Patents

Literature

43results about How to "Wear out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

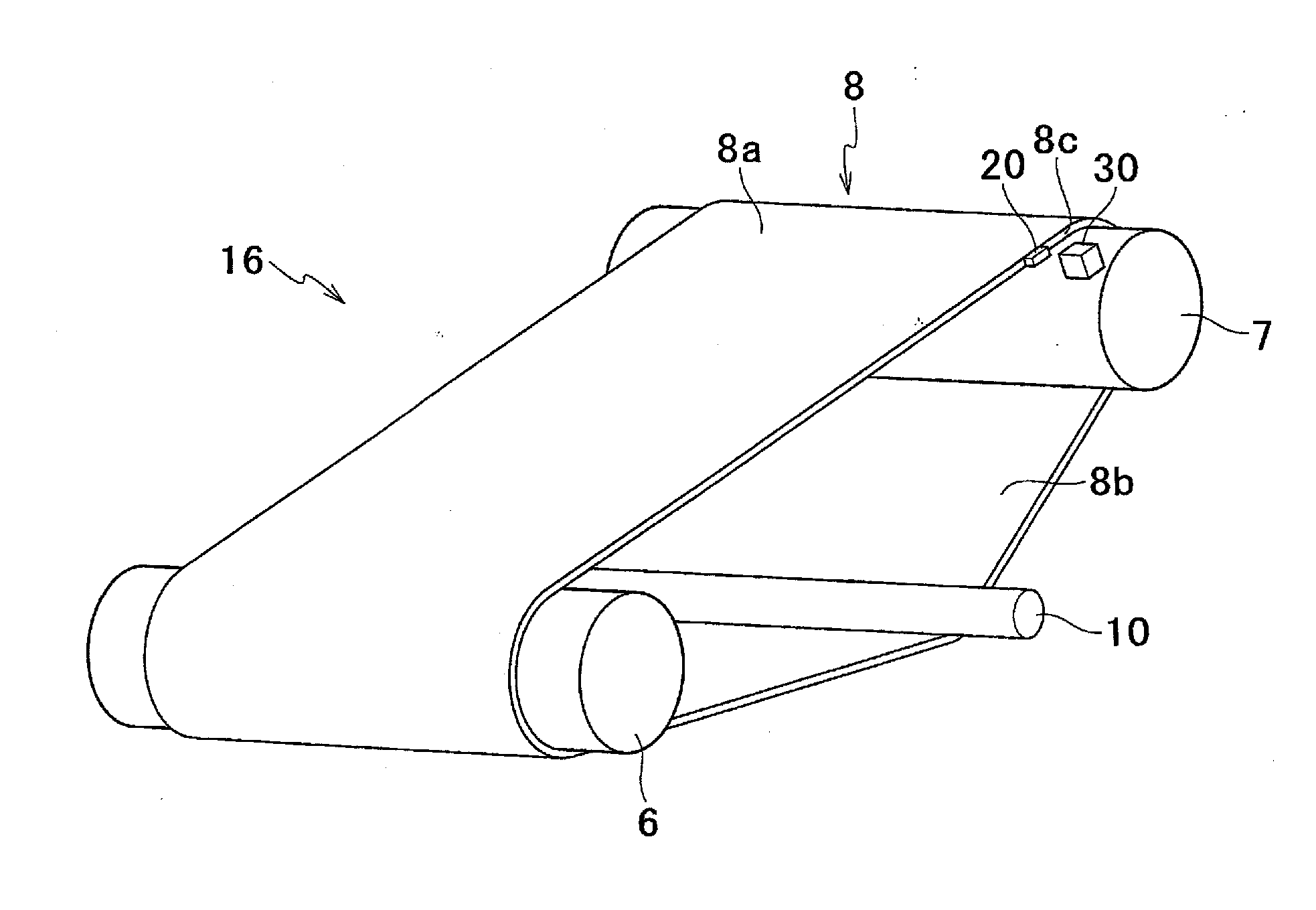

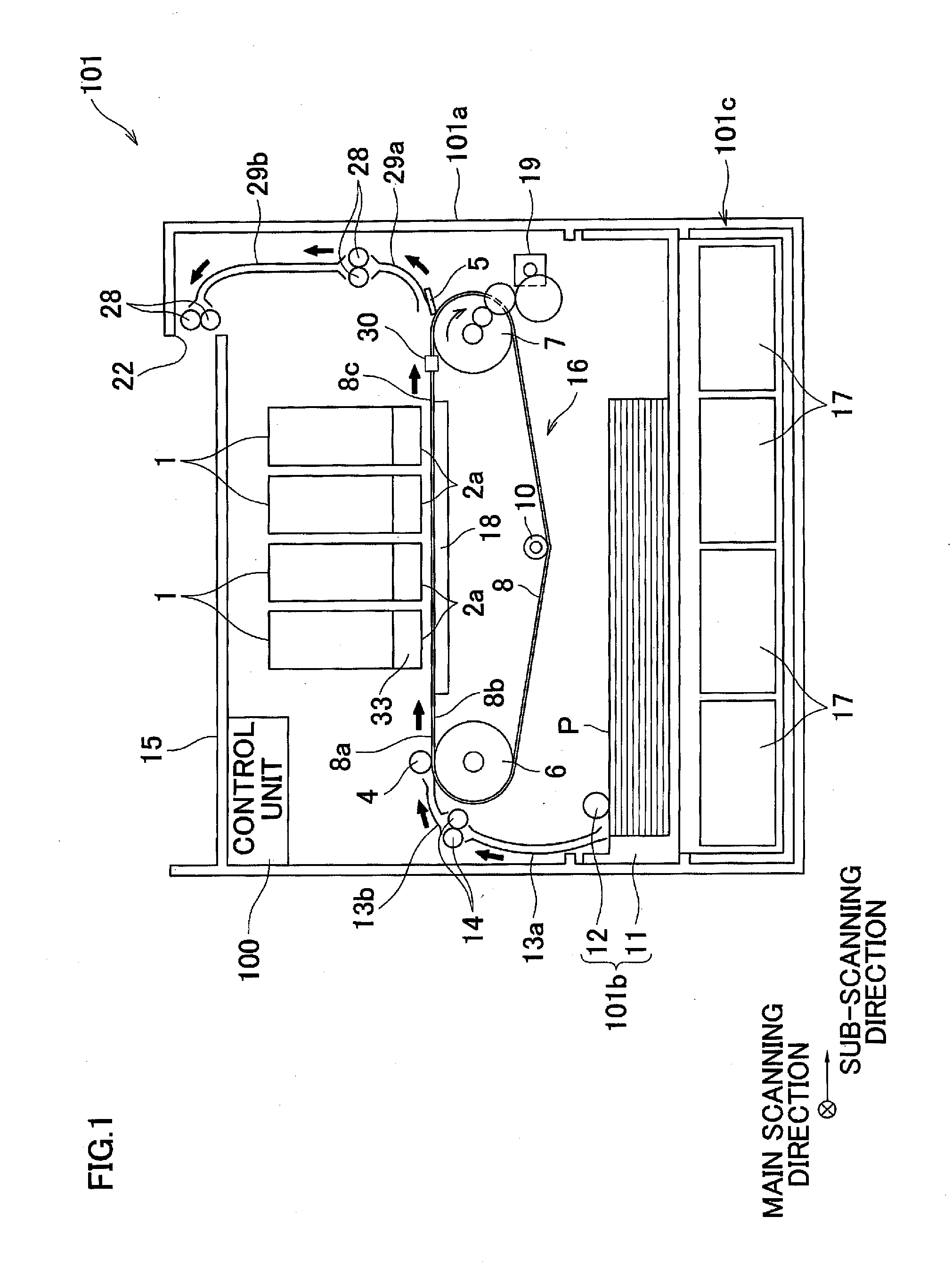

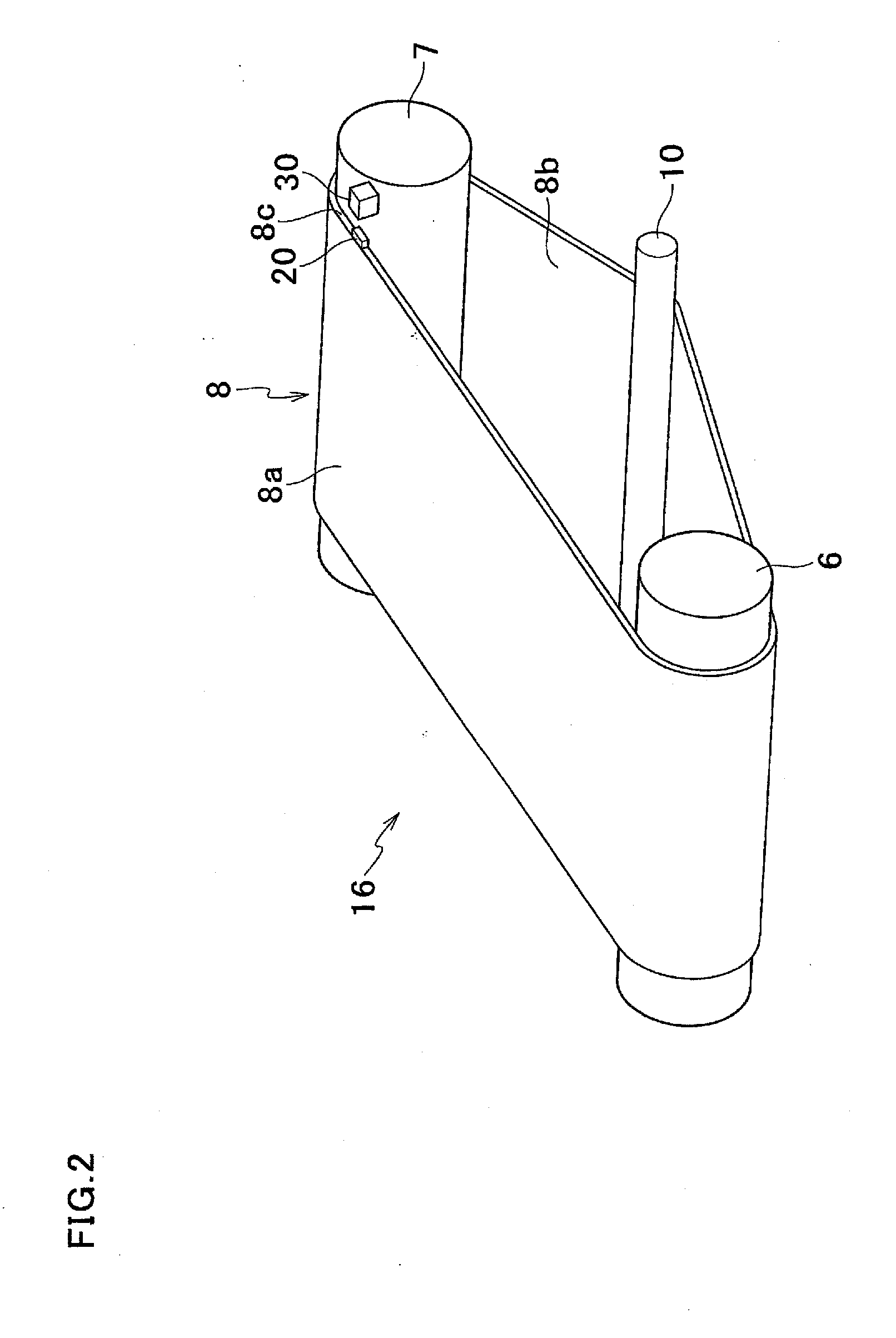

Liquid ejection apparatus

A recording apparatus includes a recording unit recording an image, an endless belt which is stretched between rollers such that the inner circumferential surface thereof contacts the rollers and the outer circumferential surface thereof opposes the recording unit, a mark arranged on the profile of the belt, and a mark detection unit which detects that the mark moving in accordance with the travel of the belt is positioned at a predetermined position.

