Patents

Literature

45results about How to "Connection flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

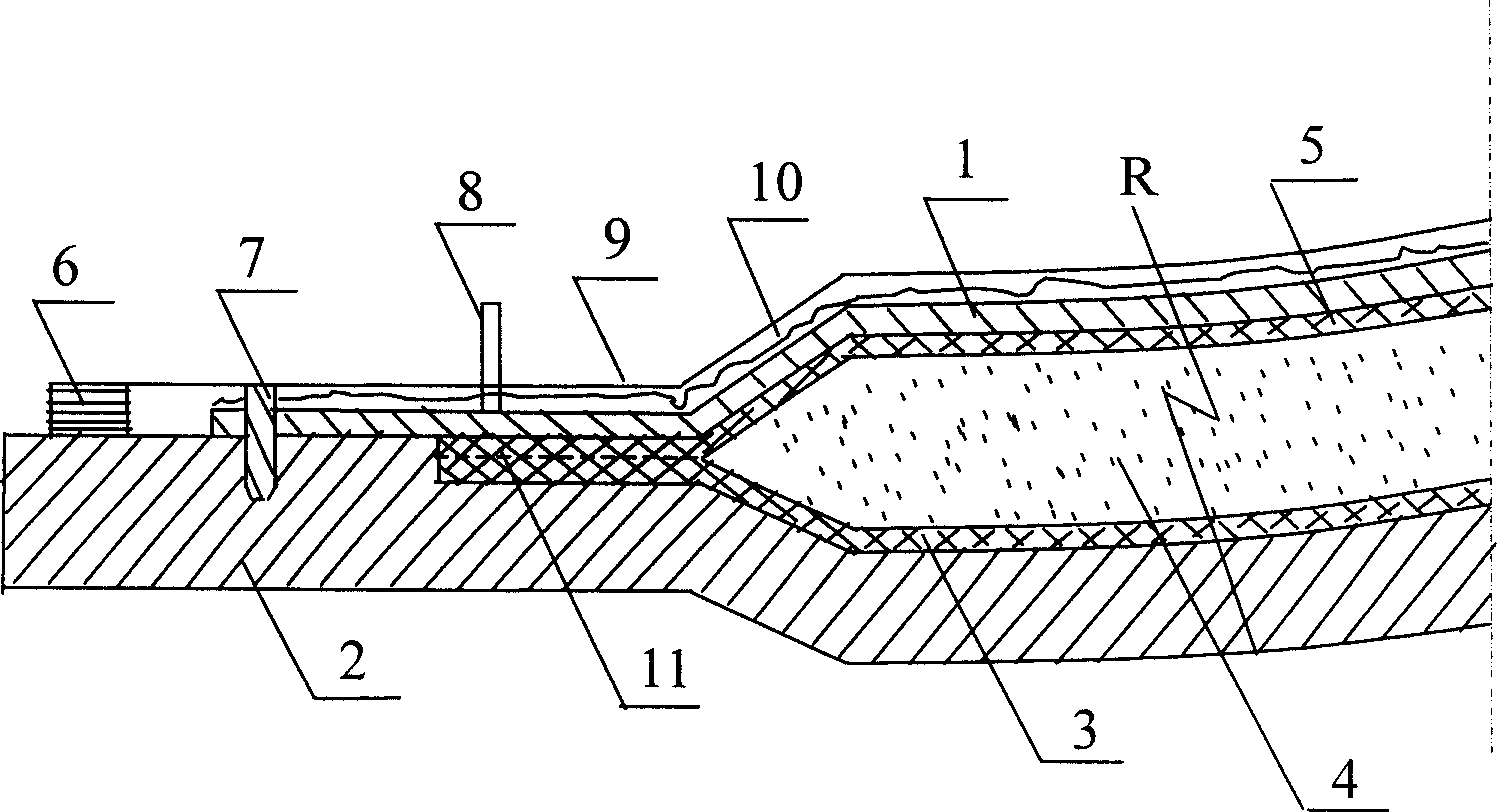

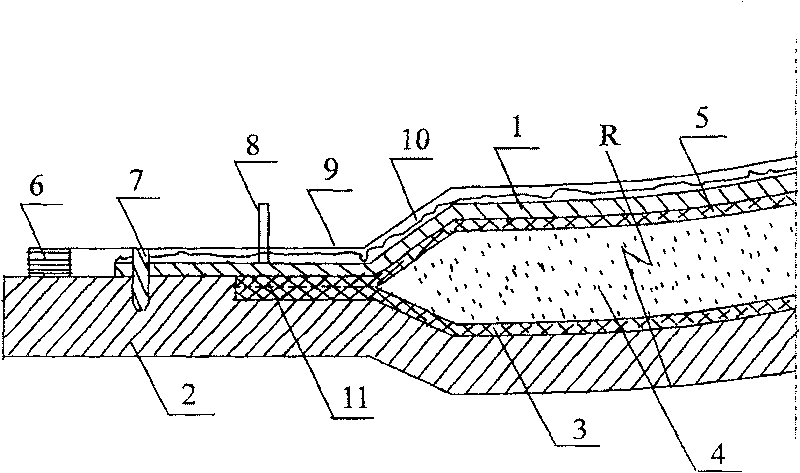

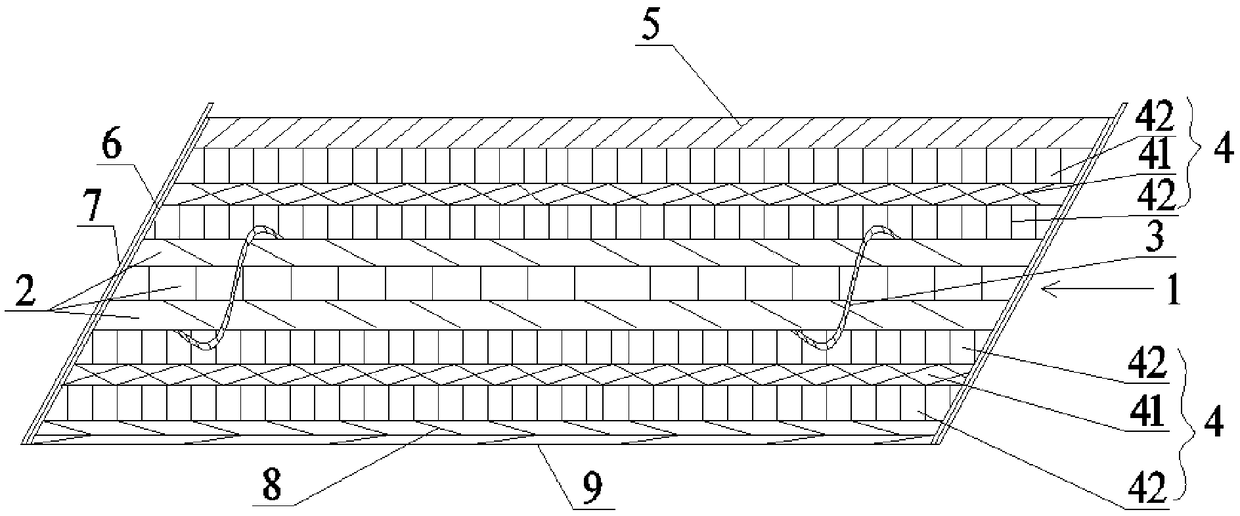

Vacuum forming technique for sandwich structure piece of composite material of fiberglass-reinforced plastics

ActiveCN1915650AFlat surfaceNo stratificationSynthetic resin layered productsGlass fiberOptoelectronics

A composite glass fiber reinforced plastics material with sandwich structure is composed of an external layer made of glass fiber reinforced plastics and coated by water-proof resin, an internal layer made of glass fiber reinforced plastics, and a core layer with cellular structure or made of foam plastics. Its vacuum forming technology includes such steps as respectively preparing mould, external layer, internal layer and core layer, molding, and vacuum solidifying.

Owner:上海之合玻璃钢有限公司

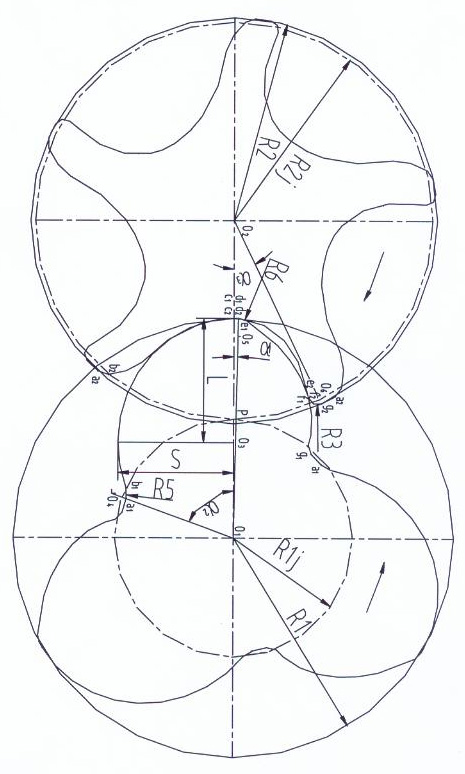

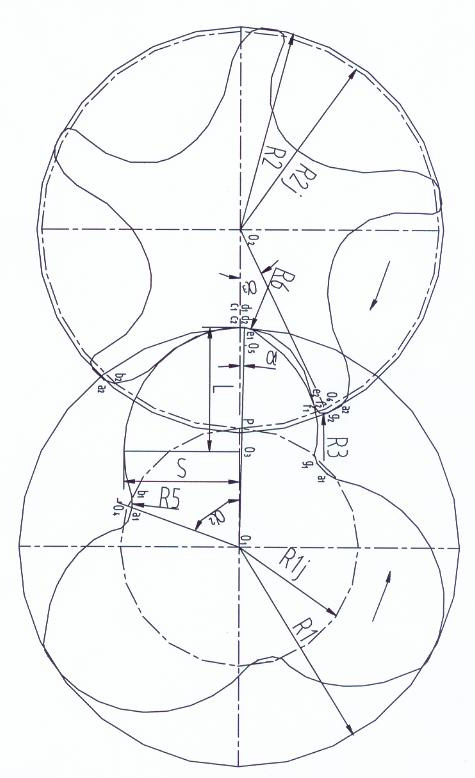

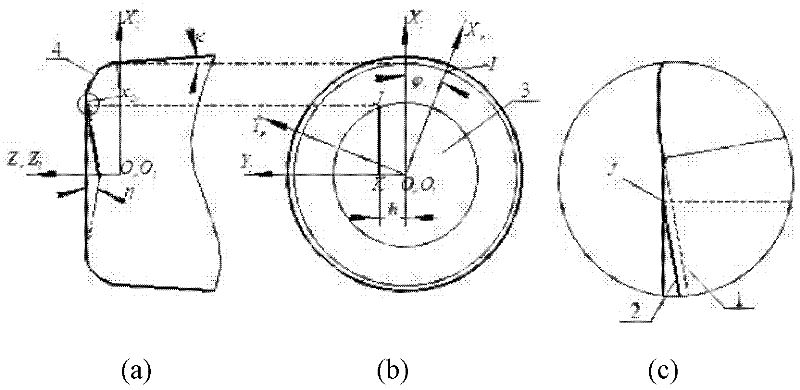

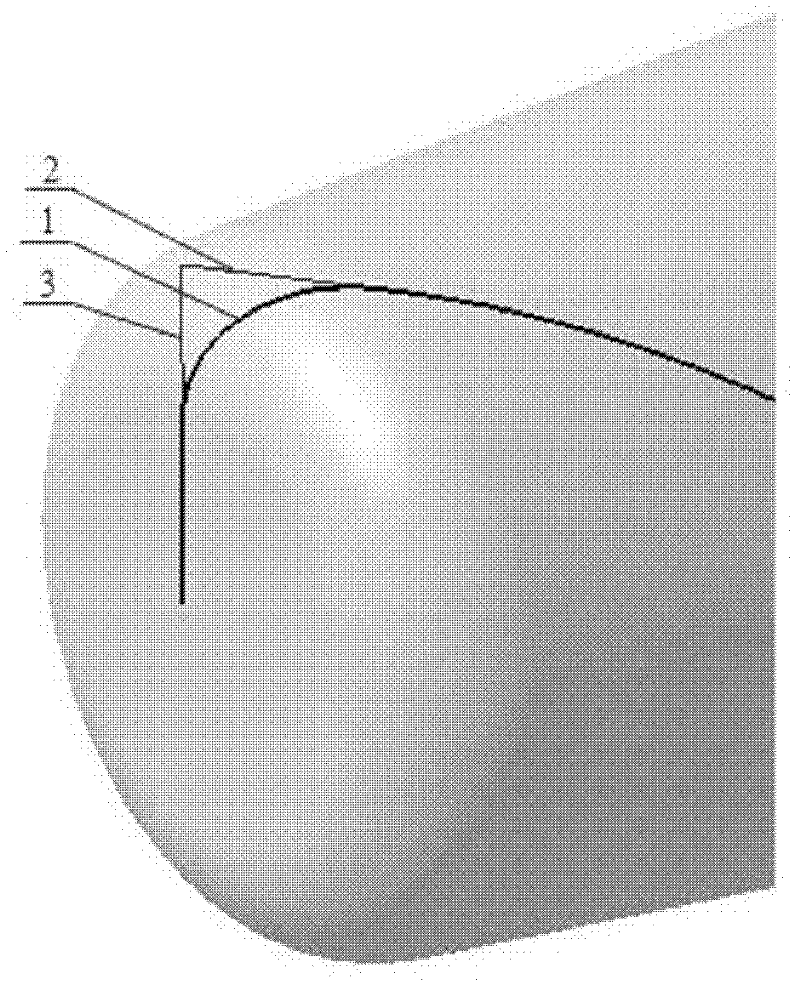

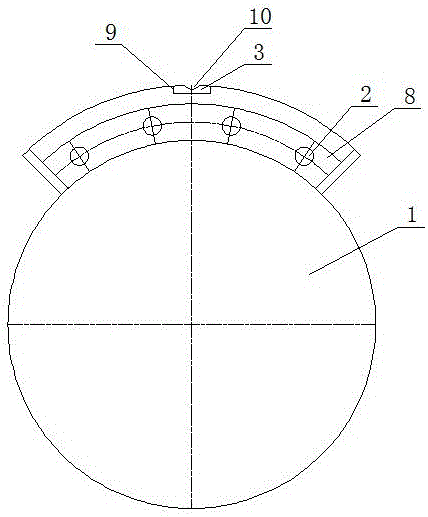

Twin-screw compressor rotor profile

InactiveCN102052322AContact wire shortLeaky triangle smallRotary piston pumpsRotary piston liquid enginesBilateral asymmetryEllipse

The invention relates to a twin-screw compressor rotor profile, wherein a two-side asymmetric profile is adopted, six sections of profiles are combined to form end face profiles of a female rotor and a male rotor, and the female rotor and the male rotor which are identical in central distance A and different in size are combined to a form a female / male rotor profile series of a screw compressor. An arc f2g2 with a certain radius and an arc envelope d2e2 at the addendum circle on the passive side of the female rotor end face profile are in smooth connection through taking a straight line e2f2 as a common tangent. The elliptic arc b1c1 on the male rotor end face profile is different from the ordinary arc pin tooth curve or the envelope and can enable the engagement and releasing of the male and female rotors to be more stable through properly adjusting the length ratio of the major and minor axes of the ellipse, so as to reduce noise and vibration. The included angle of the addendum arc c1d1 on the male rotor end face profile can be adjusted, and the addendum arc c1d1 is in tangent and smooth connection with both the elliptic arc b1c1 and an arc d1e1. The invention endows the rotors with the advantages of short contact line, small disclosed triangle, big flow passage area, streamlined rotor profile, reduced aerodynamic resistance and the like.

