Patents

Literature

81results about How to "E-buy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building structure adhesive suitable for underwater construction

InactiveCN109852313AGood underwater construction performanceHigh bonding strength under waterNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

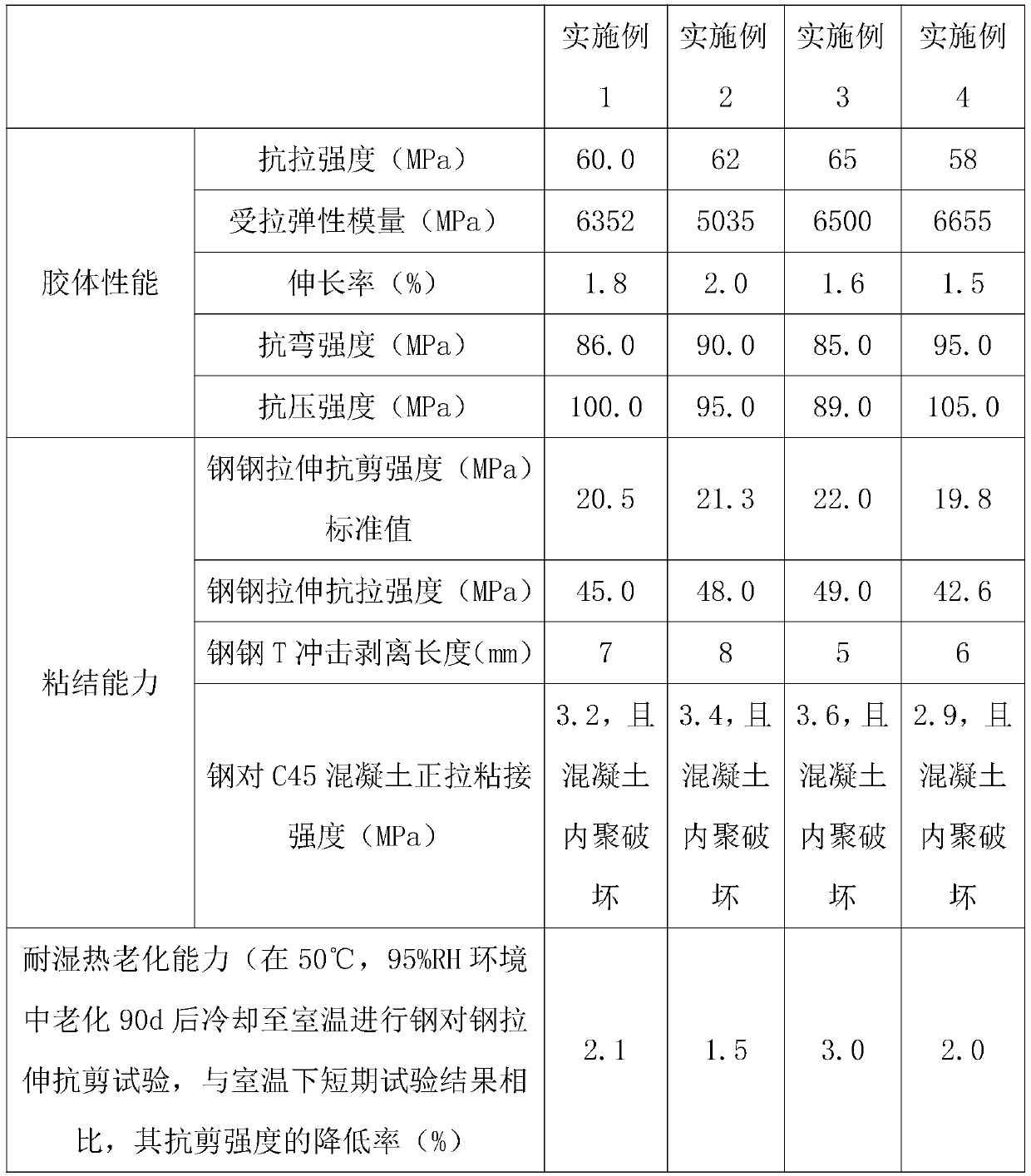

The invention discloses a building structure adhesive suitable for underwater construction. The component A comprises the following raw materials in parts by weight: 60-80 parts of epoxy resin, 5-10 parts of active diluent, 5-10 parts of toughening agent, 1-2 parts of coupling agent, 50-200 parts of filler, 1-4 parts of thixotropic agent and 1-4 parts of wetting dispersant. The second component Bcomprises the following raw materials in parts by weight: 100 parts of phenolic amine curing agent, 50-200 parts of active filler, 1-4 parts of thixotropic agent and 1-4 parts of wetting dispersant. The raw materials used in the building structure adhesive suitable for underwater construction are all highly hydrophobic raw materials, The structure adhesive has good underwater construction performance, can be insoluble, not float and not shrink in underwater construction, can be easily adhered and coated, leveled and adhered on the bonding surface, and can be applied to the bonding of underwater environment building structure. Its underwater bonding strength is high, and its mechanical properties and moisture-heat aging properties conform to the national standard GB50367-2013, GB50550-2010,GB50728-2011 requirements.

