Patents

Literature

171 results about "Phenolic amine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of tyramine : a phenolic amine C8H11NO found in various foods and beverages (such as cheese and red wine) that has a sympathomimetic action and is derived from tyrosine : a phenolic amine C8H11NO that is found in various foods and beverages (as cheese and red wine), has a sympathomimetic action, and is derived from tyrosine

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

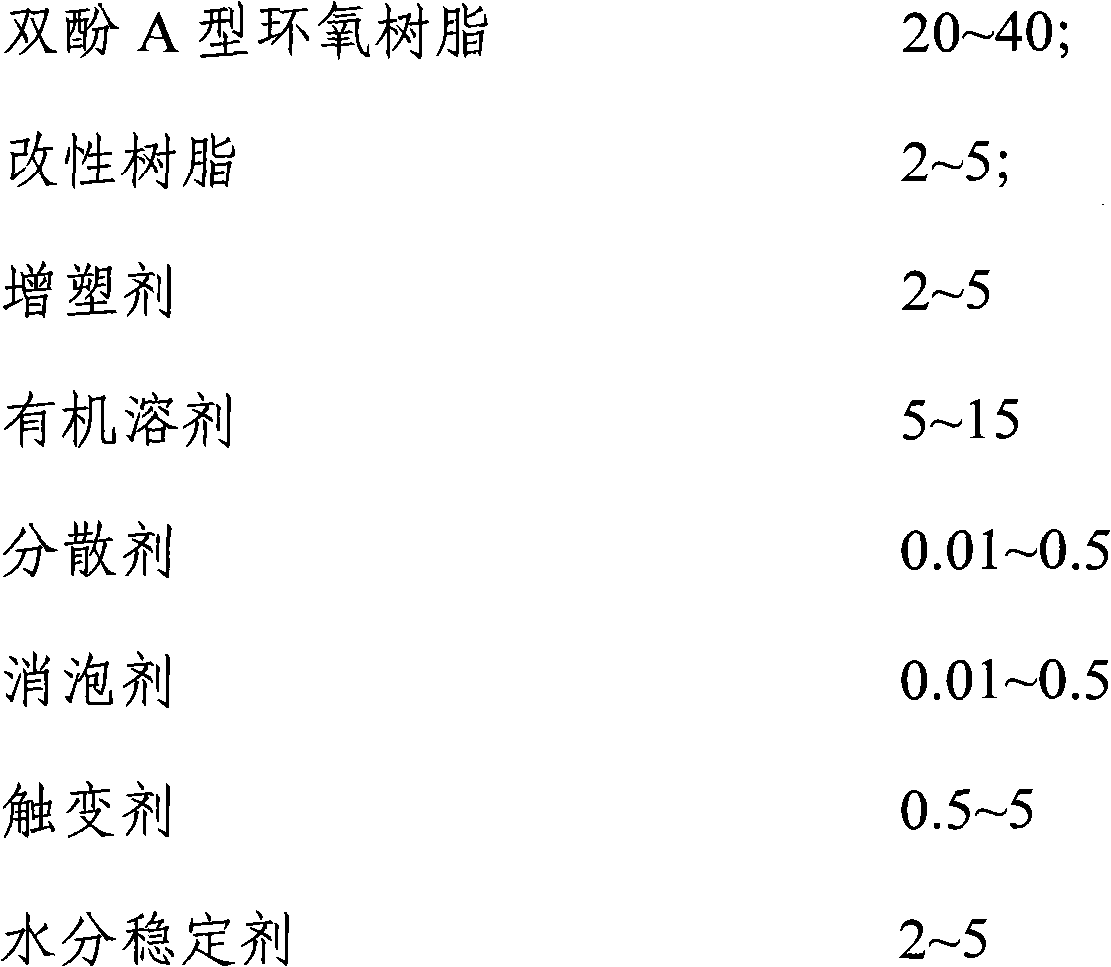

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

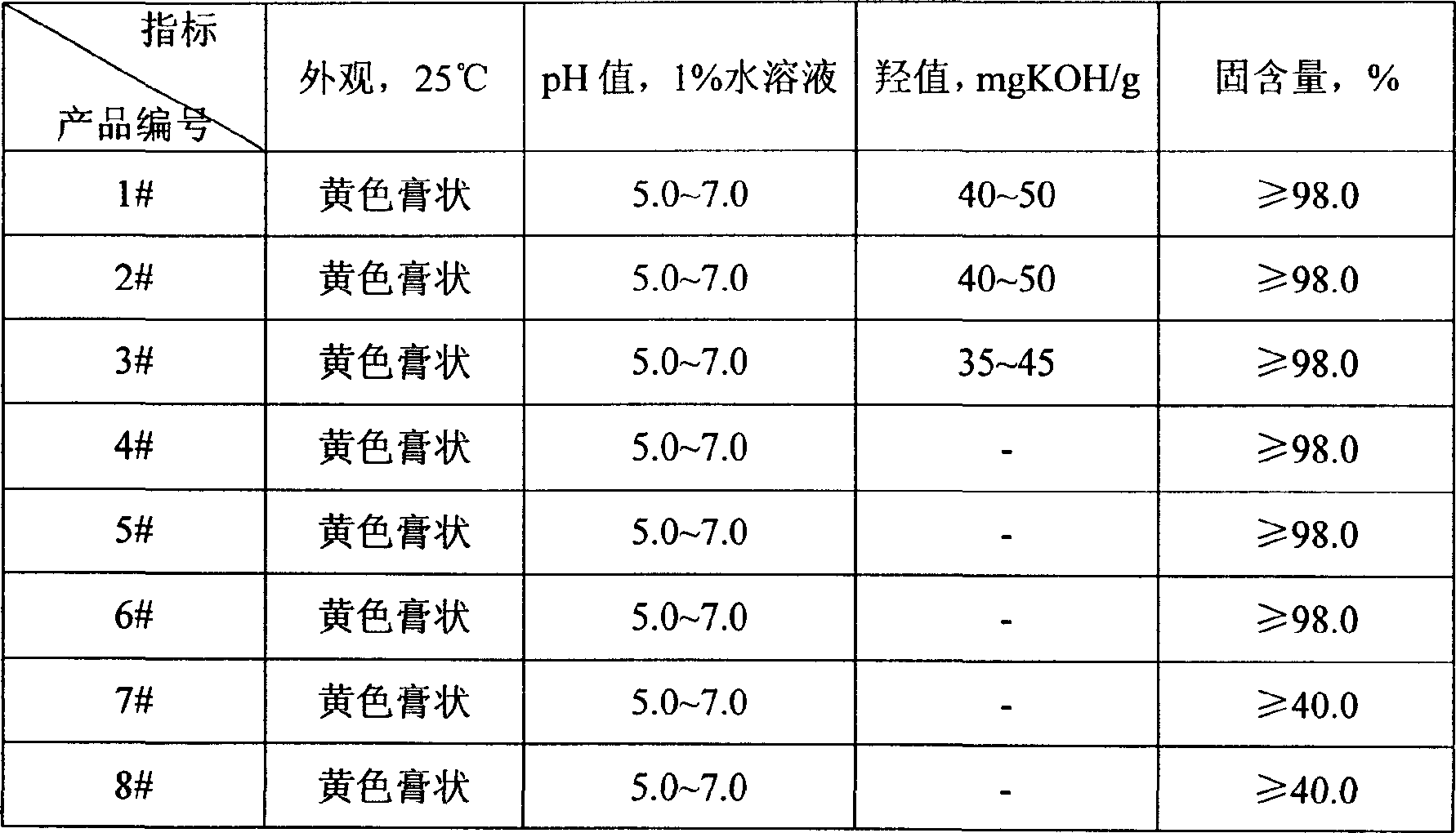

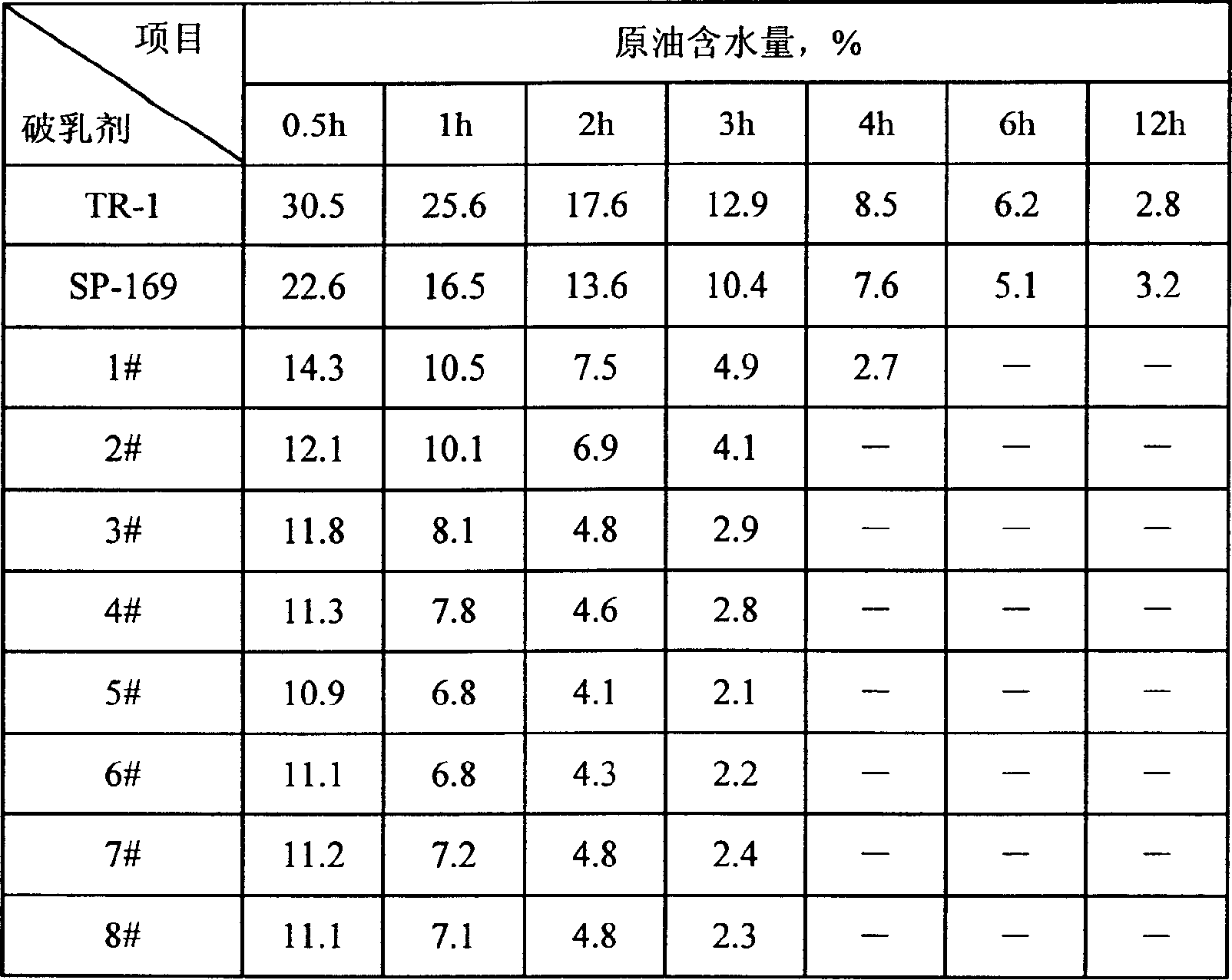

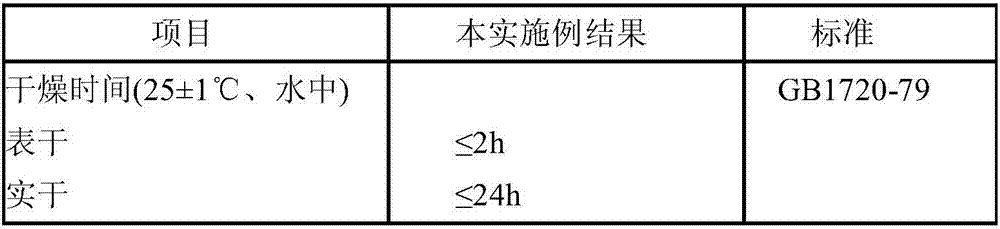

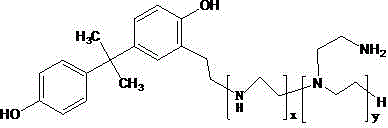

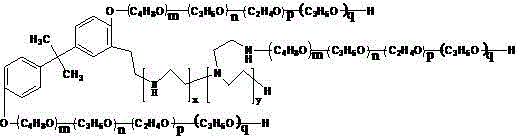

Thick oil demulsifier and its prepn

ActiveCN1810933ALow densityIncrease viscosityHydrocarbon oil dewatering/demulsificationEpoxyDemulsifier

The present invention is one kind of thick oil demulsifier and its preparation process, and belongs to the field of petrochemical technology. The present invention features that phenol-amine resin as the initial material is block polymerized with epoxy propane ad epoxy ethane under the action of catalyst to obtain stereo netted macromolecular polyether as the thick oil demulsifier. The polyether as the thick oil demulsifier may be further chain expanded for even high demulsifying effect. The thick oil demulsifier can reach the oil-water interface fast to lower the elasticity and viscosity of the interface film, speed the aggregation of liquid drops and demulsify effectively. The thick oil demulsifier has simple preparation process, is suitable for industrial production, and may be used in the efficient dewatering of oil field produced liquid with different water contents.

Owner:LIAONING OXIRANCHEM INC

Low-temperature quick deemulsifying agent for water-containing wax-containing erude oil and its preparation method

InactiveCN1537924AFast dehydrationGood demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationEpoxyOil processing

Owner:SHANDONG UNIV

Bi-component corrosion-proof dope

InactiveCN101100578AGood oil resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

A titanium-nickel nanometer alloy powder contains A and B components; A components consist of epoxy-resin, titanium-nickel nanometer alloy powder, antirust pigment, filler corrosion stabilizer and anti-sagging accessory; B components consist of composite curing agent with cashew nut shell modified phenolic amine curing agent and polyamide epoxy curing agent; the proportion of A and B is 10:1. It has excellent adhesion and physical performance and better oil, water, acid-alkali and salt fog resistances and mating ability. It can be used as universal base coat and used for various substrate materials such as steel, aluminum and stainless steel etc.