Owner:南通永力液压设备有限公司

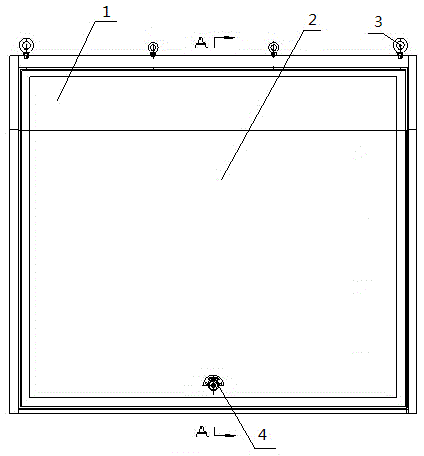

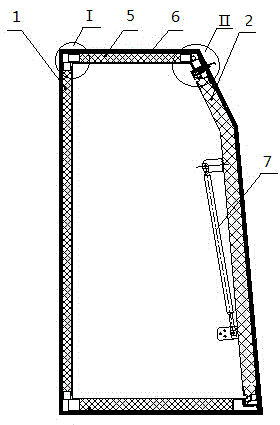

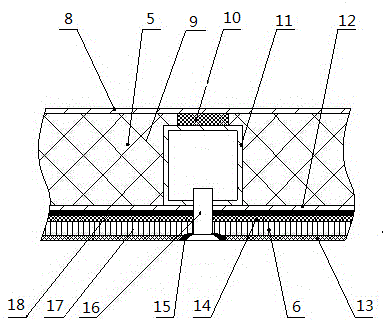

Special-shaped square cabin

InactiveCN104457432AHas a stealth effectWith electromagnetic shieldingArmoured vehiclesThermal insulationEaves

A special-shaped square cabin comprises a square cabin body composed of an upper wallboard, a lower wallboard, a left wallboard, a right wallboard, a front wallboard and a right wallboard. The square cabin body is provided with a door. Each wallboard comprises an inner covering board, a metal frame and an outer covering board; the metal frame is scattered between the inner covering board and the outer covering board and is connected with the outer covering board; a thermal insulating layer is disposed between the metal frame and the inner covering board; light filler is provided between the inner covering board and the outer covering board. The outer surface of the square cabin body is provided with an invisible board which is seamlessly connected to the outer surfaces of the wallboards and the outer surface of the door in a bonding manner and in the mechanical fixation manner without steps; the upper end of the door is provided with an eaves board. The whole cabin body of the special-shaped square cabin has good thermal insulation, electromagnetic shielding performance and invisibility, and a missile launching vehicle is imparted better mobility and environmental adaptability.

Owner:衡阳泰豪通信车辆有限公司

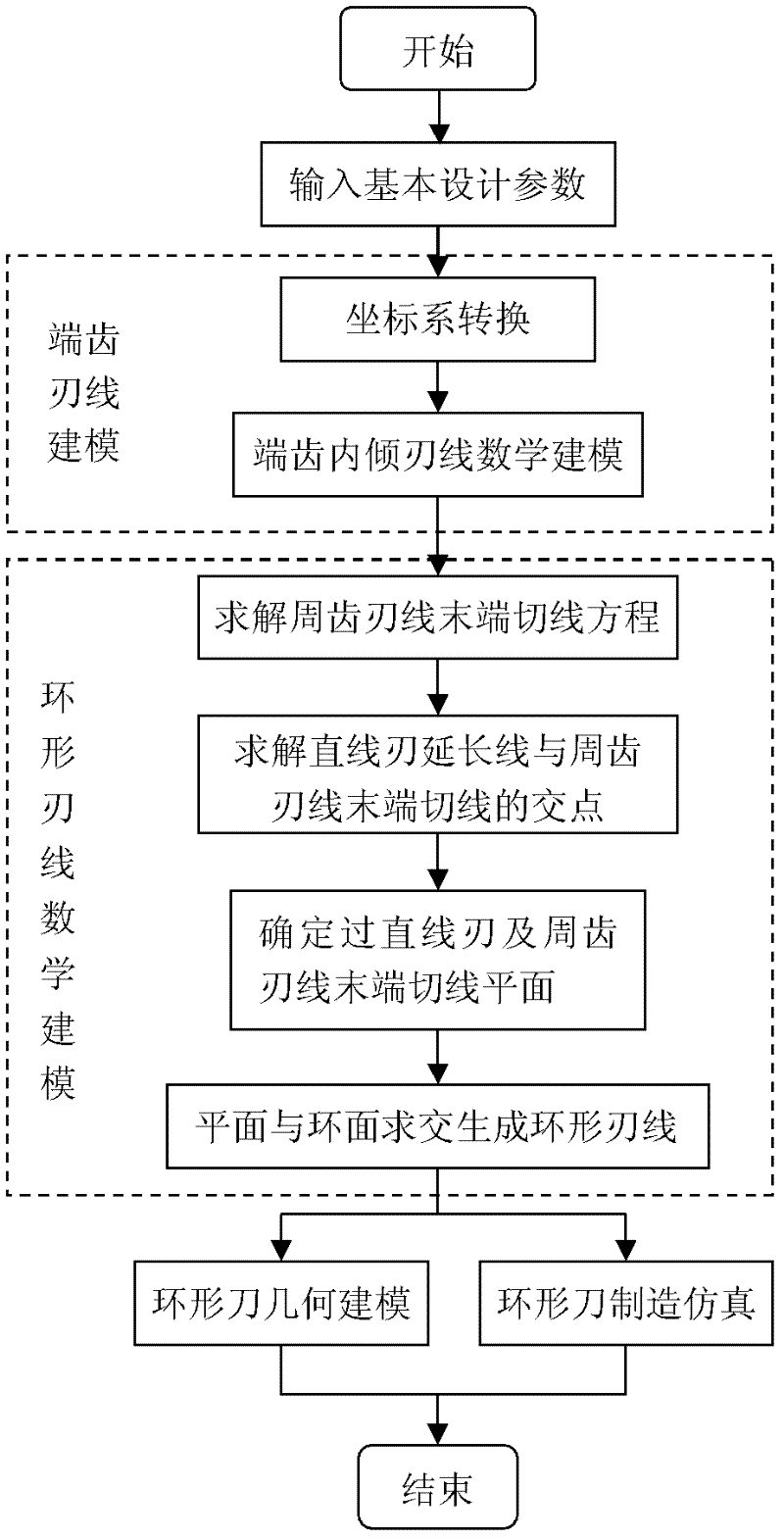

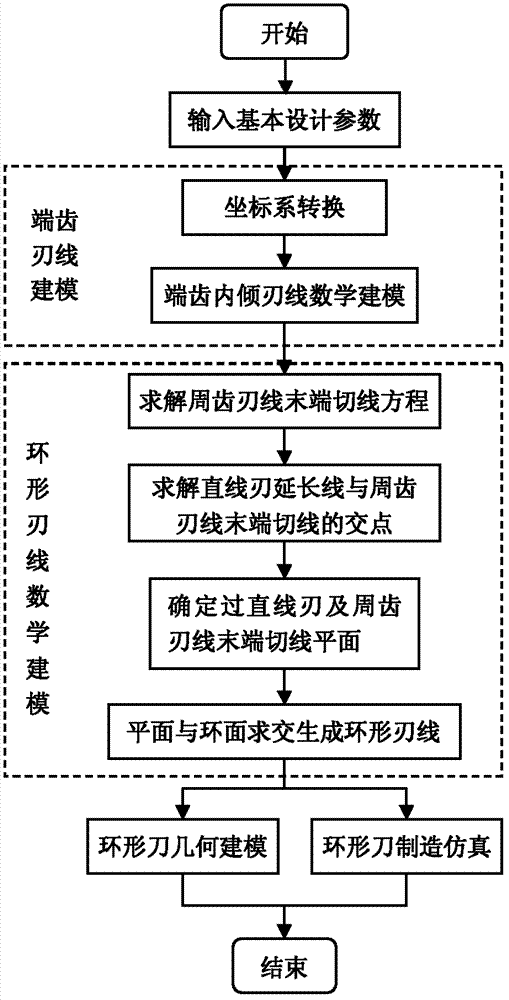

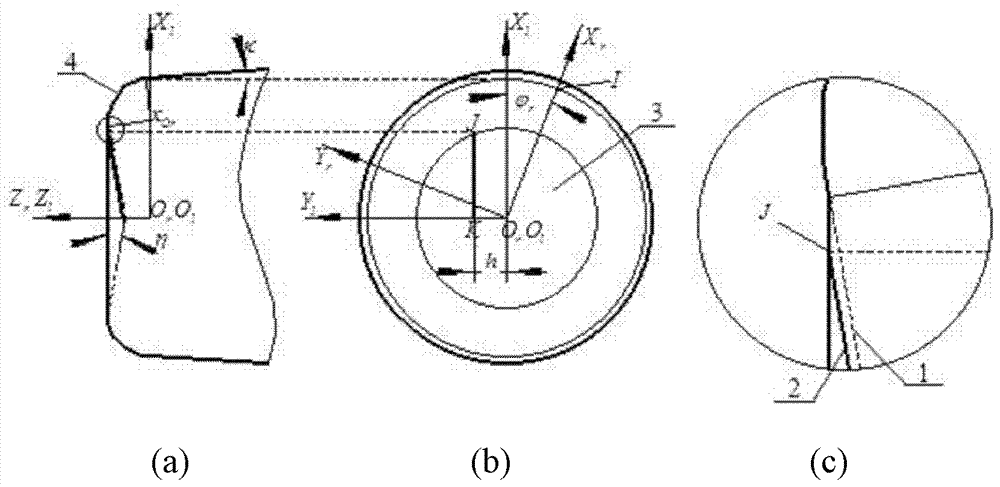

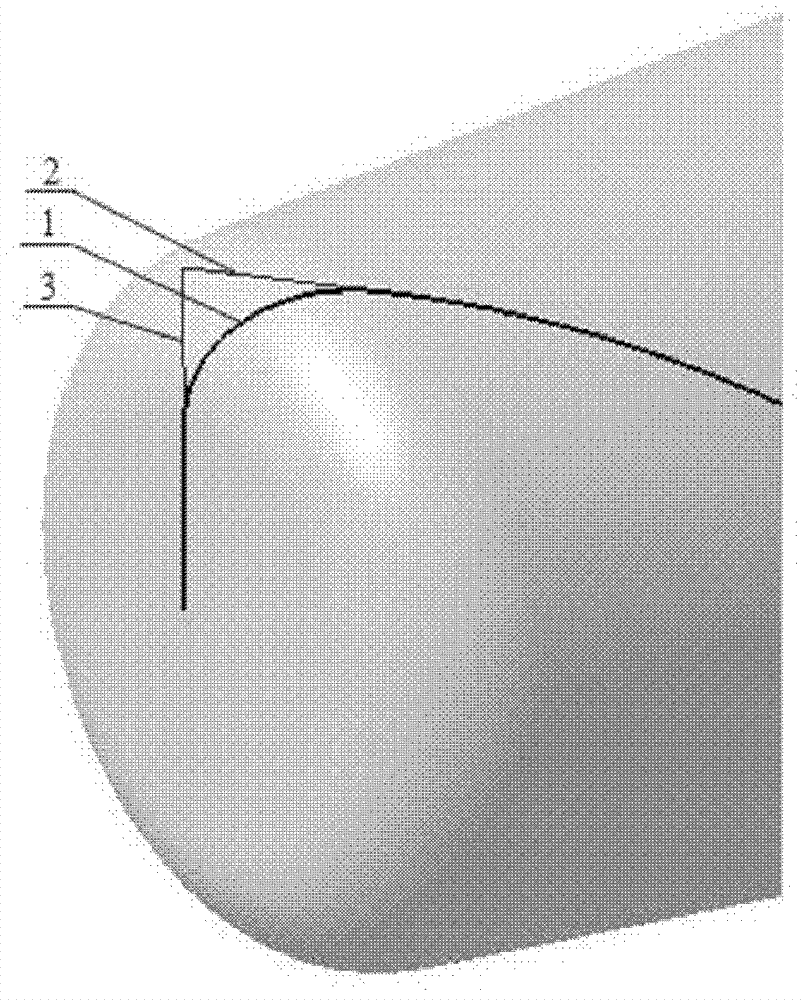

Method for forming annular end tooth edge line of arc-shaped end tooth vertical mill

The invention discloses a method for forming an annular end tooth edge line of an arc-shaped end tooth vertical mill. In the method, a tool making unit processes and forms the arc-shaped end tooth vertical mill according to a mathematical model built by a data control unit and parameter data output by the data control unit. The data control unit builds the mathematical model and output the parameter data by the following steps: inputting the diameter and helical angle of the tool; building the mathematical model of the end tooth edge line; building a mathematical model of the annular end tooth edge line by resolving equation of tangent at the end of a peripheral tooth edge line, resolving the intersection point of the extended line of a straight edge and the tangent at the end of the peripheral tooth edge line, determining the plane defined by the straight edge and the tangent at the end of the peripheral tooth edge line, and resolving the intersection line of the plane and an annularsurface to form an annular edge line; and finally outputting the parameter data of the annular edge line to the tool manufacturing unit. The invention establishes a method for forming the end tooth straight edge line and annular edge line of a vertical mill, which is used for building the mathematical model of the annular vertical mill and instructing manufacturing and processing in order to ensure the smooth connection of the peripheral tooth edge line and the end tooth straight edge.