Owner:BROTHER KOGYO KK

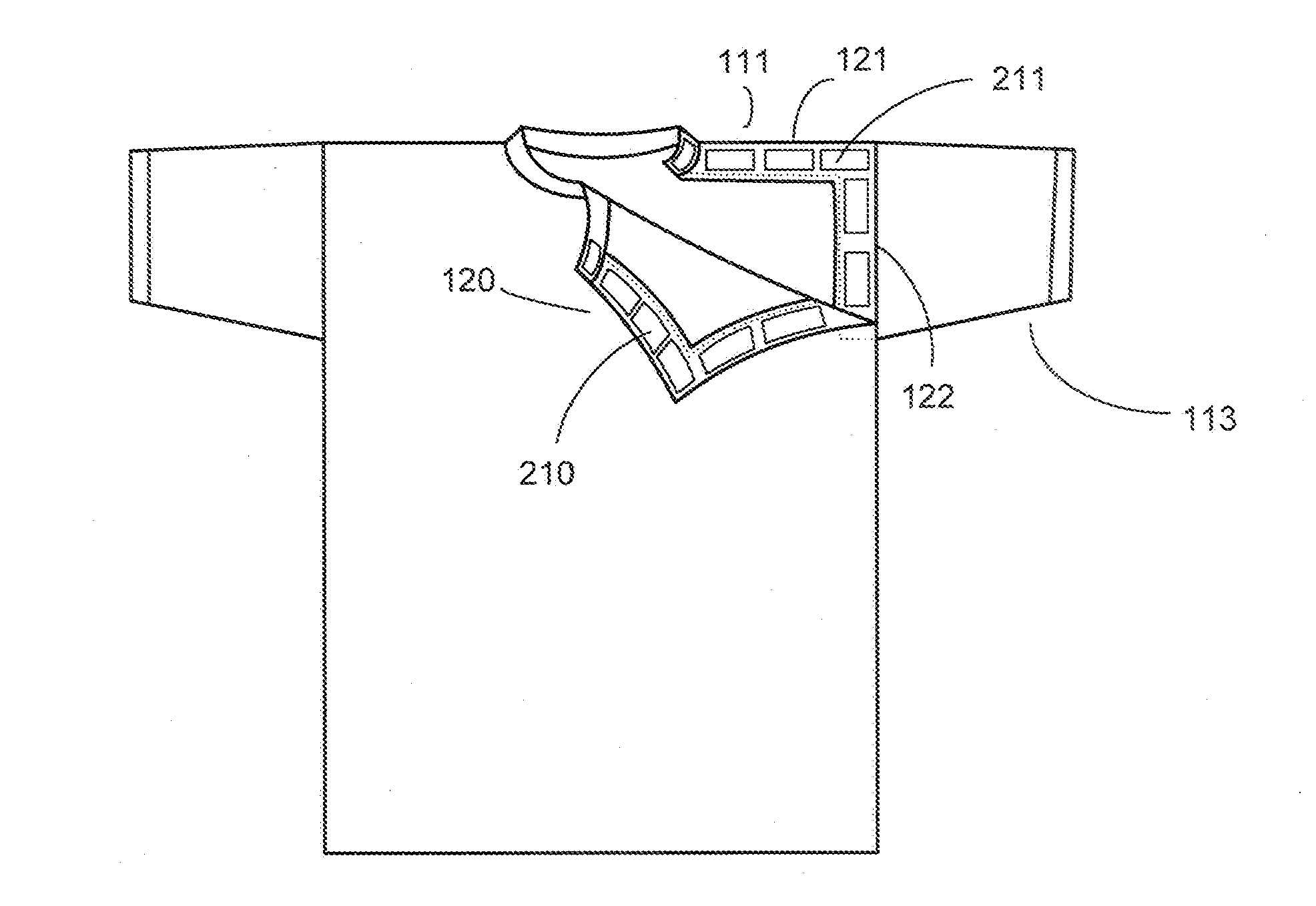

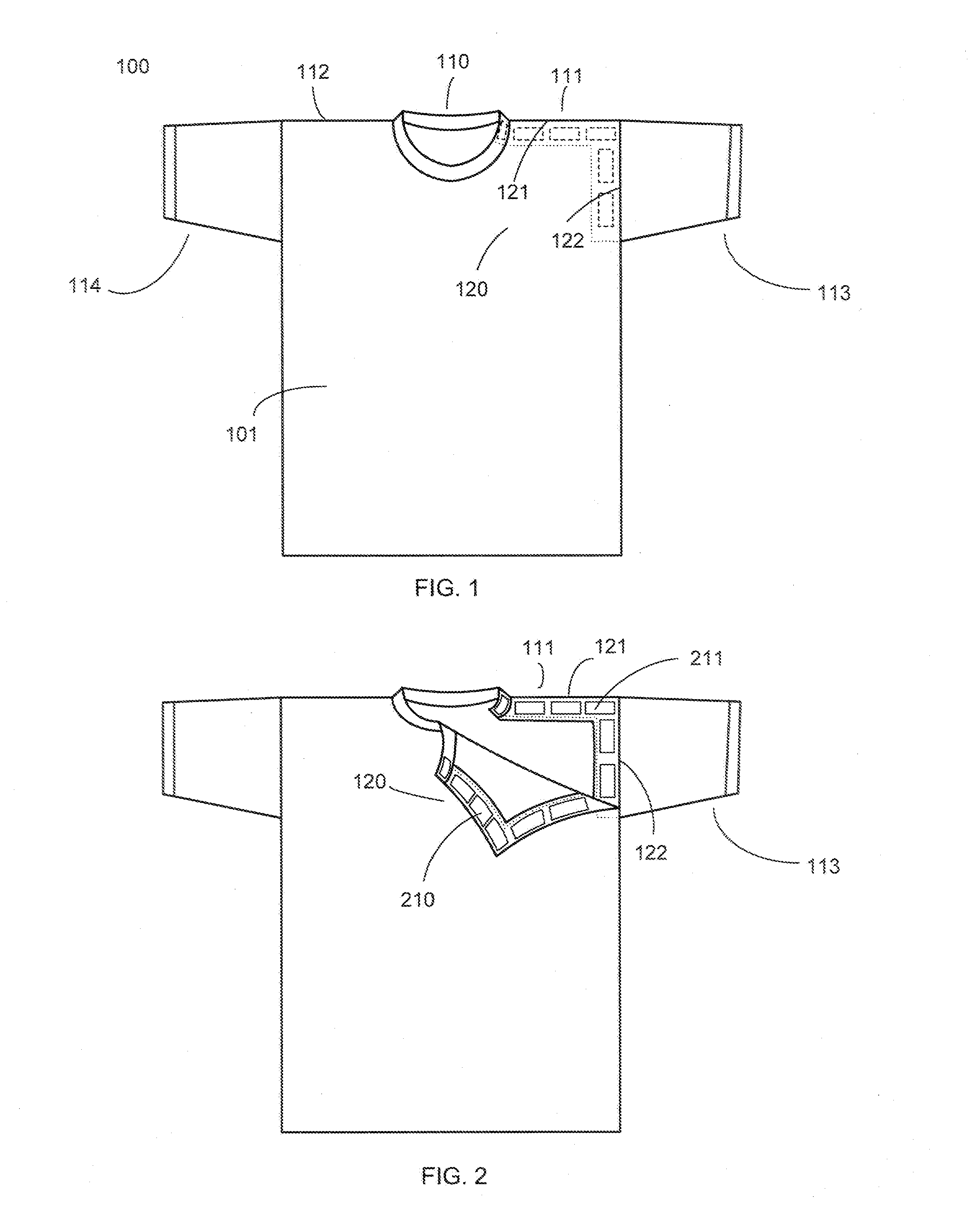

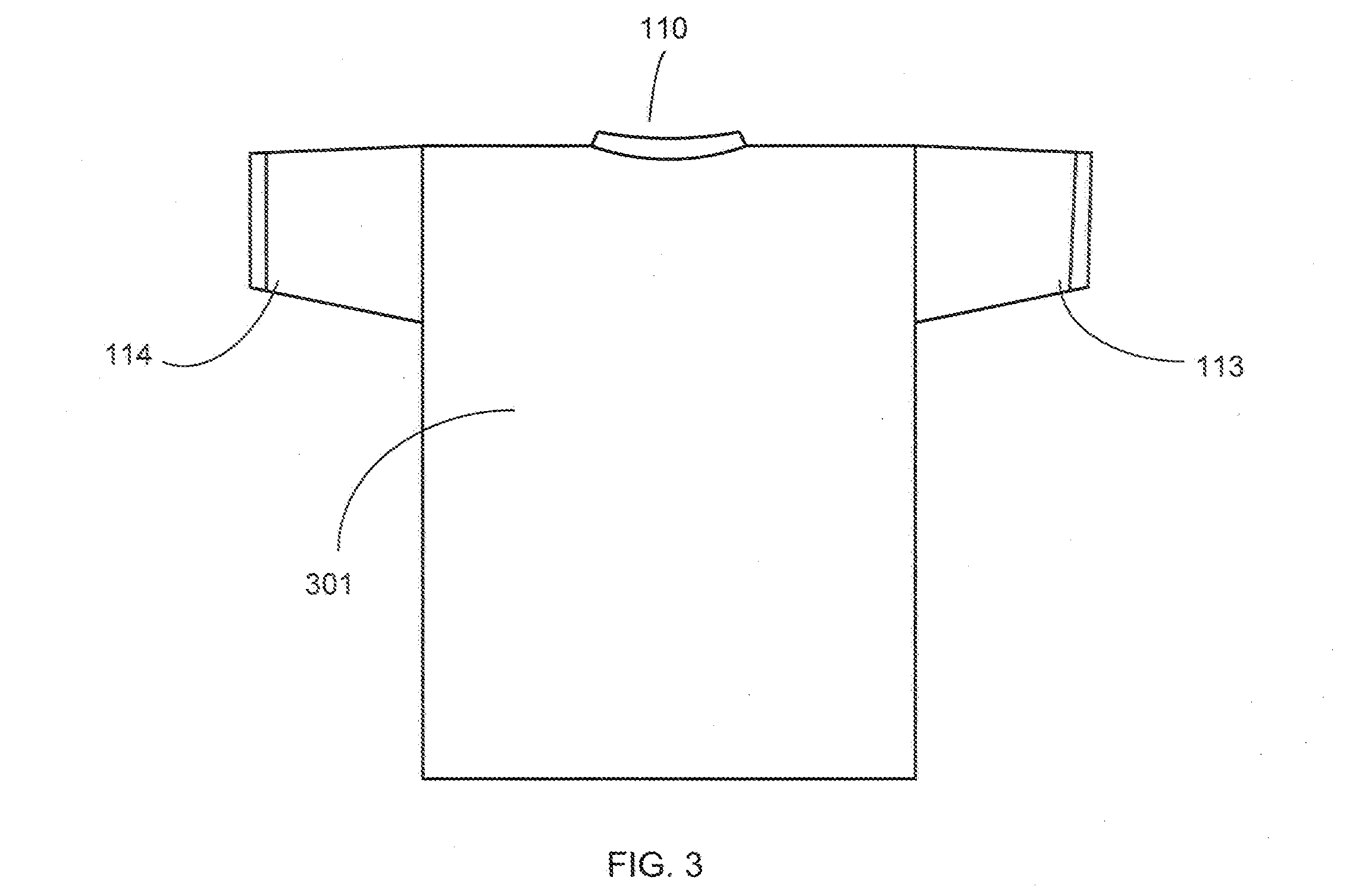

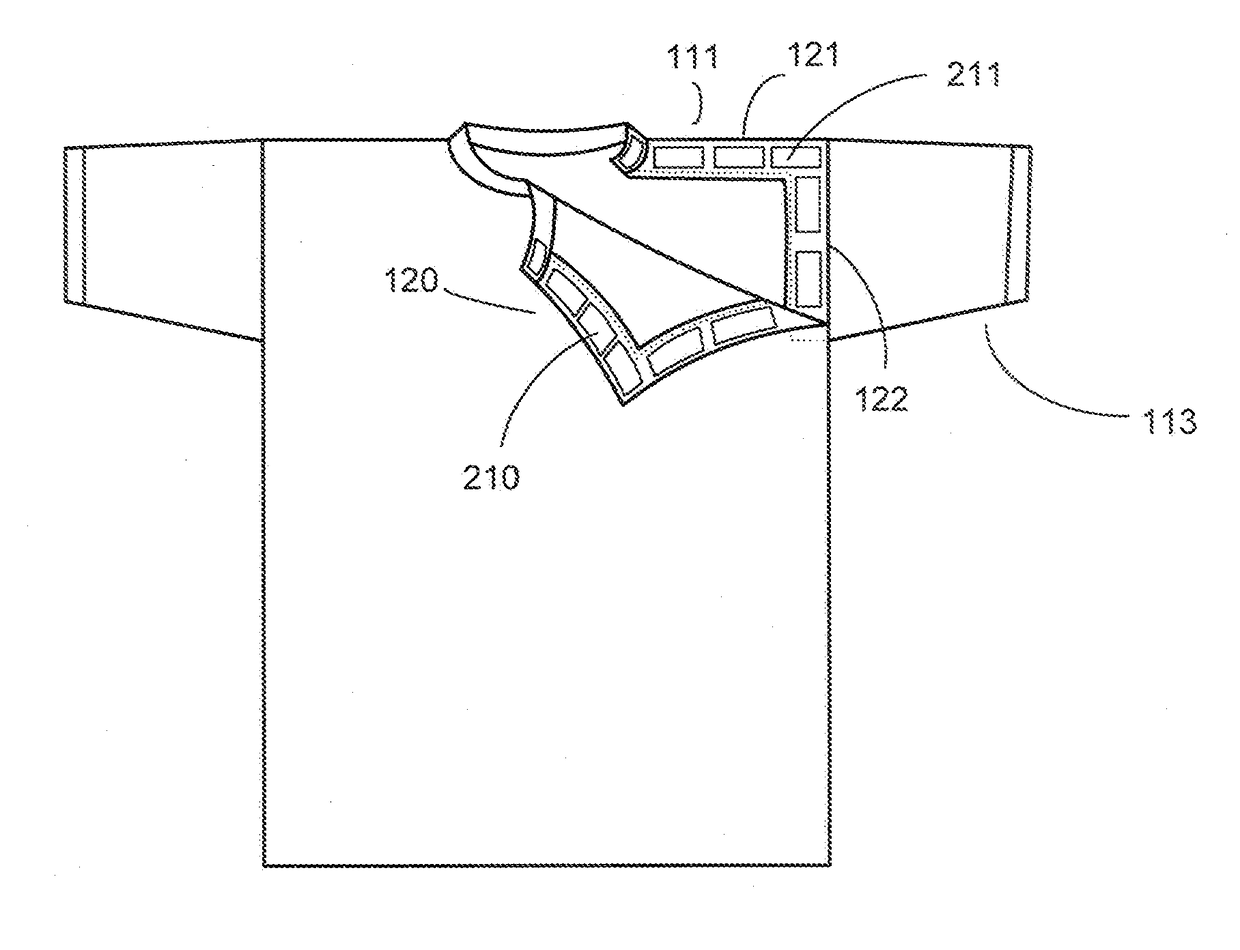

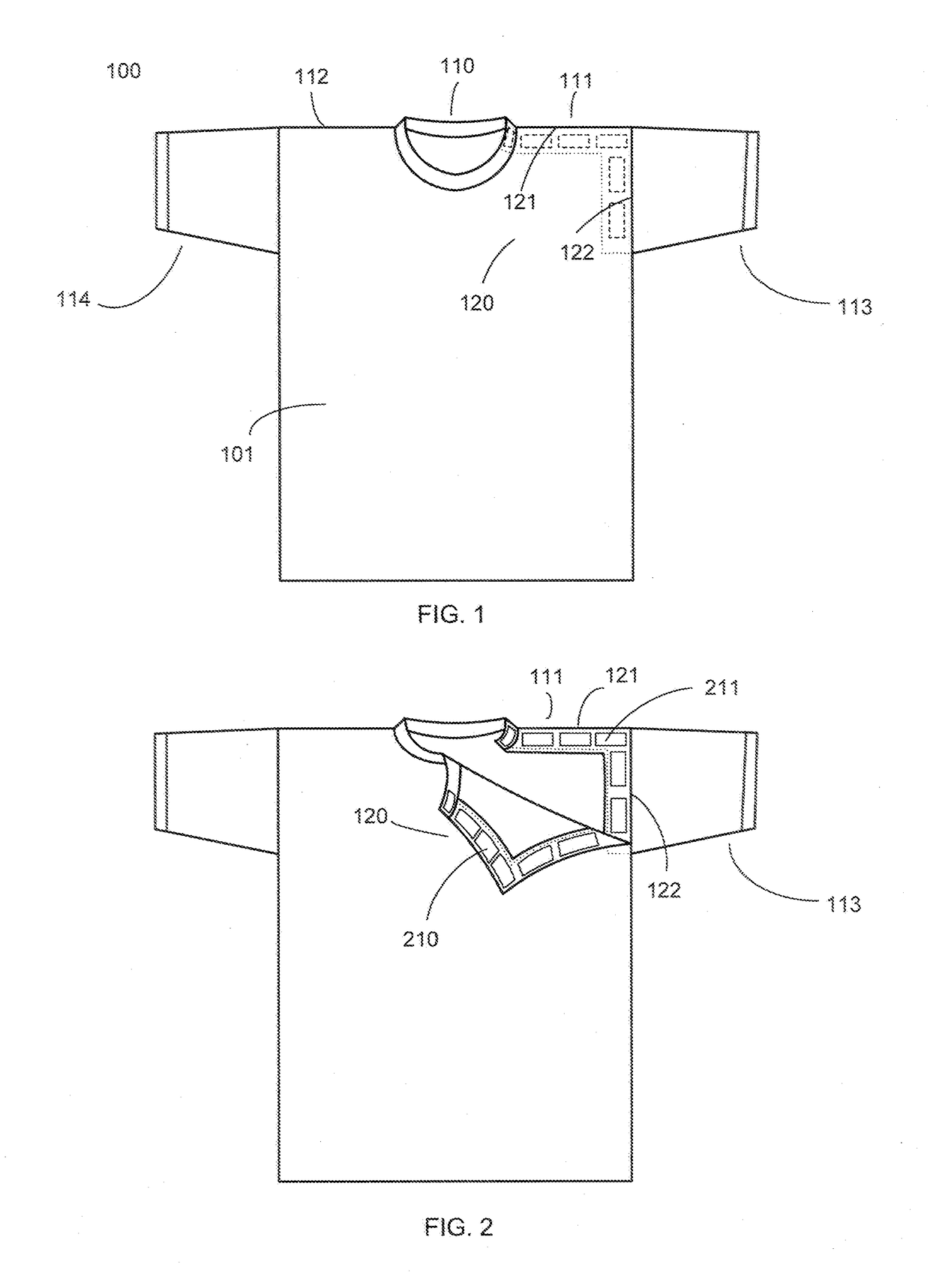

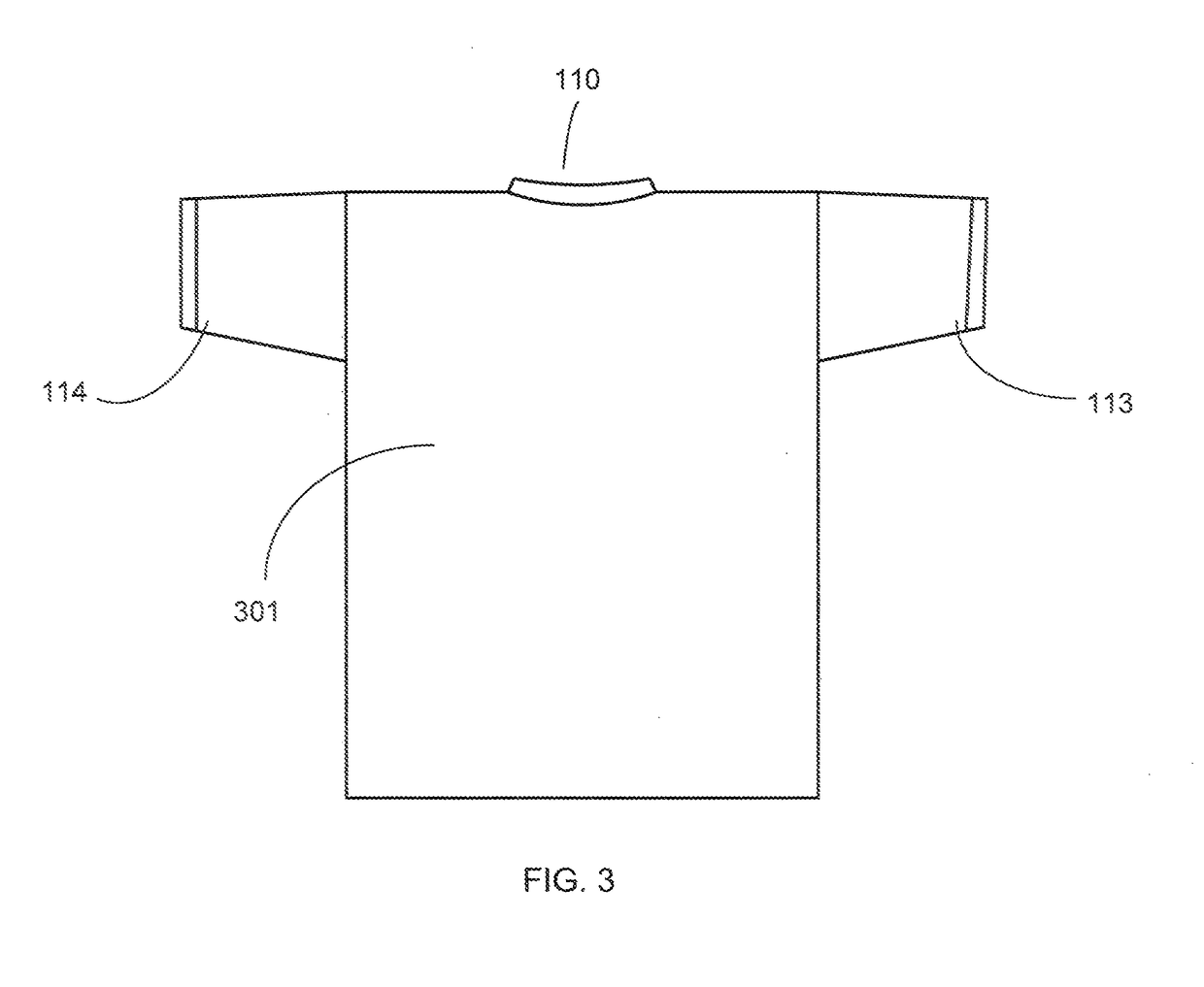

Medical Garment for Chest Devices and Procedures

A medical garment for accessing a patient's chest area, comprising a front portion, a back portion, and at least one sleeve. A flap is formed by two partable seams on the front portion at a shoulder region and the sleeve, with fasteners attached to the flap, back portion, and sleeve to hold the flap in the closed position. The medical garment is configured to expose the patient's chest area when the flap is in the open position, and resembles a standard t-shirt when the flap is in the closed position.

Owner:THE EMILIO NARES FOUND

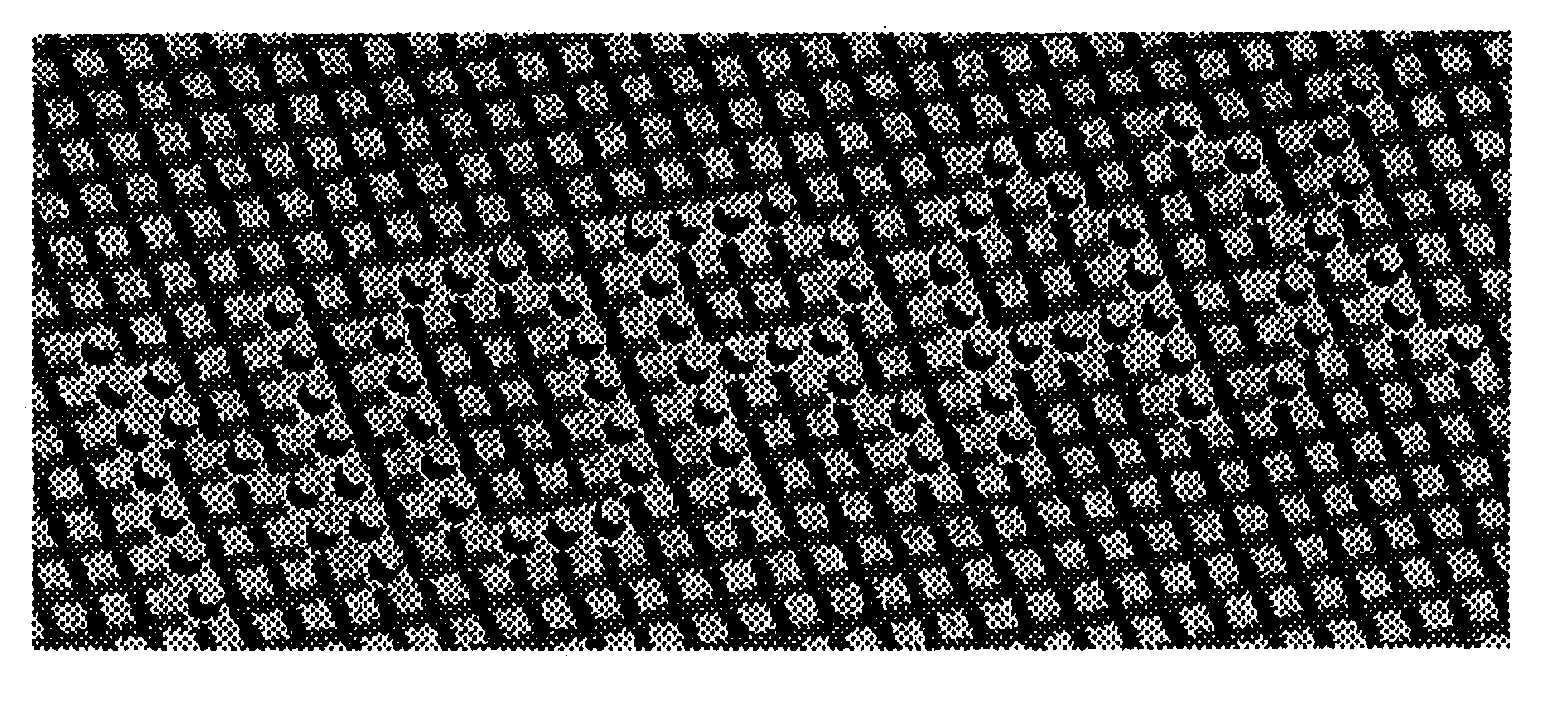

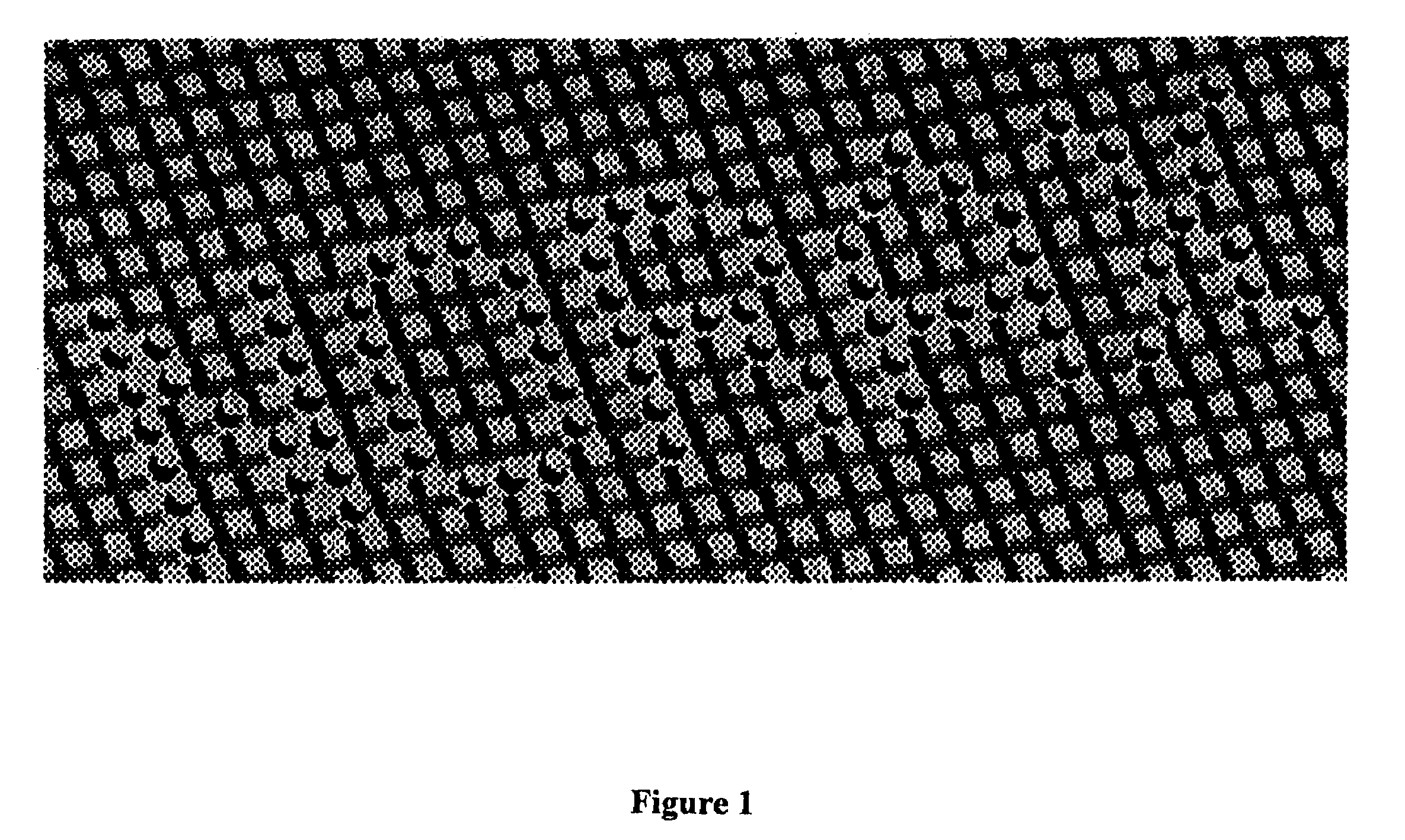

Coated abrasives with indicia

InactiveUS7108596B2Active connectionWear outAdditive manufacturing apparatusAbrasion apparatusEngineeringAbrasive

Owner:SAINT GOBAIN ABRASIVES TECH CO

Medical garment for chest devices and procedures

A medical garment for accessing a patient's chest area, which includes a front portion, a back portion, and at least one sleeve. A flap is formed by two partable seams on the front portion at a shoulder region and the sleeve, with fasteners attached to the flap, back portion, and sleeve to hold the flap in the closed position. The medical garment is configured to expose the patient's chest area when the flap is in the open position, and resembles a standard t-shirt when the flap is in the closed position.

Owner:THE EMILIO NARES FOUND

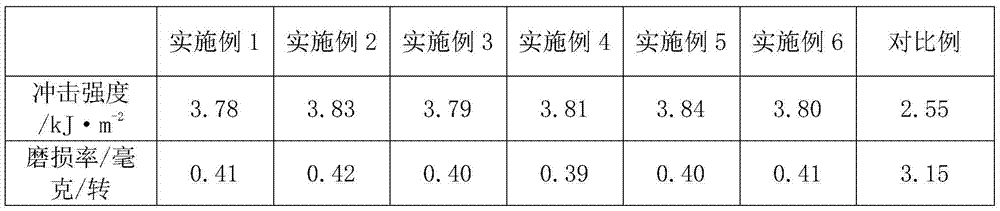

Grinding fluid for optical sapphire

InactiveCN108559407AImprove grinding efficiencyImprove suspensionPolishing compositions with abrasivesSodium silicateNonionic surfactant

The invention discloses a grinding fluid for optical sapphire, belonging to the technical field of grinding and polishing. The grinding fluid comprises the following raw materials by weight: 4-7 partsof fine boron nitride powder, 5-9 parts of fine quartz sand powder, 3-6 parts of stearic acid, 4-7 parts of ethylene glycol, 2-5 parts of sodium lignosulfonate, 5-9 parts of montmorillonite, 2-4 parts of sodium hydroxide, 5-10 parts of polyethylene glycol, 2-4 parts of a lubricant, 5-10 parts of a nonionic surfactant, 3-7 parts of sodium gluconate, 5-8 parts of sodium silicate and 30-40 parts ofwater. The grinding fluid of the invention has high polishing efficiency and high precision; workpieces treated with the grinding fluid are small in surface scratch loss and have smooth surfaces; andwhen the grinding fluid is used for grinding and polishing of optical sapphire, a sapphire sheet is allowed to have flatness of 0.1 nm, so good conditions are provided for subsequent precision polishing.

Owner:安徽全兆光学科技有限公司

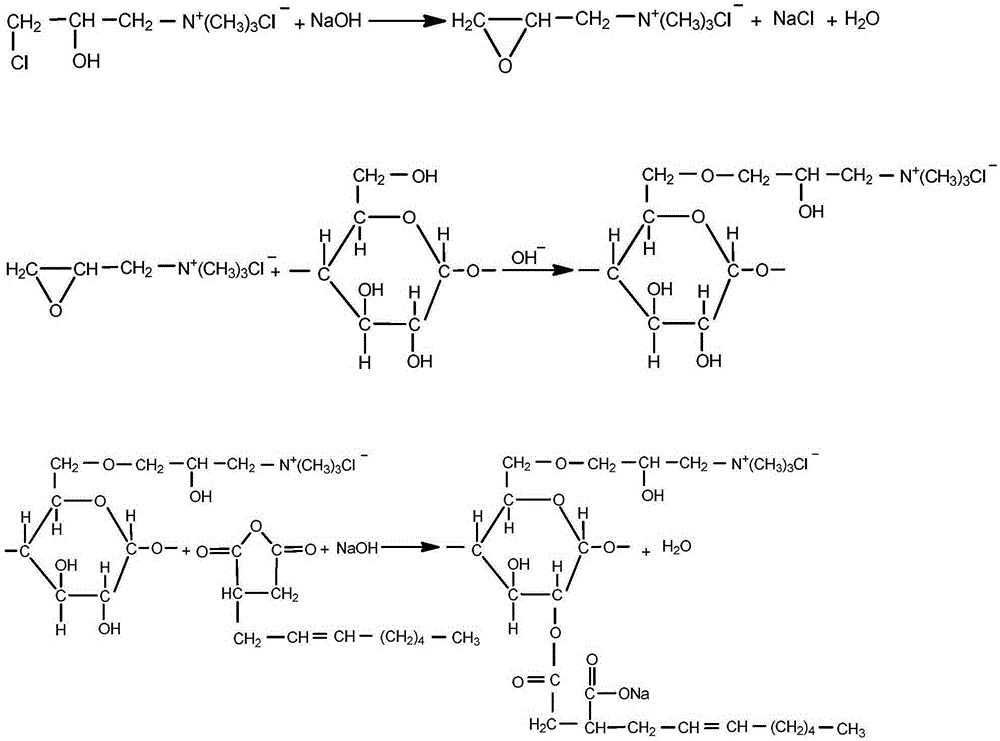

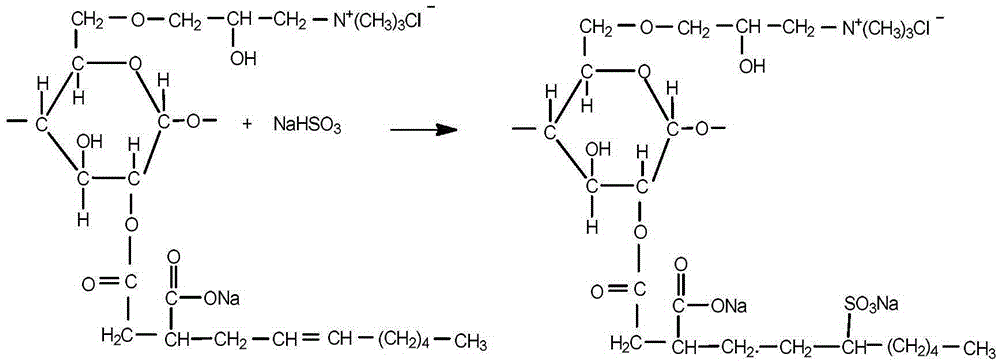

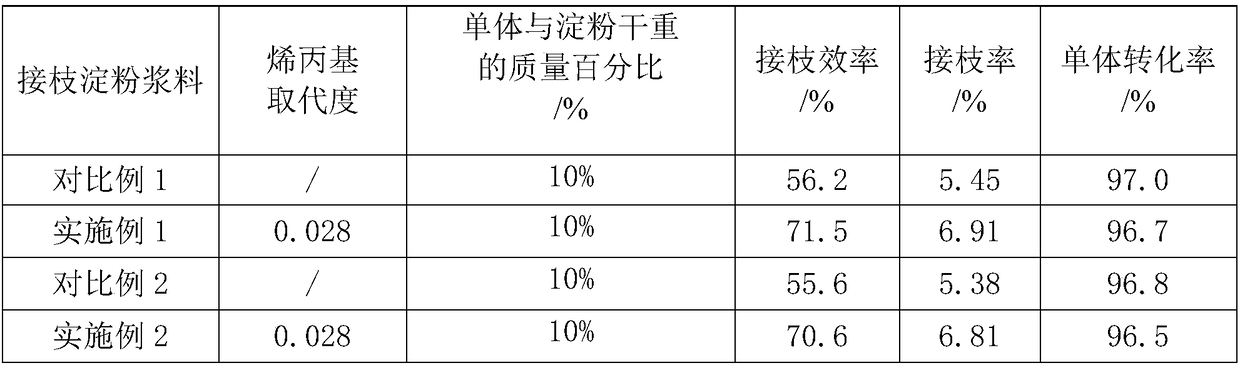

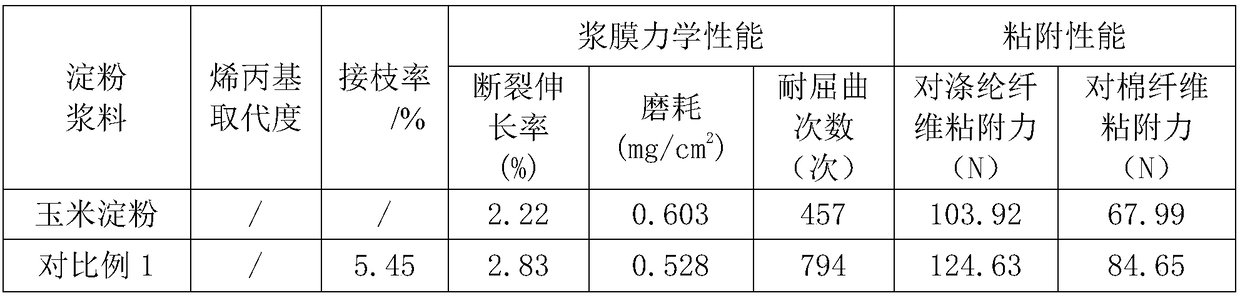

Preparation method for sulfonation modification type composite modified starch size

The invention discloses a preparation method for sulfonation modification type composite modified starch size. The preparation method comprises the following steps: carrying out cationic denaturation on starch by using a cationic etherifying agent, i.e., 3-chloro-2-hydroxypropyltrimethyl ammonium chloride, so as to prepare cation starch; then subjecting the prepared cationic starch and octenyl succinate anhydride to an esterification reaction so as to prepare cation-octenyl succinate composite modified starch; and reacting the prepared cation-octenyl succinate composite modified starch with sodium bisulfite so as to prepare the sulfonation modification type composite modified starch size. Compared with the prior art, the prepared sulfonation modification type composite modified starch size has substantially improved size film performance and enhanced adhesion on synthetic fibers like terylene, better meets requirements of sizing of warp yarns, especially sizing of synthetic fibers like terylene, and can be applied to sizing of the warp yarns of cotton, hemp, viscose, polyester / cotton, polyester / hemp, polyester / viscose and other fibers on a common warp sizing machine or high-speed warp sizing machine.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

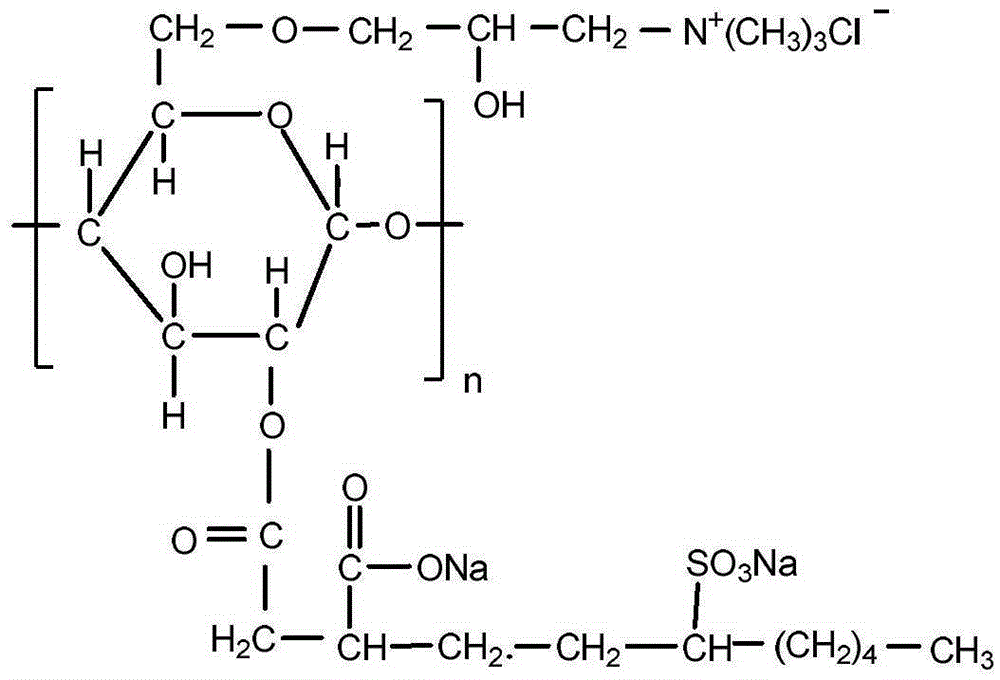

Preparation method of etherification pretreatment type quaternary ammonium cation grafted starch sizing agent

ActiveCN109485793AReduce hard and brittle defectsImprovement of hard and brittle defectsFibre typesFiberQuaternary ammonium cation

The invention provides a preparation method of an etherification pretreatment type quaternary ammonium cation grafted starch sizing agent. The preparation method comprises the following steps: by taking allyl chloride as an etherifying agent, performing etherification pretreatment on starch raw materials, and introducing allyl atomic groups containing carbon-carbon double bonds onto starch molecular chains; carrying out a graft copolymerization reaction on the allyl etherification pretreatment starch containing the carbon-carbon double bonds and a quaternary ammonium cation monomer in an aqueous phase non-gelatinized state in the presence of an initiator, thereby obtaining the etherification pretreatment type quaternary ammonium cation grafted starch sizing agent. Compared with the prior art, the starch sizing agent prepared by the method disclosed by the invention inherits the biodegradability of starch, the defects that the starch size film is hard and brittle and insufficient in fiber adhesion can be further improved, the grafting efficiency can be improved, and the warp sizing requirement is well met.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

