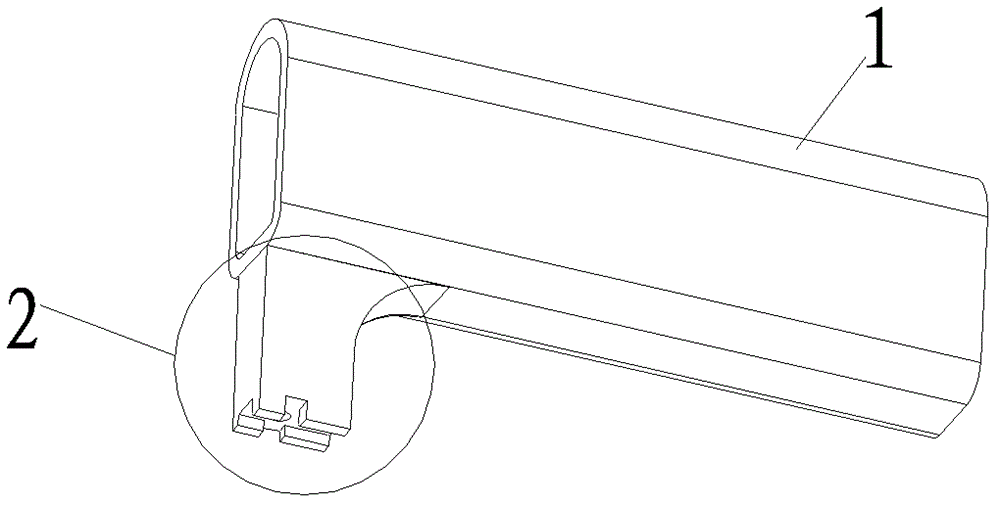

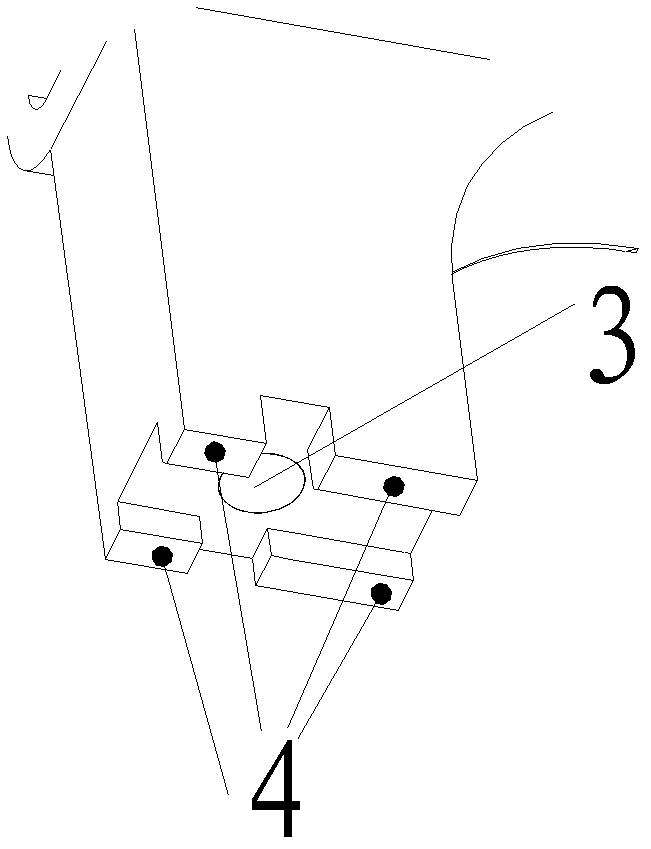

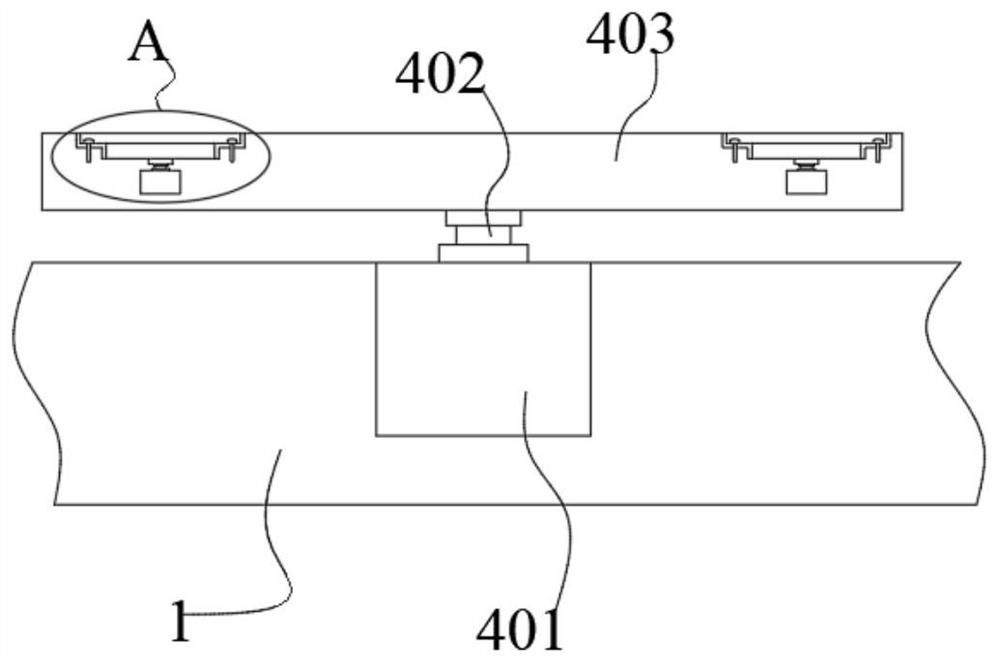

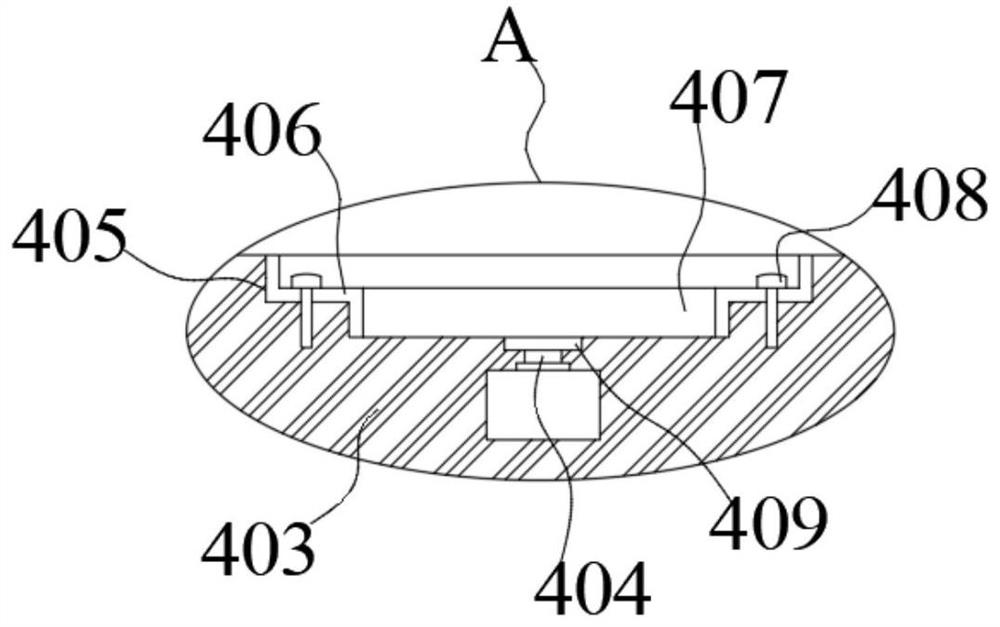

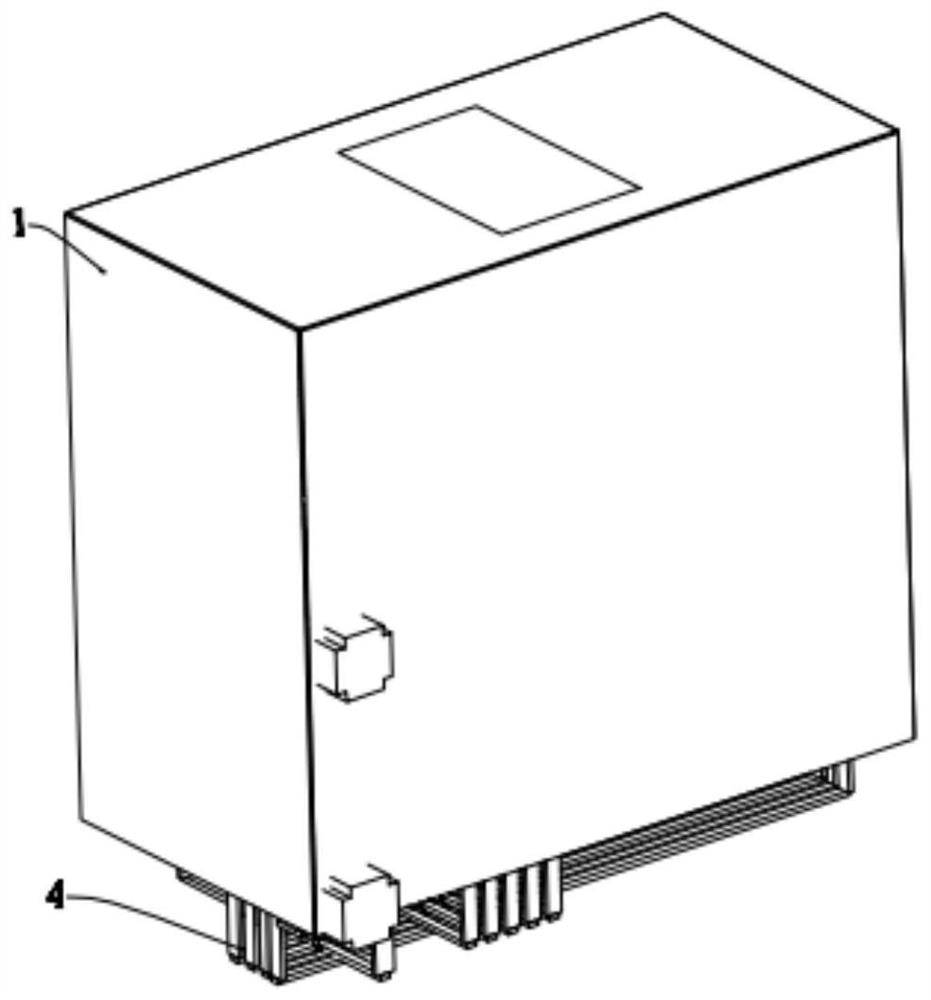

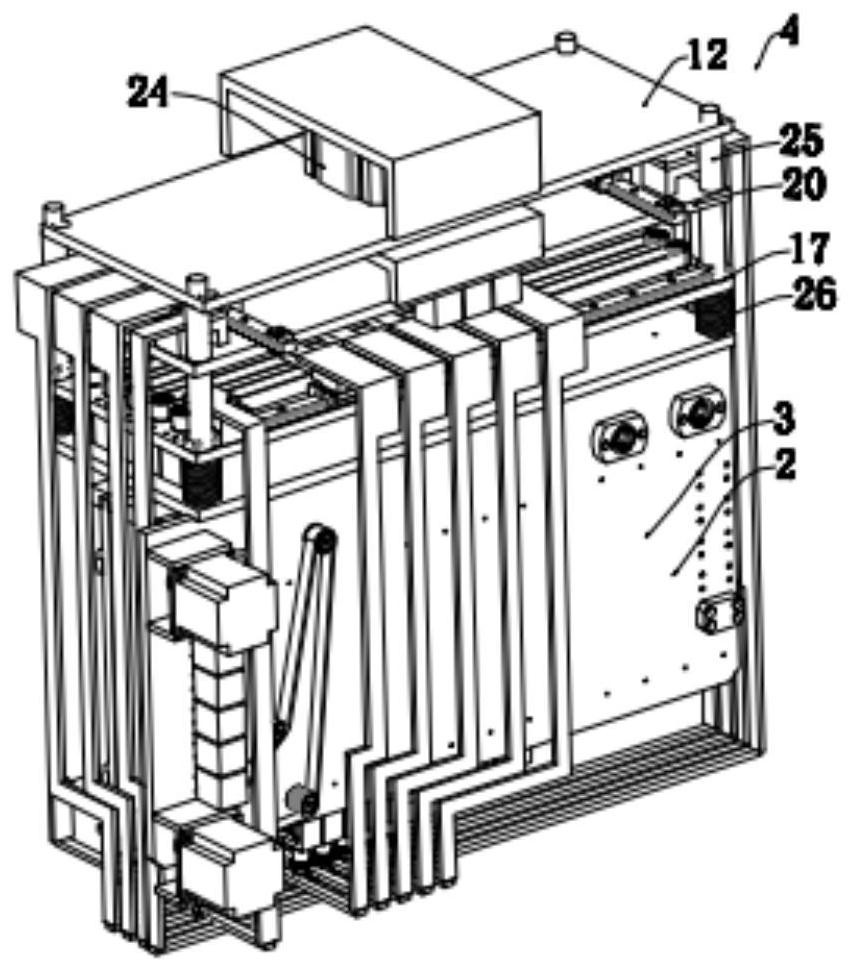

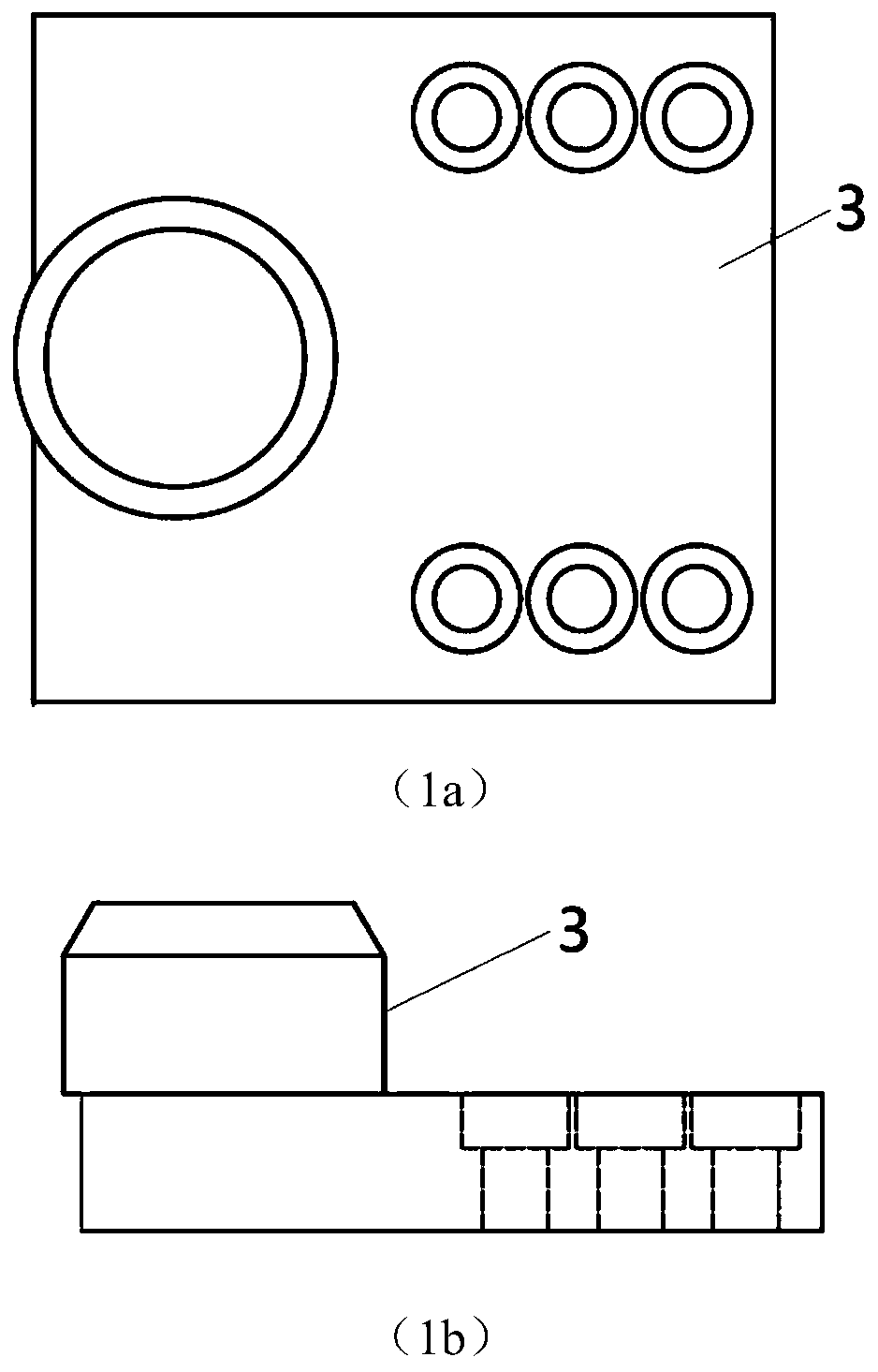

Implant fixing seate in sand blasting station

PendingCN107116484AImprove tooling efficiencyCompact structureAbrasive machine appurtenancesSand blastingStructural engineering

The invention discloses an implant fixing seat in a sand blasting station. The seat comprises a bearing table (1), a base (2) and an air compressor (3); an air flow channel B (6) is formed in the bearing table (1), one end of an air flow channel A (5) is connected with the air flow channel B (6), the other end of the air flow channel A (5) is communicated with the bottom of a groove (4), the other end of the air flow channel B (6) is connected with an air outlet of the air compressor (3), clamping mechanisms (8) are arranged on the left side wall and the right side wall of the base (2), one end of a sleeve (12) is fixedly arranged on the side wall of the base (2), a compression spring (9) is connected with the position, between a piston (11) and the base (2), in the sleeve (12), and a pressing rod (10) sequentially penetrating the compression spring (9) and a guide hole (7) is fixedly arranged on the piston (11). The implant fixing base has the beneficial effects of being compact in structure, improving the implant tool efficiency, reducing labor intensity and being easy to operate.

Owner:CHENGDU BESMILE BIOTECH

Overturning method of large face plate material and large unit plate of large-sized curtain

InactiveCN110616900AShorten the timeAvoid bumps and scratchesWallsBuilding material handlingFloor slabDevices fixation

The invention provides an overturning method of a large face plate material and a large unit plate of a large-sized curtain. The overturning method comprises the following steps that firstly, an overturning device is fixed to the edge of a floor slab, and a rope is tied to a detachable carrying pole at the back end of the unit plate; secondly, the unit plate is placed on an upper sliding steel frame on the upper part of the overturning device with the facade face being upward and fixed; thirdly, the upper sliding steel frame is pushed to slide frontwards until the upper sliding steel frame andthe front part of the unit