Owner:SOUTHWEST JIAOTONG UNIV +1

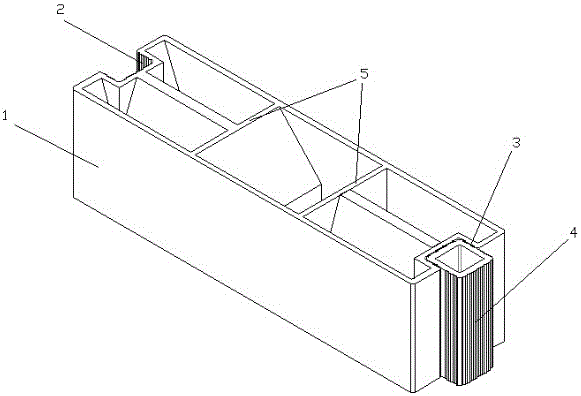

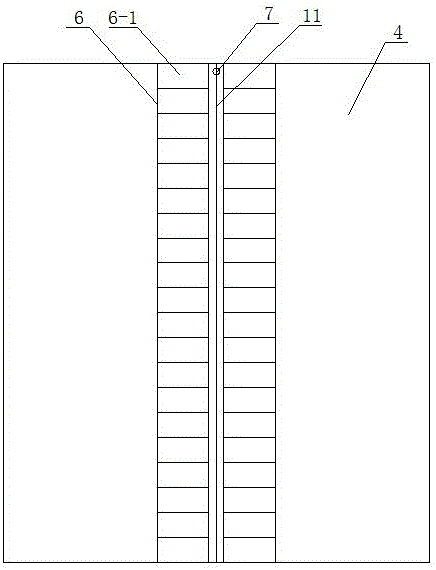

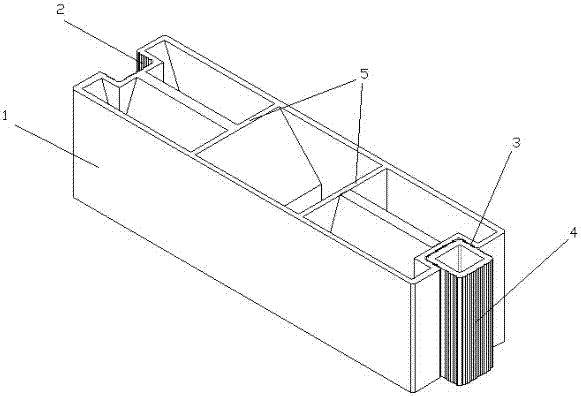

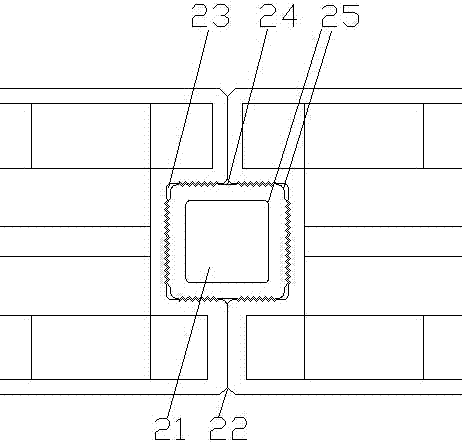

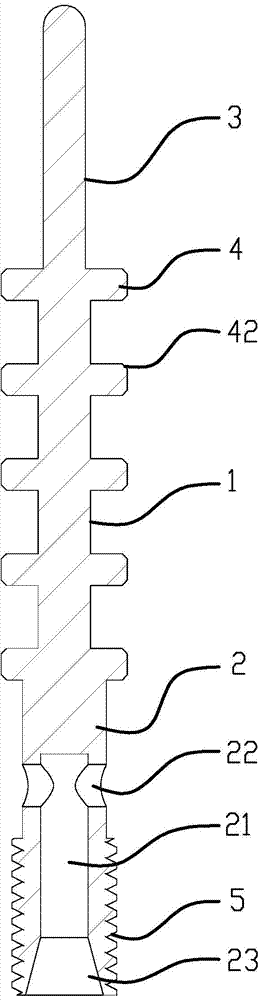

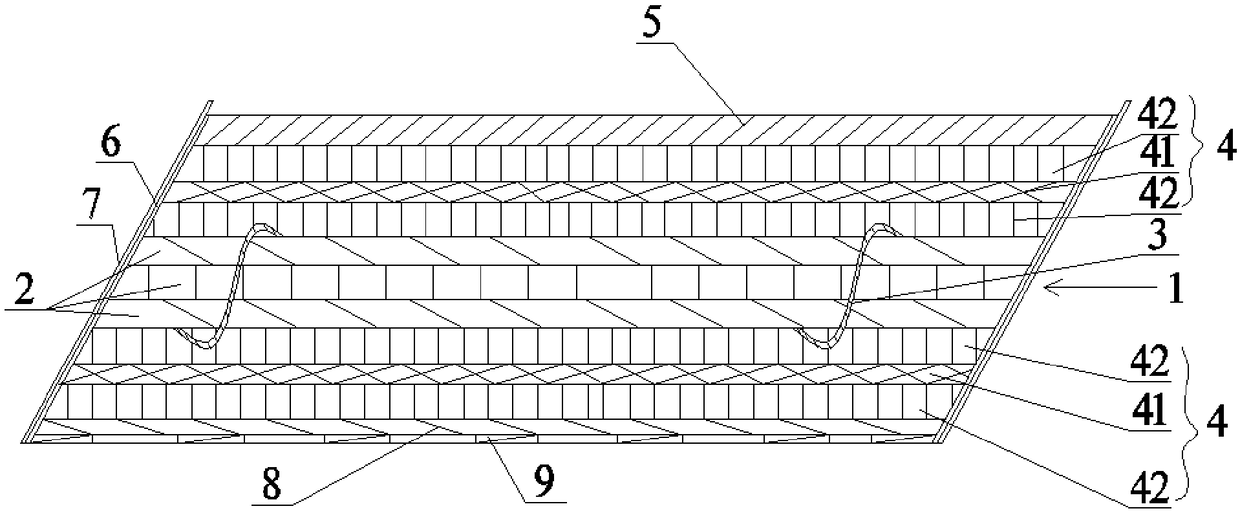

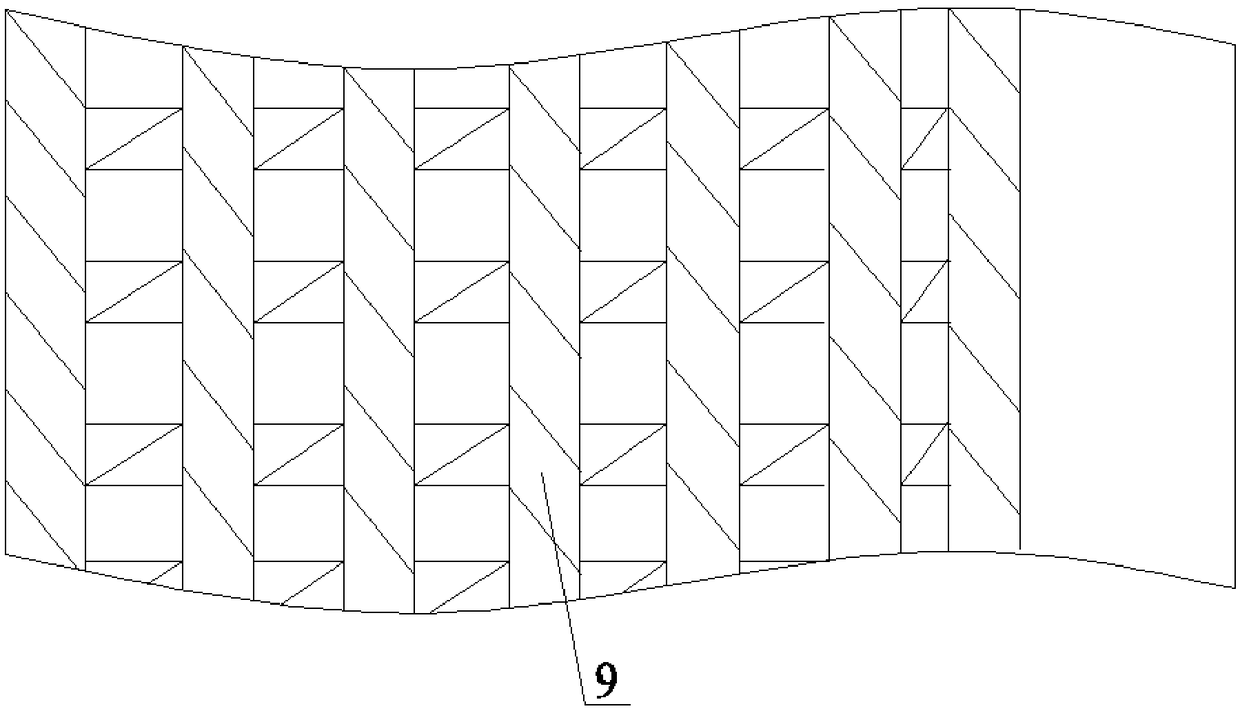

Embedded and assembled composite wall panel

ActiveCN105863158AImprove installation efficiencyHigh strengthSound proofingBuilding insulationsRelative displacementEngineering

The invention belongs to building wall panels and particularly relates to an embedded and assembled composite wall panel. According to the technical scheme, the embedded and assembled composite wall panel comprises a wall panel body and mounting clamping strips, the wall panel body is enclosed, two straight arm frames which are perpendicular to a width-direction outer frame and of the same thickness divide the wall panel body into three equal parts, the centers of the two sides of the wall panel body are vertically provided with rectangular mounting clamping grooves which are open in the upper ends and the lower ends, the sawtooth-shaped teeth are formed in three faces of the concave outer wall of each rectangular mounting clamping groove, the mounting clamping strips are provided with teeth in occlusion with the outer walls of the rectangular mounting clamping grooves, and in the splicing process, the mounting clamping strips are in embedded occlusion with the rectangular mounting clamping grooves in the two sides. The embedded and assembled composite wall panel aims to be convenient to splice and detach, relative displacement between connected wall panels and mechanical bending and turning generated at the joint of the connected wall panels are prevented, the structure is stable, and connection is firm.

Owner:浙江昱美创新建筑科技有限公司

Vacuum forming technique for sandwich structure piece of composite material of fiberglass-reinforced plastics

ActiveCN1915650BFlat surfaceNo stratificationSynthetic resin layered productsGlass fiberOptoelectronics

A composite glass fiber reinforced plastics material with sandwich structure is composed of an external layer made of glass fiber reinforced plastics and coated by water-proof resin, an internal layermade of glass fiber reinforced plastics, and a core layer with cellular structure or made of foam plastics. Its vacuum forming technology includes such steps as respectively preparing mould, externallayer, internal layer and core layer, molding, and vacuum solidifying.

Owner:上海之合玻璃钢有限公司

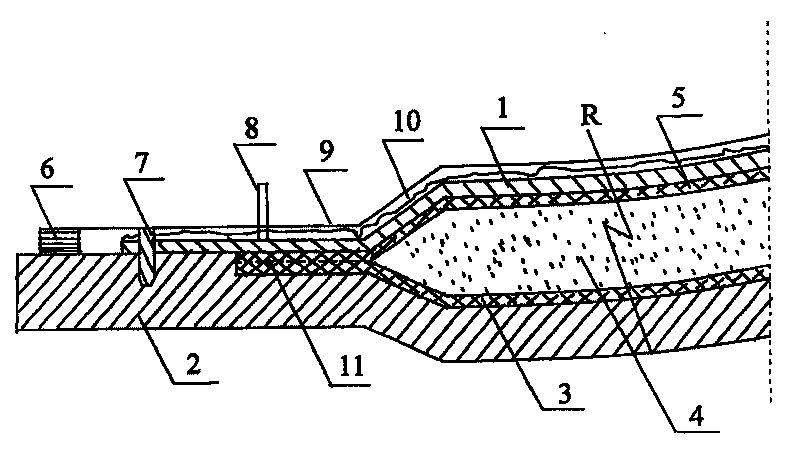

Ellipse drawing method and ellipse perimeter calculation method

InactiveCN104978473AConvenient for later construction needsConnection flatSpecial data processing applicationsEllipseCalculation methods

The invention relates to an ellipse drawing method and an ellipse perimeter calculation method, and discloses an ellipse drawing method and an ellipse perimeter calculation method which are used in architecture, machinery and interior decoration engineering. The ellipse drawing method comprises the following steps of: calculating the length of a long side of an inscribed rectangle of an ellipse; calculating the radius of a large arc; drawing the large arc; drawing the inscribed rectangle; calculating the radius of a small arc; and drawing the small arc and the like. The ellipse drawing method is simple in operation and low in engineering amount, and the requirement of ellipse drawing in fields such as engineering construction, interior decoration and the like can be met better.

