Fabricated box culvert vertical prefabricated light formwork and manufacturing method thereof, and box culvert prefabricating method

A prefabricated, box culvert technology, applied in supply devices, unloading devices, manufacturing tools, etc., can solve the problems of unsatisfactory appearance, difficult installation, and difficult pouring, and achieves high automation, reduced construction height, and vibration. pounding convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

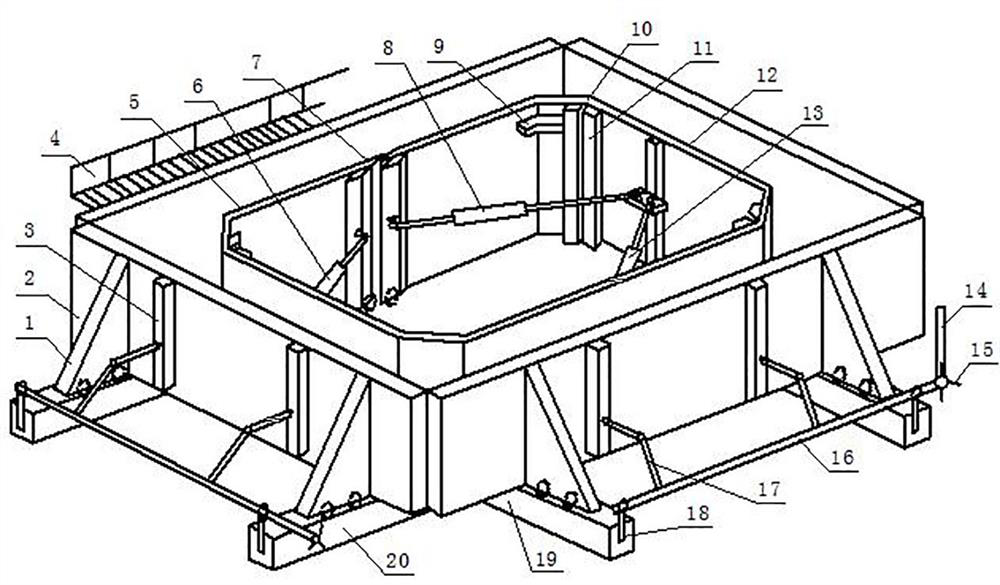

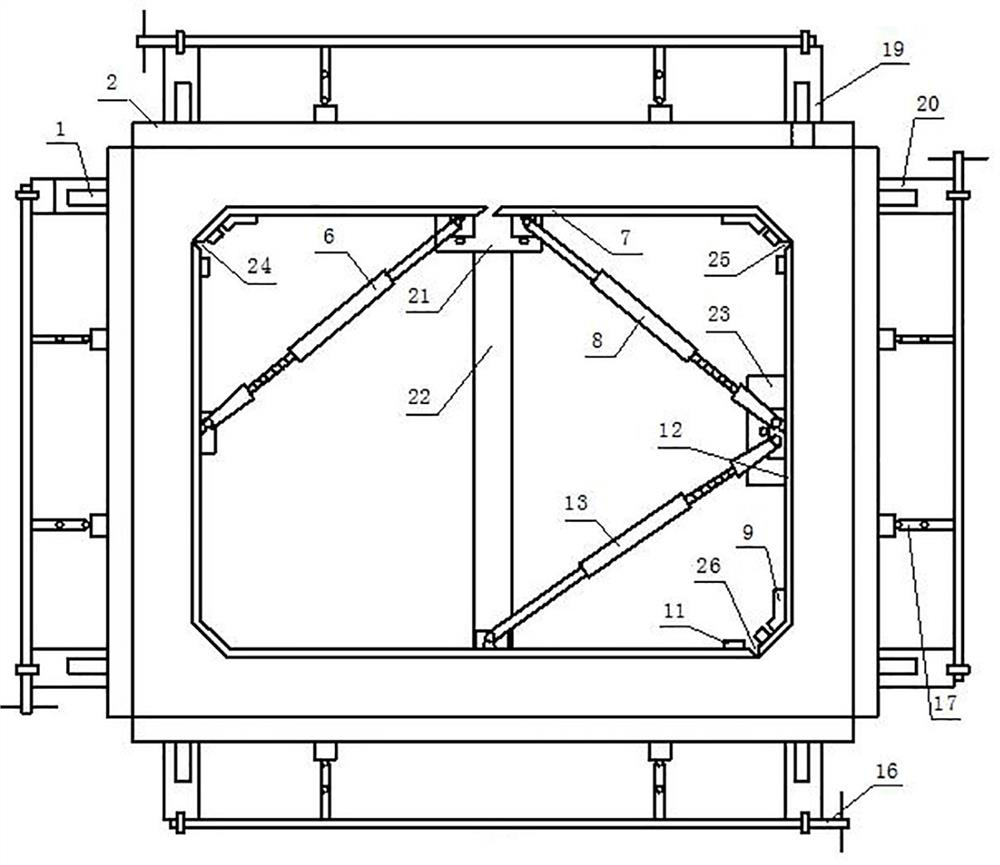

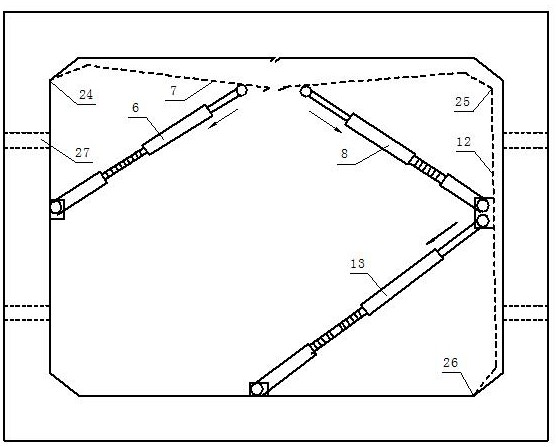

[0085] Example: see Figure 1-Figure 4 , in the figure, 1-slanting brace, 2-outer mold, 3-longitudinal rib, 4-fence, 5-inner mold, 6-first hydraulic rod, 7-folding section of inner mold, 8-second hydraulic rod, 9 -Corner rib, 10-Bending point, 11-Strengthening rib, 12-Side shifting section of inner mold, 13-Third hydraulic rod, 14-Handle, 15-Short rib, 16-Rod, 17-Connecting rod, 18-support frame, 19-base beam, 20-base longitudinal beam, 21-walking platform of inner mold half-folding section, 22-middle beam, 23-walking platform of inner mold side shift section, 24-first bending point, 25- The second bending point, 26-the third bending point, 27-reserved holes.

[0086] First, the production of templates:

[0087] 1. Production of the base:

[0088] Cutting according to the design size and model, carry out lofting and splicing on the flat ground or pedestal. During the splicing process, the distance between the base longitudinal beam 20 and the base beam 19 and the positions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com