Patents

Literature

78results about How to "Solubilize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

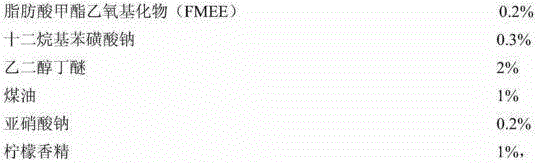

Powerful cleaning agent

InactiveCN105273861AEasy to useSafe storageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSide effectAlcohol

The invention relates to a powerful cleaning agent and belongs to the field of fine chemical automotive chemicals. The cleaning agent is prepared from surface active agents, alcohol additives, oiliness additives, auxiliary agents and water. The surface active agents and the oiliness additives play roles of solubilization, dissolving and washing, the alcohol additives jointly act with the two mentioned components for forming stable microemulsion and have certain permeation, moistening and dissolving functions, the three components jointly act so that the cleaning agent can achieve a good cleaning effect, and the auxiliary agents are functional additives. The cleaning agent has no side effect on cast iron, cast aluminum, leather, fabric, rubber, plastic and the like and can effectively clean an engine or the surface of the interior without generating phenomena of corrosion, color fading, bubbling, falling and the like.

Owner:蚌埠市神丰贸易有限公司

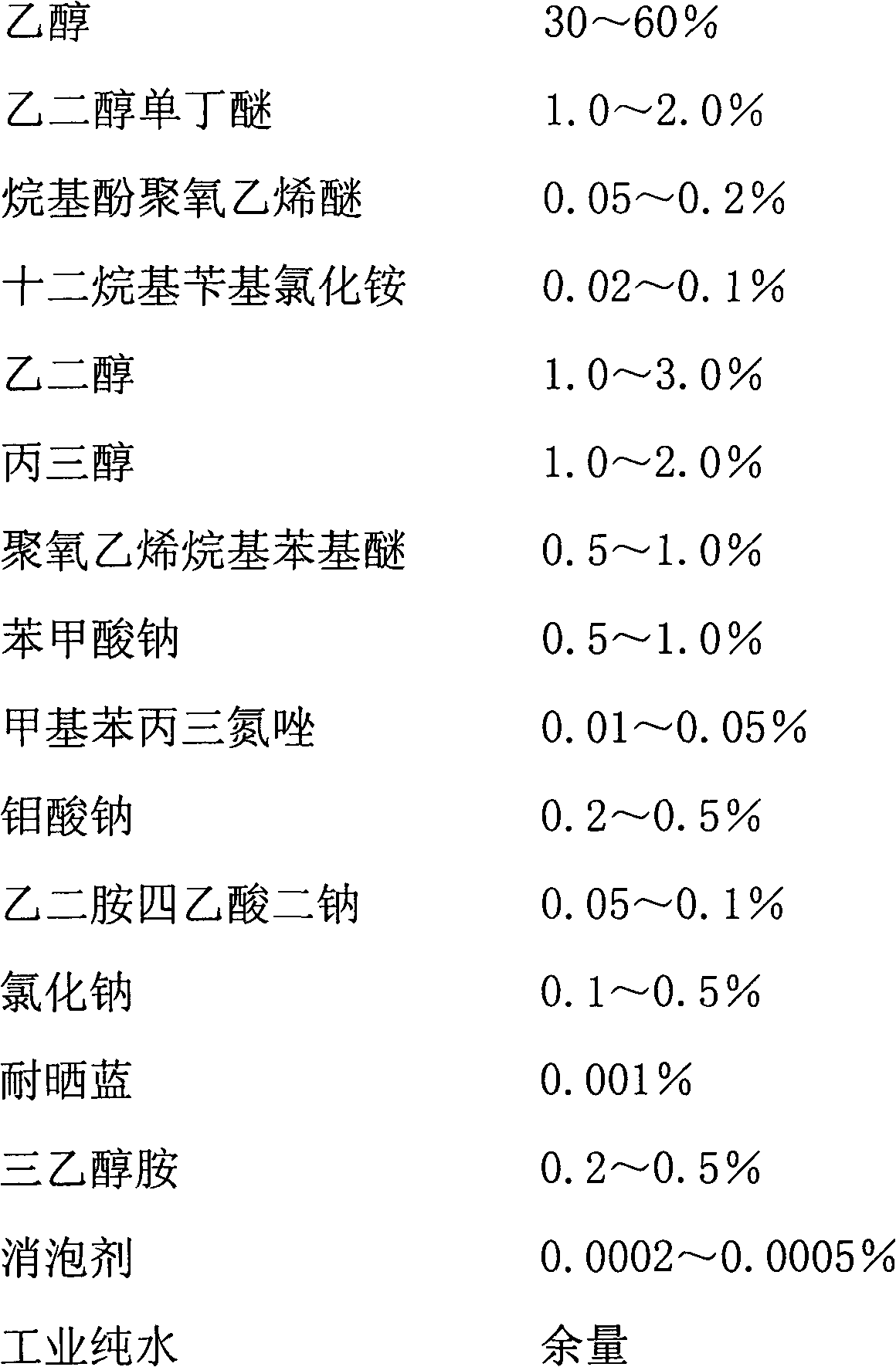

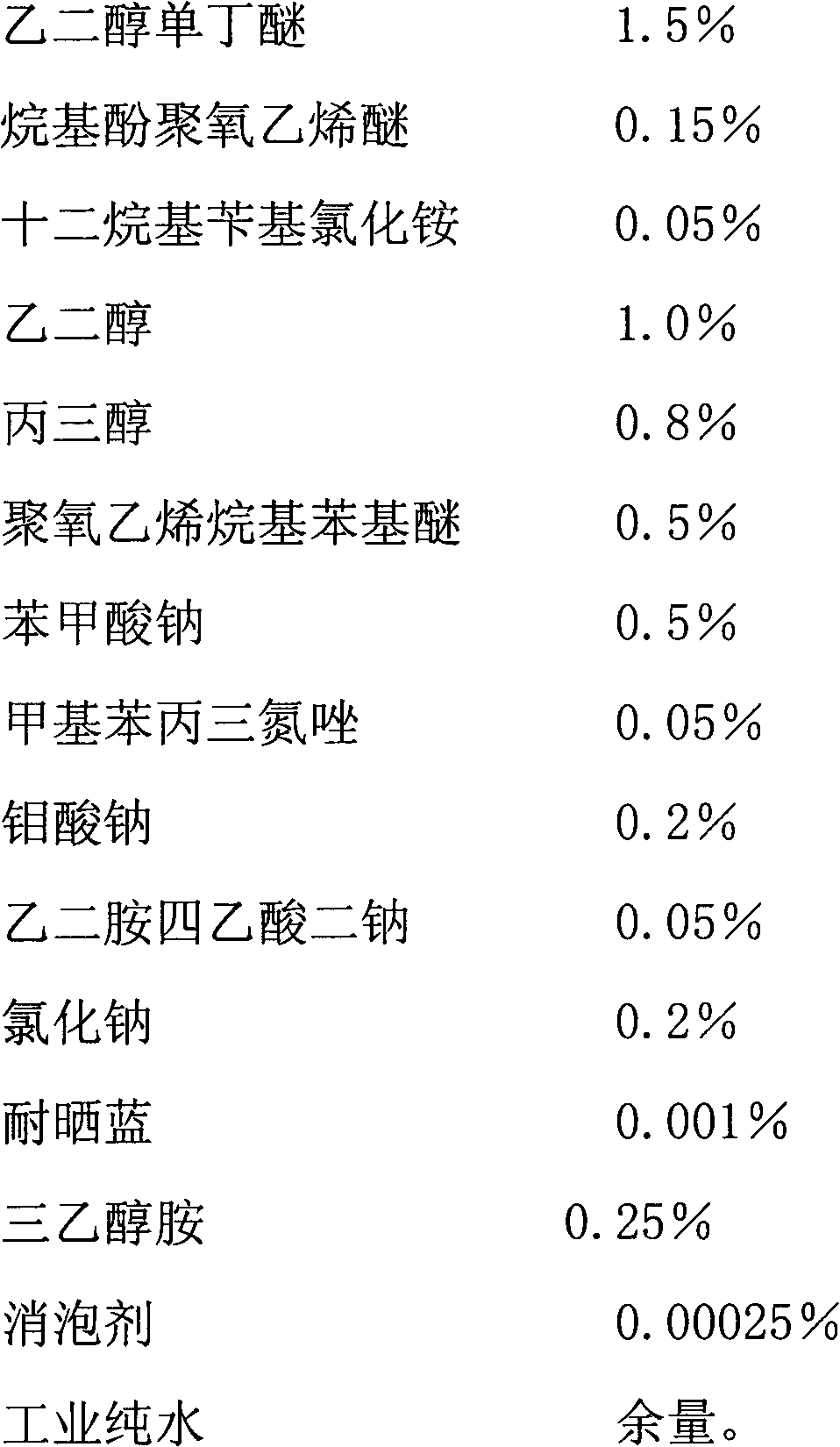

Long-acting environment-friendly automobile air window glass washing liquid

ActiveCN102492582ASolubilizeHigh speedSurface-active non-soap compounds and soap mixture detergentsPhenyl EthersGlycerol

The invention relates to a long-acting environment-friendly automobile air window glass washing liquid which is a non-toxic environment-friendly automobile air window glass washing liquid which can prevent freezing, prevent fog and remove ice and snow. The washing liquid is formed by stirring and reacting the following components by mass weight: ethanol, ethylene glycol monobutyl ether, alkylphenol polyoxyethylene ether, dodecyl benzyl ammonium chlorine, glycol, glycerol, polyoxyethylene alkyl phenyl ether, sodium benzoate, methyl benzotriazole, sodium molybdate, disodium ethylene diamine tetraacetate, sodium chloride, sunlight-resisting blue, triethanolamine, a defoaming agent and industrial pure water. By using the washing liquid, industrial methanol is prevented from being used as a solvent in the traditional formula; and simultaneously, the washing liquid and ethylene glycol monobutyl ether are matched and used, thereby greatly improving the dissolution effect of a single solvent on blots. The washing liquid disclosed by the invention is prepared by using non-toxic and easily biodegradable raw materials and is environment-friendly, can not pollute environment if being used for a long term, and prevents toxic gases from volatilization to harm a driver in the use process. The washing liquid has the characteristics of preventing fog, removing ice and snow, maintaining no icing on the surface of the glass for a long term, is not burnt and does not corrode.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