Owner:马金身

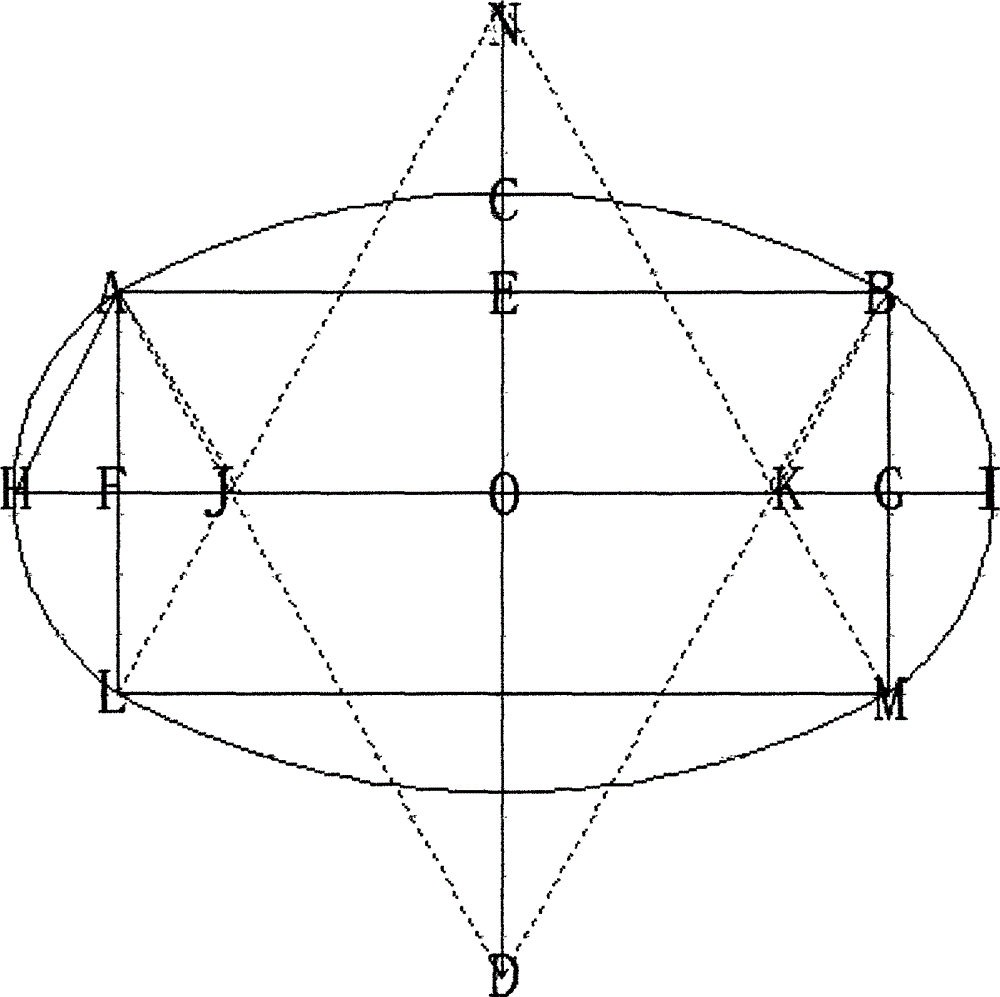

Automatic welding device for aluminum alloy longitudinal joints

InactiveCN106425184AHeating evenlyAvoid lostWelding/cutting auxillary devicesAuxillary welding devicesKey pressingHeat losses

The invention provides an automatic welding device for aluminum alloy longitudinal joints and relates to a structure of a welding lathe. The automatic welding device comprises a welding gun, a mandrel and two rows of key pressing finger assemblies, wherein each row of key pressing finger assemblies comprises a plurality of pressing fingers; an arc-shaped steel pipe is arranged on the upper surface of the mandrel, an electric heating pipe penetrates through the arc-shaped steel pipe, the upper surface of the arc-shaped steel pipe is connected with a liner, and the liner is arranged below a workpiece longitudinal joint; the length direction of the arc-shaped steel pipe, the length direction of the electric heating pipe and the length direction of the liner are all consistent with the length direction of the workpiece longitudinal joint; and a heat insulating plate is connected below each pressing finger, and the heat insulating plates are arranged on the outer surface of a workpiece for insulating heat. By adopting the mandrel electric heating, key pressing finger and product surface heat insulating mode, heat losses caused by heat conduction in a welding process are minimized, heat is used for fully melting aluminum materials in a concentrated manner, the cooling and condensation of a welding pool are prolonged, and oxides and gas in the pool fully overflow, so that high-quality weld joints are obtained, and the welding efficiency is increased.