Owner:LANGFANG JINDAO QISHI PLASTIC IND CO LTD

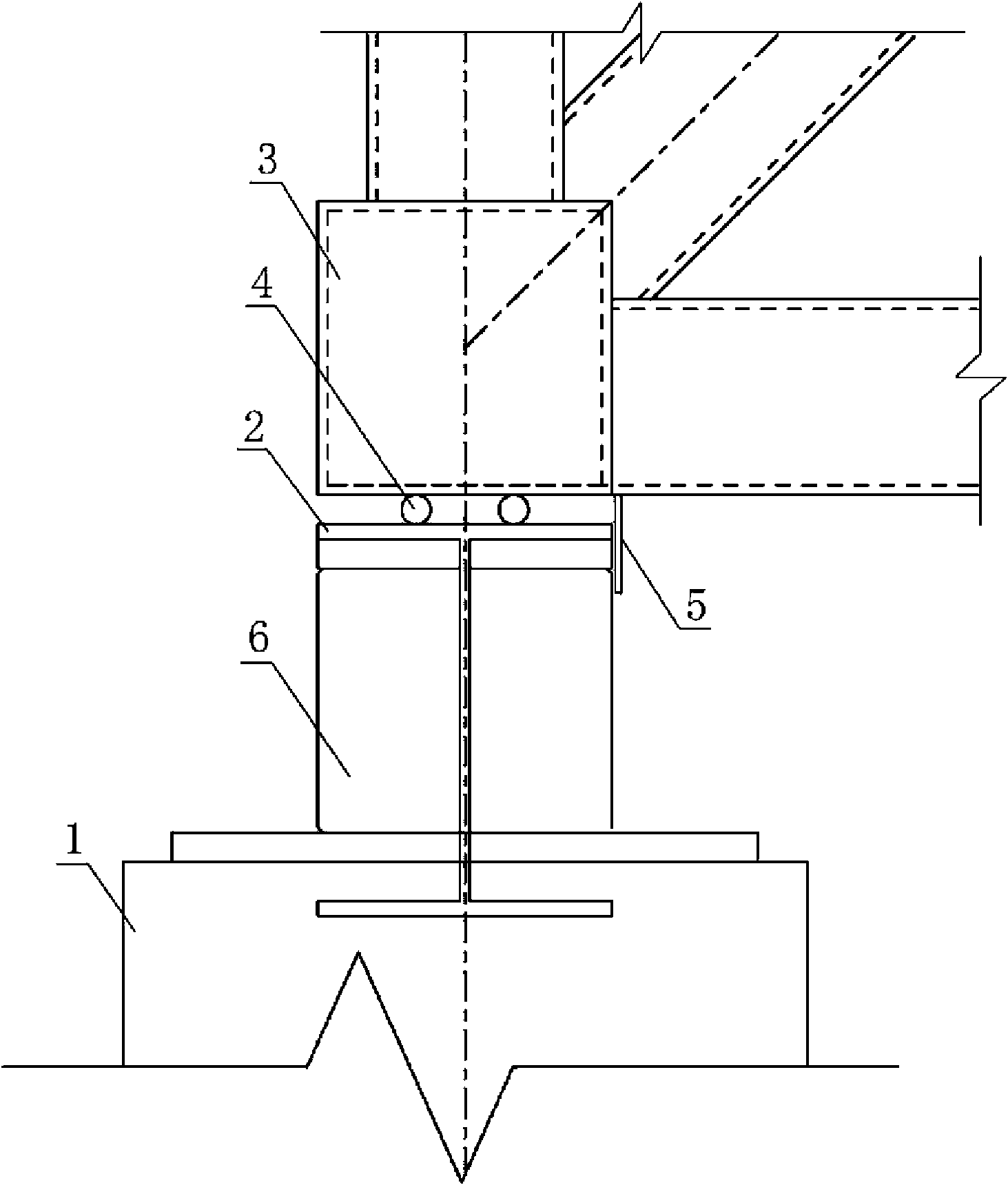

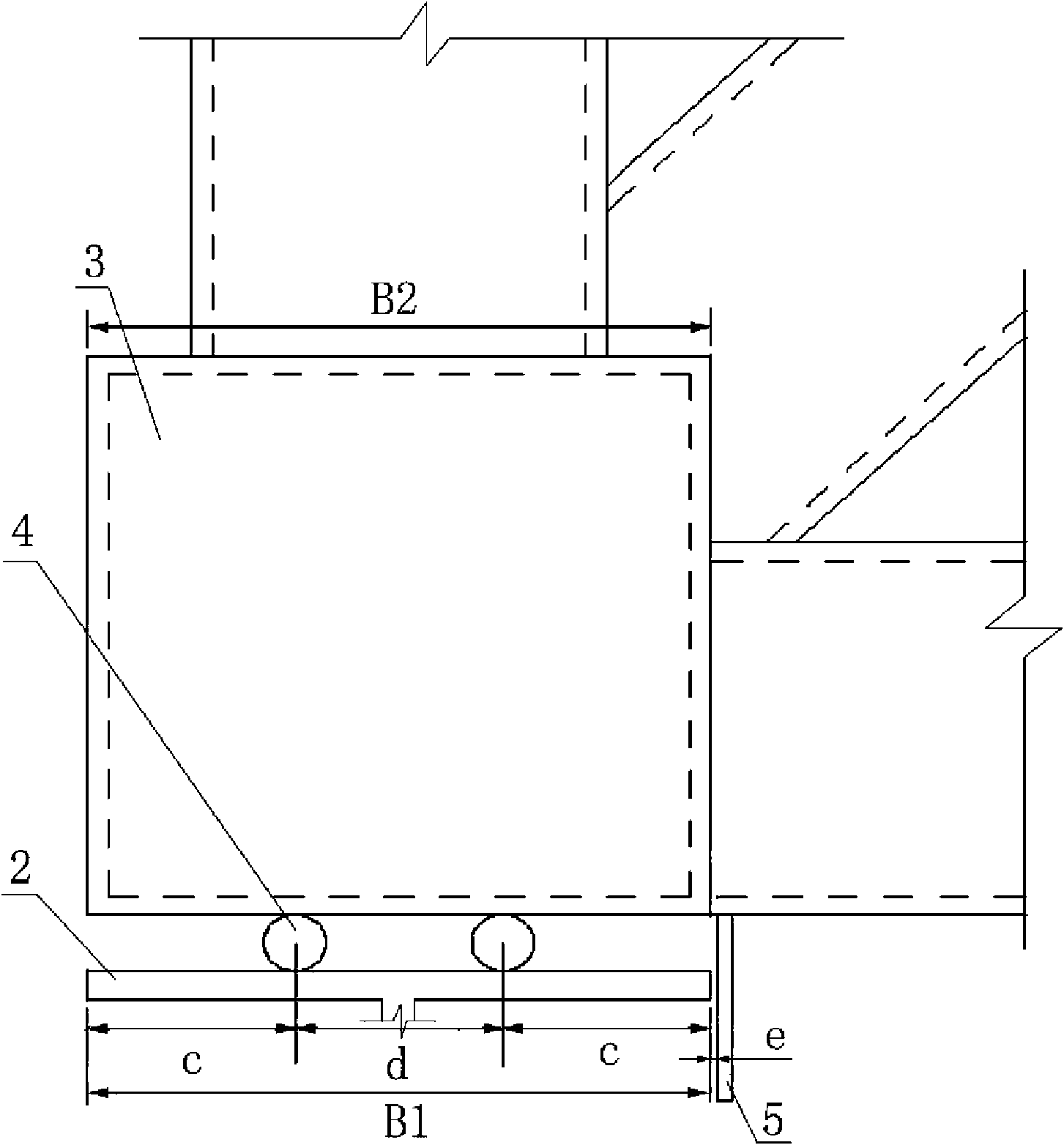

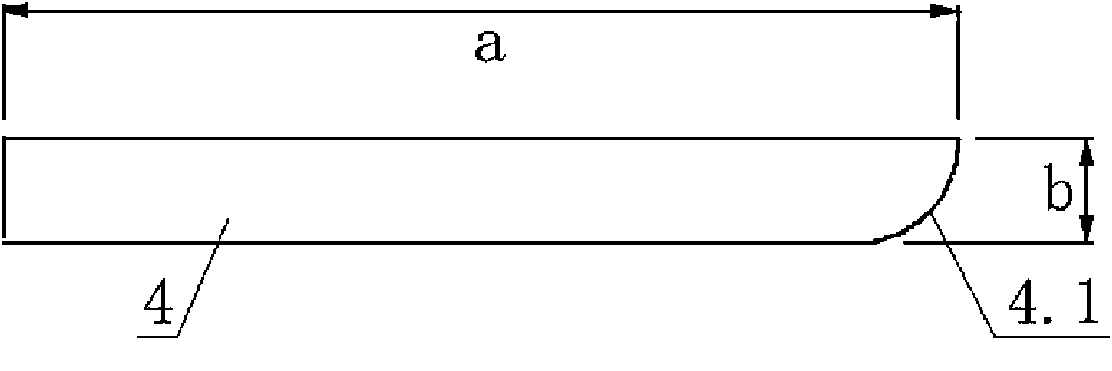

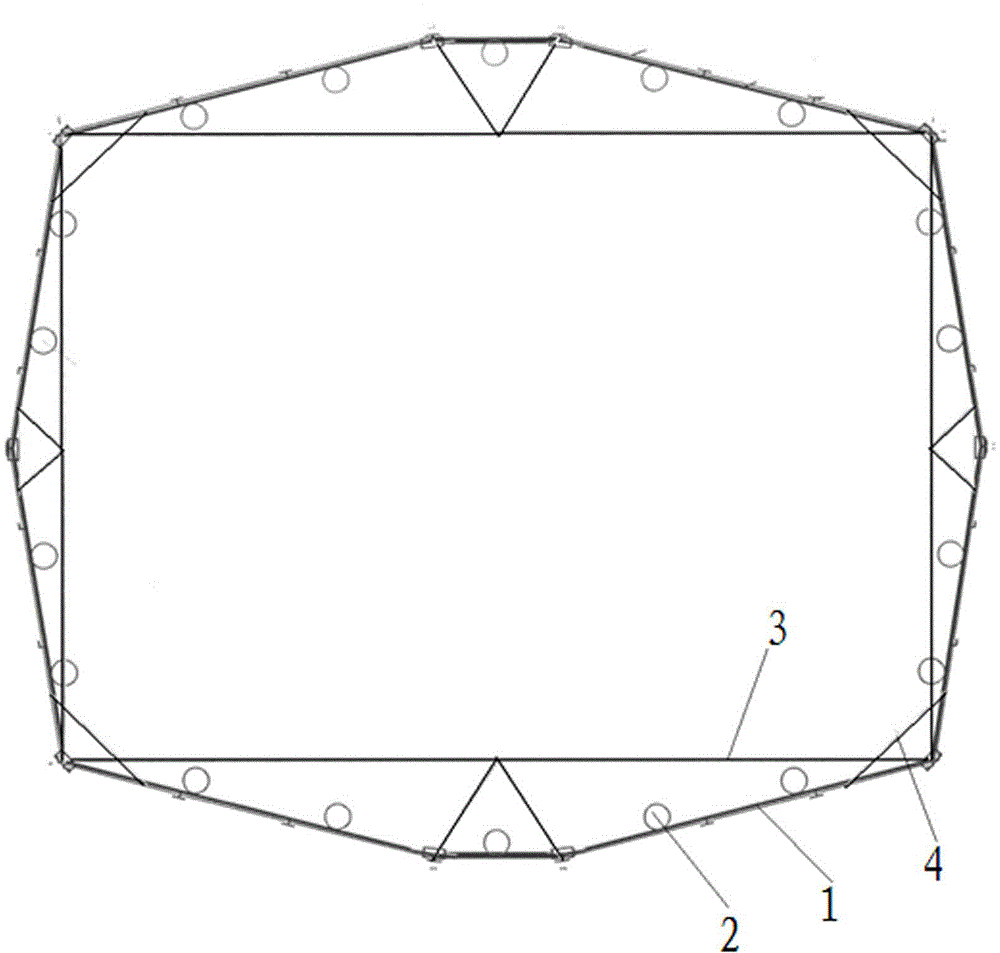

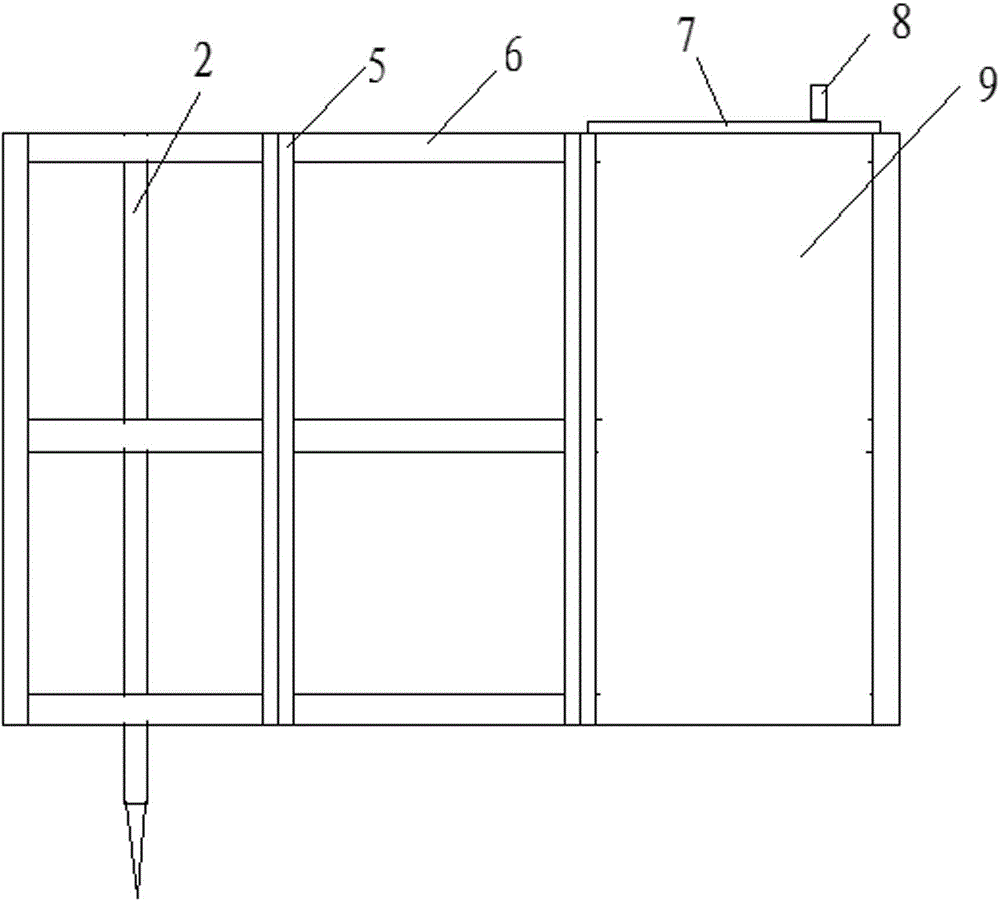

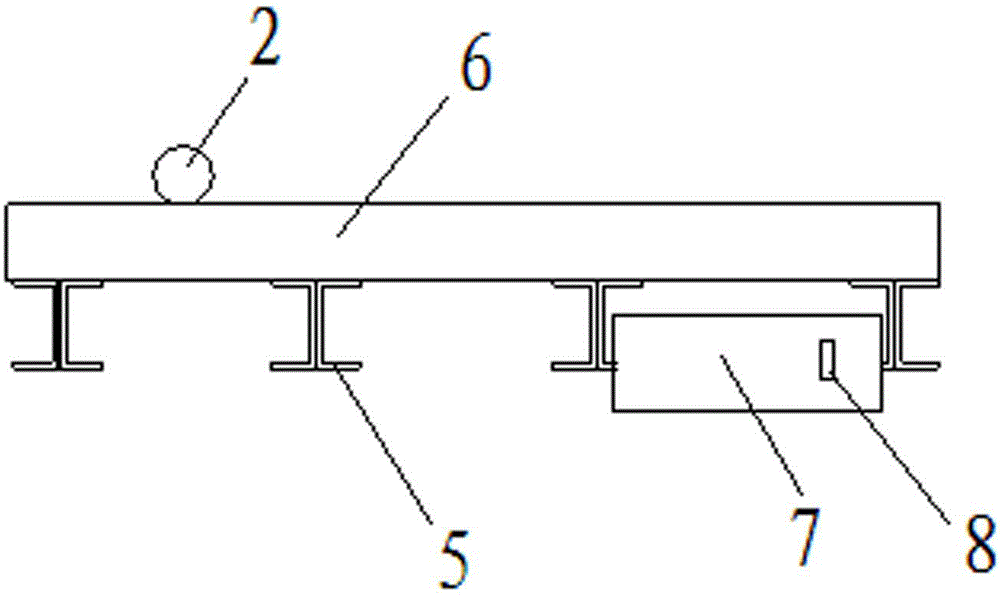

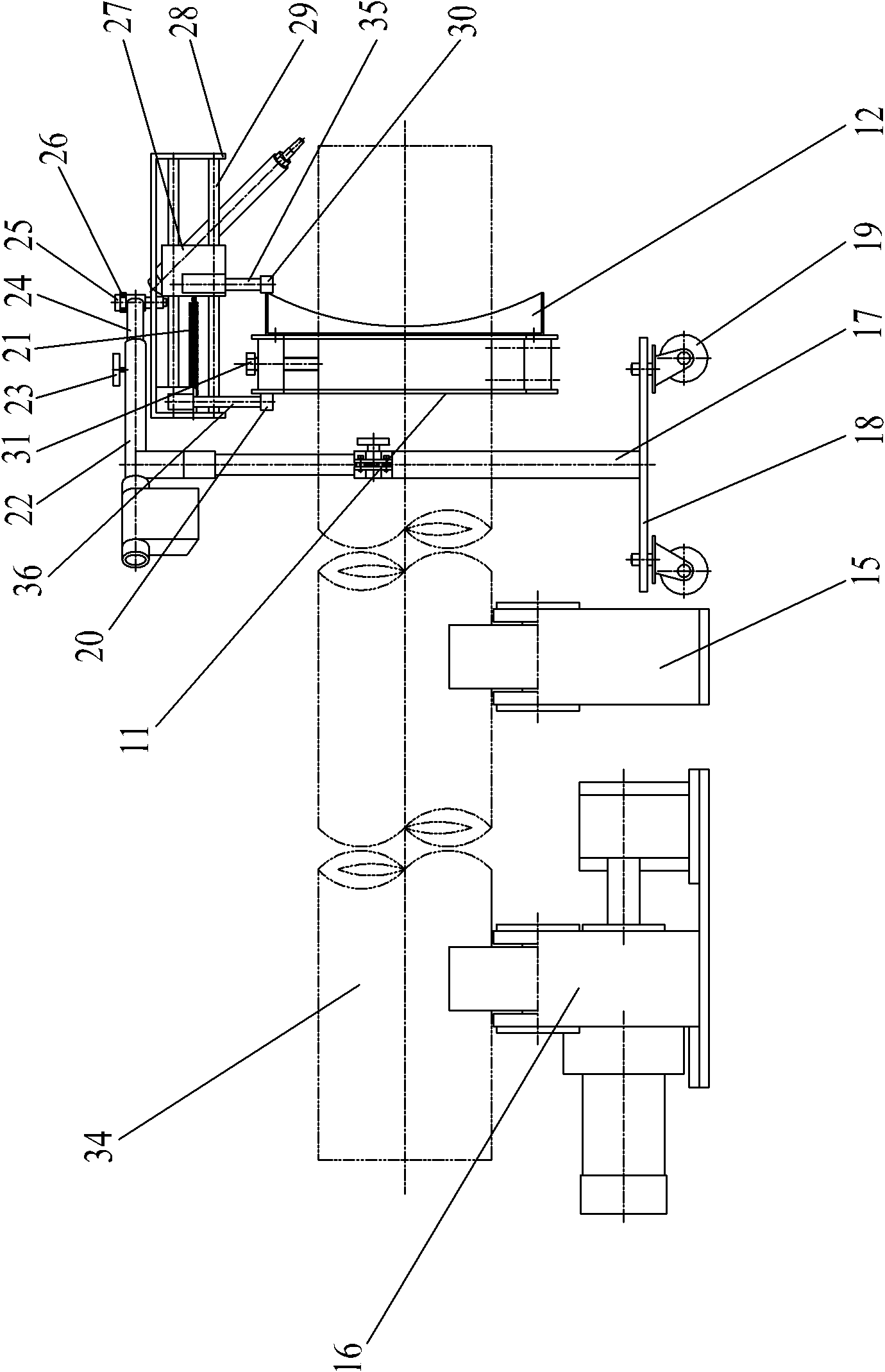

Accumulation slippage construction device in icesword manner and construction method thereof

The invention relates to an accumulation slippage construction device in an icesword manner and a construction method thereof. The accumulation slippage construction device comprises gliders at the lower part of a steel truss and a slide rail fixed above a steel truss support, wherein the gliders are icesword-type gliders distributed at the lower part of the steel truss at intervals along the direction of the slide rail; each section of icesword-type glider is two plain round bars parallel to the slide rail; the top of the plain round bar is welded together with the bottom of the steel truss; the bottom of the plain round bar is linearly contacted with the upper surface of the slide rail; and the bottoms of the steel truss closed to the slide rail are respectively connected with limit baffle plates. Using slippage contacting plain round bars with profile steel flat rails to replace slippage contacting flat gliders with train steel rails, the invention is economical, convenient, practical and effective, is applicable to places where cranes can not enter into the construction area in the presence of basement or other structures, as well as steel structures of small and intermediate spans where pushing jacks and train steel rails are difficult to purchase or the construction is not economical, and has great influence on the construction period by other construction methods.

Owner:北京城建精工钢结构工程有限公司

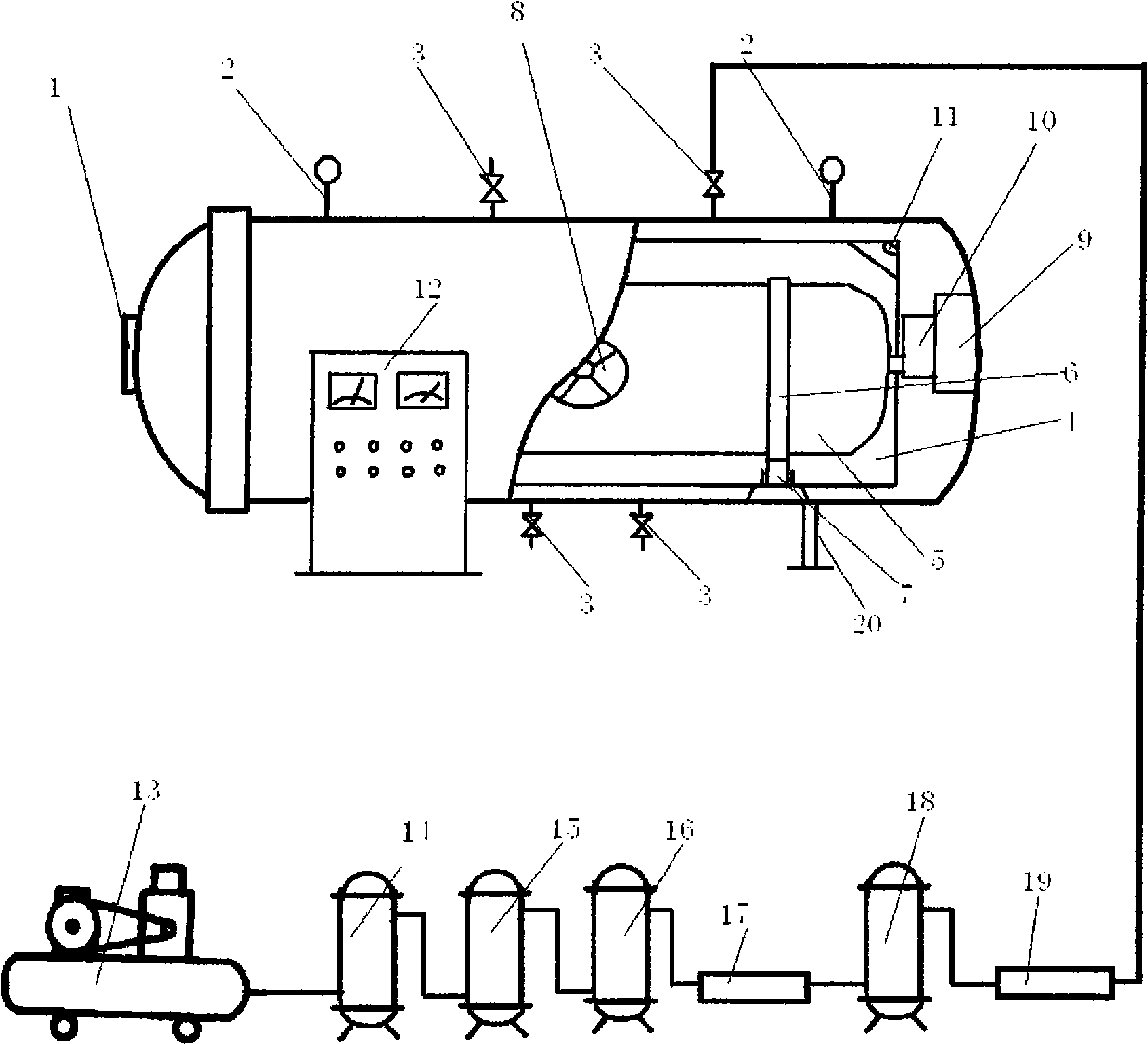

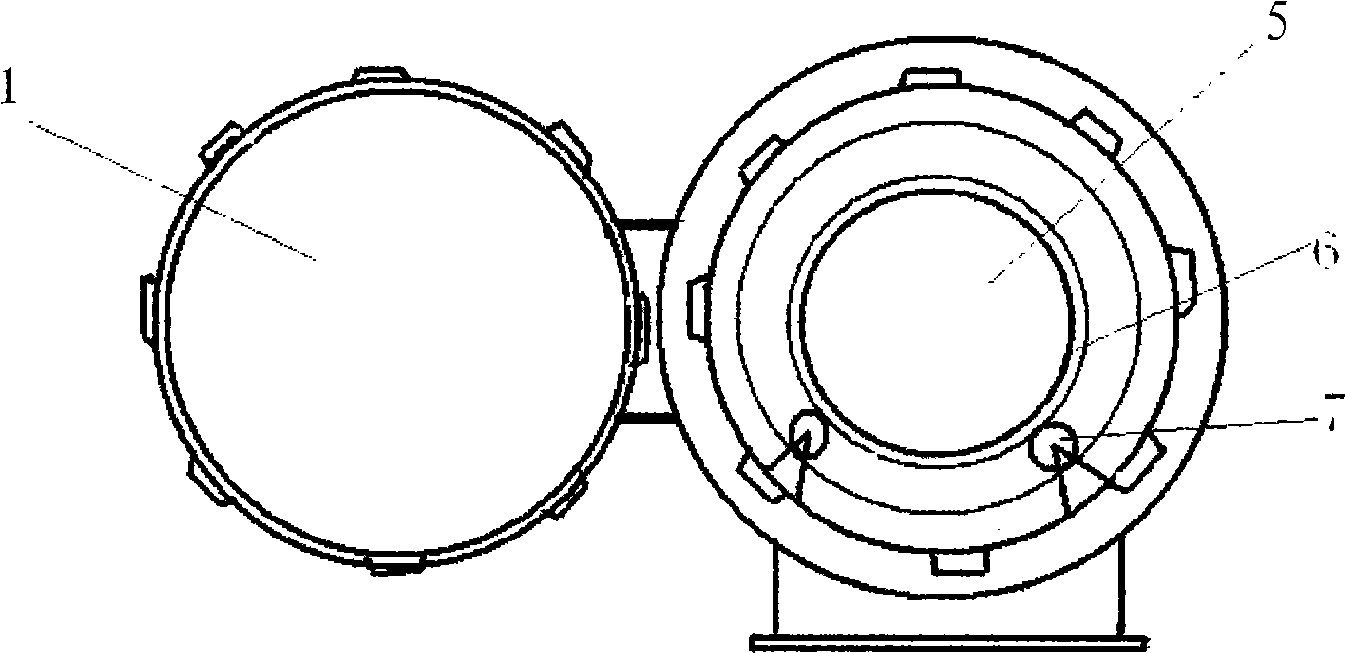

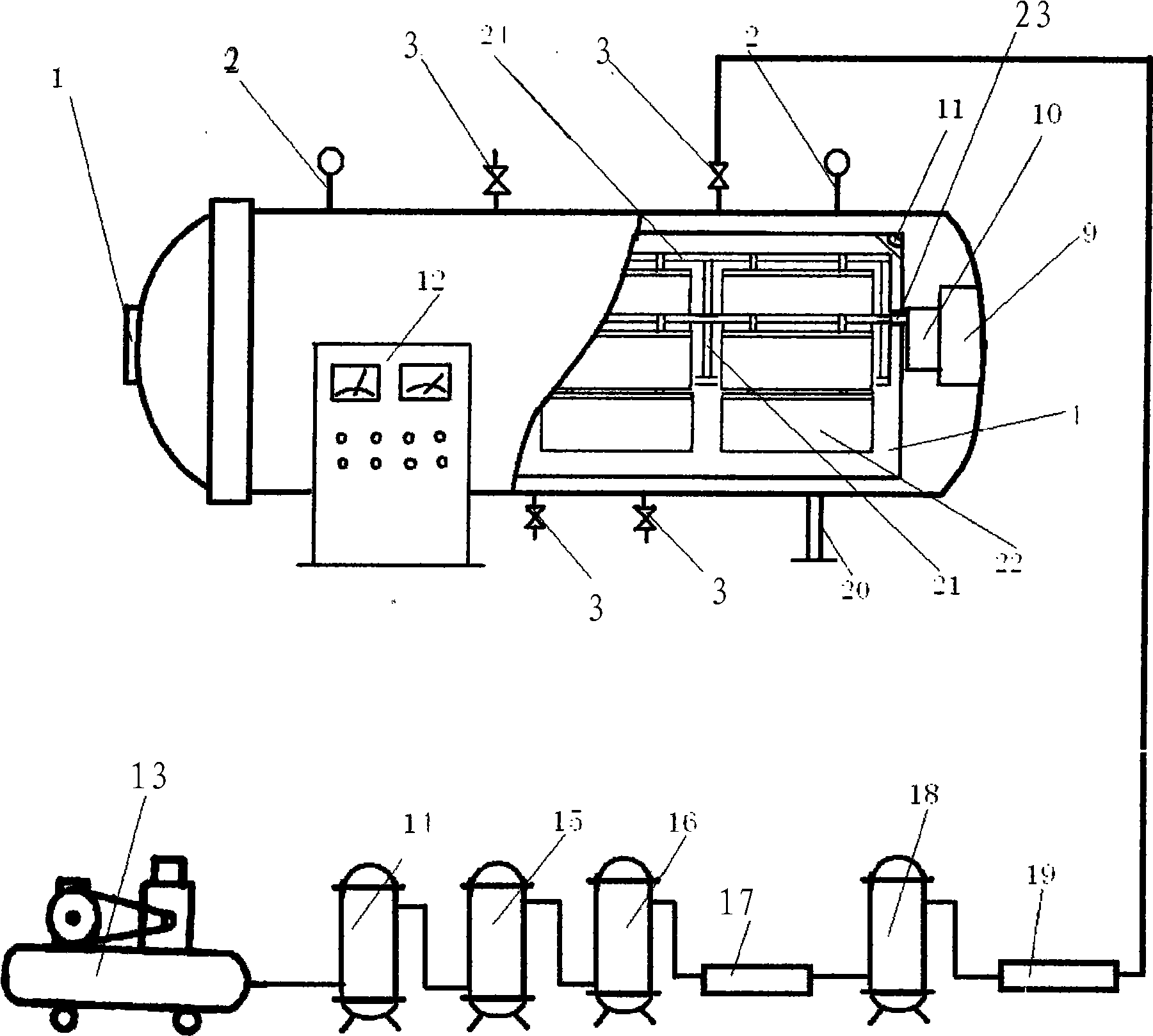

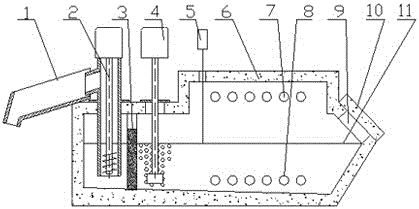

Microwave sterilization method and device

InactiveCN101507823AAdjustable powerMature production processFood preservationLavatory sanitoryMicrowave sterilizationEnergy consumption

The invention provides a method and a device for microwave sterilization. Problems of heating and sterilizing materials often happen in the prior food, pharmacy, agricultural byproduct processing, brewing, solid-state fermentation, chemical engineering and other fields. When various foods, fermentation materials and water-containing solid materials are treated with microwave, the temperature of the materials reaches more than 120 DEG C through pressurization to kill bacterial spores and thoroughly sterilize the materials. By adopting a method of pressing heated under-pressure aseptic air into a microwave device, the water-containing materials can be sterilized through microwave heating. Compared with the prior steam heating sterilization, the method can obviously shorten sterilization time and cause no environmental pollution, and has the advantages of simple device, low energy consumption, easy operation and automation-realizing easiness.