Owner:中国人民解放军海军装备技术研究所

Crack pouring adhesive for concrete cracks and application of crack pouring adhesive

The invention discloses a crack pouring adhesive for concrete cracks and an application of the crack pouring adhesive. The crack pouring adhesive for the concrete cracks consists of a component I and a component II which are independently packaged, and the mass ratio of the component I to the component II is (5-2):1; the component I consists of raw materials in parts by mass as follows: 70 parts of an E-51 bisphenol A liquid epoxy resin, 30 parts of a 6002 bisphenol A liquid epoxy resin, 15-30 parts of a toughening agent,5-15 parts of benzyl glycidyl ether and 5-15 parts of benzyl alcohol; and the component II consists of 30-65 parts of a curing agent, 5-10 parts of diluent and 0.5 part of a sticking accelerating agent; the curing agent consists of 30-50 parts of a polyether amine curing agent and 0-15 parts of a phenolic amine epoxy curing agent; and the diluent is benzyl alcohol. The crack pouring adhesive for the concrete cracks is a solvent-free double-component low-viscosity crack pouring adhesive and can be used for filling the concrete cracks to seal the concrete cracks.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

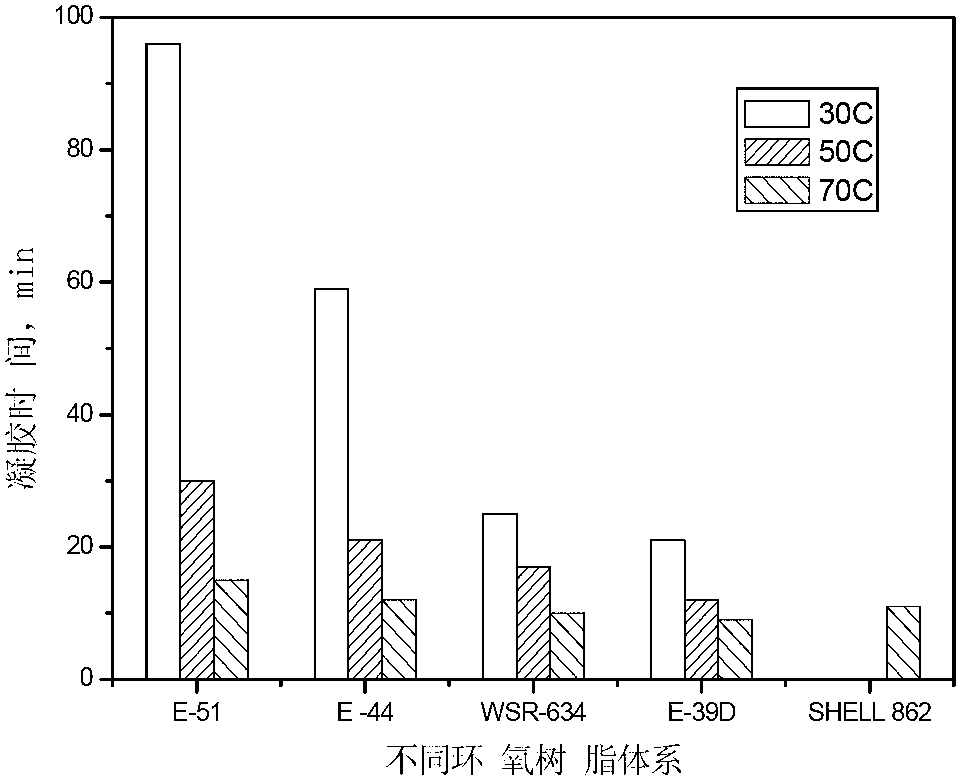

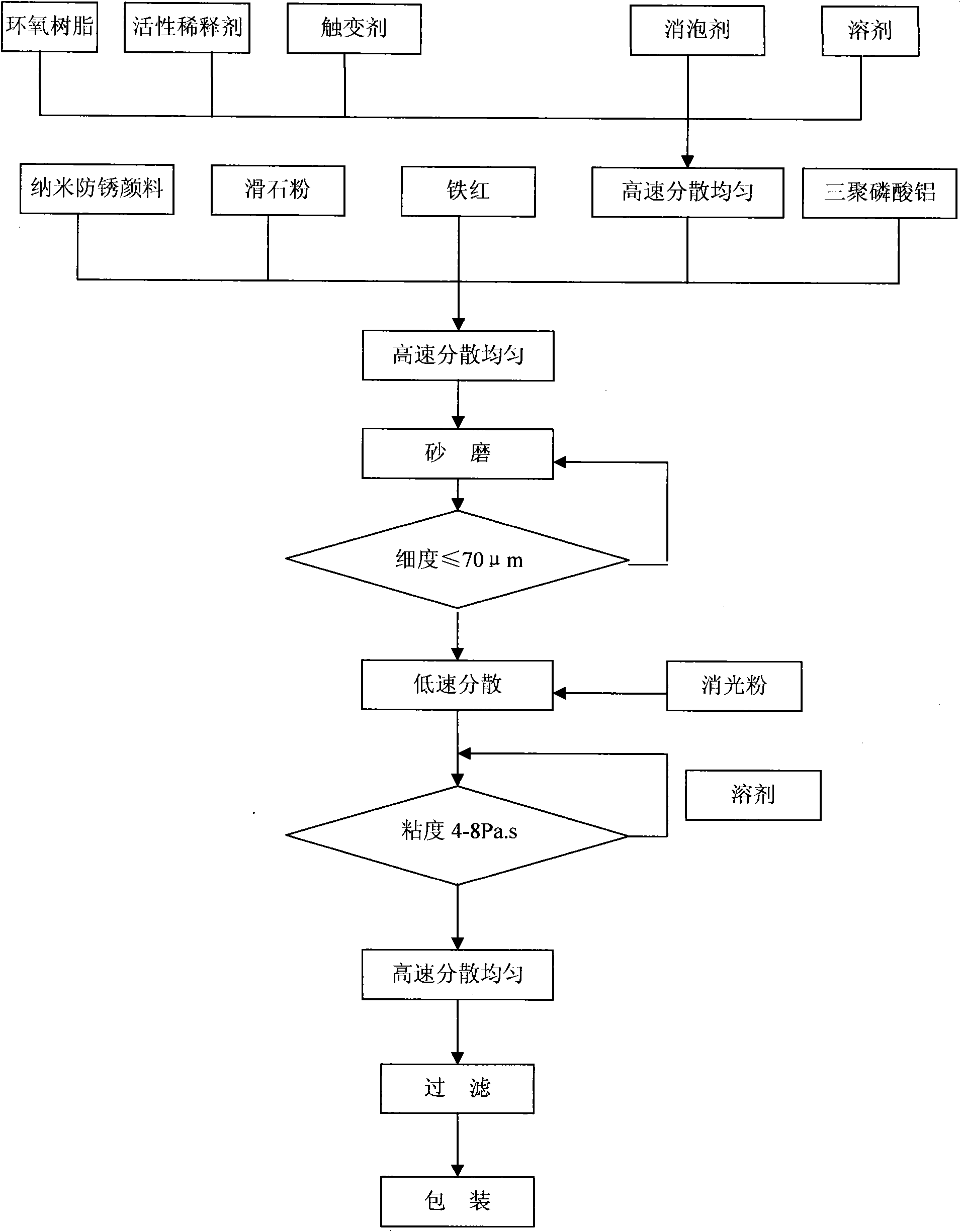

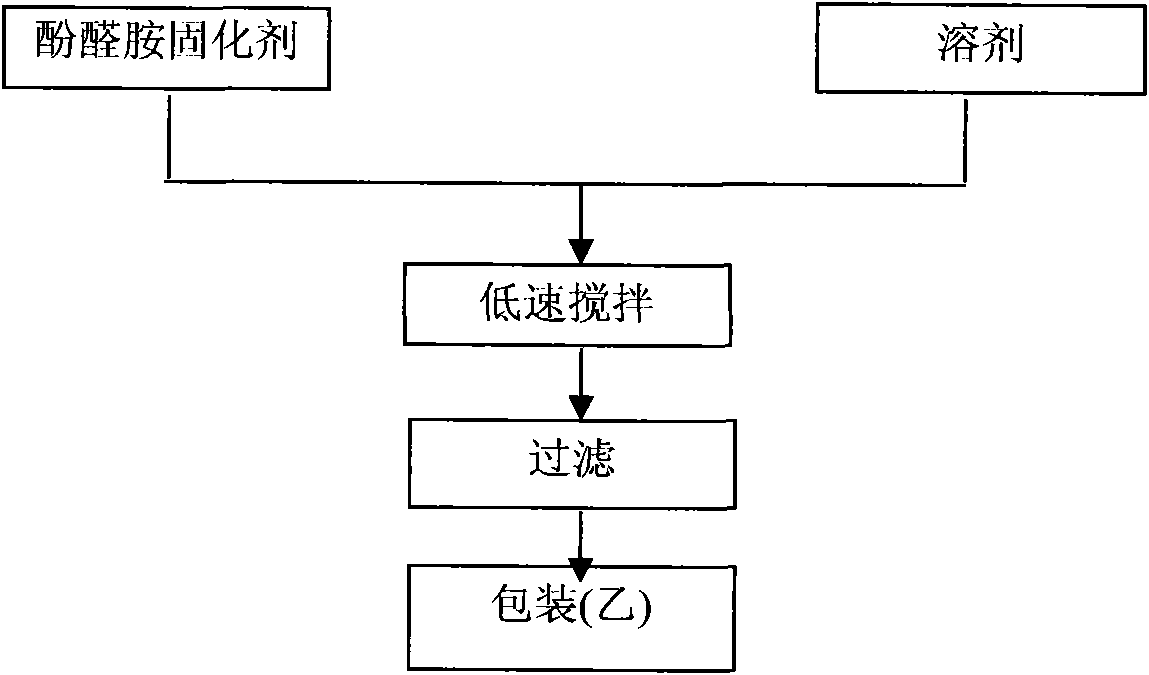

Recoating type universal epoxy anticorrosive paint for achieving four-season constructions with single curing agent

InactiveCN101638550ASimple coating processImprove coating efficiencyAnti-corrosive paintsEpoxy resin coatingsReactive diluentPigment

The invention discloses a recoating type universal epoxy anticorrosive paint for achieving four-season constructions with a single curing agent. A low molecular weight bisphenol A epoxy resin is usedas a resin base, a solvent system of an reactive diluent with branched chains, such as a glycidyl ether type reactive diluent, is introduced into the formulation to form an effective steric effect andprolong the usable life of a product after mixing, and after a coating layer is formed, the curing speed is not influenced, so the construction at the environment temperature of between 10 DEG C below zero and 40 DEG C is achieved, and the problem of the four-season constructions is solved by using one curing agent. A nano anticorrosive pigment, a phenolic amine curing agent, an adhesion promoter, adjusting PVC and a proper amount of dimming powder are selected, and the coating layer is ensured to contain a proper amount of polar groups so that the product has good cathodic disbonding resistance and can be matched with various types of finishing paints. The recoating type universal epoxy anticorrosive paint can be used as an anticorrosive primer for a plurality of positions from a ship bottom to a hull, and has very significant functions of improving the efficiency and the benefit of ship painting.

Owner:XIAMEN SUNRUI SHIP COATING

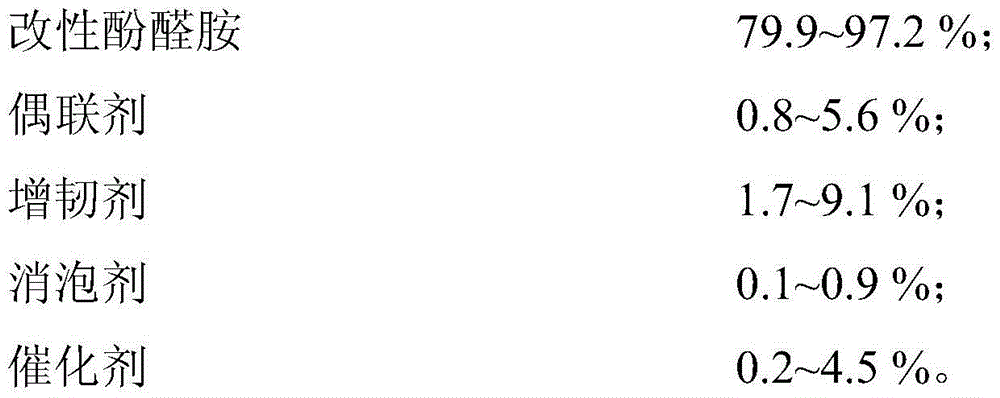

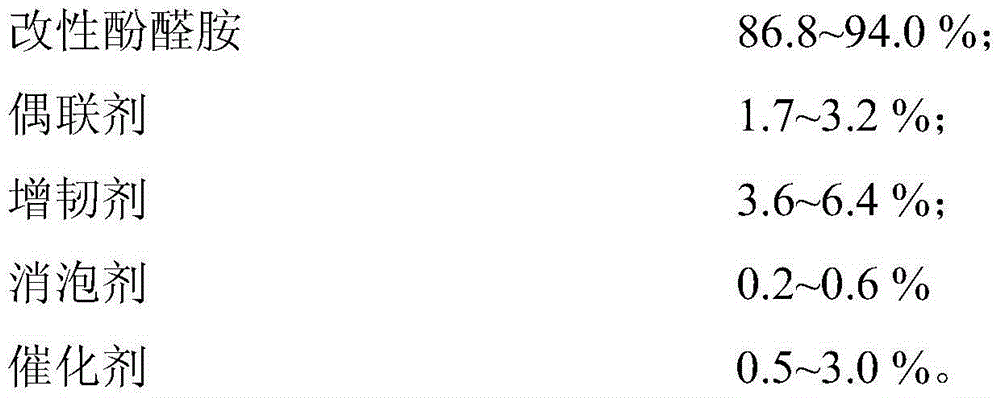

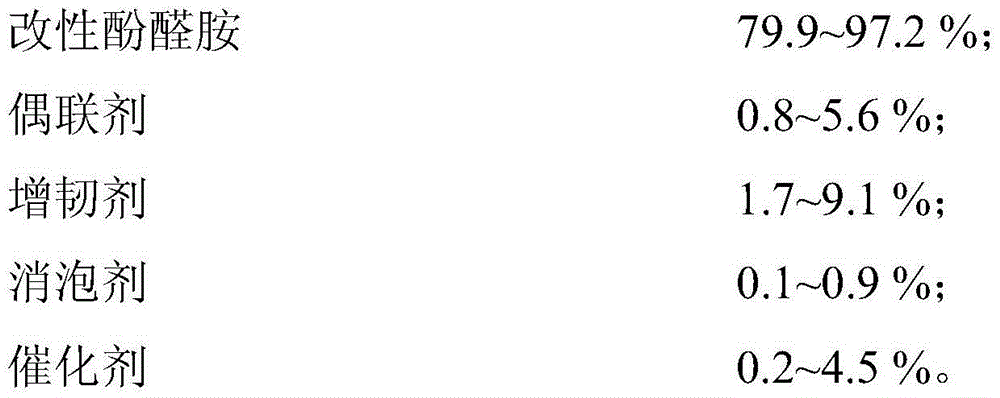

Epoxy resin solvent-free low temperature curing agent, preparation method and application thereof

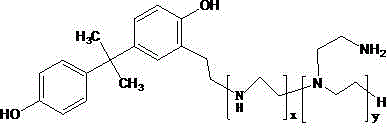

The invention belongs to the technical field of epoxy resin curing agent preparation technology, and discloses an epoxy resin solvent-free low temperature curing agent, a preparation method and an application. The curing agent can be better used in cement mortar and used for preparing epoxy grouting material under low temperature in water environment. The curing agent comprises the following components by mass percentage: 79.9-97.2% of modified phenolic amine, 0.8-5.6% of coupling agent, 1.7-9.1% of flexibilizer, 0.1-0.9% of antifoaming agent and 0.2-4.5% of catalyst. According to the invention, thiourea group is introduced, thiourea modified amine, polyamine, long chain alkylphenol and paraformaldehyde are performed a Mannich reaction to synthesize novel thioureido-containing Mannich base, so that solidification rate under low temperature environment is increased, disadvantage of poor solidification efficiency under wet surface and water can be overcome, and a silane coupling agent is added for improving surface tension of system contact surface and increasing the solidification efficiency under water environment.