Owner:JIANGSU JINXIN ELECTRIC CO LTD

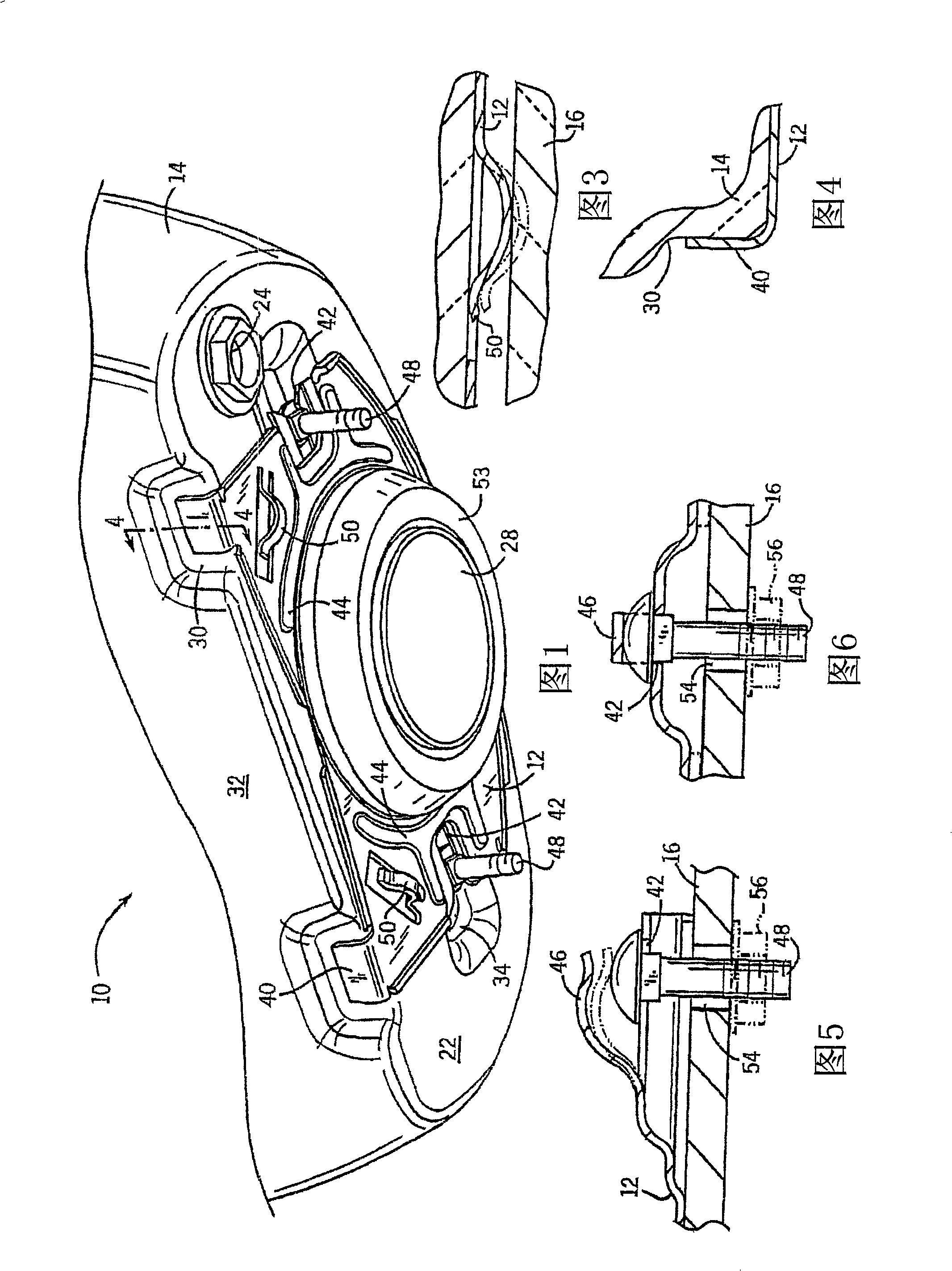

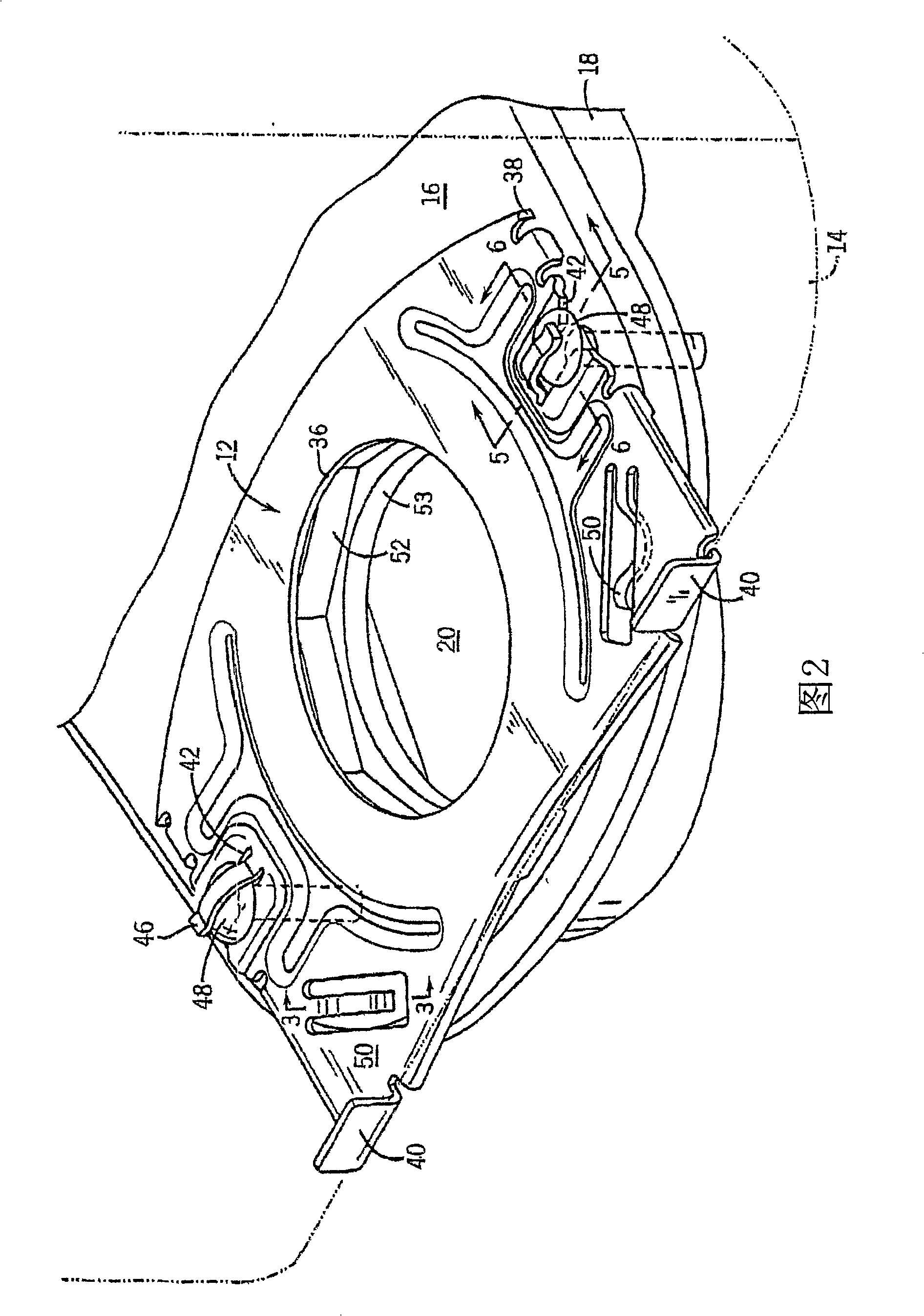

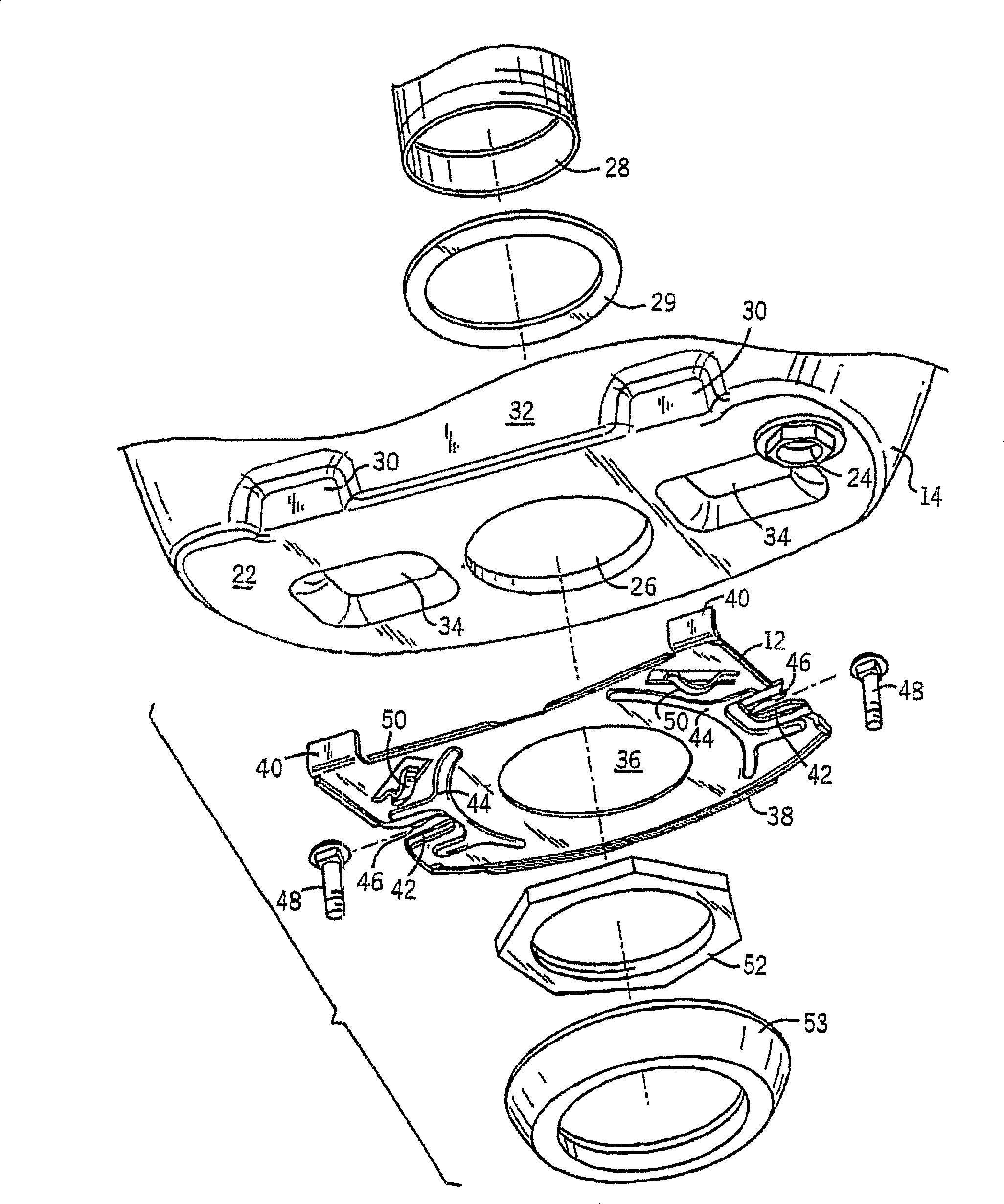

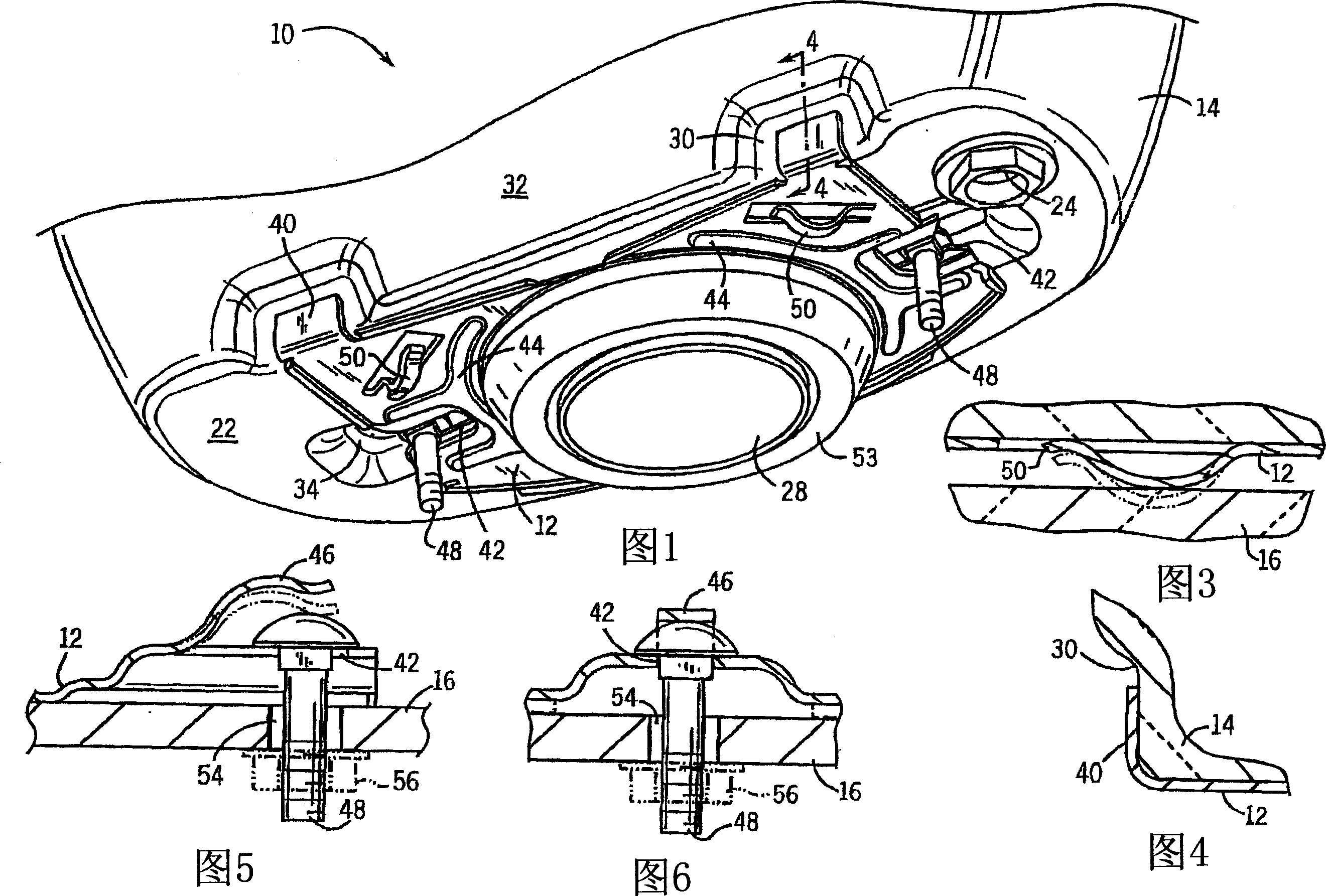

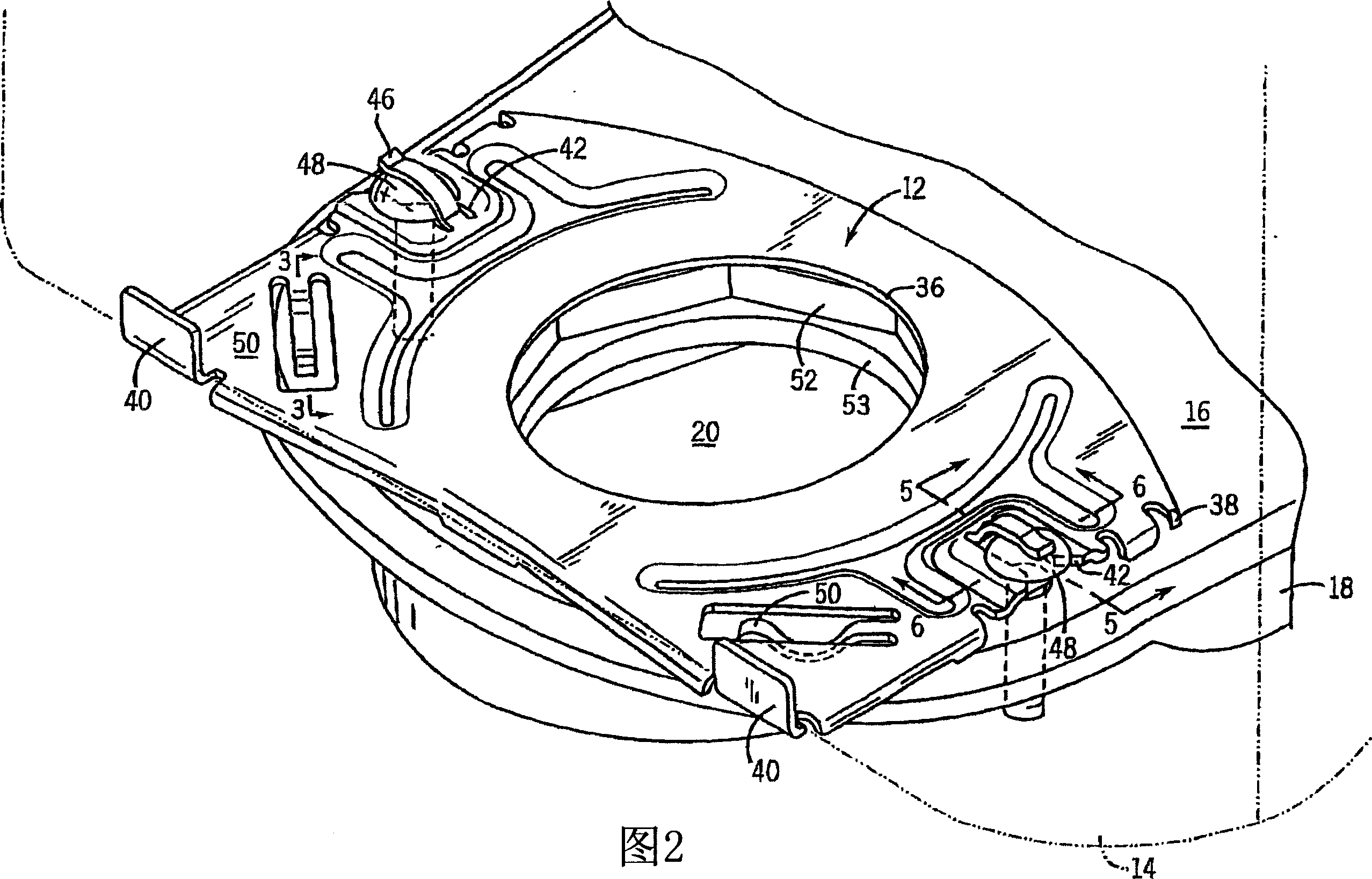

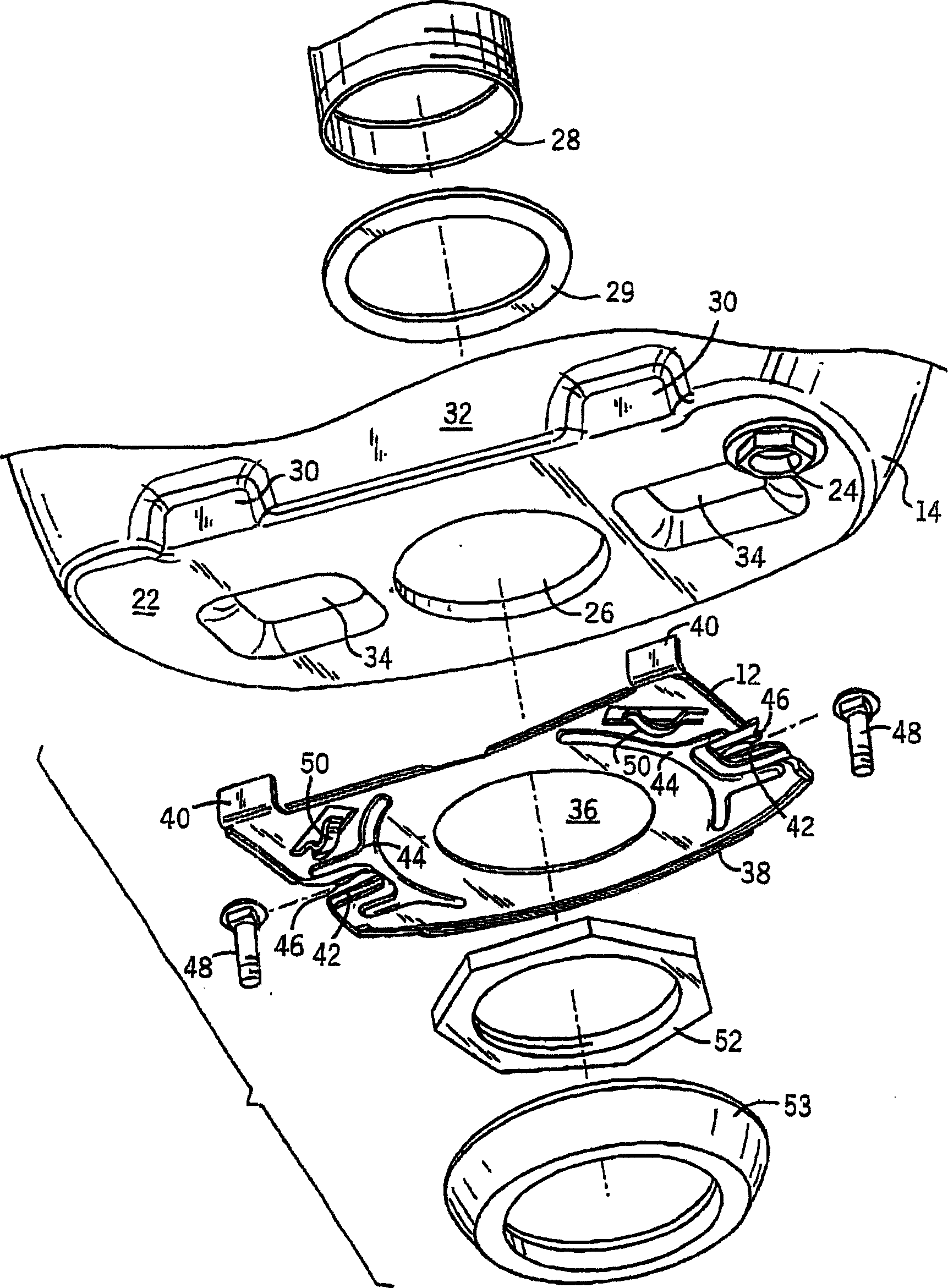

Toilet tank attachment bracket with unitary spring arm

ActiveCN100419174CConnection flatConnect for a professional lookFlushing devicesEngineeringMechanical engineering

