Rubber homogenization wear-resistant agent

A wear-resistant agent and rubber technology, applied in the field of rubber homogenization and wear-resistant agent, can solve the problems of large performance fluctuation, research lag, poor reliability, etc., and achieve the effects of promoting uniform dispersion, low cost, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

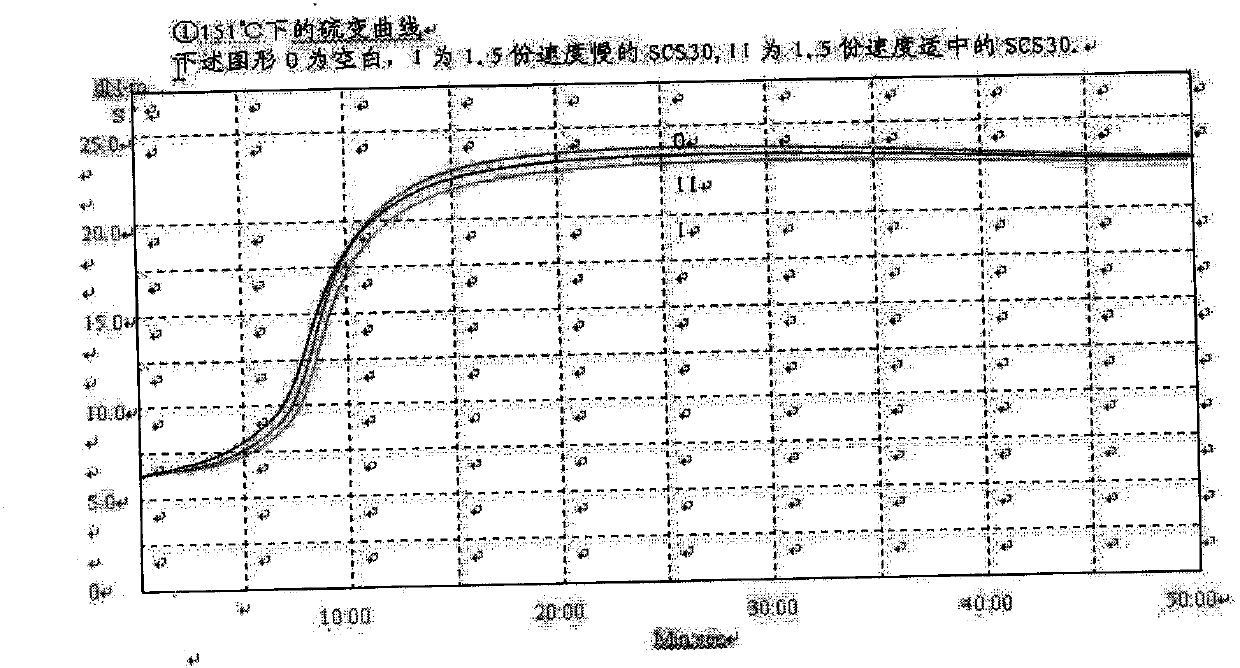

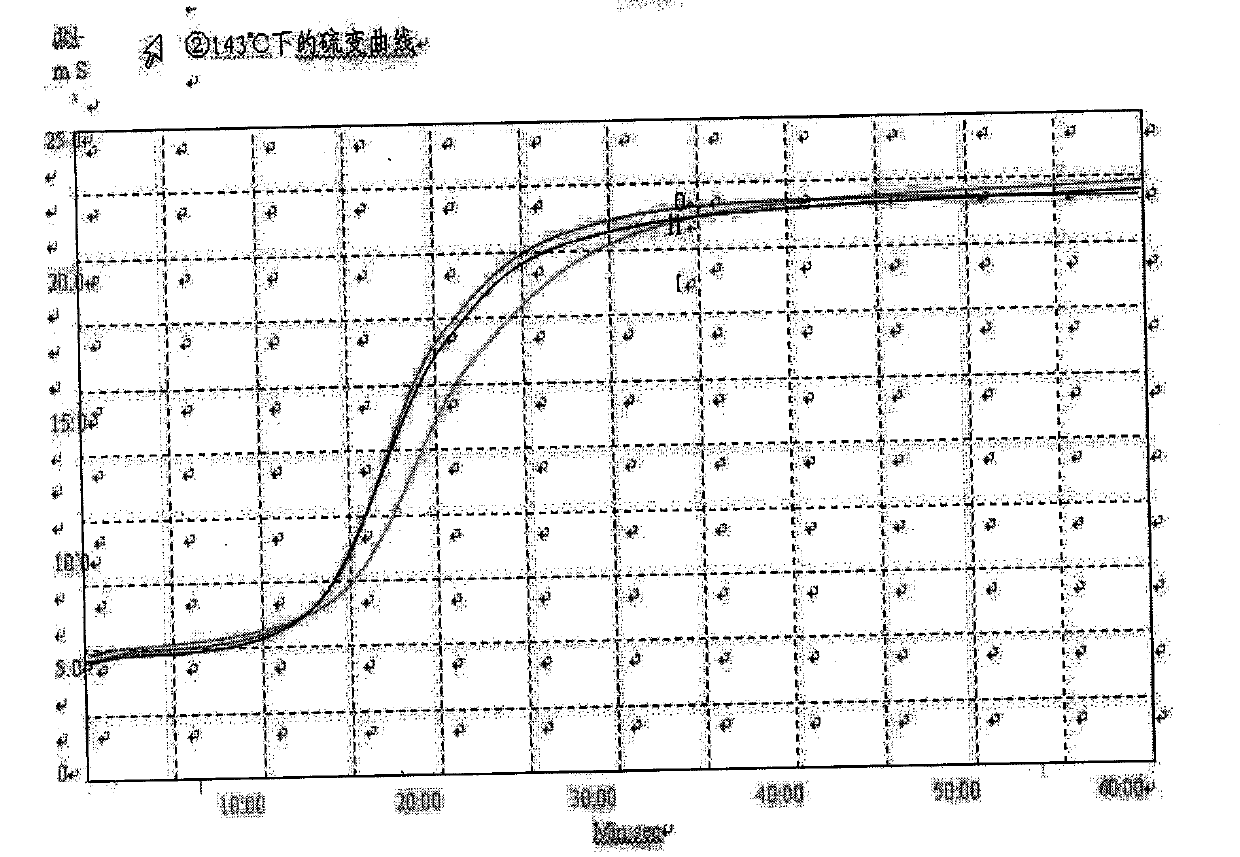

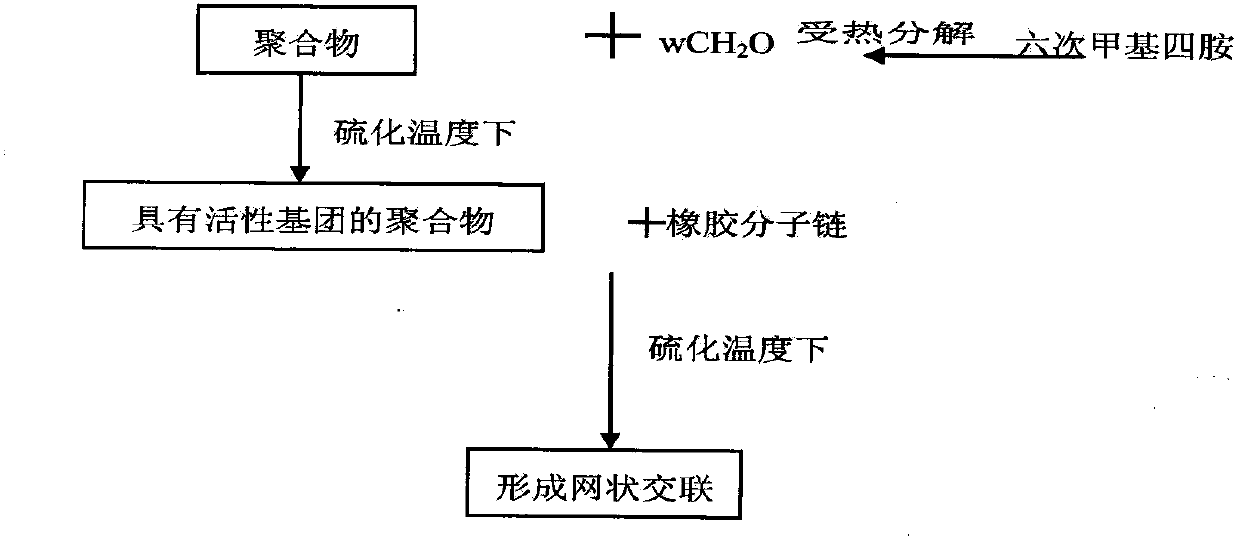

[0023] The product of this project, SCS30, is a compound of sodium urealate polymer, which is a physical and chemical modifier. It has good compatibility with rubber, can accelerate the uniform dispersion of rubber and rubber, and rubber and filling materials, and penetrate into The polymer inside the rubber and the rubber produce secondary vulcanization, and cooperate with the sulfur vulcanization network to form a denser vulcanization new network, thereby producing reinforcement, wear resistance and reducing tire heat generation, while improving the thermochemical stability of the rubber. It is a rubber-modified anti-wear agent that can improve the wear resistance of tires.

[0024] The technical route design idea is based on four points: First: the homogenizing anti-wear agent SCS30 can promote the uniform dispersion between high-viscosity rubber and additives, so it must be able to reduce the interfacial tension between the phases, which can better increase the Soluble, we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com