Owner:国科广化(南雄)新材料研究院有限公司

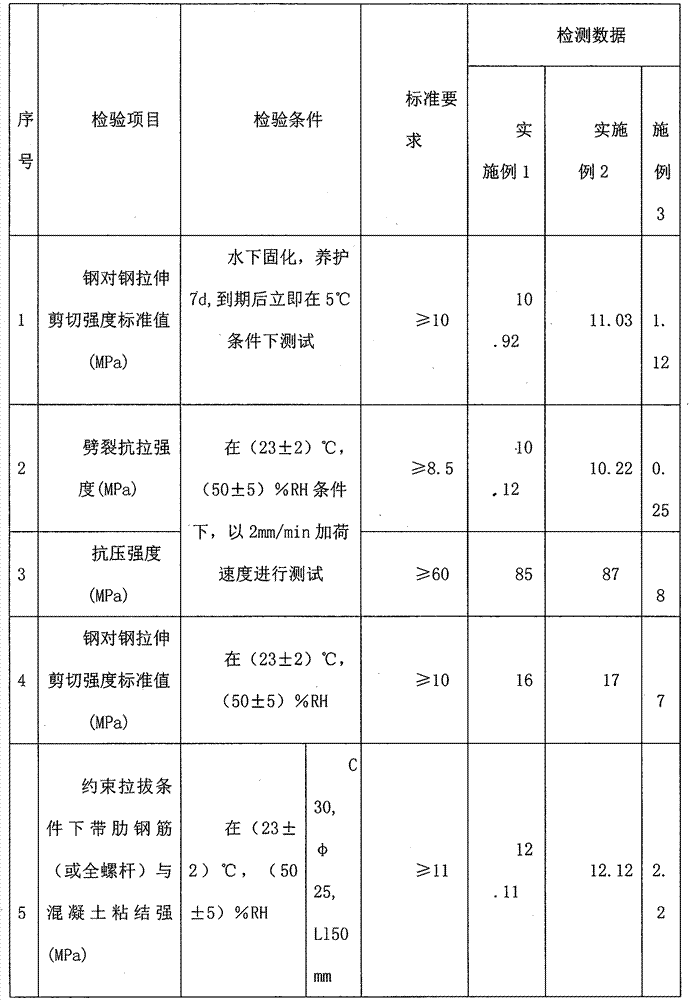

Building structure adhesive suitable for underwater construction

InactiveCN109852313AGood underwater construction performanceHigh bonding strength under waterNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention discloses a building structure adhesive suitable for underwater construction. The component A comprises the following raw materials in parts by weight: 60-80 parts of epoxy resin, 5-10 parts of active diluent, 5-10 parts of toughening agent, 1-2 parts of coupling agent, 50-200 parts of filler, 1-4 parts of thixotropic agent and 1-4 parts of wetting dispersant. The second component Bcomprises the following raw materials in parts by weight: 100 parts of phenolic amine curing agent, 50-200 parts of active filler, 1-4 parts of thixotropic agent and 1-4 parts of wetting dispersant. The raw materials used in the building structure adhesive suitable for underwater construction are all highly hydrophobic raw materials, The structure adhesive has good underwater construction performance, can be insoluble, not float and not shrink in underwater construction, can be easily adhered and coated, leveled and adhered on the bonding surface, and can be applied to the bonding of underwater environment building structure. Its underwater bonding strength is high, and its mechanical properties and moisture-heat aging properties conform to the national standard GB50367-2013, GB50550-2010,GB50728-2011 requirements.

Owner:LANGFANG JINDAO QISHI PLASTIC IND CO LTD

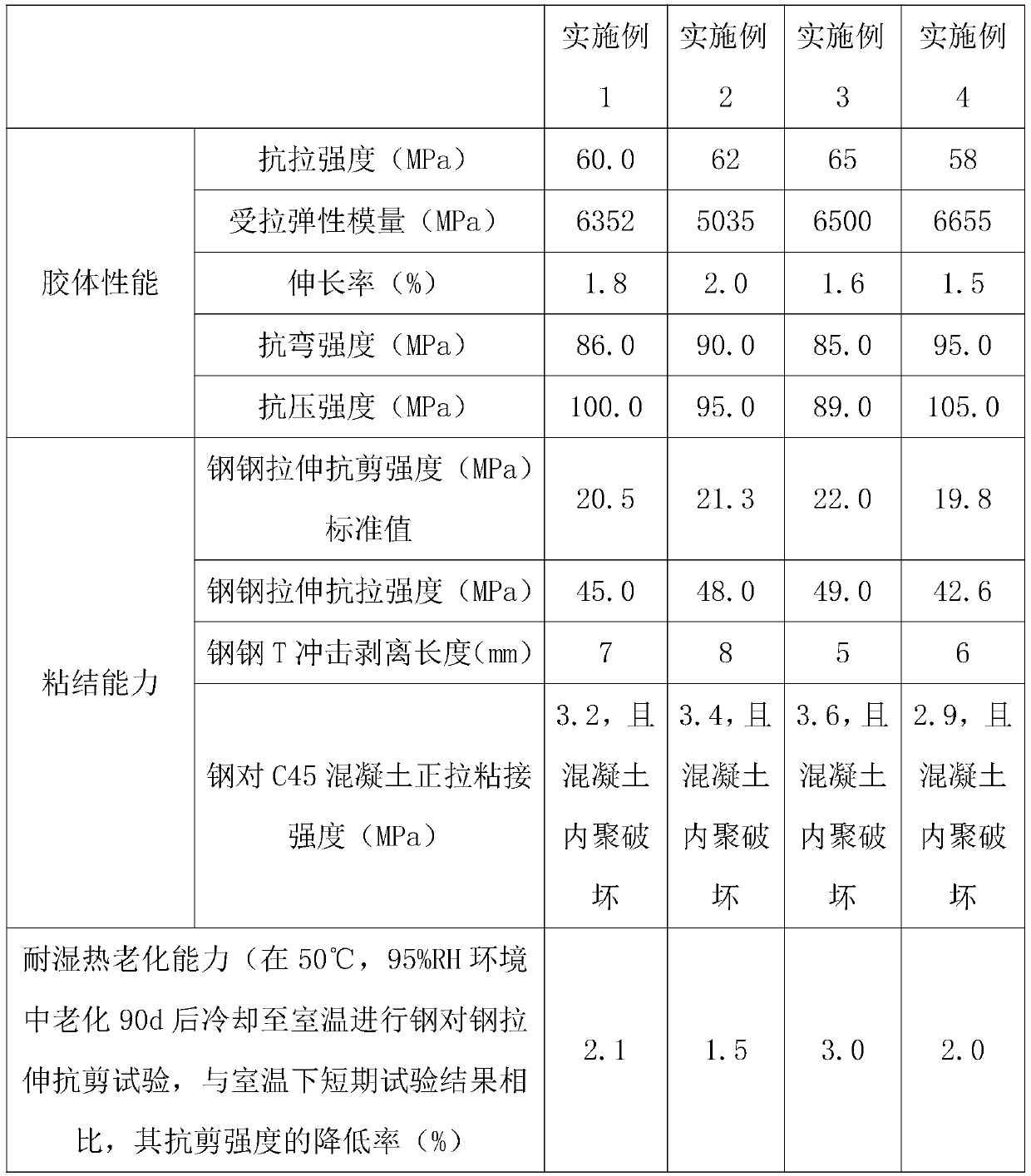

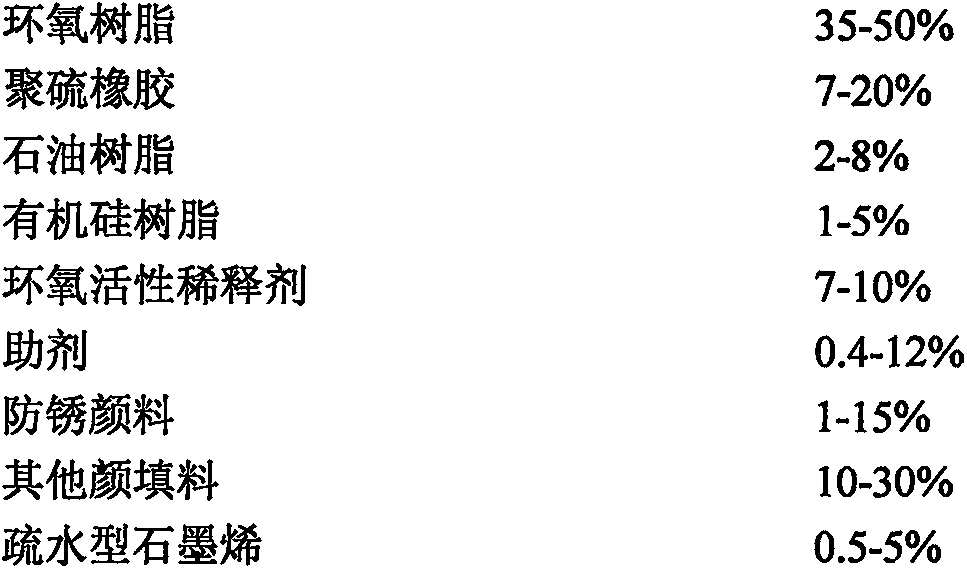

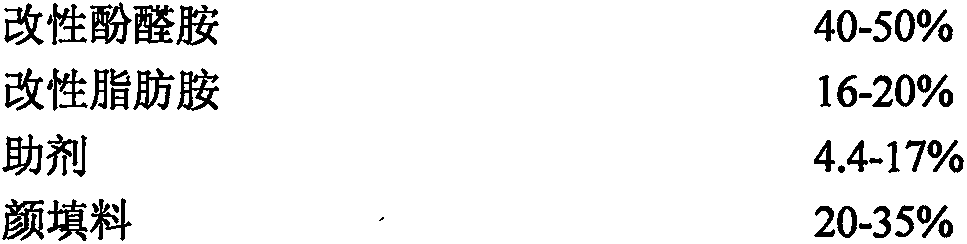

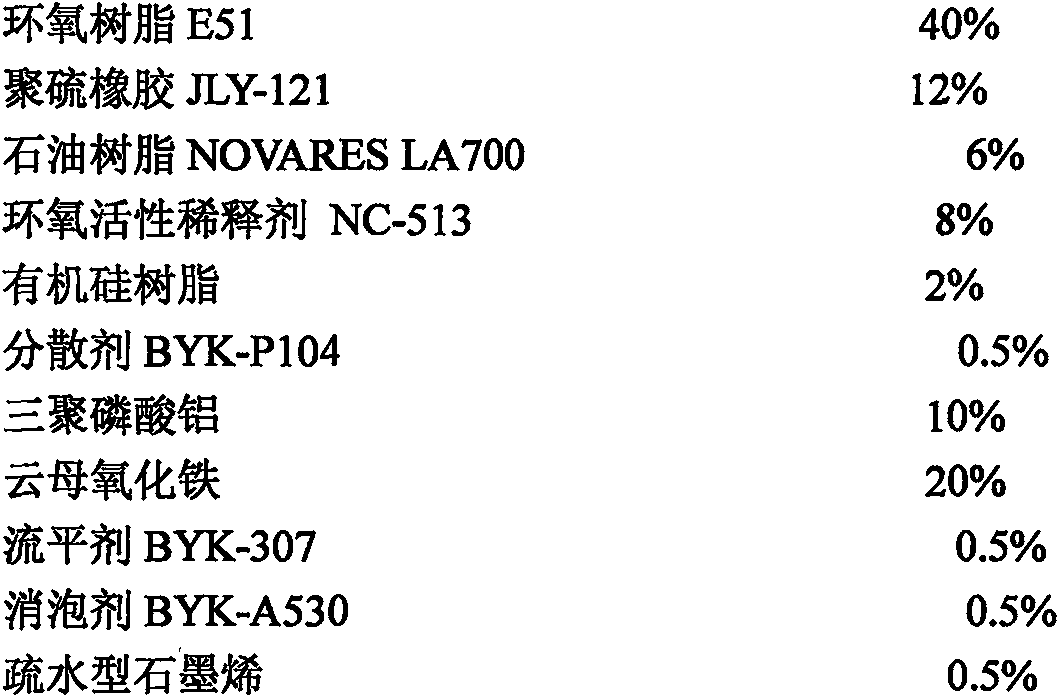

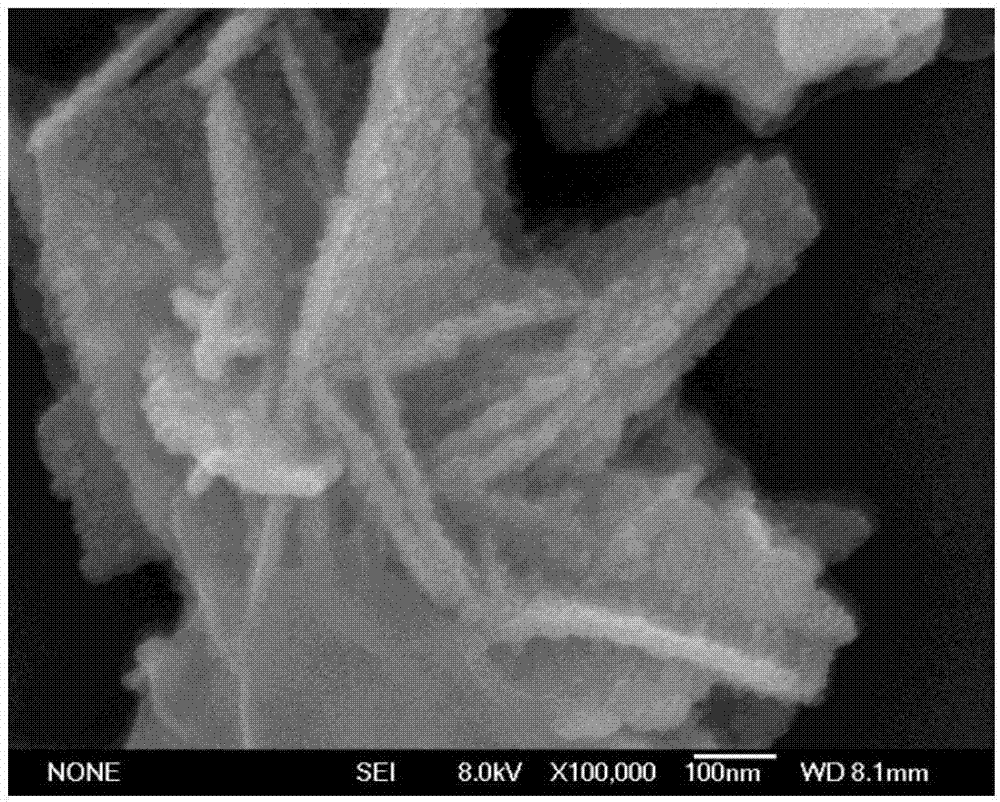

Hydrophobic graphene solvent-free epoxy underwater curing coating and preparation method thereof

The invention provides a hydrophobic graphene solvent-free epoxy underwater curing coating and a preparation method thereof. The hydrophobic graphene solvent-free epoxy underwater curing coating is prepared from a component A and a component B in the weight ratio being 100:(30-55), wherein the component A comprises raw materials as follows: 35%-50% of epoxy resin, 6%-10% of polysulfide rubber, 2%-8% of petroleum resin, 7%-10% of a reactive diluent, 1%-5% of organic silicon resin, 20%-40% of antirust pigments, 0.2%-6% of an aid and 0.5%-5% of hydrophobic graphene; the component B comprises rawmaterials as follows: 40%-50% of modified phenolic amine, 15%-20% of modified aliphatic amine, 0.5%-15% of an aid and 18%-30% of pigment and filler. The invention provides the hydrophobic graphene solvent-free epoxy underwater curing coating and the preparation method thereof, and the hydrophobic graphene solvent-free epoxy underwater curing coating can be constructed on surfaces of underwater substrates, can be cured quickly and has excellent adhesive force and corrosion resistance.