Owner:KOHLER CO

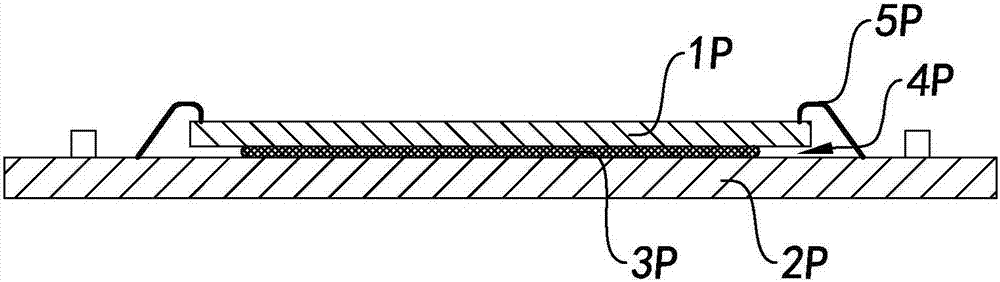

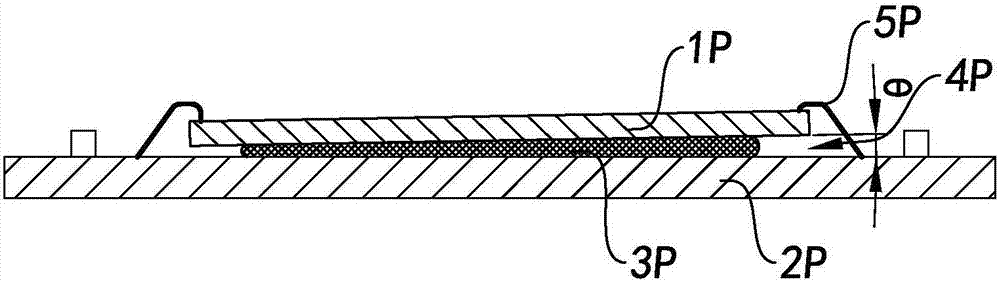

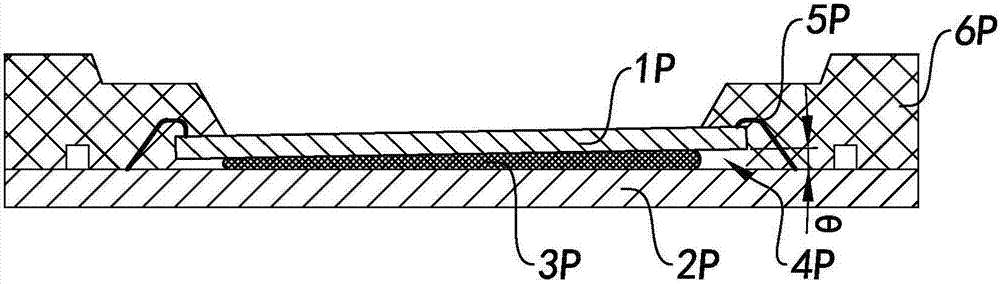

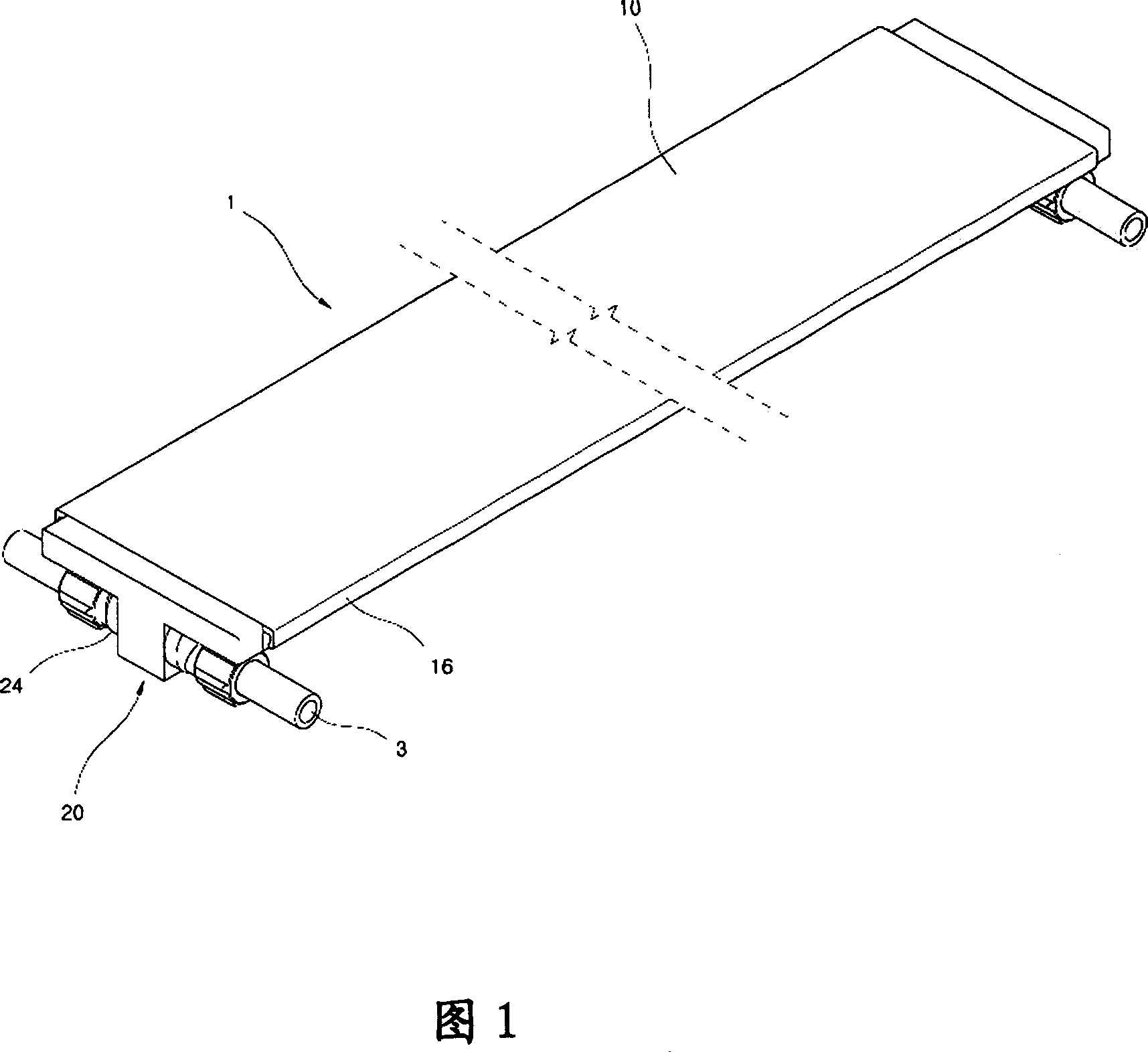

Photosensitive assembly, shooting module group and manufacture method thereof

ActiveCN107516651AConnection flatTelevision system detailsSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

Disclosed are a photosensitive assembly, a shooting module group and a manufacture method thereof. The photosensitive assembly comprises a circuit board body, a photosensitive chip and a connection medium, wherein the photosensitive chip is attached to the circuit board body through the connection medium, and the connection medium and the photosensitive chip are matched with each other in shape, so that the photosensitive chip is flatly connected to the circuit board body.

