Apparatus and method for grinding the outer surface of a circuit board for a new energy vehicle

A technology for new energy vehicles and circuit boards, which is applied to grinding drive devices, machine tools suitable for grinding workpiece planes, and grinding machines. , The effect of improving grinding efficiency and shortening tooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

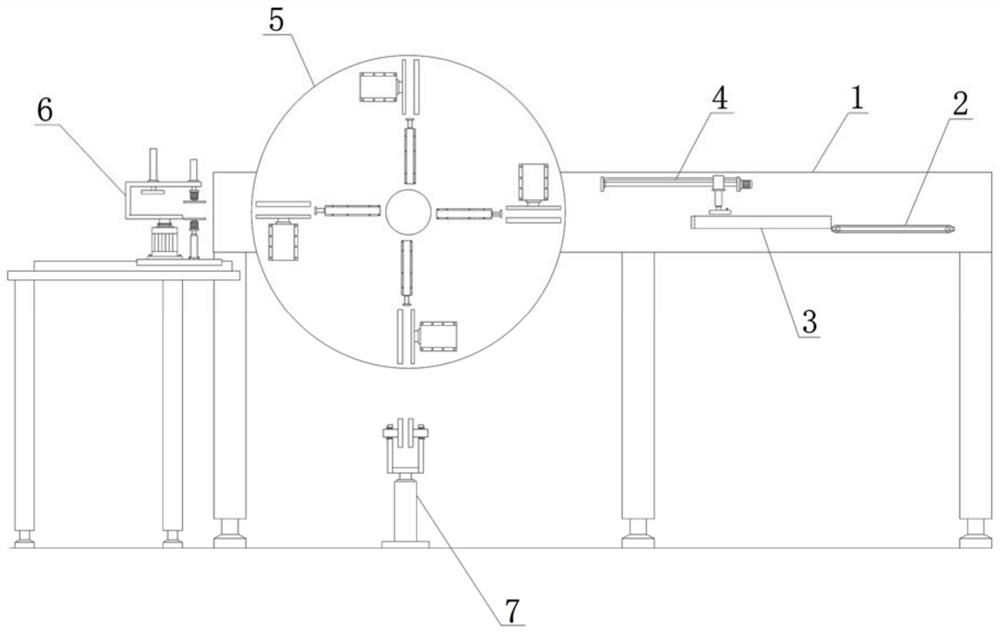

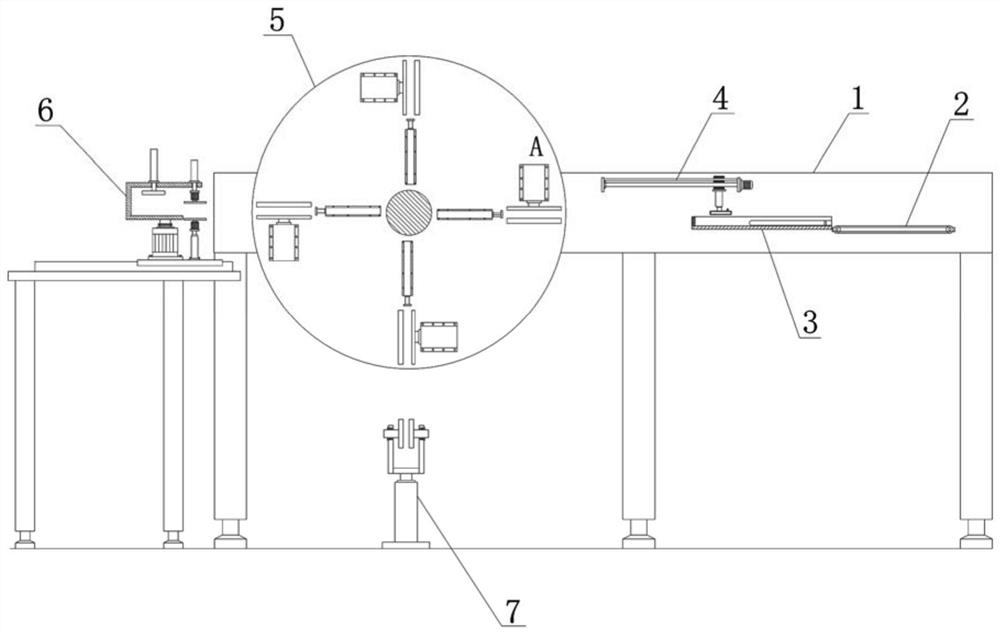

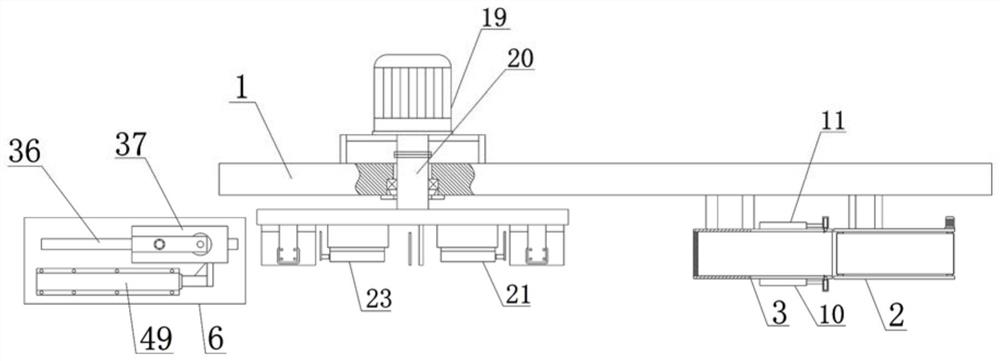

[0058] Embodiment one: if Figure 1~3 As shown, a device for grinding the outer surface of a circuit board for a new energy vehicle, which includes a gantry 1, a belt conveyor 2 arranged on the gantry 1 and arranged in sequence from right to left, and a new energy circuit board positioning device 3 , a screw drive device 4 , a new energy circuit board clamping device 5 and a second grinding device 6 , and a first grinding device 7 is arranged below the new energy circuit board clamping device 5 .

[0059] Such as Figure 5-6 As shown, the new energy circuit board positioning device 3 includes a channel steel 8, a limiting plate 9, a positioning mechanism A10 and a positioning mechanism B11, the channel steel 8 is set horizontally, the opening of the channel steel 8 is set upward, and the channel steel 8 Fixed on the front end face of the gantry 1 beam, the bottom surface of the channel steel 8 is flush with the belt 54 of the belt conveyor 2, and the front and rear side plate...

Embodiment 2

[0082] Embodiment two: if Figure 15 As shown, a new energy vehicle circuit board outer surface grinding device, the difference between this embodiment and Embodiment 1 is that: the outer cylinder of the vertical oil cylinder 31 is welded with a conical cylinder 63 with an upward opening. Grinding device also comprises PLC controller, described PLC controller and horizontal positioning cylinder 13, longitudinal positioning cylinder 14, vertical oil cylinder 31, drive motor 55, stepper motor I19, stepper motor II38, upper motor 43, lower motor 47 , vertical cylinder 16, vacuum pump, horizontal cylinder 49, clamping cylinder I27 and clamping cylinder II42 are electrically connected, wherein the conical cylinder 63 can collect the waste produced after grinding to avoid waste splashing, and can also control the level through the PLC controller Positioning cylinder 13, longitudinal positioning cylinder 14, vertical cylinder 31, drive motor 55, stepper motor I19, stepper motor II38,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com