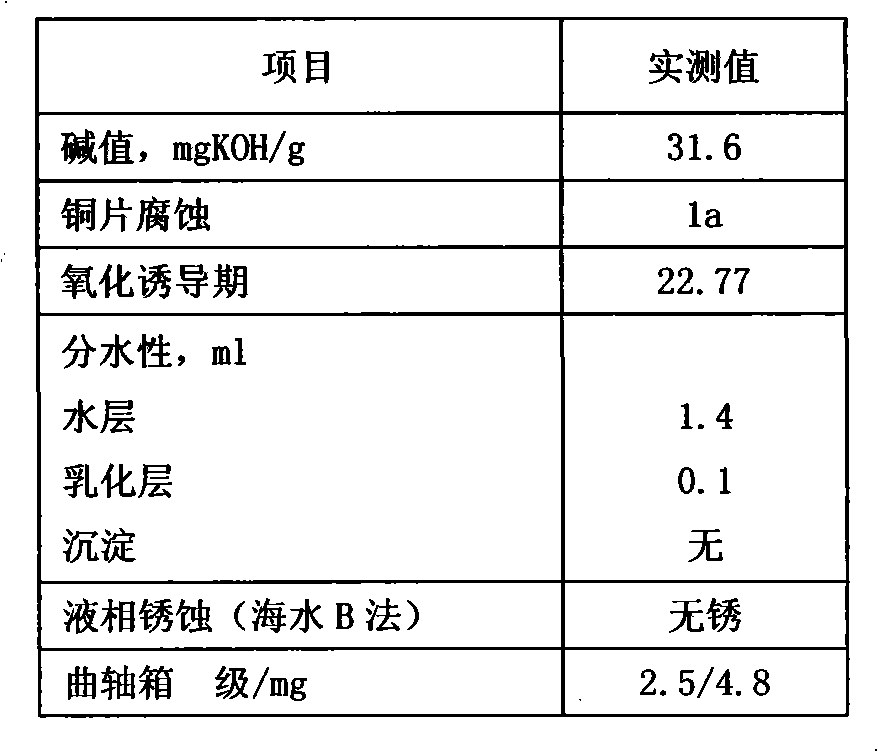

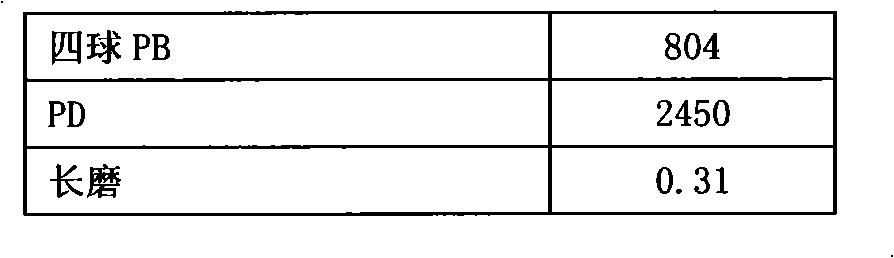

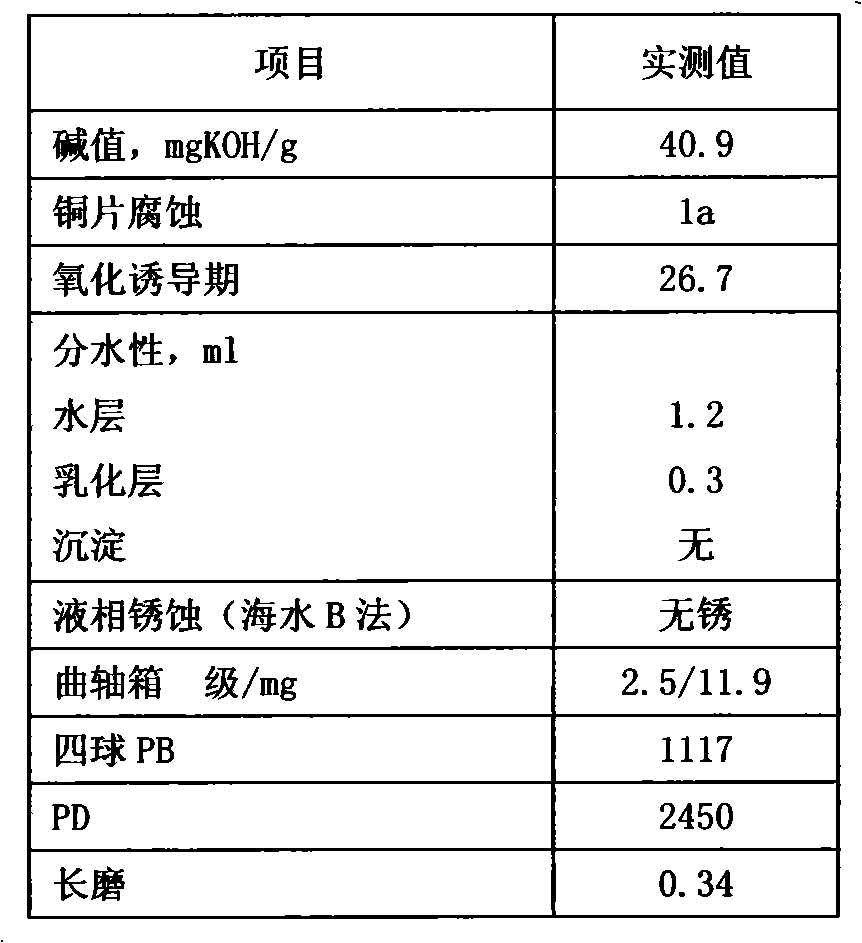

Lubricating oil composition for marine medium-speed cylindrical diesel engine

The invention relates to a lubricating oil composition for a marine medium-speed cylindrical diesel engine, which comprises the following components in percentage by weight: 12-22% of high temperature detergent, 1-3% of ashless dispersant, 0.5-1.5% of antioxidant, 0.002-0.005% of antifoam agent and the balance of base oil, wherein the high temperature detergent is compounded from the following components in percentage by weight: 30-70% of high base number alkyl calcium salicylate and 30-70% of high base number sulfurized calcium alkyl phenate; the ashless dispersant is bis-succinimide; the antioxidant is zinc dialkyl dithiophosphate; and the antifoam agent is methylsilicone oil. The invention can satisfy the operational requirements of advanced marine medium-speed cylindrical piston diesel engine oil; and the lubricating oil composition has the function of inhibiting the generation of black oil sludge, reduces the faults of the medium-speed cylindrical piston diesel engine due to bad lubrication and the like, prolongs the service life of the engine, and has the advantages of accessible raw materials, simple production technique and low cost.

Owner:PETROCHINA CO LTD

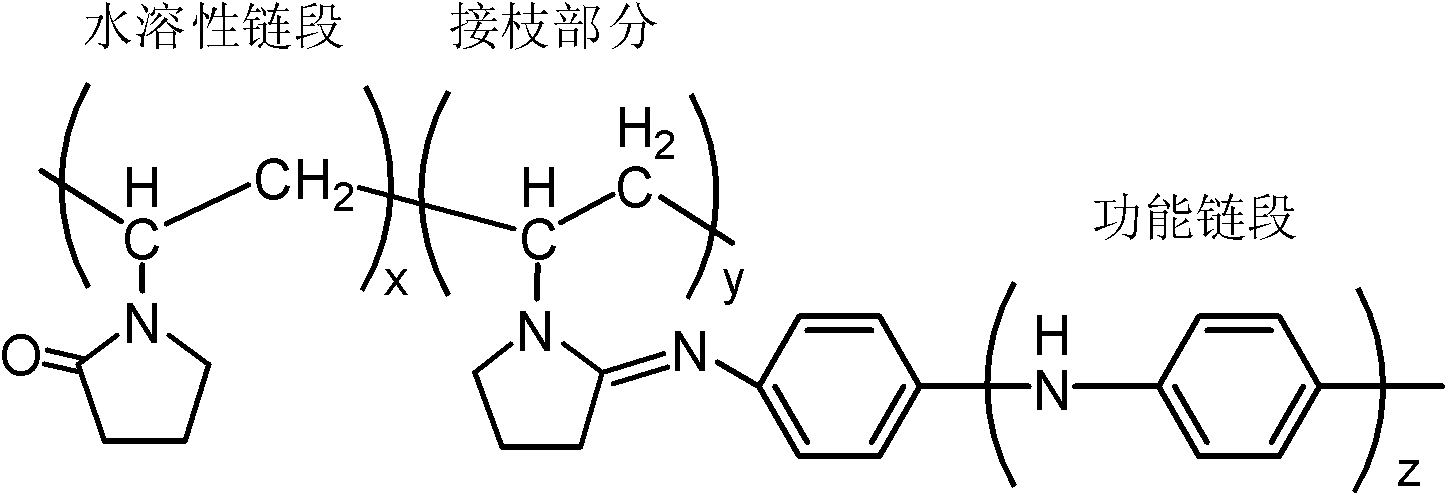

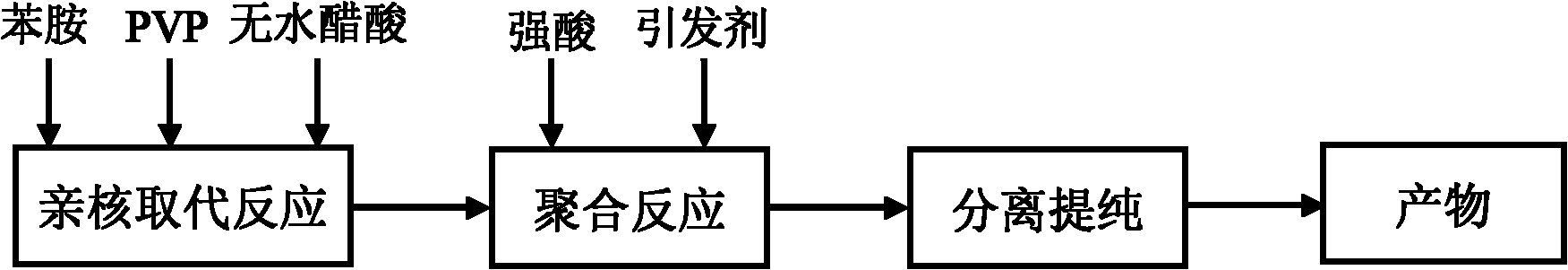

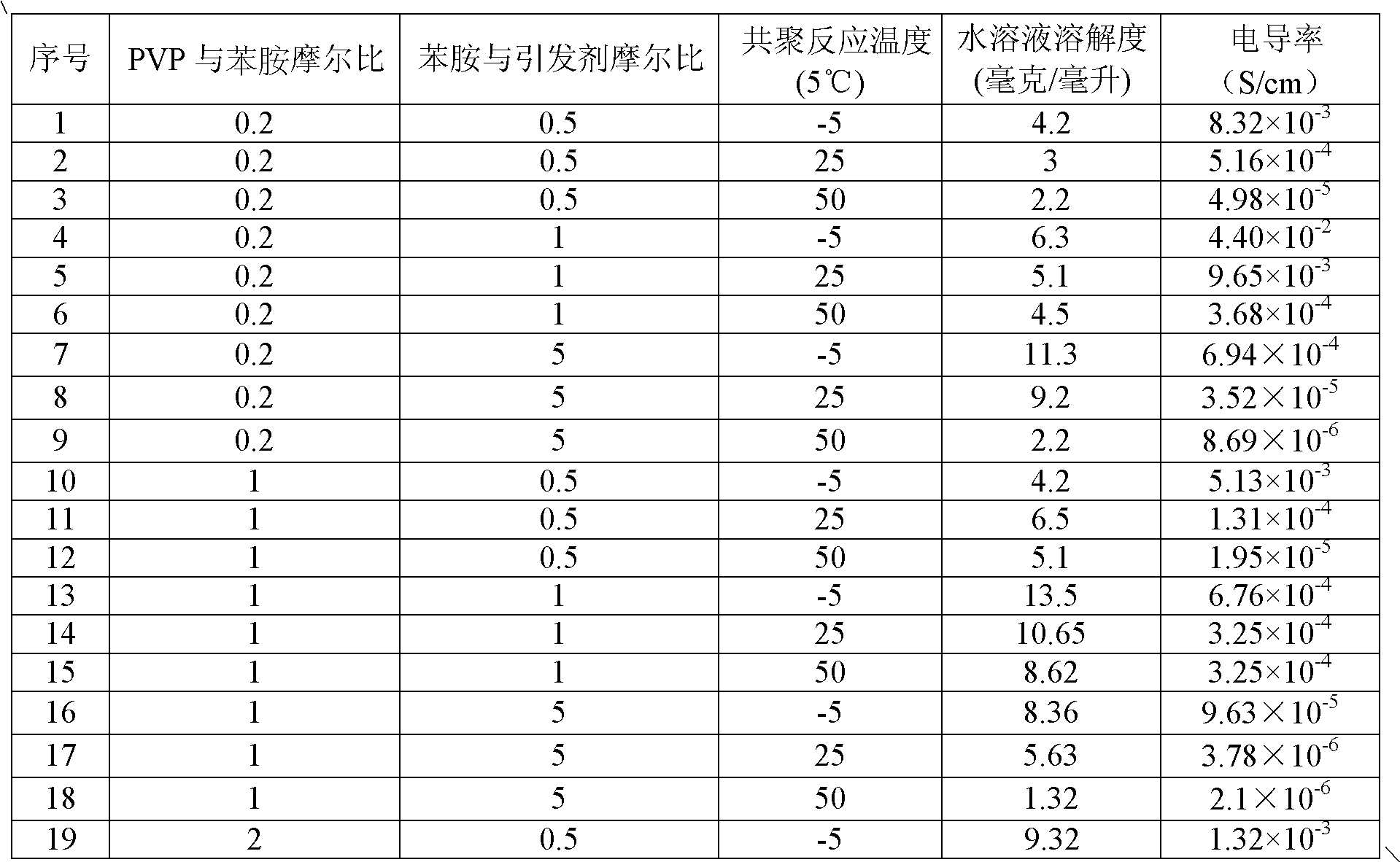

Preparation method of water-soluble polyvinylpyrrolidone grafted polyaniline (PVP-g-PANI) copolymer

InactiveCN102040695AHigh reactivityGuaranteed nucleophilic reactionTenebresent compositionsSolubilitySocial benefits

The invention discloses a preparation method of a water-soluble polyvinylpyrrolidone grafted polyaniline (PVP-g-PANI) copolymer. In order to overcome the defects of the traditional preparation methods of a water-soluble electrochromic PANI material and space-dispersive-type soluble PANI, the novel preparation method of the PVP-g-PANI copolymer is provided, which has the advantages of simple process, high yield and small pollution to the environment, and a product has favorable dissolubility, electrical conductivity and controllability in infrared band electrochromic emissivity. The method comprises the following steps of: firstly, carrying out nucleophilic substitution reaction on aniline and the PVP in a faintly acid environment, then carrying out graft copolymerization on the PANI and the PVP, and finally, separating and purifying the copolymer. The method is simple in process, has high economic and social benefits, and can be used for obtaining the graft copolymer with favorable water solubility, and the reaction is easy to control and generates no corrosion and pollution.