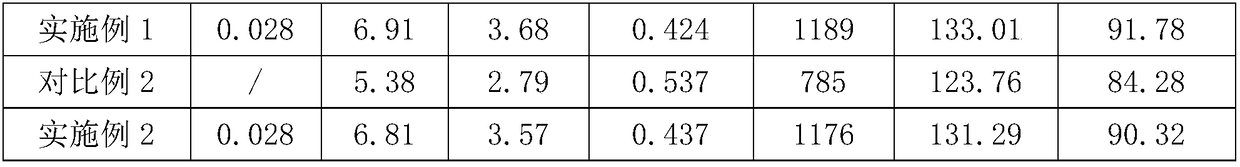

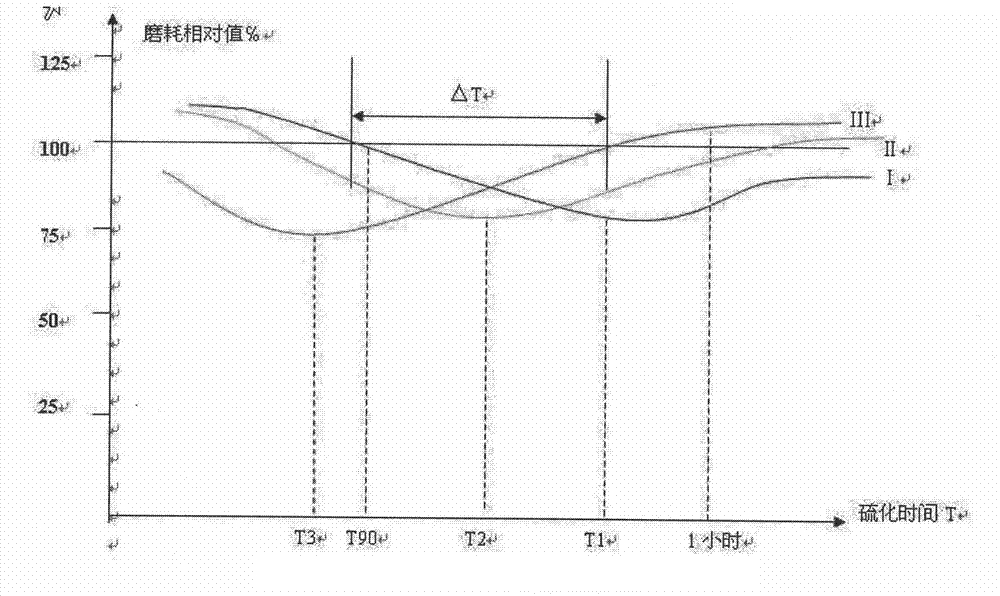

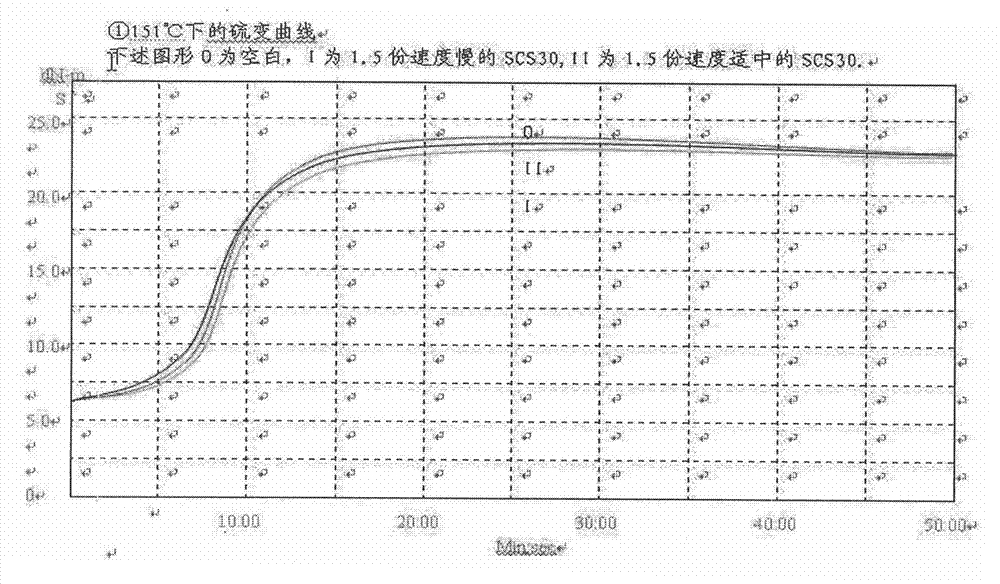

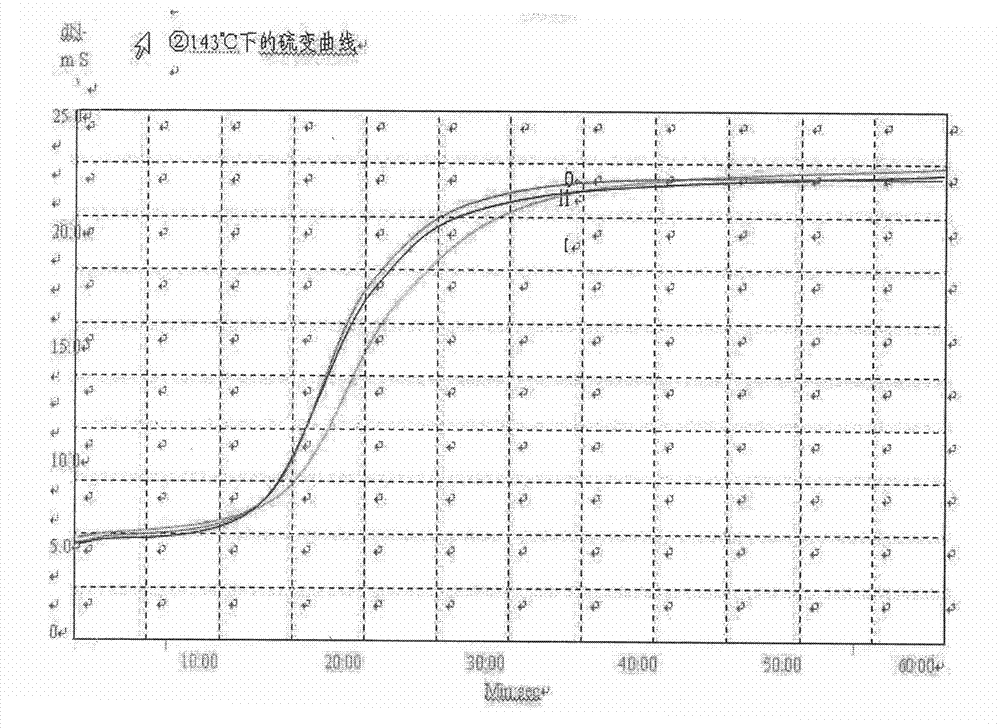

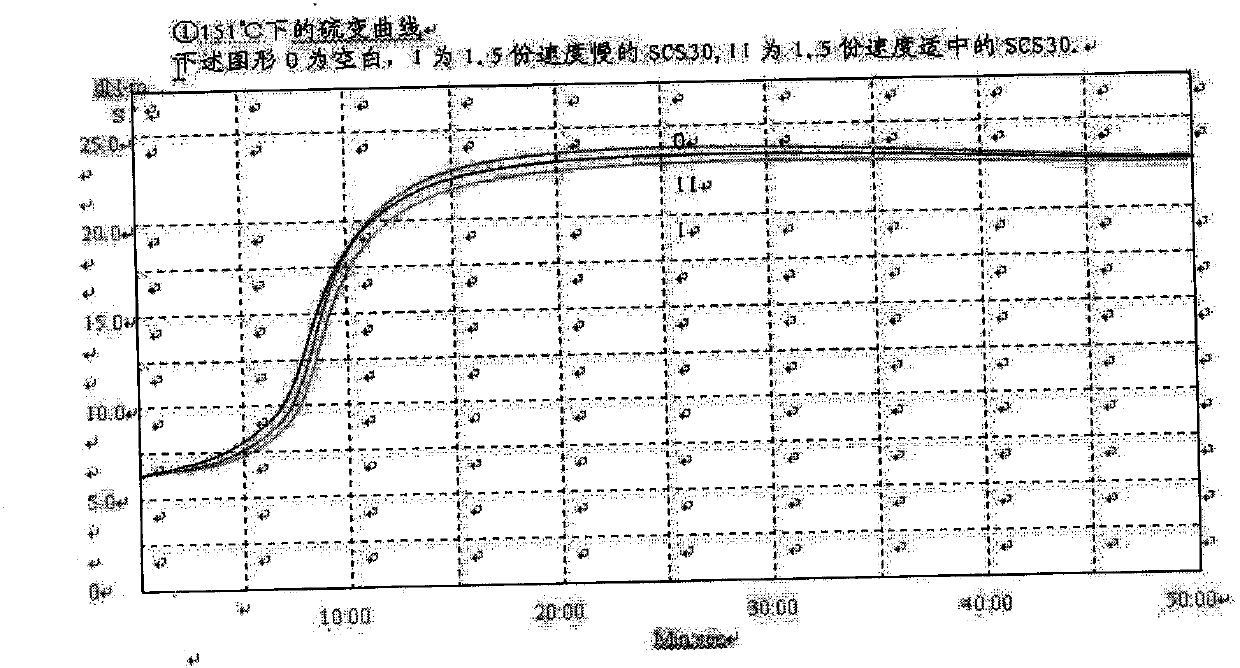

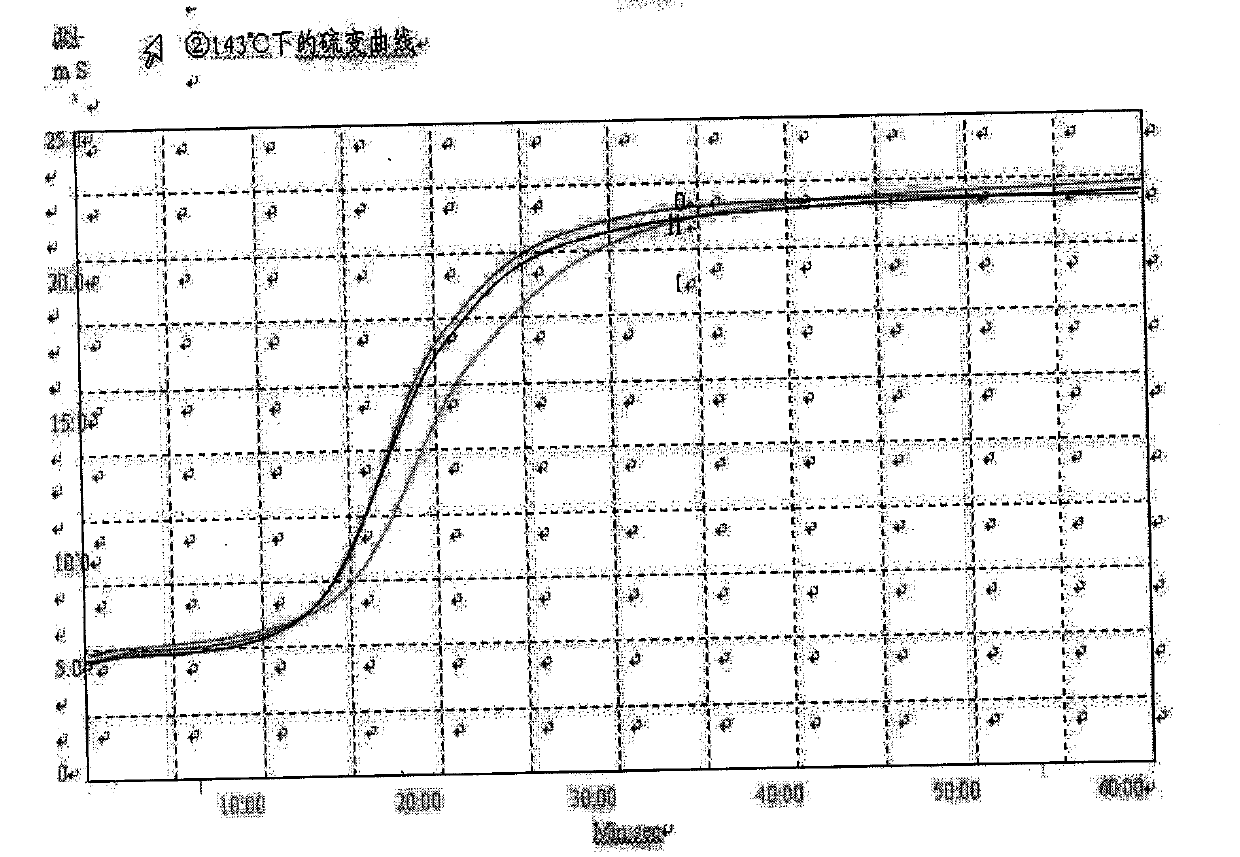

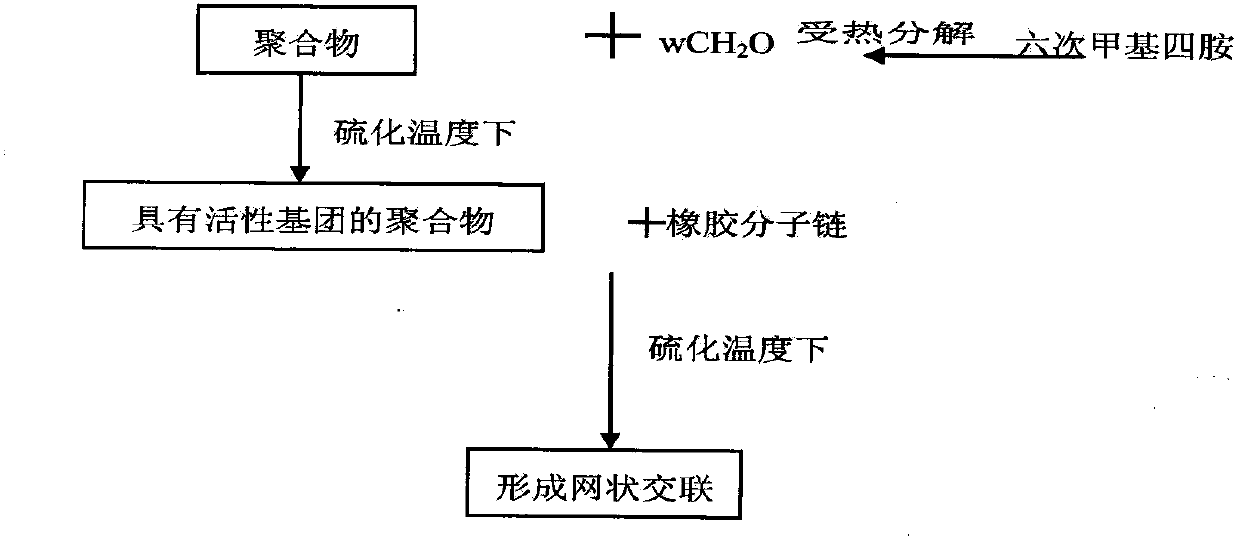

Rubber homogenization wear-resistant agent

The invention relates to a rubber homogenization wear-resistant agent. According to a formula, the rubber homogenization wear-resistant agent comprises, by weight: 30 of a urea-aldehyde acid sodium polymer, 12 of hexamethylenetetramine, and 2.5 of NH4CL. Preferably, the rubber homogenization wear-resistant agent can be added with 15 of octadecanol, 20 of white carbon black, and 20 of a plasticizer. The rubber homogenization wear-resistant agent creatively can promote uniform dispersion of high viscosity rubber and the additives, and can well reach the effects of solubilizing, wear resisting, and wetting, etc. The raw materials and the formed product are compatible with rubber, and do not get in the way of rubber products. The rubber homogenization wear-resistant agent has easily available raw materials, a low cost and economical efficiency. During sulfidation of rubber, a cross-linking effect can be generated, and a new sulfidation network can be formed, thus reaching the purpose of modification. The rubber homogenization wear-resistant agent provided in the invention can reduce wear by 13-24%.

Owner:盛柏松

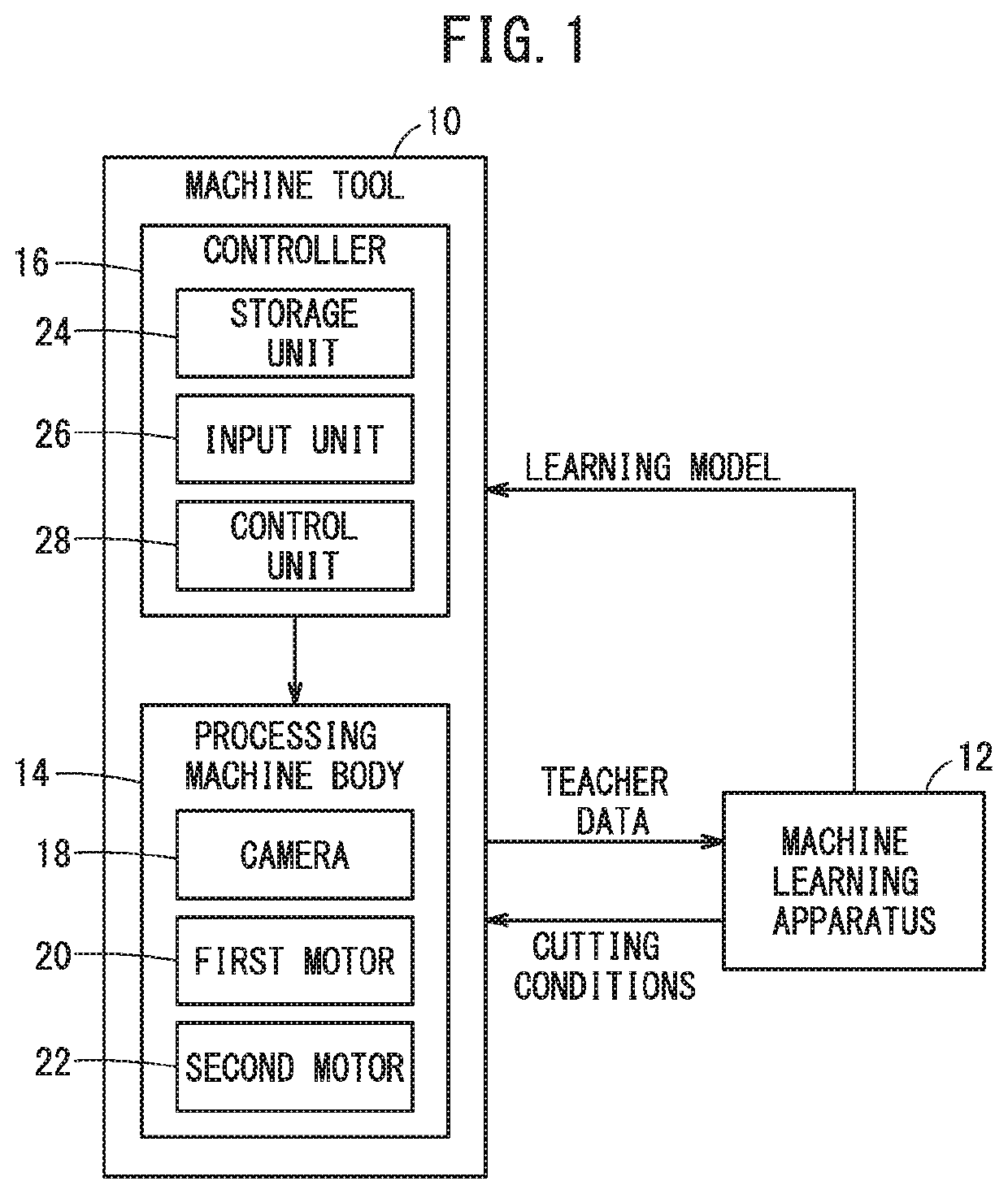

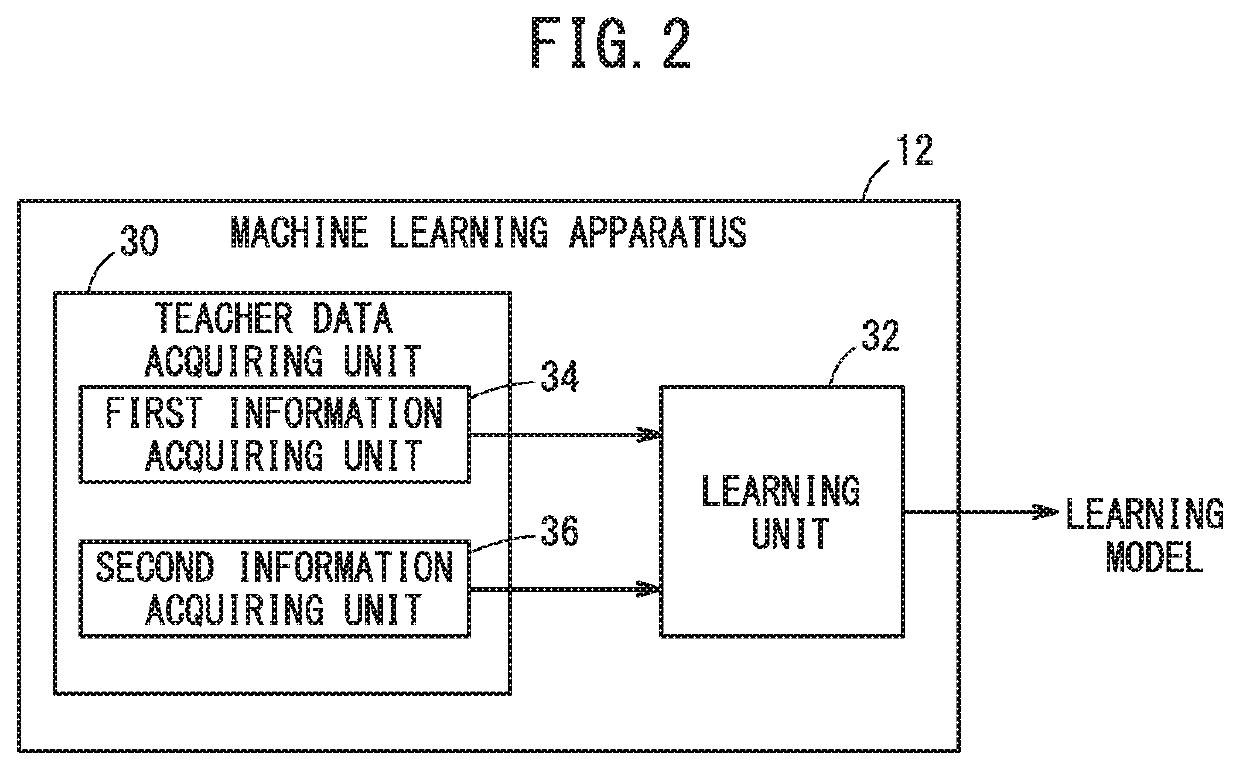

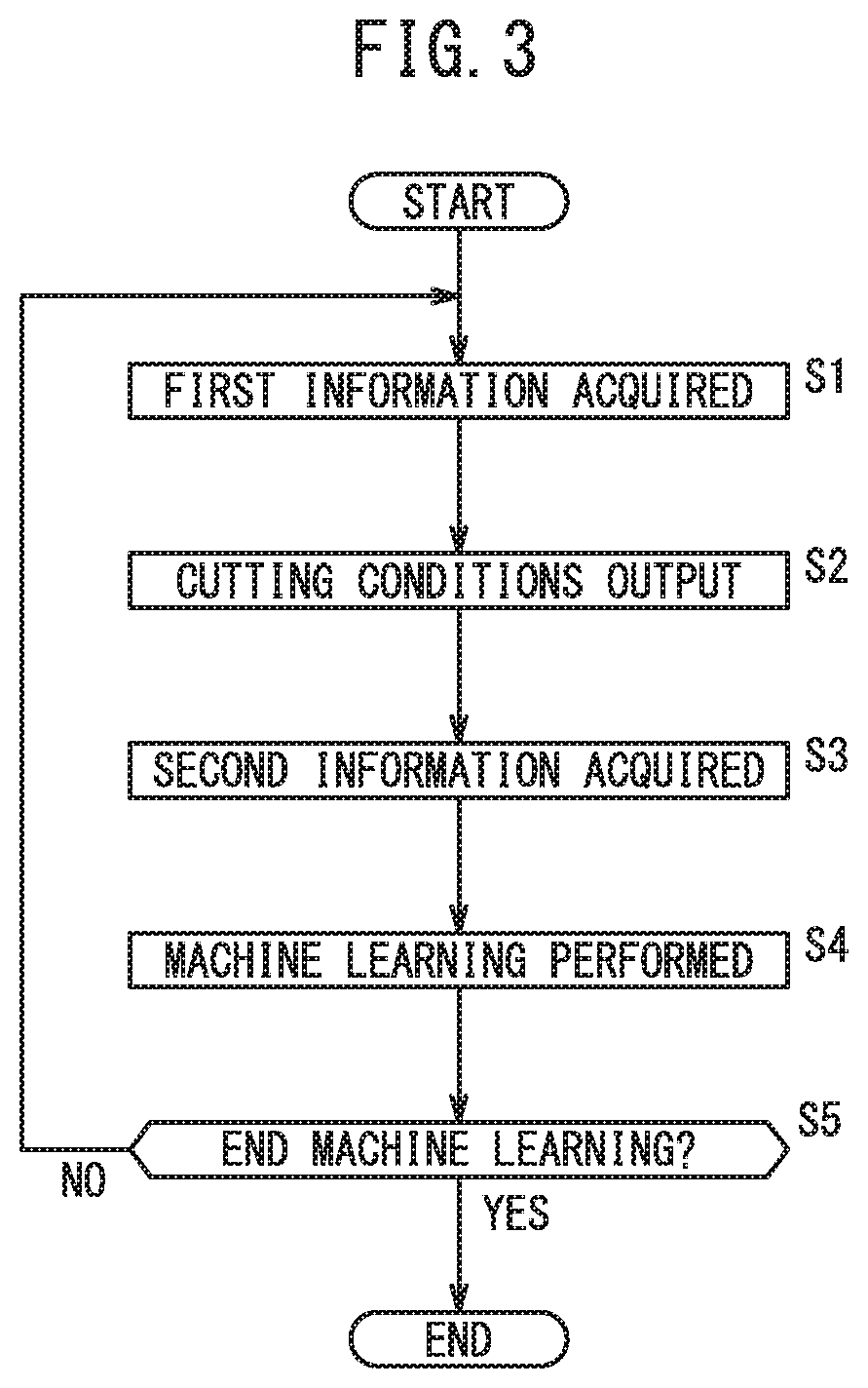

Machine learning apparatus, controller, generation method, and control method

ActiveUS20210080922A1Wear outKeep for a long timeImage analysisComputer controlLearning unitControl engineering

A machine learning apparatus includes a first information acquiring unit that acquires first information including at least one of a shape of a workpiece, a material of the workpiece, a cutting path of a cutting process, a type of a tool, and an amount of wear of the tool; a second information acquiring unit that acquires second information correlated with an evaluation of a burr occurring on the workpiece due to the cutting process; and a learning unit that executes learning processing using a plurality of pieces of the first information and a plurality of pieces of the second information, and generates a learning model that outputs a cutting condition, according to another piece of first information that is different from the plurality of pieces of first information.