plate slide out of the edge of the floor; fourthly, the overturning mechanism drives the upper sliding steel frame and the front end of the unit plate to be inclined downwards and conduct vertical rotation until the upper sliding steel frame and the unit plate are located outside the floor and are perpendicular to the horizontal plane and the facade face of the unit plate is outward; fifthly, a pulling rope is lifted, the unit plate is hoisted, and then the overturning process is completed. The large-sized curtain unit plate is rapidly and safely overturned by meansof the overturning device, the unit plate does not need to be overturned outdoors in the air, finished-product protection is facilitated, the unit plate is not prone to collision, and personal safetyis facilitated.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

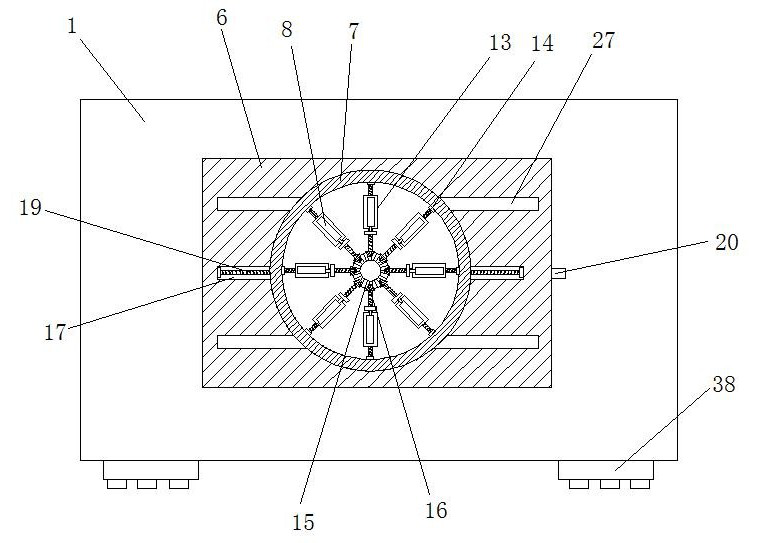

Full-automatic carton packaging sealing device

InactiveCN110921000ARealize automatic sealingImprove tooling efficiencyWrapper twisting/gatheringAdhesive beltCarton

The invention relates to the technical field of carton packaging, and discloses a full-automatic carton packaging sealing device. The device comprises a machine frame and work frames fixedly installedat the two sides of the machine frame. A rotating bearing platform is embedded in the middle of the machine frame; the center of the rotating bearing platform is movably sleeved with a rotating disc;four towing rods are annularly arrayed on the peripheral side of the rotating disc; one end of the each towing rod is hinged to the peripheral side of the rotating disc in an up-down rotating mode; an annular sliding rail is arranged at the top end of the rotating bearing platform, and the annular sliding rail is a rotating rail at the other end of the towing rod; a horizontal air cylinder is fixedly installed on the inner side of a vertical rod of each work frame; and the horizontal air cylinders are used for horizontal line centering and positioning. The rotating disc is arranged in the center of the work frame, and the rotating disc drives the towing rods to rotate, so that rotation of a carton can be achieved; and a linear adhesive tape sealing mechanism at the work frame completes cross-shaped sealing operation under the single-machine working condition, and automatic sealing is achieved, so that the work efficiency is improved, and the equipment procurement cost is reduced.