Owner:XINJIANG UNIVERSITY

Medium prescription for production of fungus-treated tobacco rooted seedlings by floating nursery

InactiveCN101297632AWide variety of sourcesE-buyCultivating equipmentsSoilless cultivationBiotechnologySnow mold

The invention relates to a special matrix formula suitable for culturing mycorrhizal tobacco seedling in the condition of flue-cured tobacco seedling by floating system; all the constituents and the volume thereof are as follows: 60 percent of peat, 20 percent of perlite and 20 percent of vermiculite. The formula can improve the comprehensive quality of the tobacco seedling, cultures sound seedlings and has the advantages of wide material sources, easy acquisition, easy matrix preparation, simple production, simple inoculating operation, little fungicide dosage and easy promotion, etc. The culture medium, the inoculating technique and the corresponding Glomus intraradices Smith and Schenck are combined together, infection rate of mycorrhiza is up to over 40 percent and the effect of the mycorrhiza is good.

Owner:SOUTHWEST UNIVERSITY

Construction method for supports of box iron supporting rack of small foundation pit

The invention belongs to the technical field of building construction, and particularly relates to a construction method for supports of a box iron supporting rack of a small foundation pit. Supporting of the small foundation pit can be implemented. The construction method for the supports of the box iron supporting rack of the small foundation pit comprises the following steps of machining the box iron supporting rack of the foundation pit in advance according to the size of the foundation pit; timely hoisting the supporting rack into the foundation pit after the foundation pit is excavated; hoisting the rack out of the foundation pit by using a crane after foundation construction is finished; performing construction of a next foundation; and detaching and recycling box iron and steel plates after overall construction is finished. The construction method for the supports of the box iron supporting rack of the small foundation pit has the advantages of convenience in construction, easiness in machining and manufacturing and high recyclability. Engineering construction cost can be saved effectively, and construction progress is accelerated. The construction method for the supports of the box iron supporting rack of the small foundation pit is environment-friendly and has wide application prospects and wide application markets.

Owner:CHINA SHANXI SIJIAN GRP

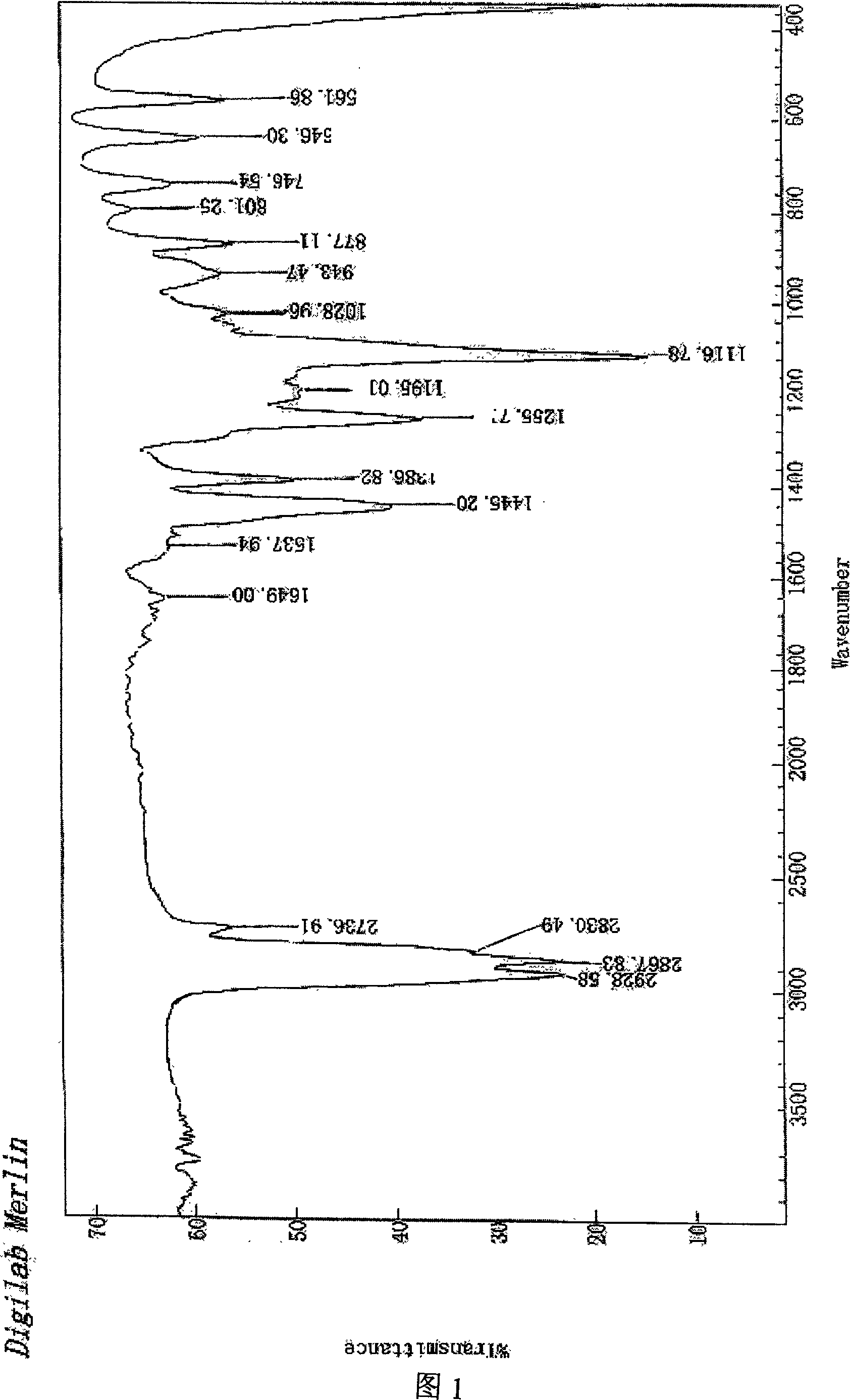

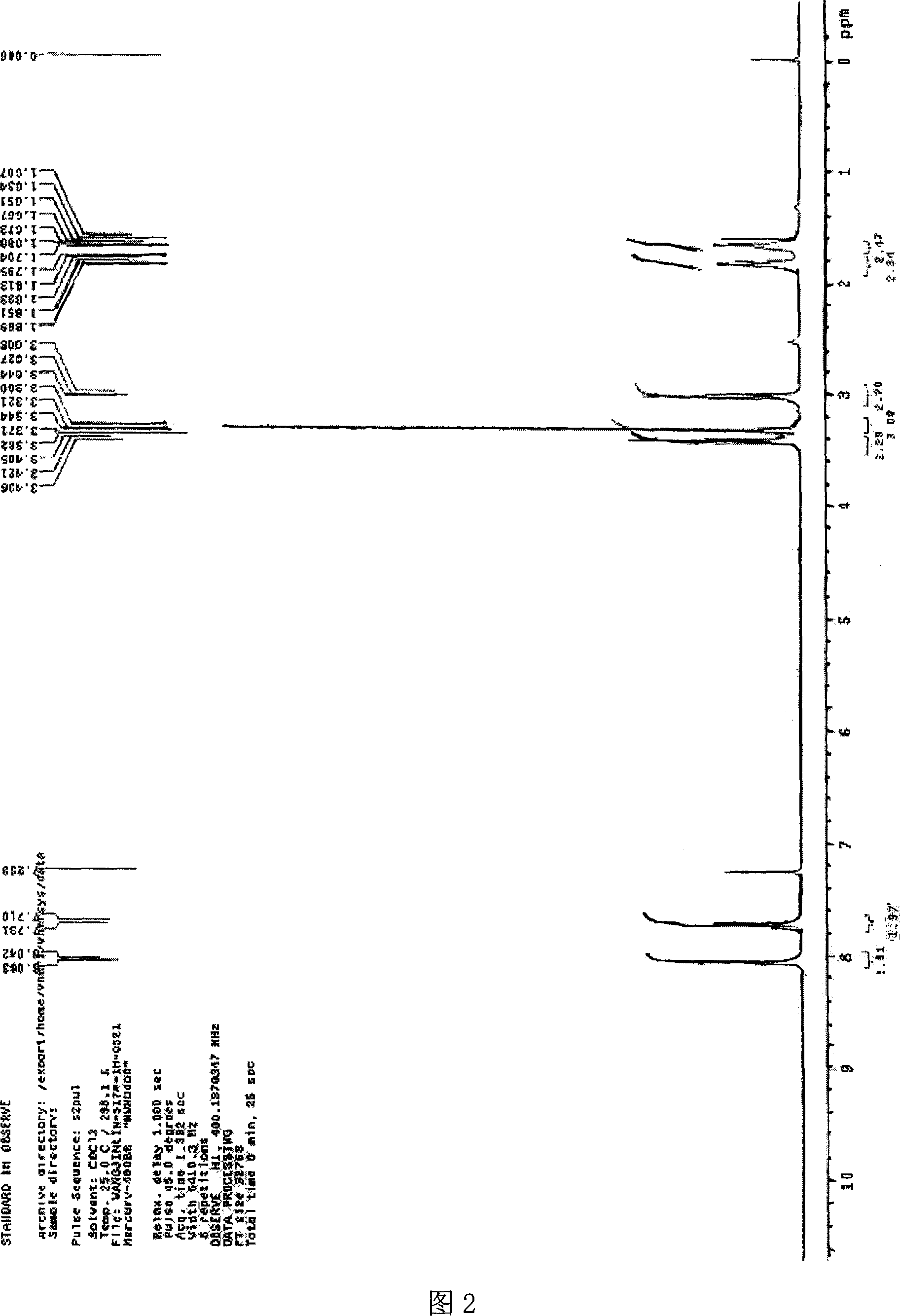

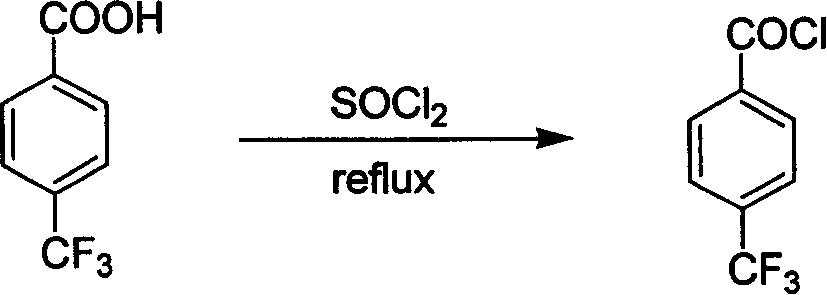

Method for preparing 5-methoxy-1-(4-trifluoromethyl phenyl)pentanone

The present invention discloses process of preparing 5-methoxyl-1-(4-trifluoromehyl phenyl) pentanone as one key intermediate for preparing depression treating medicine fluvoxamine maleate with p-trifluoromethyl benzoyl chloride and magnesium 4-methoxyl butyl halide in the presence of catalyst. The process includes following four steps: 1. preparing p-trifluoromethyl benzoyl chloride with p-trifluoromethyl benzoic acid and thionyl chloride through chlorination; 2. preparing 1-halo-4-methoxyl butane; 3. preparing Grignard reagent through reaction of 1-halo-4-methoxyl butane and metal Mg; and 4. preparing 5-methoxyl-1-(4-trifluoromehyl phenyl) pentanone through reaction of p-trifluoromethyl benzoyl chloride and the Grignard reagent. The process has the features of facile material, low cost, short reaction period, high efficiency and environment friendship.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for leaching and recovering rare earth element from rare earth slag

InactiveCN103225023AImprove leaching effectGood for cracking and penetratingProcess efficiency improvementRecovery methodRare-earth element

The invention relates to a method for leaching and recovering earth element from rare earth slag. According to the invention, a sulfuric acid aqueous solution is adopted as a leaching solution, and ore slurry obtained by wet ball milling of rare earth slag is adopted as a powder slurry; the rare earth powder slurry and the leaching solution are added into a reaction kettle; the reaction kettle is sealed; oxygen is delivered into the reaction kettle for discharging air; an air discharge valve is closed; stirring and leaching is carried out in the reaction kettle under a pressure of 0.6-1.0MPa and a temperature of 140-180 DEG C; when leaching is finished, a material is discharged, and solid-liquid separation is carried out; the pH value of the leachate is regulated to 4-5, and rare earth element is recovered with an extraction method; or a proper amount of sodium carbonate is added, and a carbonic acid-rare earth mixture is prepared. The rare earth element recovery method provided by the invention has the advantage of simple method, low raw material cost, and low production cost. With the method, rare earth large-scale digestion and industrial production are convenient. The method has considerable economic benefit, social benefit, environmental benefit, and ecological civilization benefit.

Owner:连云港市丽港稀土实业有限公司

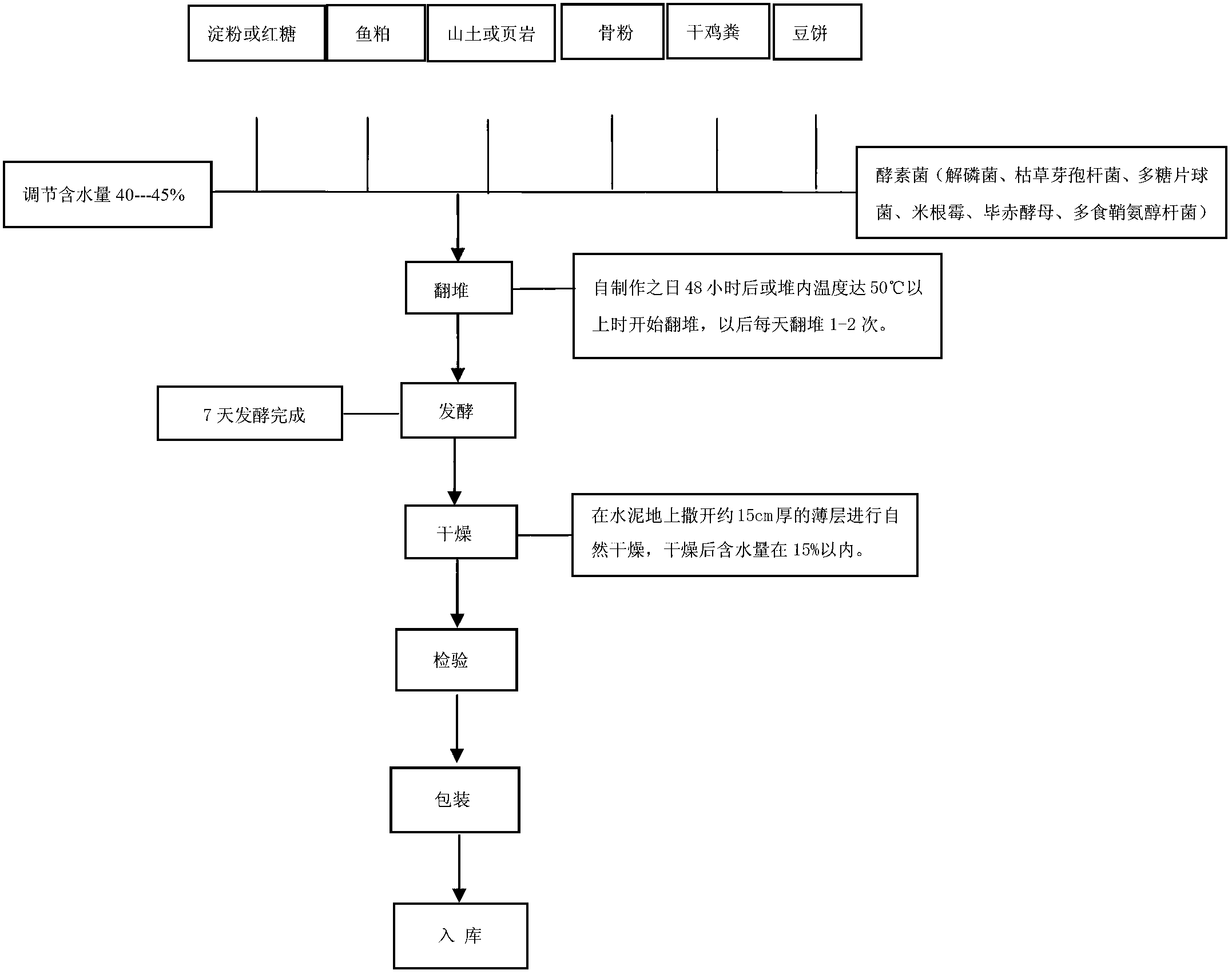

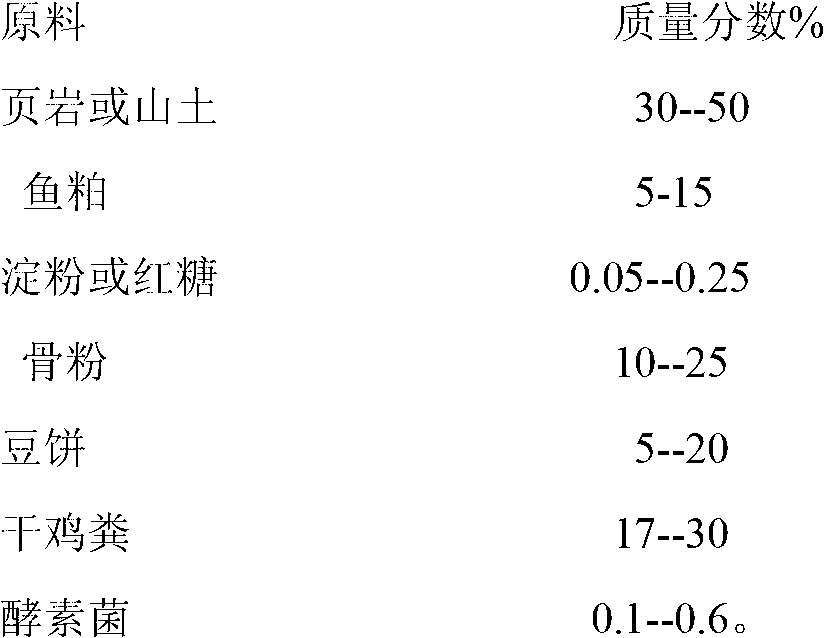

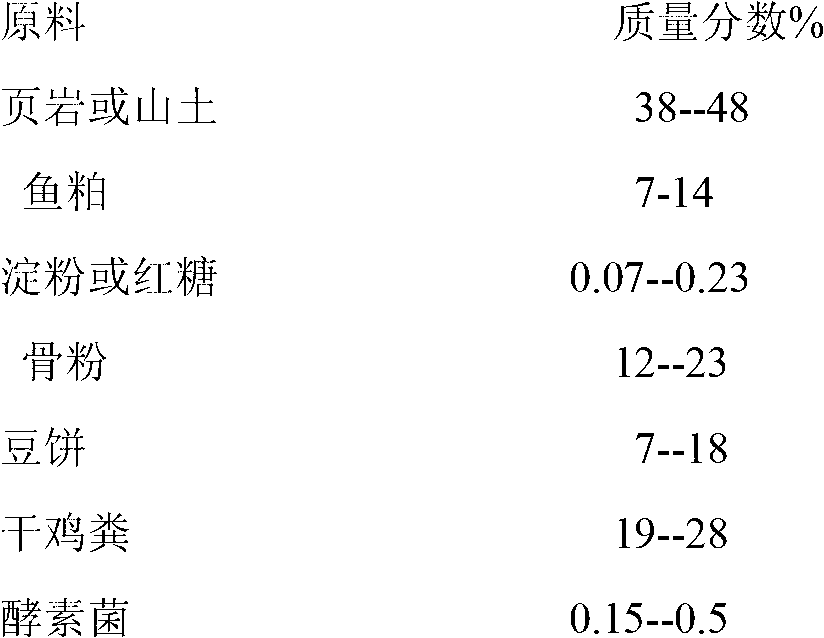

Biofertilizer capable of decomposing insoluble phosphorus and preparation method

InactiveCN102701842AImprove decomposition abilityLow priceFertilizer mixturesWater insolubleMoisture