Owner:NAT UNIV OF DEFENSE TECH

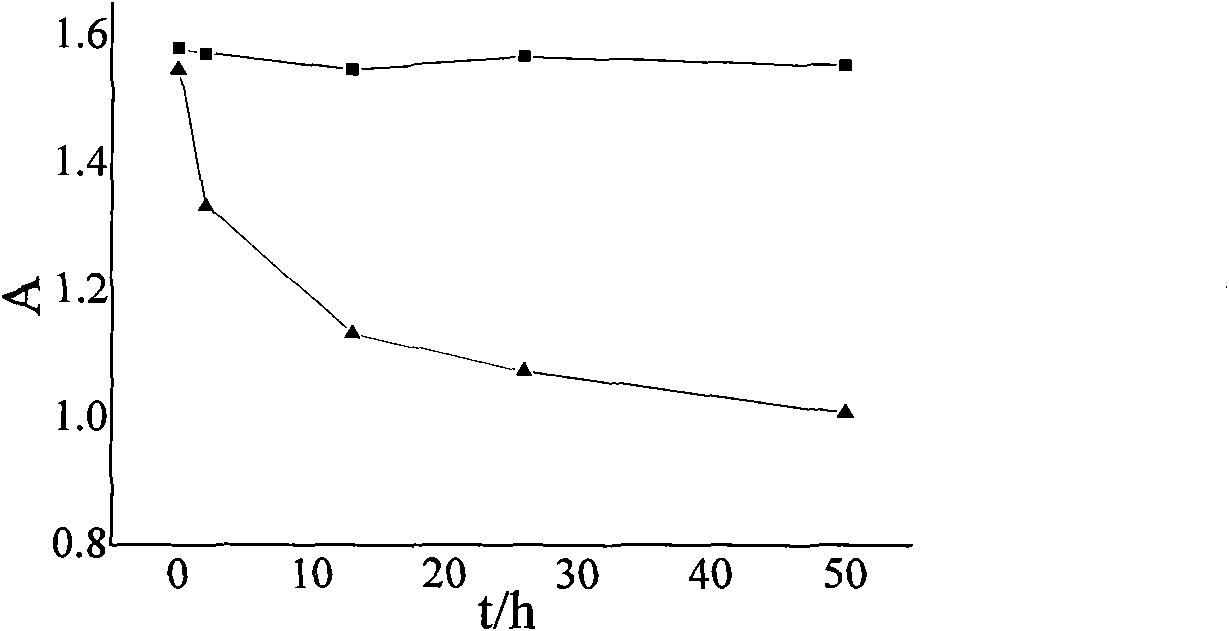

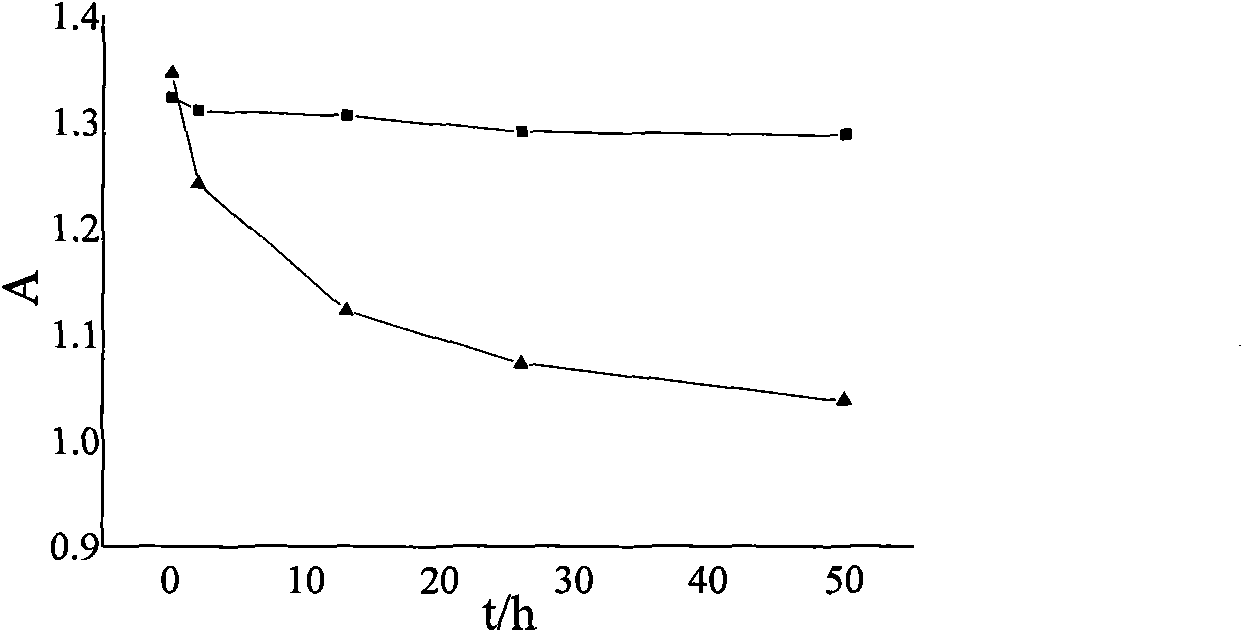

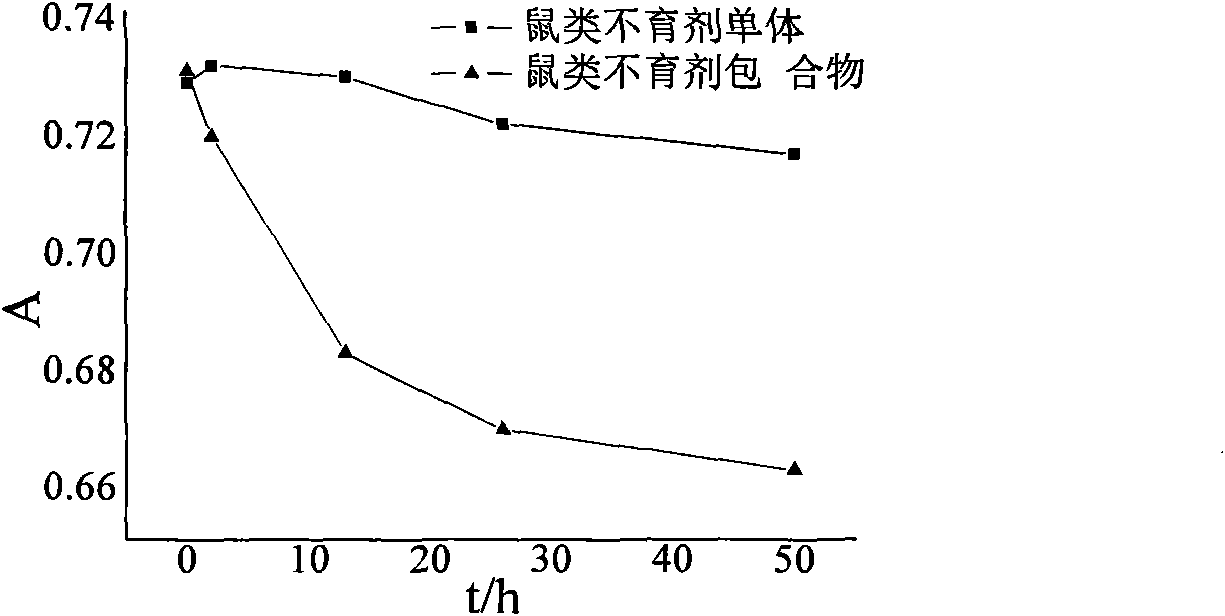

Cyclodextrin inclusion compound of rodents sterilant and preparation method thereof

InactiveCN101869113AGood water solubilityImproves UV stabilityBiocideChemosterilantsSolubilityMass ratio

The invention relates to the field of medicaments, in particular to a cyclodextrin inclusion compound of a rodents sterilant and a preparation method thereof. By the method, the rodents sterilant is mixed with cyclodextrin or a derivative of the cyclodextrin in a mass ratio of 1:1-200 to prepare the inclusion compound. The obtained inclusion compound not only has high water solubility, but also has a high ultraviolet stability. The invention initially provides the cyclodextrin inclusion compound of the rodents sterilant. The cyclodextrin inclusion compound has a tubular structure formed by glucosamine residues to form a unique conformation which is externally hydrophilic and internally hydrophobic, and can form a compound supramolecular system with an indissolvable compound to play a solubilization role and solve the problem of low water solubility of the conventional rodents sterilant; moreover, the inclusion compound has the high ultraviolet stability to meet the requirement of field administration; in addition, the cyclodextrin compound has no toxicity or low toxicity and is a good carrier for performing a medicinal effect research.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

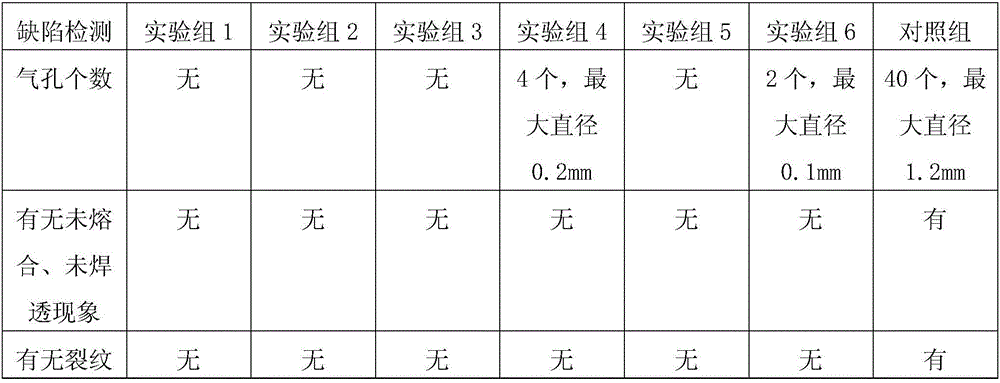

Aluminum alloy welding process

InactiveCN106825871AHigh tensile strengthDoes not affect aestheticsArc welding apparatusWelding/cutting media/materialsSlagMegasonic cleaning

The invention discloses an aluminum alloy welding process and belongs to the technical field of metal welding. The aluminum alloy welding process comprises the following steps: (1) a welding area of the surface of an aluminum alloy plate is put into a cleaning fluid for ultrasonic cleaning and then dried; (2) the welding area of the to-be-welded aluminum alloy plate is heated to 150-200 DEG C; (3) the welding area of the to-be-welded aluminum alloy plate is heated to 750-830 DEG C, a degasifier is sprayed to the welding area of the aluminum alloy plate, and the aluminum alloy plate is welded with a special aluminum alloy welding wire; (4) the welded part of the aluminum alloy plate is subjected to solid solution at the temperature of 300-450 DEG C, and the aluminum alloy plate is subjected to degasification treatment through ultrasonic waves; (5) the welded part of the aluminum alloy plate after solid solution treatment is transferred to cold water and cooled to the room temperature; (6) clearing and removal of welding powder or slag are performed. With the adoption of the aluminum alloy welding process, the pore problem can be effectively solved, and incomplete fusion, incomplete penetration and cracking phenomena are unlikely to occur.

Owner:玉林博飞商贸有限公司

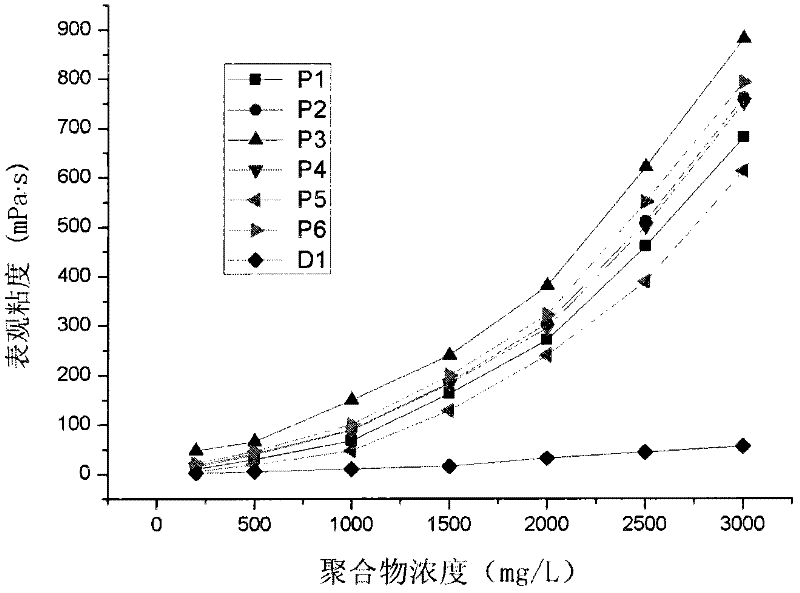

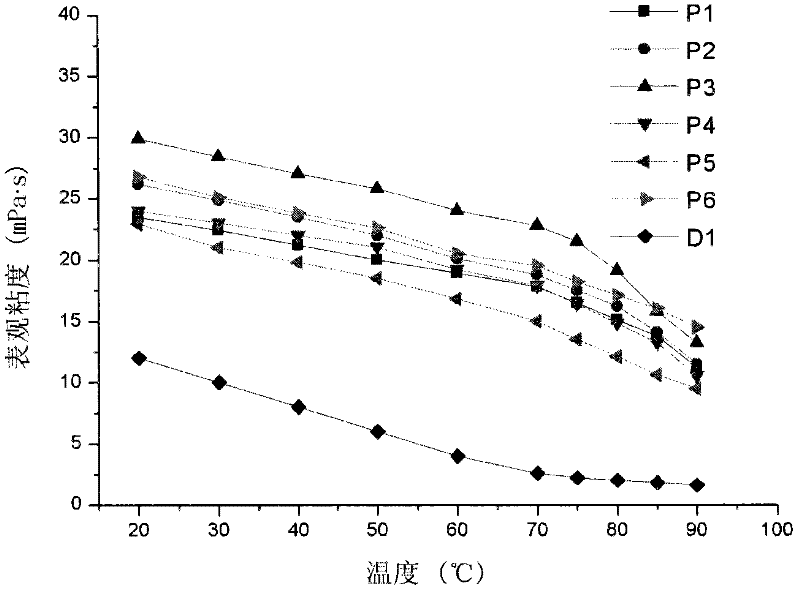

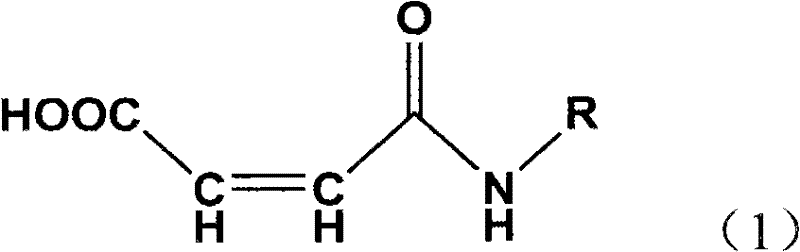

Amphiphilic polymerizable monomer and amphiphilic tackifying copolymer, and preparation methods and application thereof

ActiveCN102452950AHigh polymerization activitySelf-solubilizingOrganic compound preparationCarboxylic acid amides preparationSalt resistanceApparent viscosity

The invention provides an amphiphilic polymerizable monomer and an amphiphilic tackifying copolymer, and preparation methods and application thereof. The amphiphilic polymerizable monomer provided in the invention has both hydrophilic groups and hydrophobic groups in terms of its molecular structure; when used for preparation of a polymer, the monomer is capable of self-dissolving without addition of a surfactant and enables a copolymer with an amphiphilic micro-block structure to be obtained. A solution of the amphiphilic tackifying copolymer provided in the invention has good temperature tolerance, salt resistance and apparent viscosity and good stability under the conditions of high temperature and high salinity; the amphiphilic tackifying copolymer can be used as a polymer flooding agent and has effective effects of solubilizing, dispersing and the like on crude oil, which enables the copolymer to carry and draw residual crude oil difficult to displace, thereby improving oil displacement efficiency of the copolymer, and the amphiphilic tackifying copolymer is applicable to high temperature high salinity oil reservoirs and polymer-displaced oil reservoirs and can further improve a recovery rate of crude oil in tertiary oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fiberglass-reinforced cement and preparation method thereof

ActiveCN106186751AGuaranteed and improved strengthGood alkali resistanceCement productionGlass fiberEmulsion

The invention discloses fiberglass-reinforced cement, made from, by weight: 40-50 parts of cement clinker, 5-10 parts of alkali-resistant fiberglass, 1-5 parts of mineral residue, 1-5 parts of pulverized coal residue, 5-10 parts of limestone powder, 1-5 parts of sodium methyl silicate, 1-5 parts of anionic polyacrylamide, 1-5 parts of sodium methyl silicate, and 1-5 parts of acrylic emulsion; the alkali-resistant fiberglass is 5-15 Mum in diameter and 15-30 mm in length and includes the chemical components: 60-65% of SiO2, 15-20% of Na2O, 4.0-5.0% of Al2O3, 5-10% of ZrO2, 4.0-5.0% of CaO, 5-8% of B2O3, and 0-0.7% of BaO. The invention also discloses a preparation method of the fiberglass-reinforced cement, including: subjecting the cement clinker, mineral residue, pulverized coal residue and limestone powder to mixing, crushing and calcining to obtain semi-finished cement, and adding water and the remaining materials sequentially, stirring, drying, and crushing to obtain the finished cement. The fiberglass-reinforced cement prepared herein has the advantages of high strength, alkali resistance and water resistance, and is widely applicable to the severe environments such as alkaline environments and low-temperature environments, and the cement market is widened.