Owner:桐乡市崇福鑫伟纸箱厂

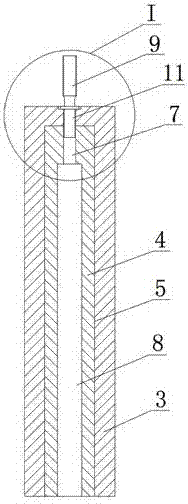

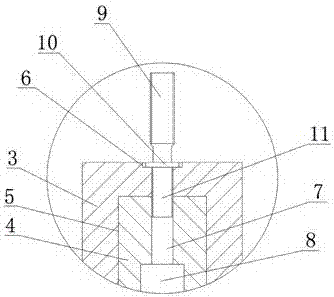

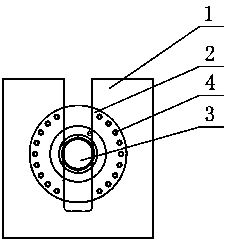

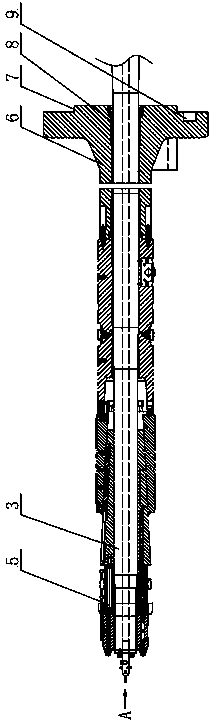

Implant acid etching fixture device

The invention discloses an implant acid etching fixture device which comprises a ceramic outer cylinder (3), an inner cylinder (4) and a cross-shaped threaded rod, wherein a step hole (5) is formed in the bottom of the ceramic outer cylinder (3); an annular groove (6) communicating with the step hole (5) is formed in the top of the ceramic outer cylinder (3); the inner cylinder (4) is inserted in a big hole of the step hole (5); a threaded hole A (7) is formed in the top of the inner cylinder (4); a threaded holes B (8) is formed in the bottom of the inner cylinder (4); the cross-shaped threaded rod is composed of an upper thread head, a ring-shaped part (10) and a lower thread head (11) which are connected in sequence; the lower thread head (11) penetrates through the annular groove (6) and a small hole of the step hole (5) in sequence and is in threaded connection with the threaded hole A (7); and the ring-shaped part (10) is arranged in the annular groove (6) and is pressed at the bottom of the annular groove (6). The implant acid etching fixture device disclosed by the invention has the beneficial effects of being compact in structure, effectively protecting an annular plain face, rapidly clamping an implant, and being simple to operate.

Owner:CHENGDU BESMILE BIOTECH

Automobile glass tool for mounting metal clip

The invention relates to an automobile glass tool for a mounting metal clip. The tool consists of a handle and a mounting head which is arranged at the front end of the handle, wherein the mounting head consists of a central cylindrical magnet and peripheral notch-shaped chucks; the metal clip is directly attracted to the mounting head by the cylindrical magnet; and the metal clip is positioned by the peripheral notch-shaped chucks. Compared with the prior art, the automobile glass tool has the advantages of high efficiency and convenience in use, and the labor intensity of workers is reduced.

Owner:SHANGHAI FUYAO BUS GLASS

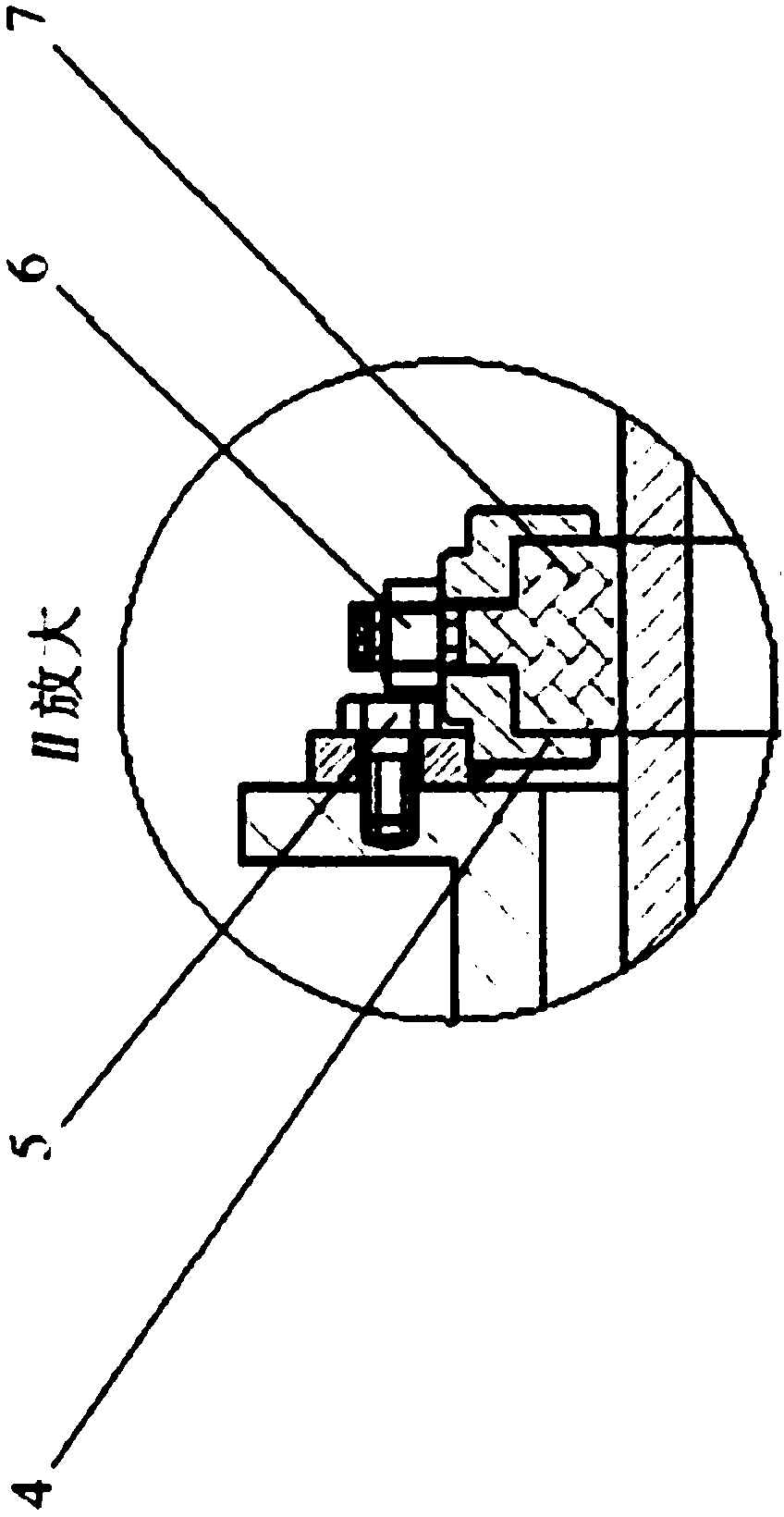

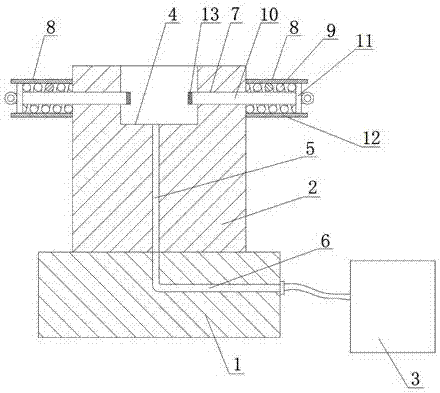

Processing device

InactiveCN104416209AReduce adverse effectsImprove tooling efficiencyMilling cuttersPositioning apparatusSteel ballScrew thread

The invention relates to a processing device. The processing device comprises a main shaft locating device, wherein the main shaft locating device is connected with an outer support body which is connected with a power transmission device, the power transmission device is connected with a cutter clamping device which is connected with a cuter, the cutter clamping device comprises a cutter mounting base, an outer sleeve and a locking screw, a radial hole and an axial cutter mounting hole are formed in the cutter mounting base, the radial hole of the cutter mounting base is formed by a straight hole section and a spherical hole section, the spherical hole section is directly communicated with the cutter mounting hole, a steel ball is arranged in the spherical hole section, the outer sleeve sleeves the cutter mounting base, a radial through hole is formed in the outer sleeve, the locking screw stretches into the radial hole of the cutter mounting base to be in threaded connection with the straight hole section of the radial hole after penetrating through the radial through hole of the outer sleeve, and the steel ball can be pressed in the spherical hole. According to the processing device, the assembling precision of the cutter can be improved, and the adverse effect on the cutter during processing can be reduced.

Owner:CHANGZHOU XILI ALLOY TOOLS

Edge folding tool for front top light support of automotive trim ceiling

PendingCN111375675ADimension accuracy requirements are lowReduced dimensional accuracy requirementsMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention particularly relates to an edge folding tool for a front top light support of an automotive trim ceiling. The edge folding device comprises a ceiling support, a base and a push plate, wherein the upper part of the base is provided with a shaping module and an edge folding module, and the two sides of the base are provided with ejection modules; the push plate can penetrate through the base and reciprocate vertically; the shaping module is arranged in a ring-shaped mode; the number of the edge folding modules is the same as that of folded edges of the support, and each edge folding module comprises a connecting block, connecting rods and a pressing block which are sequentially hinged; and each pressing block is arranged in a V shape, the bending parts of the pressing blocks are hinged to the shaping module, one side of the bending part of each pressing block serves as a connecting part, the other side of each pressing block serves as a turning folding part, and each turning folding part is hinged to the connecting rods; the connecting blocks are fixedly connected with the push plate; and each ejection module is provided with a second clamping groove, and the ejection modules can reciprocate in the vertical direction. The edge folding tool for the front top light support of the automotive trim ceiling has the advantages that the assembly success rate is high, and the requirement for precision of a metal support is not high.