Owner:FANUC LTD

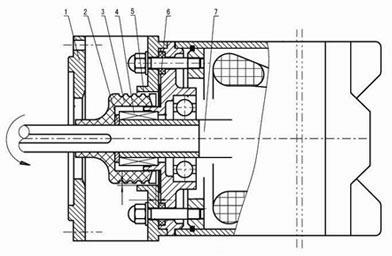

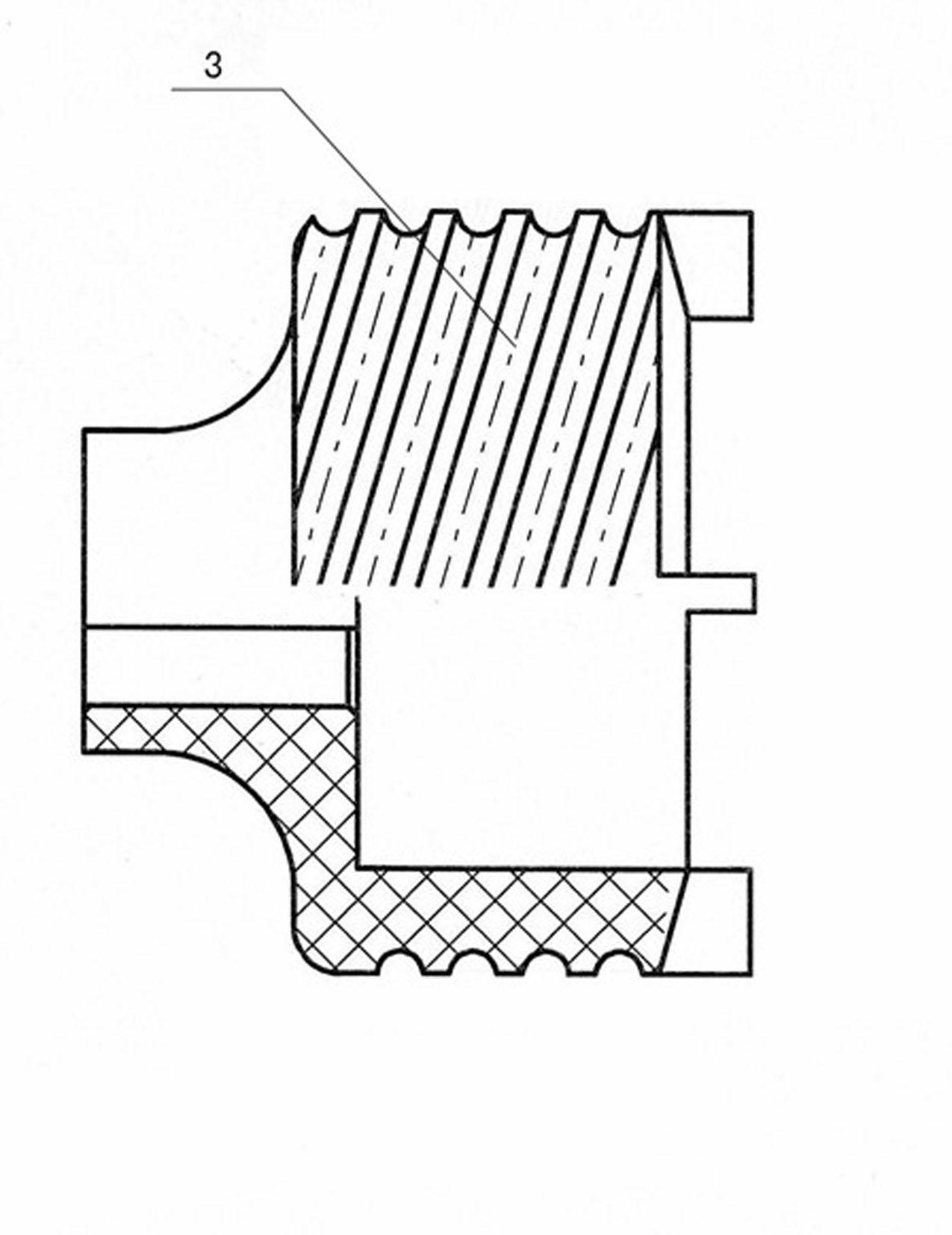

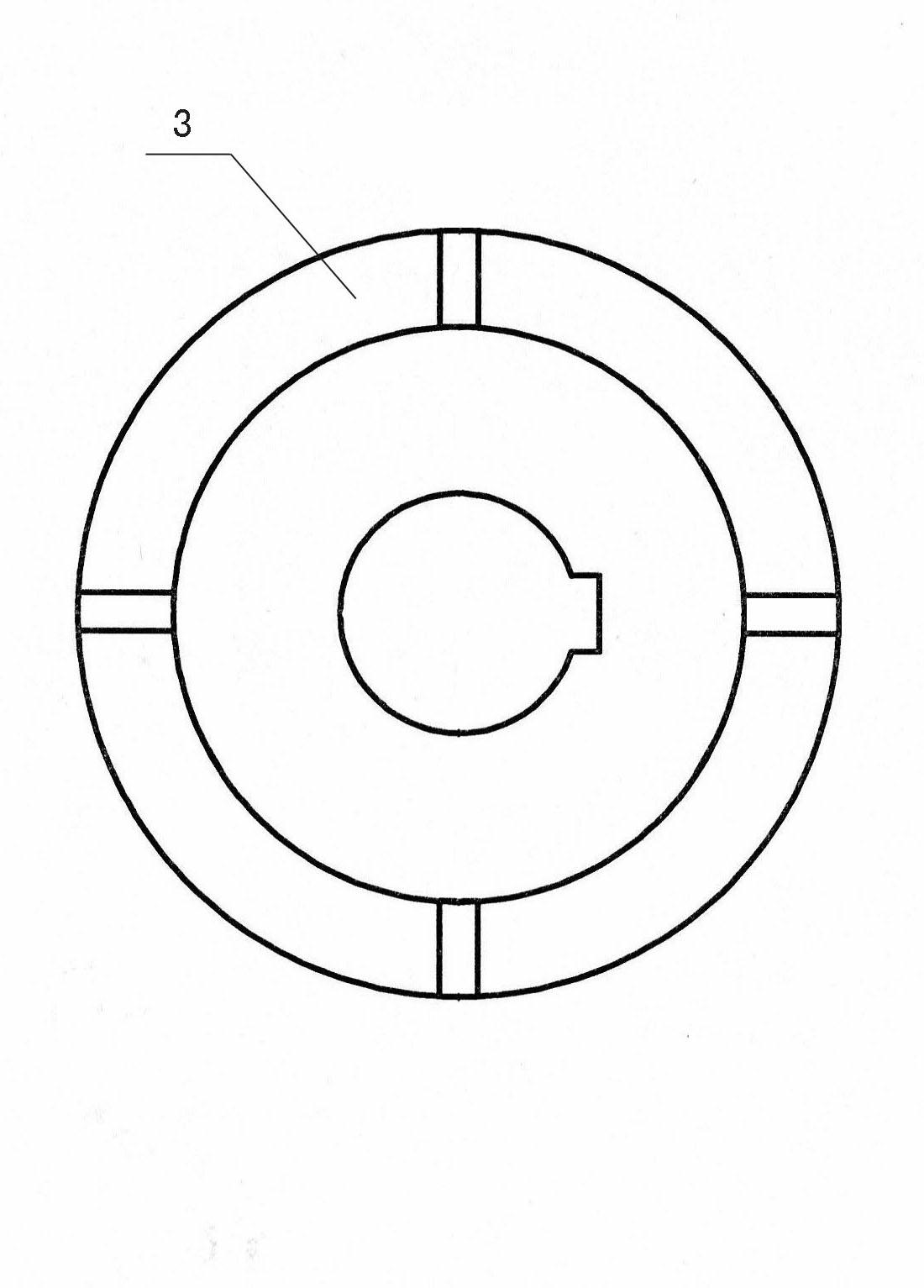

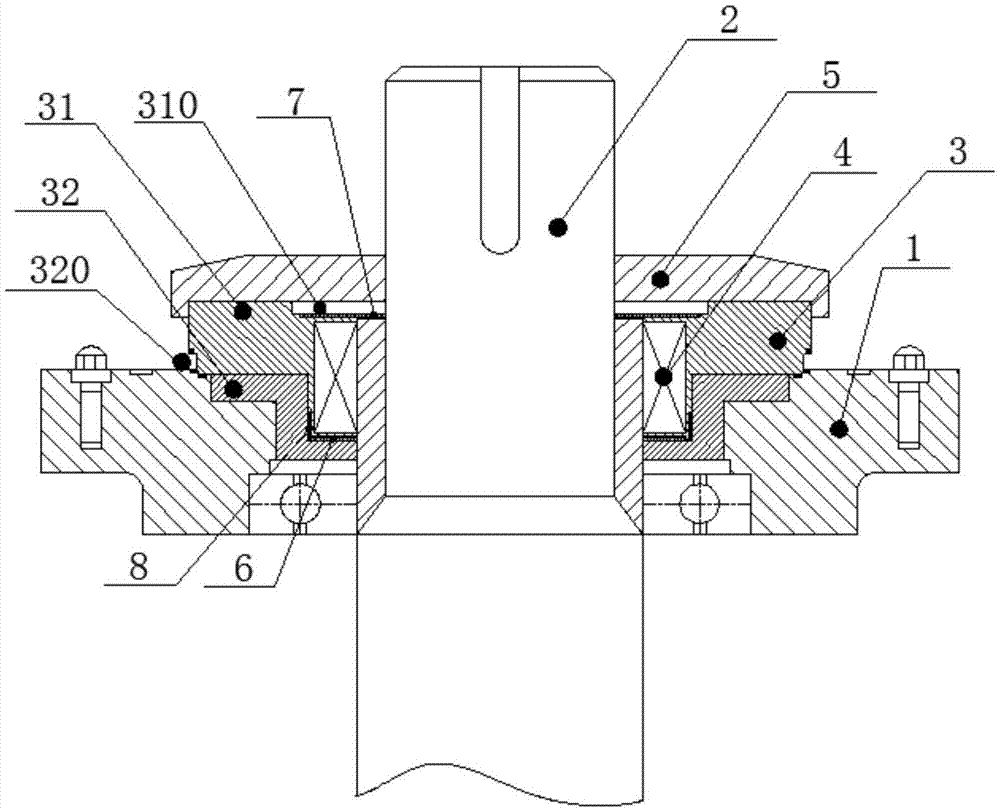

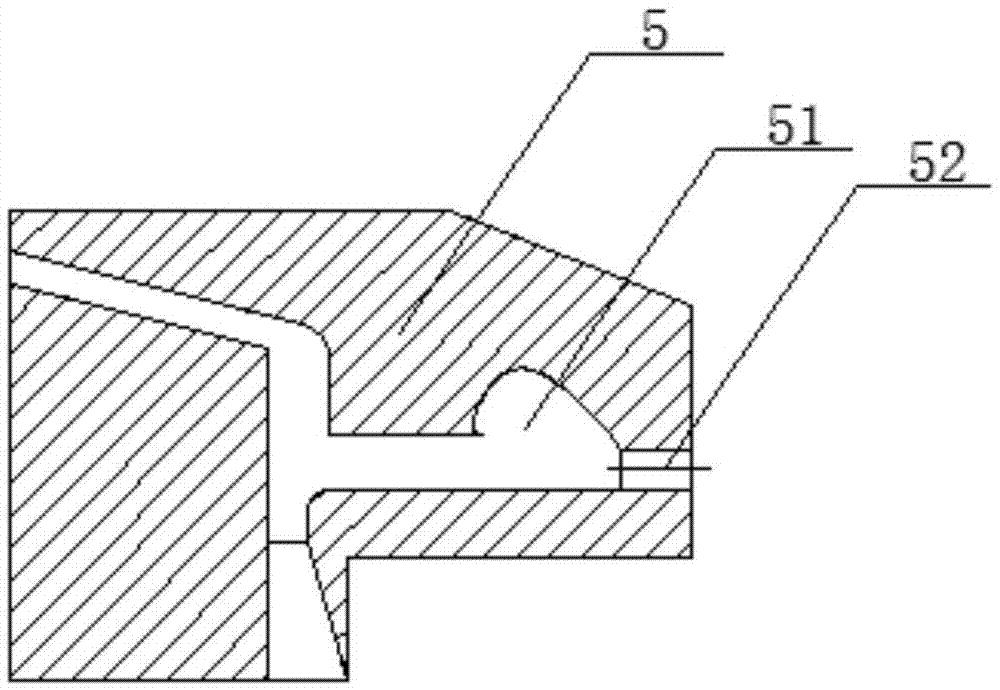

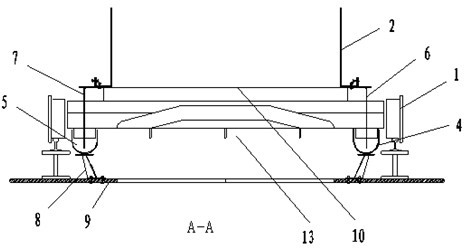

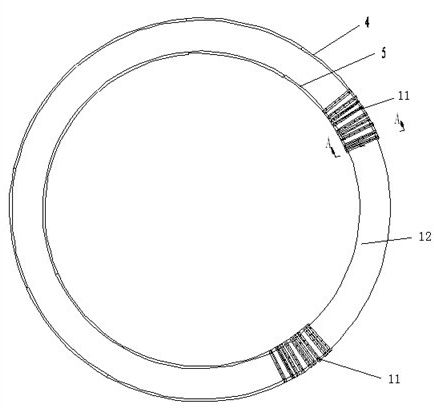

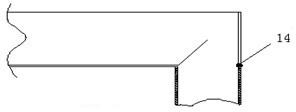

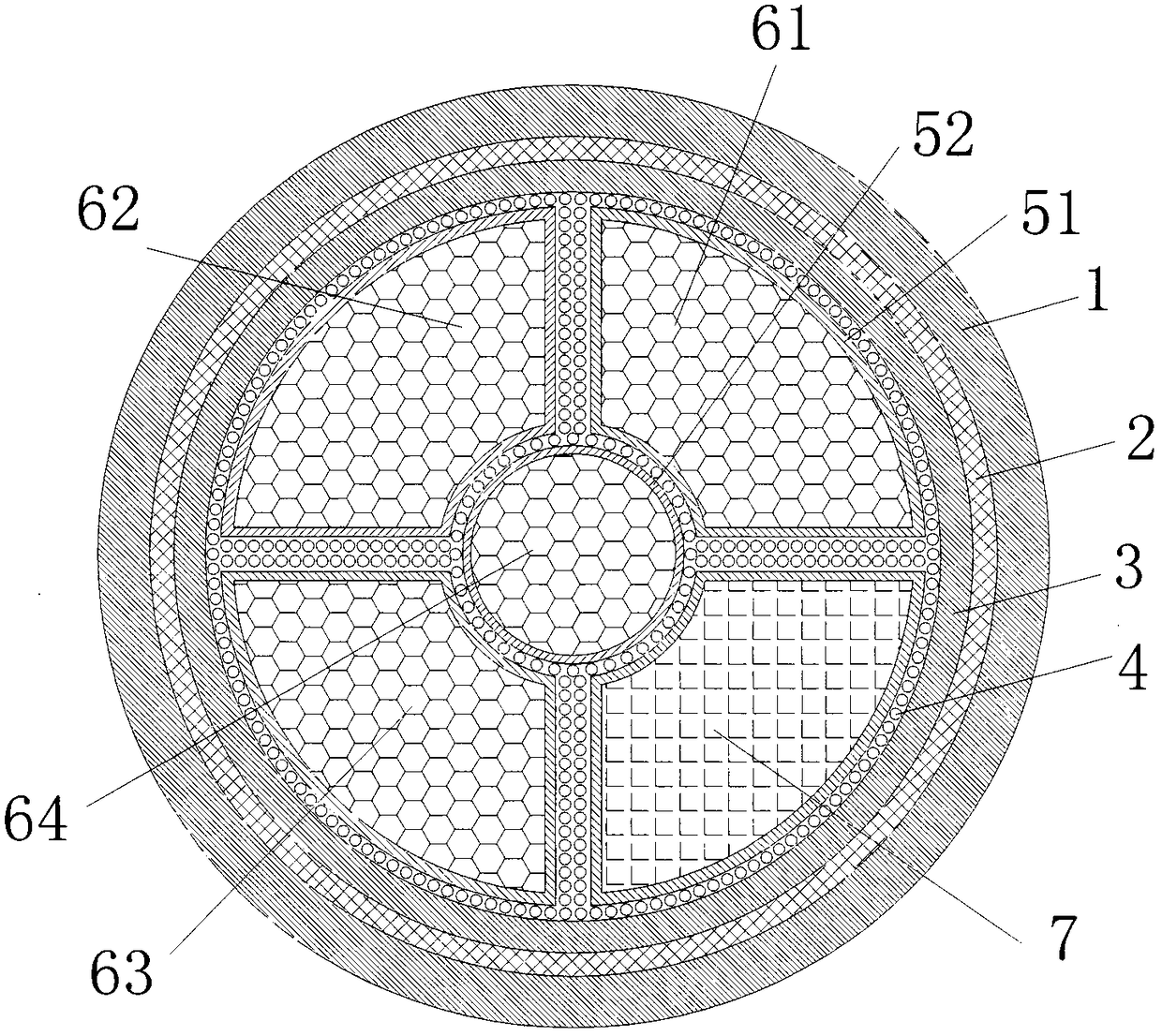

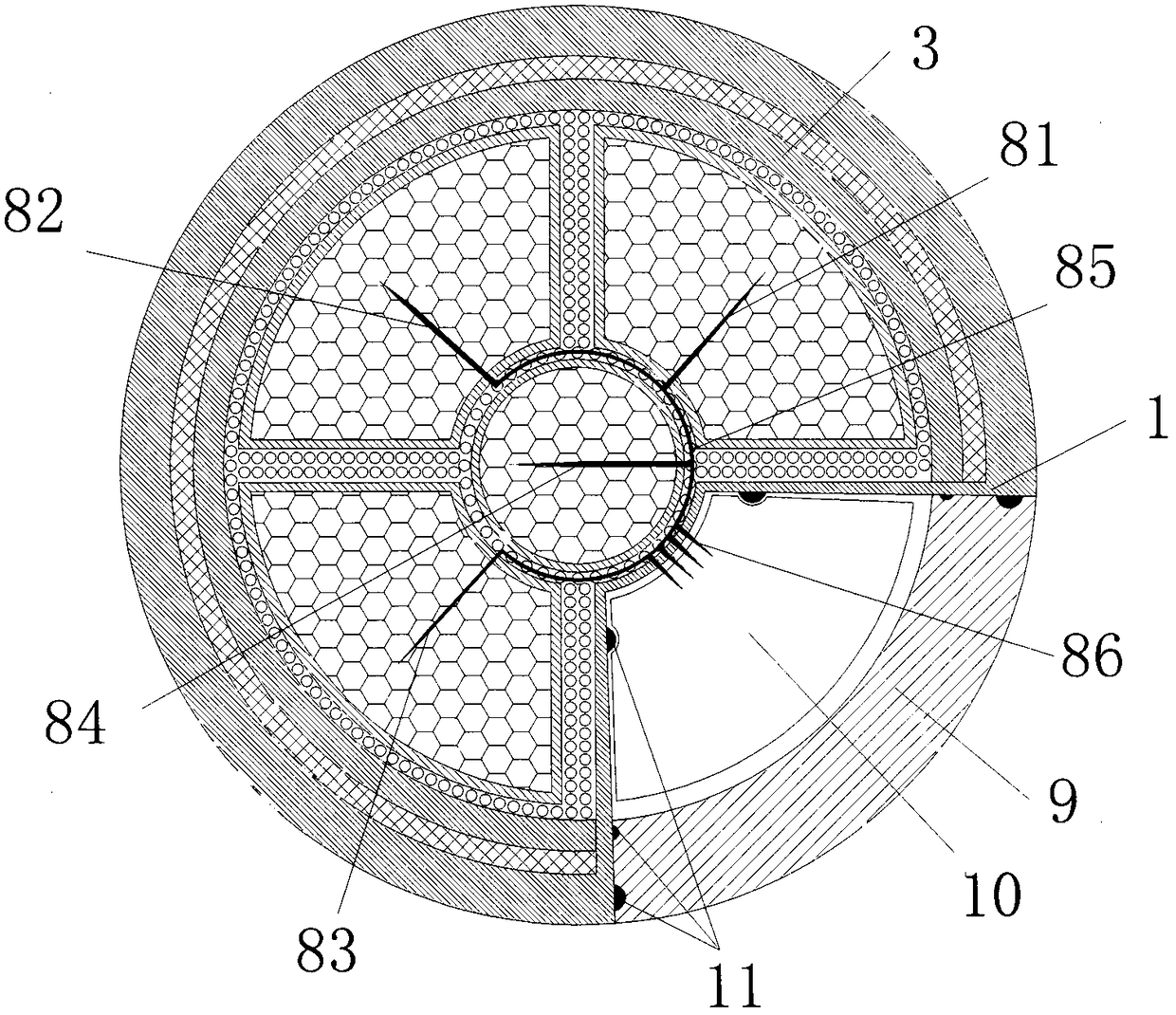

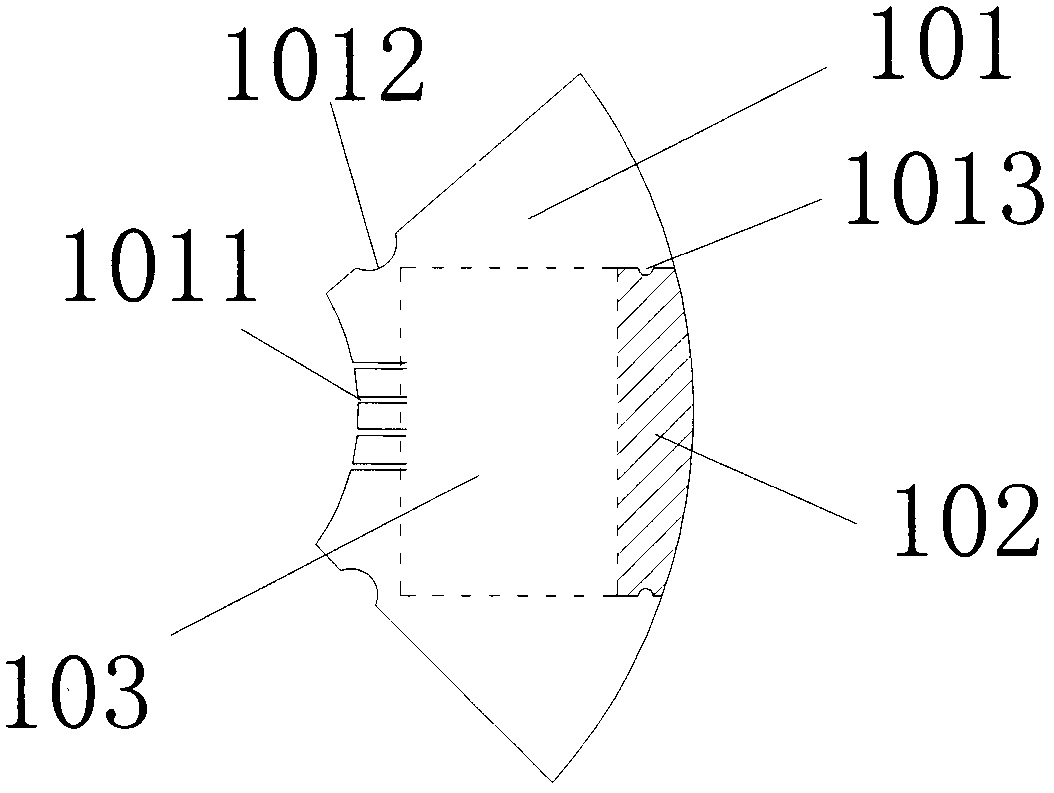

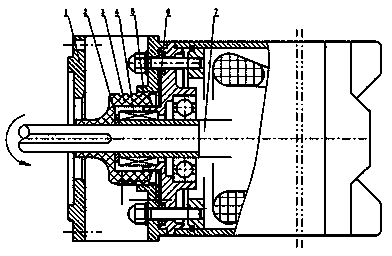

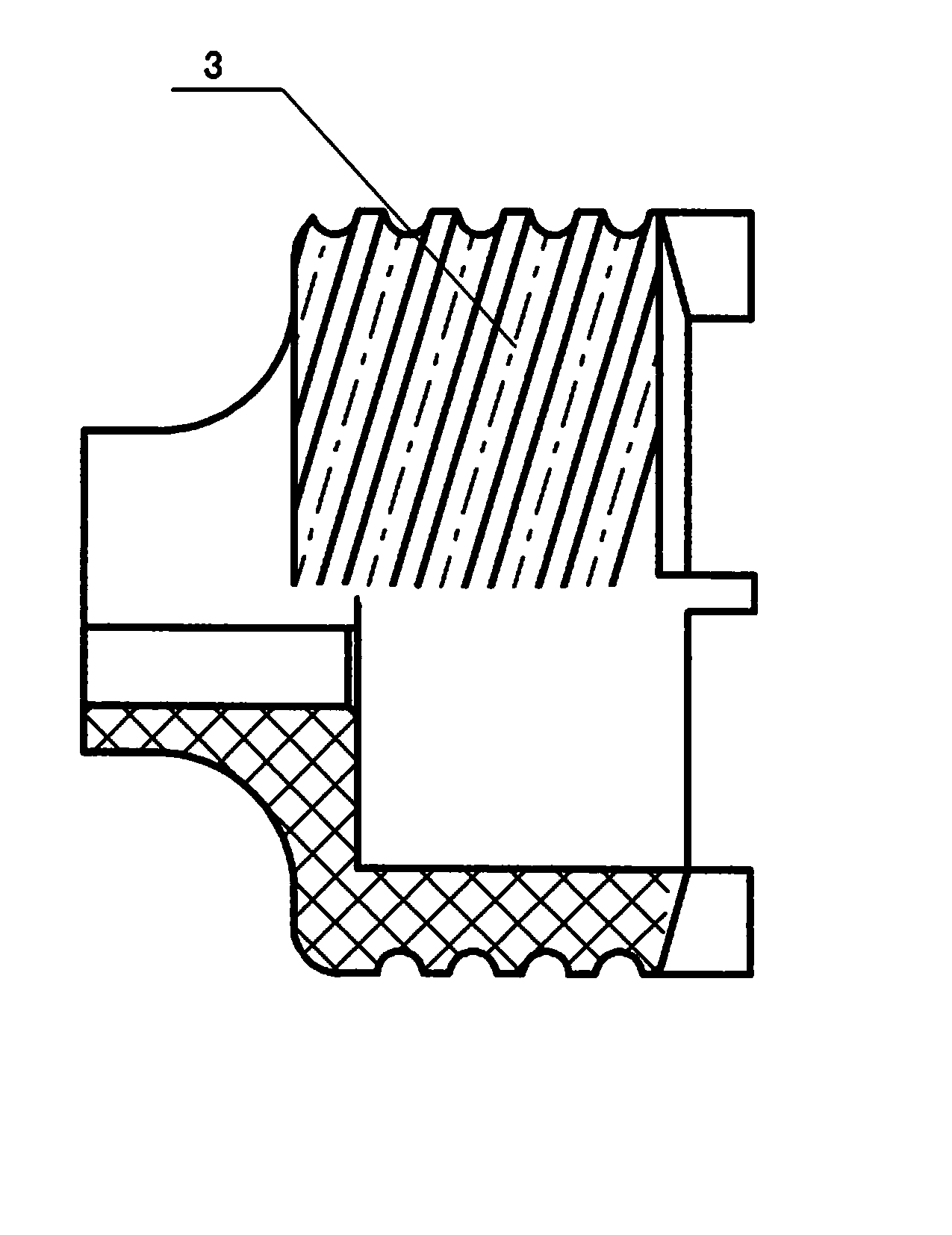

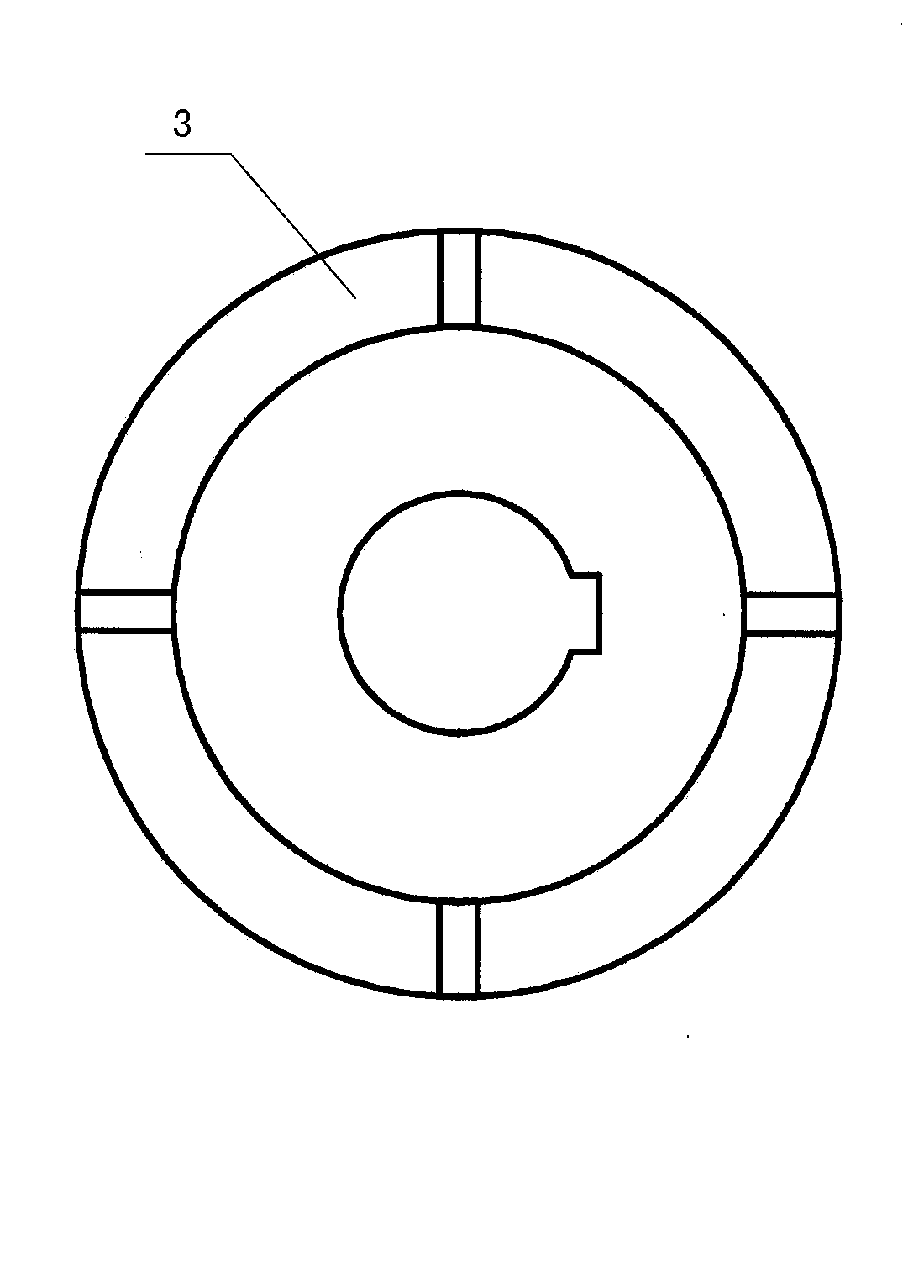

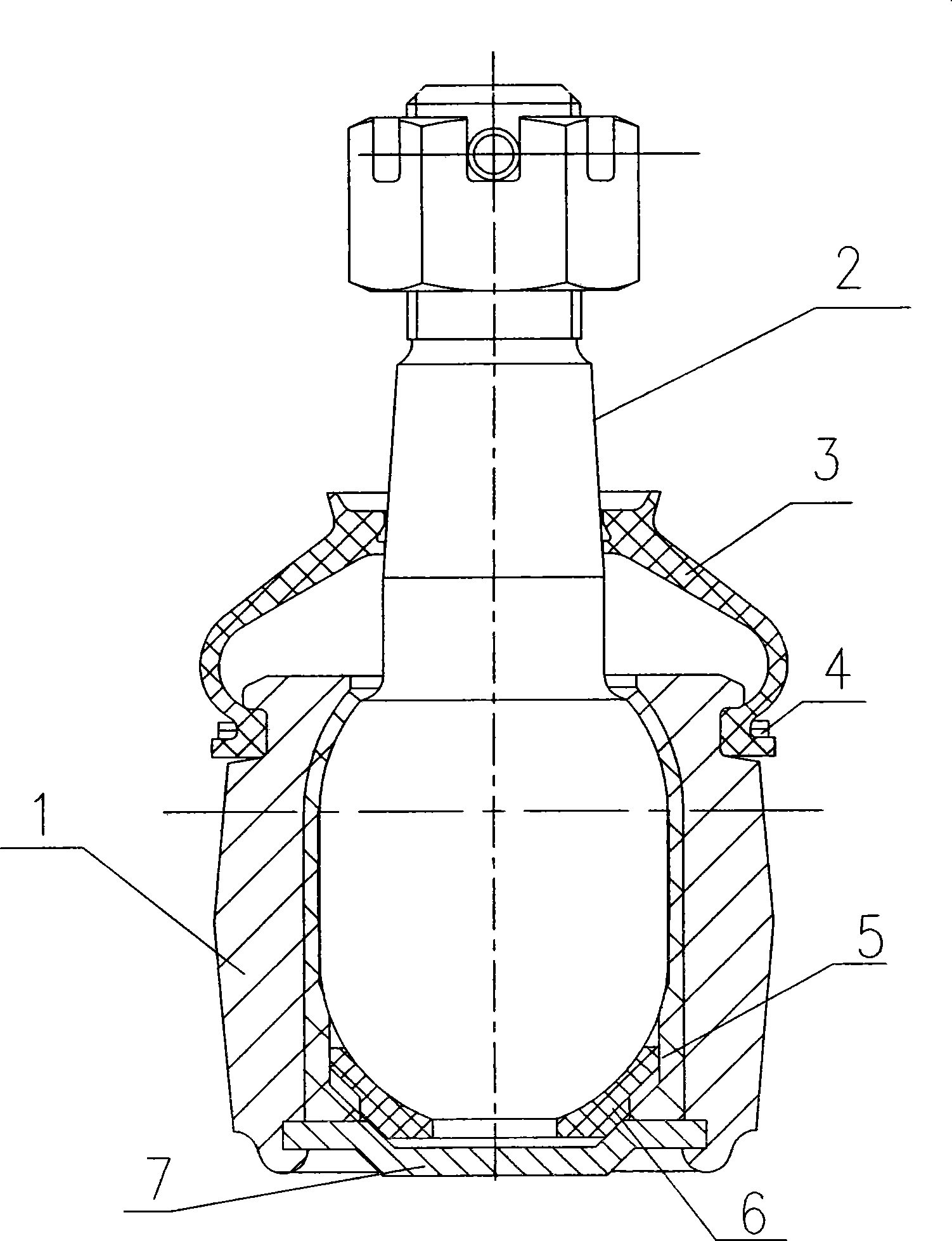

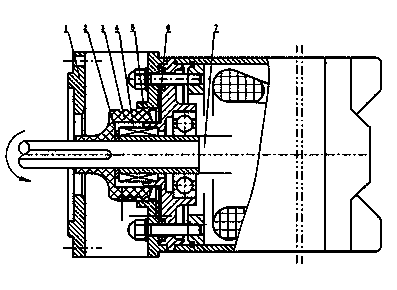

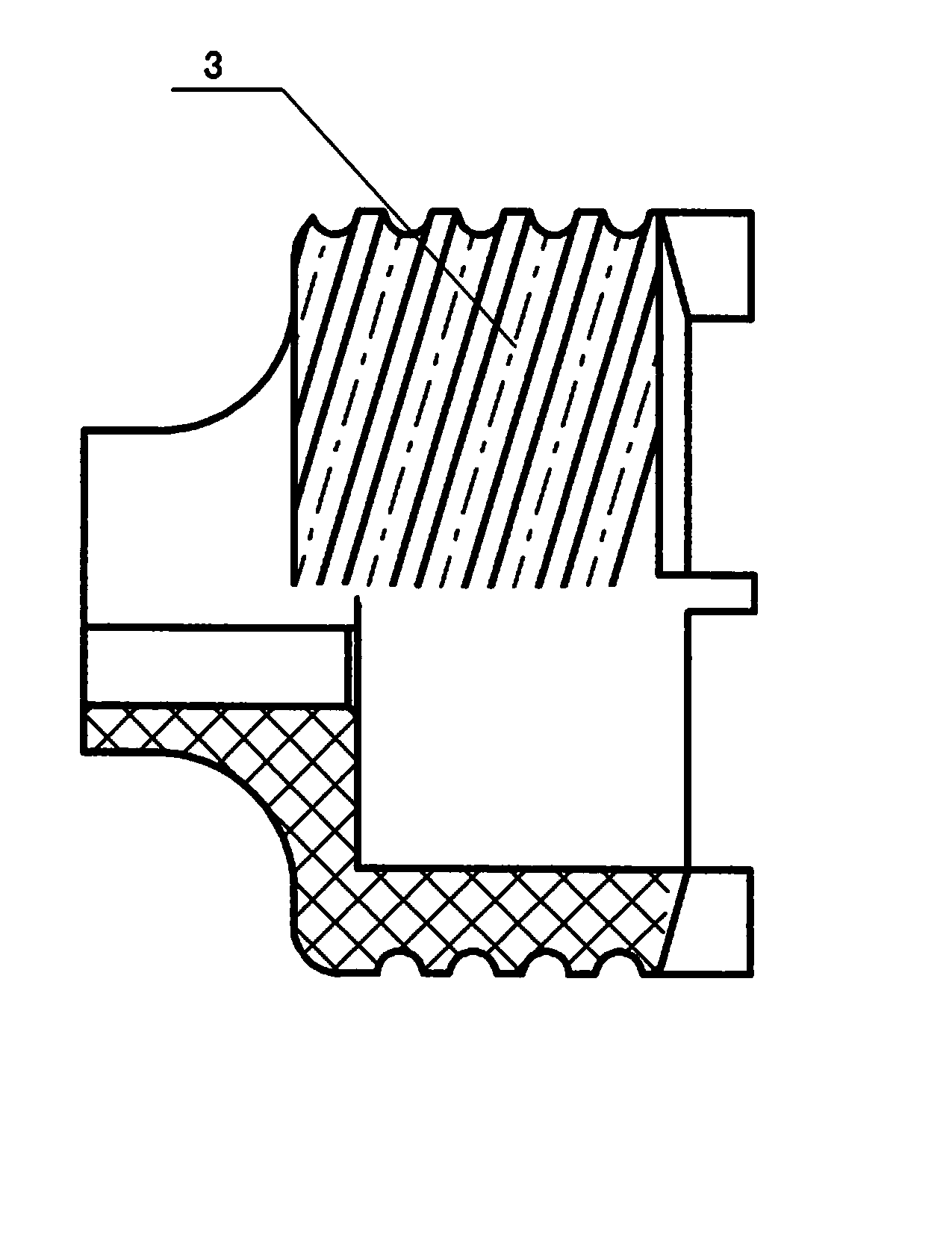

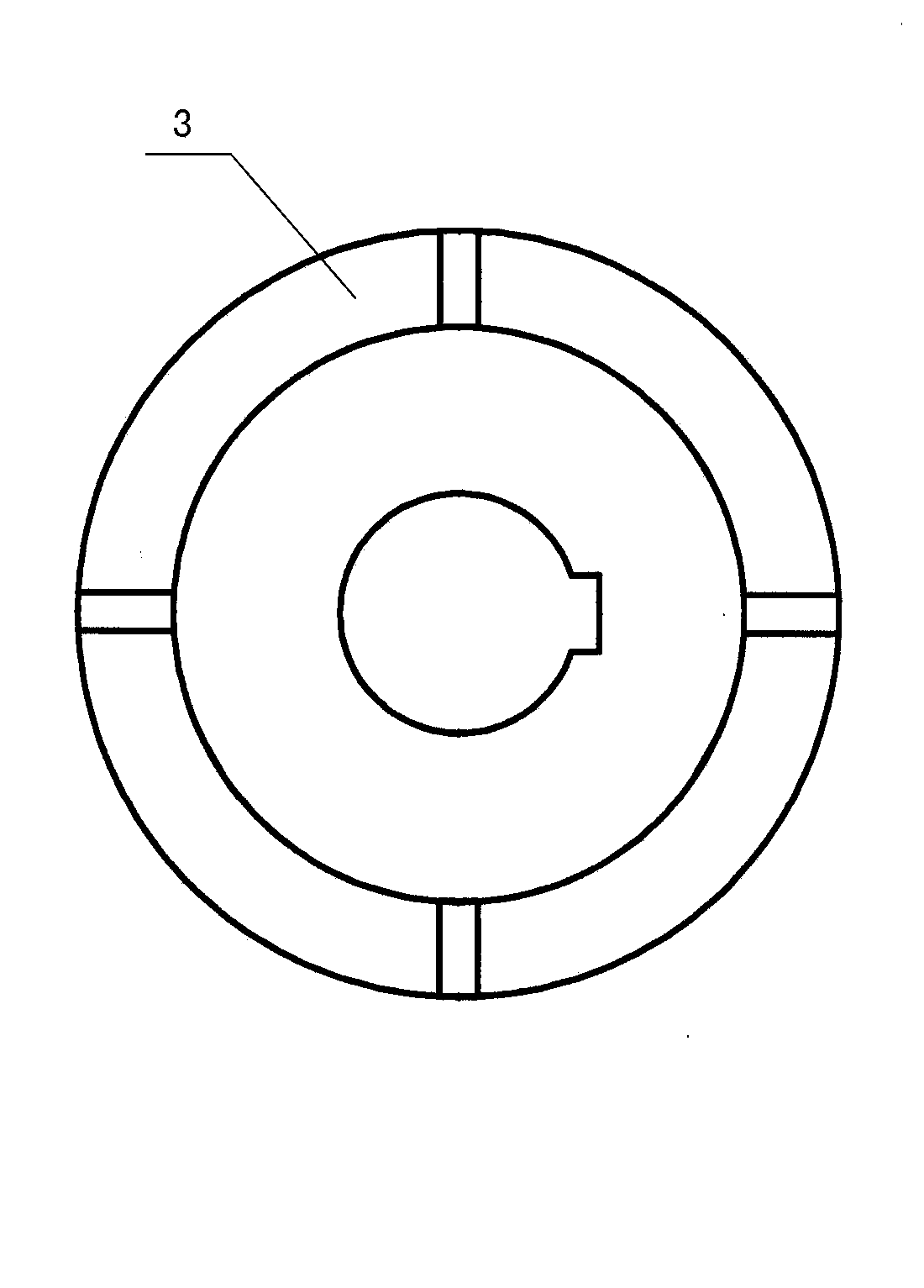

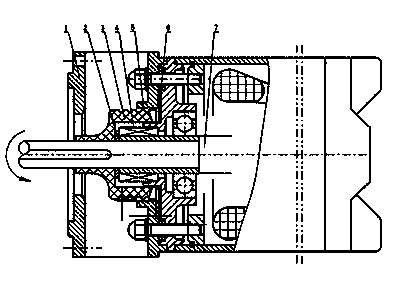

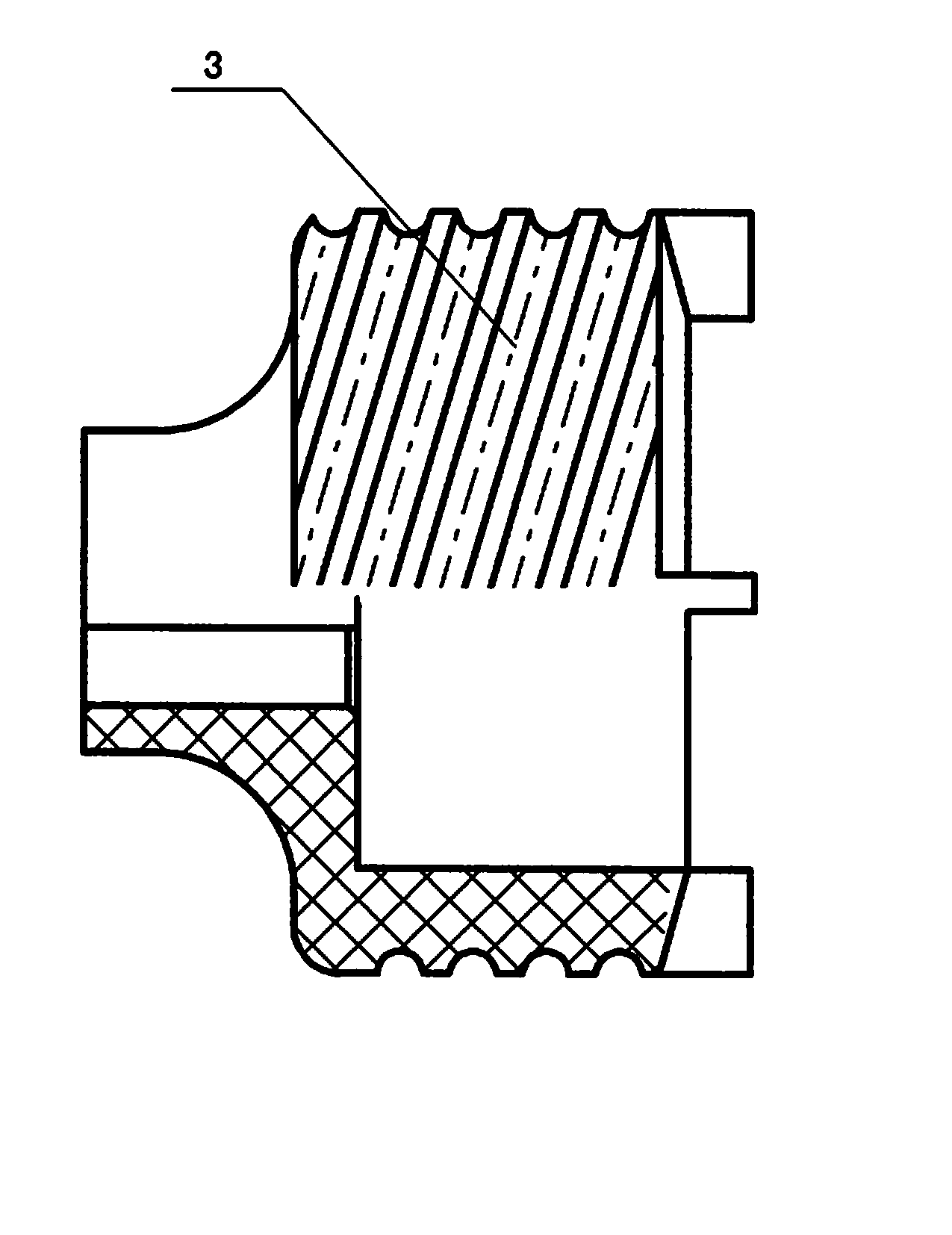

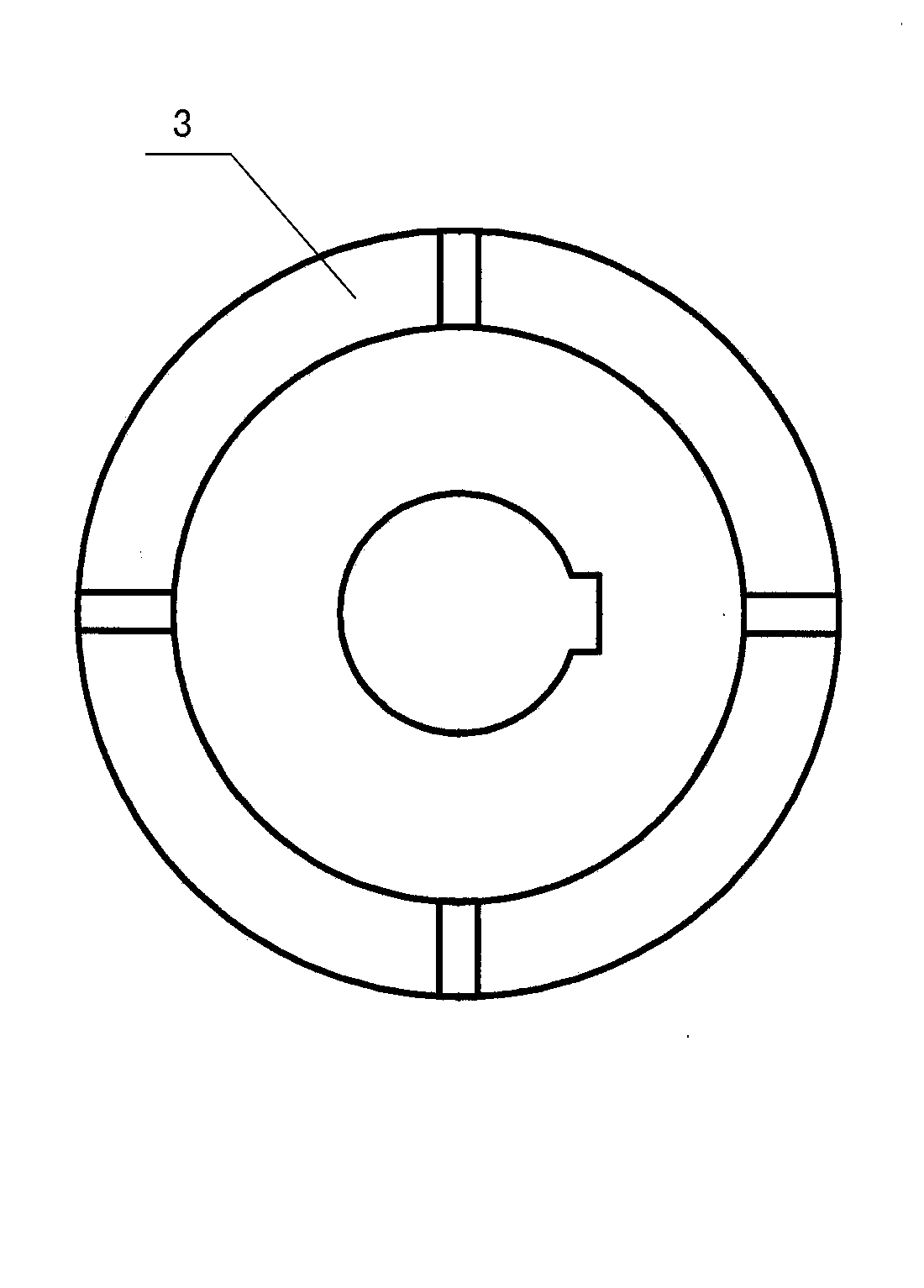