Owner:宿迁空天新材料有限公司

Method for rapidly manufacturing nano-palladium/iron with scattered dispersing agent and scattered surface active agent

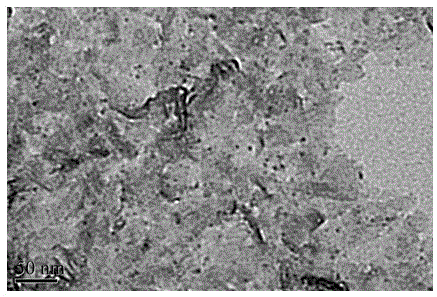

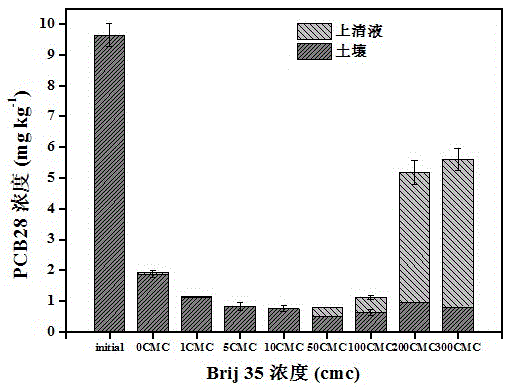

InactiveCN105458290AImprove stabilitySolubilizeMaterial nanotechnologyTransportation and packagingPolychlorinated biphenylPotassium

The invention relates to a method for rapidly manufacturing nano-palladium / iron with a scattered dispersing agent and a scattered surface active agent. A liquid phase reduction method is adopted, under the condition that sodium carboxymethylcellulose exists, a strong reducing agent KBH4 is used for reducing Fe2+, and zero-valent nano-iron is obtained; the surface of the zero-valent nano-iron is loaded with palladium through potassium chloropalladite, the surface active agent Brij35 at certain concentration and the dispersed nano-palladium / iron are mixed, and therefore the nano-palladium / iron with the scattered dispersing agent and the scattered surface active agent is manufactured. The method has the beneficial effects that the particle diameter of manufactured nano-palladium / iron particles is small, distribution is even, the particle diameter is about 8 nanometers, stability is good and can be kept over 5 d, reaction activity is high, the degradation efficiency of polychlorinated biphenyl in soil is 12.2% higher than that obtained without the addition of the surface active agent, and the method can be widely applied to the field of environmental modification; and required manufacturing equipment is simple, the process is convenient, a reaction is conducted at the normal temperature under the normal pressure and can be finished within only 60 min, secondary pollution can be avoided, and the method is suitable for large-scale industrial production.

Owner:中建中环新能源有限公司 +1

Edible fungus lip balm and preparation method thereof

InactiveCN105106102AKeep dryEasy to crackCosmetic preparationsToilet preparationsBiotechnologyPholiota

The invention belongs to the field of skin care product preparation and particularly relates to edible fungus lip balm and a preparation method thereof. The edible fungus lip balm comprises, by weight parts, 5-7 parts of pholiota nameko, 10-15 parts of pholiota nameko, 7-8 parts of lentinula edodes, 9-11 parts of coix seed extracting solution, 12-13 parts of honey, 19-22 parts of beeswax and 6-8 parts of almond oil. Fresh pholiota nameko and lentinula edodes are soaked into the coix seed extracting solution, and nutritional ingredients of pholiota nameko and lentinula edodes can be extracted efficiently; and pholiota nameko is soaked in the honey, so that glairing and nutritional ingredients on the surface of pholiota nameko are fully fused with the honey. The manufactured lip balm is rich in nutritional ingredients of edible fungi and can supplement various required vitamins and the like against xerochilia and cleft lip and the like.

Owner:福建绿宝食品集团有限公司

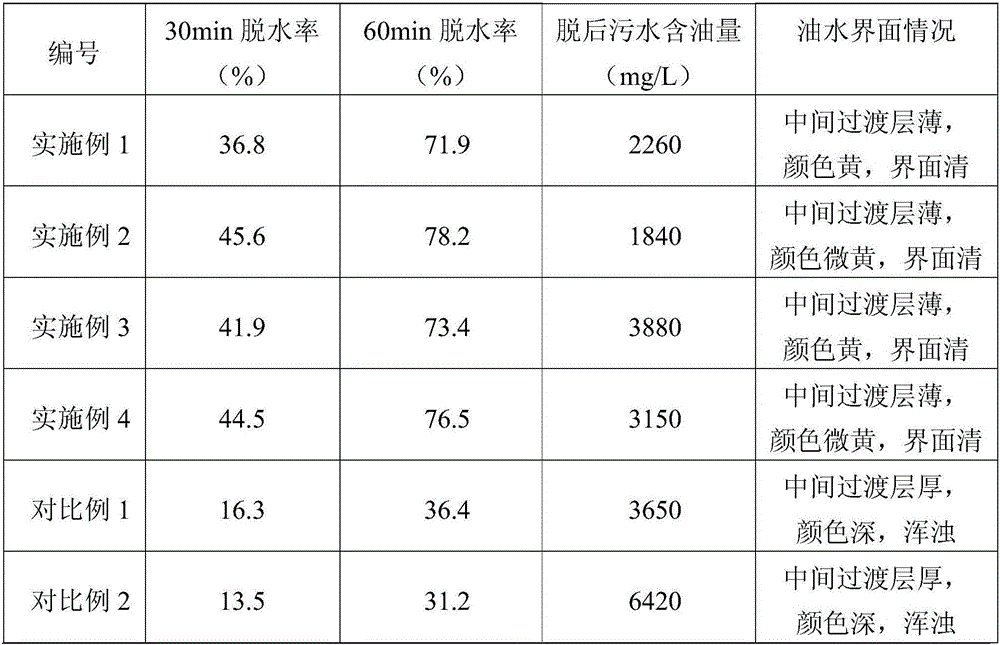

Method for efficiently treating oil field complex oil-water emulsion

ActiveCN106701156AReduce or eliminateChange stabilityDewatering/demulsification with chemical meansAlkaneDemulsifier

The invention provides a method for efficiently demulsifying and dehydrating oil field complex oil-water emulsion. The method comprises the following steps: 1) adding a demulsifier into crude oil and mixing uniformly to obtain primarily treated crude oil; 2) adding a mixture of alkane, alcohol and alcohol ether into the primarily treated crude oil and mixing uniformly, wherein the mixture of the alkane, the alcohol and the alcohol ether consists of three components, namely alkane, monohydric alcohol or polyhydric alcohol, and alcohol ether or alcohol ether ester. The method for efficiently demulsifying and dehydrating the oil field complex oil-water emulsion, provided by the invention, specially aims at a special oil-water emulsifying layer (an intermediate transition layer), ageing oil and the like which are easily formed after dehydration is conducted by singly adopting a demulsifier, the stability of an interfacial film of the oil-water emulsifying layer is effectively broken and the polar environment of interfacial phase is changed on the basis of not changing the use variety and the use mode of the original demulsifier by cooperatively using the specially composed mixture of the alkane, the alcohol and the alcohol ether, and the solubilization effect on asphaltene, colloid, polymers and the like is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Formula of biological compound type degreasing agent

The invention discloses a formula of a biological compound type degreasing agent, which relates to the technical field of surface degreasing of metal materials. According to the formula, the degreasing agent consists of a microorganism component and a chemical component, wherein each liter of microorganism component comprises 2.5 to 3mL of zoogloea sp., 4 to 5mL of Mohave bacillus, 2 to 2.5mL of bacillus subtilis and 3 to 4mL of Serratia marcescens; and each liter of chemical component comprises 2g of polyethyleneglycol fatty alcohol ether sulfonate, 5g of nonylphenol polyoxyethylene ether, 4g of fatty alcohol polyurethane alkyl ether, 2.5g of fatty alcohol polyoxyethylene ether, 2g of nonylphenol polyoxyethylene ether sodium sulfate, 2.5g of sodium metasilicate, 3g of isopropyl alcohol, 0.1g of ethylene diamine tetraacetic acid and the balance of water. By the formula, greasy dirt on a metal surface can be treated in advance, and then the emulsified greasy dirt in water is decomposed on the basis of the microorganism component, so that the metal surface has an efficient, economic and environment-friendly degreasing process; and the degreasing agent has a wide degreasing range, high degreasing efficiency and a simple preparation method, is biologically degradable and is convenient to use.

Owner:BENGBU YUCHENG NEW MATERIAL TECH

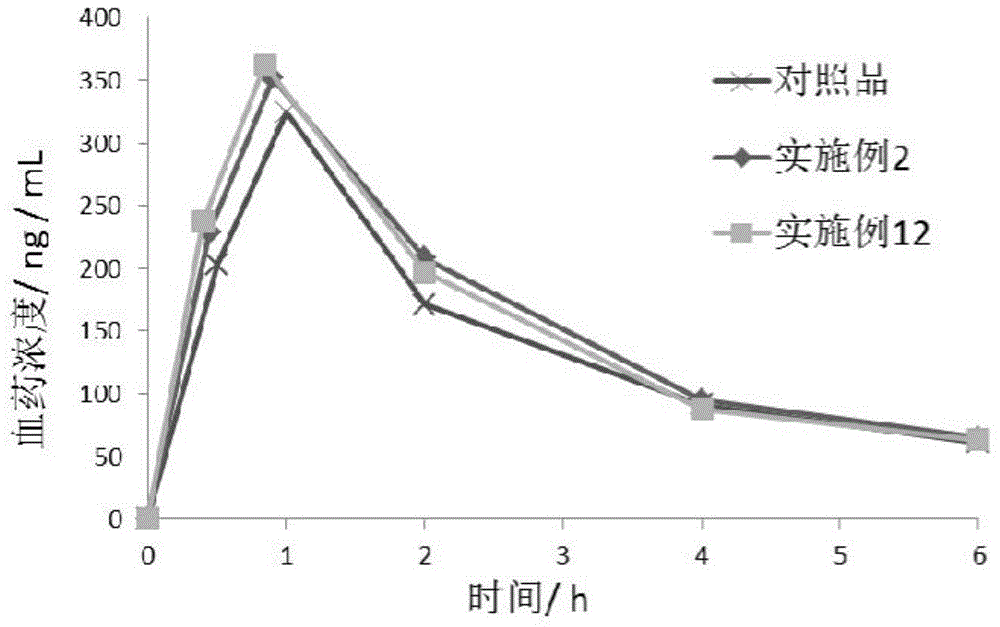

Composite for treating myelodysplastic syndrome and preparation method thereof

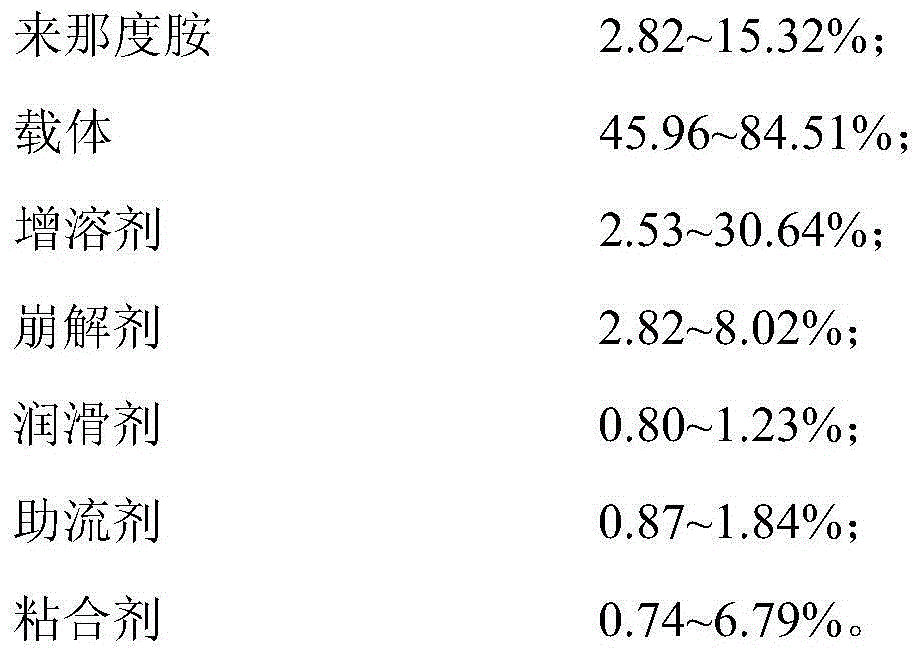

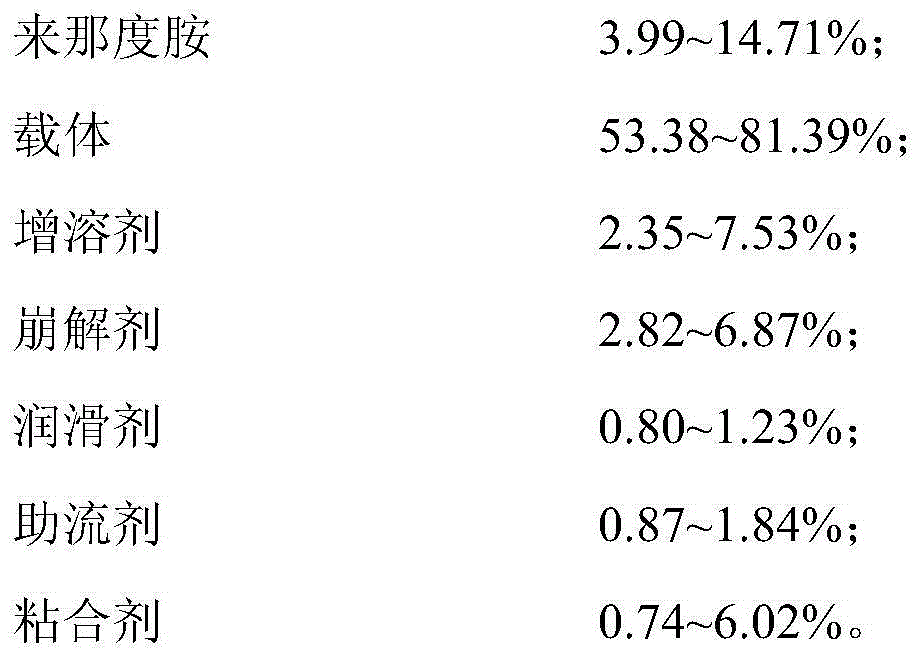

ActiveCN103705485BImprove bioavailabilityGood water solubilityOrganic active ingredientsPill deliverySolubilityAdhesive

The invention discloses a composite for treating myelodysplastic syndrome. The composite comprises the following components: lenalidomide, a carrier, a solubilizing agent, a disintegrating agent, a lubricating agent, a flow aid and an adhesive, wherein the carrier is a mixture of any one or several of a high-molecular water-soluble polymer, a water-soluble small molecule compound, a hydrophilic auxiliary material and an inorganic carrier; the solubilizing agent is a mixture of one or several of lauryl sodium sulfate, poloxamer, beta. cyclodextrin and a derivative thereof, polysorbate and polyoxyethylene alkyl ether. The invention also provides a preparation method of the composite, and the preparation method comprises the steps of grinding, mixing, dry granulation, total mixing and tabletting or capsule filling. The preparation method disclosed by the invention effectively enhances the water solubility and bioavailability of the lenalidomide; the dry granulation preparation process simplifies the preparation steps, reduces the cost, saves the energy resources, reduces the labor expenditure and realizes the energy conservation and environment protection in production.