Owner:重庆市久满汽车内饰件有限公司

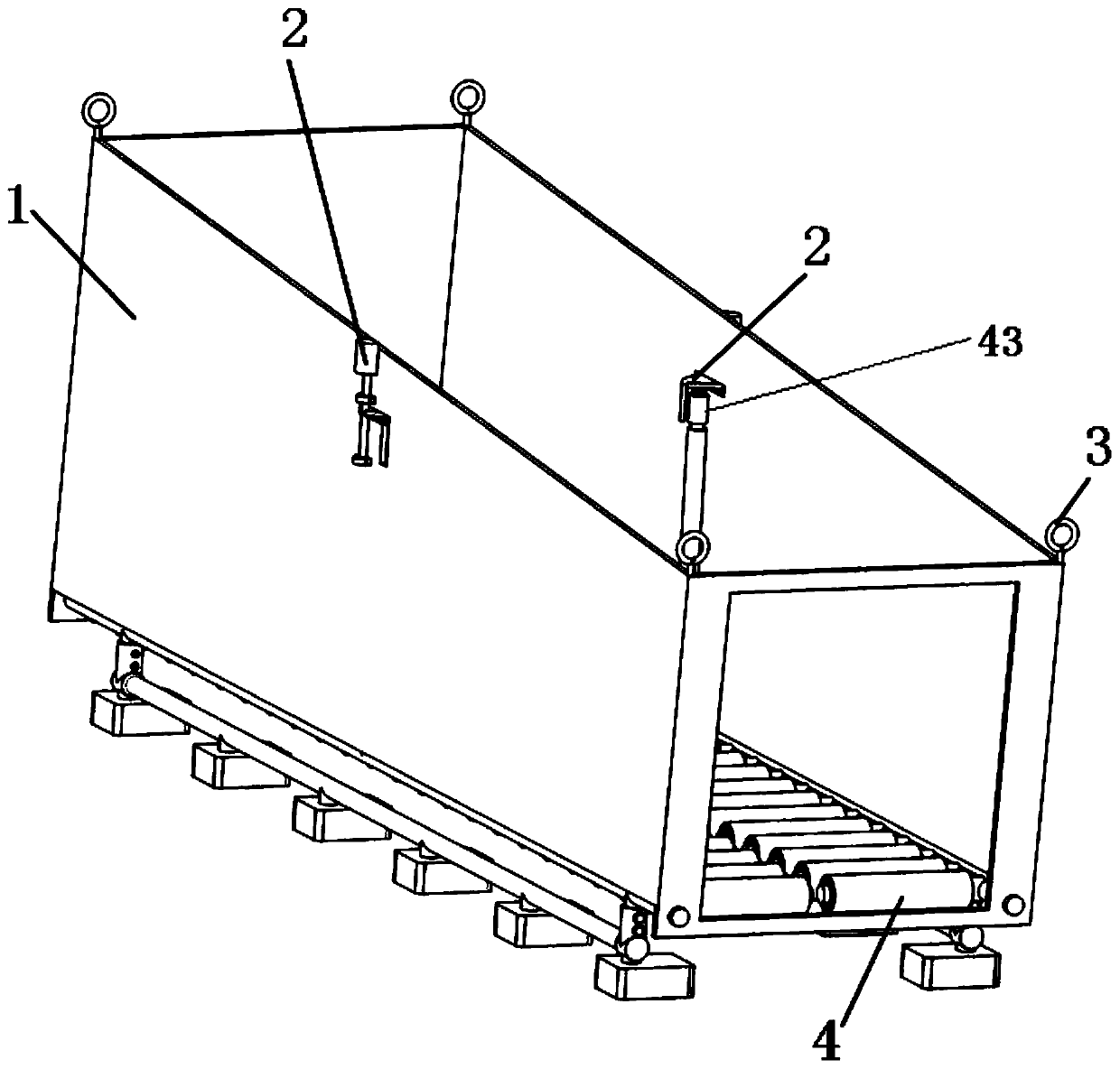

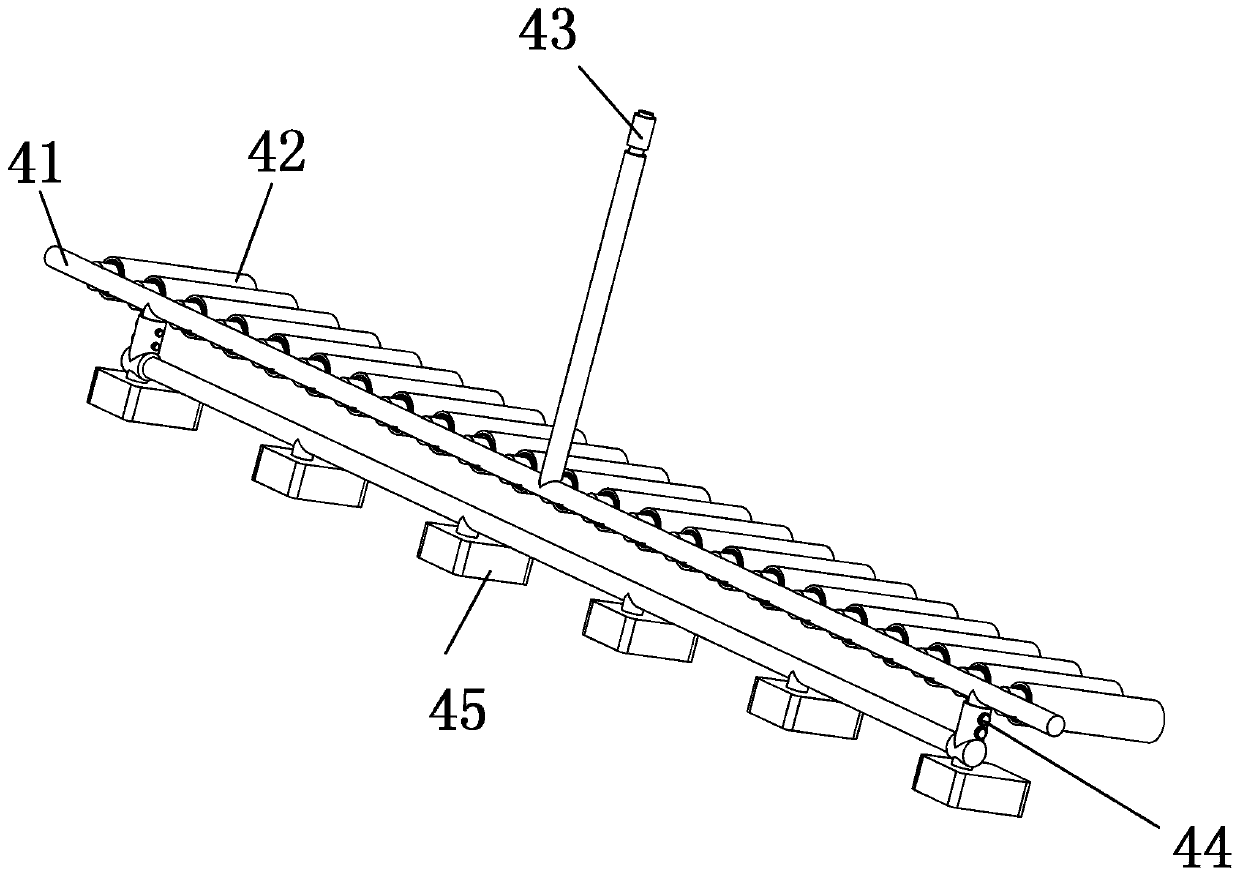

Counterweight type roller transfer device capable of being opened and closed

ActiveCN109733753AAchieve teleportationRealize functionLarge containersEngineeringMechanical engineering

The invention provides a counterweight type roller transfer device capable of being opened and closed. The counterweight type roller transfer device capable of being opened and closed comprises a toolhopper and a counterweight roller conveyor belt unit, wherein a rotary locking device is separately arranged on the two side parts opposite to the tool hopper; the counterweight roller conveyor beltunit comprises two counterweight roller conveyor belts which are symmetrically arranged; each counterweight roller conveyor belt comprises a rotary shaft, a conveying roller, a rolling sleeve, a pin and a counterweight block, wherein the counterweight block is connected with the rotary shaft through the pin, the conveying roller is arranged on the rotary shaft, the rolling sleeve is vertically arranged on the rotary shaft; and each rotary locking device is in contact with the counterweight roller conveyor belt unit by being indirectly in contact with the corresponding rolling sleeve. Accordingto the counterweight type roller transfer device disclosed by the invention, goods can enter the tool hopper without drive, automatically glide and are automatically stacked in the tool hopper; and moreover, multiple goods can be placed once, so that tool efficiency is greatly improved. The counterweight type roller transfer device has the characteristics of being simple in structure, relativelylow in cost, wide in scope of application, simple in operation, convenient in use, and the like.

Owner:YANSHAN UNIV

Pipeline expansion pull rod sleeve fixing device for steel pipe

The invention relates to a pipeline expansion pull rod sleeve fixing device for a steel pipe. The pipeline expansion pull rod sleeve fixing device comprises a pull rod, wherein an expanding head is arranged on the pull rod, a flange sleeve is sleeved on one end of the pull rod, and a lug boss is arranged on the outer side of the flange sleeve; the pipeline expansion pull rod sleeve fixing device also comprises a wall body, wherein a groove cooperatively connected with the lug boss is arranged on one side of the wall body, the top and the bottom of the flange sleeve which is connected with the wall body are respectively provided with a connecting plate, and the connecting plates are fixed through set screws. The pipeline expansion pull rod sleeve fixing device is reasonable in structure and convenient to assemble and disassemble; the efficiency of a tool between the flange sleeve of the pull rod and the wall body is greatly improved, and the time of a track change procedure of an expanded product is shortened.

Owner:SUNYO S&T CO LTD

Efficient full-automatic set top box remote controller tool jig and using method thereof

ActiveCN113182805AEasy to disassembleEasy to installMetal working apparatusControl engineeringElectric machinery

The invention discloses an efficient full-automatic set top box remote controller tool jig and a using method thereof. The efficient full-automatic set top box remote controller tool jig comprises a base, a material conveying mechanism, a tool mechanism and a monitoring mechanism; a groove with a rightward opening end is formed in the outer wall of the right side of the base, a controller is arranged on the inner wall of the bottom face of the groove, and the material conveying mechanism is installed at the left side of the controller; the tool mechanism is arranged on the inner wall of the top face of the groove, and the monitoring mechanism is detachably connected to the outer side wall of the base; and the material conveying mechanism comprises a motor, a rotating shaft, a supporting plate, a clamping groove, a mold plate, a mold hole, a screw and an ejection plate, and the motor is arranged on the inner wall of the bottom face of the groove. According to the efficient full-automatic set top box remote controller tool jig, a finished set top box remote controller can be automatically taken out through the material conveying mechanism, the taking-out process is rapid and convenient, the set top box remote controller can be automatically assembled through the tool mechanism, and the function of monitoring before and after product assembling is achieved through the monitoring mechanism.