Owner:NINGBO SUNNY OPOTECH CO LTD

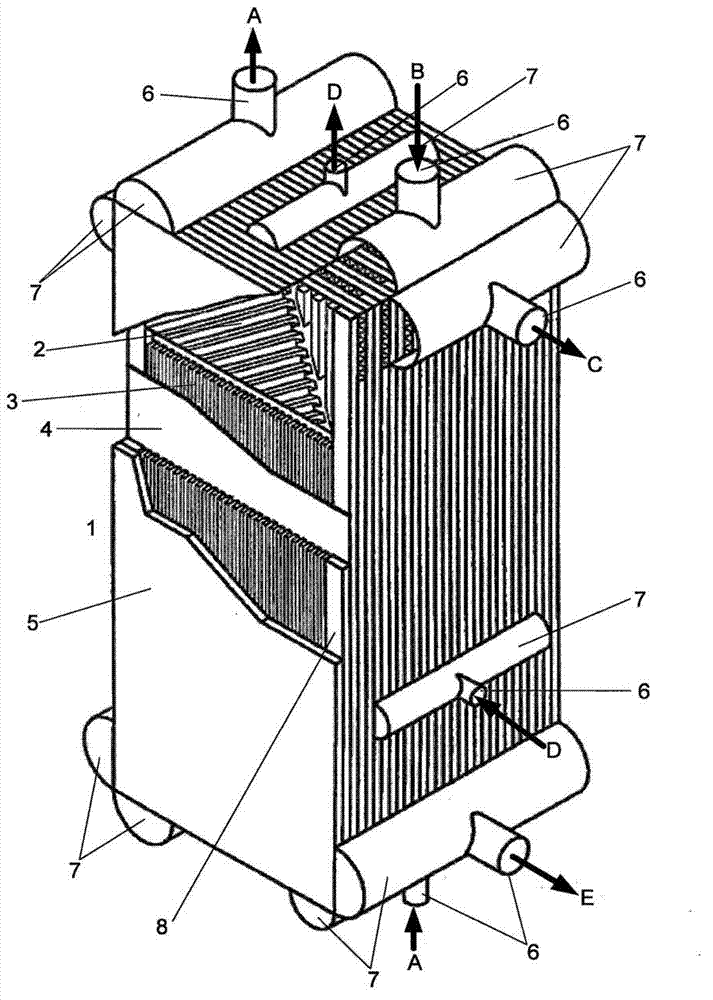

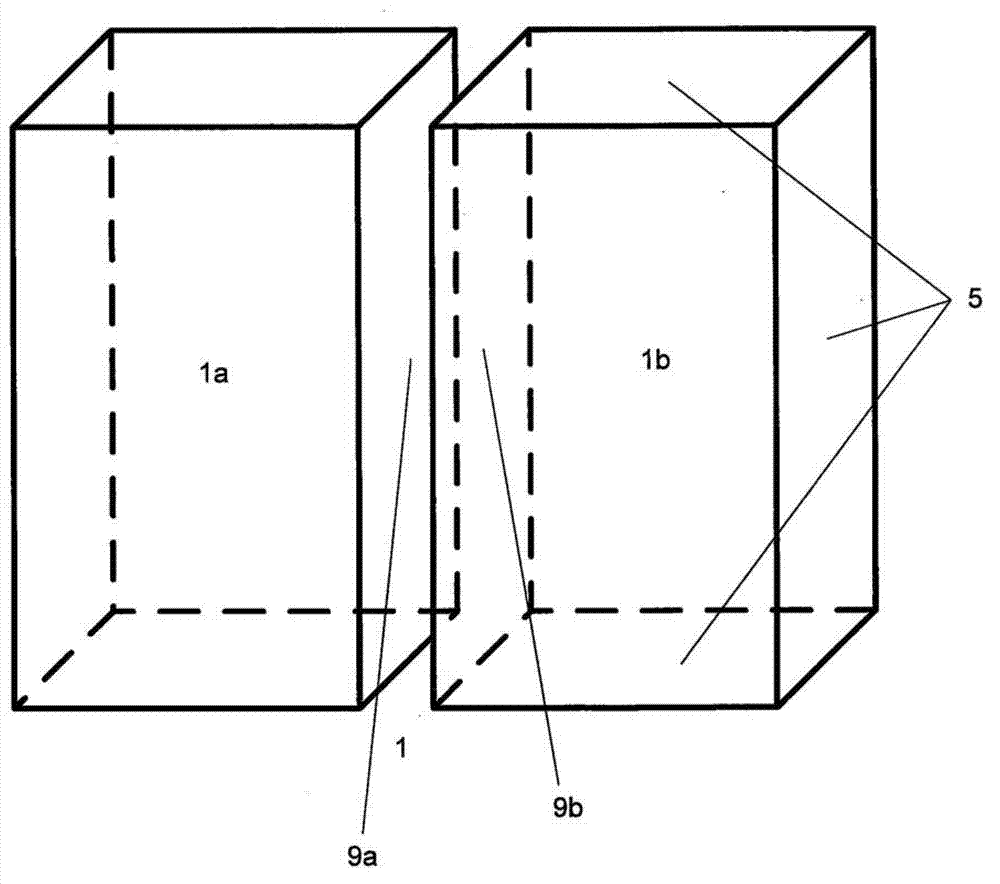

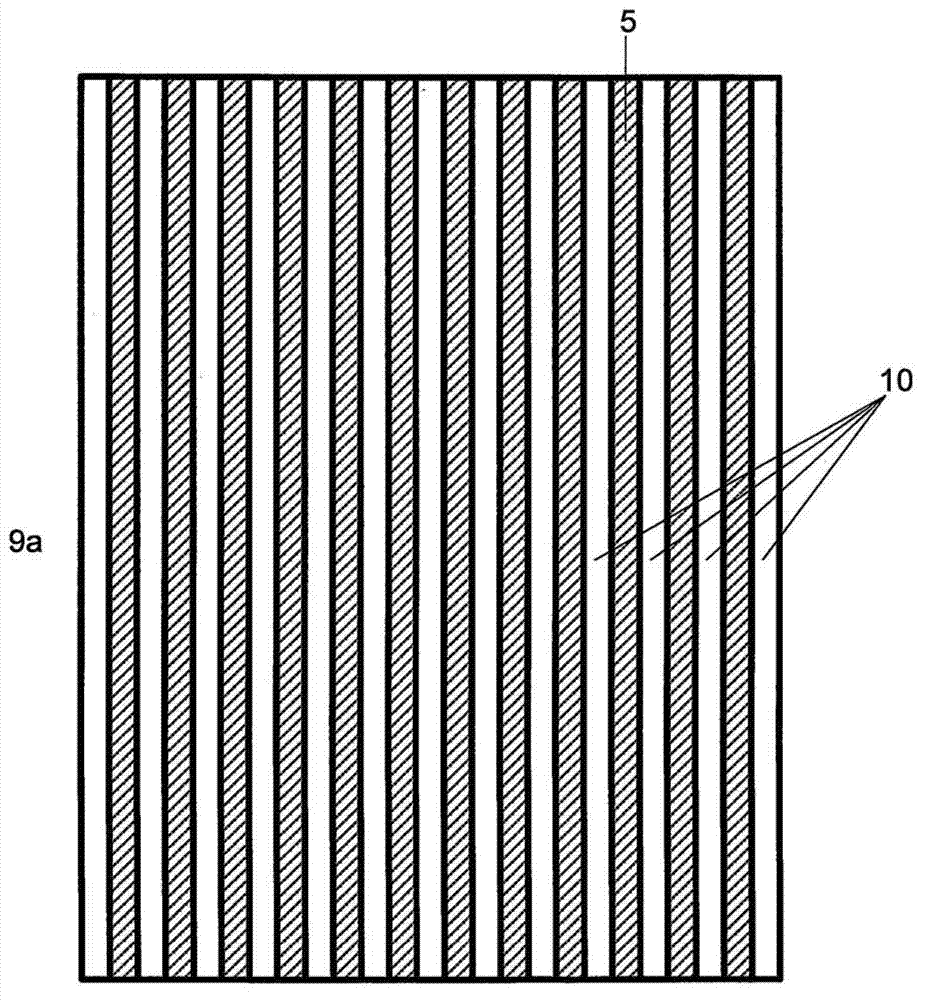

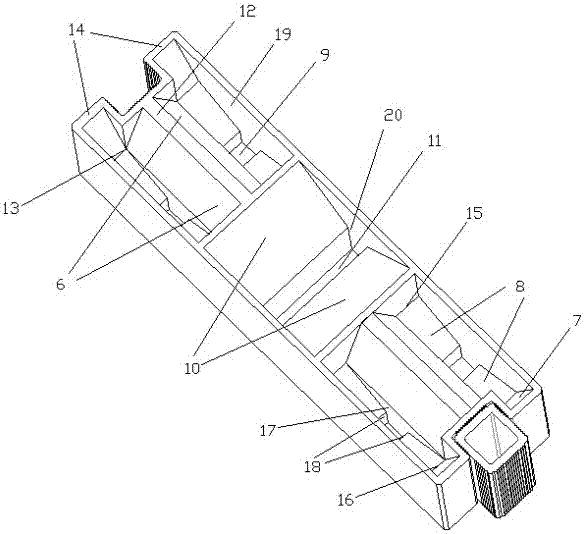

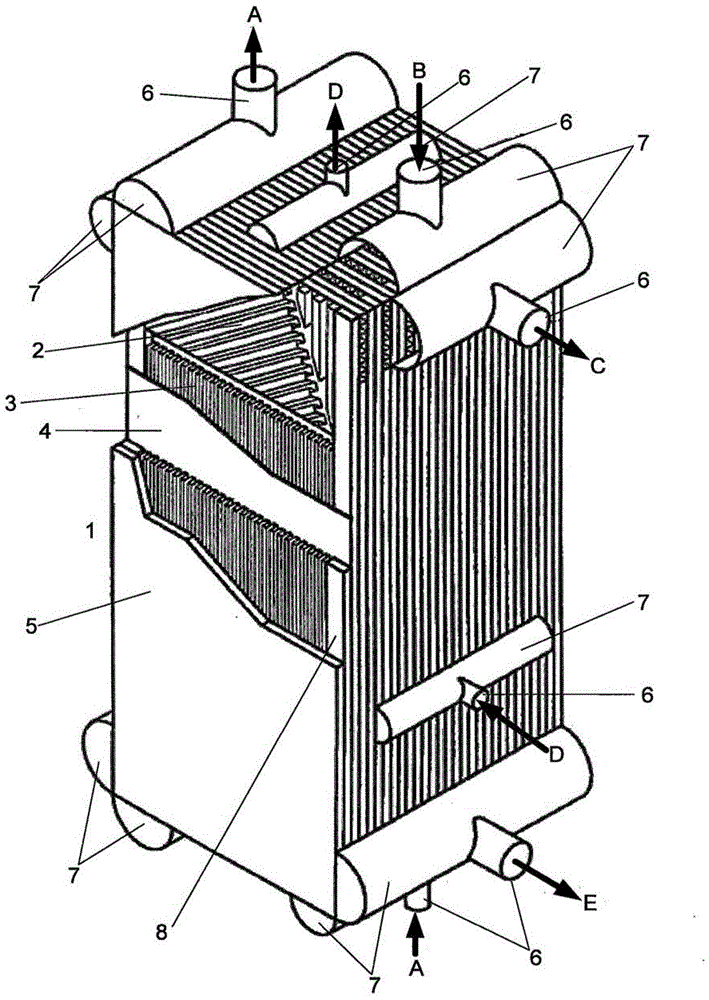

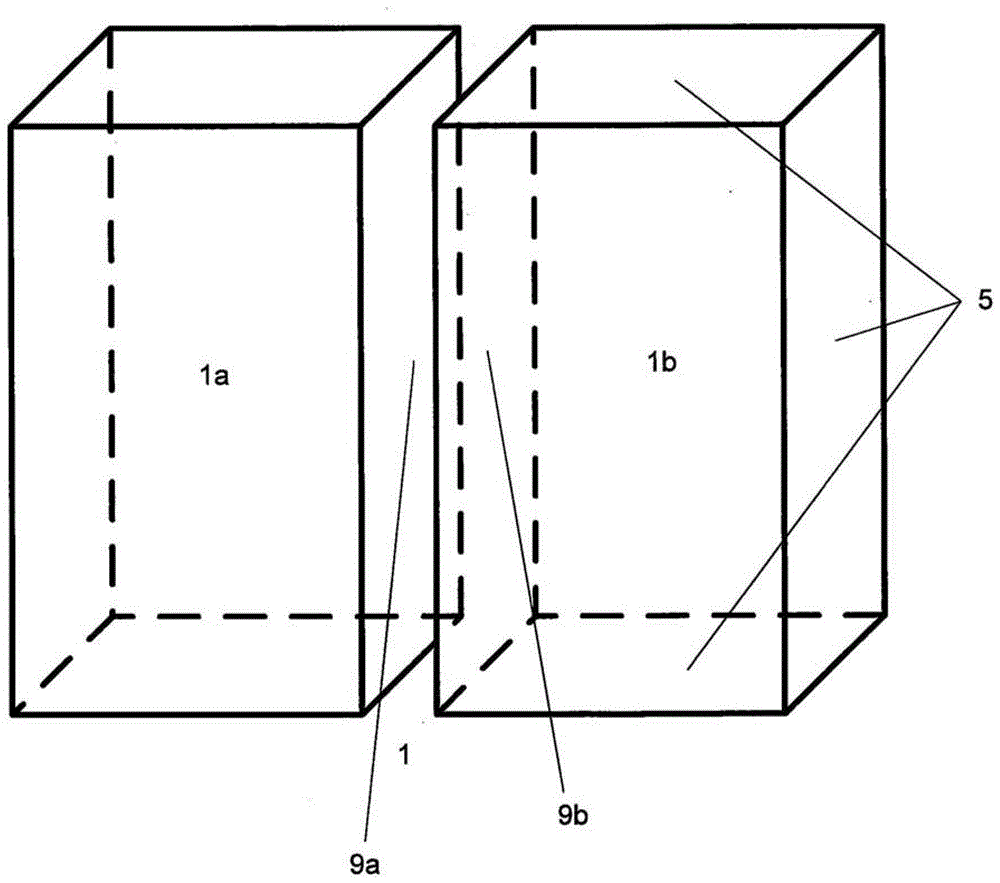

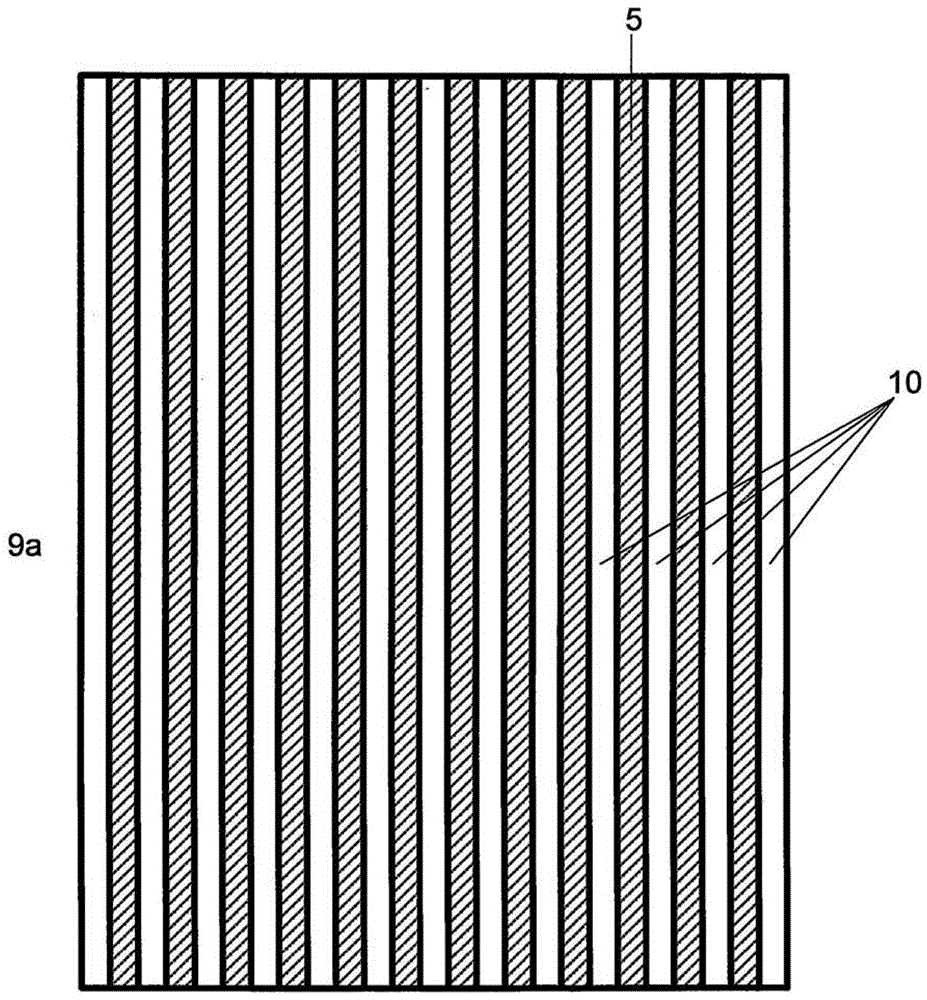

Plate heat exchanger with several modules connected by sheet-metal strips

ActiveCN103363824AIncreased durabilityConnection flatSolidificationLiquefactionMetal stripsPlate heat exchanger

The invention describes a plate heat exchanger 1 comprising two modules 1a and 1b. The two modules 1a and 1b are cuboidal and in each case are closed off to the outside by cover sheets 5. The two modules 1a and 1b are arranged such that cover sheets 9a and 9b of the same size are directly adjacent. The two cover sheets 9a and 9b form the contact surface between the two modules 1a and 1b of the plate heat exchanger 1. The two contact surfaces 9a and 9b are joined to one another via a suitable adhesive.

Owner:LINDE AG

A hot water circulation floor for heating using a flooring board

InactiveCN101113629AReduce thicknessHigh heating thermal efficiencyCovering/liningsLighting and heating apparatusEngineeringWater circulation

The present invention relates to a terrestrial heat hot-water circulating floor, including: a floor strip, which is composed of an upper board exposing outside and a lower board contacting the ground. A flow path through which the hot water can pass locates in the floor strip, as well as a plurality of vertical clapboards which support the upper board and the lower board with length direction and divide the flow path into multiple layers; a two-way flow path, which size is equal to that of the forming surface of the floor strip flow path, and is used for supplying flow path hot water; a cover, which is composed of connecting tubes connected by the two-way flow paths for supplying hot water; the two lateral surfaces of the floor strip is closed by the cover, then to assemble one by one, so as to form hot water circulating floor. By means of the structure, preventing hot water from effusing, improving hot efficiency when supplying heat and reducing fuel cost and floor thickness with the mode of flow path circulating hot water.

