Fixture for machining depth cavity for dynamic and static pressure bearings by using inner-aperture grinder

A technology of dynamic and static pressure bearings and inner hole grinding machines, which is applied to grinding machines, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces. The efficiency of tooling and the effect of ensuring the uniformity of cavity opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

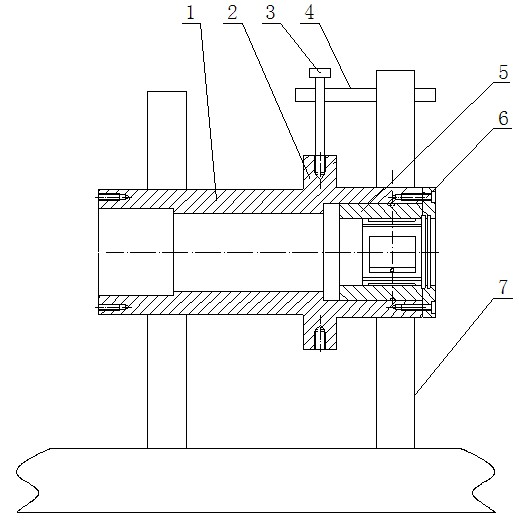

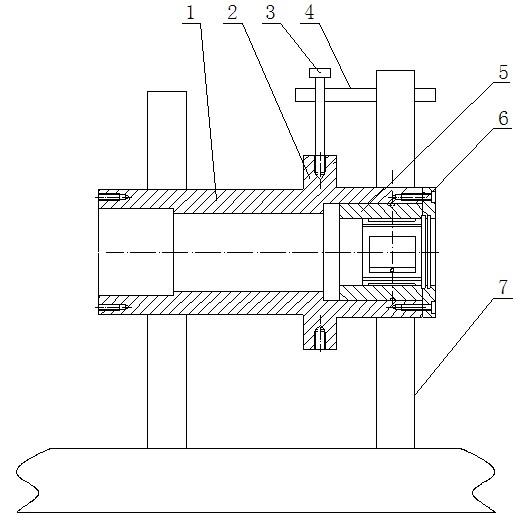

[0011] see figure 1 , the present invention is a tooling for deep and shallow chambers of dynamic and static pressure bearings processed by an inner hole grinder, including a sleeve 1, an annular boss 2 is arranged on the sleeve 1, and angle control screw holes are uniformly distributed radially on the annular boss 2, and the angle An angle control screw 3 is set on the control screw hole, a gear lever 4 is fixed on the inner hole grinder 7, and the gear lever 4 is blocked between the two angle control screws 3, and fixed dynamic and static pressure bearings are set on the two end surfaces of the sleeve 1 5 fixing screw holes and fixing screws 6.

[0012] When in use, the sleeve 1 is clamped on the inner hole grinding machine 7, the inner and outer circles of the sleeve 1 are found, the dynamic and static pressure bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com