The invention discloses a fermented fertilizer capable of decomposing insoluble phosphorous and a preparation method of the fermented fertilizer. The fermented fertilizer is composed of shale or mountain soil, dry chicken manure, bone meal, fish scrap, bean cake, starch or brown sugar, and enzyme bacteria according to a certain ratio. The preparation method comprises the steps of: A. preparing raw materials: preparing shale or mountain soil, dry chicken manure, bone meal, fish scrap, bean cake, starch or brown sugar, enzyme bacteria and water; B. mixing: dissolving brown sugar or starch with water, spraying to a mixture of shale or mountain soil, dry chicken manure, bone meal, fish scrap, bean cake and enzyme bacteria, mixing and stirring uniformly, adjusting the moisture content to 40-45%, stacking into a chevron, and covering with ventilating cloth; C. overturning: beginning overturning after 48h of the production day or the temperature in the stack is more than 50 DEG C, and then overturning 1-2 times every day; D. fermenting: finishing fermentation within 7d; E. drying: spraying on cement land at a thickness of 15cm, and airing; F. inspecting; and G; packaging. According to the Biofertilizer provided by the invention, fermentation microorganisms are used for decomposing water-insoluble phosphorus into water-soluble phosphorus, thereby being beneficial to crop absorption, saving resources and protecting environment.

Owner:湖北嘉益田生物肥业有限公司

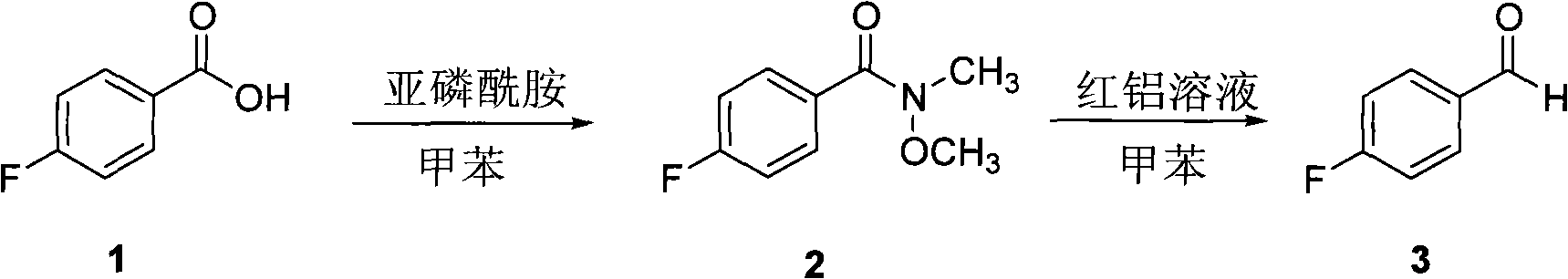

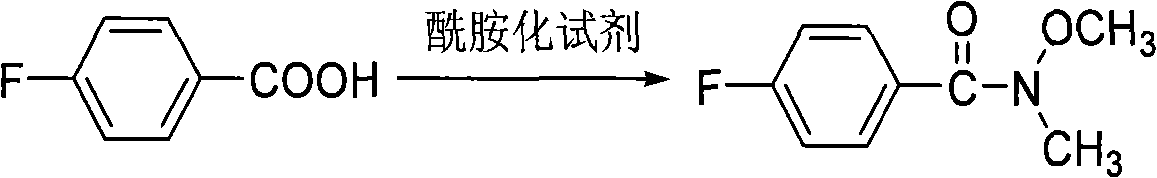

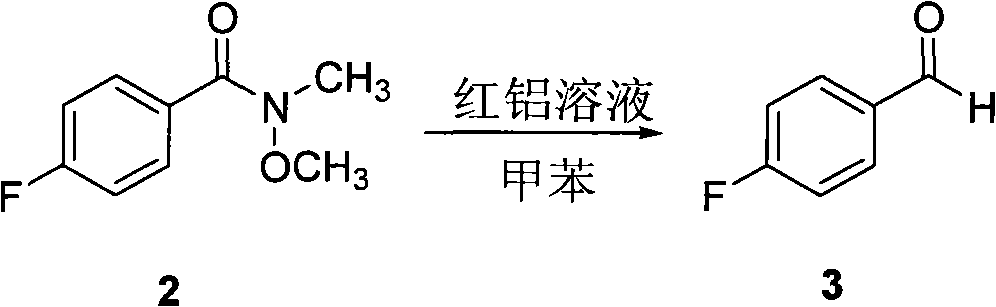

Method for preparing p-fluorobenzaldehyde

InactiveCN102040494AFew synthetic stepsEasy to operatePreparation by hydrogenolysisChemical synthesisMethyl group

The invention discloses a method for preparing p-fluorobenzaldehyde, and belongs to the technical field of chemical analysis. N-methyl-N-methoxyl p-fluorobenzamide is synthesized by parafluorobenzoic acid serving as a raw material under the action of an amidation reagent and reduced by vitride solution to directly obtain the p-fluorobenzaldehyde, so that synthesis steps are a few, the method is easy to operate, the product is single, and the yield is high (the total yield of 59.4 percent); the vitride solution serving as a reducing agent has higher reducibility, stable property and lower price, and is convenient to store; the parafluorobenzoic acid serving as the raw material is easy to purchase and has low cost, so that good conditions are created for the mass industrial production and commercialization of the product; and the adopted raw material is nontoxic, and a catalyst is not used in the production process, so that the method is environmental-friendly, and low in emission and accords with the national industrial policy.

Owner:NORTHWEST NORMAL UNIVERSITY

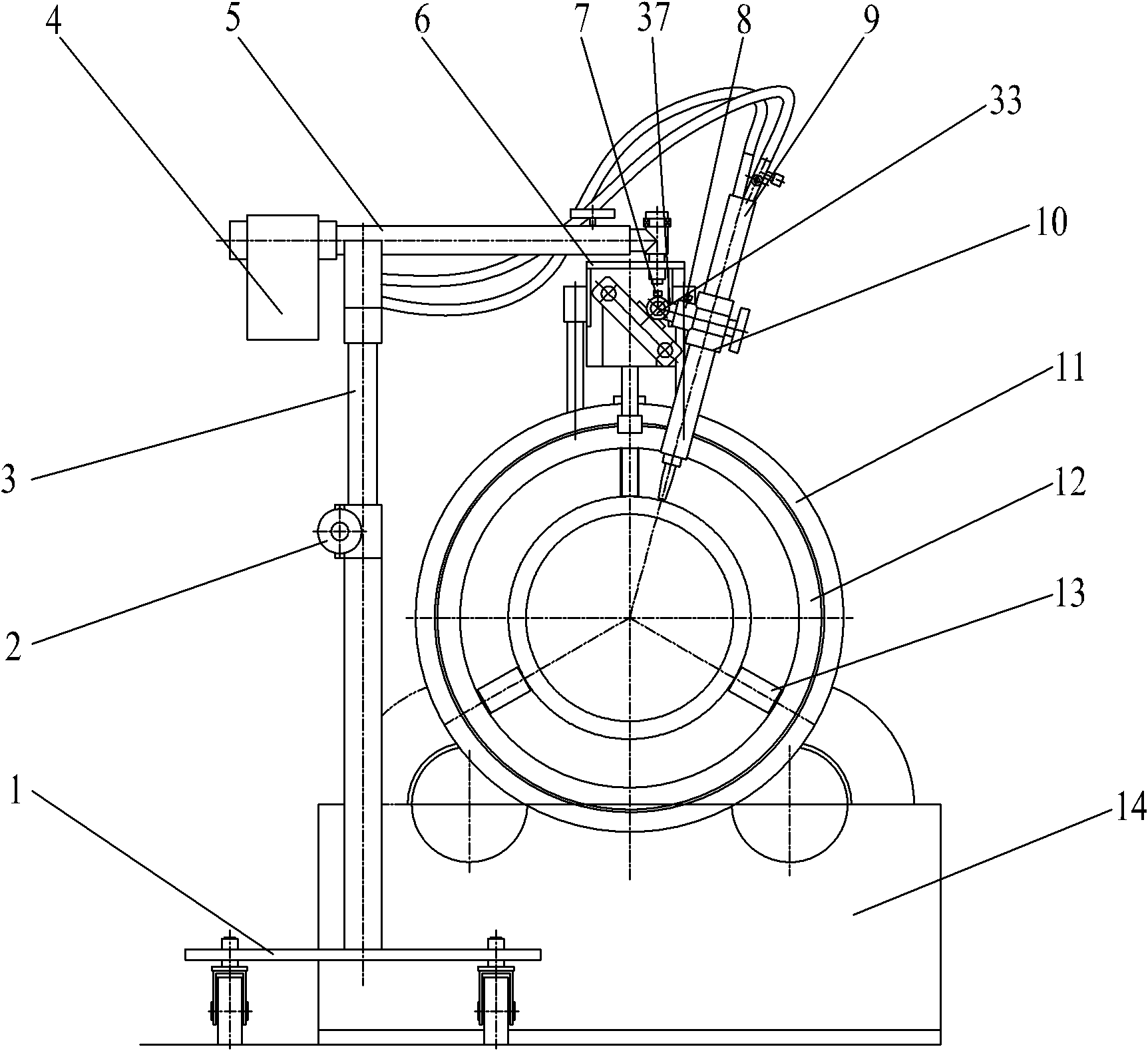

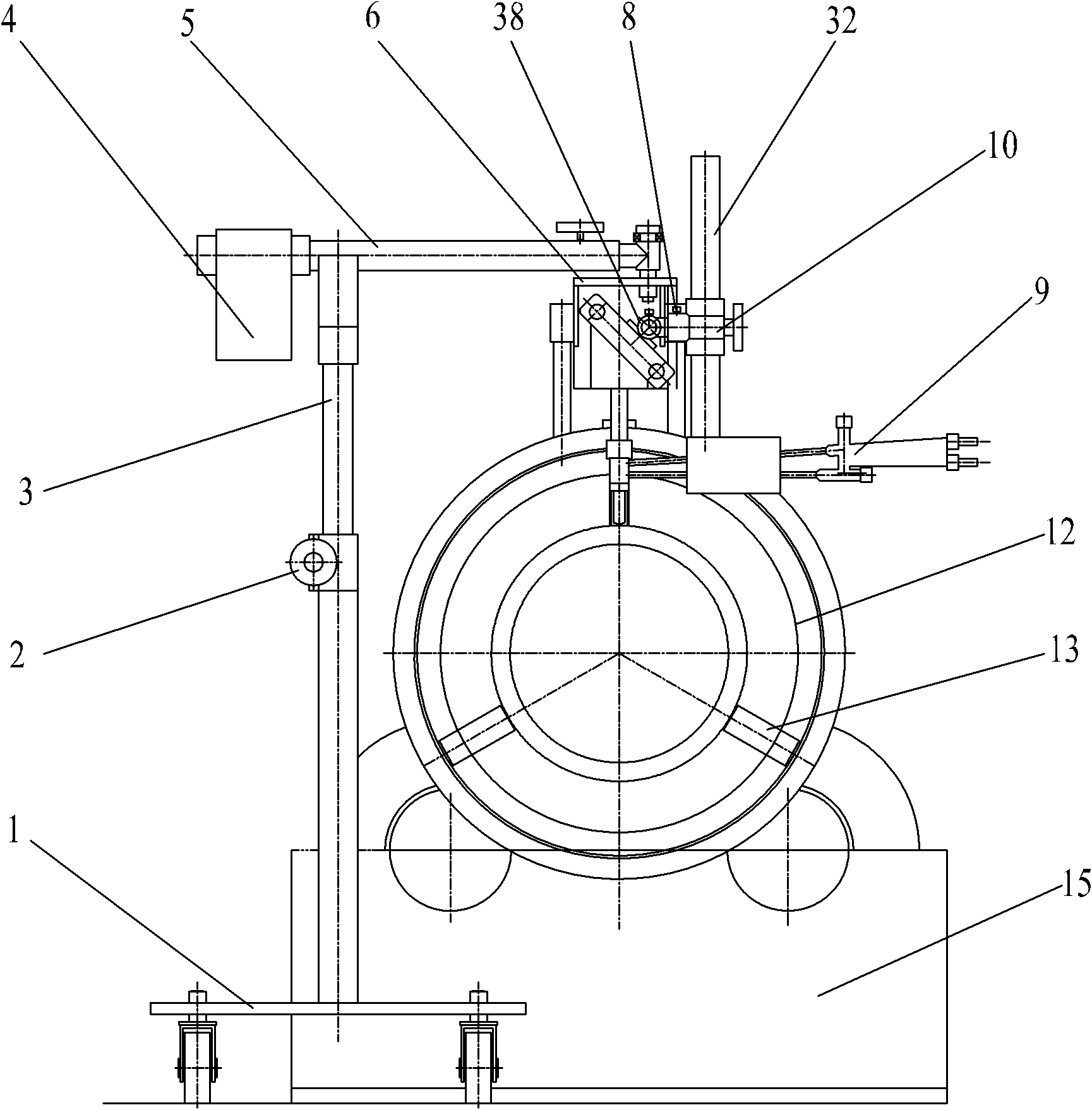

Saddle-shaped pipe end cutting device

The invention relates to a saddle-shaped pipe end cutting device, comprising a roll-over stand and a base, wherein the base is provided with a stand column which is provided with a cross arm; end part of the cross arm is provided with a hanging bracket by a pin roll; the hanging bracket comprises a s bracket body which is provided with a slider shaft; the slide shaft is in slip connection with a slider which is provided with a regulating spring; the slider is provided with a cutting torch adjusting sleeve in a hinged mode, and the cutting torch adjusting sleeve is provided with a cutting torch; a fixed pinch roller and a movable pinch roller are arranged at the lower part of the bracket body; a locating sleeve is arranged between the movable pinch roller and the fixed pinch roller; the locating sleeve is provided with an explorator; the fixed pinch roller and the locating sleeve are in rolling contact opposite to the other side the side in which the explorator is arranged; and the movable pinch sleeve and the explorator are in rolling contact. The saddle-shaped pipe end cutting device of the invention has the advantages of compact structure, low processing cost and high processingprecision and is convenient to process and operate, is used for saddle-shaped pipe ends and cutting processing of beveled edges of the saddle-shaped pipe ends, and processing of parallel and level pipe ends and cutting processing of beveled edges of the flush pipe ends.

Owner:WUXI HUAGUANG IND BOILER

Daily ration for milking cow producing high-conjugated linoleic acid (CLA) milk

The invention relates to daily ration for milking cows producing high-conjugated linoleic acid (CLA) milk, which comprises the following components in percentage by weight of dry matter: 23.40 percent of green hay, 20.45 percent of corn silage, 30.14 percent of corn, 5.00 percent of wheat bran, 4.70 percent of soybean meal, 6.69 percent of cotton seed meal, 4.18 percent of corn vinasse and soluble substance, 0.90 percent of sesame meal, 1.11 percent of calcium hydrophosphate, 0.84 percent of calcium carbonate, 1.00 percent of sodium bicarbonate, 0.39 percent of magnesium oxide, 0.50 percent of table salt, 0.40 percent of CLA calcium salt, 0.20 percent of additive premixing material and 0.10 percent of common mildewproof agent. Compared with an oil fat or pasture supplementing and feeding method, the daily ration can improve the c9,t11-CLA content in milk by more than 100 percent; and compared with a single CLA calcium salt adding method, the daily ration can improve the c9,t11-CLA content in the milk by more than 30 percent.

Owner:SOUTHWEST UNIV

Soilless culture method for greenhouse vegetable in gobi desert

InactiveCN104642072AAvoid humidityTake advantage ofAgriculture gas emission reductionCultivating equipmentsSoil organic matterGreenhouse

The invention provides a soilless culture method for greenhouse vegetable in the gobi desert, which belongs to the field of soilless organic matter cultivation of crops. According to the method, a greenhouse is built on the land of the gobi desert; trenches are dug and filled with soilless organic matters; water-saving irrigation is carried out; water and fertilizer management measures like seedling management are taken; and perennial cultivation of vegetable and floral crops is carried out without replacement of soil. The method has the characteristics of saving of labor, water and fertilizer, high efficiency, economic performance and cyclic utilization.

Owner:汪世松

Simple method for chromizing small-axis parts and special chromizing agent thereof

The invention refers to a simple method for small shaft part chromizing, the method includes: (1) the small shaft part and chromizing agent are mixed even and put into the chromizing bottle; (2) seals the bottle and puts the bottle into electrical furnace and seals the furnace door tightly; (3) carries on segmented heating and thermal retardation; (4) chromizing process; (5) cooling; (6) opens the chromizing bottle, pours out the mixer, and takes out the small shaft piece, filters it and eliminates the chromizing agent; (7) hardening and tempering; the special chromizing agent is made up of aluminium oxide, chrome iron powder, ammonium chloride according to the proportion of 55%: 42%: 3%. The device in the invention is simple, low investment; small harm to device. It enhances the wearing resisting and corrosion resisting property of small shaft.