Owner:JIANGSU ASTARTE ELECTRONICS

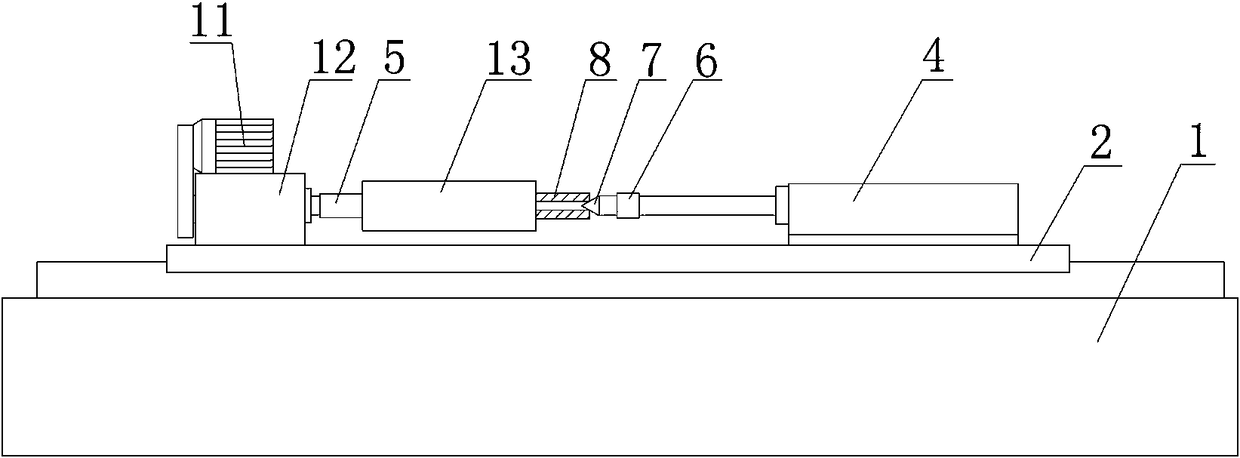

Motorcycle throttle body inclined hole machining device

PendingCN110142630AGuaranteed stabilityImprove machining accuracyWork clamping meansPositioning apparatusBiomedical engineeringThrottle

The invention discloses a motorcycle throttle body inclined hole machining device. The motorcycle throttle body inclined hole machining device comprises a clamp body, a clamp limiting unit, a clamp pressing unit and a limiting block unit, wherein the clamp limiting unit, the clamp pressing unit and the limiting block unit are arranged on the clamp body, through the clamp limiting unit, the positioning face of the part is tightly attached to the positioning face of the clamp limiting unit in a gapless manner, the part is pressed downwards through the clamp pressing unit, and through the limiting block unit, front and back moving of the part is limited. The device has the beneficial effects of being compact in structure, capable of improving the inclined hole drilling precision, improving the product yield and improving the tool efficiency and easy to operate.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

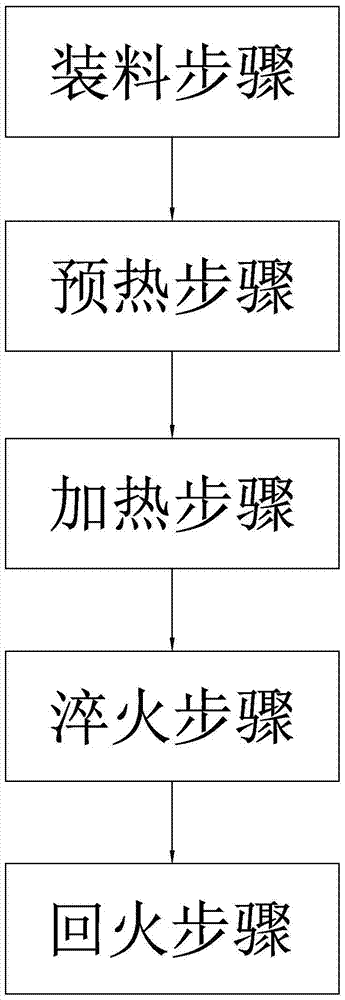

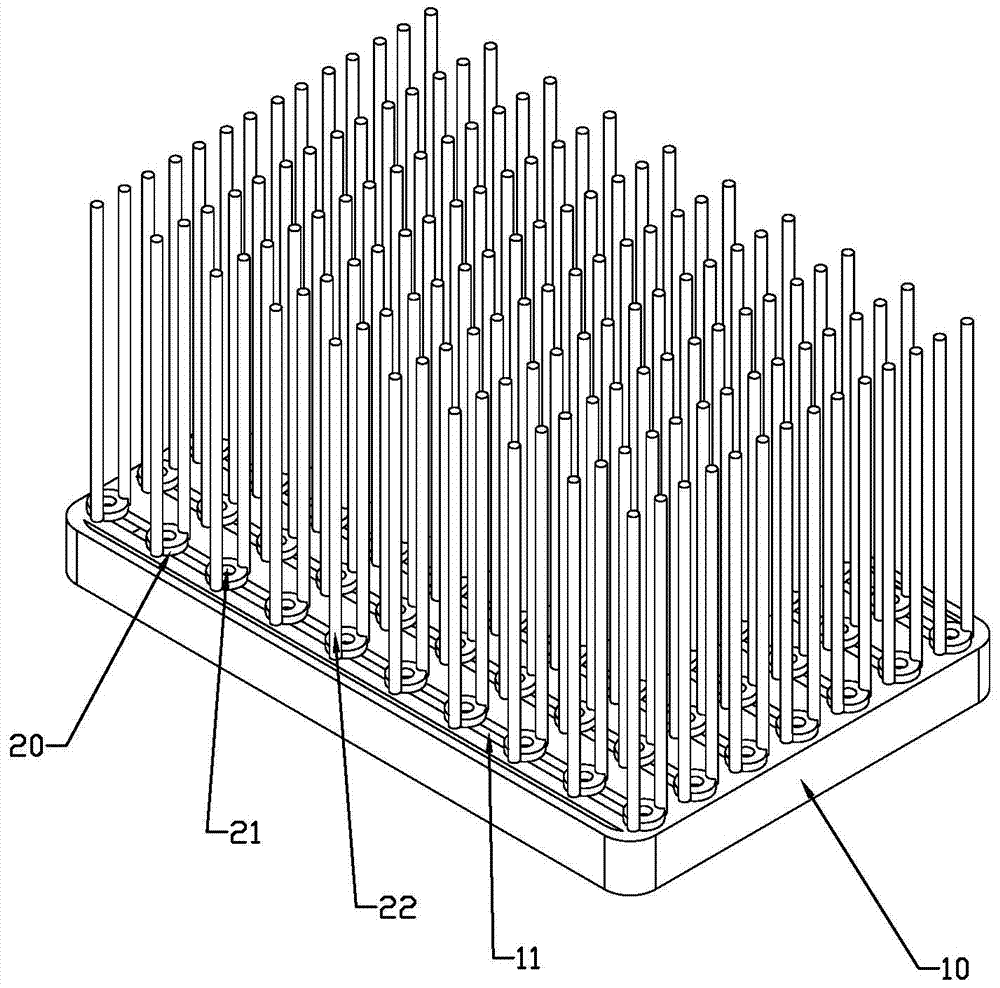

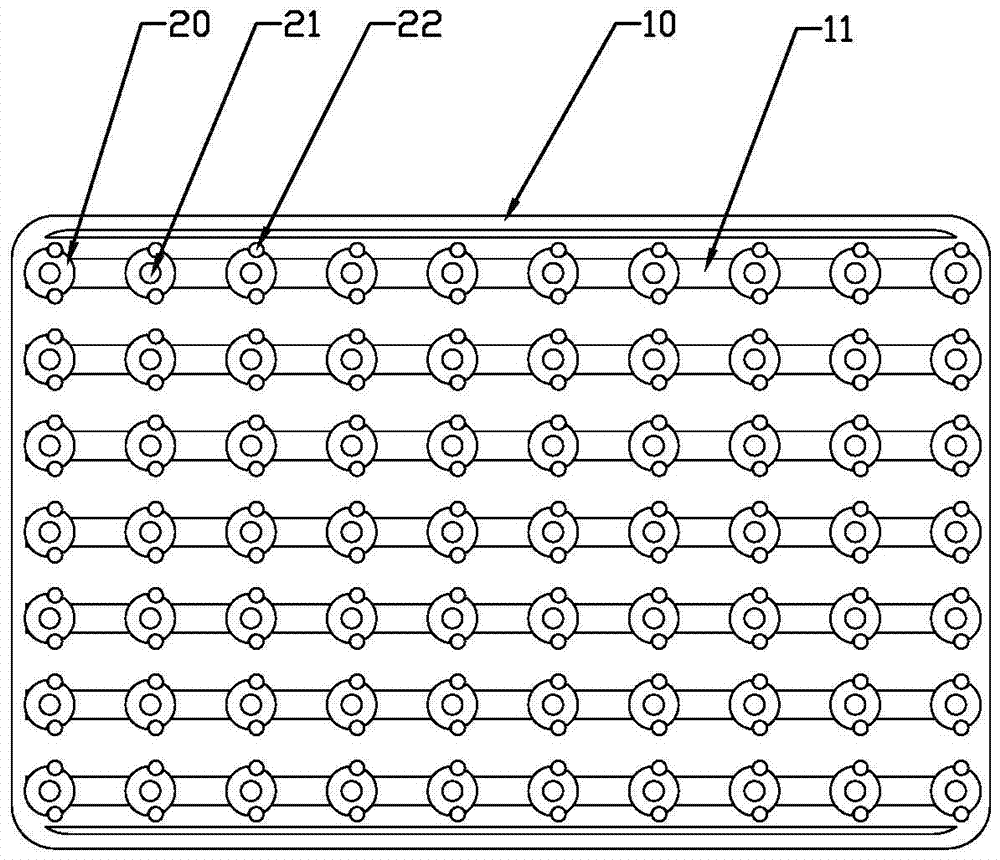

Heat treatment method and special tooling for lawn mower sprocket

ActiveCN104818377BSmall amount of deformationImprove hardenabilityFurnace typesHeat treatment furnacesCascodeHardness

The invention discloses a method for heat treatment of lawnmower sprockets and special tooling, which performs batch heat treatment of sprockets through the special tooling, and the special tooling includes a mounting chassis and a mounting seat arrayed on the mounting chassis, the mounting seat There is a positioning rod on the outer edge, and a flow hole is provided in the middle of the mounting seat. The sprocket is stacked on the mounting seat. The outer tooth groove of the sprocket corresponds to the position of the positioning rod of the mounting seat. The inner hole corresponds to the position of the flow hole of the mounting seat, and the charging step, preheating step, heating step, quenching step, and tempering step are carried out in sequence during the heat treatment process, and each is set according to the charging method of the special tooling. The temperature parameters and time parameters of the steps are used to achieve a better heat treatment effect, which not only improves the production efficiency through batch processing, but also can control the deformation of the heat treatment and improve the hardness accuracy of the sprocket.

