Lubricating oil composition for marine medium-speed cylindrical diesel engine

A technology for lubricating oil composition and diesel engine, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve the problems of inability to solve the problem of black sludge, increase product cost, unqualified anti-rust performance, etc., and achieve inhibition of black sludge formation. , prolong the service life, the effect of simple production process

Active Publication Date: 2011-06-08

PETROCHINA CO LTD

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

To make matters worse, these deposits will adhere to other solid insoluble substances such as sludge in the oil, causing many engine problems

[0003] Find by novelty search, foreign relevant the bibliographical report of the marine medium-speed trunk piston diesel engine oil research that contains salicylate or alkylphenate respectively a lot, wherein Japanese patent discloses a kind of lubricating oil composition (EP1992678 A1), its In the formulation of diesel engine oil, 2-3 kinds of salicylate and alkylphenate are compounded and a boron-containing dispersant is used. Salicylate with different base values is used in this formulation system, which makes the oil blend The process is complicated and increases the cost of the product, and the boron-containing dispersant is also expensive

Chinese invention patent discloses a kind of engine lubricating oil composition (CN1523086-A) that is called three types of base oil compatible Salt, salicylic acid, ashless succinimide dispersant, boron-containing succinimide dispersant, zinc alkyl dithiophosphate and phenolic amine auxiliary antioxidant, the sulfonate in the formula can Improve the high-temperature detergency and anti-rust performance of oil products, but the sulfonate cannot solve the problem of black sludge, and the anti-rust performance is often unqualified due to the quality of the sulfonate, and the formula is due to the addition of boron-containing dispersants and phenolic amine antioxidants, the cost will be high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

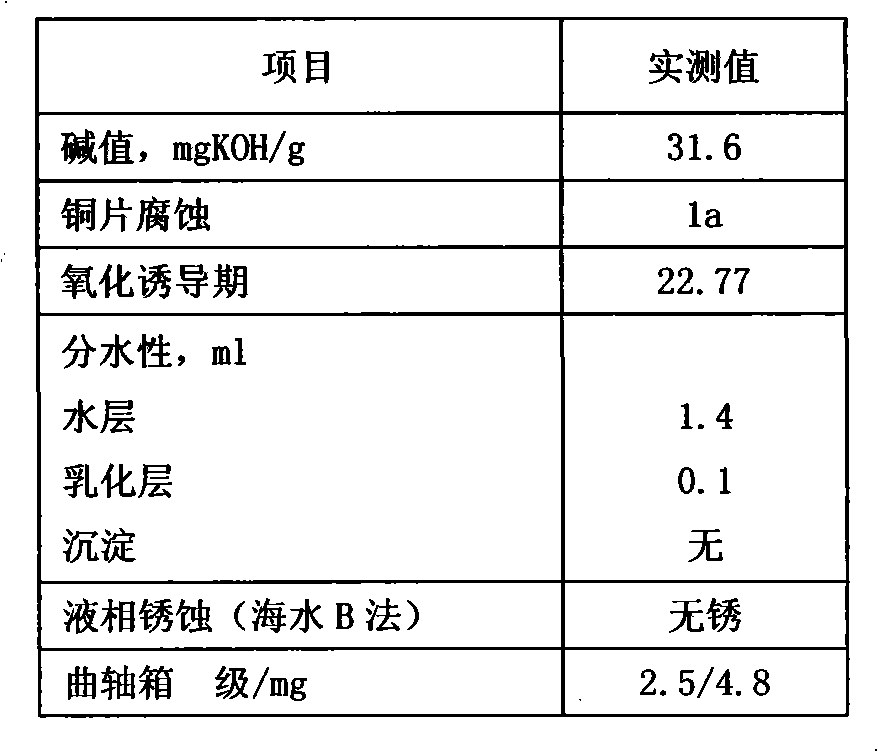

Embodiment 1-3

[0022] Prepare DCB4030H full formula oil, the specific components and contents are shown in the table below

[0023]

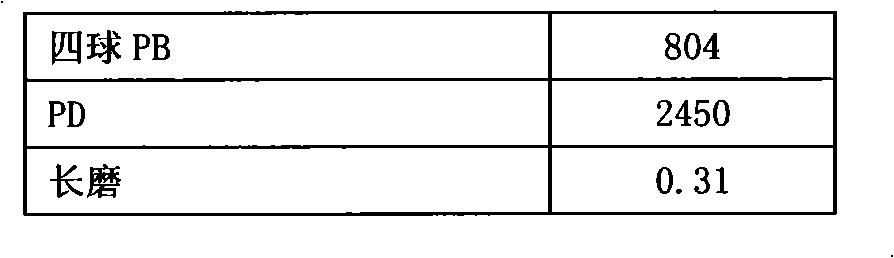

Embodiment 4-6

[0025] Prepare DCB4040H full formula oil, the specific components and contents are shown in the table below