Owner:许长荣

Aluminum alloy furnace

InactiveCN106513648AEasy to manufactureLow costMolten metal supplying equipmentsCrucible furnacesPneumatic pressureLiquid transfer

The invention relates to an aluminum alloy furnace. The aluminum alloy furnace comprises a liquid transfer chute, a mechanical pump, a ceramic filter plate, a refining degassing device, an aluminum liquid level detecting device, a furnace body, a top heating device or a bottom heating device, a charging opening and a furnace door. During usage, the furnace door is opened, then aluminum alloy liquid or solid aluminum alloy is added into the furnace body through the charging opening, heated to set process temperature through the top heating device or the bottom heating device, subjected to dehydrogenation through the refining degassing device, filtered through the ceramic filter plate so that solid impurities can be removed, and then lifted through the mechanical pump, the lifted aluminum alloy liquid flows through the liquid transfer chute to enter a casting device, and dynamic accurate compensation of quantitative accuracy of the mechanical pump is performed through the liquid level detected by the aluminum liquid level detecting device. The aluminum alloy furnace, namely a pouring furnace, can provide high-quality melt for aluminum alloy casting, the quantitative accuracy of the mechanical pump after compensation is high, and compared with an aluminum alloy air pressure pouring furnace, the aluminum alloy furnace has the advantages that the furnace body does not need to be sealed, the manufacturing difficulty of the furnace body is low, the cost is low, and the furnace is suitable for large-scale application.

Owner:熊运海

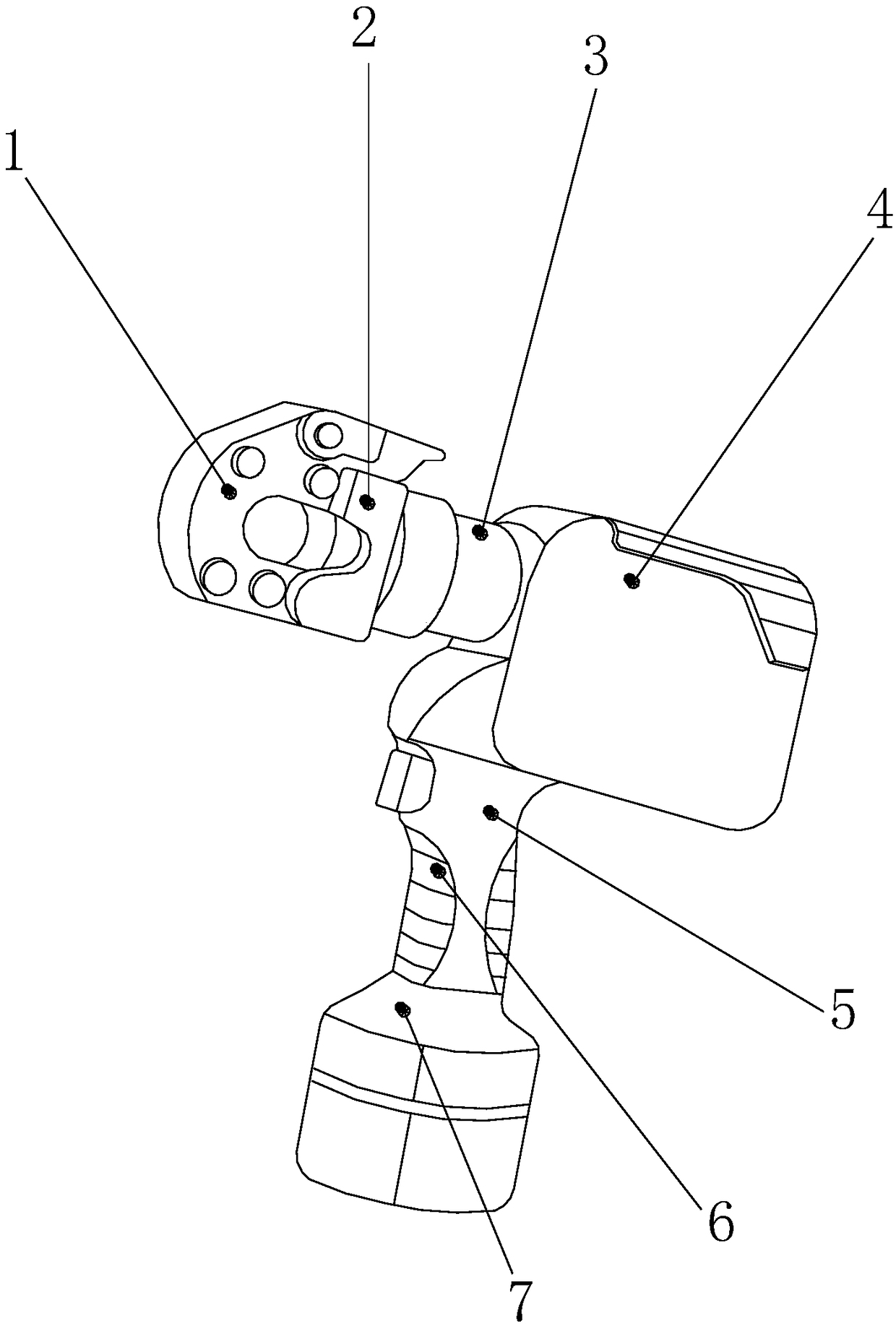

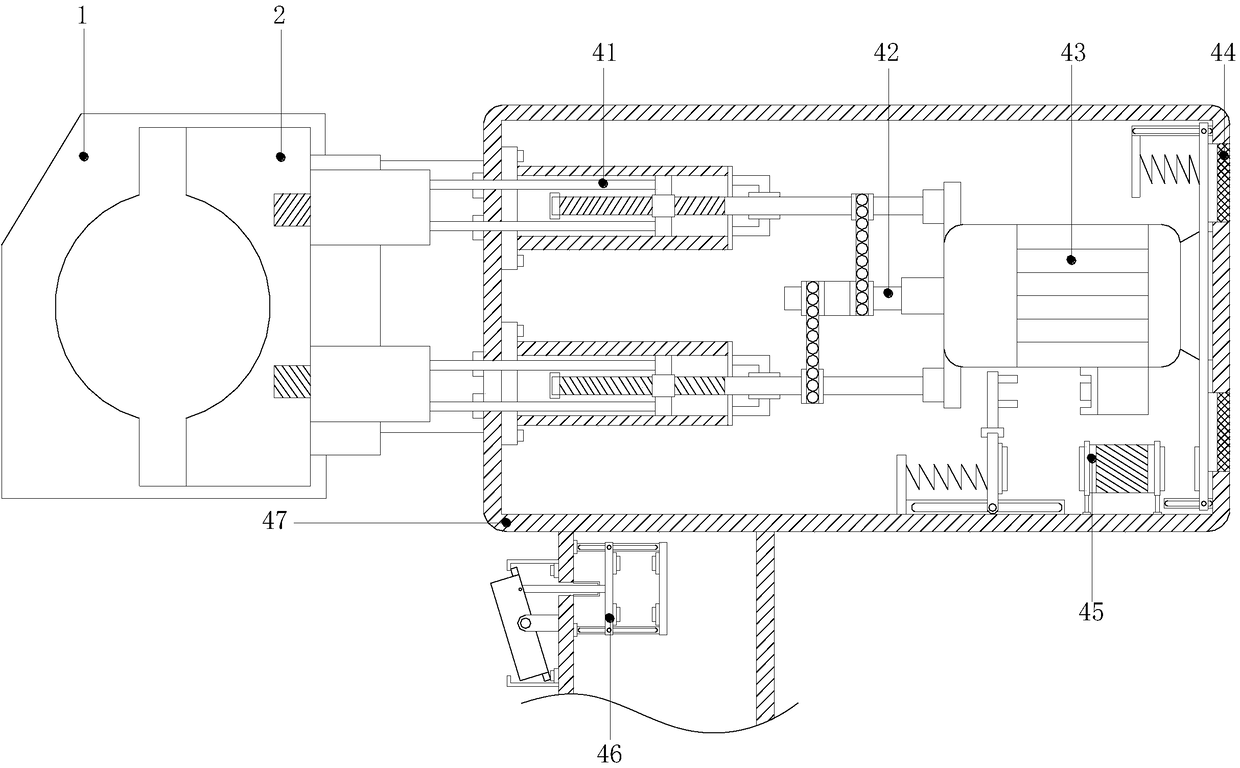

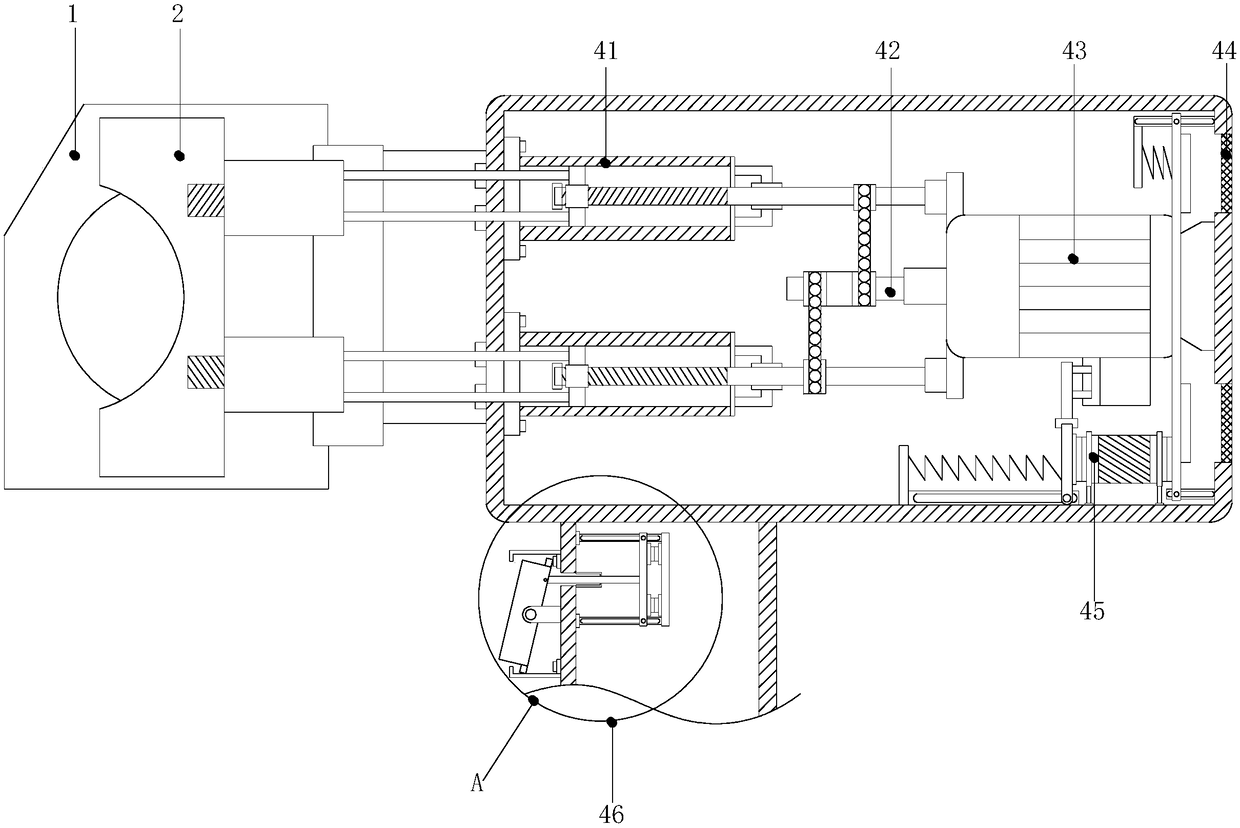

Handheld type electric cable shearer

InactiveCN108723474AImprove work efficiencyFully diffusedPortable handheld shearing machinesSteel jacketElectric cables

The invention discloses a handheld type electric cable shearer. The handheld type electric cable shearer structurally comprises a static shearing head, a movable shearing head, an engagement fixed steel jacket, an electric shearing device, a handle, an anti-skidding adhesive layer and a detachable battery, wherein the static shearing head is arranged at the head end of the engagement fixed steel jacket; the static shearing head and the engagement fixed steel jacket are fastened; the movable shearing head is arranged on the static shearing head; and the movable shearing head and the static shearing head are in sliding fit. Two propulsion shearing mechanisms arranged inside the electric shearing device are driven through a rotating shaft arranged at the front end of an intelligent motor, sothat a driving solid circular rod is pushed forwards and engaged with a circular column, and a circular part formed by the movable shearing head and the static shearing head shrinks gradually so as toachieve the shearing effect; and the propulsion shearing mechanisms are simple in structure, and easy and convenient to install; and parts for maintenance are easy to purchase and long in service life.

Owner:陈秀珍

Color oil flow formula for specifically calibrating range of Mach numbers and suitable for high speed wind tunnel

InactiveCN108489703AImprove solubilityFully and evenly dissolvedAerodynamic testingCoatingsSilicone oilColoring agents

The invention relates to a color oil flow formula for specifically calibrating range of Mach numbers and suitable for a high speed wind tunnel, and particularly relates to the color oil flow formula suitable for the oil flow experiment of the range of Mach numbers of 0.5-0.9. Using the tracer particle-calcium carbonate powder, the carrier oil-silicon oil and the coloring agent-red oil paste, yellow oil paste and green oil paste is determined, and the mass percentage relationship of the three is determined. A large number of oil flow display experiments prove that the oil flow formula can acquire high-quality color oil flow experiment image which is used for analyzing the model surface air flow pattern and deepening the understanding of the flow field information so as to achieve the flow visualization effect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