Owner:厦门真冈热处理有限公司

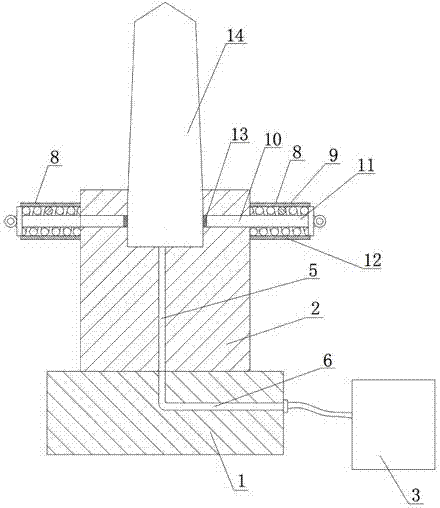

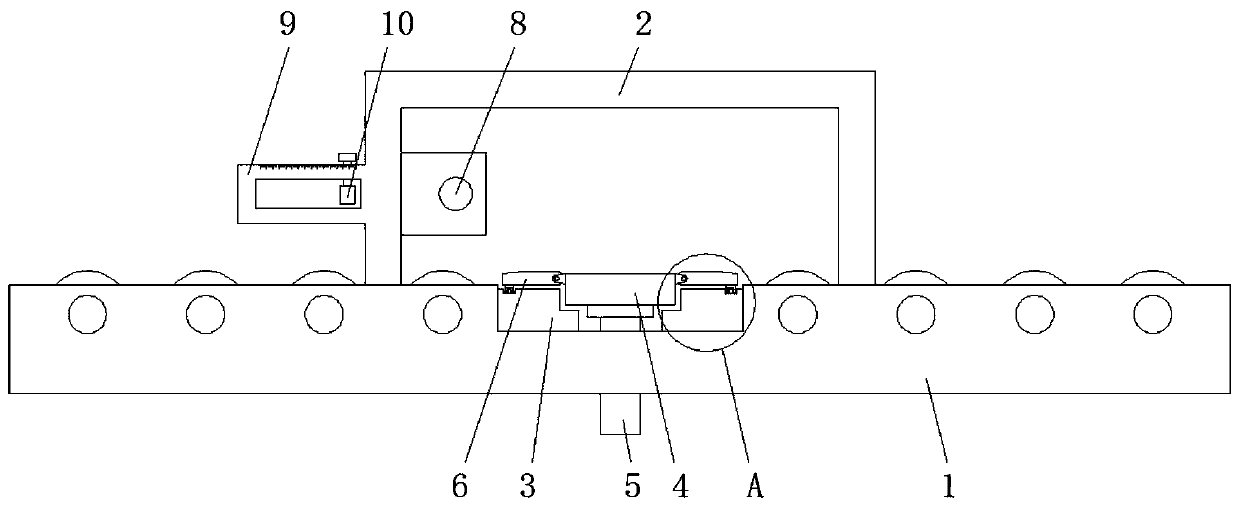

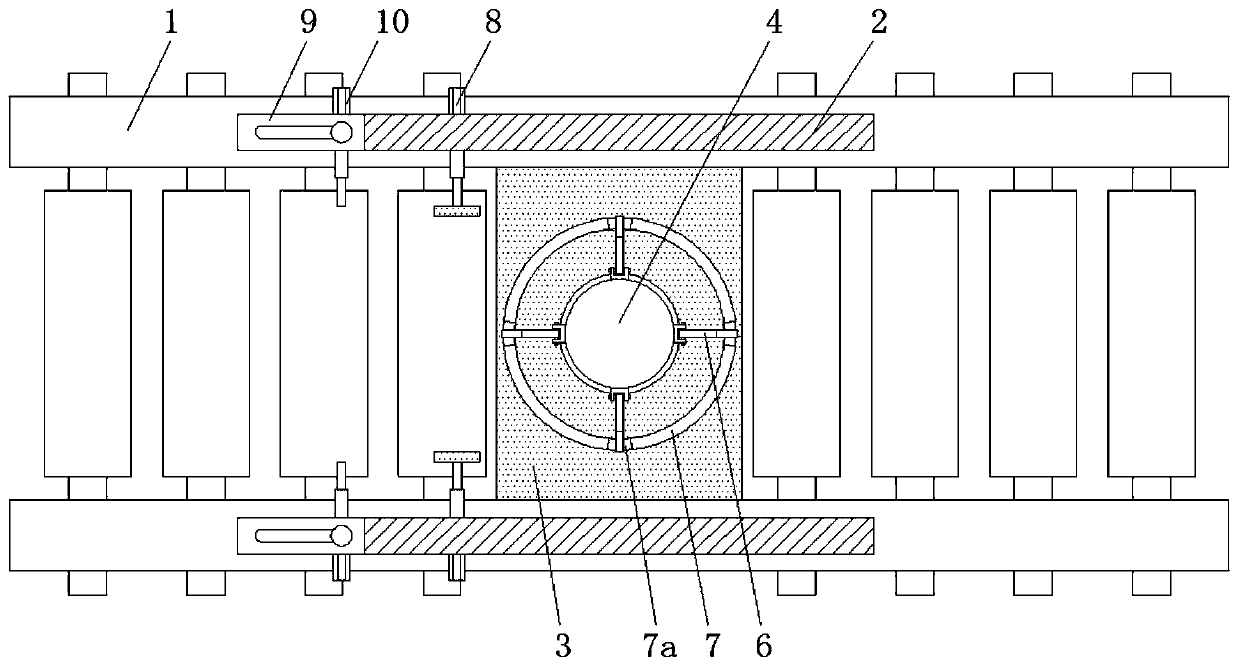

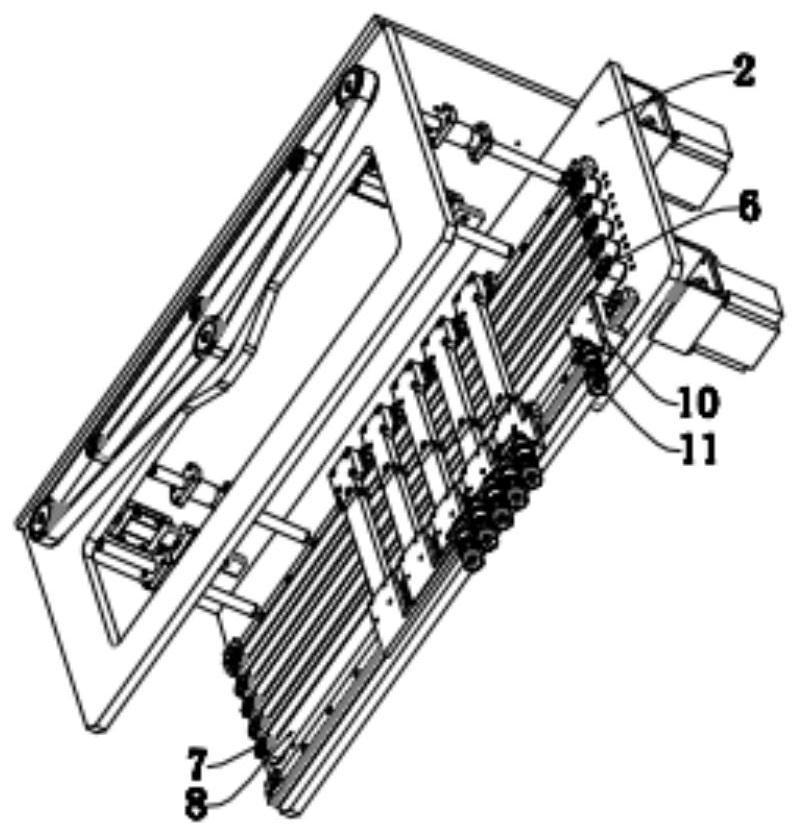

Modular variable-stroke multi-head wafer collecting mechanism

ActiveCN112551154AExcellent control performanceImprove tool efficiencyConveyorsMetal working apparatusElectric machineryManufacturing engineering

The invention discloses a modular variable-stroke multi-head wafer collecting mechanism which comprises a protective shell, a wafer collecting frame, a wafer collecting assembly and a wafer shifting assembly. The protective shell is a hollow cavity with an opening in the lower end; the wafer collecting frame is arranged in the protective shell; the wafer collecting assembly is arranged on the wafer collecting frame; the wafer collecting assembly comprises a wafer collecting motor, a wafer collecting rotating wheel, a wafer collecting synchronous wheel, a wafer collecting synchronous belt, a wafer collecting synchronous rod, a suction cup base and a suction cup; the wafer collecting motor is arranged between the wafer collecting frame and the protective shell; the wafer collecting motor isarranged at one end of the wafer collecting frame; and the wafer collecting rotating wheel is arranged at the output end of the wafer collecting motor. The modular variable-stroke multi-head wafer collecting mechanism provided by the invention belongs to the technical field of polaroid production, and particularly provides the modular variable-stroke multi-head wafer collecting mechanism which canmeet the capacity requirement on a production line and the requirement that the direction consistency of collected polaroids is kept during polaroid storage at the same time, adapts to collection ofpolaroids with different specifications and other similar wafers, and is beneficial to saving a large amount of manpower and time cost.

Owner:广东谨诺科技有限公司

A window glass adjustment device for a frameless door

The invention discloses a window glass adjustment device for a frameless vehicle door, which relates to the field of tooling and comprises a tooling bracket, a vehicle door fixing mechanism and a vehicle window glass fixing mechanism. The door Y-direction limit assembly and the door Z-direction limit assembly, the door X-direction limit assembly is used to stop the left and right sides of the door outer panel, and the door Y-direction limit assembly is used to clamp the inner side and outer side of the door outer panel On the side, the door Z-direction limit assembly is used to stop the upper and lower sides of the door outer panel; the window glass fixing mechanism includes the window glass X-direction limit assembly and the window glass Z-direction limit assembly arranged on the tooling bracket. The window glass X-direction limit assembly is used to stop the right side of the window glass, and the window glass Z-direction limit assembly is used to stop the upper side of the window glass. The device shortens the length of the dimension chain, making the fit between the window glass and the door outer panel more precise.