Owner:燕园众欣纳米科技(北京)有限公司

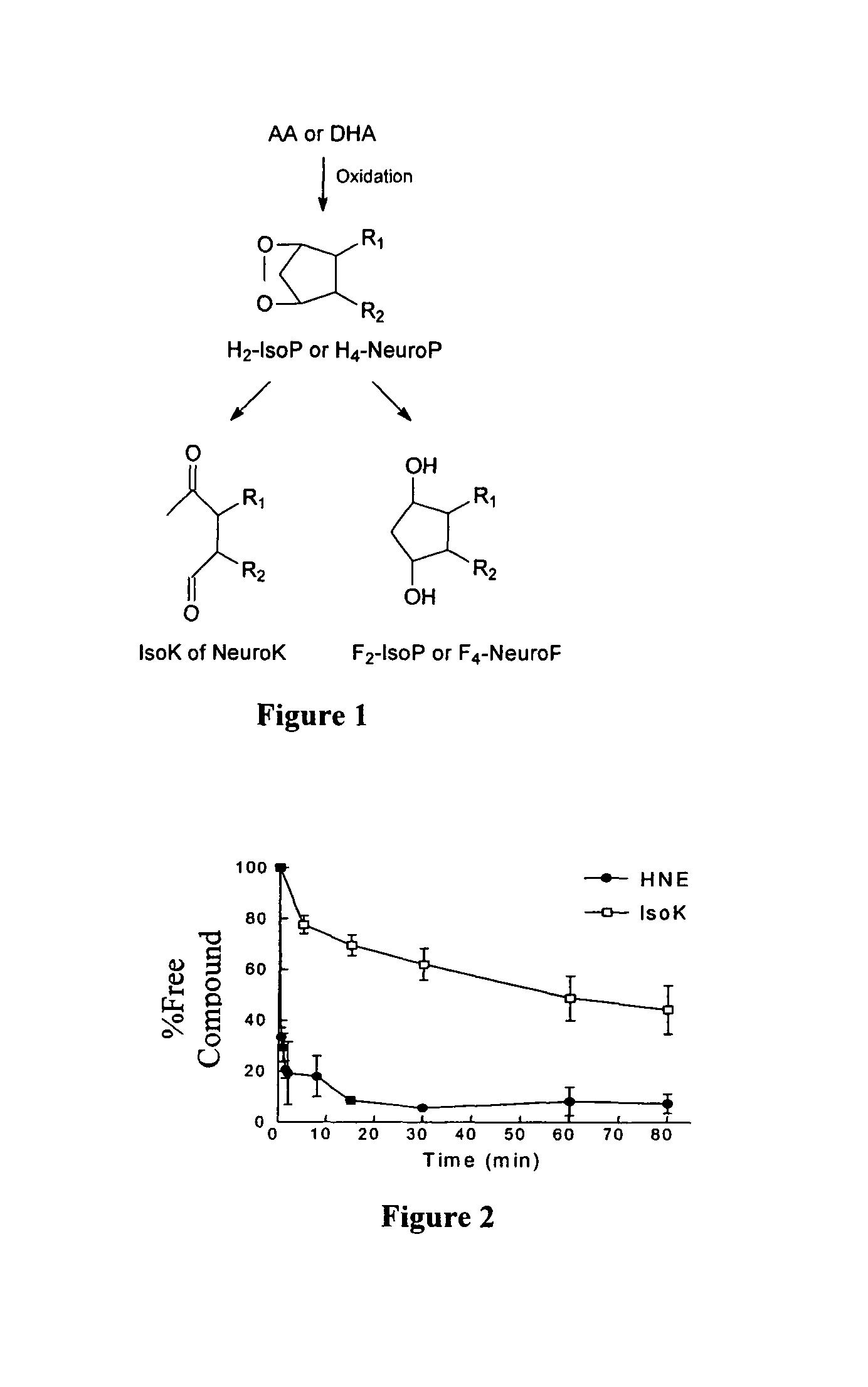

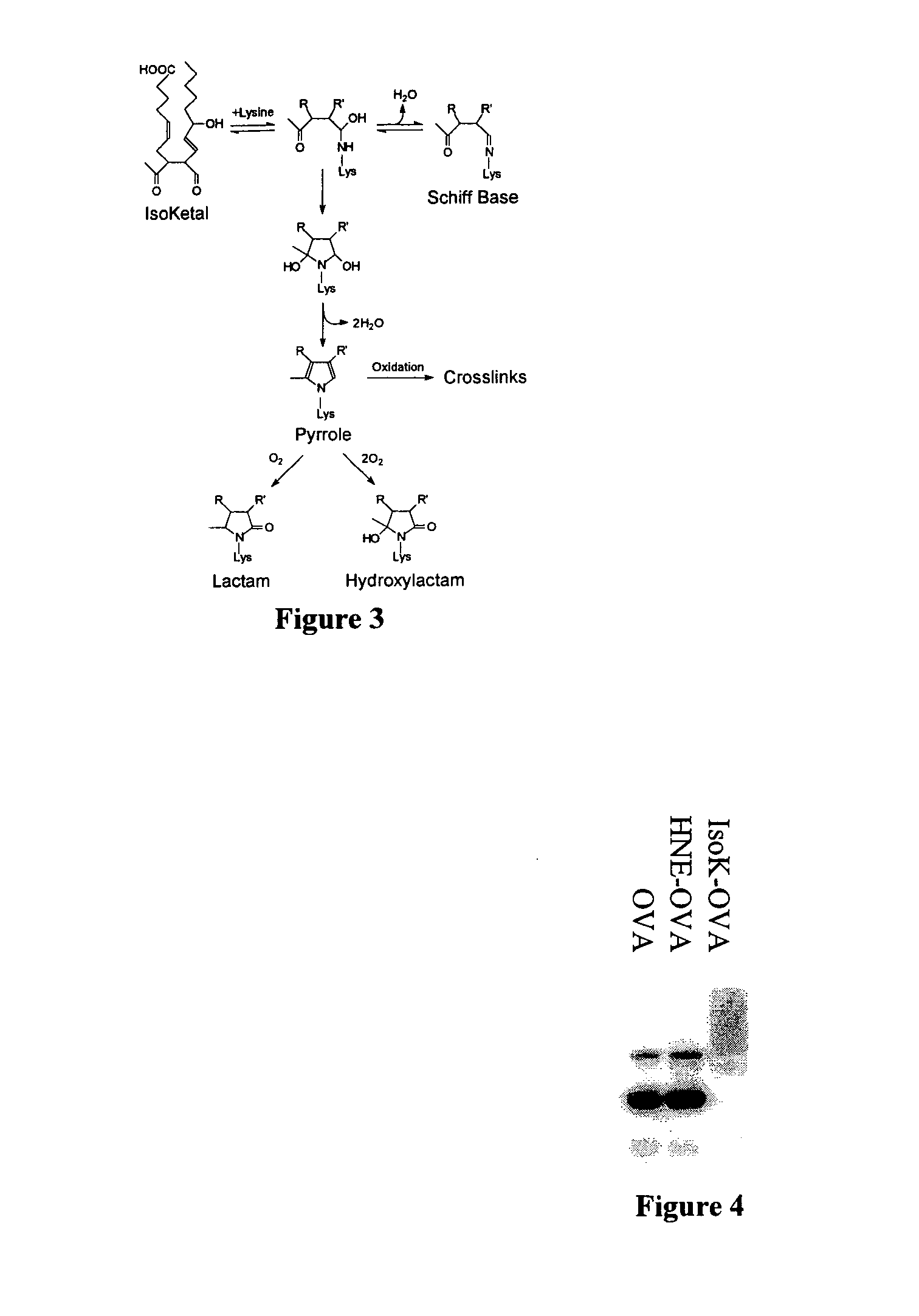

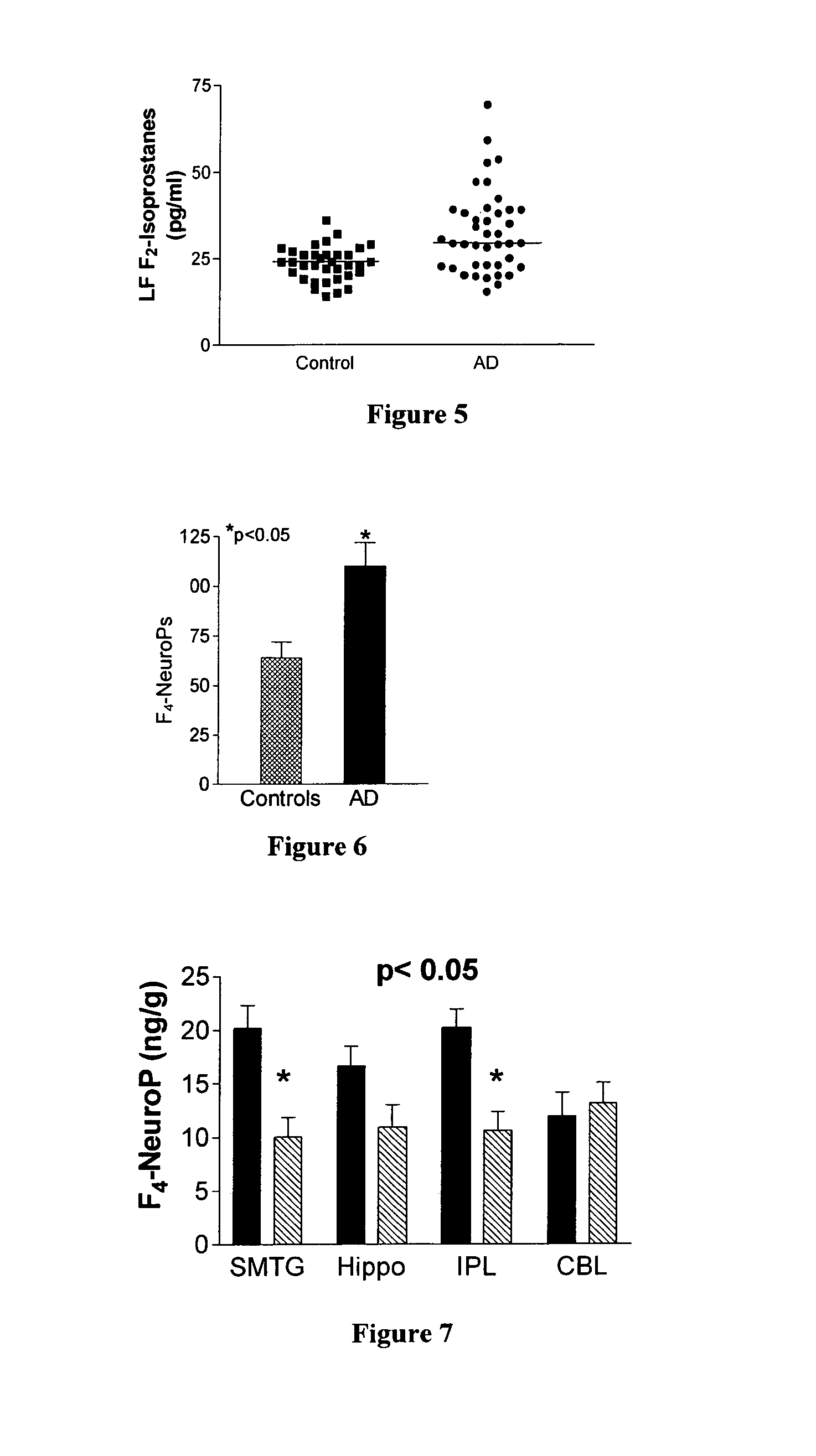

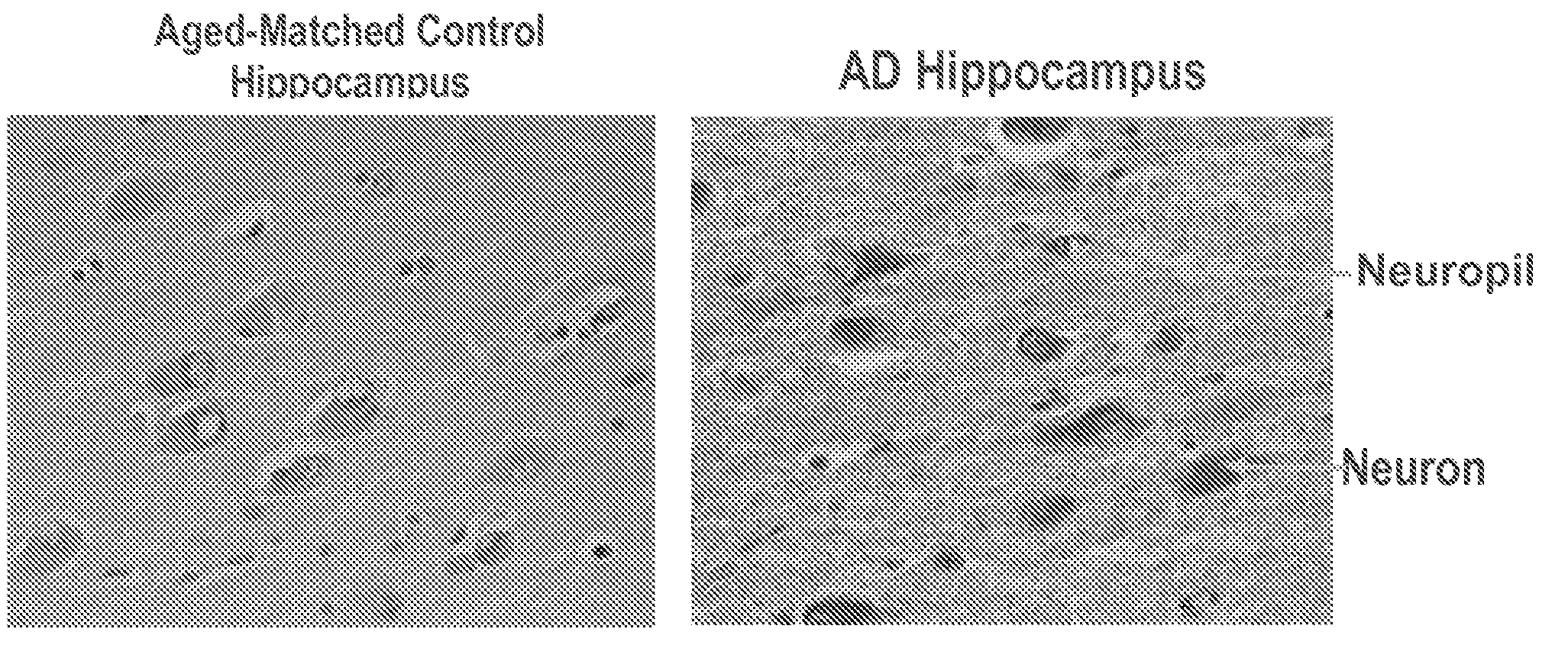

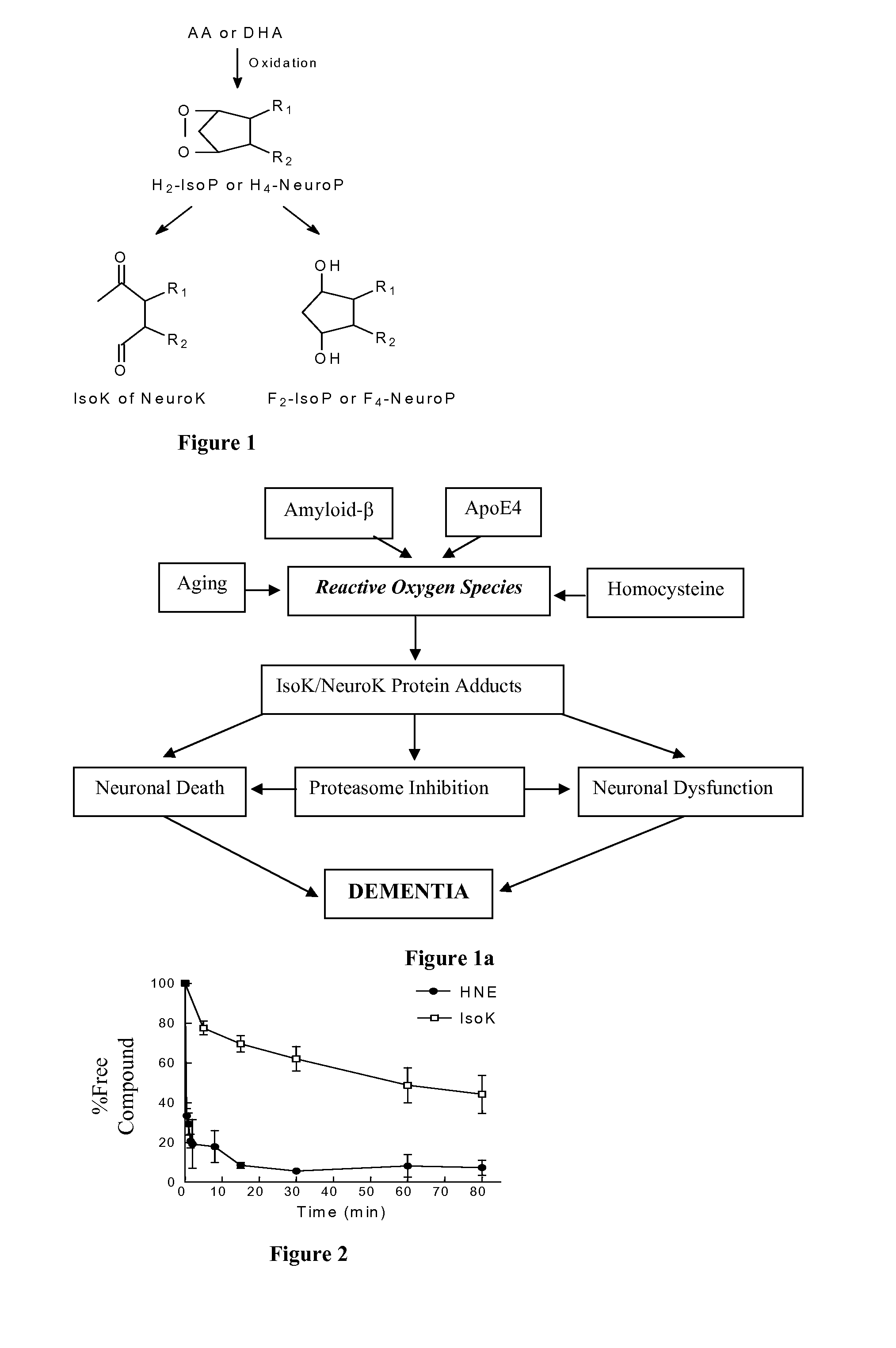

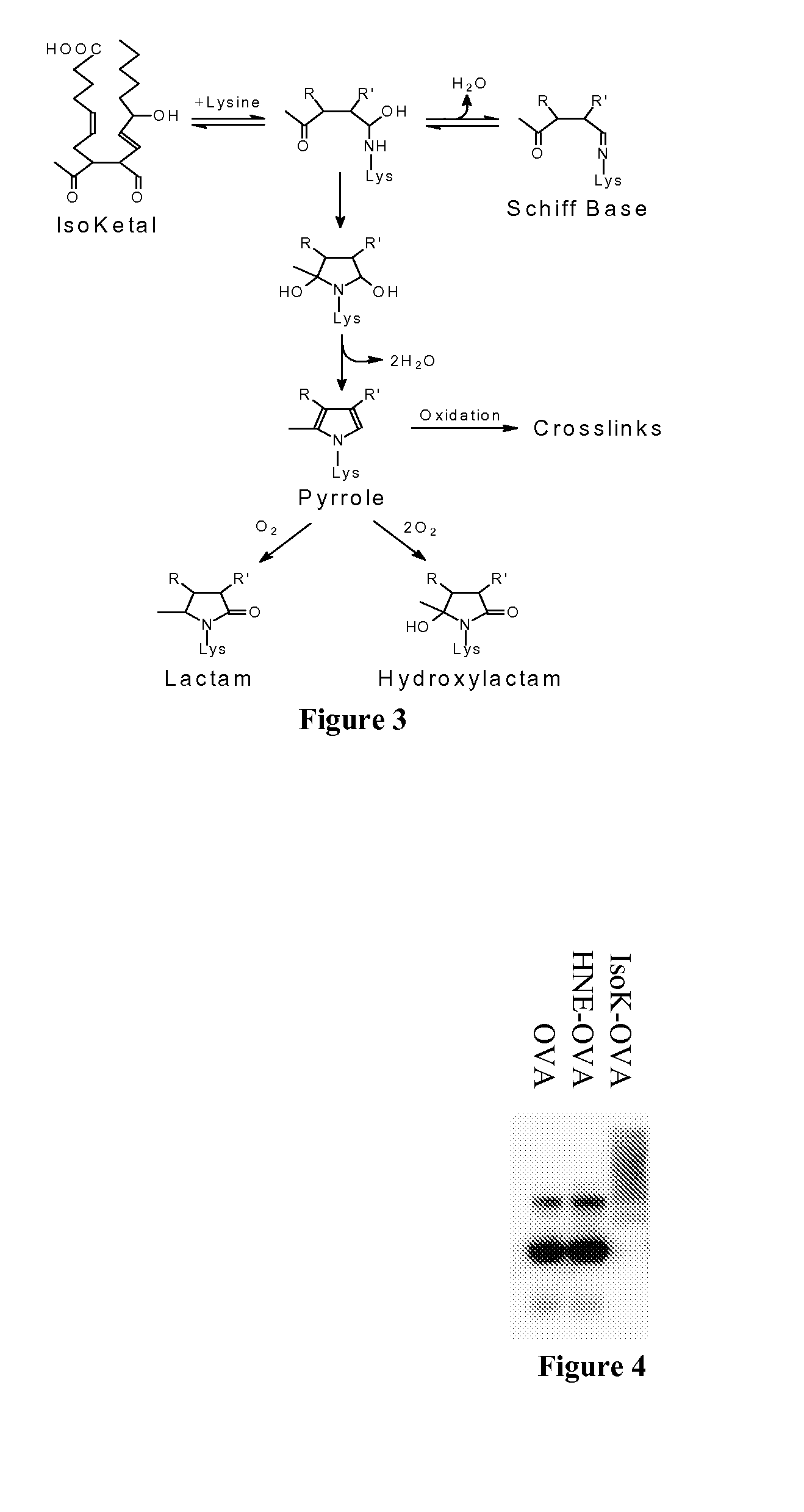

Method of preventing and/or treating oxidant injury in neurodegenerative and oxidative diseases

A method of treating and / or preventing oxidative damage, comprising administering an effective IsoK / NeuroK adduct formation suppressing amount of a phenolic amine compound and / or pyridoxamine or pyridoxamine analog, including embodiments where the phenolic compound is at least one of a pyridoxamine, salicylamine, tyrosine compound or an analog thereof.

Owner:VANDERBILT UNIV

Waterborne anticorrosive coating and preparation method

InactiveCN105176313AReduce surface tensionIncrease wettabilityAnti-corrosive paintsEpoxy resin coatingsMeth-Sodium phosphates

The invention discloses a waterborne anticorrosive coating. The waterborne anticorrosive coating comprises the following components: waterborne epoxy resin emulsion, a pigment filler, a film forming assistant, a leveling agent, a defoaming agent, a thickening agent, a dispersing agent, water and a curing agent, wherein the pigment filler is mixture of iron oxide red and zinc phosphate which are mixed according to a mass ratio of 1:1; the film forming assistant is glycol; the leveling agent is polyacrylic acid or hydroxymethyl cellulose; the defoaming agent is tributyl phosphate; the thickening agent is hydroxymethyl cellulose; the dispersing agent is sodium hexametaphosphate; the curing agent is one of diethylenetriamine, m-phenylenediamine, modified phenolic amine and diamino diphenyl sulfone (DDS). The invention further discloses a preparation method of the waterborne anticorrosive coating, the coating has good anticorrosive performance, the preparation method is simple and feasible and the cost is low.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Isoketal scavengers and mitigation of disorders involving oxidative injury