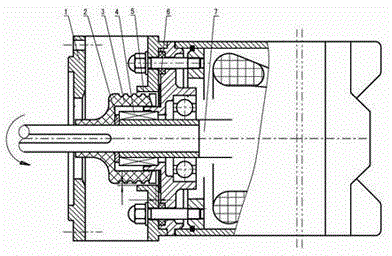

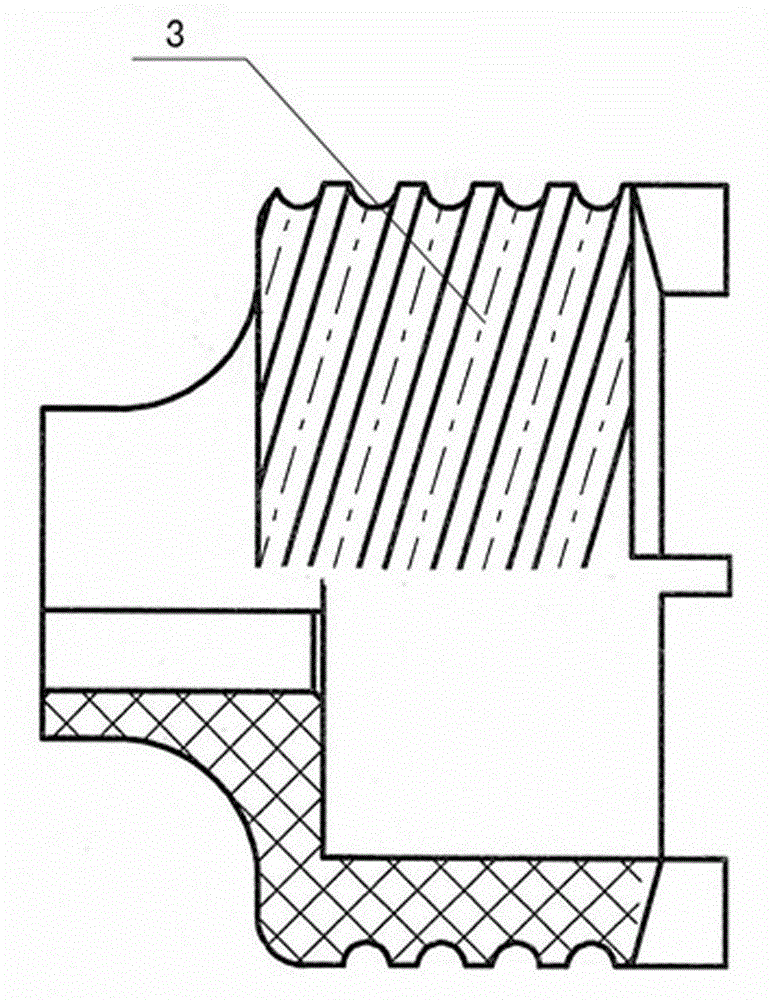

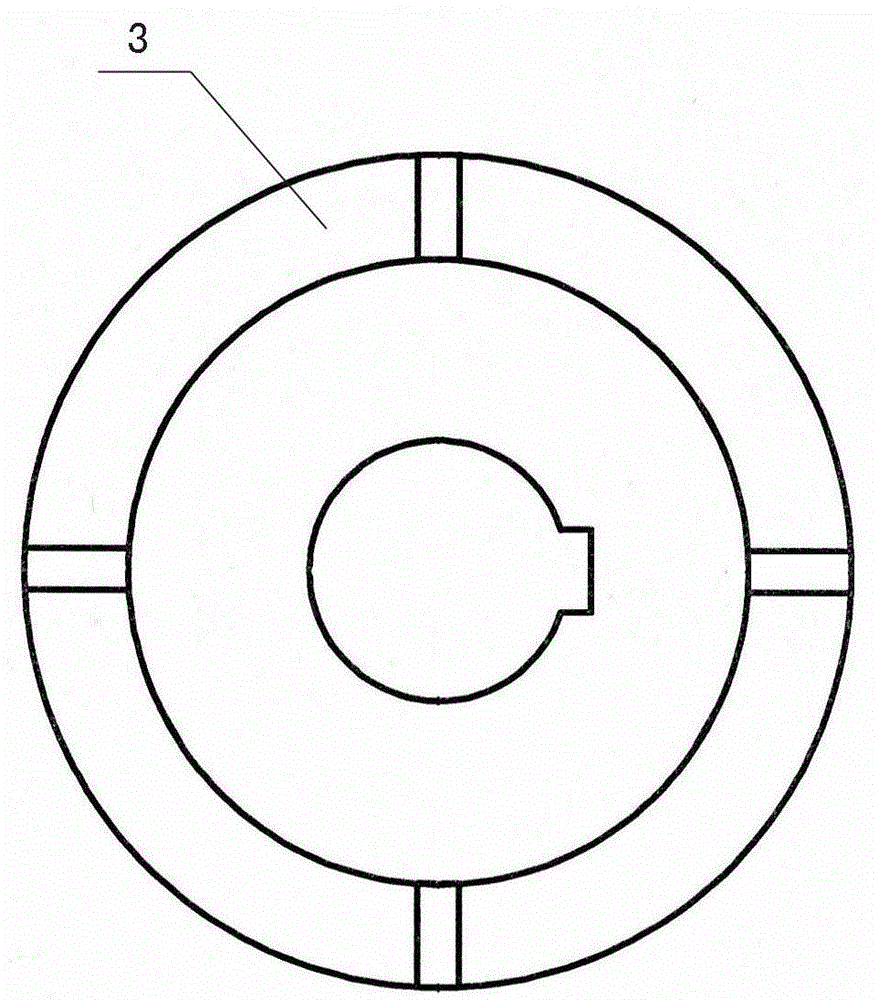

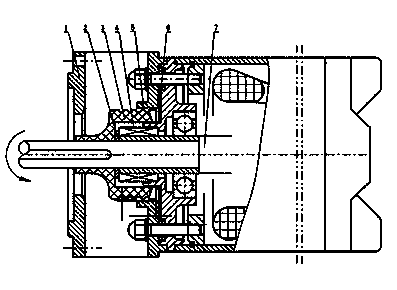

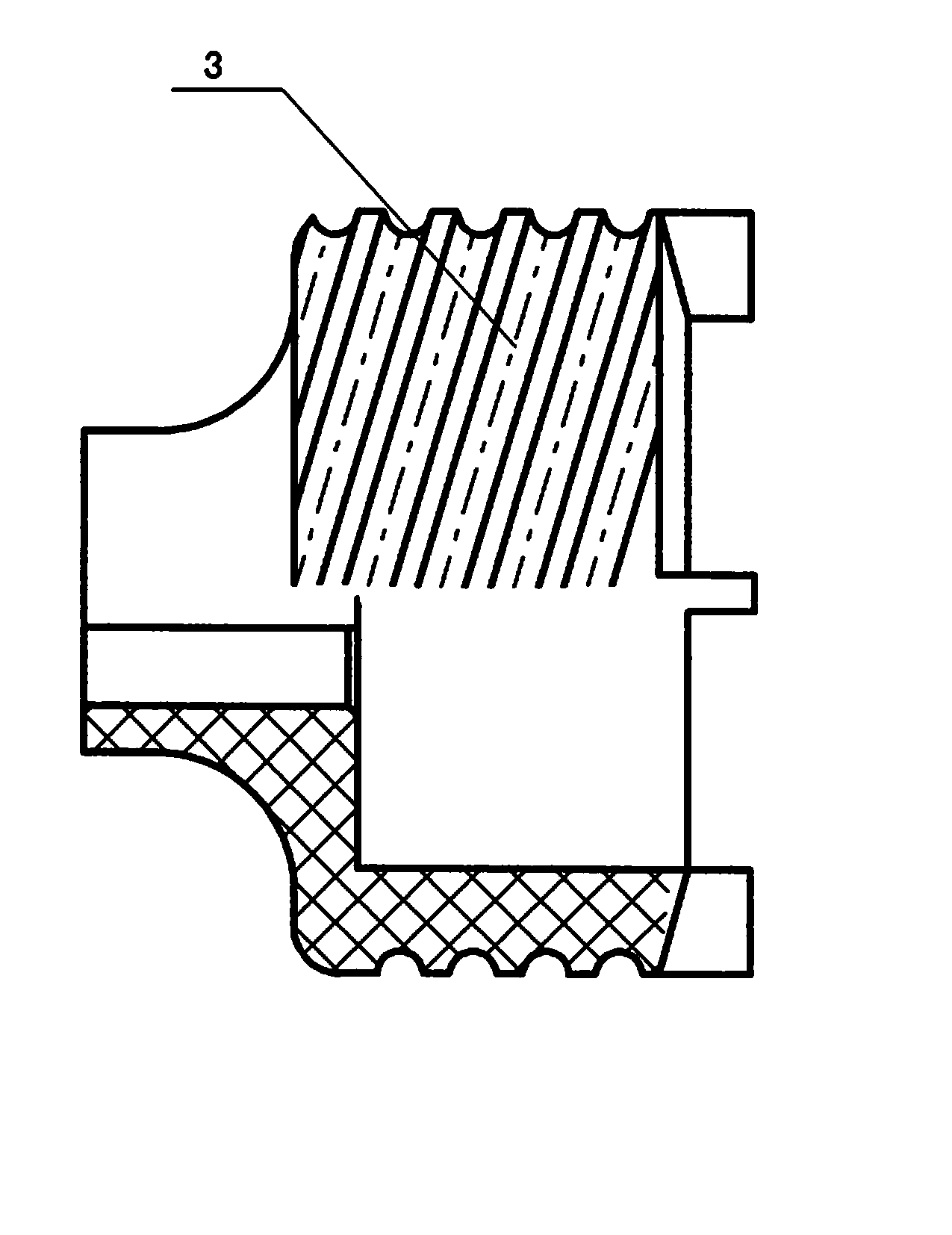

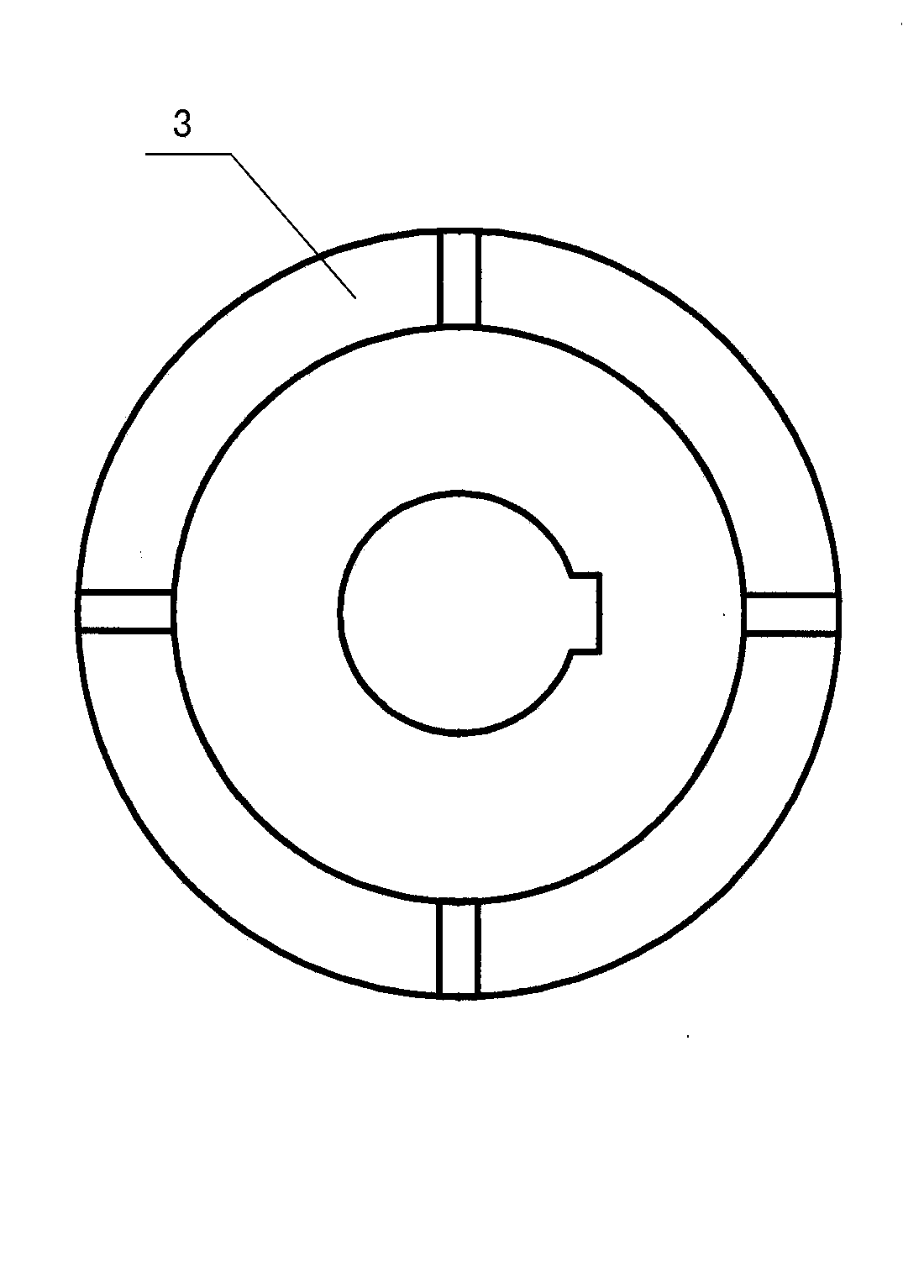

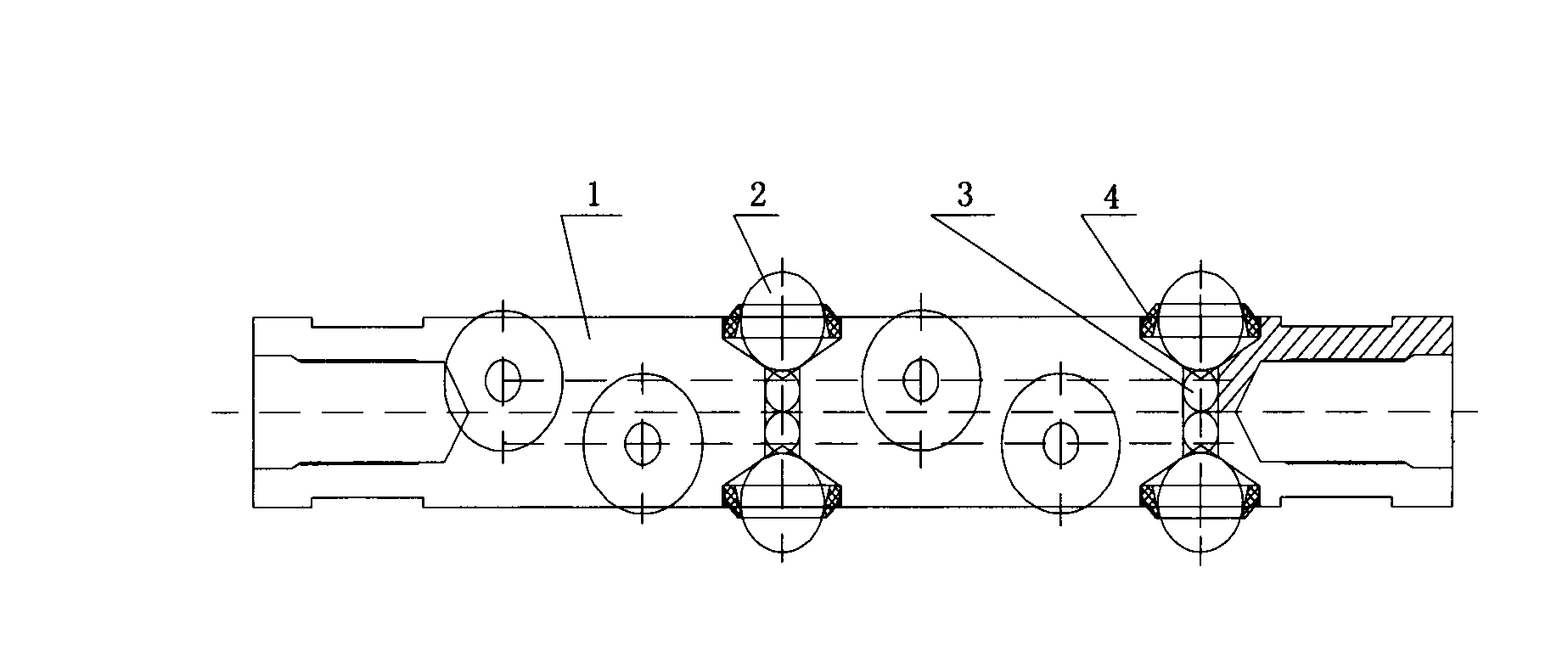

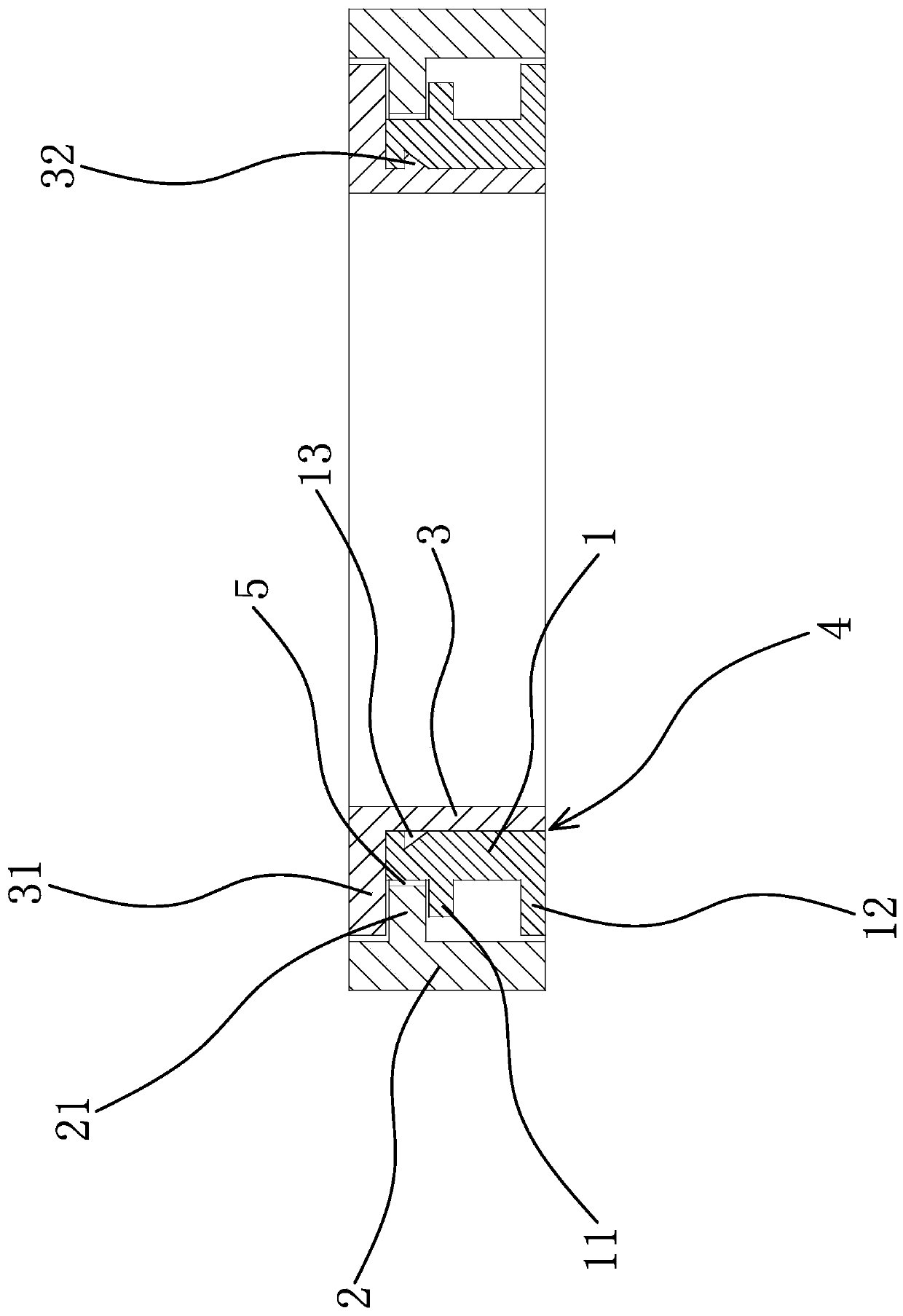

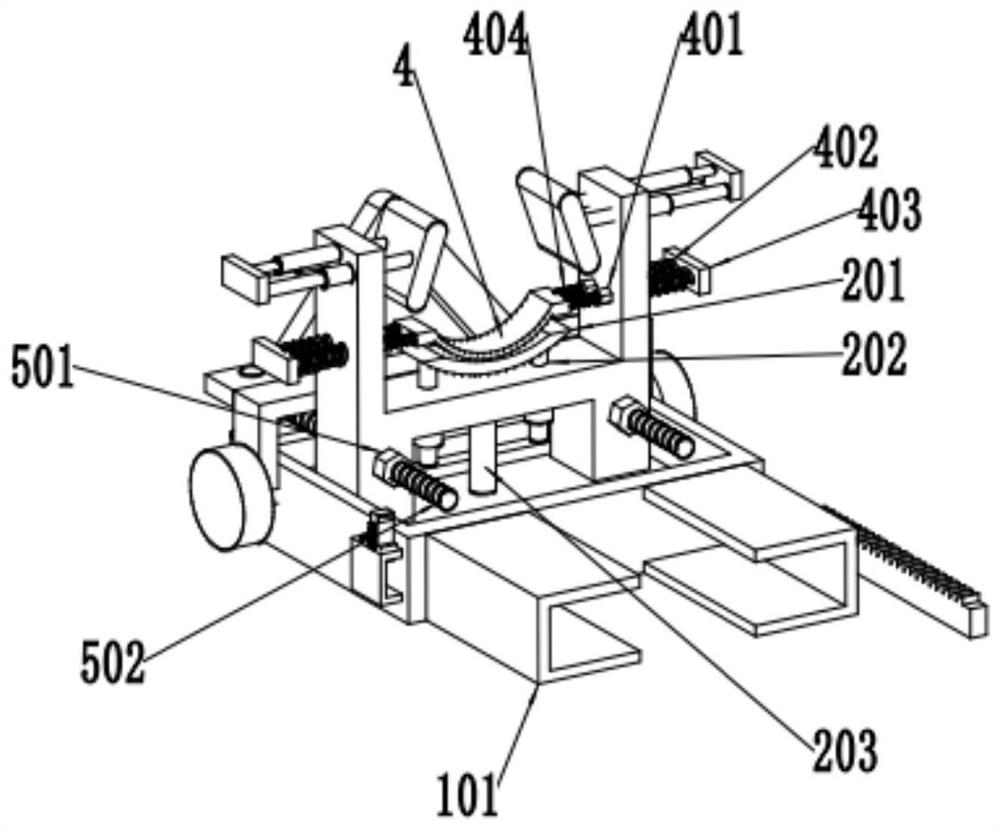

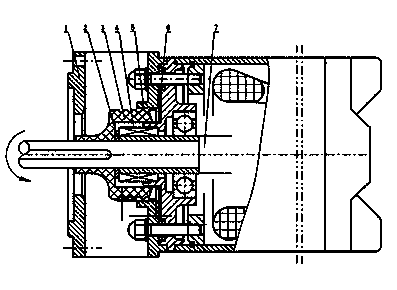

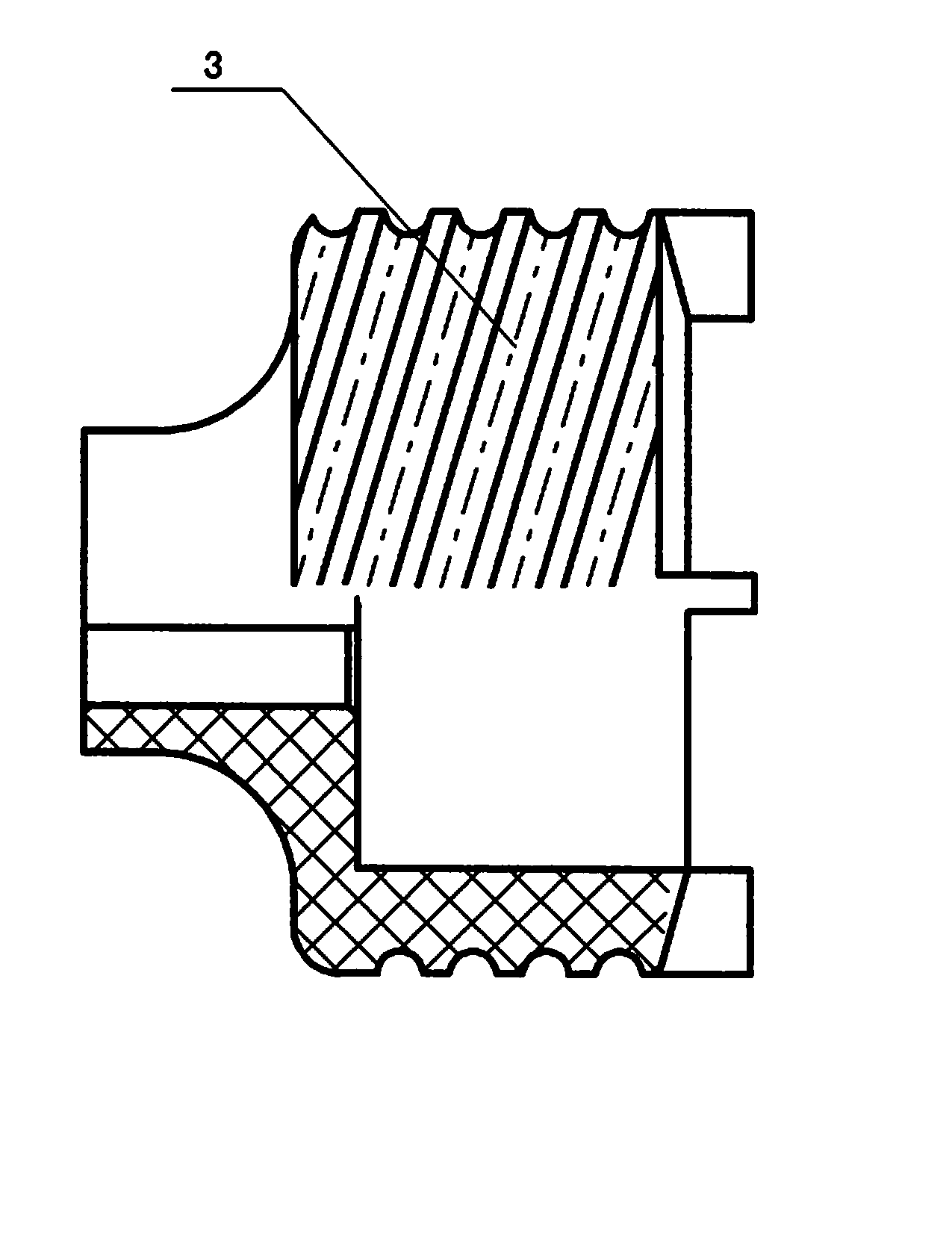

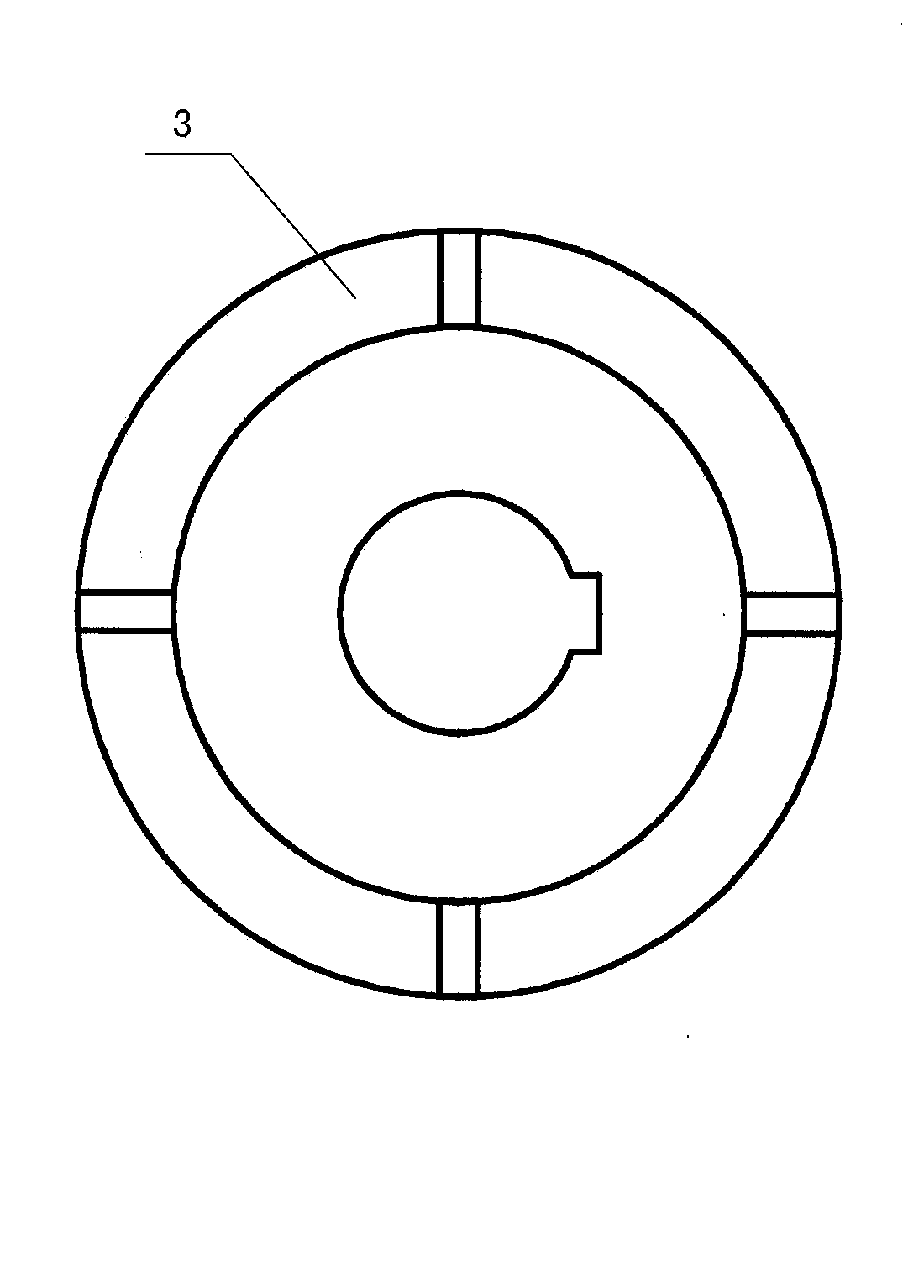

Anti-sand submersible electric pump

The invention relates to an anti-sand submersible electric pump. The anti-sand submersible electric pump comprises a motor, a motor bearing seat and a water pump, and is characterized in that an anti-sand sealing device is arranged between the motor and the water pump, a double-helix sand throwing ring (3) is arranged on the anti-sand sealing device, the double-helix sand throwing ring (3) is annularly sheathed on a motor rotor shaft (7), a sand discharge circle (5) is fixedly arranged on the motor bearing seat, and a gap is arranged between an inner hole of the sand discharge circle (5) and an outer circle of the double-helix sand throwing ring (3). A metal gasket (2) is sheathed between the motor rotor shaft (7) and the double-helix sand throwing ring (3), one end of the double-helix sand throwing ring (3) is fixed by the metal gasket (2), the other end of the double-helix sand throwing ring (3) is fixed by a connecting flange (1), and the double-helix sand throwing ring (3) is further fixed and sealed through a mechanical seal or a framework oil seal (4) in the metal gasket. A wear-resistant pad (6) is fixedly arranged on the motor bearing seat, and the wear-resistant pad (6) is positioned between the motor bearing seat and sand throwing blades of the double-helix sand throwing ring (3).