Owner:欧恩科(北京)自动门科技有限公司

A radiator water chamber water pipe angle positioning riveting tooling

The invention relates to an angle positioning riveting tool for a radiator water chamber water pipe. The angle positioning riveting tool comprises a riveting cushion block set and a riveting pressing block set. The riveting cushion block set comprises a cushion block base and an angle positioning cushion block sleeve. The cushion block base is in a rectangular body shape, and the end, inserted into a water chamber, of the cushion block base is provided with a round through hole with a notch. The angle positioning cushion block sleeve is of an integrated structure and comprises a first cylinder and a second cylinder. The section of the outer contour of the first cylinder is in a circular shape, and the section of the inner contour of the first cylinder is in a circular shape with a notch. The sections of the inner contour and the outer contour of the second cylinder are each in a circular shape with a notch. The inner contour of the first cylinder coincides with the inner contour of the second cylinder. An annular groove is formed in the top face of the first cylinder. The middle portion of the top face of the first cylinder is in the shape of a circular truncated cone. Compared with the prior art, angle positioning is added, riveting and angle positioning are completed at a time, a riveting pressing block is additionally arranged so that a water inlet pipe and a water outlet pipe are not likely to be damaged in the riveting process, and the production efficiency and the product quality are improved.

Owner:SHANGHAI DELANG AUTO RADIATOR MFG

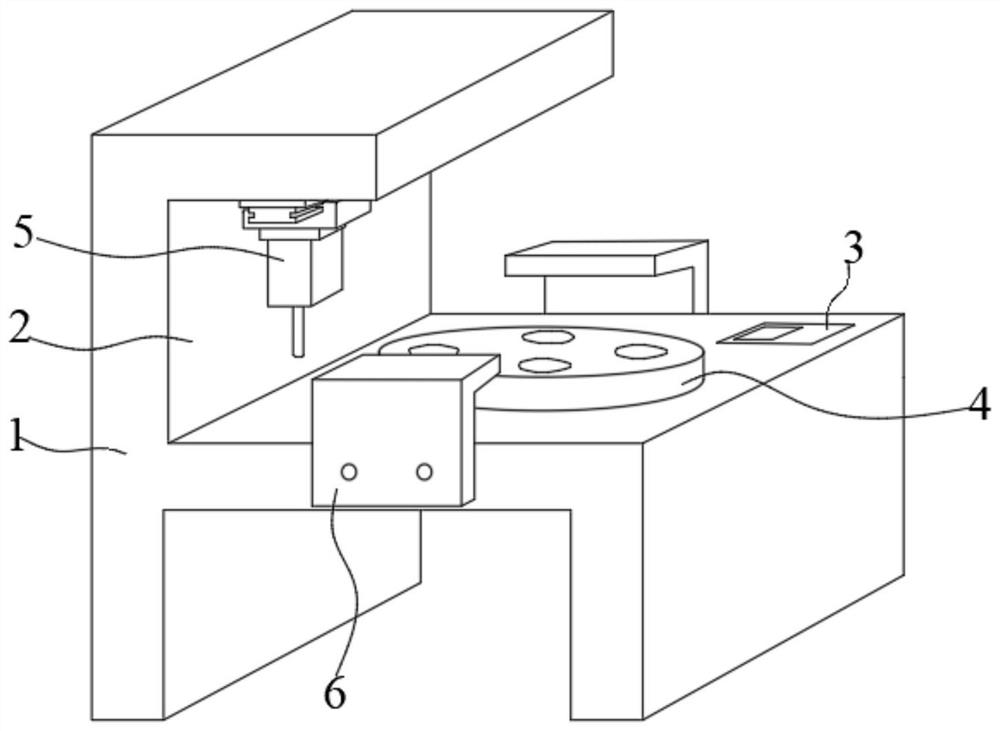

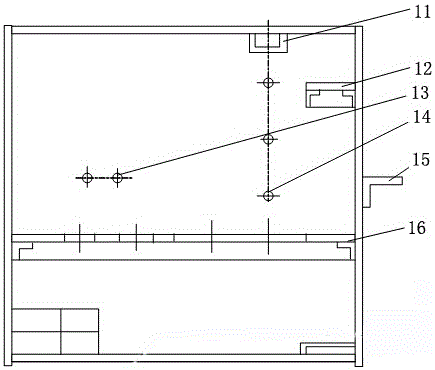

Thin film resistor laser automatic repairing and engraving machine

ActiveCN105364316BHigh precisionImprove efficiencyLaser beam welding apparatusElectrical resistance and conductanceLaser processing

The invention discloses an automatic laser trimmer for thin-film resistors. The automatic laser trimmer for thin-film resistors comprises a rack, an automatic workpiece loading and unloading device, an automatic workpiece lifting device, a workpiece outlet, an automatic focusing laser device, a trimming table, an electric brush lifting mechanism, an industrial personal computer with a resistance automatic detection system, display, input and output equipment, and an air pump, wherein the rack is used as a supporting structure and a shell of the automatic laser trimmer for thin-film resistors; the automatic focusing laser device is arranged on a suspension of the rack; and the industrial personal computer with the resistance automatic detection system is arranged on a platform of the rack. The height of the laser gathering plane and the height of the plane of a machined film resistor are made to be coincident through an automatic focusing lens, the laser machining accuracy and efficiency are improved, efficient and accurate trimming is ensured, and the trimming accuracy of the trimmer can reach more than 0.1%.