Owner:AC PHARMA CO LTD

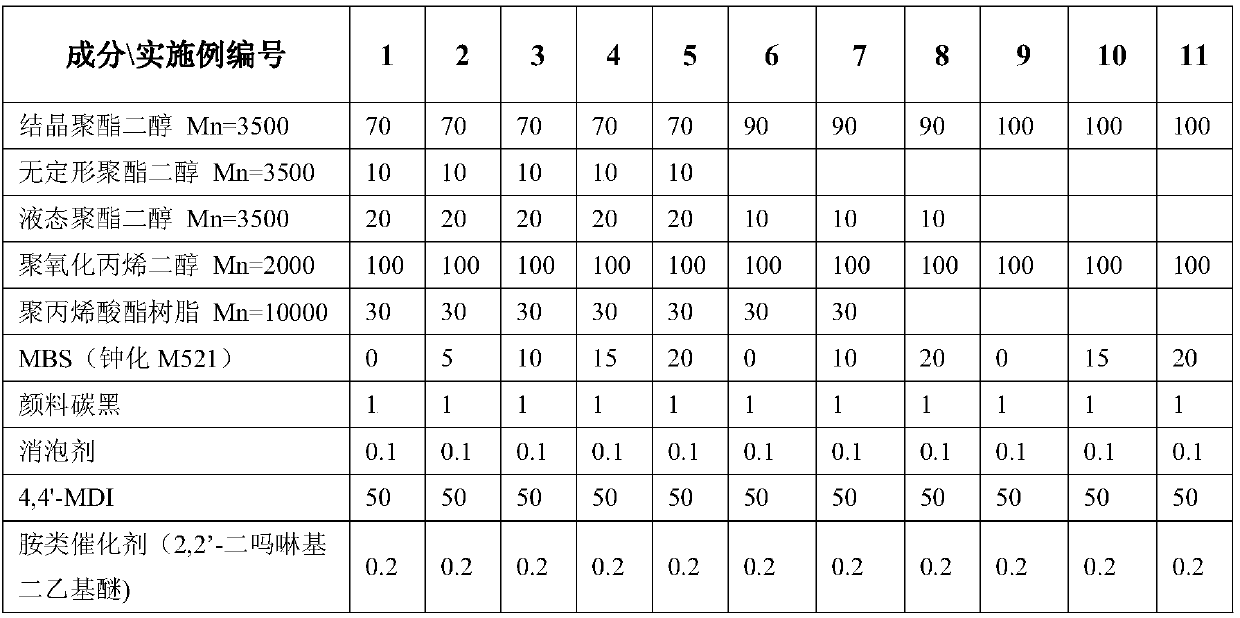

Reactive polyurethane hot melt adhesive with low wall removal rate, and preparation method thereof

ActiveCN110791248AStress reliefReduce shrinkage stressNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesThermoplasticPolyester

The invention provides a reactive polyurethane hot melt adhesive with low wall removal rate, and a preparation method thereof. According to the technical scheme, the components of a formula are subjected to innovative design to relieve the internal stress of a hot melt adhesive; based on the principle of deformation and energy absorption of an MBS rubber core under the action of stress, the shrinkage stress generated in a cooling process of HM PUR is relieved so as to reduce the wall removal rate; and by adding an acrylate type thermoplastic resin into the formula, the obtained reactive polyurethane hot melt adhesive has good compatibility with polyether polyol, and has solubilizing effect on MBS particles. According to the invention, the internal stress of the hot melt adhesive is fully relieved, and the wall removal rate can be effectively reduced; the dosage of the crystalline polyester is ensured by the formula, so that the good initial bonding force and the final bonding strengthcan be maintained; and on the basis, the invention further provides a preparation method and a pouring process of the hot melt adhesive so as to establish a foundation for large-scale production of the hot melt adhesive.

Owner:TIANJIN AUSP COMM EQUIP COMPONENTS

Finishing liquid for hot-galvanized plate and preparation method for finishing liquid

ActiveCN104194908AGood anti-rust functionImprove rust resistanceLubricant compositionSodium metasilicateTricarboxylic acid

The invention relates to finishing liquid for a hot-galvanized plate and a preparation method for the finishing liquid. The finishing liquid comprises a component I and a component II, wherein the component I comprises following ingredients in parts by weight: 23-33 parts of water, 5-8 parts of dibasic acid, 8-12 parts of tricarboxylic acid and 54-57 parts of triethanolamine; the component II comprises following ingredients in parts by weight: 47-68 parts of water, 4-8 parts of sodium carbonate, 3-5 parts of potassium hydroxide, 2-4 parts of disodium ethylenediamine tetraacetate, 6-10 parts of sodium metasilicate pentahydrate, 8-12 parts of reverse block polyether, 6-8 parts of neodecanoic acid and 3-6 parts of sodium benzoate. The finishing liquid has relatively good rust-proof and lubricating effects, has excellent wetting and cleaning properties and relatively high cleaning ability, and can lubricate and repair the surface of a roll; the finished galvanized plate is smooth in surface, and defects of finishing spots and coating moire can be effectively eliminated or reduced; the finishing liquid has good foam-inhibiting and defoaming functions, so that liquid can be avoided from remaining on the surfaces of the roll and a steel plate and the foam can be avoided from overflowing around to affect the working environment.

Owner:江苏苏北能源科技有限公司

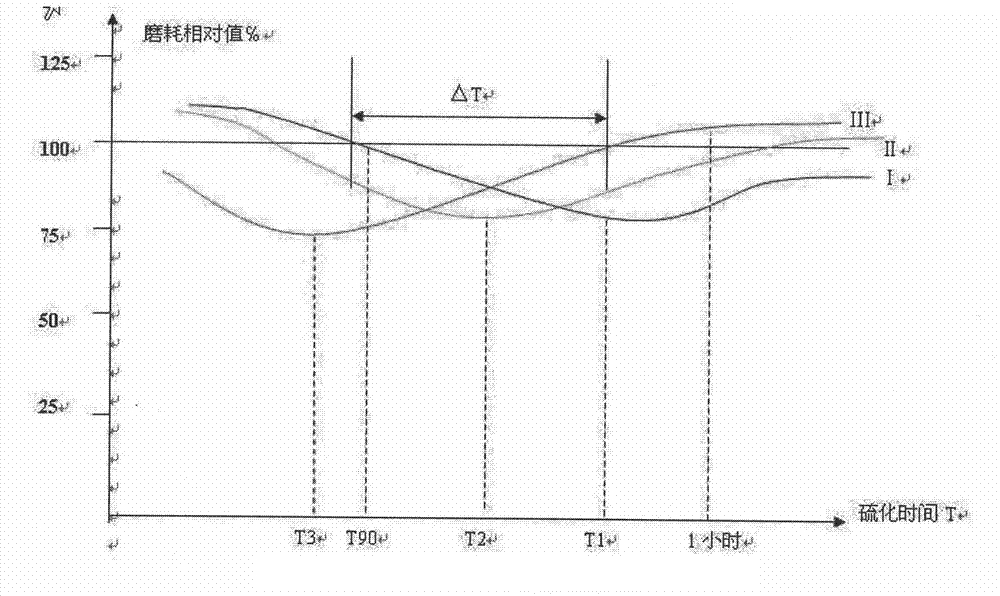

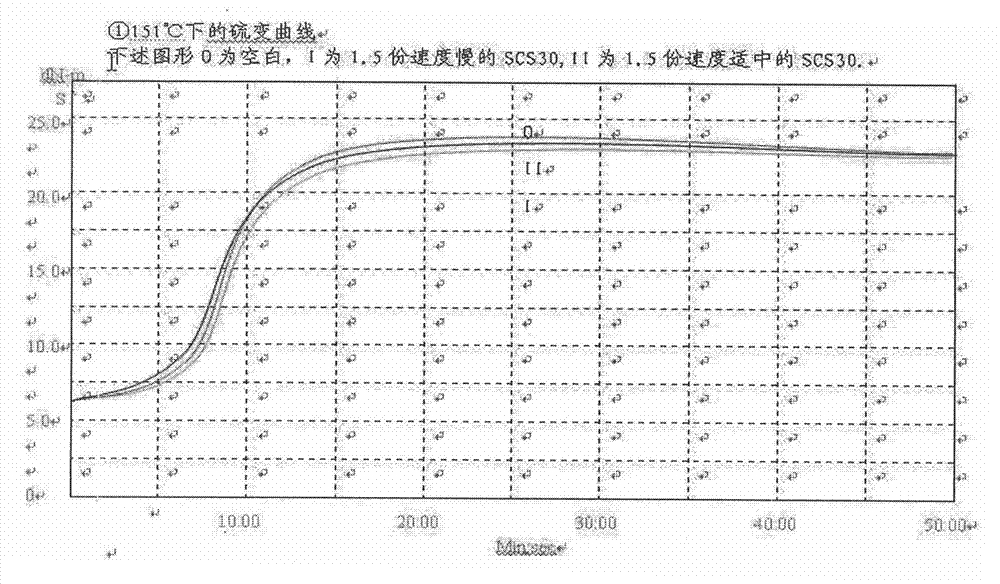

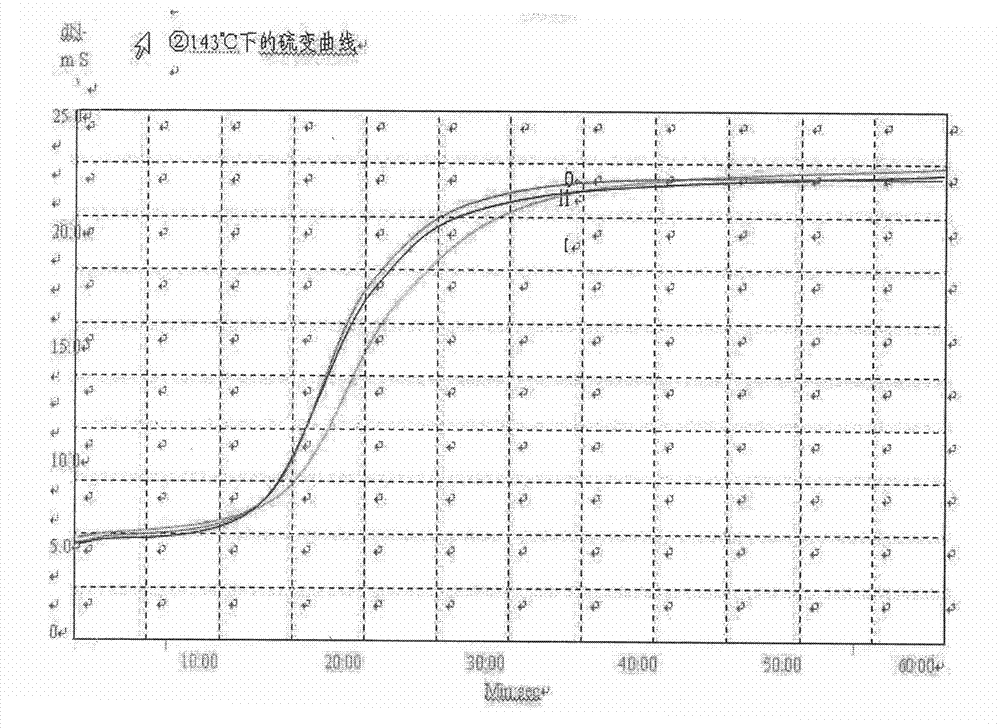

Rubber homogenization wear-resistant agent

The invention relates to a rubber homogenization wear-resistant agent. According to a formula, the rubber homogenization wear-resistant agent comprises, by weight: 30 of a urea-aldehyde acid sodium polymer, 12 of hexamethylenetetramine, and 2.5 of NH4CL. Preferably, the rubber homogenization wear-resistant agent can be added with 15 of octadecanol, 20 of white carbon black, and 20 of a plasticizer. The rubber homogenization wear-resistant agent creatively can promote uniform dispersion of high viscosity rubber and the additives, and can well reach the effects of solubilizing, wear resisting, and wetting, etc. The raw materials and the formed product are compatible with rubber, and do not get in the way of rubber products. The rubber homogenization wear-resistant agent has easily available raw materials, a low cost and economical efficiency. During sulfidation of rubber, a cross-linking effect can be generated, and a new sulfidation network can be formed, thus reaching the purpose of modification. The rubber homogenization wear-resistant agent provided in the invention can reduce wear by 13-24%.