[0026]

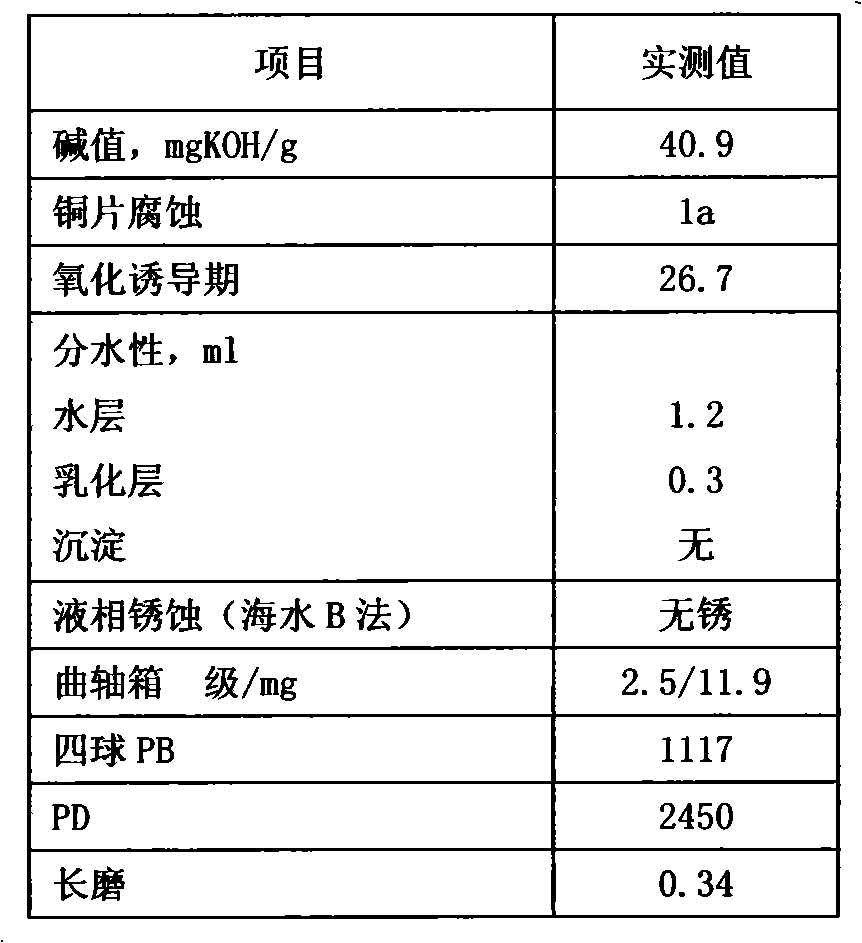

Embodiment 7-9

[0028] Prepare DCB4050H full formula oil, the specific components and contents are shown in the table below

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a lubricating oil composition for a marine medium-speed cylindrical diesel engine, which comprises the following components in percentage by weight: 12-22% of high temperature detergent, 1-3% of ashless dispersant, 0.5-1.5% of antioxidant, 0.002-0.005% of antifoam agent and the balance of base oil, wherein the high temperature detergent is compounded from the following components in percentage by weight: 30-70% of high base number alkyl calcium salicylate and 30-70% of high base number sulfurized calcium alkyl phenate; the ashless dispersant is bis-succinimide; the antioxidant is zinc dialkyl dithiophosphate; and the antifoam agent is methylsilicone oil. The invention can satisfy the operational requirements of advanced marine medium-speed cylindrical piston diesel engine oil; and the lubricating oil composition has the function of inhibiting the generation of black oil sludge, reduces the faults of the medium-speed cylindrical piston diesel engine due to bad lubrication and the like, prolongs the service life of the engine, and has the advantages of accessible raw materials, simple production technique and low cost.

Description

technical field [0001] The invention relates to a lubricating oil composition, in particular to a lubricating oil composition for marine medium-speed tubular diesel engines. Background technique [0002] Marine engines use heavy residual oil as fuel, and the oil has a high content of asphaltene. During use, a small amount of unburned fuel (mainly asphaltene) escapes between the engine piston and cylinder liner, and enters the lubricating oil system. If the lubricating oil has poor dispersibility to asphaltenes, it will often cause black spots ("black paint" or "black sludge") and increased sludge on the crankcase, cam tappets and other parts of the marine medium-speed engine, and Once bitumen comes into contact with a metal surface, it sticks to the surface and is difficult to remove, forming a "black sludge". To make matters worse, these deposits will adhere to other solid insoluble substances such as sludge in the oil, causing many engine problems. [0003] Find by novel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M161/00C10M129/54C10M137/10C10N40/25C10N30/04C10N30/10C10N30/18

Inventor 刘建新于军刘功德丛文

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com