Novel device for machining back shroud for automobile clutch

A rear cover and clutch technology, which is applied in the direction of driving devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing the production output of the rear cover, difficult to meet the national standard, and increasing the labor load of workers, so as to save The effect of reducing the time required, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

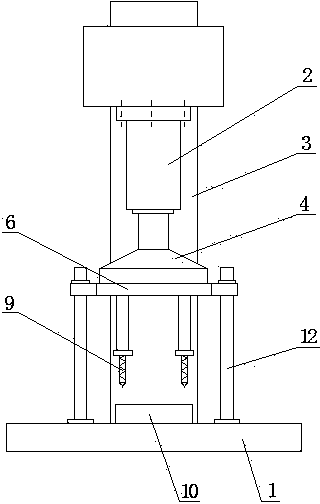

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

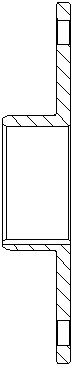

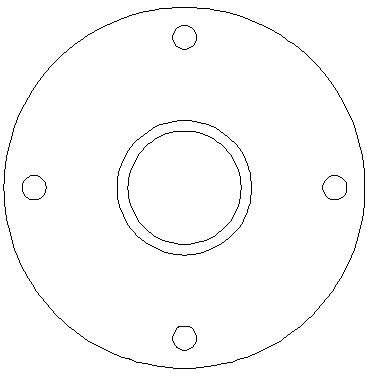

[0017] Such as Figure 3-5 As shown, a new type of device for processing rear cover plates for automobile clutches includes a workbench 1 and an oil cylinder 2. The workbench 1 is provided with a column 3 perpendicular to the workbench 1, and the oil cylinder 2 is perpendicular to the workbench 1 and is fixedly installed. On the side of the column 3, the piston rod of the oil cylinder 2 is set downwards and the end of the piston rod is welded with a protective cover 4, the protective cover 4 is in the shape of a cone, and the protective cover 4 is provided with a servo motor 5 perpendicular to the workbench 1. The bottom of the cover 4 is provided with a casing 6, the rotating shaft in the casing 6 is equipped with a central gear 7 and four star gears 8, the central gear 7 and the four star gears 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com