Insert welding pin radiating fin assembly machine

A technology of heat sink and solder pin is applied in the field of assembly machines for automatic assembly of pin type heat sinks, which can solve problems such as low efficiency and occupation of labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

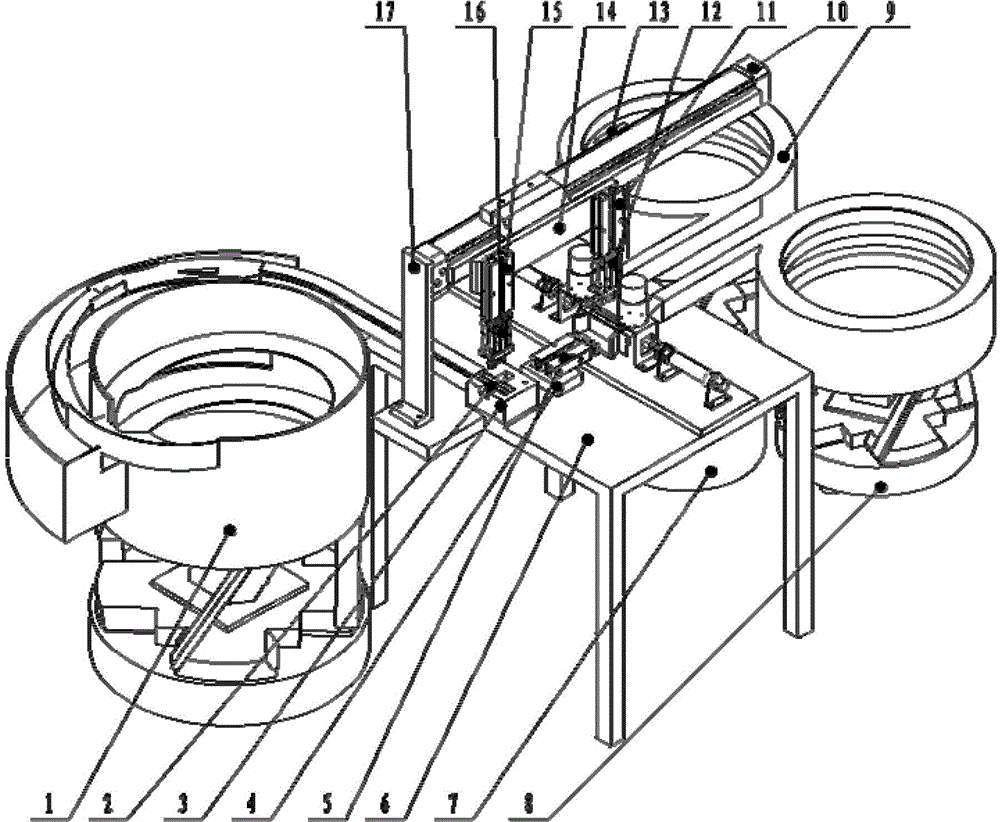

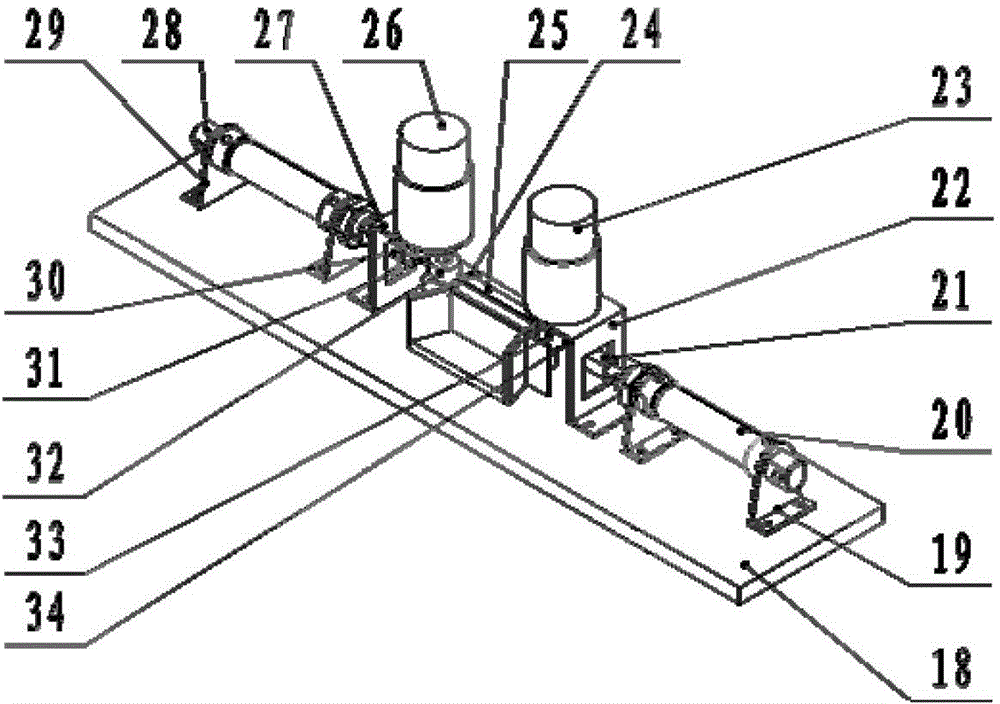

[0009] Such as figure 1 , figure 2 Shown: a heat sink assembly machine for inserting welding pins, which is composed of a first heat sink vibrator, a first heat sink 2, a temporary storage bin 3, a push cylinder pad 4, a push cylinder 5, a first bracket 6, and a finished product Material silo 7, first welding needle vibration plate 8, second welding needle vibration plate 9, rodless cylinder 10, first vertical cylinder 11, first air claw 12, second bracket 13, connector 14, second Vertical cylinder 15, second air claw 16, third support 17, base plate 18, small cylinder first support 19, first small cylinder 20, first connecting block 21, first DC motor fixing plate 22, first DC motor 23 , clamp 24, second heat sink 25, second DC motor 26, second DC motor fixing plate 27, second small cylinder 28, small cylinder second bracket 29, second connecting block 30, second pin 31, the second The second insertion welding is for the middle block 32, the first insertion welding is for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com