ActiveUS20120157501A1Reduction in choline acetyltransferase activityReduced activityBiocideNervous disorderScavengerMedicine

A method of treating and / or preventing oxidative damage, comprising administering an effective IsoK / NeuroK adduct formation suppressing amount of a phenolic amine compound and / or pyridoxamine or pyridoxamine analog, including embodiments where the phenolic compound is at least one of a pyridoxamine, salicylamine, tyrosine compound or an analog thereof.

Owner:VANDERBILT UNIV

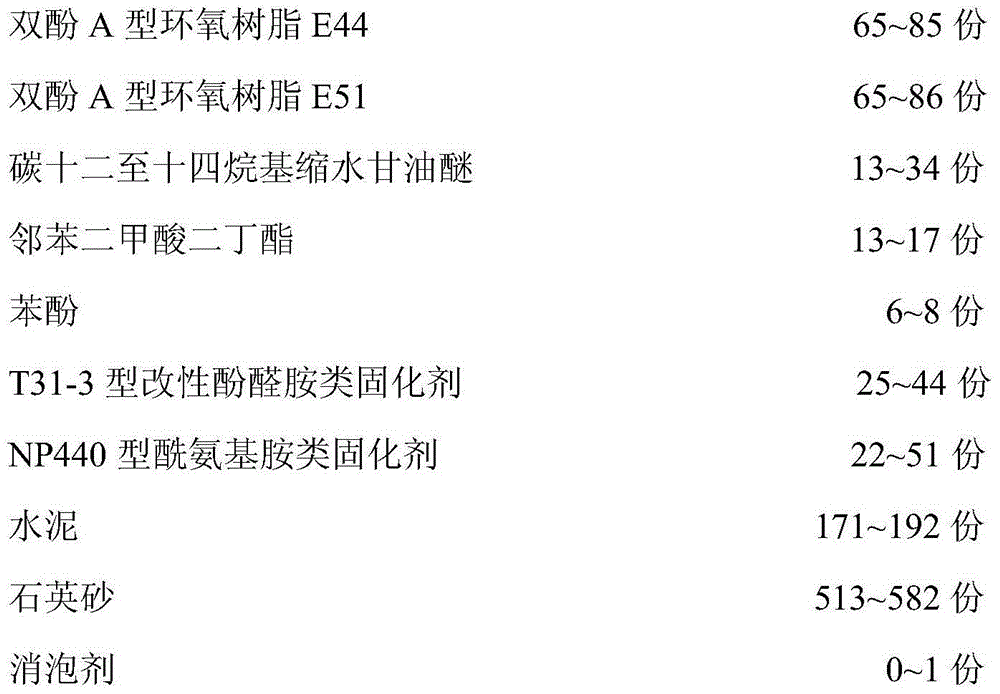

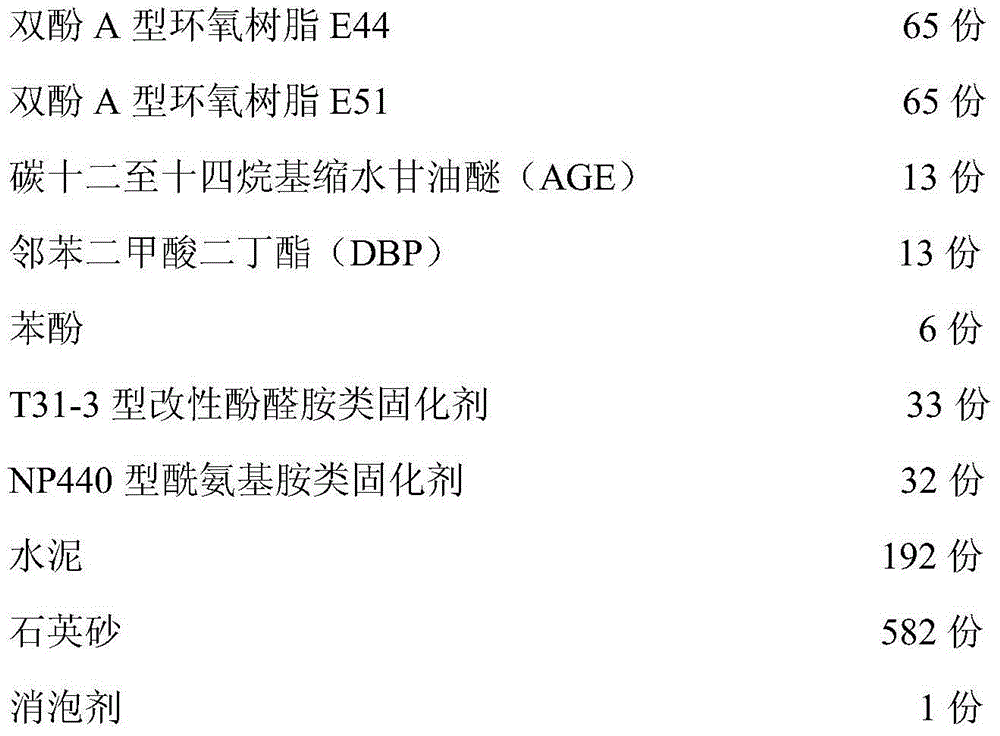

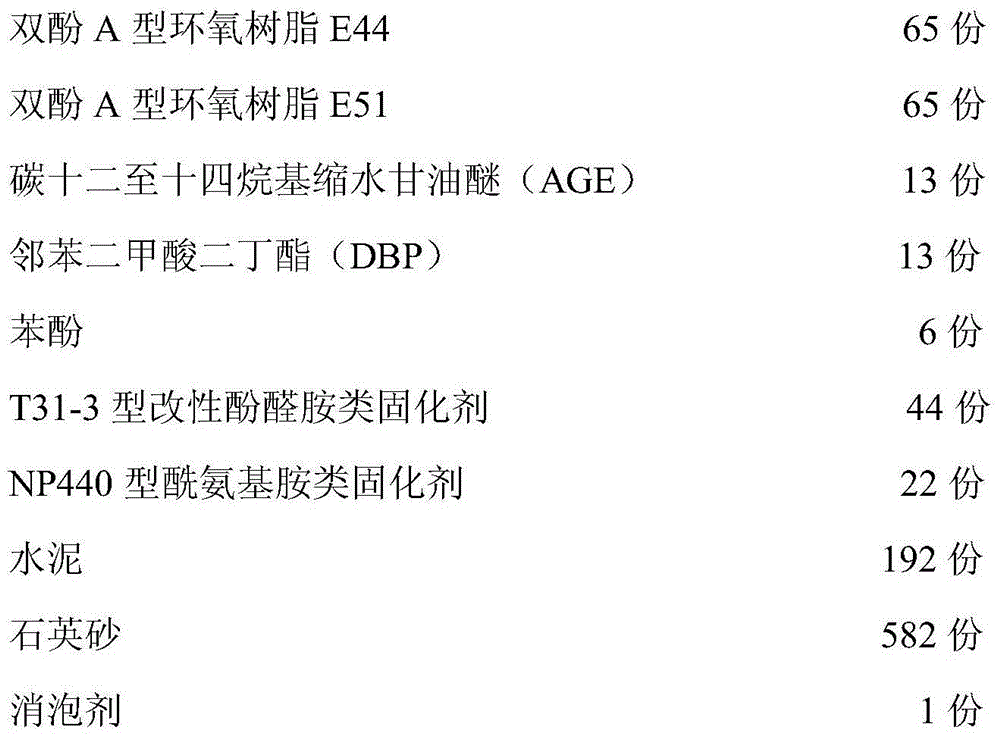

Epoxy mortar used for repairing sea oil gas pipeline and preparation method thereof

The invention discloses an epoxy mortar used for repairing sea oil gas pipeline and a preparation method thereof, which belongs to the technical field of polymer mortar application. The epoxy mortar is composed of a component A, a component B and a component C, the component A is prepared by bisphenol A epoxy resin E44, E51 and a certain amount of auxiliary agent, the component B is prepared by mixing a T31-3 type modified phenolic amine curing agent and a NP440 amidoamines curing agent according to a certain proportion, and the component C is an aggregate by mixing cement and quartz sand according to a certain proportion. The preparation method comprises the following steps: heating the component A to the temperature of 30-50 DEG C, stirring to homogeneous phase, then mixing the component A and the component B according to a certain proportion, uniformly mixing, adding the component C according to a certain proportion, and uniformly blending to obtain the epoxy mortar. The preparation method has simple technology, the epoxy mortar has strong cohesiveness, the epoxy mortar through solidification has excellent anti-compression, anti-punching and anti-seawater corrosion performances, and the epoxy mortar can be used for repairing and reinforcing a concrete coating on the sea oil gas pipeline and a thin layer of an underwater concrete structure.