Owner:盛柏松

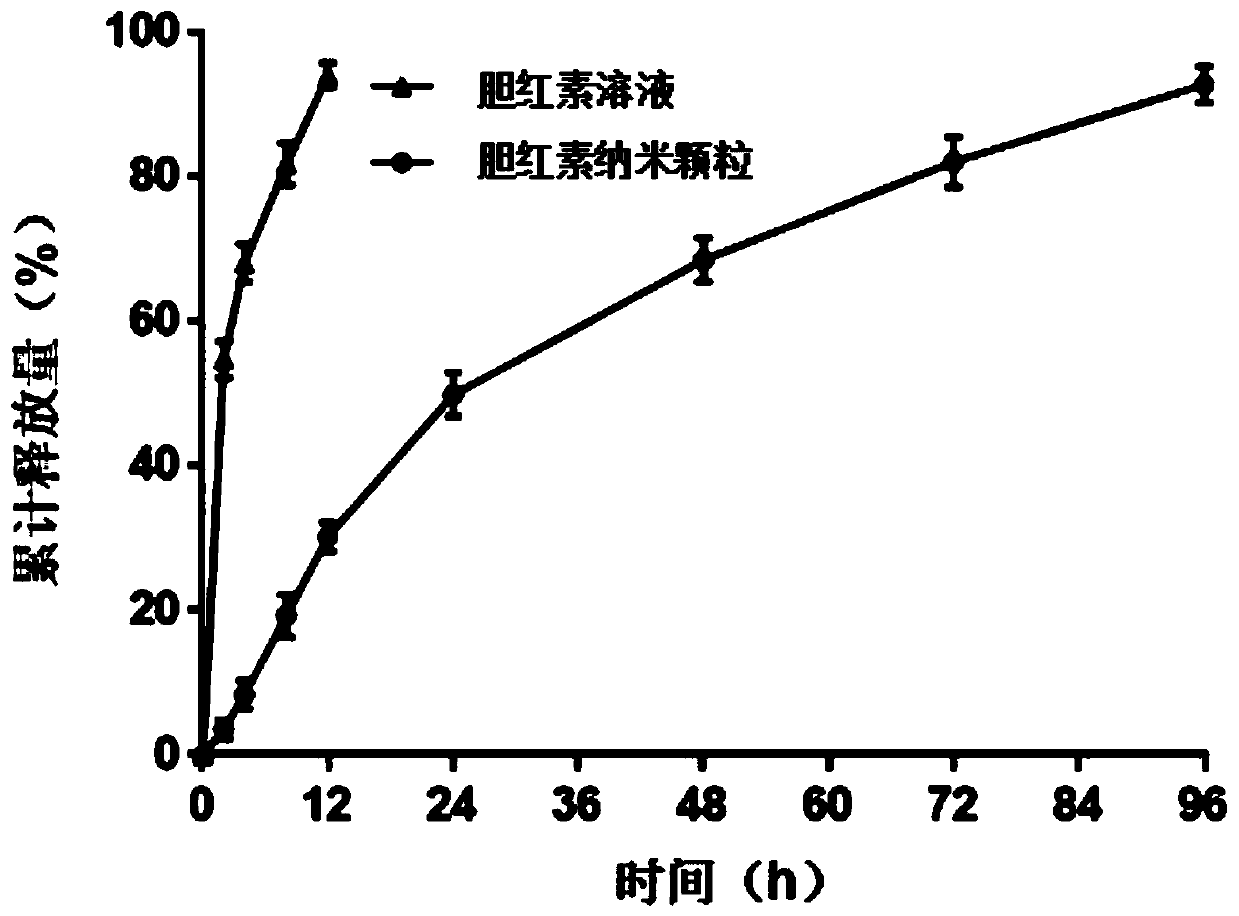

Bilirubin nanoparticles for treating acute pancreatitis and preparation method thereof

ActiveCN110063945AOptimize prescriptionGood treatment effectOrganic active ingredientsDigestive systemGenipinAcute pancreatitis

The invention discloses bilirubin nanoparticles for treating acute pancreatitis and a preparation method thereof. The nanoparticles are mainly composed of silk fibroin, bilirubin, genipin and ceramide. The method comprises the steps that firstly, the bilirubin, the genipin and the ceramide are dissolved in a mixed organic reagent; secondly, the silk fibroin is dissolved in an aqueous solution, then the mixed solution of the bilirubin, the genipin and the ceramide is slowly added into the silk fibroin solution dropwise and continuously stirred, the organic solvent is removed through dialysis, and an obtained nanoparticle suspension is diluted with pure water to obtain the bilirubin nanoparticles. The bilirubin nanoparticles can be used for treating acute pancreatitis and relieving tissue edema caused by pancreatitis, can be applied to preparation of medicines for treating acute pancreatitis, and has wide clinical application prospects.

Owner:WENZHOU MEDICAL UNIV

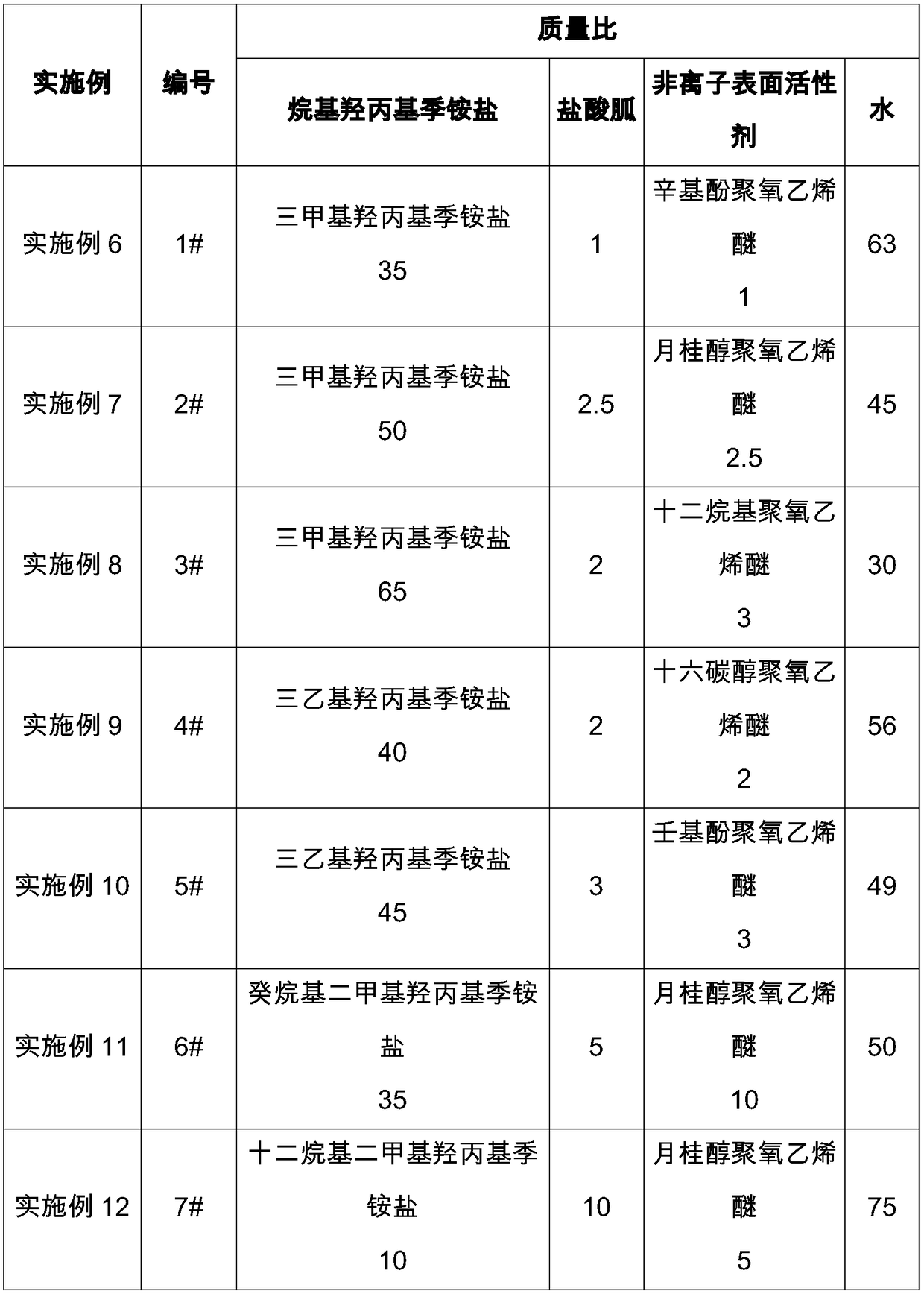

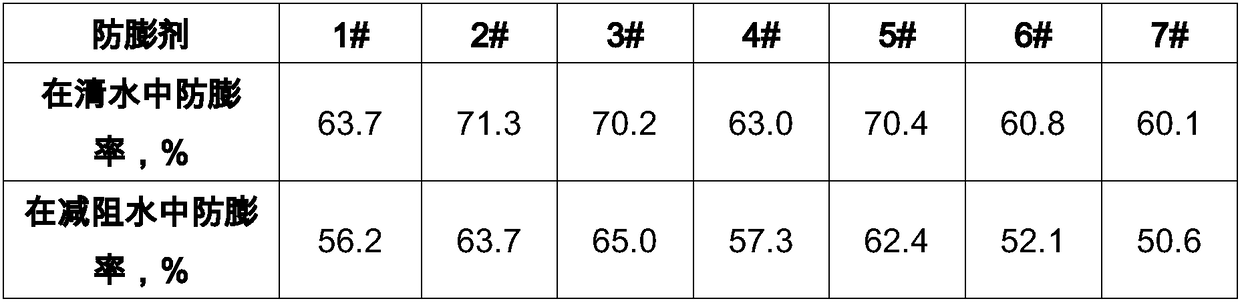

Small-molecular liquid anti-swelling agent, clay anti-swelling agent for fracturing and preparation method

ActiveCN108977190AInhibits hydration swellingAvoid harmDrilling compositionInorganic saltsAlkylphenol

The invention discloses a small-molecular liquid anti-swelling agent, a clay anti-swelling agent for fracturing and a preparation method. The anti-swelling agent comprises the following components byweight percent: 10-65% of alkyl hydroxypropyl quaternary ammonium salt, 1-10% of guanidine hydrochloride, 1-10% of nonionic surfactant and the balance of water, wherein the nonionic surfactant is alkylphenol polyoxyethylene or fatty alcohol-polyoxyethylene ether with 8-18 alkyl carbon atoms and degree of polymerization within 8-20. The liquid anti-swelling agent disclosed by the invention is composed of small-molecular components, has the characteristics of low relative molecular weight, no harm to hydrocarbon reservoir and convenience in onsite preparation, and is low in dosage and high in anti-swelling rate; the anti-swelling rate of an anti-swelling rate aqueous solution can reach up to 71%; after the liquid anti-swelling agent is compounded with an inorganic salt, the anti-swelling rate can reach up to 79%; the small-molecular liquid anti-swelling agent is specially suitable for fracturing modification of low-permeability and water-sensitive stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

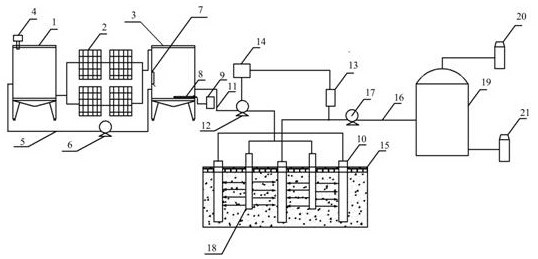

System for repairing contaminated soil by thermal leaching with solar energy

PendingCN112517624AImprove rinsing effectStimulate growthContaminated soil reclamationInjection wellContaminated soils

The invention discloses a system for repairing contaminated soil by thermal leaching with solar energy, which comprises a solar heating system, an auxiliary heating system, an in-situ leaching systemand a waste gas and waste liquid treatment system, and is characterized in that the solar heating system comprises a leacheate preparation tank, a solar heat collection plate and a leacheate storage tank, and a vacuum tube heater is arranged in the solar heat collection plate; the prepared leacheate is heated through a vacuum heating pipe and then enters the leacheate storage tank, the auxiliary heating system comprises a heating rod and a control device and plays a role in auxiliary heating of the leacheate, the in-situ leaching system comprises a heatable injection well, a multiphase extraction well and a heat preservation layer, the leacheate is injected into soil through the injection well, and the multiphase extraction well is communicated with the heat preservation layer. After the leacheate reacts with the polluted soil for a period of time, the multiphase extraction well extracts the waste leacheate containing the organic pollutants to a waste gas and waste liquid treatment system. The contaminated soil remediation efficiency is high, solar energy can be fully utilized, environmental protection and energy conservation are achieved, and the advantages of thermal desorption and in-situ leaching can be combined.

