Tarpaulin composite board, connecting structure and mounting method of composite board

A technology for connecting structures and composite panels, which is applied to building components, building structures, and thermal insulation. It can solve the problems of high cost, difficult transportation, and large amount of welding, and achieves time-saving and labor-saving installation. It saves welding processes and is versatile. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

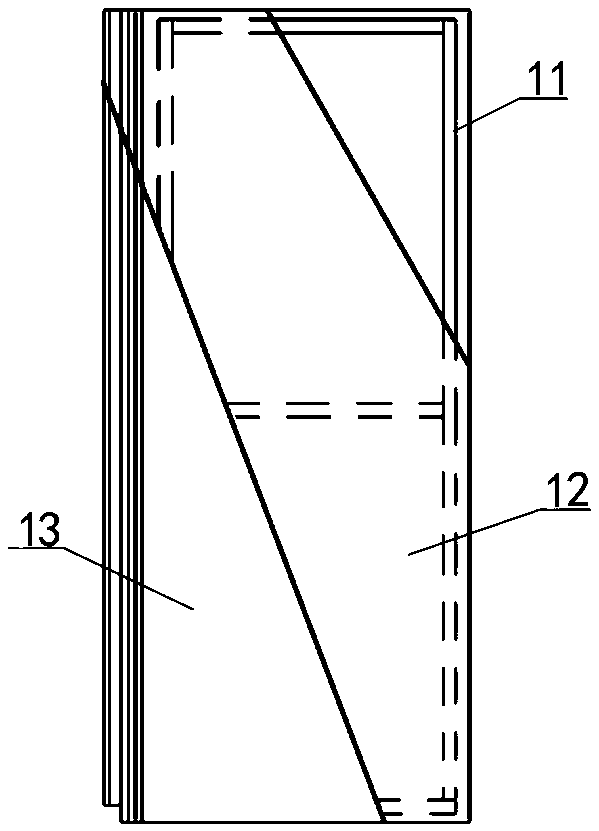

[0044] Examples see figure 1 As shown, a tarpaulin composite board includes a light steel dragon frame 11, an insulation core material 12, and a tarp cover 13, and the light steel dragon frame 11 is rectangular.

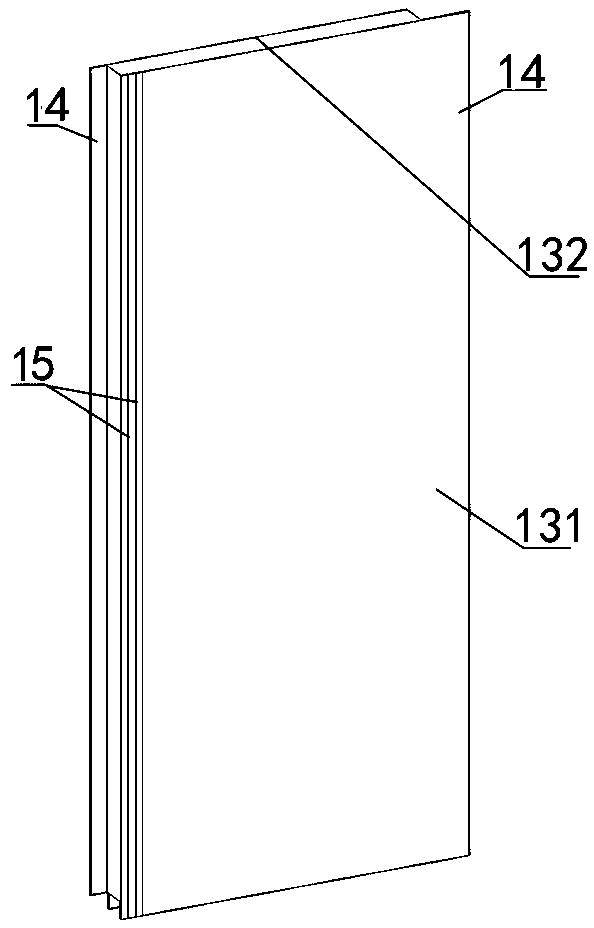

[0045] See figure 2 As shown, the thermal insulation core material 12 fills the inside of the light steel dragon frame and wraps the outside of the light steel dragon frame. The thermal insulation core material is made of foamed material, and the outer side of the foamed material is covered with a tarp cover 13. The tarp cover 13 includes a front side 131, a rear side 132, an upper side 133, a lower side 134, a left side 135, and a right side 136. The right end of the front side surface extends outwardly along the vertical edge of the board with a lap cloth edge 14, and the left end of the front side has at least two parallel bonding strips 15 along the vertical length of the board.

[0046] The left end of the rear side surface extends outward along the vertical edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com