Owner:嘉兴金日升工具股份有限公司

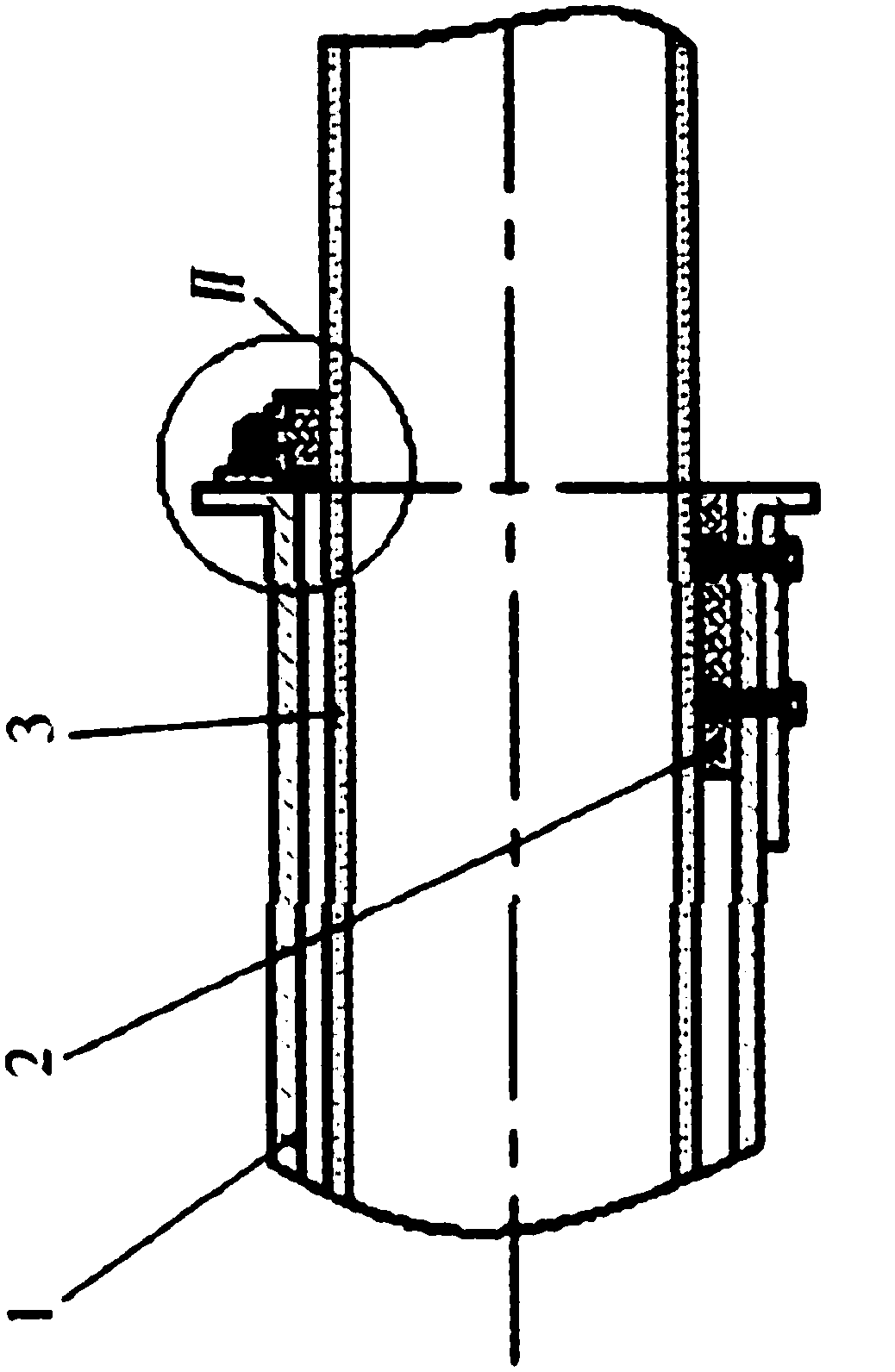

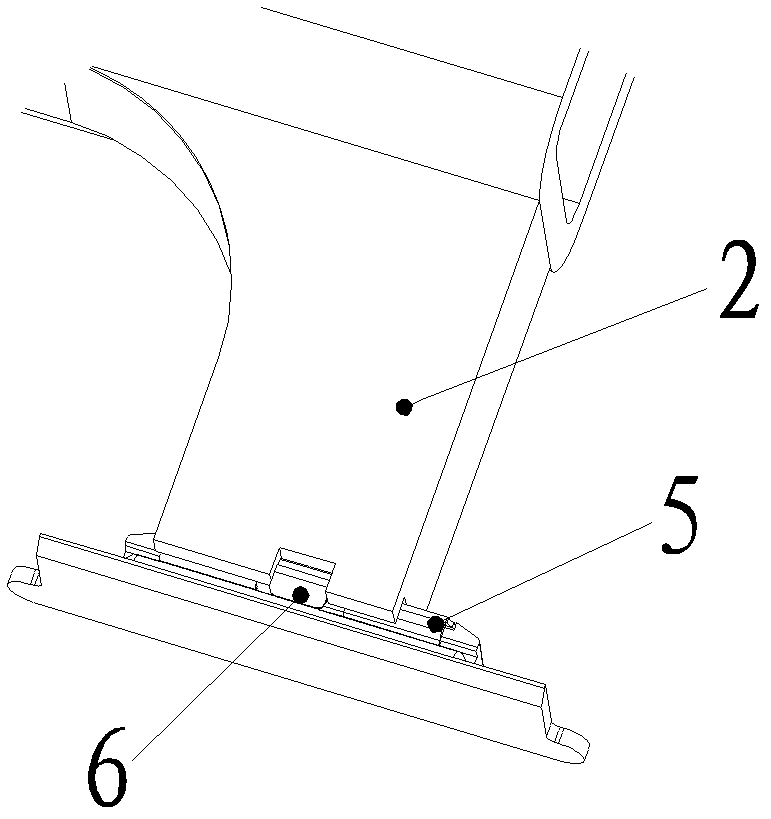

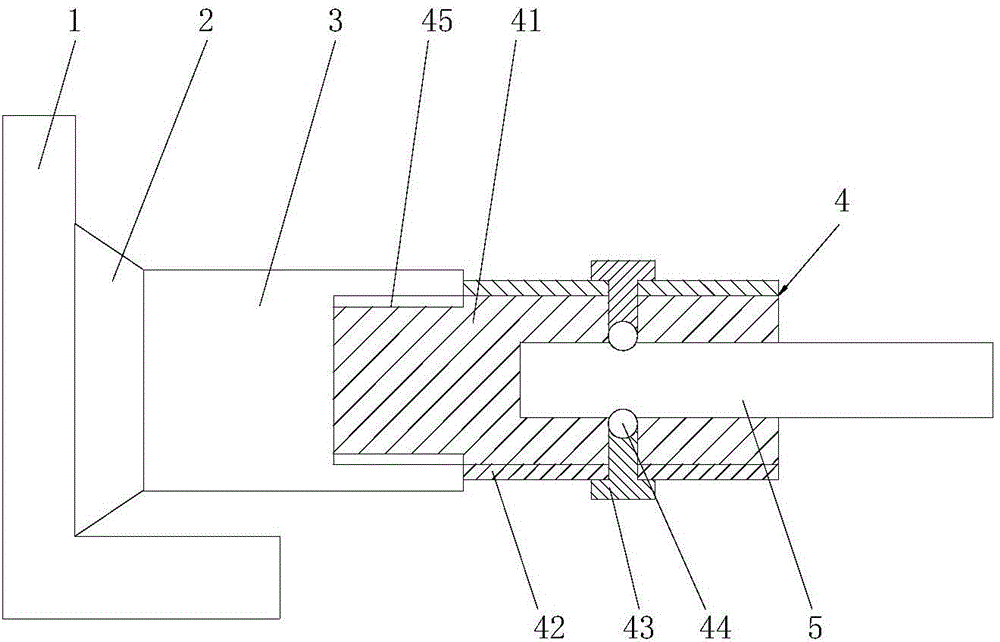

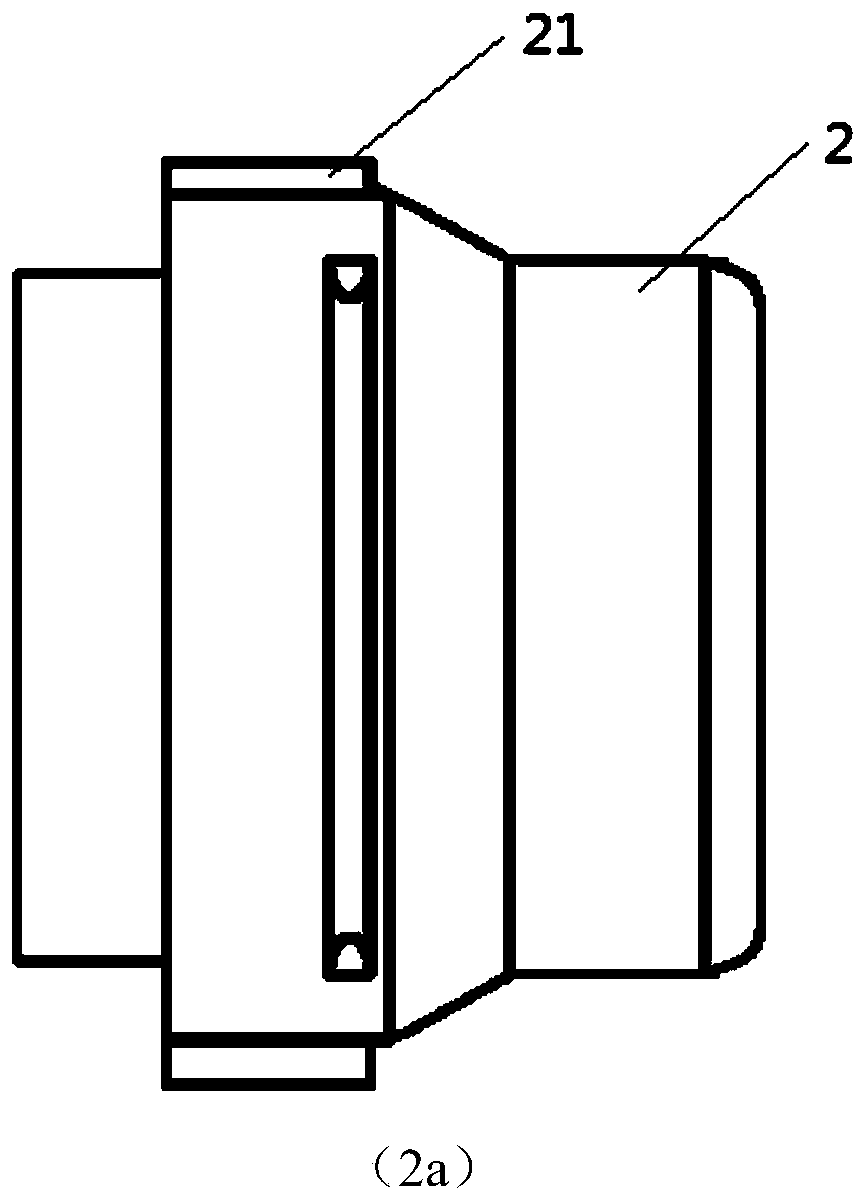

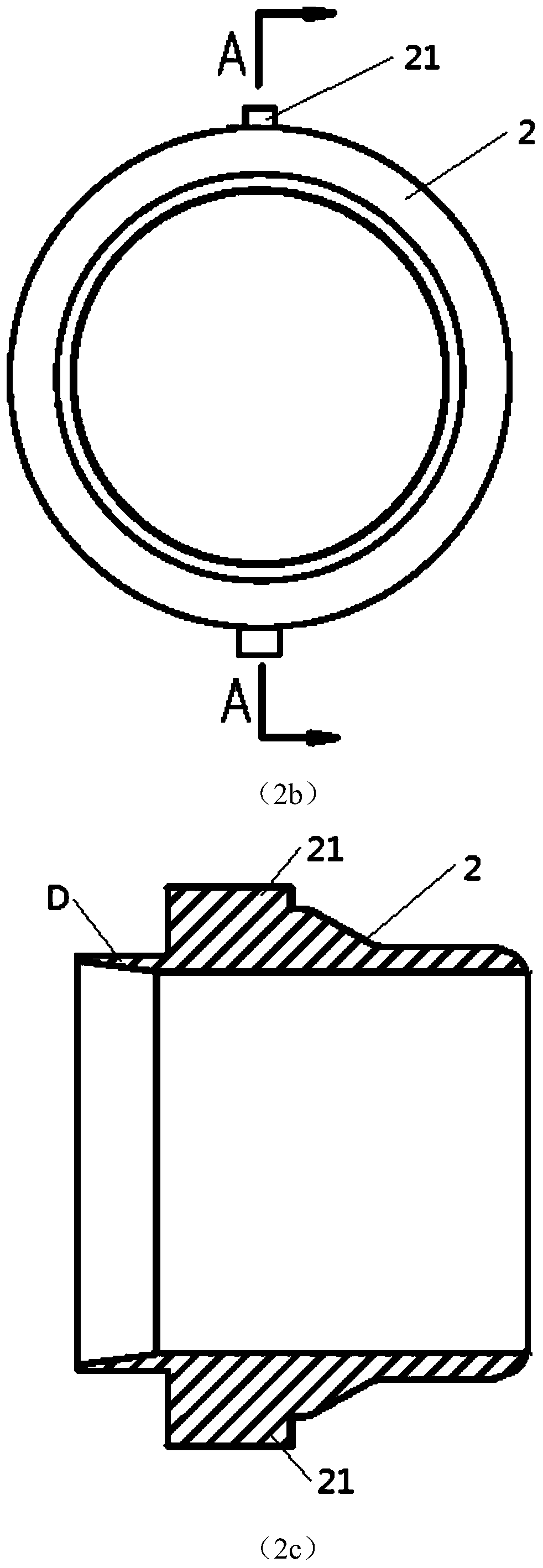

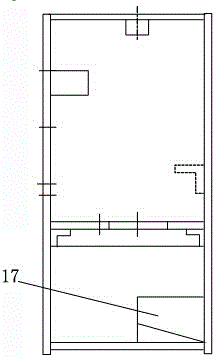

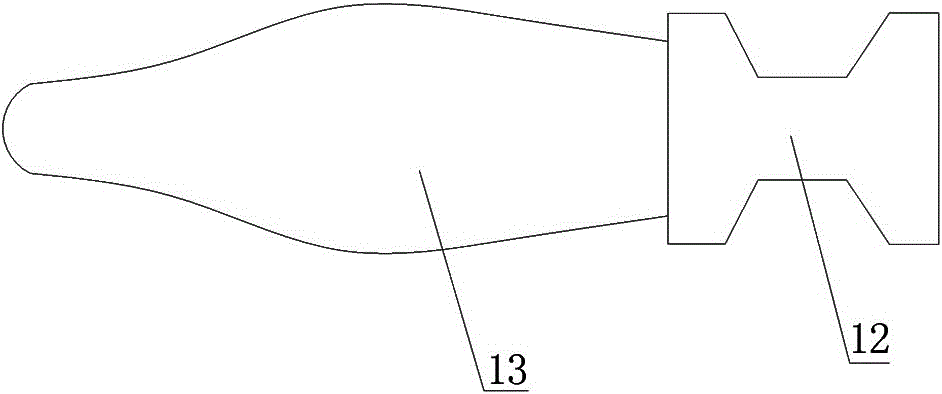

Novel hinge adjustable missile blade clamping device

ActiveCN106563963ACompact structureImprove tooling efficiencyPositioning apparatusMetal-working holdersMissileEngineering

The invention discloses a novel hinge adjustable missile blade clamping device. The device comprises a fixture body (1), an upper chuck (2), a lower chuck (3) and a guide rail (4) arranged below the fixture body (1); the guide rail (4) is parallel to the fixture body (1); a fixed block (6) is in threaded connection with a locking screw (7) for penetrating through the fixed block (6); the lower end part of the locking screw (7) is butted against the guide rail (4); the lower chuck (3) is opposite to the fixture body (1), and is fixed on the lower surface of the fixture body (1); wedges (8) are respectively arranged at the left end parts of the upper chuck (2) and the lower chuck (3); and extension springs (9) are fixed on the right sides of the wedges (8) between the upper chuck (2) and the lower chuck (3). The novel hinge adjustable missile blade clamping device has the beneficial effects of high tool efficiency, capability of clamping missile blades with different specifications and improvement of the blade production efficiency.

Owner:成都久欣时代科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com