Synchronous running mechanism of hydraulic oil cylinder

A technology of synchronous operation and hydraulic cylinders, which is applied in the direction of mechanical equipment, fluid pressure actuators, servo motors, etc., and can solve the problems that cannot adapt to the narrow installation space of construction machinery, the synchronization of oil cylinders is not completely consistent, and the volume of oil cylinder assemblies is increased. , to ease the lifting action, prevent noise or vibration, and improve the lifting balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

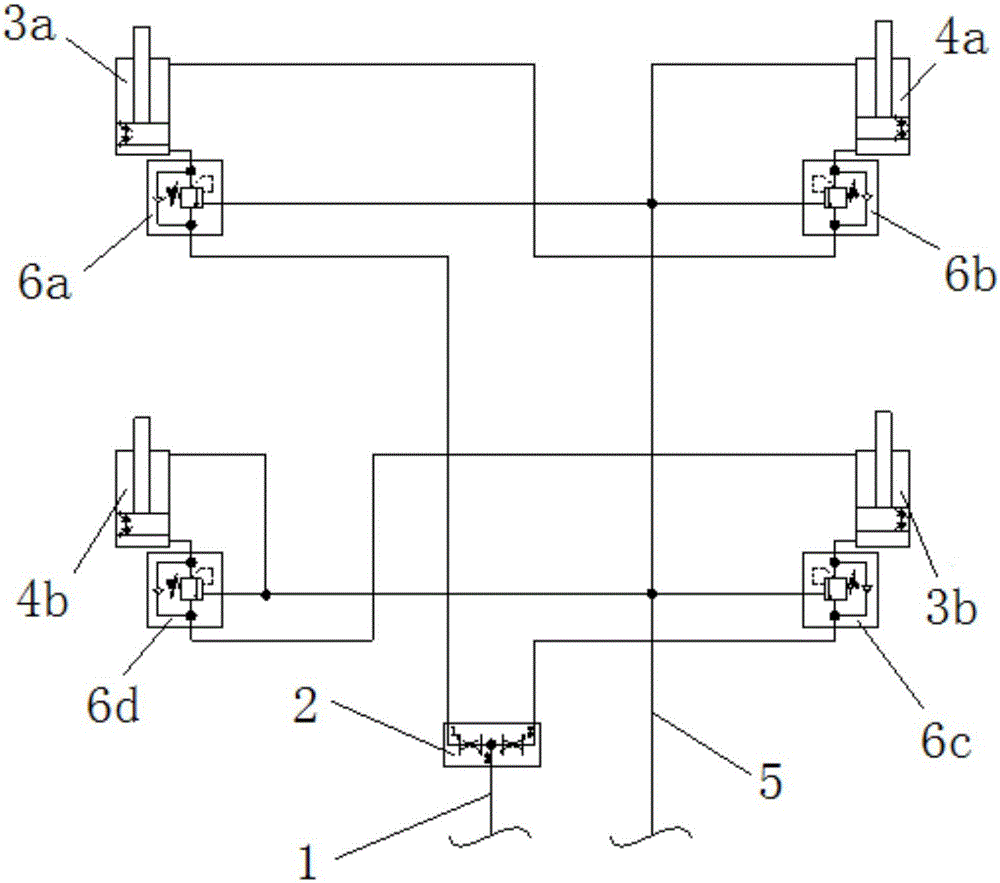

[0036] like figure 1 As shown, a hydraulic cylinder synchronous operation mechanism of the present invention includes a first oil pipe 1, and the first oil pipe 1 divides into two branches connected to the rodless cavity of the first active oil cylinder 3a and the rodless chamber of the second active oil cylinder 3b respectively. Rod chamber, the rod chamber of the first active cylinder 3a is connected to the rodless chamber of the first slave cylinder 4a, the rod chamber of the second master cylinder 3b is connected to the rodless chamber of the second slave cylinder 4b, the first slave cylinder The rod chamber of 4a and the rod chamber of the second slave cylinder 4b are connected to the second oil pipe 5; the cross-sectional area of the hollow part of the rod chamber of the first active cylinder 3a is equal to the hollow part of the rodless chamber of the first slave cylinder 4a Cross-sectional area; the cross-sectional area of the hollow part of the rod chamber of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com