Owner:TIANJIN UNIV OF SCI & TECH +1

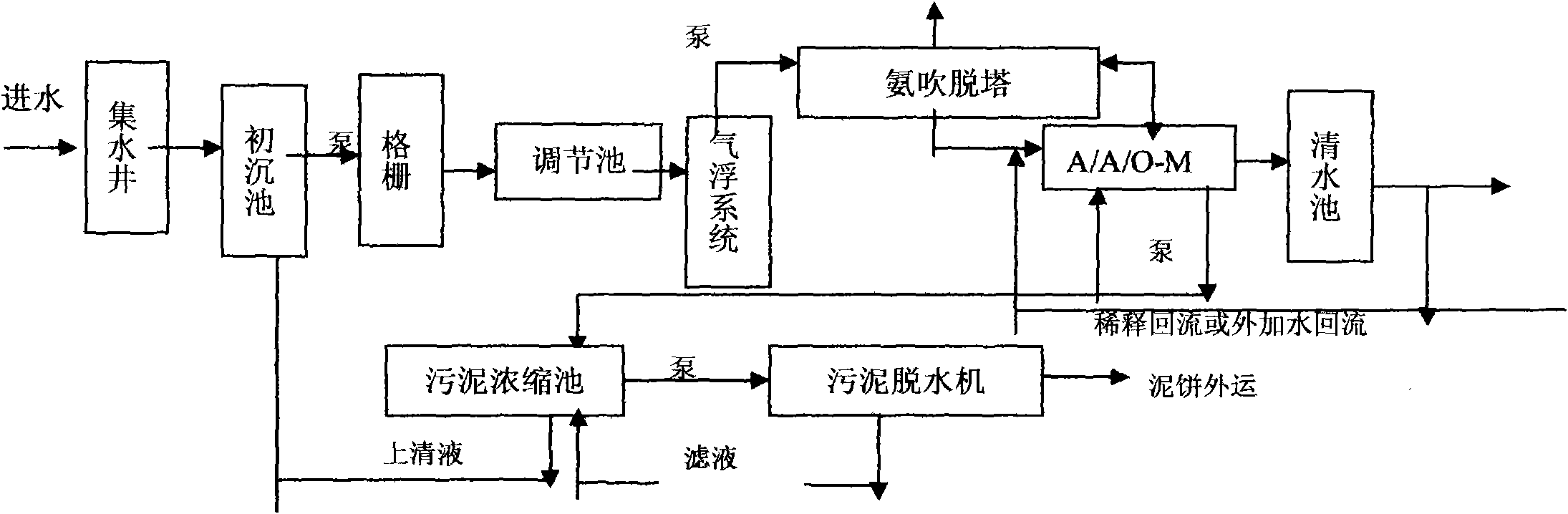

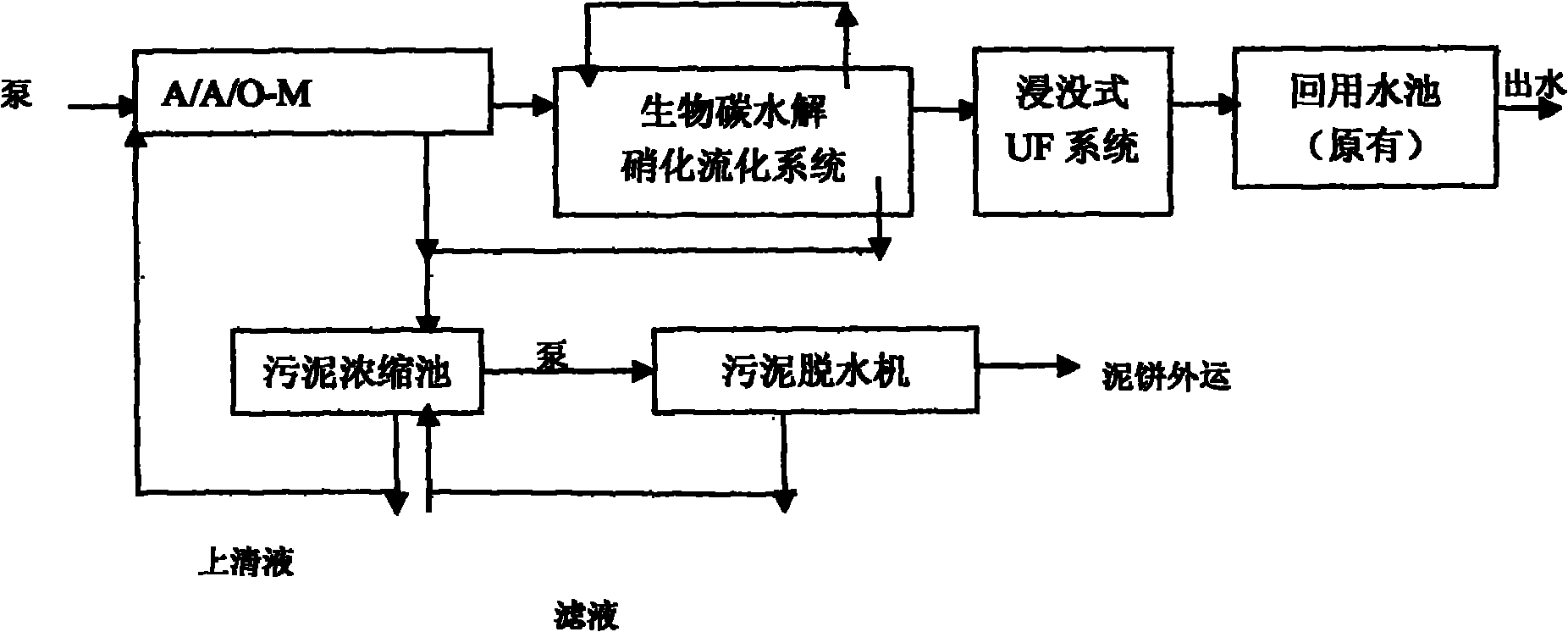

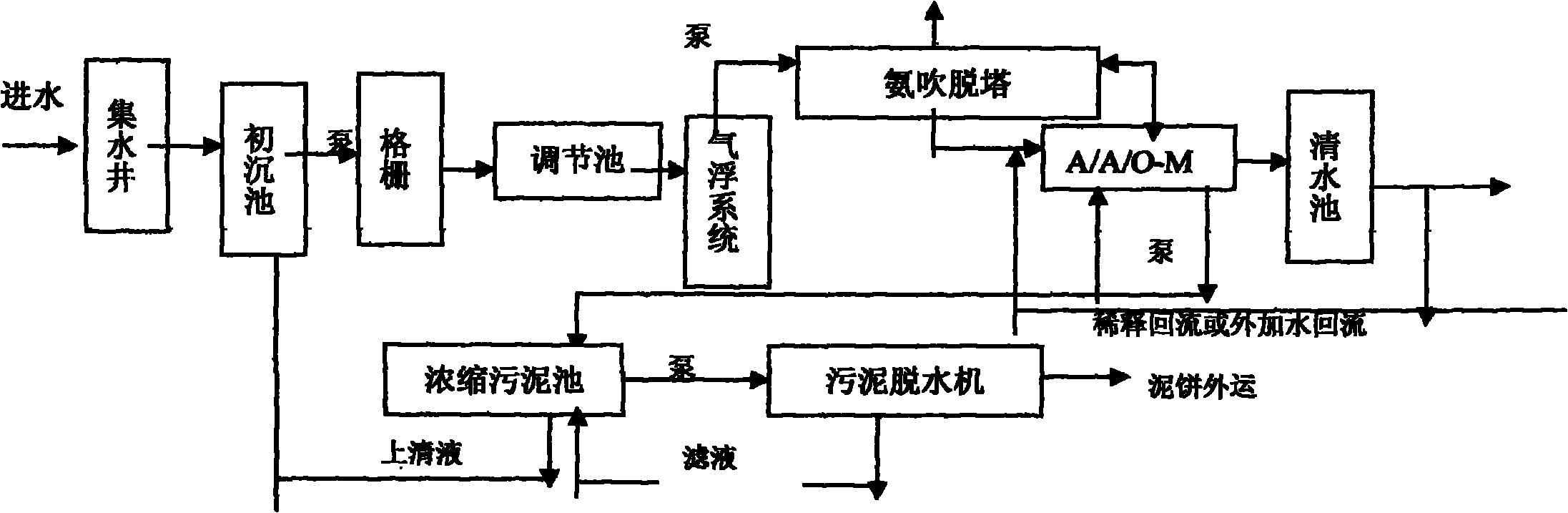

Phenol-amine wastewater treatment and recycling method and device

ActiveCN102107988AReduce concentrationEasy to handleMultistage water/sewage treatmentTreatment effectUltrafiltration

The invention discloses a phenol-amine wastewater treatment and recycling method and device. The device comprises a water collection tank, a primary settling tank, an adjusting tank, a stripping and ammonia absorption system, an A / A / O-the MBR reaction tank, a biochar hydrolysis, nitrification and fluidization system and an immersed ultrafiltration system which are connected in series according tothe flow of the wastewater treatment. The device of the invention adopts the method combining the main physicochemical technology and the auxiliary biochemical technology, thus effectively reducing the operating cost, wherein the physicochemical technology is mainly used to reduce the concentration of ammonia nitrogen, remove suspended matter (SS) and insoluble, slightly soluble and refractory CODcr and increase the B / C ratio; and the biochemical technology is mainly used to remove CODcr and BOD5 and reduce the chroma. The device of the invention has very good treatment effect on the wastewater with high ammonia nitrogen and high phenolic compounds; and the treated wastewater meets the discharge standards and can be directly discharged or further treated for reuse, thus saving the energy.

Owner:SHANGHAI KANGSHENG ENVIRONMENTAL PROTECTION ENERGY TECH

Agglomerated particles of finely divided polymers which are water-soluble or capable of swelling in water and contain ammonium carboxylate groups

InactiveUS6586534B1Narrow particle size distributionAgglomeration effectCarboxylic saltCarboxylic acid

Agglomerated polymer particles of finely divided, water-soluble or water-swellable polymers containing ammonium carboxylate groups are prepared by azeotropic removal of water from water-in-oil emulsions of the water-soluble or water-swellable polymers which contain ammonium carboxylate groups in the presence of from 0.1 to 40% by weight, based on the polymers, of polyalkylene glycols which have an agglomerating effect and which are obtainable by an addition reaction of C2-C4-alkylene oxides with alcohols, phenols, amines or carboxylic acids and contain at least two polymerized alkylene oxide units and additionally of from 0.1 to 20% by weight, based on the polymers, of protective colloids which are obtainable by free radical copolymerization of C8-C40-monoolefins with monoethylenically unsaturated C4-C6-dicarboxylic anhydrides by a mass polymerization method at from 80 to 300° C. to give copolymers having molecular weights of from 500 to 20,000 g / mol, and said agglomerated polymer particles are used as thickeners for textile pigment print pastes.

Owner:BASF AG

Graphite-based anti-corrosive coating material for underwater curing construction and preparation method thereof

ActiveCN107325684AImprove anti-corrosion performanceReduce coating thicknessAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphate

The invention discloses a graphene-based anti-corrosive coating material for underwater curing construction and a preparation method thereof. The graphene-based anti-corrosive coating material for underwater curing construction comprises a component A and a component B, wherein the component A is prepared from the following raw materials of modified epoxy resin, epoxy active thinner, nanoparticle / graphene composite material, water-borne phosphate chelating matter, organosilicone resin, and emery; the component B is prepared from the following raw material of cashew nut shell oil-modified phenolic amine resin. The preparation method comprises the following steps of uniformly stirring all components of the component A and the component B; uniformly mixing the component A and the component B according to a weight ratio of (5 to 10):1, so as to obtain the graphene-based anti-corrosive coating material. The graphene-based anti-corrosive coating material and the preparation method have the characteristics that the graphene-based anti-corrosive coating material can be applied to the construction of underwater steel structure surfaces, and be quickly cured under water, and the effect is lasting; by adopting the nanoparticle / graphene composite material in the coating material, the anti-corrosive property is enhanced.

Owner:山东孚日宣威新材料科技有限公司

Efficient emulsion breaker containing polymer for processing crude oil and preparation method thereof

InactiveCN104945612AImprove demulsification and dehydration rateDewatering/demulsification with chemical meansPtru catalystPotassium hydroxide

The invention discloses an efficient emulsion breaker containing polymer for processing crude oil and a preparation method thereof. Phenol-amine resin is used as an initiator, block polymerization is conducted between the phenol-amine resin and epoxybutane, epoxypropane and ethylene oxide under the action of a potassium hydroxide catalyst, and thus the efficient emulsion breaker containing the polymer for processing crude oil is obtained. The preparation method comprises the steps of synthesis of the phenol-amine resin for the initiator, synthesis of the phenol-amine resin initiator and synthesis of the efficient emulsion breaker containing the polymer for processing crude oil. The prepared emulsion breaker can increase the demulsification dehydration rate of crude oil emulsion driven by polymer and has great practical significance in production of oil fields.

Owner:克拉玛依市天明化工有限责任公司

Anticorrosive coating

ActiveCN104356816AHigh bonding strengthReduce the amount addedConjugated diene hydrocarbon coatingsAnti-corrosive paintsAdhesiveSilicon oxide

The invention discloses an anticorrosive coating which comprises the following components in parts by weight: 50-60 parts of zinc acrylate resin, 10-15 parts of coalescing agents, 10-20 parts of magnesium oxide, 12-22 parts of silicon oxide, 1-2 parts of ferric oxide, 5-8 parts of toluenesulfonic acid, 5-8 parts of calcium carbonate, 2-3 parts of suspending agent, 3-5 parts of alcohol solvent, 1-2 parts of adhesive, 4-6 parts of phenolic amine, 1-2 parts of nitrile rubber, 0.7-1.2 parts of thickening agent, 0.5-1 part of defoaming agent, 0.4-0.8 part of flatting agent and 20-30 parts of deionized water. The coating disclosed by the invention is good in sulfur resistance and good in anticorrosive performance.