Owner:苏州精英环保有限公司

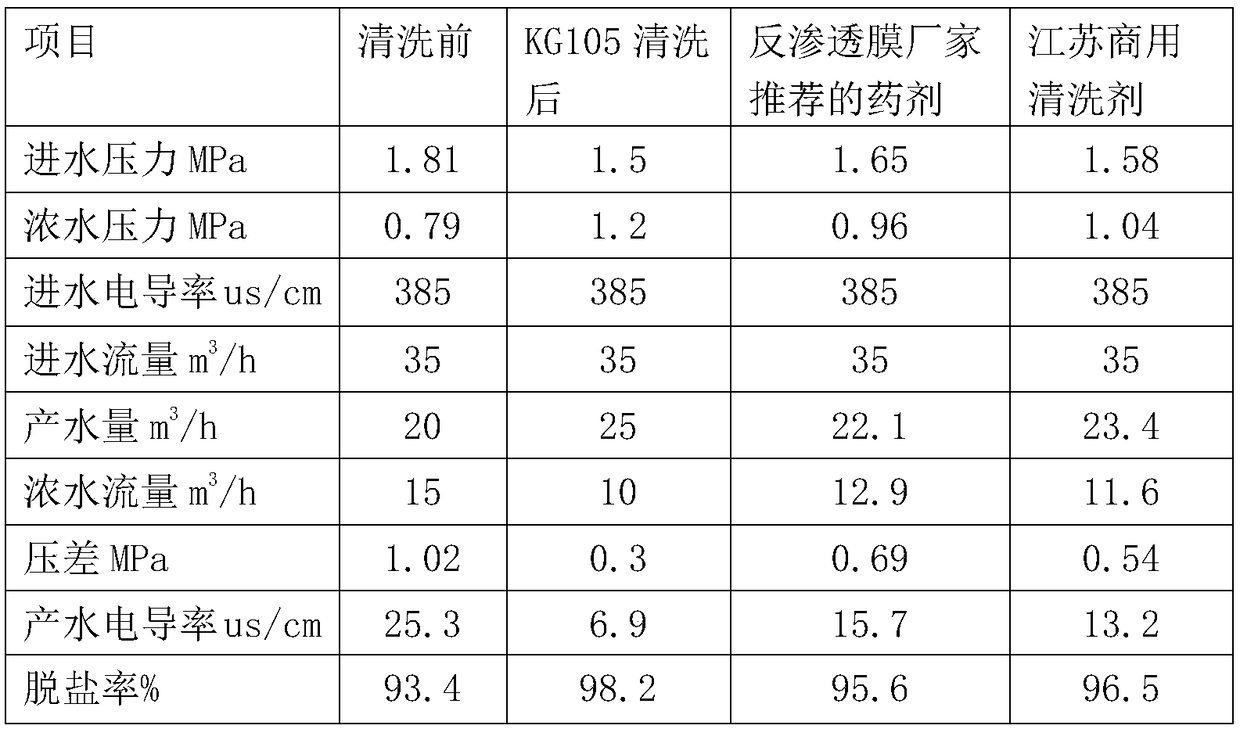

Cleaning composition for reverse osmosis membrane and preparation method of cleaning composition

The invention belongs to the technical field of cleaning of reverse osmosis membranes and discloses a cleaning composition for a reverse osmosis membrane and a preparation method of the cleaning composition. The composition is prepared from the following components in percentage by weight: 3 to 6 percent of HCl, 8.5 to 17 percent of H3PO4, 1.96 to 3.92 percent of NH4HF2, 1.4 to 5.6 percent of carboxyethyl thiodisuccinic acid, 0.5 to 1.0 percent of fatty acid methyl ester ethoxylate sulfonate, proper amount of a pH modifier enabling the pH of the composition to be 2 or above and the balance ofdemineralized water. The preparation method comprises the following steps: A, uniformly mixing the NH4HF2 with the demineralized water to obtain an NH4HF2 solution; B, sequentially adding the HCl, theH3PO4, the carboxyethyl thiodisuccinic acid and the fatty acid methyl ester ethoxylate sulfonate into the NH4HF2 solution and uniformly mixing until the solution is clear to obtain a clear solution;C, uniformly mixing the clear solution with NH3 and curing to obtain a cleaning agent. The cleaning composition for the reverse osmosis membrane disclosed by the invention has the characteristics of good cleaning effect, less foam and easiness in flushing.

Owner:CHENGDU WANCHAO SURFACE TECH CO LTD

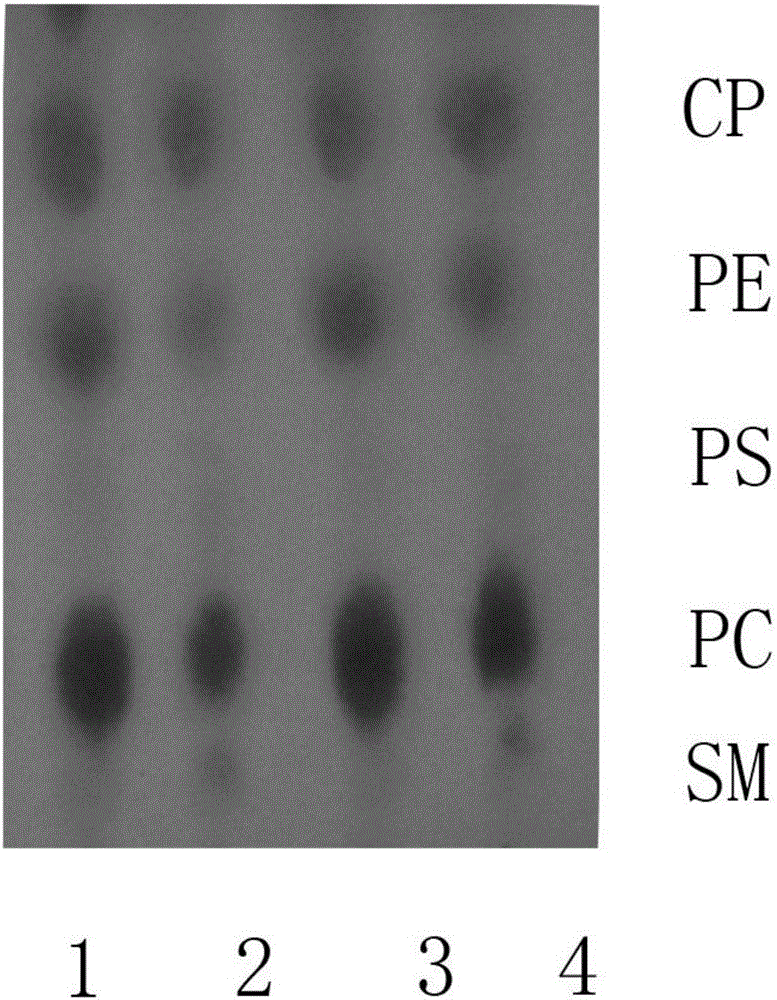

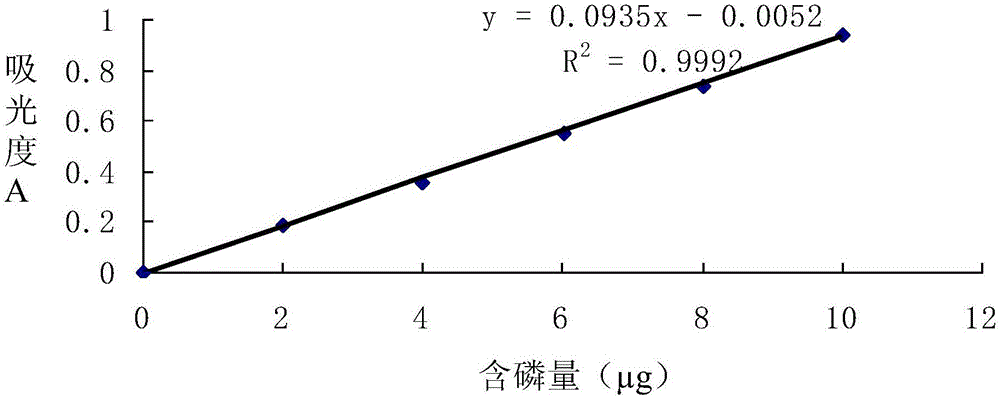

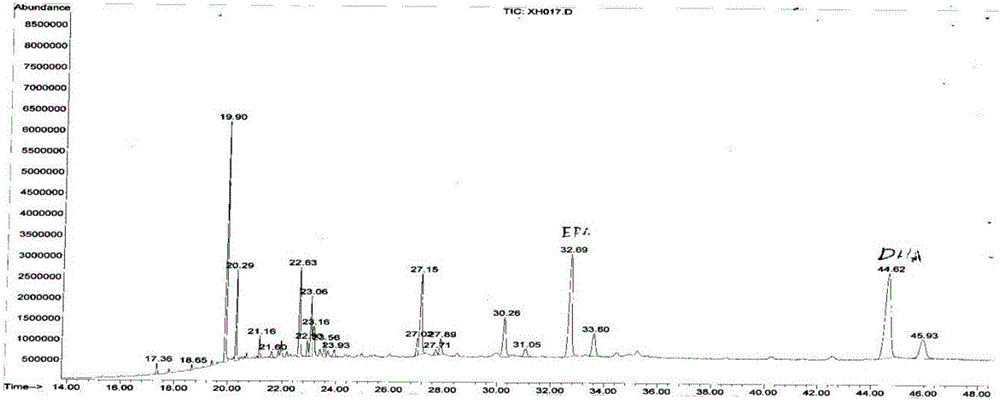

Method for preparing high-purity marine polyunsaturated fatty acid phospholipid by virtue of codfish viscera

ActiveCN106632459ASolve wasteReduce pollutionGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsPhysical chemistryPolystyrene

The invention provides a method for preparing high-purity marine polyunsaturated fatty acid phospholipid by virtue of codfish viscera. Processes of efficient solvent extraction, rapid purification, ultrasonic-enhanced supercritical extraction, polystyrene gel column chromatography and the like are adopted, so that the method has the advantages of environment friendliness, energy saving and high efficiency. The high-purity marine polyunsaturated fatty acid phospholipid is extracted by virtue of codfish processing wastes. An extraction process is convenient to operate, and extraction efficiency is high; the purity of the phospholipid is more than or equal to 97 percent. According to the method, on one hand, the problem of waste of a large number of residual marine byproduct resources is solved, and environmental pollution is reduced; on the other hand, preparation sources for the phospholipid are enriched, the raw materials are intensive and low-cost, the extraction cost of the phospholipid is reduced, and great ecological, economic and social significance is achieved.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

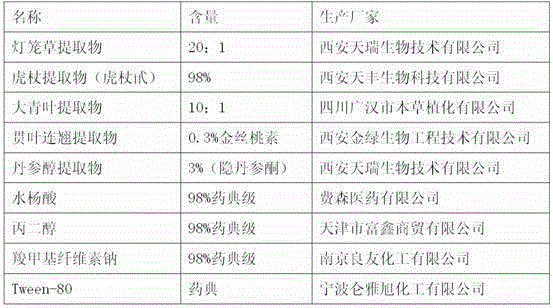

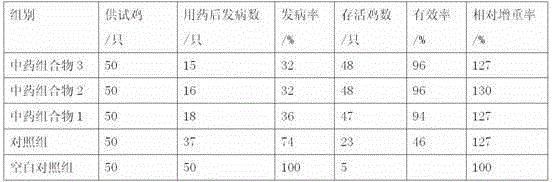

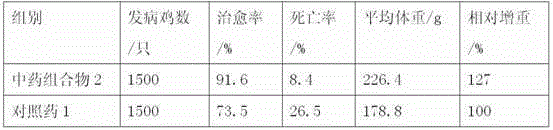

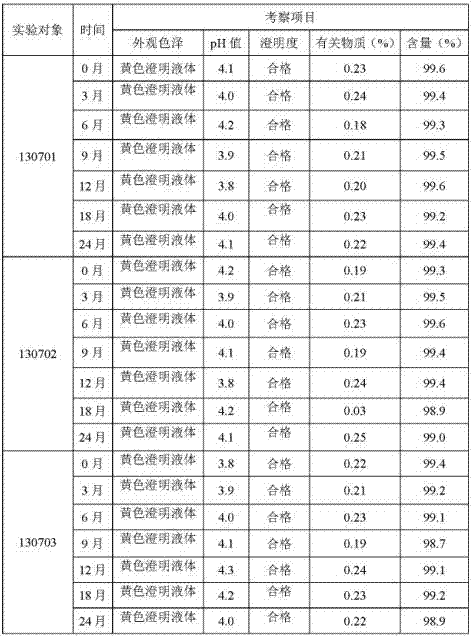

Traditional Chinese medicine combination for treating avian respiratory tract infection and preparation method and application thereof

InactiveCN105232763AHas antibacterial propertiesHas antiviral effectAntibacterial agentsAntiviralsBiotechnologyCellulose

The invention discloses a traditional Chinese medicine combination for treating avian respiratory tract infection. The traditional Chinese medicine combination is prepared by adding 0.1-1g of physalis peruviana extract, 0.1-1g of giant knotweed extract, 0.1-2g of indigowoad leaf extract, 0.1-2g of hypericum perforatum extract, 0.1-2g of tanshinol extract, 0.25-2.5g of salicylic acid, 0.25-2.5g of sodium carboxymethylcellulose, 0.5-5ml of propylene glycol and 0.5-5ml of Tween-80 into each 100ml of deionized water. The invention further provides a preparation method and application of the traditional Chinese medicine combination. The traditional Chinese medicine combination, the preparation method and the application have the advantages that the traditional Chinese medicine combination is a novel preparation prepared with antibacterial medicine, antimycoplasma medicine and antiviral medicine through scientific blending and scientific composing according to disease infection laws; the traditional Chinese medicine combination is reasonable in composition, is safe and effective, and is low in production cost; the raw materials of the traditional Chinese medicine combination are easy to obtain; and the preparation method is simple and easy to operate.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Lubricating oil composition for marine medium-speed cylindrical diesel engine

Owner:PETROCHINA CO LTD

Coenzyme Q10 glucose injection and preparation method thereof

InactiveCN106852908ASolubilizeQuality improvementOrganic active ingredientsNervous disorderMedicineGlucose polymers

The invention discloses a coenzyme Q10 glucose injection and a preparation method thereof. The injection is composed of, by weight, 1-10 parts of coenzyme Q10, 20-80 parts of polysorbate 80, 1-50 parts of a solubilizer, and 400-4000 parts of a 5% glucose solution. In the invention, the solubilizer is matched with the Tween-80 so as to achieve solubilization to the coenzyme Q10. By means of the preparation method, the coenzyme Q10 glucose injection has stable quality and solves a problem of medicine separation-out within the range of period of validity.