Owner:TAIZHOU TAIFENG PUMP IND

Sand prevention device of submersible pump motor

The invention provides a sand control device for a submersible pump motor, which includes a motor casing, a motor shaft, a sealing end cover, a skeleton oil seal and a sand throwing ring, wherein the sand throwing ring is sleeved on the motor shaft and is located above the sealing end cover; the sealing end The cover includes an upper sealing end cover and a lower sealing end cover. A plane and a positioning circular step are processed on the inner side of the upper sealing end cover. The skeleton oil seal is fixedly installed on the positioning circular step. Between the skeleton oil seal and the lower sealing end cover, the top end of the edge of the lower sealing end cover is sealed and welded to the shell wall of the motor casing. The invention has the beneficial effects of good sealing performance and high production efficiency, can effectively prevent mud and sand from entering the motor, and improve the service life of the submersible motor.

Owner:TIANJIN ZHENDA PUMP CO LTD

Improved sealing device of circular cooler,

InactiveCN102564144ATo achieve the purpose of sealing and coolingPurpose of sealed cooling NoneEngine sealsHandling discharged materialEconomic benefitsSlide plate

The invention discloses an improved sealing device of a circular cooler, which belongs to the technical field of iron-making sintering equipment and is used for improving the sealing of the sintered-ore circular cooler. The technical scheme is as follows: the improved sealing device comprises lower sealing water grooves and lower sealing sliding plates, wherein the lower sealing water groove is a ring-shaped water groove; the lower sealing sliding plates are of a circular shape consisting of a plurality of sections of ring-shaped pieces; the circumferential diameter of the ring-shaped pieces of the lower sealing sliding plate is matched with that of the center of the lower sealing water grooves; a lower sealing water sliding plate is fixedly arranged at the lower end of a rotary frame and below a trolley shaft; the lower sealing water grooves are fixed below the rotary frame; trolley operating guide rails are positioned above an installation base; the lower sealing sliding plates are inserted into the lower sealing water grooves which are connected with a water supplementing device and a water recovering device. The improved sealing device has the obvious advantages of no wear for sealing pieces, simplicity in manufacture, reliability in working, convenience in maintenance and obvious economic benefit.

Owner:张志良

Acrylate screw glue and preparation method thereof

InactiveCN105440960AImprove wear resistanceImprove wettabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePlasticizerTitanium carbide

The invention provides acrylate screw glue. The acrylate screw glue is prepared from the following components in parts by weight: 100 parts of acrylate monomers, 3-8 parts of an initiator, 1-4 parts of an accelerant, 0.2-0.7 part of an acceleration aid, 1-2 parts of a thickening agent, 0.3-0.6 part of a thixotropic agent, 1.5-3 parts of a plasticizer, 0.1-0.6 part of a stabilizer, 12-15 parts of IIR and 8-11 parts of titanium carbide. The invention further provides a preparation method of the acrylate screw glue. The provided acrylate screw glue has very good impact resistance wear resistance.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

A well-tunnel structure whole-area on-line monitoring bus bar and a method for installing and using the bus bar

PendingCN109065251AImprove installation quality and efficiencyNot easily oxidizedMining devicesMeasurement devicesTunnel constructionStructural stability

The invention discloses a well-tunnel structure whole-area on-line monitoring bus bar and a method for installing and using the same. The on-line monitoring bus bar at least comprises a conductor andan insulator, wherein the insulator is provided with a plurality of sensors spaced apart in the length direction and electrically connected with the conductor. The installation and use method comprises the following steps: S1, sensor installation test is completed, S2, laying and installation area leveling treatment; S3, installation and monitoring; By monitoring and analyzing the signals of the sensors in the monitoring bus, the position of the roadway test point is determined to be in the range between two adjacent sensors, so as to realize the structural health monitoring in the whole rangeof the shaft and tunnel structure. The invention realizes the transfer of the sensor installation work from the well tunnel construction site to the ground workshop, and improves the installation quality and efficiency of the sensor. The busbars are arranged along the whole length of the well and tunnel, and the deformation and vibration at any section can be transmitted to the sensors in the adjacent sensing bin through the busbars, so the global monitoring and early warning of the stability of the well and tunnel structure can be realized.

Owner:姬松涛

Sand-preventing submersible electric pump

InactiveCN103452861AWear outAnti-wearPump componentsPump installationsWear resistantElectric machinery

The invention relates to a sand-preventing submersible electric pump which comprises a motor, a motor bearing seat and a water pump. The sand-preventing submersible electric pump is characterized in that a sand-preventing sealing device is arranged between the motor and the water pump, a double-screw sand throwing ring (3) is arranged on the sand-preventing sealing device and sleeved on a motor rotor shaft (7), a sand draining ring (5) is fixed on the motor bearing seat, a gap is formed between an inner hole of the sand draining ring (5) and an outer circle of the double-screw sand throwing ring (3), a metal gasket (2) is sleeved between the motor rotor shaft (7) and the double-screw sand throwing ring (3), the double-screw sand throwing ring (3) is fixed by the metal gasket (2) at one end and a connecting flange (1) at the other end and then fixed and sealed by a mechanical seal or a framework seal (4) in the metal gasket, and a wear-resistant pad (6) is fixed on the motor bearing seat and positioned between the motor bearing seat and a sand throwing blade on the double-screw sand throwing ring (3).

Owner:TAIZHOU TAIFENG PUMP IND

Guide ball-pin assembly

InactiveCN101380968AImprove handling stabilityEasy rideSteering linkagesEngineeringOperational stability

The invention discloses a guidance ball pin assembly which comprises a casing body, a ball seat which is arranged in the casing body and a guidance ball pin which is arranged in the ball seat, wherein, the ball seat consists of a big ball seat that is arranged in the casing body and a small ball seat that is arranged on the bottom of the big ball seat; a spherical hollow cavity which is matched with the guidance ball pin comprises the big ball seat and the small ball seat; a cover plate is arranged below the small ball seat; dustproof covers are respectively arranged at both sides of the guidance ball pin; other ends of the dustproof covers are arranged on the casing body through a clamp ring; the guidance ball pin adopts a ball pin of column jacket type, wherein, both ends of the column jacket type ball pin are spherical and the middle part of the column jacket type ball pin is a cylinder tube; and synthetic resin is adopted as the raw material of the small ball seat. The invention has double excellences of excellent rotation resistance and tensile pressure resistance and can guarantee the good operational stability and the ride comfort of a whole vehicle.

Owner:沈百庆

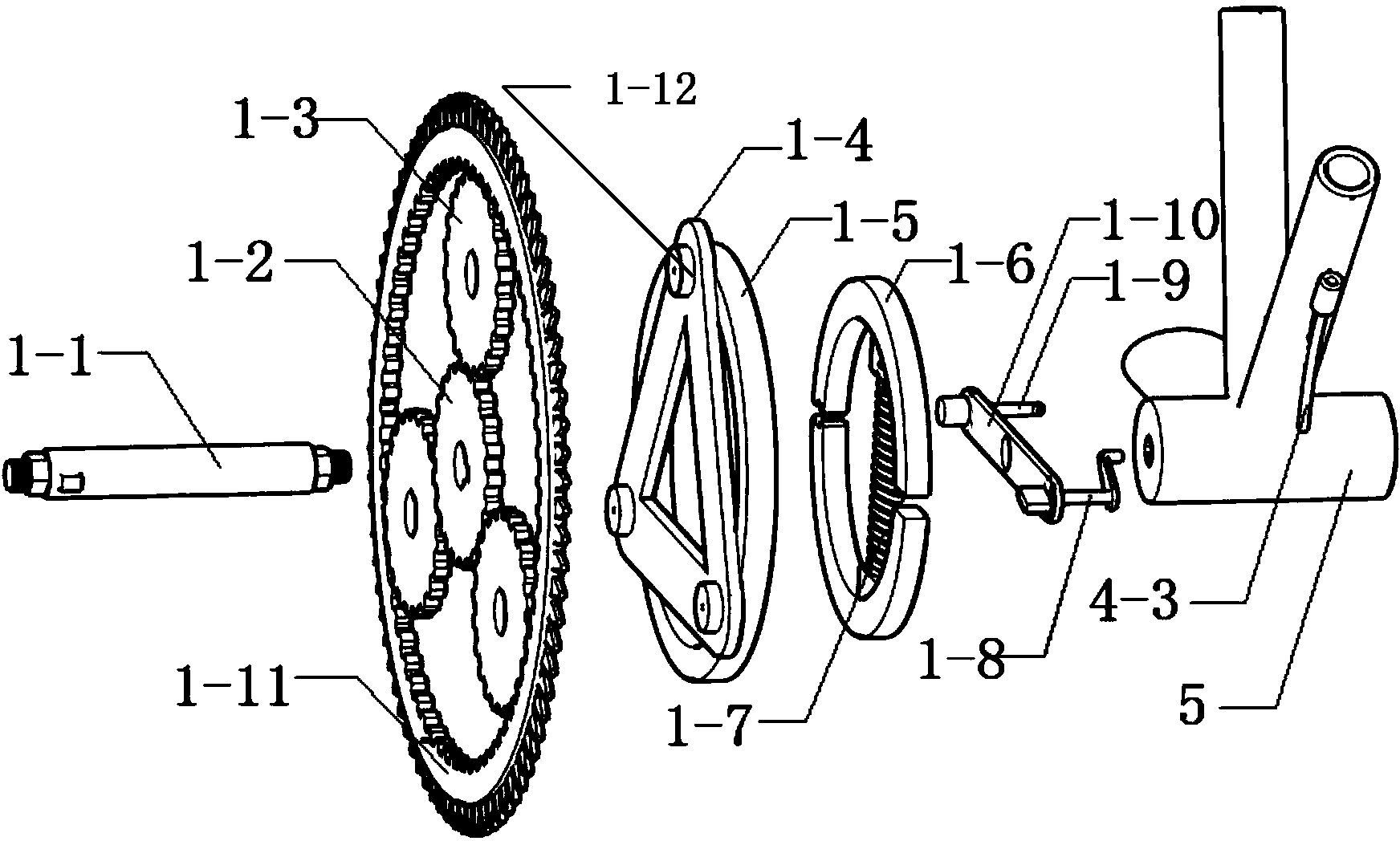

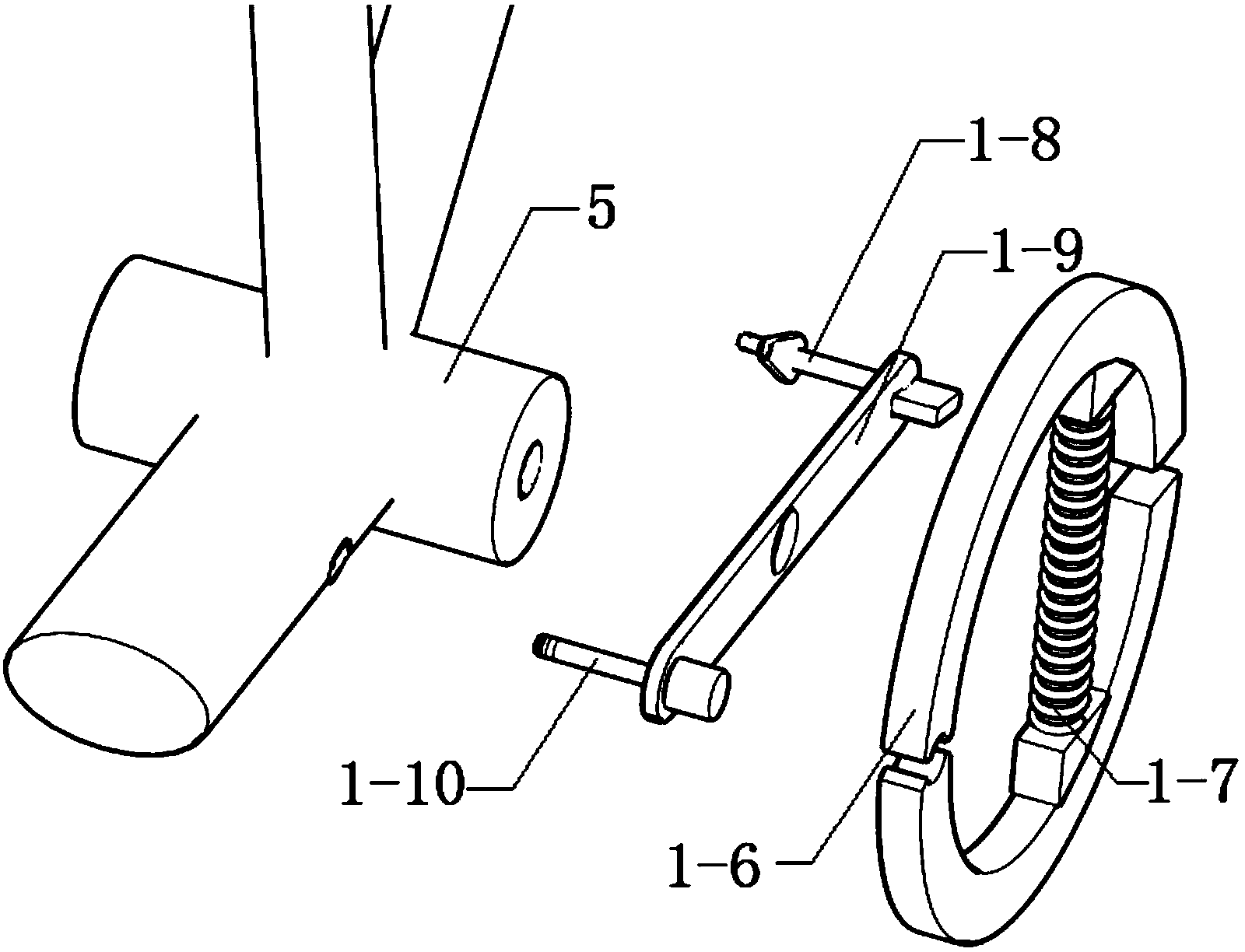

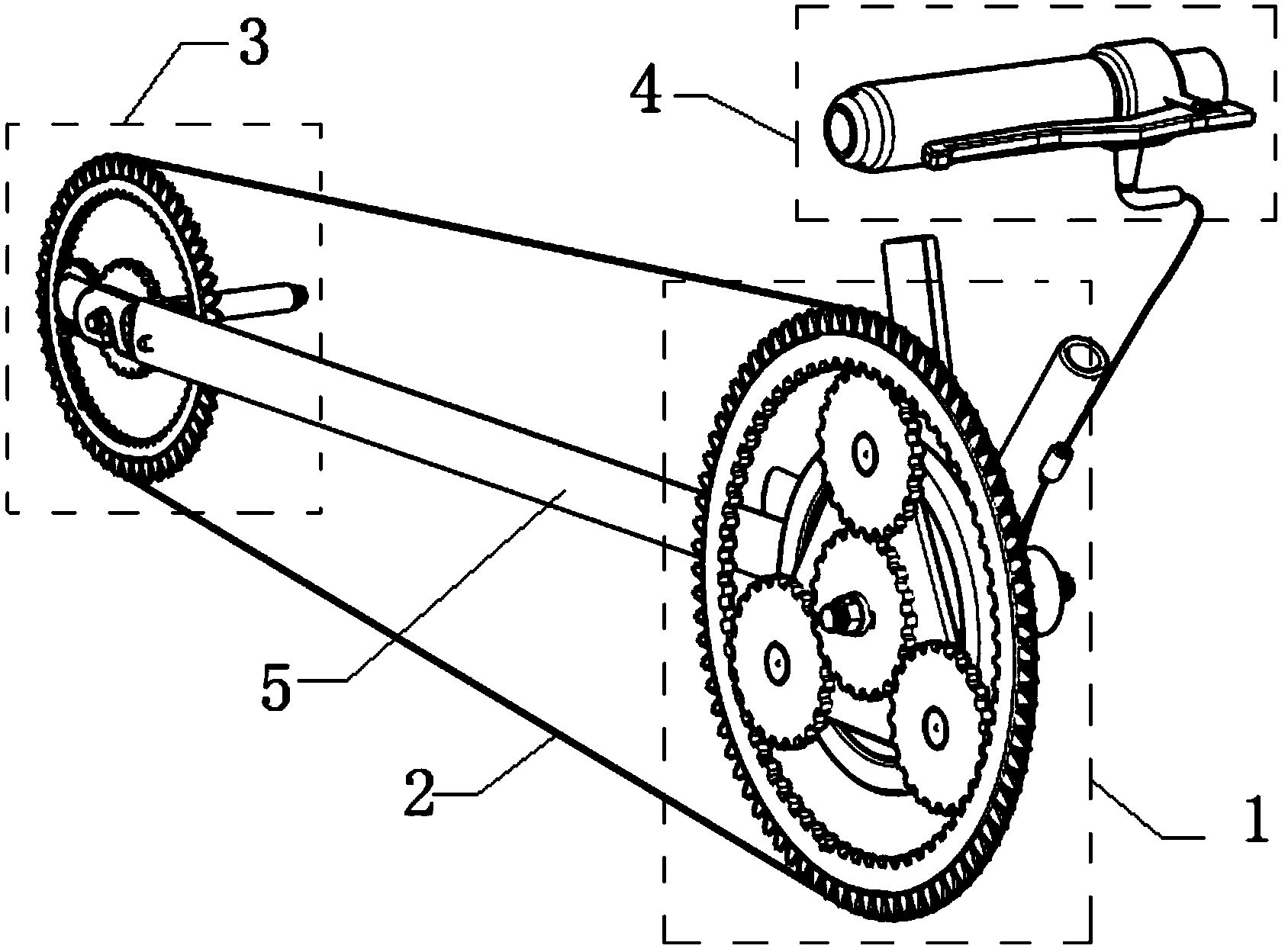

Novel linear speed change device for bicycle

ActiveCN104015868ARealize off-chainRealize linear continuous variable speedWheel based transmissionCycle actuatorsVehicle frameDrive shaft

The invention provides a novel linear speed change device for a bicycle. The novel linear speed change device comprises a driving shaft, a sun gear, a planet gear, a friction ring, a friction piece, a prepressing spring, a friction piece separator, a friction piece supporting frame, a fixing pin of the friction piece supporting frame and a gear ring, wherein the sun gear is installed on the driving shaft; the planet gear is arranged between the gear ring and the sun gear and meshed with internal teeth of the sun gear and internal teeth of the gear ring, and the planet gear is installed on the friction ring through a planet axle; the friction piece is installed in the friction ring and composed of an upper friction piece body and a lower friction piece body, the prepressing spring is arranged in the middle of the friction piece, and a square notch and a round notch are formed in the two ends respectively; the fixing pin, in a round shaft shape, of the friction piece supporting frame is installed at one end of the friction piece supporting frame, the friction piece separator in a square block shape is installed at the other end, the round-shaft-shaped end of the fixing pin of the friction piece supporting frame is installed in the round notch of the friction piece, and the other end of the fixing pin of the friction piece supporting frame is installed on a bicycle frame, and the square-block end of the friction piece separator stretches into the square notch of the friction piece. The novel linear speed change device can perform linear speed change and real-time speed change, and speed change is stable.

Owner:HARBIN ENG UNIV

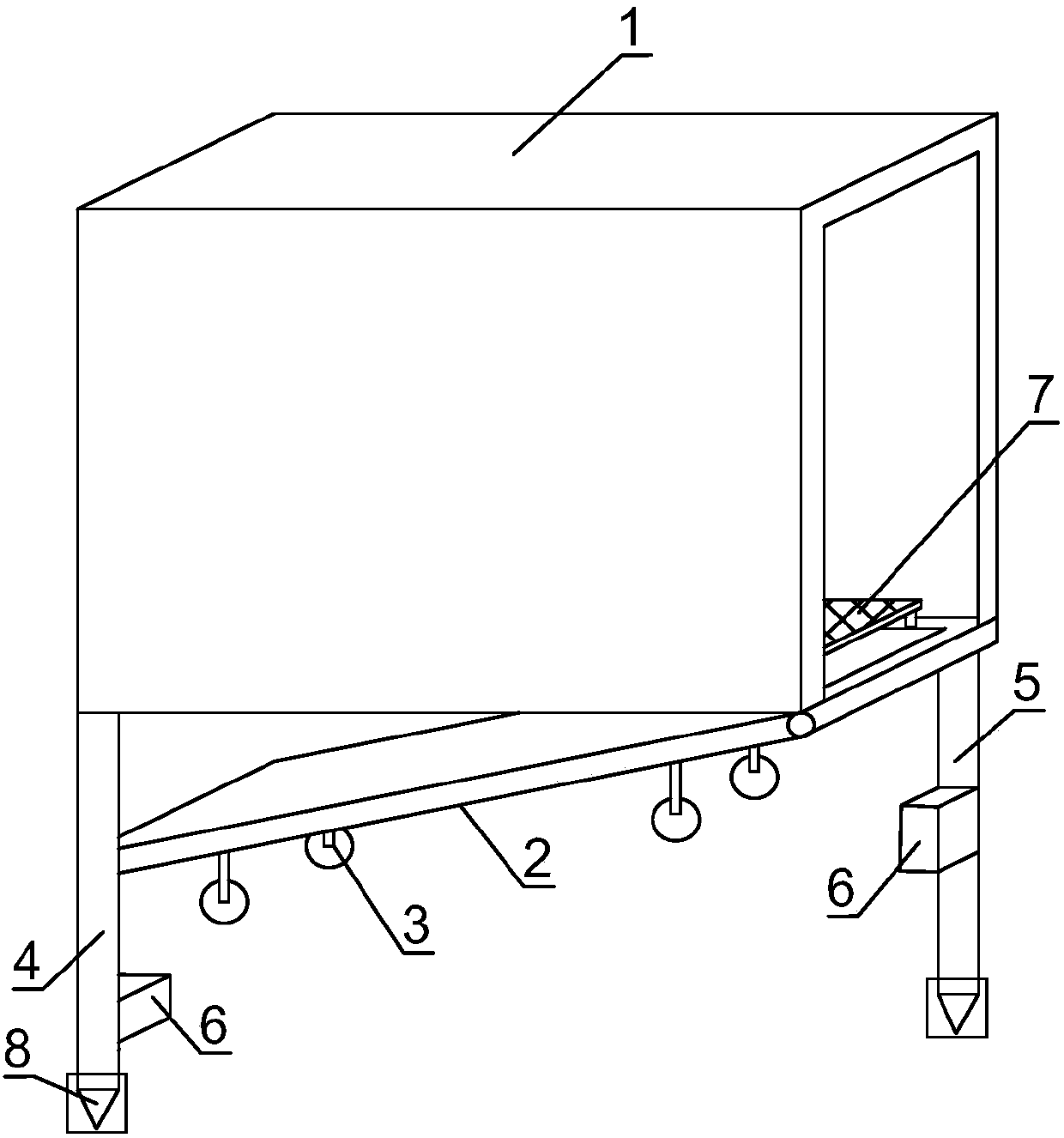

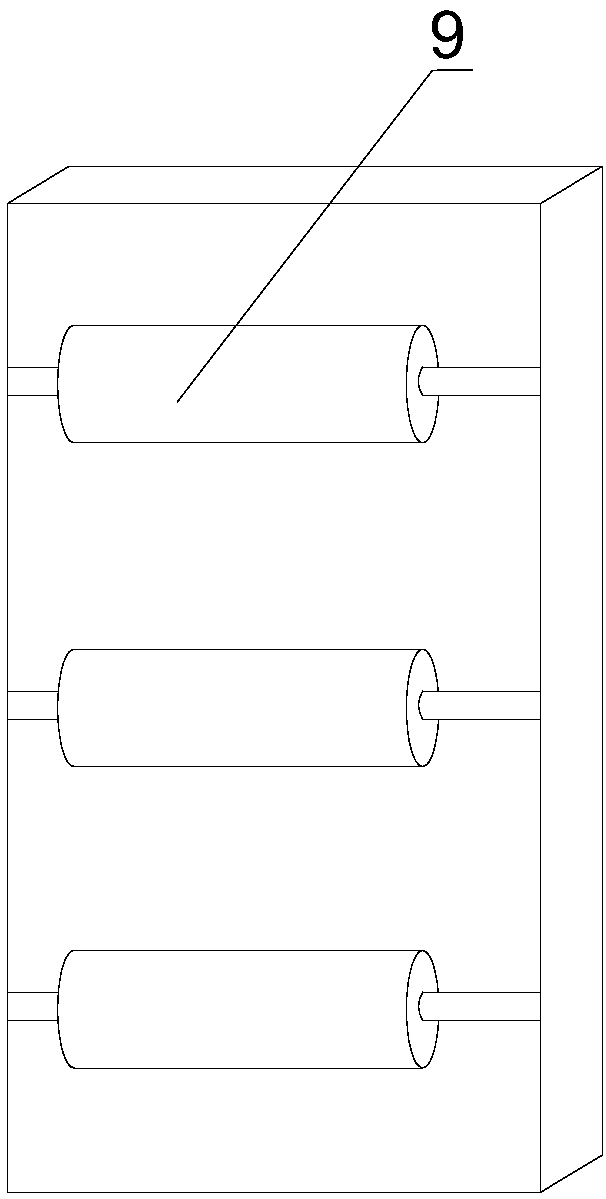

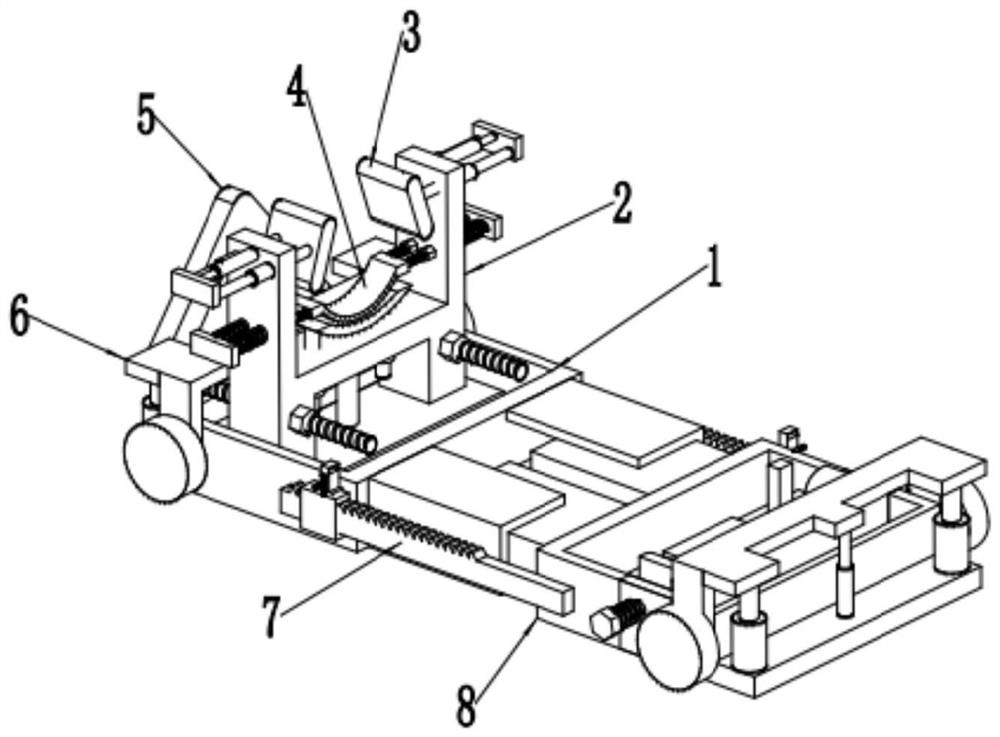

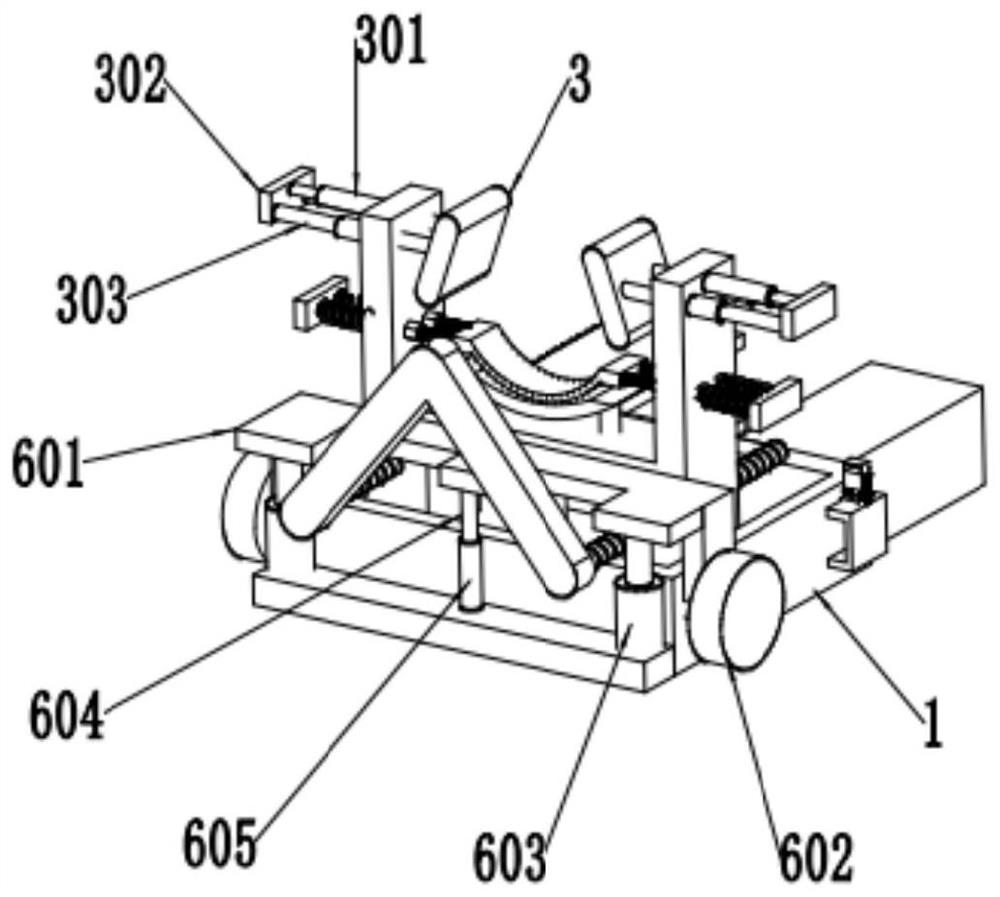

Geological radar protection device with abrasion-resistant function

PendingCN107607912APlay a protective effectProtection fromWave based measurement systemsReciprocating motionRadar

The invention discloses a geological radar protection device with an abrasion-resistant function. The geological radar protection device comprises a rectangular shell, the rectangular shell wraps theoutside of an antenna shell, openings are formed in one side surface and the bottom surface of the rectangular shell, a bottom plate is hinged on the outer wall of one side of the bottom surface of the shell and used for plugging the opening in the bottom surface, the bottom plate reciprocates between the openings of the side surface and the bottom surface of the shell around a hinge end, at leastthree rollers are arranged on one side surface of the bottom plate and contact with the ground, at least one pair of telescopic rod groups are connected on the lower portion of the bottom of the shell and include first telescopic rods and second telescopic rods, each first telescopic rod and the corresponding second telescopic rod are positioned at two corners on the same diagonal line on the bottom surface of the shell, horizontal plates are arranged on the first telescopic rods and the second telescopic rods and used for locking the bottom plate and contact with the bottom plate, and the horizontal plates are positioned below the bottom plate. The protection device solves the problems of abrasion and collision of the geological radar antenna shell by the aid of the shell with the rollers.

