Building structure adhesive suitable for underwater construction

A technology for building structure and underwater construction, which is applied in the direction of adhesives, adhesive additives, epoxy resin glue, etc., and can solve the problems of inability to judge standard requirements and unclarified use of underwater building structural adhesives, and achieve moderate price and excellent construction Moderate effect of performance, performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

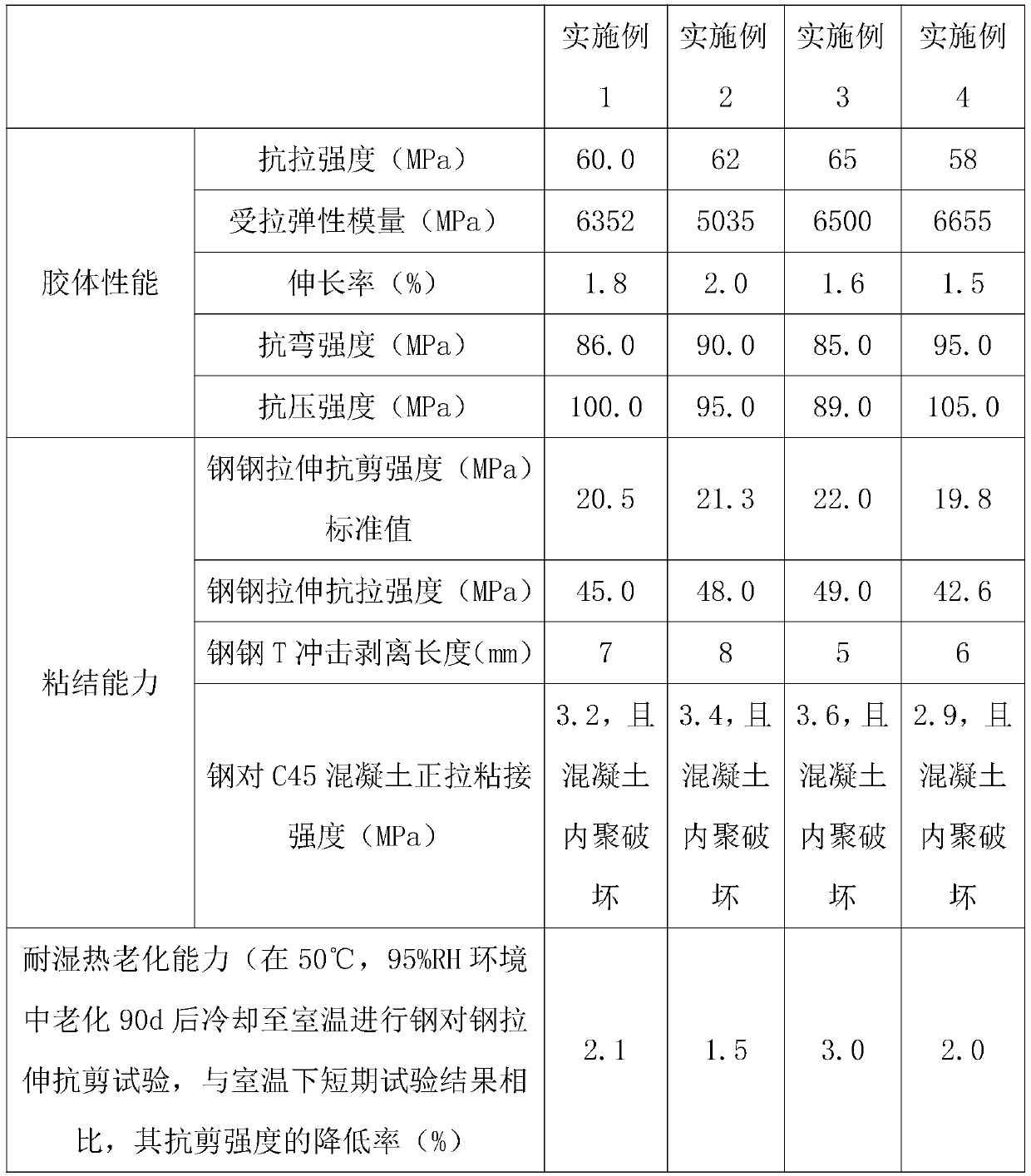

Examples

Embodiment 1

[0056] A kind of preparation method of the building structure adhesive suitable for underwater construction of the present embodiment, comprises the following steps:

[0057] Step 1, preparation of component A: First, weigh the liquid component bisphenol A epoxy resin CYD128: 80 parts, diluent XY748: 10 parts, toughening agent QS-BE: 6 parts, coupling agent KH560: 2 parts, wetting and dispersing agent 1202: 2 parts and add to the mixer in turn, stir evenly, then weigh the solid component active silicon micropowder (400 mesh): 100 parts and thixotropic agent R202: 2 parts and order Add it into the liquid component mixing system, stir for 1 to 2 hours, discharge, and pack to obtain the finished product of component A;

[0058] Step 2, preparation of component B: first weigh the liquid component phenalkamine curing agent 701:80 parts, wetting and dispersing agent 1202:2 parts according to the weight ratio and add them to the mixer in turn, stir evenly, and then weigh the solid ac...

Embodiment 2

[0061] A kind of preparation method of the building structure adhesive suitable for underwater construction of the present embodiment, comprises the following steps:

[0062] Step 1, preparation of component A: First, weigh the liquid component bisphenol F epoxy resin NPEF-170: 80 parts, diluent XY767: 10 parts, toughening agent QS-BC: 4 parts, coupling agent KH560: 1 part, wetting and dispersing agent 1201: 3 parts and add them to the mixer in turn, stir evenly, and then weigh the solid component active silica powder (400 mesh): 50 parts and thixotropic agent R202: 3 parts And sequentially add to the liquid component mixing system, stir for 1 to 2 hours, discharge, pack, and obtain the finished product of component A;

[0063] Step 2, preparation of component B: first weigh the liquid components phenalkamine curing agent 810:100 parts, wetting and dispersing agent 1201:1 parts according to the weight ratio and add them to the mixer in turn, stir evenly, and then weigh the sol...

Embodiment 3

[0066] A kind of preparation method of the building structure adhesive suitable for underwater construction of the present embodiment, comprises the following steps:

[0067] Step 1, preparation of component A: First, weigh the liquid component epoxy resin NPEL-128 / NPEL-170: 60 parts / 20 parts, diluent MD2013: 5 parts, toughening agent QS-BE: 7 parts according to the weight ratio , coupling agent KH560: 1 part, wetting and dispersing agent 1201: 3 parts and add them to the mixer in turn, stir evenly, and then weigh the solid component active silicon micropowder (400 mesh): 120 parts and thixotropic agent R202: 2.5 parts and added to the liquid component mixing system in turn, stirred for 1 to 2 hours, discharged, packaged, and the finished product of component A was obtained;

[0068] Step 2, preparation of component B: first weigh the liquid components phenalkamine curing agent 7120: 90 parts, wetting and dispersing agent 1201: 2 parts according to the weight ratio and add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com