Graphite-based anti-corrosive coating material for underwater curing construction and preparation method thereof

A graphene-based, anti-corrosion coating technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor anti-corrosion performance, easy to fall off, difficult construction, etc., and achieve excellent anti-cathode disbondment performance and enhanced Coating anti-corrosion performance, the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

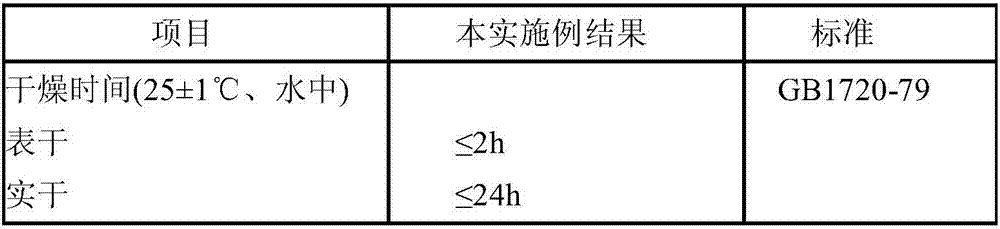

Embodiment 1

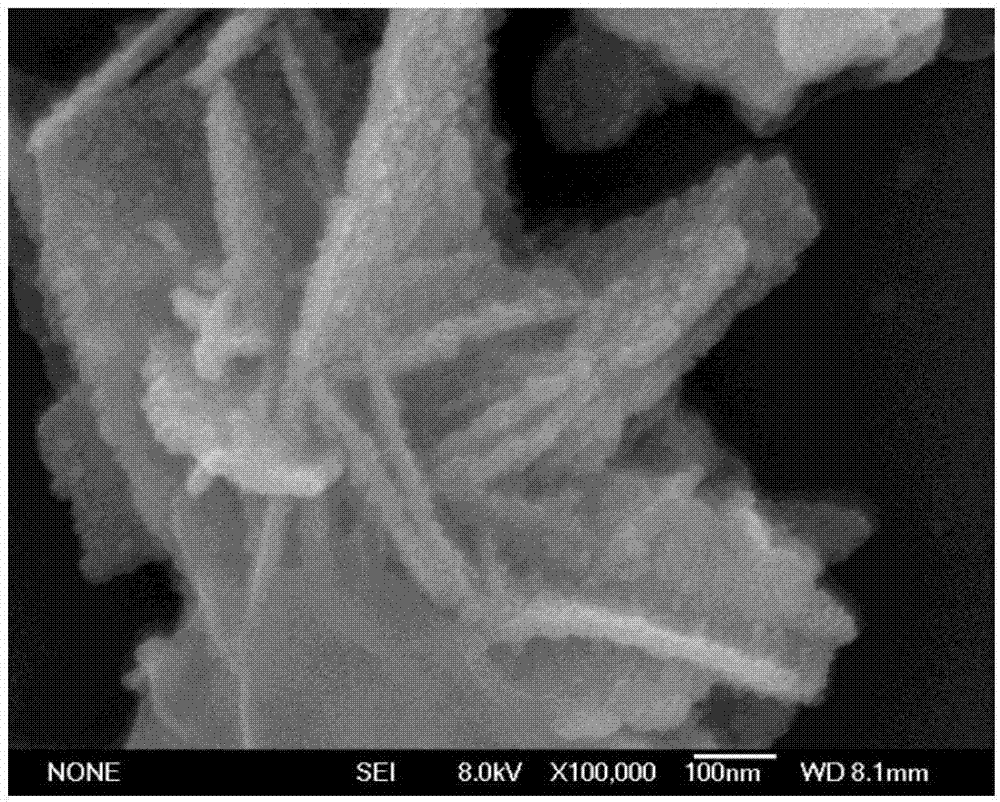

[0029] A graphene-based anti-corrosion coating material for underwater curing construction, including component A and component B. Its main components are by weight:

[0030] The components of said component A are: 45 parts of modified epoxy resin, 20 parts of epoxy reactive diluent, 10 parts of nanoparticle / graphene composite material, 10 parts of water-based phosphate chelate, 5 parts of silicone resin , 10 parts of emery;

[0031] The components of the B component are: 100 parts of cashew nut shell oil modified phenalkamine resin.

[0032] 45 parts of modified epoxy resin, 20 parts of epoxy reactive diluent, 10 parts of nanoparticle / graphene composite material, 10 parts of water-based phosphate chelate, 5 parts of silicone resin, and 10 parts of emery in component A , use a high-power high-speed dispersing machine at 1500 rpm, disperse for 2 hours and then pack it into the warehouse;

[0033] The product is obtained by uniformly mixing the obtained component A and compon...

Embodiment 2

[0044] A graphene-based anti-corrosion coating material for underwater curing construction, including component A and component B. Its main components are by weight:

[0045] The components of said component A are: 50 parts of modified epoxy resin, 18 parts of epoxy reactive diluent, 8 parts of nanoparticle / graphene composite material, 9 parts of water-based phosphate chelate, and 5 parts of silicone resin , 10 parts of emery;

[0046] The components of the B component are: 100 parts of cashew nut shell oil modified phenalkamine resin.

[0047] 50 parts of modified epoxy resin, 18 parts of epoxy reactive diluent, 8 parts of nanoparticle / graphene composite material, 9 parts of water-based phosphate chelate, 5% of silicone resin, and 10 parts of corundum in component A , use a high-power high-speed disperser at 2000 rpm, disperse for 1.5 hours and then pack it into the warehouse;

[0048] The product is obtained by uniformly mixing the prepared component A and component B accor...

Embodiment 3

[0059] A graphene-based anti-corrosion coating material for underwater curing construction, including component A and component B. Its main components are by weight percentage:

[0060] The components of said component A are: 55 parts of modified epoxy resin, 16 parts of epoxy reactive diluent, 6 parts of nanoparticle / graphene composite material, 10 parts of water-based phosphate chelate, 4 parts of silicone resin , 9 parts of emery;

[0061] The components of the B component are: 100 parts of cashew nut shell oil modified phenalkamine resin.

[0062] 55 parts of modified epoxy resin, 16 parts of epoxy reactive diluent, 6 parts of nanoparticle / graphene composite material, 10 parts of water-based phosphate chelate, 4 parts of silicone resin, and 9 parts of emery in component A , use a high-power high-speed disperser at 2500 rpm, disperse for 1 hour and then pack it into the warehouse;

[0063] The product is obtained by uniformly mixing the prepared component A and component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com