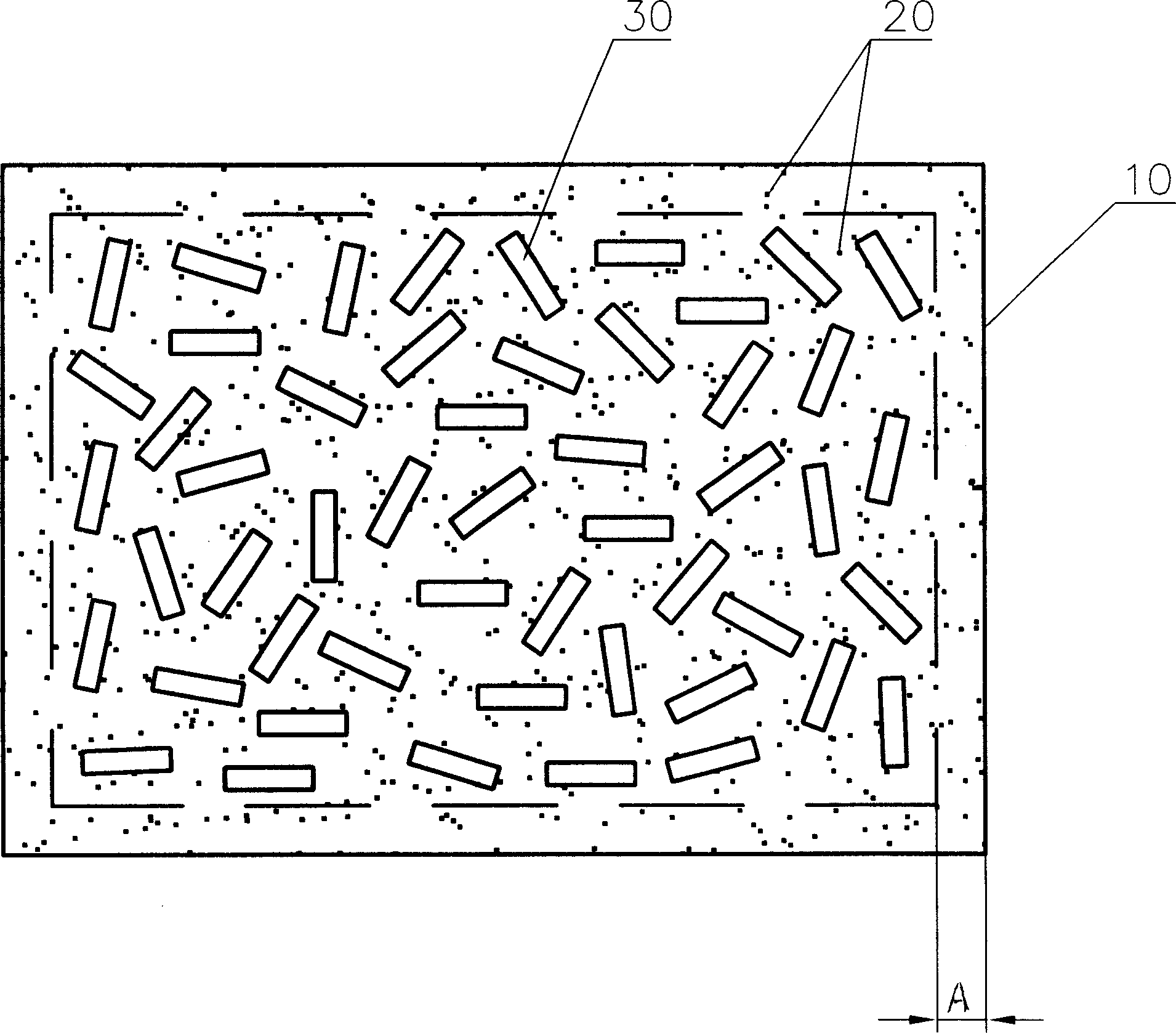

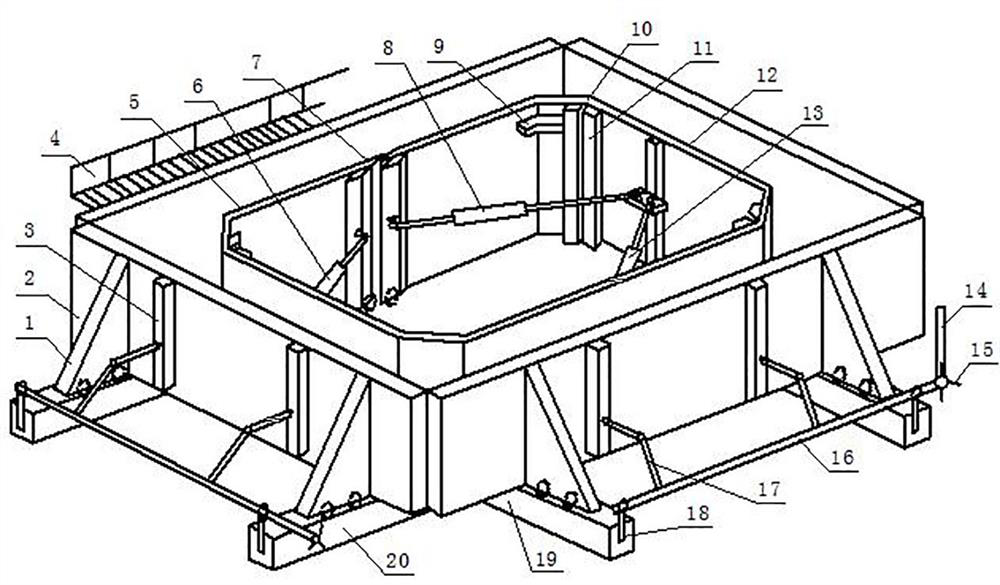

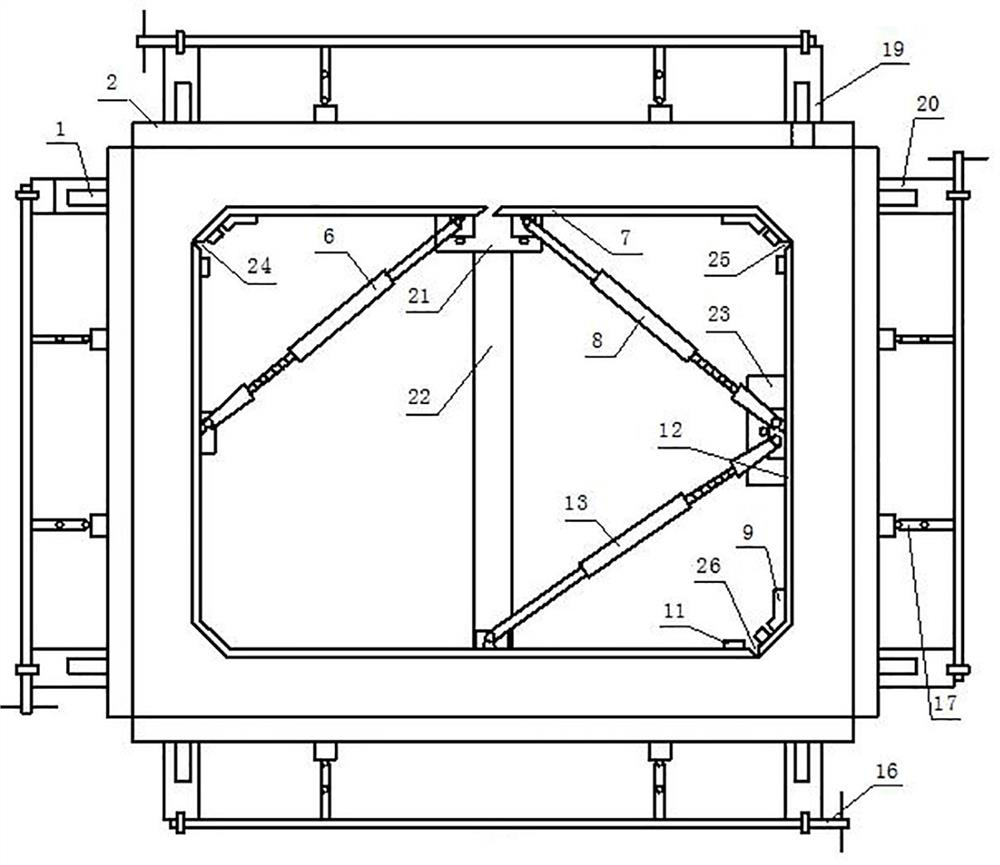

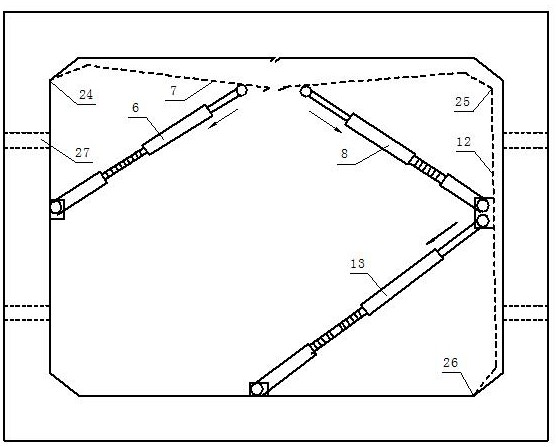

Fabricated box culvert vertical prefabricated light formwork and manufacturing method thereof, and box culvert prefabricating method

PendingCN112720806AEasy to manufactureE-buyDischarging arrangementGround-workArchitectural engineeringStringer

The invention discloses a fabricated box culvert vertical prefabricated light formwork and a manufacturing method thereof, and a box culvert prefabricating method. The fabricated box culvert vertical prefabricated light formwork comprises a base, an outer formwork body, a connecting rod mechanism, an inner formwork body, an end formwork body and a hydraulic supporting mechanism; the base is composed of two longitudinal beams, three cross beams and two walking platforms, the outer formwork body is composed of four integral formwork plates, a steel plate is attached to the interior of each formwork plate, inclined struts are welded to the exterior of each formwork plate, the inner formwork body is composed of an inner-layer grid rib plate and an outer-layer inner formwork steel plate, each inner formwork steel plate is formed by stamping a whole steel plate, only one abutted seam is formed in the whole section, two longitudinal ribs are arranged at the abutted seam of the folded section, walking wheels are arranged at the lower ends of the longitudinal ribs, and the inner formwork body is assembled and disassembled through stretching and retracting of the hydraulic supporting mechanism. The outer formwork body adopts an integral and large-block formwork plate design and can be driven by the connecting rod mechanism or the hydraulic system, the inner formwork body is driven by a full-hydraulic support, only one abutted seam is formed in the whole section, vertical pouring and end plate matching production are adopted, and the appearance effect of a segment finished product is good.

Owner:HENAN HIGHWAY ENG GROUP +1

Oil flow formula of high speed wind tunnel oil flow experiment clearly demarcating Mach number range

InactiveCN108760225AEasy to buyGuaranteed performanceAerodynamic testingChemistryOleic Acid Triglyceride

The invention relates to an oil flow formula of a high speed wind tunnel oil flow experiment clearly demarcating the Mach number range, and particularly relates to an oil flow formula suitable for theoil flow experiment of which the Mach number range is 0.5-0.9. Use of the trace particle-powdery titanium dioxide, the carrier oil-silicone oil and the diluent-oleic acid is determined through a series of experiments and the mass percent relationship of the three components is determined. A large number of oil flow display experiments are completed and indicate that the oil flow formula can acquire the high-quality oil flow test image for analyzing the model surface air flow pattern so as to achieve the effect of flow visualization.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Boer goat milk production improving fermented feed

InactiveCN105410379AImprove palatabilityE-buyAnimal feeding stuffAccessory food factorsWater contentProtein content

The present invention discloses a Boer milk goat milk production improving fermented feed which is made from the following raw materials: longan shells, corn, soybean meal, eggshells, ziziphus montana branches, compound trace elements, compound microbial agents, urea, honey, and edible salt. Compared with the prior art, the Boer goat milk production improving fermented feed has the following advantages: the feed is better in palatability, each of the raw materials is easy to purchase, the cost is relative low, and the feed can meet the goat daily nutritional needs. The corresponding water content is adjusted the in the process, the fermentation time is shortened in the condition that each of the raw materials is fully fermented. Due to the fact that the protein content is low in the longan shells, by adding the urea, the protein in the longan is converted into a body protein taken advantaged by the Boer goats. Each raw material acts together and the feed can improve the milk production of ewes in the lactation period and enhance the digestion and absorption functions of the goats, and the economic benefit is obvious.

Owner:全椒县马厂镇周巷山羊养殖场

Method for synthesizing methyl 2-methyl-4-acetyl benzoate

InactiveCN109553528AE-buyEasy to operateOrganic compound preparationCarboxylic acid esters preparationHydrolysisPhotochemistry

The invention provides a method for synthesizing methyl 2-methyl-4-acetyl benzoate. The method comprises the following steps: (1) adding an acylating reagent to a solution with dissolved 2-fluorotoluene, and carrying out an acylation reaction so as to obtain 4-fluoro-3-methylacetophenone; (2) dissolving the obtained 4-fluoro-3-methylacetophenone, adding a cyanation reagent, and carrying out a cyanation reaction so as to obtain 3-methyl-4-cyanoacetophenone; (3) adding acid to the 3-methyl-4-cyanoacetophenone, and carrying out a hydrolysis reaction so as to obtain 2-methyl-4-acetylbenzoic acid;and (4) adding methanol to the 2-methyl-4-acetylbenzoic acid, and carrying out an esterification reaction so as to obtain methyl 2-methyl-4-acetyl benzoate. The method has simple operation, a high reaction yield, easily purchasable reagents and instruments and low cost, and is feasible in specific practical application.