Owner:广州前延新材料发展有限公司

Antiwear conductive polymer paint for detecting high voltage cable plastic sheath

InactiveCN101067063AImprove conductivityImprove wear resistanceTesting dielectric strengthFault locationPolymer scienceConductive polymer

The present invention is antiwear conductive polymer paint for detecting high voltage cable plastic sheath and its preparation and application, and belongs to the field of conducting paint and wire and cable producing technology. The antiwear conductive polymer paint is compounded with component A and component B in the weight ratio of 3-5 to 1. The component A consists of thermosetting polymer resin 35-54 wt%, conducting stuffing 35-62 wt%, solid lubricant 0.5-7.0 wt%, coupling agent 0.1-2.0 wt%, organic thixotropic agent 0.1-2.0 wt% and defoaming agent 0.1-2.0 wt%; and the component B is curing agent phenolic amine T31. The antiwear conductive polymer paint is coated to the outer surface of polyvinyl chloride sheath of high voltage transmission cable to form coating of 0.2-0.8 mm thickness through curing at 20-100 deg.c, and the coating is suitable for DC voltage withstand detection.

Owner:SHANGHAI UNIV +1

Low-temperature underwater anchoring adhesive and preparation method thereof

InactiveCN106928889AHigh molecular weightImprove water resistanceEpoxy resin adhesivesPolymer scienceAdhesive

The invention provides a low-temperature underwater anchoring adhesive and a preparation method thereof. The low-temperature underwater anchoring adhesive is prepared from a bi-component of A and B, and is prepared by mixing A and B at a mass ratio of 2:1, wherein A comprises bisphenol A-type epoxy resin, reactive diluents, flexibilizers, silane coupling agents, thixotropic agents and stuffing; B comprises an anacardol-modified phenolic amine hardener, accelerators, silane coupling agents, thixotropic agents and stuffing. The low-temperature underwater anchoring adhesive owns excellent water tolerance, and can realize complete underwater solidification. Through specific formula design, the anchoring adhesive is capable of soaking and adhering to a structural layer. In an environment of 0 DEG C or so, the anchoring adhesive still owns excellent reactivity, and rapidly conducts low-temperature solidification. Through combination of excellent hydrophobic property with good soaking property and rapid solidification, the anchoring adhesive can conduct implantation and anchoring well in low-temperature water, and completely solve the problem that implantation and anchoring can not be conducted in low-temperature water in the construction industry.

Owner:CARBON COMPOSITESTIANJIN CO LTD

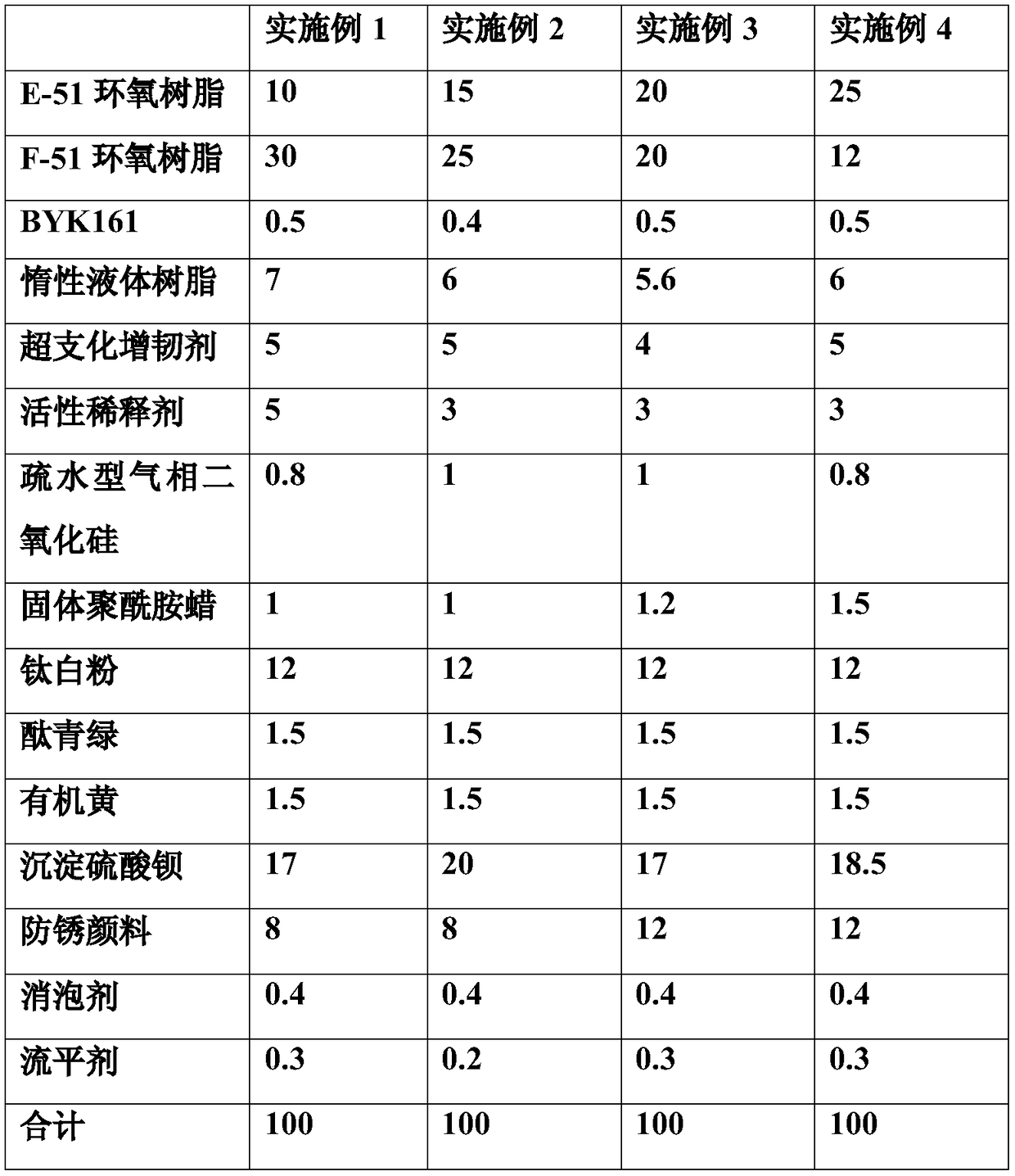

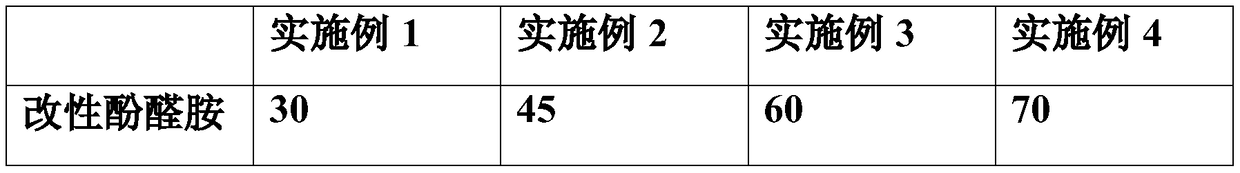

Solvent-free epoxy heavy anti-corrosion paint extruded and coated to inner wall of crude oil gathering pipeline

InactiveCN109181477AGood chemical resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

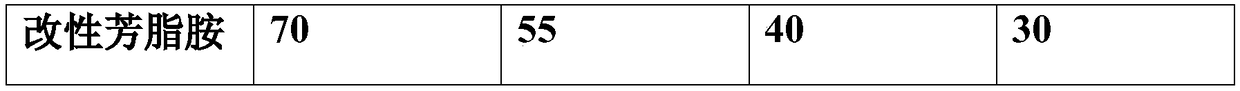

The invention discloses a solvent-free epoxy heavy anti-corrosion paint which is extruded and coated to the inner wall of a crude oil gathering pipeline. The paint comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 10-25 parts of E-51 epoxy resin, 12-30 parts of F-51 epoxy resin, 10-15 parts of titanium dioxide, 1-2 parts of phthalocyanine green, 1-2 parts of organic yellow, 1.5-3 parts of a thixotropic agent, 0.3-0.5 part of a wetting dispersant, 5-8 parts of inert liquid resin, 3-5 parts of an active diluting agent, 3-5 parts of a hyperbranched toughening agent, 15-20 parts of precipitated barium sulfate, 8-15 parts of anti-rust pigment, 0.3-0.5 part of a defoaming agent, 0.2-0.4 part of a flatting agent; the component B is prepared from 30-70 parts of modified phenolic amine curing agent and 70-30 parts of modified aromatic amine curing agent; and the mass ratio of the component A to the component B is(5-7):1. The solvent-free epoxy heavy anti-corrosion paint is applicable to gathering pipeline extruding and coating processes, the pipeline inner wall coating has excellent corrosion resistance and physical performance, the coating process can be reduced, the construction time can be saved, and the work efficiency can be improved.

Owner:石家庄市油漆厂

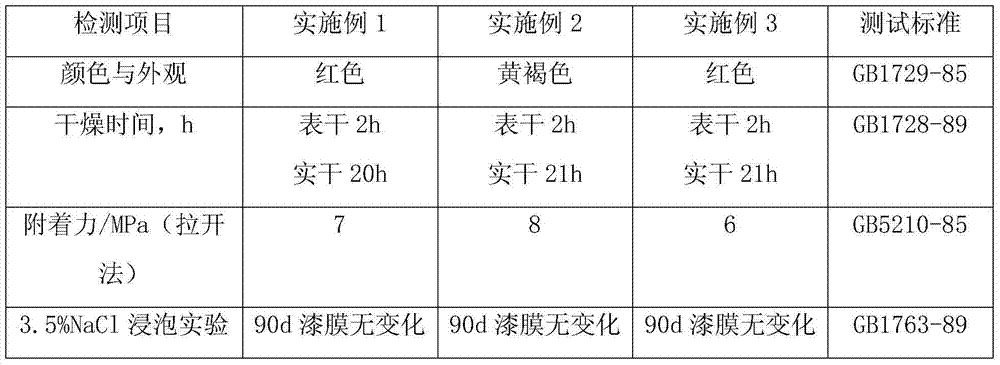

Seawater corrosion-resistant epoxy paint and manufacturing method thereof

InactiveCN102786865AStrong adhesionImprove impact resistanceAntifouling/underwater paintsPaints with biocidesDiacetone alcoholFatty amine

The invention relates to a seawater corrosion-resistant epoxy paint and a manufacturing method thereof. The manufacturing method comprises the following steps of adding modified phenolic epoxy resin and bisphenol-F-epoxy resin into a mixed solvent of dimethylbenzene, diacetone alcohol and n-butyl alcohol; adding titanium dioxide, aluminium triphosphate, alumina powder, silica micropowder, sericite powder, carbon black, an aluminate coupling agent, polymethyl alkyl siloxane solution and polyamide wax into the mixture; blending, stirring and grinding the materials to prepare A liquid of the seawater corrosion-resistant paint; adding aliphatic amine and modified phenolic amine into mixed solution of absolute ethyl alcohol and dimethylbenzene to prepare B liquid; and mixing the A liquid and the B liquid to prepare the seawater corrosion-resistant epoxy paint. The paint can be used for curing at 0 DEG C, has excellent storage stability and very good adhesion, abrasion resistance, flushing resistance and seawater resistance, and can be applied to splashing areas and underwater corrosion resistance of ships, marine platforms, marine work steel structures and the like.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC

Acid surface active agent oil well leaking stoppage technology and its formula

The invention relates to a technique used acidity surfactant to remove oil well blocking and its formula and manufacturing method. The feature of the acidity surfactant formula is that its material weight ratio is as follows: polyoxy propylene-polyoxy ethylene glycerin ether 10-40%, polyoxy propylene-polyoxy ethylene phenol amine resin 10-45%, FC-NO1 fluorocarbon surfactant 0.0001%-0.035%, FC-3B fluorocarbon surfactant 0.0001%-0.05%, hydrochloric acid 3-10%, nitric acid 2-10%, and water 30-55%. The feature of the technique is as follows: the made-up 0.4%-0.6% acidity surfactant can be injected from hollow while running; then it can be replaced by 10-20m3 clear water. The invention has good effect and can improve yield.

Owner:PETROCHINA CO LTD

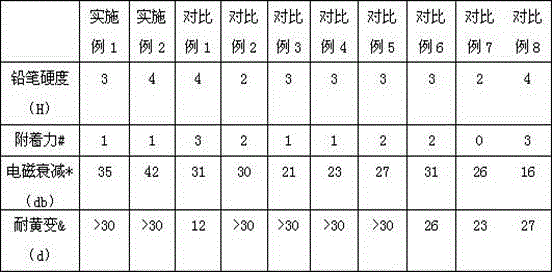

Graphene-based electromagnetic-radiation-resistant dual-component epoxy resin paint

ActiveCN106189689AImprove conductivityGuaranteed StrengthRadiation-absorbing paintsEpoxy resin coatingsAntioxidantPolyamide

The invention relates to graphene-based electromagnetic-radiation-resistant dual-component epoxy resin paint. By means of dual radiation-resistant measures, the epoxy resin paint with excellent radiation resistance and yellowing resistance is obtained. The paint is composed of a component A and a component B according to the weight ratio of (2-6):1. The component A is prepared from, by weight, 20 parts of bisphenol-A epoxy resin, 80 parts of cycloaliphatic epoxy resin, 10-15 parts of graphene, 3-10 parts of antioxidant, 1-3 parts of ultraviolet absorbent, 10-22 parts of conductive filler, 2-5 parts of dispersing agent, 1-3 parts of pigment and 20 parts of solvent. The component B is prepared from, by weight, 20-30 parts of polyamide curing agent, 10-30 parts of hydrogenated cashew phenol modified phenolic amine and 20 parts of solvent. The paint curing product has excellent electromagnetic radiation resistance, yellowing resistance and adhesive force, proper hardness and excellent comprehensive performance and is better than similar products in the prior art.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

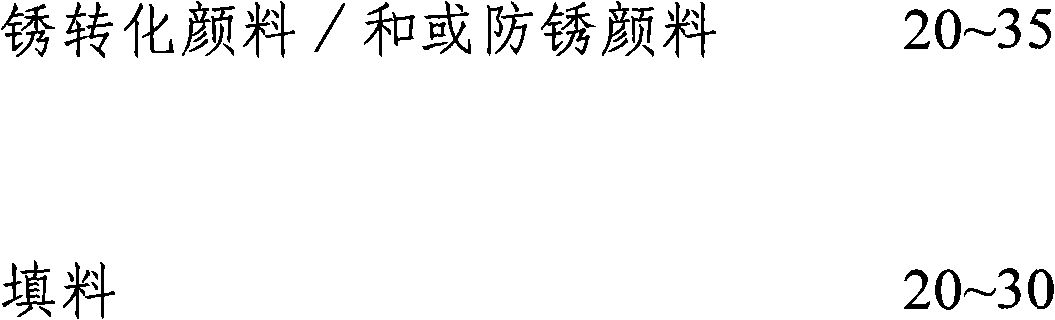

Epoxy rust coating

ActiveCN103897559AIncrease the degree of cross-linkingGood paintabilityAnti-corrosive paintsEpoxy resin coatingsPhytic acidCashew nut

The invention provides an epoxy rust coating which comprises a component A and a component B, wherein the component A comprises the following materials by weight percent: 10%-40% of bisphenol A epoxy resin, 10%-20% of xylene, 4%-8% of normal butanol, 5%-10% of ethanol, 2%-6% of phytic acid, 5%-20% of aluminum tripolyphosphate and 10%-30% of constitution fillers; the component B is a cardolite 2015 cashew-nut modified long-chain phenolic amine curing agent; the weight ratio of the component A to the component B is (3-10): 1. The epoxy rust coating is widely applied to the field of heavy corrosion protection epoxy coatings due to the characteristics of excellent coating performance, low cost and the like. Especially, phytic acid and aluminum tripolyphosphate are added into the coating and can stabilize and convert a rust layer, reduce the interface corrosion, increase an adhesive force and increase the cross-linking degree of the epoxy resin so that a paint film becomes very compact.