Owner:四川嘉义新能有限公司

Rubber homogenization wear-resistant agent

The invention relates to a rubber homogenization wear-resistant agent. According to a formula, the rubber homogenization wear-resistant agent comprises, by weight: 30 of a urea-aldehyde acid sodium polymer, 12 of hexamethylenetetramine, and 2.5 of NH4Cl. Preferably, the rubber homogenization wear-resistant agent can be added with 15 of octadecanol, 20 of white carbon black, and 20 of a plasticizer. The rubber homogenization wear-resistant agent creatively can promote uniform dispersion of high viscosity rubber and the additives, and can well reach the effects of solubilizing, wear resisting, and wetting, etc. The raw materials and the formed product are compatible with rubber, and do not get in the way of rubber products. The rubber homogenization wear-resistant agent has easily available raw materials, a low cost and economical efficiency. During sulfidation of rubber, a cross-linking effect can be generated, and a new sulfidation network can be formed, thus reaching the purpose of modification. The rubber homogenization wear-resistant agent provided in the invention can reduce wear by 13-24%.

Owner:盛柏松

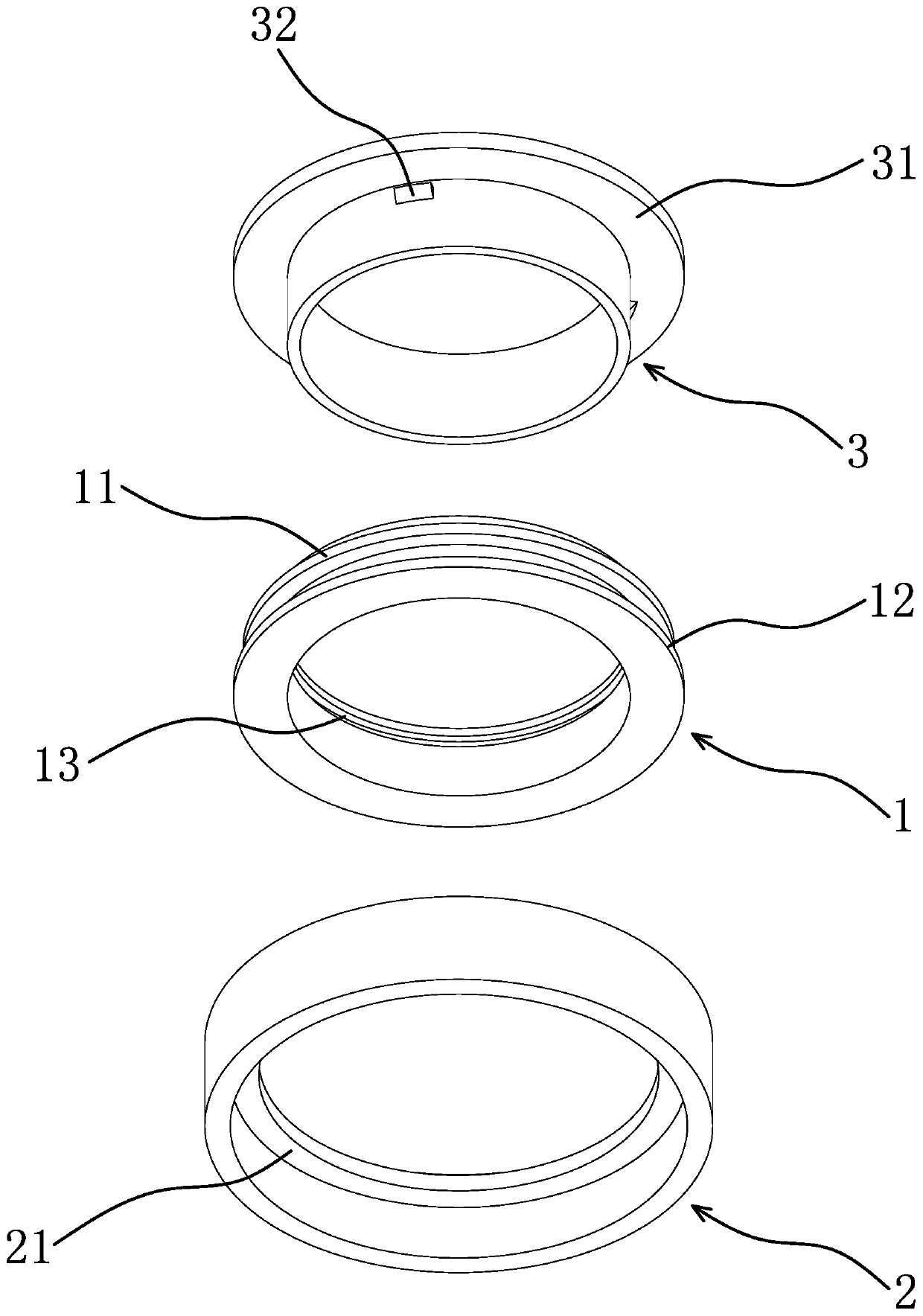

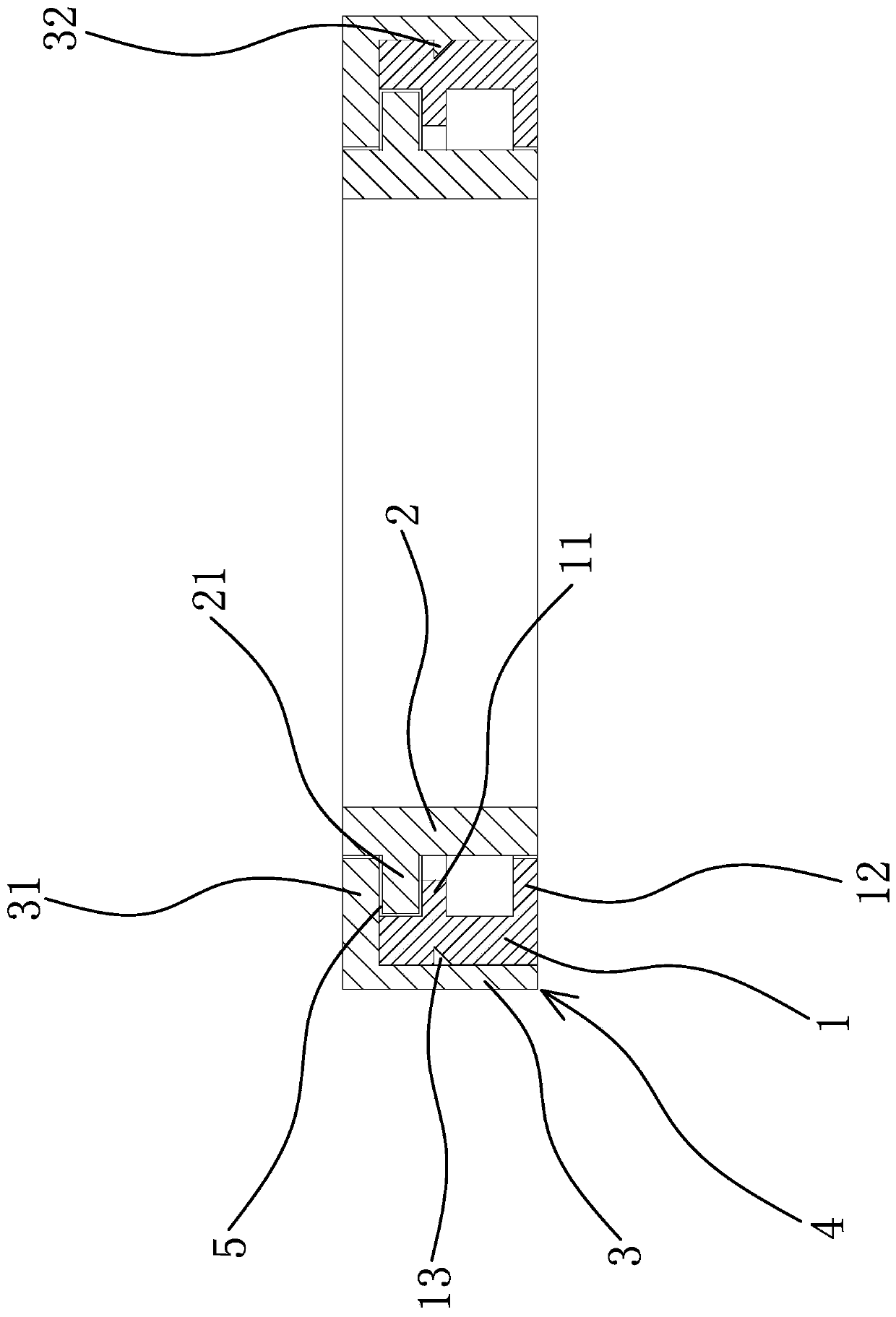

Sand-preventing sealing device of submersible electric pump

The invention relates to a sand-preventing sealing device of a submersible electric pump. The sand-preventing sealing device is arranged between a motor and a water pump and provided with a double-spiral sand slinger (3) which is sleeved on a motor rotor spindle (7), a sand-draining ring (5) is fixed on a bearing seat of the motor, a gap is formed between an inner hole of the desilting ring (5) and the outer circle of the spiral sanding throwing ring (3), a metallic gasket (2) is sleeved between the motor rotor spindle (7) and the spiral sanding throwing ring (3), and the spiral sanding throwing ring (3) is fixed via the metallic gasket (2) at one end and a connecting flange (1) at the other end and is fixedly sealed by a mechanical seal or framework oil seal (4) inside the metallic gasket (2). A wear-resisting pad (6) is fixed on the bearing seat of the motor and is arranged between a sand-throwing blade on the spiral sanding throwing ring (3) and the bearing seat of the motor.

Owner:TAIZHOU TAIFENG PUMP IND

Sand-preventing sealing device of submersible electric pump

The invention relates to a sand-preventing sealing device of a submersible electric pump. The sand-preventing sealing device is arranged between a motor and a water pump and provided with a double-spiral sand slinger (3) which is sleeved on a motor rotor spindle (7), a sand-draining ring (5) is fixed on a bearing seat of the motor, a gap is formed between an inner hole of the desilting ring (5) and the outer circle of the spiral sanding throwing ring (3), a metallic gasket (2) is sleeved between the motor rotor spindle (7) and the spiral sanding throwing ring (3), and the spiral sanding throwing ring (3) is fixed via the metallic gasket (2) at one end and a connecting flange (1) at the other end and is fixedly sealed by a mechanical seal or framework oil seal (4) inside the metallic gasket (2). A wear-resisting pad (6) is fixed on the bearing seat of the motor and is arranged between a sand-throwing blade on the spiral sanding throwing ring (3) and the bearing seat of the motor.

Owner:TAIZHOU TAIFENG PUMP IND

Wear-resistant bearing rolling body

ActiveCN107502939AImprove wear resistanceNo change in precisionAnodisationShaftsWear resistantCoconut oil

The invention discloses a wear-resistant bearing rolling body. The wear-resistant bearing rolling body is obtained by performing pressurized soaking on a bearing rolling body by adopting a coconut oil-sodium glutamate solution, adding the bearing rolling body into a low-temperature plasma treatment device for performing low-temperature plasma treatment after the bearing rolling body is cleaned and dried, wherein the treatment time is 70 to 80 seconds; after the treatment is completed, adding the bearing rolling body into a micro-arc oxidizing device for performing micro-arc oxidizing treatment within 60 seconds, wherein the treatment time is 2 to 3 minutes; then, performing soaking treatment on the bearing rolling body in castor oil; and after the bearing rolling body is soaked, taking the bearing rolling body out, and wipe-drying the surface of the bearing rolling body. The wear resistance of the bearing rolling body can be remarkably improved by treating the bearing rolling body by the method provided by the invention.

Owner:阜阳市鼎铭汽车配件制造有限公司

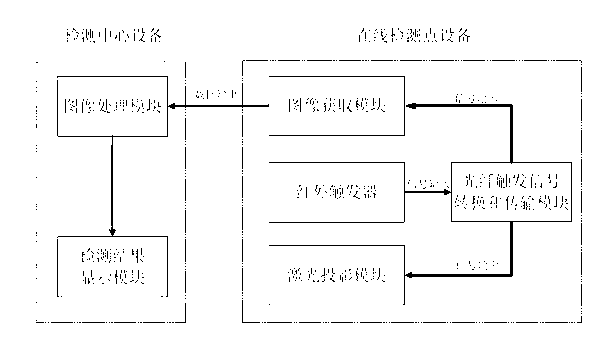

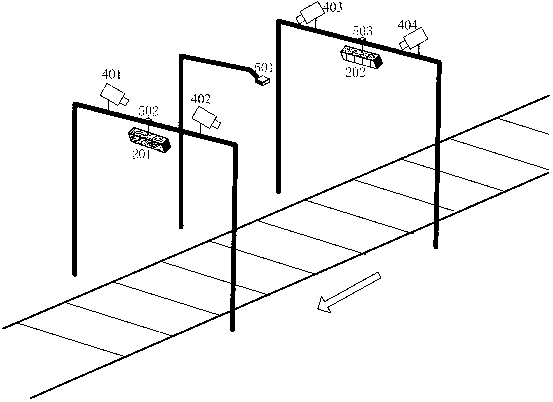

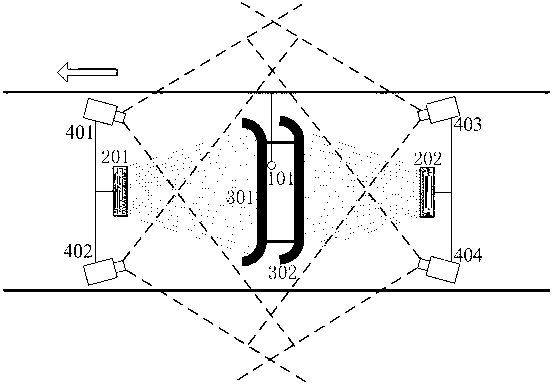

Online abrasion detection method and system for pantograph of electric locomotive

InactiveCN102507601BReduce failureDetect the degree of wearOptically investigating flaws/contaminationLaser arrayEngineering

The invention relates to an online abrasion detection method and system for a pantograph of an electric locomotive. The online abrasion real-time detection system of the pantograph comprises a laser projection module, an image acquisition module and a fiber trigger signal conversion and transmission module and is further provided with a first upright post, a second upright post and a third upright post, wherein the laser projection module consists of two linear laser arrays; each linear laser array comprises a plurality of linear lasers; laser rays emitted by the linear lasers are projected onto the pantograph in a parallel manner; the distance between the faculas of every two adjacent linear lasers is kept at the magnitude of millimeter; the first upright post, the second upright post and the third upright post are equidistantly arranged; the first linear laser array, a first digital camera and a second digital camera are mounted on the first upright post; an infrared trigger is mounted on the second upright post; the second linear laser array, a third digital camera and a fourth digital camera are mounted on the third upright post; and the infrared trigger is mounted at a position on the second upright post such that the digital cameras can photograph the pantograph by forwardly aligning to the center of a track in the depression angles of 20-30 DEG.

Owner:NANJING UNIV

Sand-prevention sealing device of submersible electric pump

Owner:TAIZHOU TAIFENG PUMP IND

Sand-preventing submersible electric pump

InactiveCN103452860AWear outAnti-wearPump componentsPump installationsWear resistantElectric machinery

The invention relates to a sand-preventing submersible electric pump which comprises a motor, a motor bearing seat and a water pump. The sand-preventing submersible electric pump is characterized in that a sand-preventing sealing device is arranged between the motor and the water pump, a double-screw sand throwing ring (3) is arranged on the sand-preventing sealing device and sleeved on a motor rotor shaft (7), a sand draining ring (5) is fixed on the motor bearing seat, a gap is formed between an inner hole of the sand draining ring (5) and an outer circle of the double-screw sand throwing ring (3), a metal gasket (2) is sleeved between the motor rotor shaft (7) and the double-screw sand throwing ring (3), the double-screw sand throwing ring (3) is fixed by the metal gasket (2) at one end and a connecting flange (1) at the other end and then fixed and sealed by a mechanical seal or a framework seal (4) in the metal gasket, and a wear-resistant pad (6) is fixed on the motor bearing seat and positioned between the motor bearing seat and a sand throwing blade on the double-screw sand throwing ring (3).

Owner:TAIZHOU TAIFENG PUMP IND

Anti-eccentric steel ball centering device

InactiveCN103670295AReduce frictional resistanceExtended service lifeDrilling rodsDrilling casingsMetallurgyReciprocating motion

The invention discloses an anti-eccentric steel ball centering device. According to the technical scheme, twelve phi18 steel balls and twelve phi10 steel balls are regularly arrayed on the outer surface of the anti-eccentric steel ball centering device, the phi18 steel balls are covered by ball covers, advanced welding technologies are applied to ball cover connectors and a rod body to prevent the steel balls from becoming separate from the ball covers and the steel balls can freely rotate in the ball cover connectors and the rod body so that rolling friction can be generated between the phi18 steel balls and the inner wall of an oil pipe because of rotating of the steel balls in the process that an oil pumping rod does reciprocating motion vertically for pumping oil, the problem that sliding friction resistance of a former nylon sleeve and the inner wall of an oil pipe is large is solved, and working efficiency is improved.

Owner:YANCHENG HUAYI GASOLINEEUM MACHINERY

Bearing for mahjong machine

PendingCN109985375AEasy to assembleImprove assembly efficiencyIndoor gamesPlastic materialsEngineering

The invention provides a bearing for a mahjong machine and belongs to the technical field of bearings. The problem is solved that an existing bearing is inconvenient to manufacture and expensive to manufacture. The bearing for the mahjong machine comprises a rotating sleeve I, a rotating sleeve II and a positioning sleeve, wherein the rotating sleeve I, the rotating sleeve II and the positioning sleeve are all made of a plastic material, the positioning sleeve sleeves with the rotating sleeve I, and the positioning sleeve and the rotating sleeve I are clamp-connected and fixed to form a rotating body, the side wall of the positioning sleeve is provided with an annular convex edge I, and the side wall of the rotating sleeve I is provided with an annular convex edge II, an annular groove isformed between the annular convex edge I and the annular convex edge II, an annular convex edge III extending into the annular groove is formed in the side wall of the rotating sleeve II, and the rotating sleeve II and the rotating body can independently rotate. The bearing is light in weight and convenient to transport, the manufacturing cost of the bearing is obviously reduced by adopting the plastic parts compared with metal parts, a steel ball structure is also omitted, and the manufacturing cost of the bearing is further reduced, so that the manufacturing cost of the bearing is low.

Owner:元丹霞

Wind power generation main shaft supporting device

PendingCN114670037AGuaranteed stability and securityAvoid wear and tearPositioning apparatusMaintainance and safety accessoriesSupport beltElectrical and Electronics engineering

The invention discloses a wind power generation main shaft supporting device which comprises a base, the base comprises a first supporting seat and a second supporting seat which are connected in a sliding mode, an H-shaped support is arranged on the first supporting seat, a supporting belt is connected in the support, a pressing block for pressing a main shaft is arranged above the supporting belt, a supporting plate for supporting the main shaft is arranged below the supporting belt, and the supporting plate is connected with the H-shaped support. The side, away from the second supporting base, of the support is provided with a stop lever in sliding connection with the first supporting base, a base plate is arranged in the second supporting base, the upper end of the base plate is provided with a baffle matched with the spindle disc, sliding blocks for fixing the spindle disc are symmetrically arranged on the base plate, and the first supporting base and the second supporting base are each provided with a liftable moving mechanism. In the supporting process, the stress area of the main shaft is increased to the maximum extent, stability is ensured, and stress damage is reduced; the whole device is movable and telescopic, the universality is improved, and the device is convenient to store and use.

Owner:SHANDONG LAIWU JINLEI WIND POWER TECH

Sand-proof submersible electric pump

The invention relates to a sand-proof submersible electric pump comprising a motor, a motor bearing seat and a water pump. The sand-proof submersible electric pump is characterized in that a sand-proof sealing device is arranged between the motor and the water pump and provided with a double-helix sand slinger (3) sleeved on a motor rotor spindle (7), a sand draining ring (5) is fixed on the motor bearing seat, and a gap is formed between the inner hole of the sand draining ring (5) and the outer circle of the double-helix sand slinger (3). Besides, a metal gasket (2) is sleeved between the motor rotor spindle (7) and the double-helix sand slinger (3), and the double-helix sand slinger (3) is fixed by the metal gasket (2) arranged at one end and a connecting flange (1) at the other end, and then is sealed by a mechanical seal or frame seal (4) in the metal gasket. Further, a wear pad (6) is fixed on a motor bearing seat and disposed between the motor bearing seat and a sand slinging blade on the double-helix sand slinger (3).

Owner:TAIZHOU TAIFENG PUMP IND

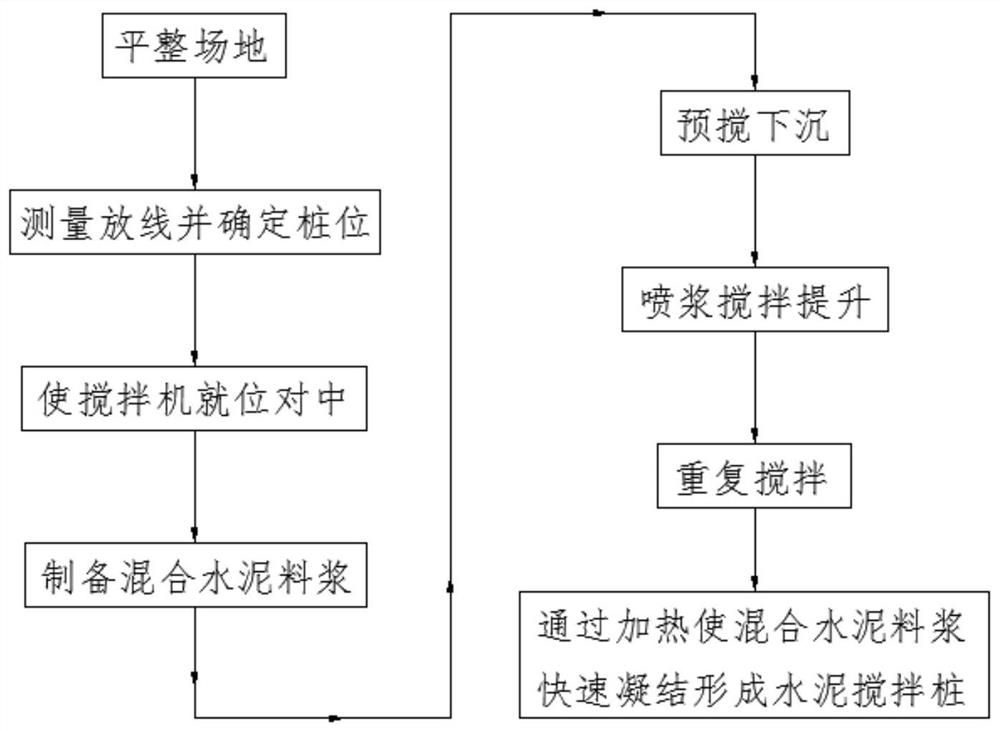

Cement mixing pile construction method

PendingCN113863292APlay a lubricating roleWear outBulkheads/pilesStructural engineeringCement slurry

The invention provides a cement mixing pile construction method. The cement mixing pile construction method comprises the following steps: leveling a site; carrying out surveying and setting out, and determining a pile position; positioning and centering a stirrer; preparing mixed cement slurry: carrying out pre-stirring and sinking: spraying slurry, and performing stirring and lifting; repeatedly stirring; and enabling the mixed cement slurry to realize rapid setting through heating to form a cement mixing pile. According to the technical scheme, the lubricating liquid is injected into the underground soil body in the pre-stirring sinking stage, the lubricating liquid plays a role in lubricating and cooling a drill rod, abrasion of the drill rod is reduced, the service life of the drill rod is prolonged, the lubricating liquid further infiltrates the underground soil body, drilling of the drill rod is easier, the construction progress is accelerated, and the construction period is shortened; and heat conduction wires are mixed in the mixed cement slurry, the top face of the cement mixing pile is heated after initial setting forming of the cement mixing pile, the setting forming process of the cement mixing pile is accelerated, all components in the cement mixing pile are tightly connected and rapidly set to the expected strength, the construction period is shortened, and the construction efficiency is improved.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com