Owner:荆门医药工业技术研究院 +1

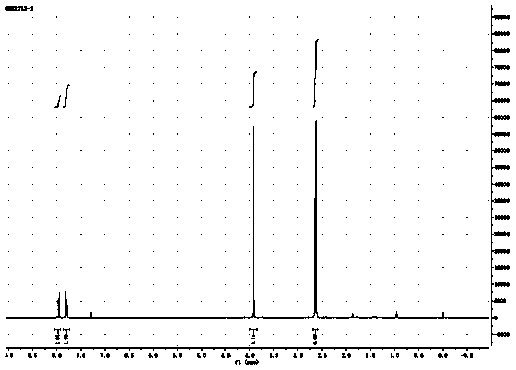

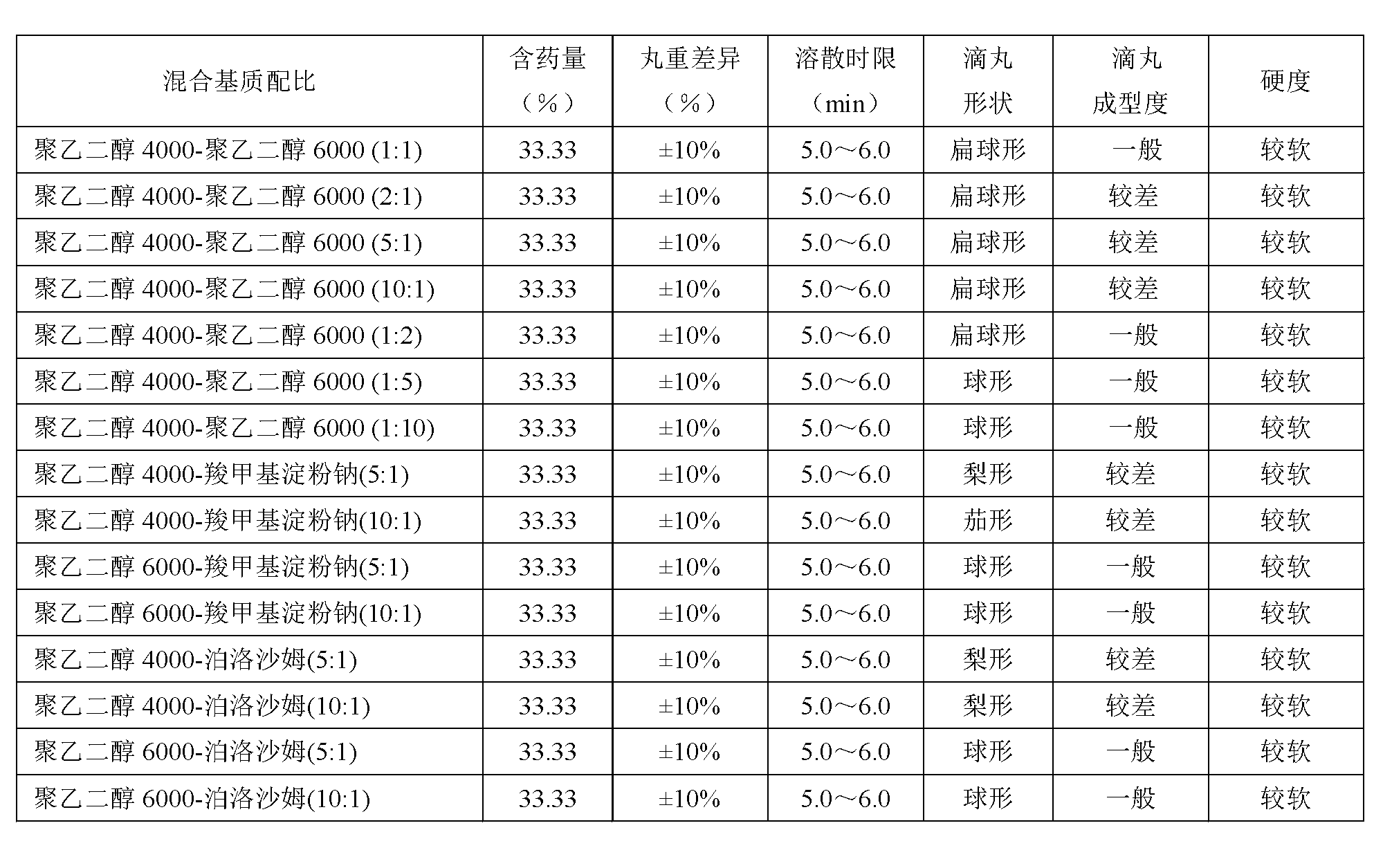

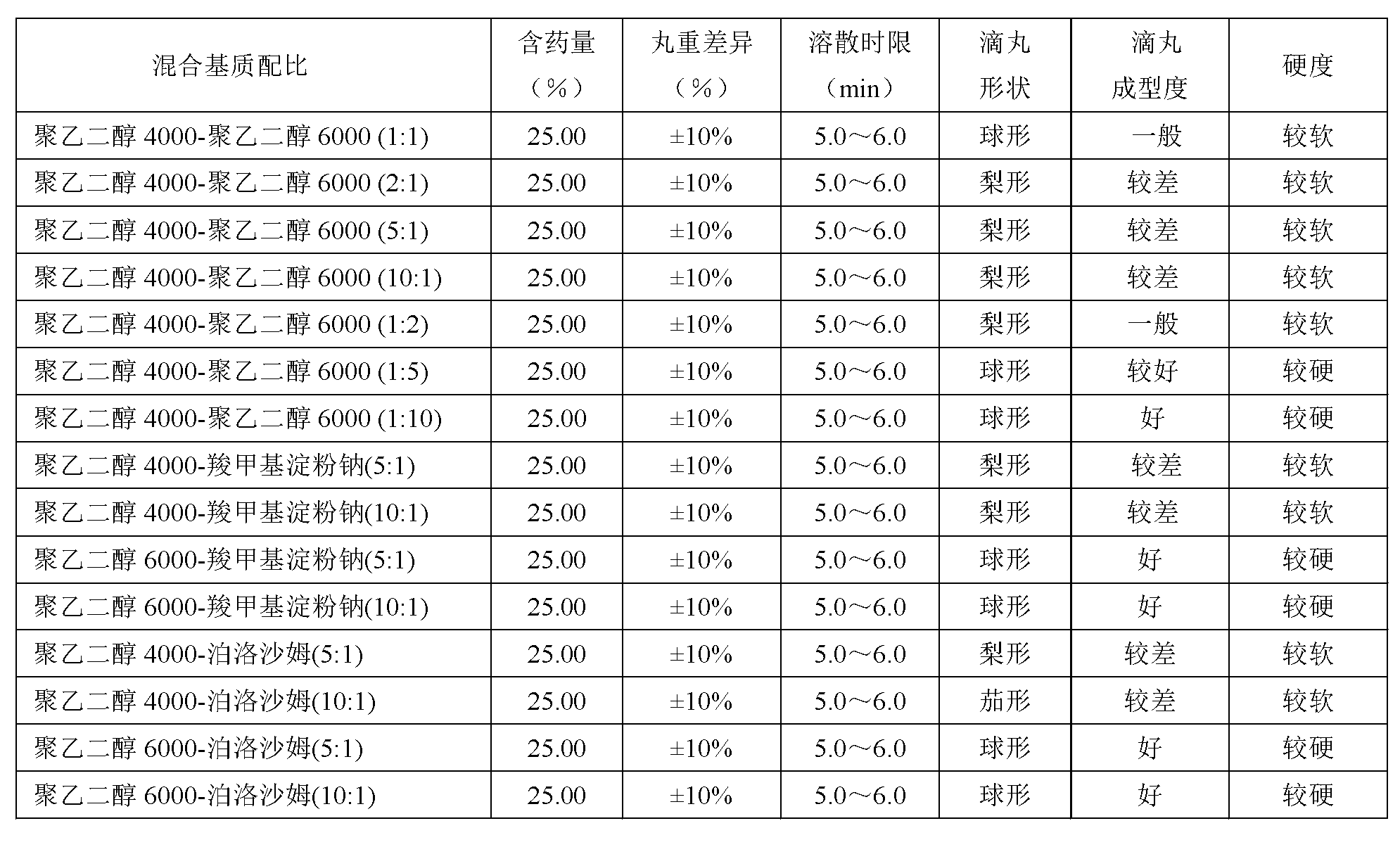

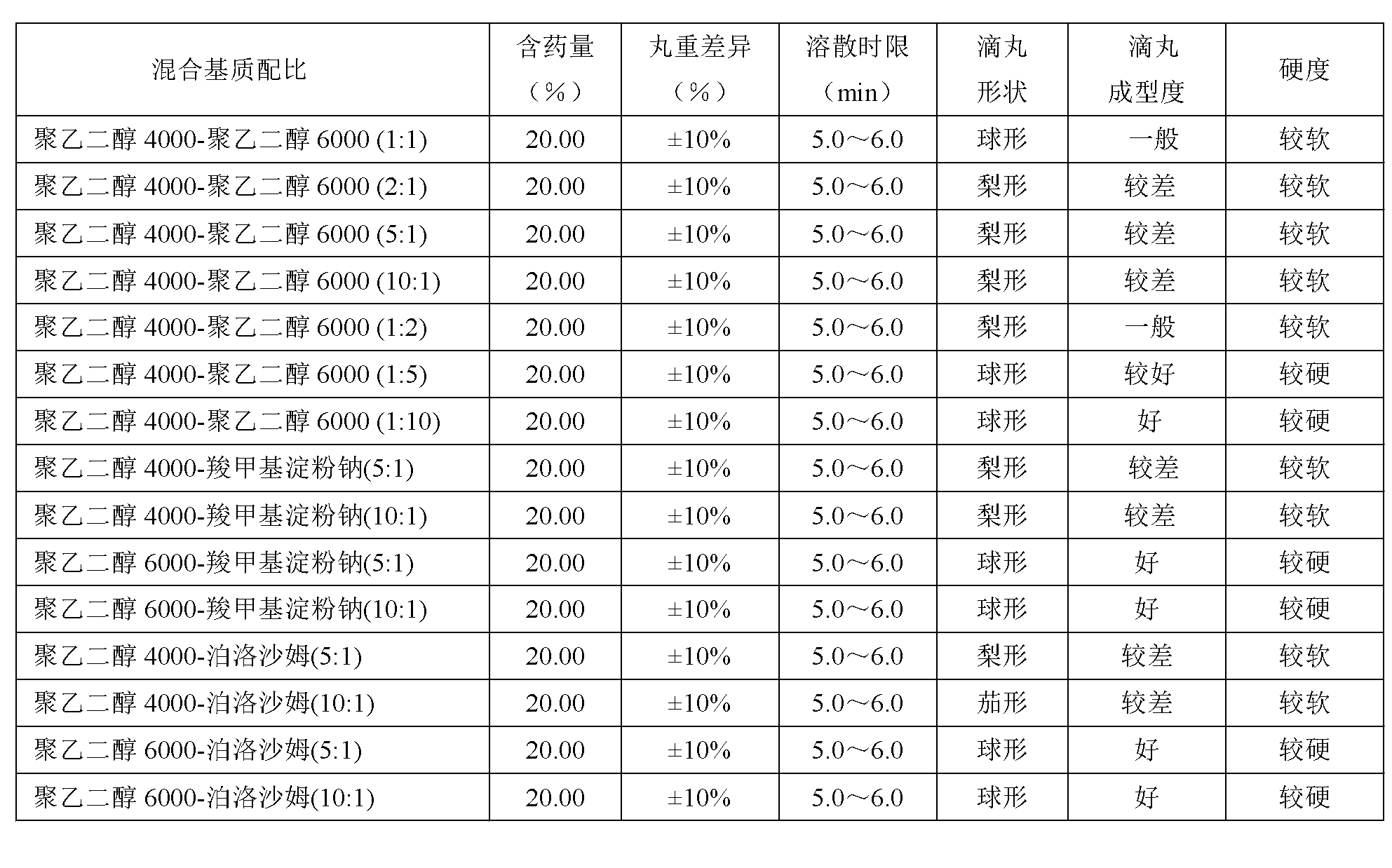

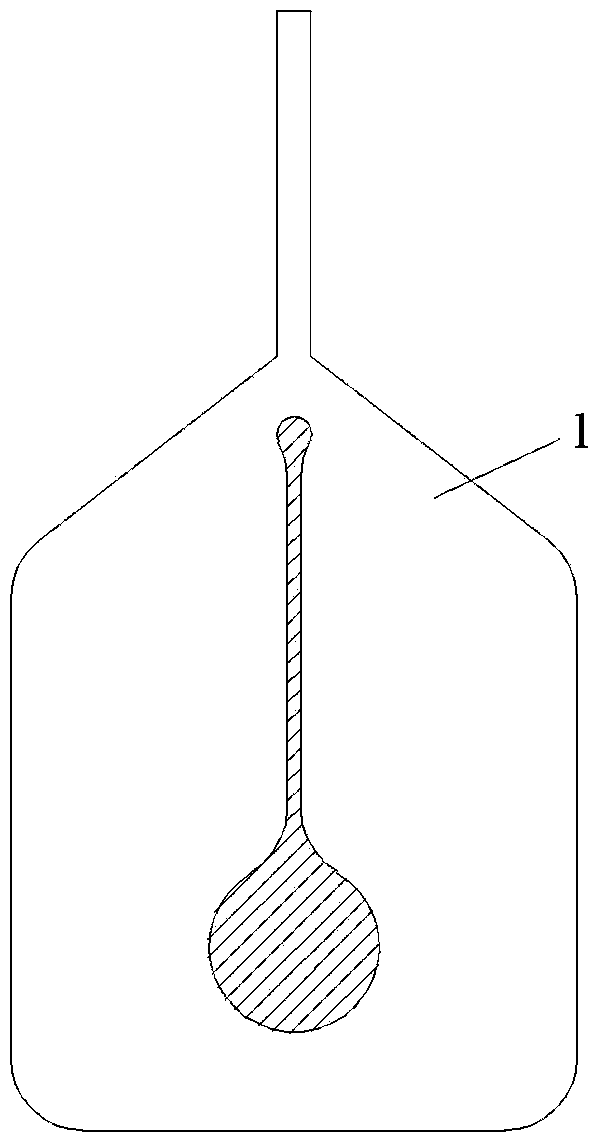

Chinese medicinal extract dripping pill for treating diabetes and hyperlipidemia

InactiveCN102697910AAbundant raw materialsE-buyMetabolism disorderPharmaceutical non-active ingredientsSecondary hyperlipidemiaPolyethylene glycol

The invention relates to a Chinese medicinal extract dripping pill for treating diabetes and hyperlipidemia, which can effectively solve the problems of long dissolving time, low dissolubility and bio-availability of existing Chinese medicinal oral preparations after administration. A technical proposal provided by the invention comprises the steps of mixing polyethylene glycol (PEG) 4000 and PEG6000, or PEG 4000 and sodium carboxymethyl starch or Poloxamer, or PEG 6000 and sodium carboxymethyl starch or Poloxamer at weight ratio of 1:(1-10), and heating and melting to obtain matrix; mixing 10-30 wt% of Fructus Rosae Laevigatae extract, 5-25 wt% of Fructus Mori extract, 10-30 wt% of Rhizoma Coptidis extract, 5-20 wt% of Radix Astragali extract, 5-20 wt% of Polygoni Multiflori Radix extract, and 5-20 wt% of Fructus Corni extract, wherein the total amount of the Chinese medicinal extracts is 100%; and mixing the Chinese medicinal extracts with the matrix at weight ratio of 1:(1.5-5). The inventive dripping pill has the advantages of abundant and easily-accessible materials, simple production, and good treatment effect, and is an innovation in aspect of medicines for treating diabetes and hyperlipidemia.

Owner:HENAN UNIV OF CHINESE MEDICINE

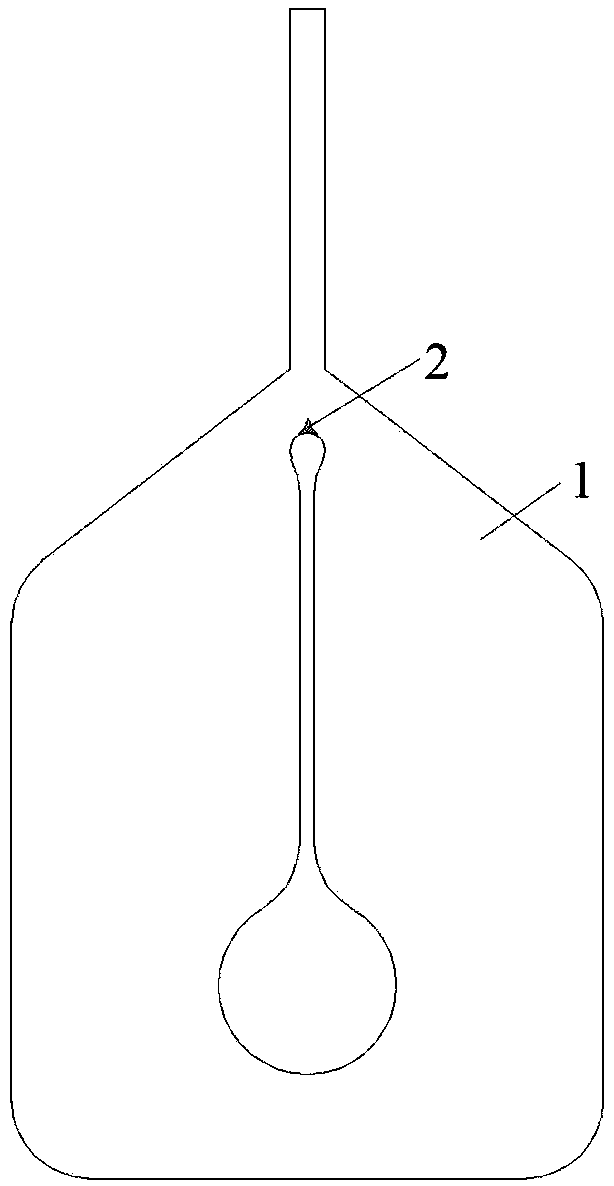

Method of utilizing swelling technology to prepare nanoscale electric jet-flow 3D printing injection needle

ActiveCN109130183AE-buyImprove product qualityNanotechnologyWelding/soldering/cutting articlesInjections needleManufacturing quality

The invention discloses a method of utilizing a swelling technology to prepare a nanoscale electric jet-flow 3D printing injection needle, belongs to the technical field of preparation of injection needles of electric jet-flow 3D printers and solves the technical problem that it is difficult to ensure the size, quality and cost of the nano injection needles during preparation of the nanoscale electric jet-flow injection needles in traditional methods. The method comprises the following steps of (1) laser cutting of a substrate of the nanoscale electric jet-flow 3D printing injection needle; (2) cleaning of the substrate of the nanoscale electric jet-flow 3D printing injection needle; (3) patterning of the substrate of the nanoscale electric jet-flow 3D printing injection needle; (4) preparation of nanoscale cracks of the substrate of the nanoscale electric jet-flow 3D printing injection needle; (5) post-treatment of the substrate of the nanoscale electric jet-flow 3D printing injectionneedle; (6) packaging of the substrate of the nanoscale electric jet-flow 3D printing injection needle. The method can effectively and better protect the structural integrity of the nano injection needle and improve the manufacturing quality of the nano injection needle, a manufacturing process is simple, the operation is convenient, and the manufacturing cost is reduced.

Owner:长沙柳腾科技有限公司

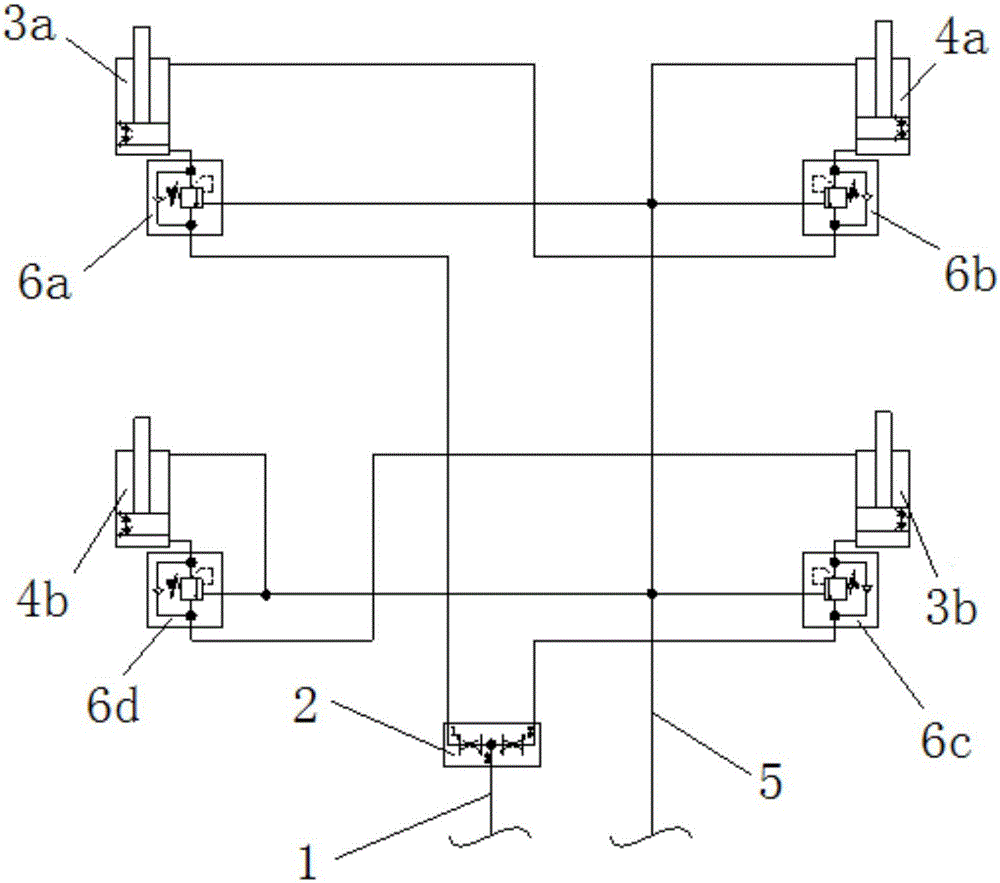

Synchronous running mechanism of hydraulic oil cylinder

InactiveCN106089830AGuaranteed synchronous operation accuracyReduce manufacturing costServomotorsServometer circuitsHydraulic cylinderPetroleum engineering

The invention belongs to the technical field of engineering vehicles, and relates to a synchronous running mechanism of a hydraulic oil cylinder. The synchronous running mechanism comprises a first oil pipe, the first oil pipe is divided into two branches, the two branches are connected with a rodless cavity of a first driving oil cylinder and a rodless cavity of a second driving oil cylinder, a rod cavity of the first driving oil cylinder is connected with a rodless cavity of a first driven oil cylinder, a rod cavity of the second driving oil cylinder is connected with a rodless cavity of a second driven oil cylinder, and a rod cavity of the first driven oil cylinder and a rod cavity of the second driven oil cylinder are both connected to a second oil pipe; the cross section area of the hollow portion of the rod cavity of the first driving oil cylinder is equal to the cross section area of the hollow portion of the rodless cavity of the first driven oil cylinder; and the sectional area of the hollow portion of the rod cavity of the second driving oil cylinder is equal to the sectional area of the hollow portion of the rodless cavity of the second driven oil cylinder. The aims that the synchronous running precision of the oil cylinder is ensured, mounting space occupied by the oil cylinder is effectively reduced, and the production cost is reduced.

Owner:昆山晋桦豹胶轮车制造股份有限公司

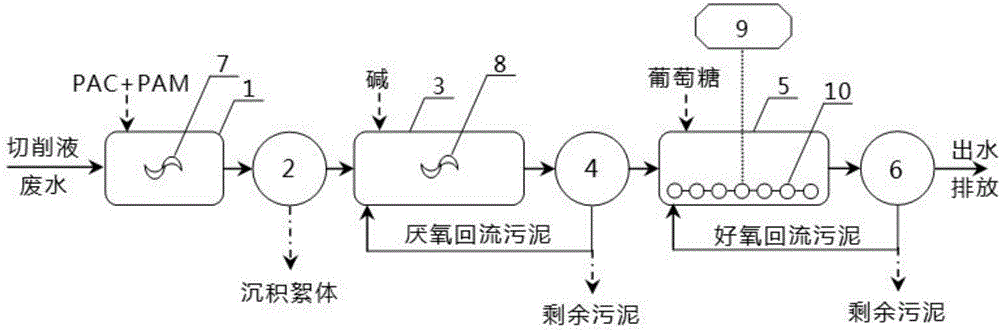

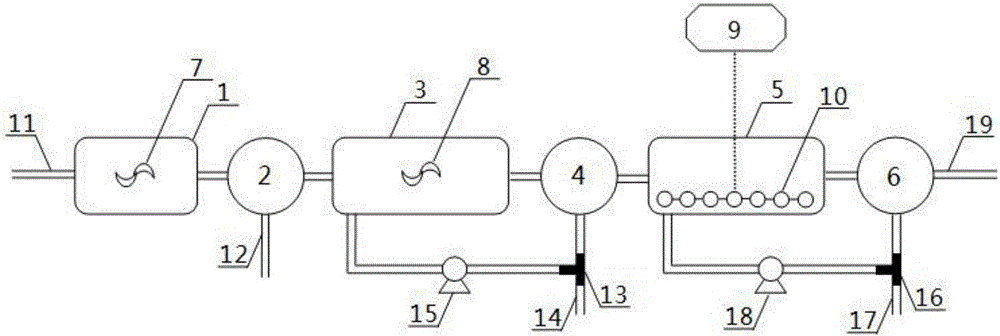

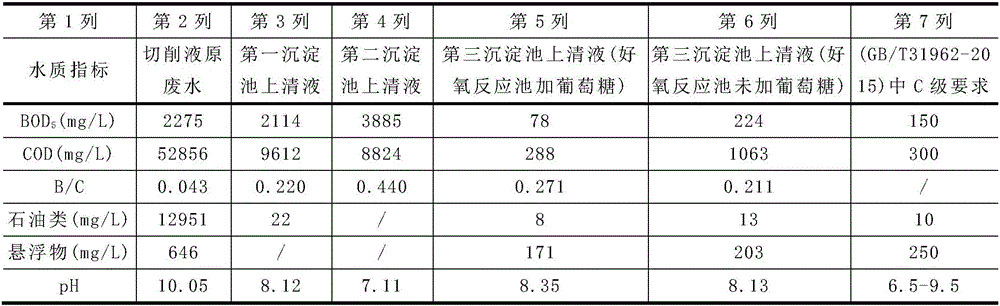

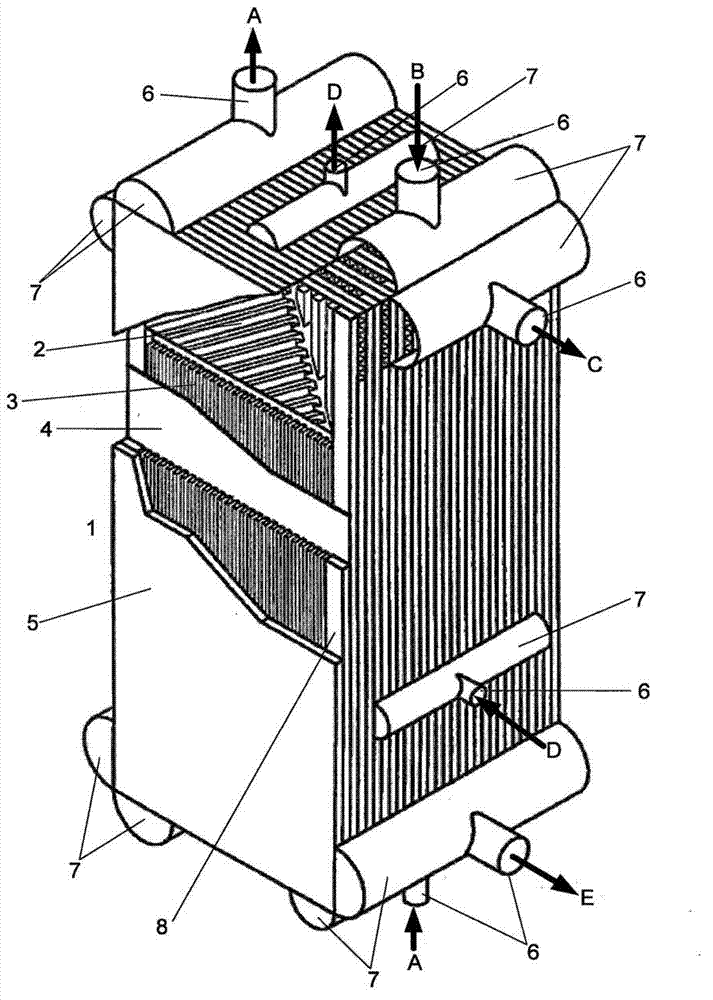

Coagulation-anaerobic hydrolysis-aerobic synergistic treatment cutting fluid wastewater device and method

InactiveCN106746223AImprove biodegradabilityEasy to operate and manageWater treatment parameter controlTreatment using aerobic processesChemical oxygen demandEmission standard

The invention discloses a coagulation-anaerobic hydrolysis-aerobic synergistic treatment cutting fluid wastewater device and method. The device comprises a coagulating basin, a first sedimentation basin, an anaerobic hydrolysis tank, a second sedimentation basin, an aerobic reaction tank and a third sedimentation basin, wherein aluminum polychloride and polyacrylamide are added into the coagulating basin; alkali is added into the anaerobic hydrolysis tank, so that the pH value of a mixed solution in the hydrolysis tank is maintained in a proper range; and glucose is added into the aerobic reaction tank to achieve synergistic degradation of partial refractory organics. The method disclosed by the invention is simple, feasible and convenient to operate and manage, so that the removal rate of COD (chemical oxygen demand) and petroleum in cutting fluid wastewater can reach 99% or higher, and the COD, BOD5, petroleum, suspended solid content and pH value of the system effluent meet the requirements of C-level emission standards in Wastewater Quality Standards for Discharge to Municipal Sewers (GB / T31962-2015).