Owner:哈尔滨工程大学科技园发展有限公司 +1

Epoxy resin steel pouring adhesive and preparation method thereof

InactiveCN106244068AImprove mechanical propertiesImprove toughnessNon-macromolecular adhesive additivesEpoxy resin adhesivesSide chainAdhesive

The invention discloses an epoxy resin steel pouring adhesive, which is synthesized from a component A and a component B in a weight ratio of 2:1. The component A is composed of the following components by weight: 100 parts of bisphenol A resin, 2-6 parts of a toughening agent, 1-5 parts of an active diluents, 1-5 parts of a silane coupling agent, 3-10 parts of white carbon black, and 150-220 parts of active silica powder, and the component B is composed of the following components by weight: 40-60 parts of a modified phenolic amine curing agent, 1-4 parts of a silane coupling agent, 1-4 parts of white carbon black, and 170-230 parts of active silica powder. The adhesive provided by the invention can be cured rapidly under water, also the aromatic ring structure of phenolic amine endows the adhesive with excellent chemical resistance, hydroxyl provides high bonding strength and excellent reaction activity for fast curing and low temperature curing, the side chain provides water resistance and toughness, the adhesive has good thixotropy, does not flow during construction, and saves adhesive consumption.

Owner:CARBON COMPOSITESTIANJIN CO LTD

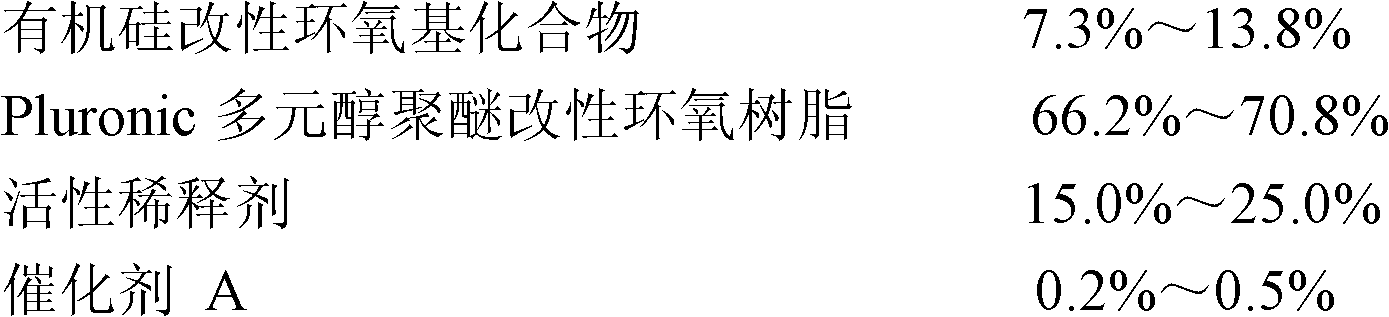

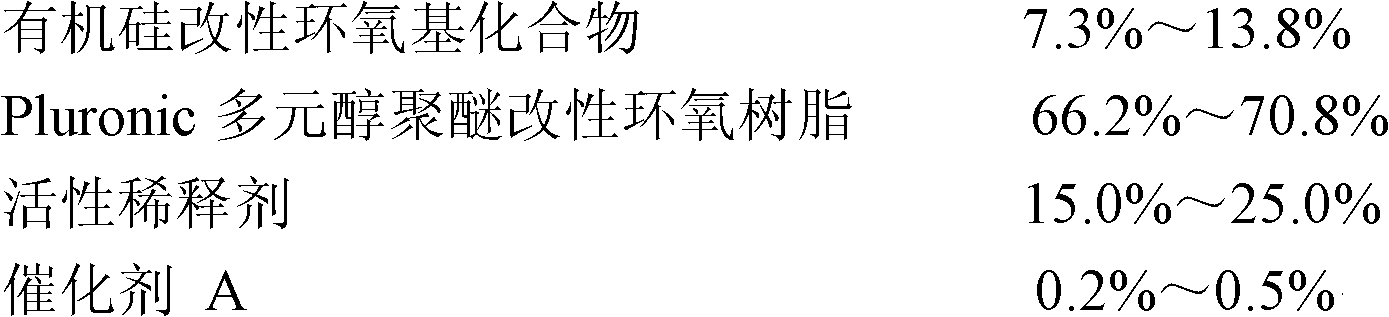

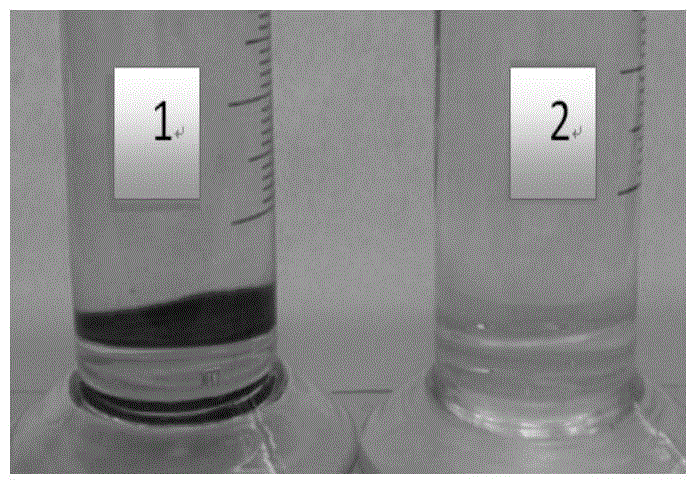

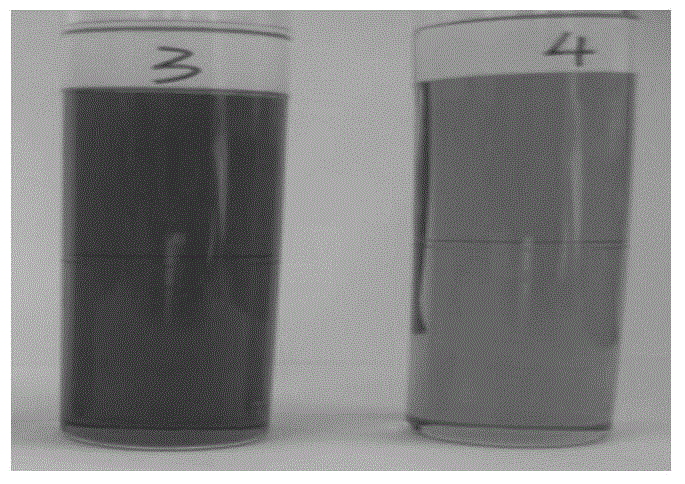

Solvent-free epoxy resin as plugging material, and preparation method and application of the solvent-free epoxy resin

The invention discloses a solvent-free epoxy resin as a plugging material and a preparation method and application of the solvent-free epoxy resin. The material is prepared from part A and part B at a ratio of 4:1 to 20:1 by weight, wherein the part A contains the following components by weight: 7.3-13.8% of organic silicon modified epoxy compound, 66.2-70.8% of Pluronic polyol polyether-modified epoxy resin, 15.0-25.0% of a reactive diluent, and 0.2-0.5% of a catalyst A, and part B contains the following components by weight: 99.0-99.7% of modified phenolic amine, 0.2-0.5% of a silicane coupling agent and 0.1-0.5% a catalyst B. According to the invention, reaction between benzyl glycidyl ether and hydroxyl silicone oil is utilized, so that the molecular weight of the reaction product is reduced, the viscosity is reduced, and the surface tension of the product is small for plugging effect. In addition, reaction between Pluronic polyol polyether and epoxy resin is adopted to improve the elasticity of a consolidating body and increase the surface activity of the system for water repelling effect. The solvent-free epoxy resin as the plugging material can be applied to engineering parts with visible water.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

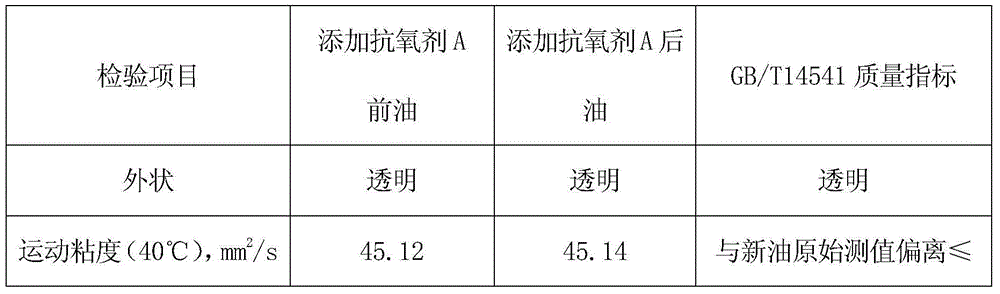

Steam turbine oil composite antioxidant as well as preparation method and addition method of steam turbine oil composite antioxidant

The invention provides a steam turbine oil composite antioxidant as well as a preparation method and an addition method of the steam turbine oil composite antioxidant. The steam turbine oil composite antioxidant is composed of a free radical terminator, a peroxide decomposer and a metal passivator; the free radical terminator is a hindered phenol antioxidant, a hindered amine antioxidant or a phenol-amine compound containing a reactive hydrogen atom; the peroxide decomposer is a sulfide or a phosphite; the metal passivator is a thiadiazole derivative or a heterocyclic derivative; the weight percent ratio of the free radical terminator, the peroxide decomposer and the metal passivator is (35wt%-78wt%) to (16wt%-59wt%) to (0.5wt%-8wt%); the preparation method comprises the following steps: adding the free radical terminator, the peroxide decomposer and the metal passivator to an aldehyde solution, mixing evenly and then shifting the mixed solution into a reactor for reacting by controlling certain parameters and increasing both temperature and pressure, and after the reaction, distilling, washing, purifying, crystalizing and drying the product, thereby obtaining the finished antioxidant. The invention also provides an addition dosage and an addition process of the antioxidant to avoid the problem of operating oil precipitation or abnormal color due to self-oxidation of the antioxidant in the prior art.

Owner:XIAN THERMAL POWER RES INST CO LTD

Cathodic disbanding resistant anti-corrosion epoxy coating and making method thereof

InactiveCN104177987AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsSolventFumed silica

The invention relates to a cathodic disbanding resistant anti-corrosion epoxy coating and a making method thereof; bisphenol A epoxy resin, novolac epoxy and petroleum resin are added into a xylene and n-butanol mixed solvent, then wet sericite powder, barite powder, titanium dioxide, carbon black, fumed silica, an active diluent, a silane coupling agent, silicone oil and fluorocarbon modified polyacrylate are added for mixing, stirring and grinding to prepare an A component of the cathodic disbanding resistant anti-corrosion epoxy coating, cashew nut shell oil modified phenolic amine and modified aliphatic amine are mixed to prepare a B component, when in use, the A component and the B component are mixed; the cathodic disbanding resistant anti-corrosion epoxy coating has good compatibility with an electrochemical protection system, has excellent cathodic disbanding resistant performance and good adhesion, flexibility, sea water resistance and chemical resistance, and can be used for corrosion protection of splash zones and full immersion zones of ships, offshore platforms and marine steel structures and the like.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

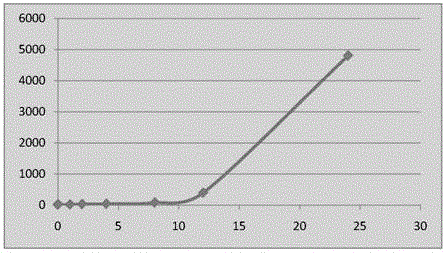

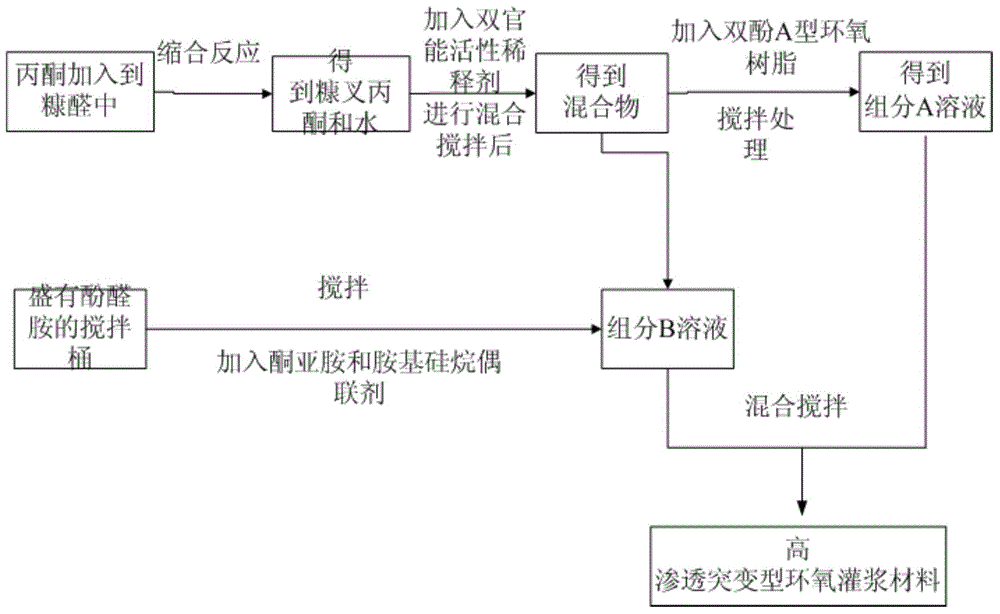

High-permeability mutant grouting material

The invention relates to the field of chemical grouting materials and particularly relates to a high-permeability mutant grouting material. The high-permeability mutant grouting material is prepared by the following steps: adding acetone into furfural to form a furfural acetone system, adding a bifunctional reactive diluent into the furfural acetone system, mixing and stirring to obtain a mixture, then adding bisphenol A type epoxy resin into the mixture, stirring, and pulping to obtain a component A solution; adding ketimine and an aminosilane coupling agent into a stirring barrel holding phenolic amine, and stirring to obtain a component B solution; stirring and mixing the prepared component A solution and the component B solution on a construction site to obtain a high-permeability mutant epoxy grouting material. The high-permeability mutant grouting material provided by the invention is good in mutability, meanwhile the slurry density is controlled within the range of 1.0-1.1 g / cm<3>, the initial viscosity can reach 10mPa.s, the operation time is up to 720 minutes, the mechanical properties are good, the preparation method is simple, and the high-permeability mutant grouting material can be produced in a large scale.

Owner:刘平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com