Owner:KAMP PHARMA

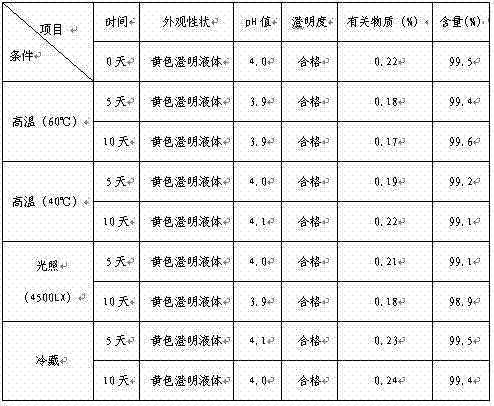

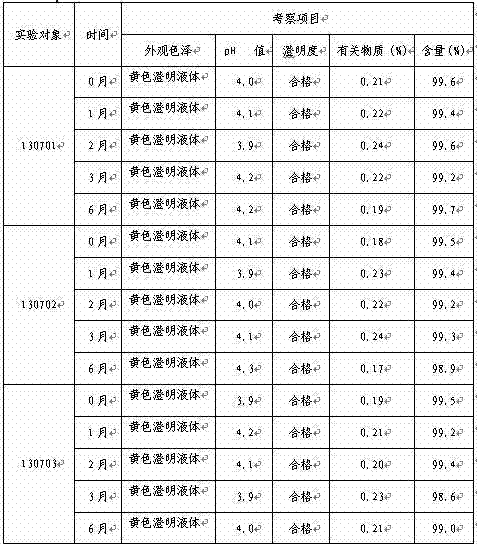

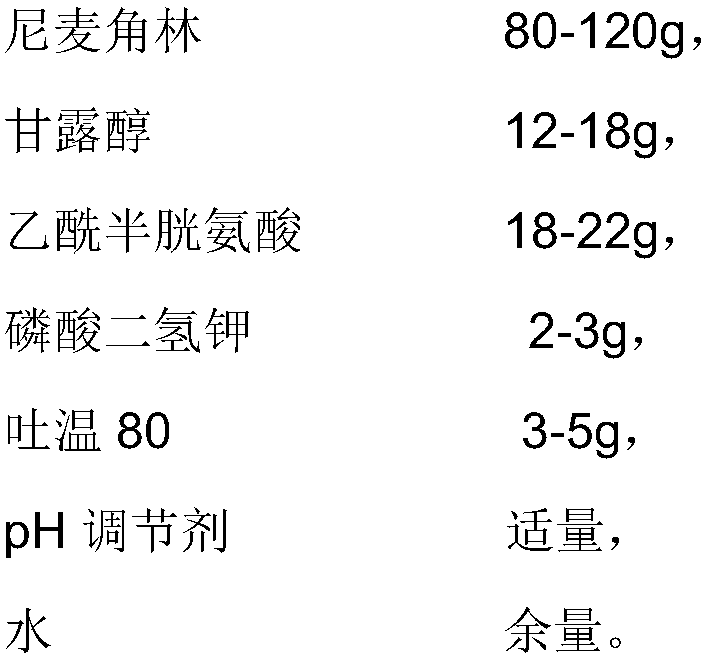

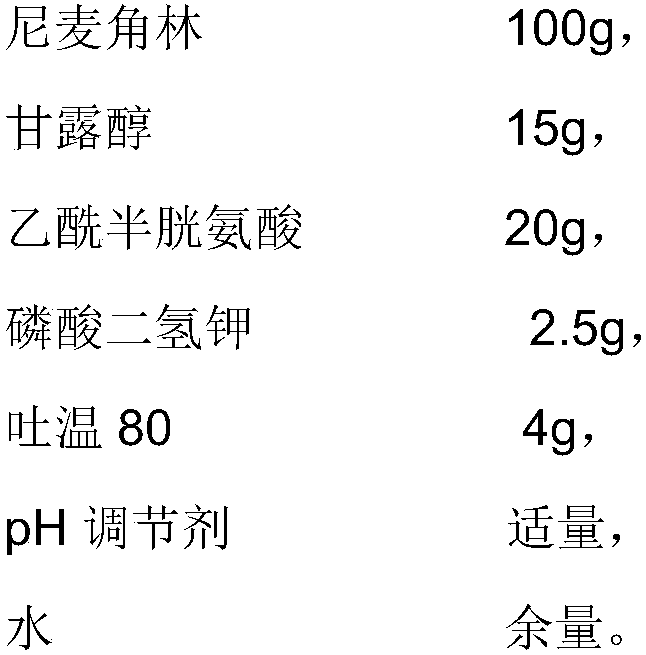

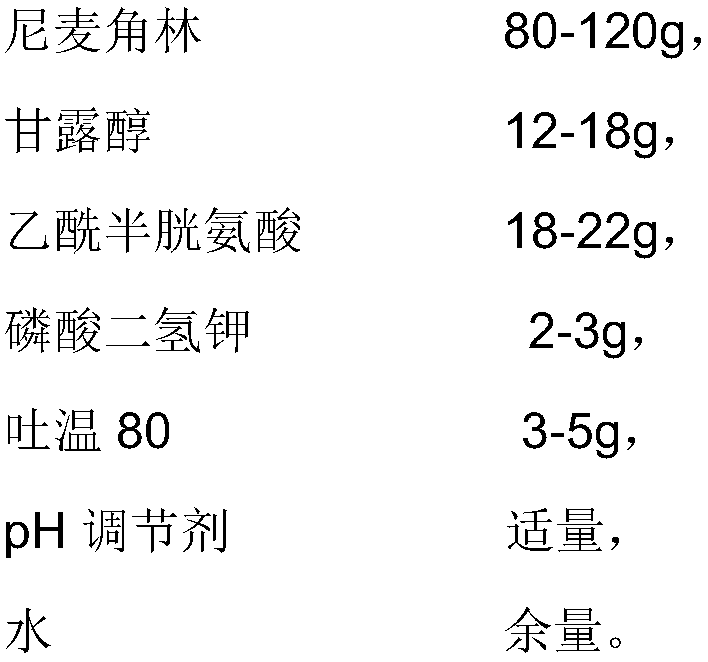

Injection used nicergoline freeze-dried powder injection and preparation method thereof

InactiveCN107669643AImprove stabilityImprove solubilityPowder deliveryNervous disorderPorosityMANNITOL/SORBITOL

The invention provides an injection used nicergoline freeze-dried powder injection which is prepared by freeze-drying a nicergoline medicine solution with the pH value being 3.2-3.5. Every 2000 ml ofthe nicergoline medicine solution contains 80-120 g of nicergoline, 12-18 g of mannitol, 18-22 g of acetylcysteine, 2-3 g of monopotassium phosphate, 3-5 g of Tween 80, a proper amount of a pH regulating agent, and the balance of water. In the formula of the nicergoline freeze-dried powder injection, the proper amounts of ingredients, such as mannitol, acetylcysteine, Tween 80 and monopotassium phosphate, are added, all components play a synergistic effect, the appearance shape and porosity of the freeze-dried product can be improved, and the surface of the product is smoother; meanwhile, medicine properties are more stable, and storage and transportation of the medicine are facilitated.

Owner:HAINAN GENERAL & KANGLI PHARMA

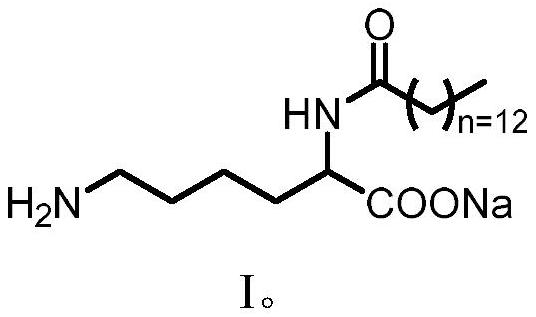

Polyurethane foaming material and preparation method thereof

The invention relates to the technical field of polyurethane foam materials, and particularly discloses a polyurethane foam material and a preparation method thereof, and the polyurethane foam material is prepared from vegetable oil polyol, isocyanate, a foaming agent, a catalyst, a surfactant, a chain extender, a cross-linking agent and a foam stabilizer as raw materials. A compound shown in theformula I is adopted as a surfactant, is high in activity, and can reduce the surface tension of a solution, form micelles and play a solubilizing role, so that materials are well dissolved, and the solubility of the materials is further improved; in addition, by controlling the mass ratio and reaction conditions of the vegetable oil polyol, the isocyanate, the foaming agent, the catalyst, the surfactant, the chain extender, the cross-linking agent and the foam stabilizer, foam holes are effectively and uniformly distributed, so that the heat conductivity coefficient of the polyurethane foaming material can be reduced, and the heat preservation performance of the polyurethane foaming material is improved.

Owner:NANJING UNIV OF TECH

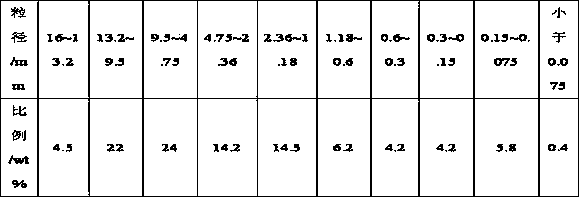

Disperse dye ink with good storage stability and good redispersibility and preparation method

ActiveCN108727900AGood redispersibilityFast dryingInksDyeing processDispersion stabilityDisperse dye

The invention provides disperse dye ink with good storage stability and good redispersibility and a preparation method. The disperse dye ink is prepared from components in parts by mass as follows: 30-35 parts of high-purity water, 10-15 parts of disperse dye, 8-12 parts of a dispersant, 5-9 parts of a lubricant, 6-8 parts of ethylene glycol and 1-5 parts of an anionic surfactant. The disperse dyeink has good dispersion stability, excellent storage stability and excellent redispersibility.

Owner:YANGZHOU RIXING BIO TECH

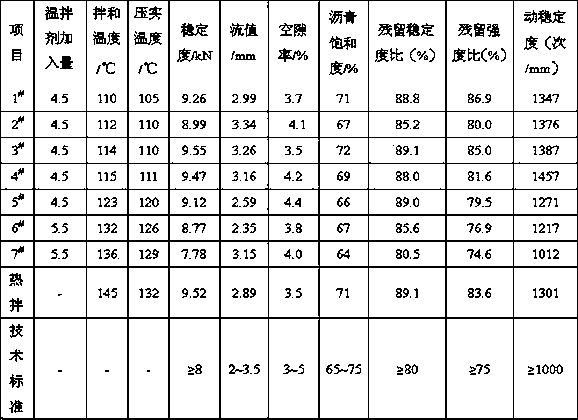

Anionic liquid-crystal-form asphalt warm-mixing agent and preparation method therefor

ActiveCN105623283ASimple ingredientsEasy to prepareClimate change adaptationBuilding insulationsSulfonateFatty alcohol

The invention discloses an anionic liquid-crystal-form asphalt warm-mixing agent and a preparation method therefor. The asphalt warm-mixing agent contains the raw materials in parts by weight: 5.5-40.6 parts of sulfosuccinate, 0.1-20 parts of fatty alcohol and 39.4-94.4 parts of water. The preparation method comprises the following steps: (1) uniformly mixing the water and the sulfosuccinate in a vessel according to a proportioning ratio; and (2) adding the fatty alcohol into a material obtained in the step (1), carrying out uniform mixing, and carrying out standing for a period of time, thereby obtaining the anionic liquid-crystal-form asphalt warm-mixing agent. The asphalt warm-mixing agent disclosed by the invention can be used for effectively lowering the high-temperature viscosity of asphalt and has the advantages that the performance is stable, the raw materials are easily acquired, the preparation method is simple and convenient, the range of application is wide, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving fire resistance and mechanical property of polyethylene/nylon 6 blend

The invention relates to a method for improving the fire resistance and mechanical property of a polyethylene / nylon6 blend. The method adopts the mode of two-step type step-by-step melt blending, controllable intumescent flame retardants are uniformly distributed in a nylon 6 phase domain in the polyethylene / nylon 6 blend, and then the fire resistance of the blend is greatly improved. Compared with a one-step processing method in the prior art, the limit oxygen index of the polyethylene / nylon 6 blend obtained through a step-by-step processing method can be increased by 15.6%-21.5%, the flame-retardant level of the blend can be increased to V-1 level or above from the phenomenon that the blend cannot be subjected to vertical combustion, and then the application value is greatly increased. The technical problem that in the prior art, for the polyethylene / nylon 6 blend, the fire resistance and the compatibilizing efficiency cannot be achieved simultaneously is solved.

Owner:HENAN UNIV OF SCI & TECH

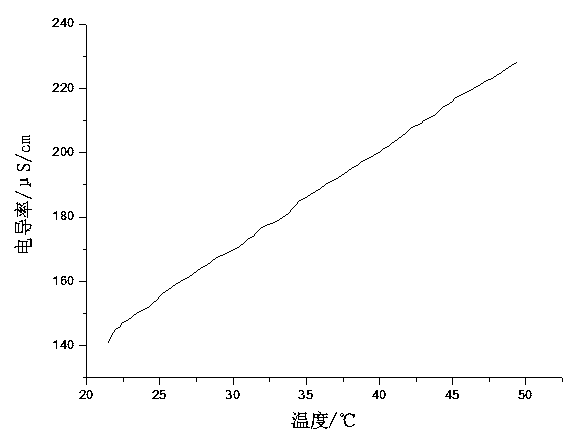

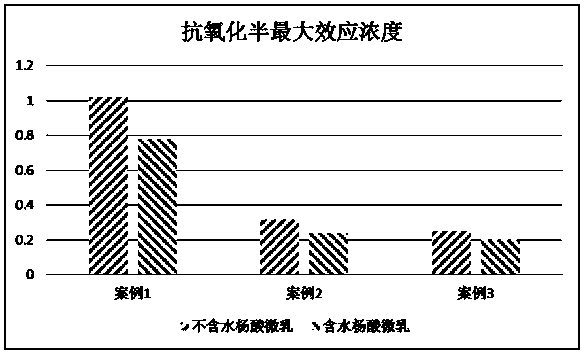

Salicylic acid-loaded vitamin E microemulsion and preparation method thereof

ActiveCN103520009AUniform stateSolubilizeCosmetic preparationsToilet preparationsSolubilitySalicylic acid

The invention relates to a salicylic acid-loaded vitamin E microemulsion and a preparation method thereof. Through a synergistic effect of the antioxidant effect of vitamin E and the antimicrobial and disinfectant effect of salicylic acid, the antioxidant effect is improved. The salicylic acid-loaded vitamin E microemulsion comprises the following components: the salicylic acid, Tween-80, absolute ethanol, vitamin E, isopropyl myristate and water; and the salicylic acid-loaded vitamin E microemulsion has the particle size of 10-60nm. The preparation method comprises the following steps: dissolving the salicylic acid into the absolute ethanol; adding the Tween-80, the vitamin E and the isopropyl myristate respectively, and stirring a mixed solution; adding deionized water; and sealing and stirring the mixed solution to obtain a light yellow transparent microemulsion. The salicylic acid-loaded vitamin E microemulsion improves the solubility, the dispersibility, the dialysis and the stability of the Vitamin E in water, improves the utilization and the absorbance, and is easily processed; and the salicylic acid-loaded vitamin E microemulsion, as a transdermal drug delivery carrier, is combined with a pharmaceutically acceptable excipient, and can be prepared into a high-bioabsorption, safe, stable and convenient transdermal drug delivery preparation by an appropriate preparation method.

Owner:广州智园生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com