Implant acid etching fixture device

An implant and acid etching technology, which is applied in the fields of implantology, medical science, dentistry, etc., can solve the problems of not being able to etch the annular smooth surface, and achieve the effects of avoiding acid corrosion, improving tooling efficiency, and fast tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

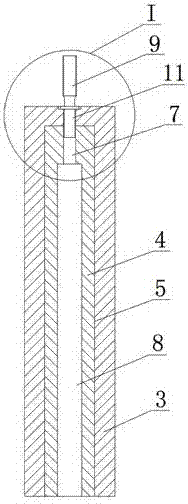

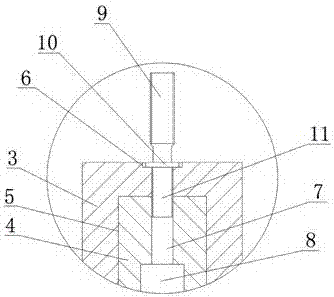

[0020] Such as Figure 2~5 As shown, the implant acid-etching tooling device includes a ceramic outer cylinder 3, an inner cylinder 4 and a cross-shaped threaded rod. The bottom of the ceramic outer cylinder 3 is provided with a step hole 5, and the top of the ceramic outer cylinder 3 is provided with a connecting step hole. 5, the centerline of the annular groove 6 coincides with the centerline of the step hole 5, the inner cylinder 4 is inserted into the large hole of the step hole 5, and the top of the inner cylinder 4 is provided with a threaded hole A7, The bottom of the inner cylinder 4 is provided with a threaded hole B8. The cross-shaped threaded rod is composed of an upper threaded head 9, a ring member 10 and a lower threaded head 11 connected in sequence. The nominal diameter of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com