Owner:TIANJIN CHENGJIAN UNIV

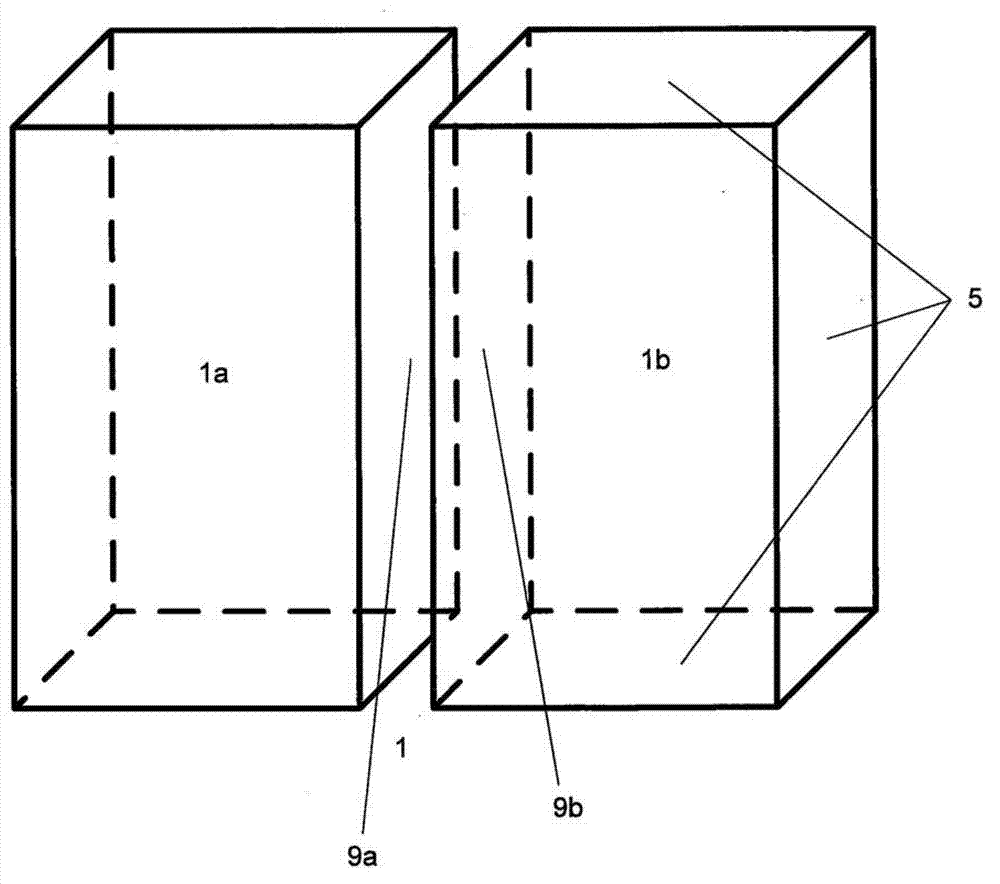

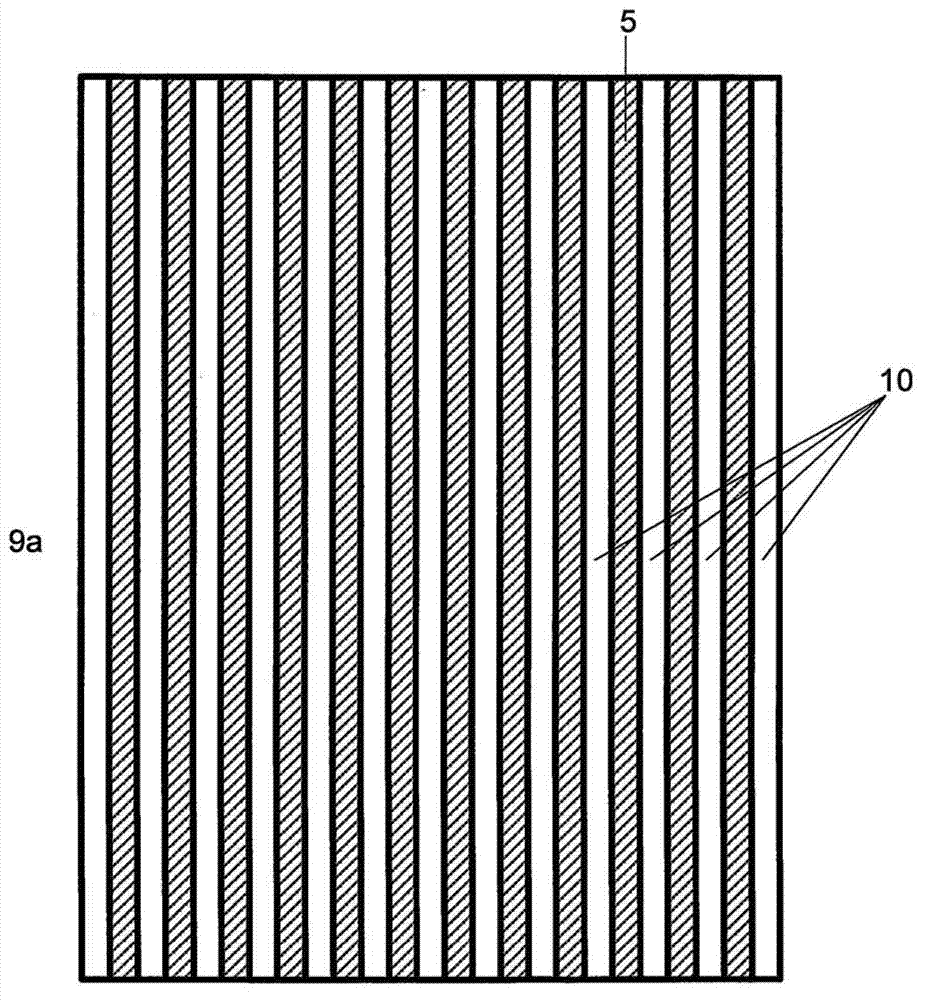

Plate heat exchanger with several modules connected by sheet-metal strips

ActiveCN103363824AIncreased durabilityConnection flatSolidificationLiquefactionMetal stripsPlate heat exchanger

The invention describes a plate heat exchanger 1 comprising two modules 1a and 1b. The two modules 1a and 1b are cuboidal and in each case are closed off to the outside by cover sheets 5. The two modules 1a and 1b are arranged such that cover sheets 9a and 9b of the same size are directly adjacent. The two cover sheets 9a and 9b form the contact surface between the two modules 1a and 1b of the plate heat exchanger 1. The two contact surfaces 9a and 9b are joined to one another via a suitable adhesive.

Owner:LINDE AG

Sodium dichlorophenolate self-emulsifying ointment

InactiveCN102614115AAbundant raw materialsE-buyOrganic active ingredientsAntipyreticGlycerolHepatic first pass effect

The invention relates to a sodium dichlorophenolate self-emulsifying ointment, which can be used for effectively reducing first pass effect and enhancing the curative effect. According to the technical scheme of the invention, the sodium dichlorophenolate self-emulsifying ointment is prepared by uniformly mixing sodium dichlorophenolate serving as a medicament and a self-emulsifying substrate serving as a medicament carrier; every gram of sodium dichlorophenolate self-emulsifying ointment contains 20-50mg of sodium dichlorophenolate; the self-emulsifying substrate is prepared from 12-20 percent by weight of an oil phase, 40-60 percent by weight of an emulsifier and 20-40 percent by weight of an auxiliary emulsifying agent; the oil phase consists of refined oil, glycerin monostearate and octadecanol in the weight ratio of 8:2:1; the emulsifier consists of polysorbate 80 and RH40 in the weight ratio of 2:8, or consists of polysorbate 80 and EL in the weight ratio of 6:4; and the auxiliary emulsifying agent is glycerol. The sodium dichlorophenolate self-emulsifying ointment is prepared by the following steps of: putting the oil phase into a constant-temperature water bath of 80 DEG Cfor heating and melting; adding the emulsifier, the auxiliary emulsifying agent and the sodium dichlorophenolate in sequence; dissolving and stirring uniformly; standing; and cooling for curing. The sodium dichlorophenolate self-emulsifying ointment has a rich raw material source, is easy to purchase, and is an innovation of a medicament for refrigerating and relieving inflammatory pain.

Owner:HENAN UNIV OF CHINESE MEDICINE +1

Vitamin E self-emulsifying ointment

InactiveCN102614114AAbundant raw materialsE-buyOrganic active ingredientsAerosol deliveryWater bathsDisease

The invention relates to a vitamin E self-emulsifying ointment, which can be used for effectively enhancing the bioavailability of external vitamin E and enhancing the curative effect. According to the technical scheme of the invention, the vitamin E self-emulsifying ointment is prepared by uniformly mixing vitamin E serving as a medicament and a self-emulsifying substrate serving as a medicamentcarrier; every gram of vitamin E self-emulsifying ointment contains 20-300mg of vitamin E; the self-emulsifying substrate is prepared from 12-20 percent by weight of an oil phase, 40-60 percent by weight of an emulsifier and 20-40 percent by weight of an auxiliary emulsifying agent; the oil phase consists of refined oil, glycerin monostearate and octadecanol in the weight ratio of 8:2:1; the emulsifier consists of polysorbate 80 and RH40 in the weight ratio of 2:8, or consists of polysorbate 80 and EL in the weight ratio of 6:4; and the auxiliary emulsifying agent is glycerol. The vitamin E self-emulsifying ointment is prepared by the following steps of: putting the oil phase into a constant-temperature water bath of 80 DEG C for heating and melting; adding the emulsifier, the auxiliary emulsifying agent and the vitamin E in sequence; dissolving and stirring uniformly; standing; and cooling for curing. The vitamin E self-emulsifying ointment has a good curative effect, and is an innovation of a medicament for externally treating skin diseases.

Owner:HENAN UNIV OF CHINESE MEDICINE

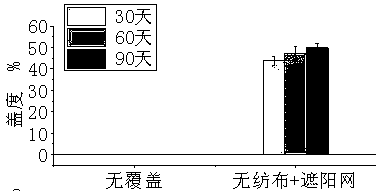

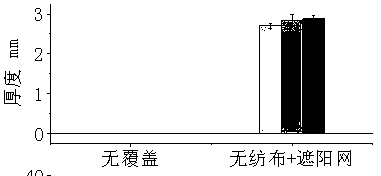

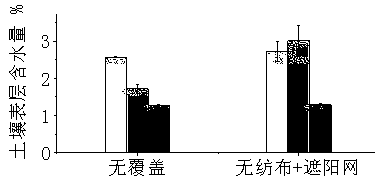

Mechanized artificial cyanobacteria crust culture construction process

InactiveCN110305809AE-buySimple processBacteriaMicroorganism based processesPhylum CyanobacteriaArid

The invention discloses a mechanized artificial cyanobacteria crust culture construction process. The method comprises the following steps: a. cyanobacteria crust sampling and algae culture; b. spraying an algae solution at high pressure, the cyanobacteria after 7-10 days of culture are poured together with a culture solution into a high-pressure sprayer, and spraying the material onto the surfaceof the sand, wherein the amount of the sprayed algae solution is 2 L m-2, and a spray thickness is 0.2-0.5 mm; c. covering the surface of the sprayed algae solution is covered with a layer of green non-woven fabric and a green shade net; and d. using a disposable chopstick, branch, sand or stone to fix the shading net to prevent the net from being blown away by the wind. The construction time ofthe process is within one month before the arrival of the rainy season, and the shading net is uncovered after 3 months of construction. The process has the advantages that the mechanized constructionof an artificial cyanobacteria crust fixing sand technology is realized, and the process is simple and easy to grasp. The construction process significantly increases the formation rate of artificialcrusts, reduces labor costs and management costs, further improves the efficiency of sand prevention and sand control work in arid sand areas, and accelerates the speed and effect of sand damage control in arid areas.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

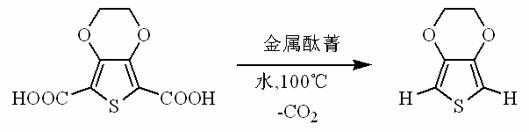

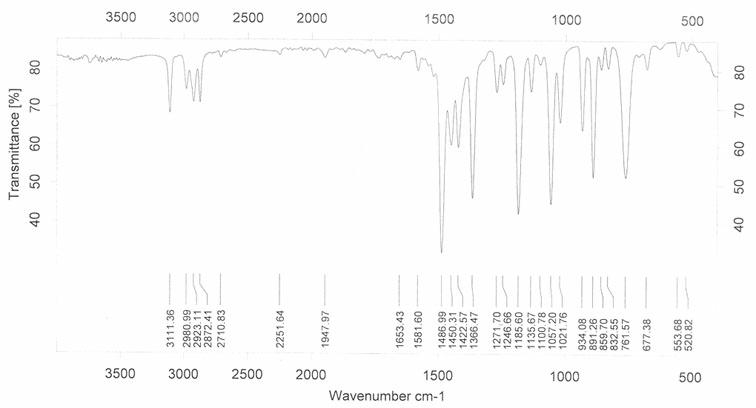

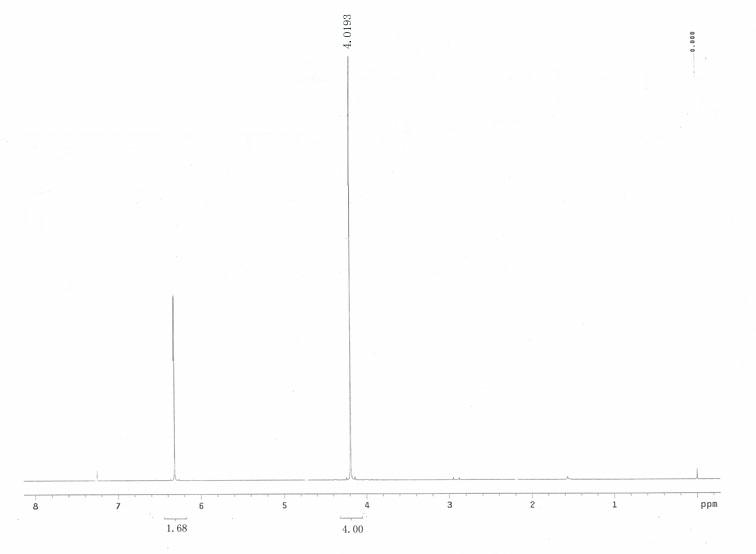

Decarboxylation method of 3,4-ethylenedioxy thiophene

The invention discloses a decarboxylation method of 3,4-ethylenedioxy thiophene. The method comprises the following step of: decarboxylating 2,5-dicarboxylic acid-3,4-ethylenedioxy thiophene by taking metal phthalocyanine with the structure shown as a general formula (I) as a catalyst to obtain 3,4-ethylenedioxy thiophene, wherein M refers to Mg, Mn, Fe, Co, Ni, Cu, Ag or Zn; and R is independently selected from -H, -Et, -OH, -OCH3, -COOH, -COOEt, -NH2, -NO2, -CN, -F, -Cl, -Br, -I and -Ph. The yield of the 3,4-ethylenedioxy thiophene is high, a solvent used in a reaction is environmentally-friendly and low-cost water, and the catalyst is reusable. The method has the advantages of simple process, low cost, high yield and environmental friendliness, and is suitable for industrial production.

Owner:NORTHWEST UNIV(CN)

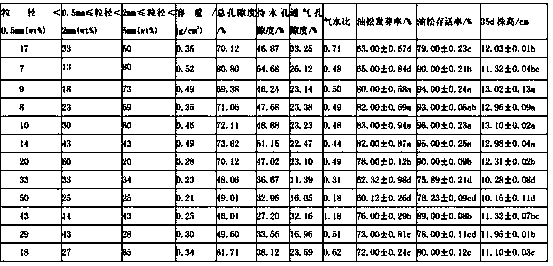

Mushroom residue culture medium suitable for growth of Chinese pine and method for precisely and accurately regulating culture medium

InactiveCN103641523ASuitable for growthImprove survival rateOrganic fertilisersThree levelBiotechnology

The invention discloses a mushroom residue culture medium suitable for growth of Chinese pine and a method for precisely and accurately regulating the culture medium. The mushroom residue culture medium suitable for growth of Chinese pine is prepared from the three types of mushroom residues which are different in grain size: 8-14% of the mushroom residue with grain size being less than 0.5mm, 18-50% of the mushroom residue with grain size being more than or equal to 0.5mm and less than 2mm, and 25-73% of the mushroom residue with grain size being more than or equal to 2mm and less than 5mm. The method for precisely and accurately regulating the culture medium comprises the following steps: gradually screening the mushroom residues by sampling screens with bore diameters of 0.5mm, 2mm and 5mm to divide the mushroom residues into three levels: the mushroom residue with grain size being less than 0.5mm, the mushroom residue with grain size being more than or equal to 0.5mm and less than 2mm, and the mushroom residue with grain size being more than or equal to 2mm and less than 5mm; and then, weighing in percentage by weight and uniformly mixing to prepare a culture matrix. According to the method, the physical and chemical properties of the Chinese pine matrix are precisely and accurately controlled, the mushroom residue culture medium is suitable for growth of Chinese pine, and the indexes such as the germination rate and the survival rate after transplant are remarkably improved.

Owner:HEBEI ACAD OF FORESTRY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com