Owner:李金顺

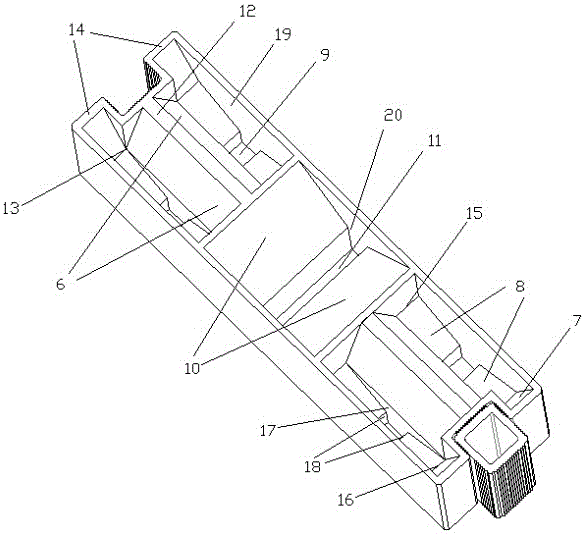

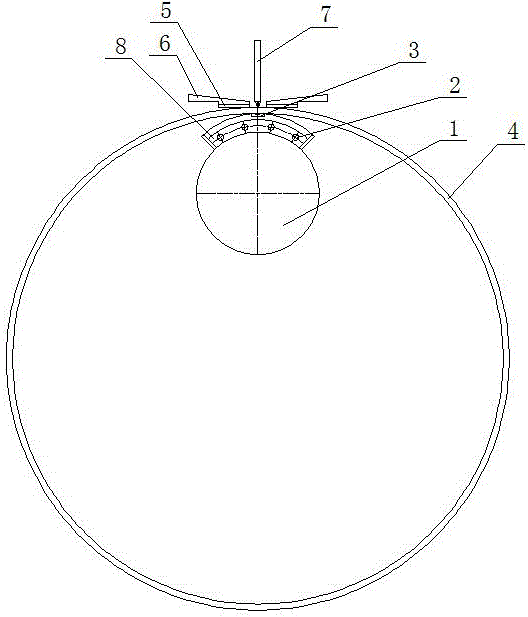

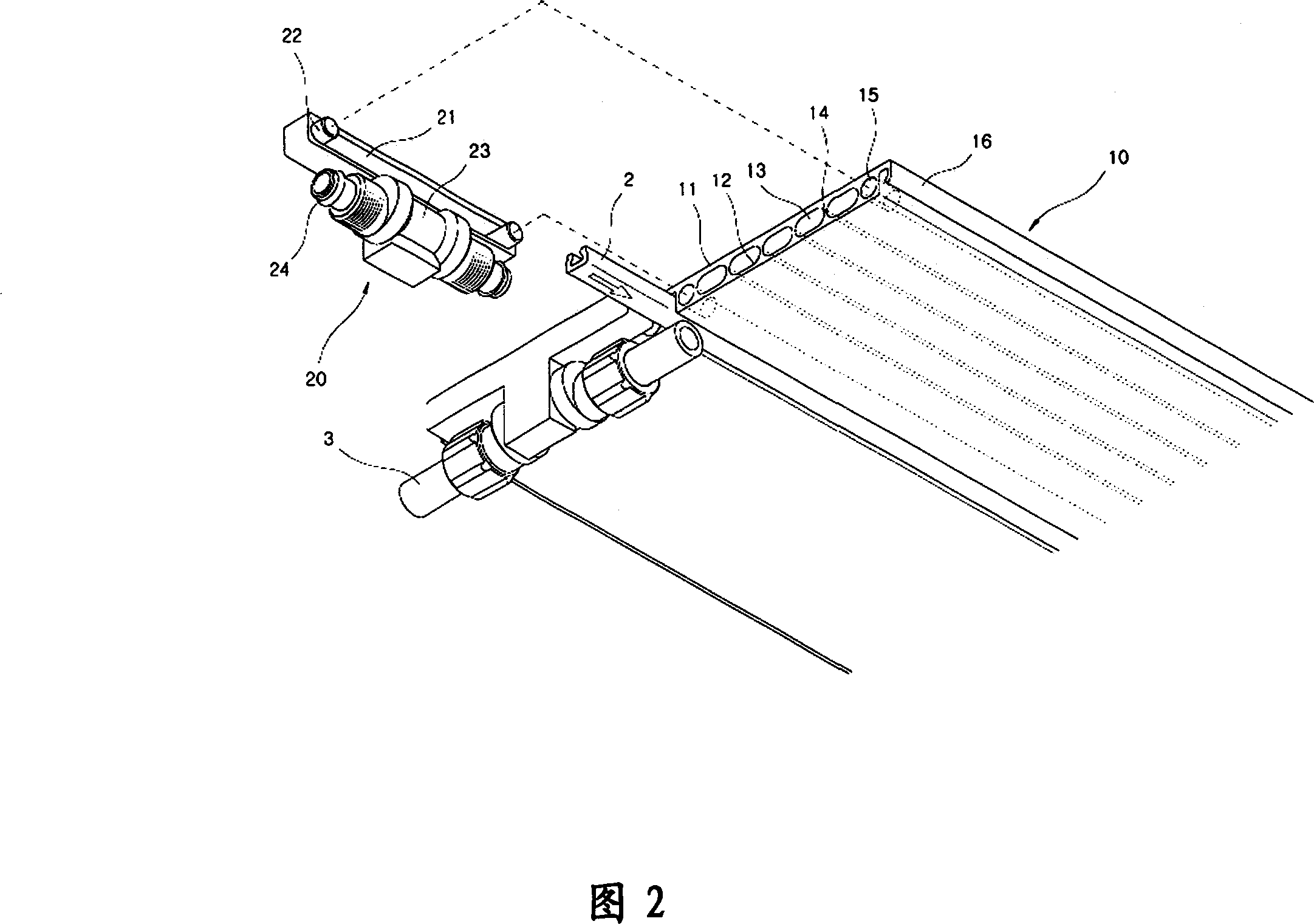

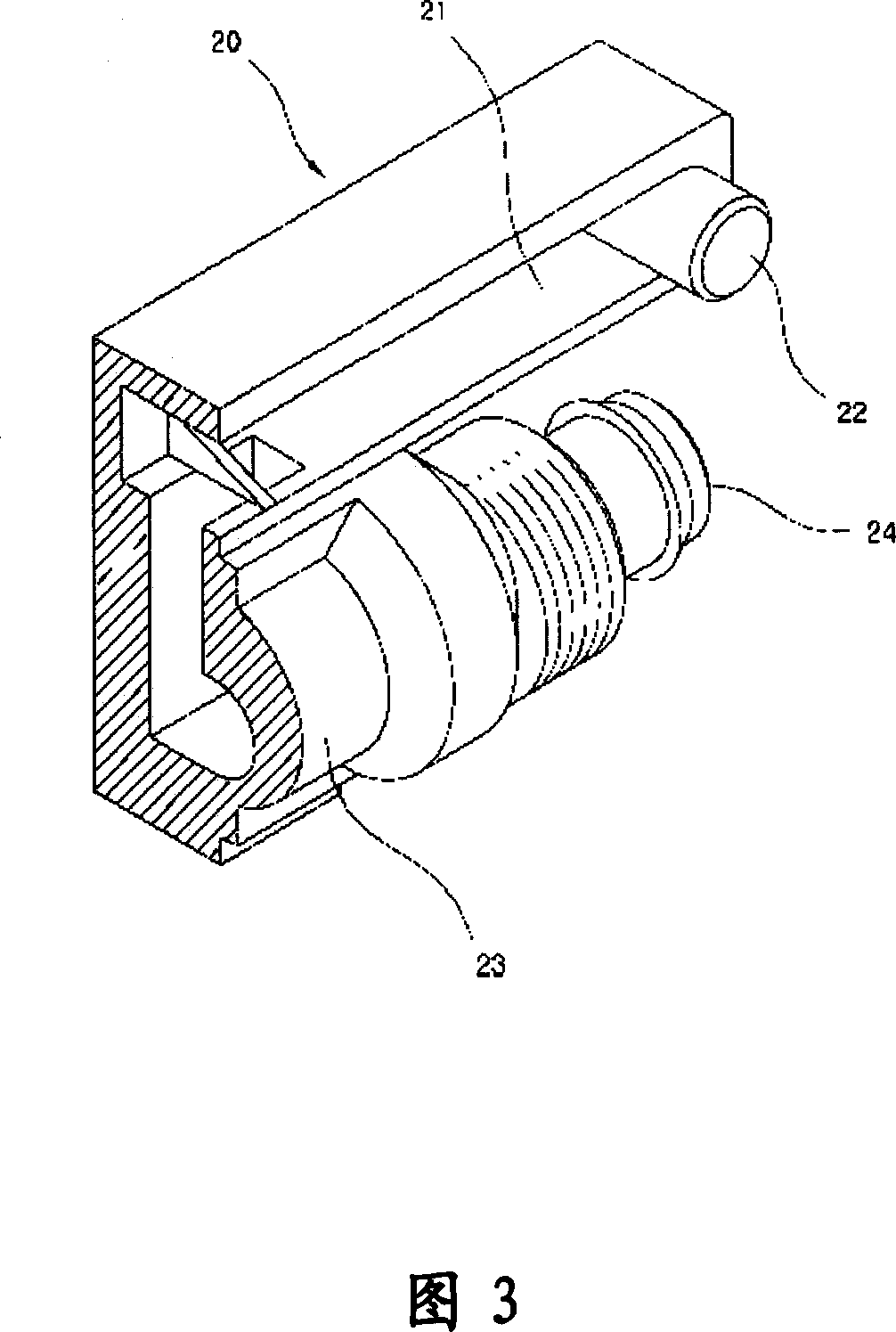

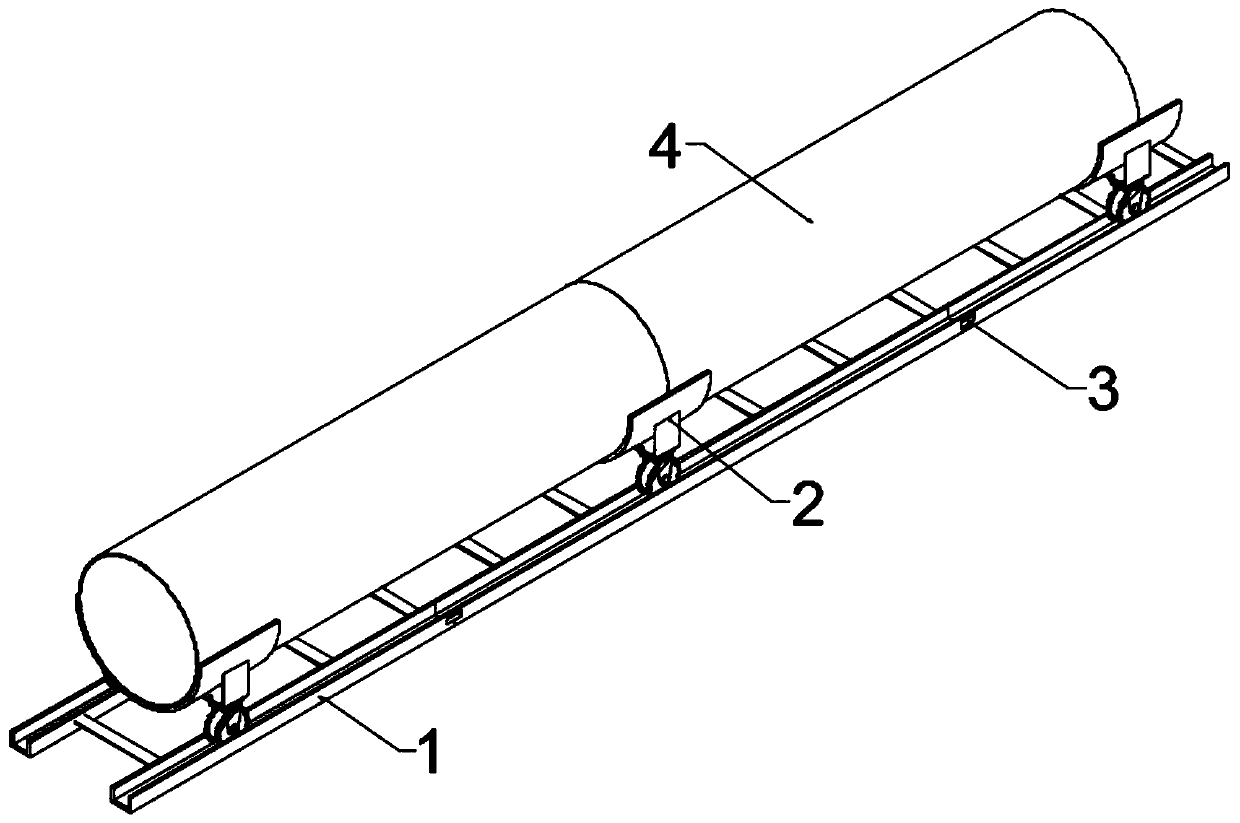

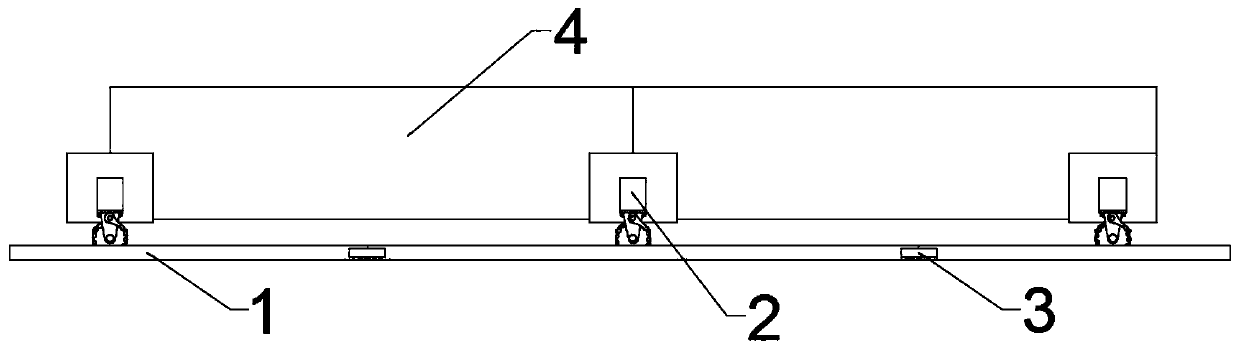

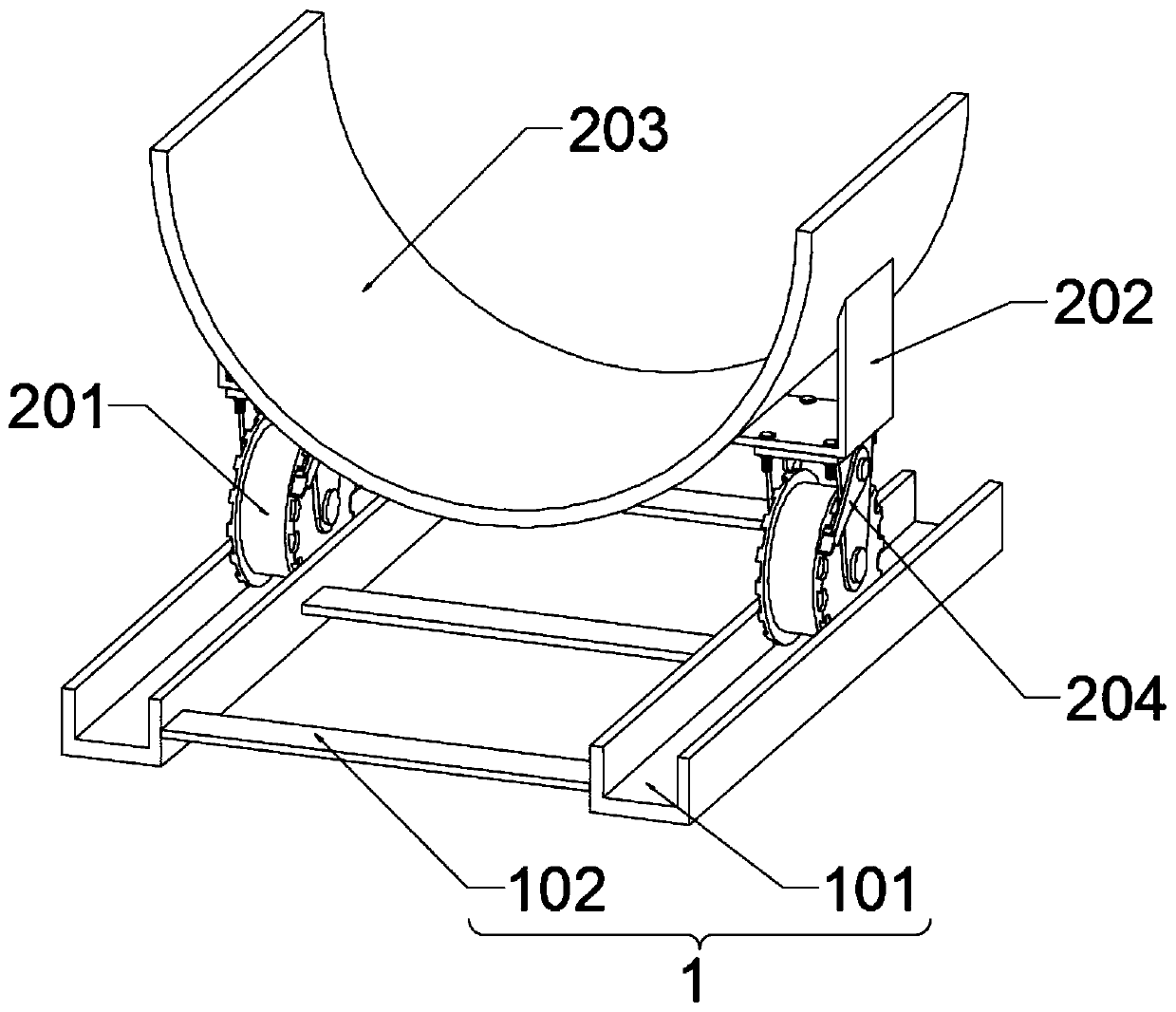

Multifunctional connecting device for tunnel escape pipeline

PendingCN110259505AEasy to moveShorten the construction scheduleSafety equipmentsRailway tunnelFunctional connectivity

The invention relates to the technical field of highway and railway tunnel safety construction, and discloses a multifunctional connection device for a tunnel escape pipeline, whichcomprises a track assembly, the track assembly is provided with a matching mobile connection assembly, the mobile connection assembly is provided with a parking part,the mobile connection assembly comprises moving parts matched with the track assembly, each of the two or more moving parts is detachably connected with a supporting part, and the supporting part is provided with a pipeline connecting part; and the pipeline connecting part is provided with an escape pipeline unit section, a pipeline connection part is of an arc-shaped structure, and the escape pipeline unit section is a circular pipe and exactly arranged in the pipeline connecting part. The device is to solve the problem of the advancing movement of the escape pipe inside the tunnel, and the connection problem between the escape pipeline unit sections is also solved, thus laying and moving of the escape pipeline are easy and quick, and the tunnel construction efficiency is greatly improved.

Owner:杭州中筑交通科技有限公司

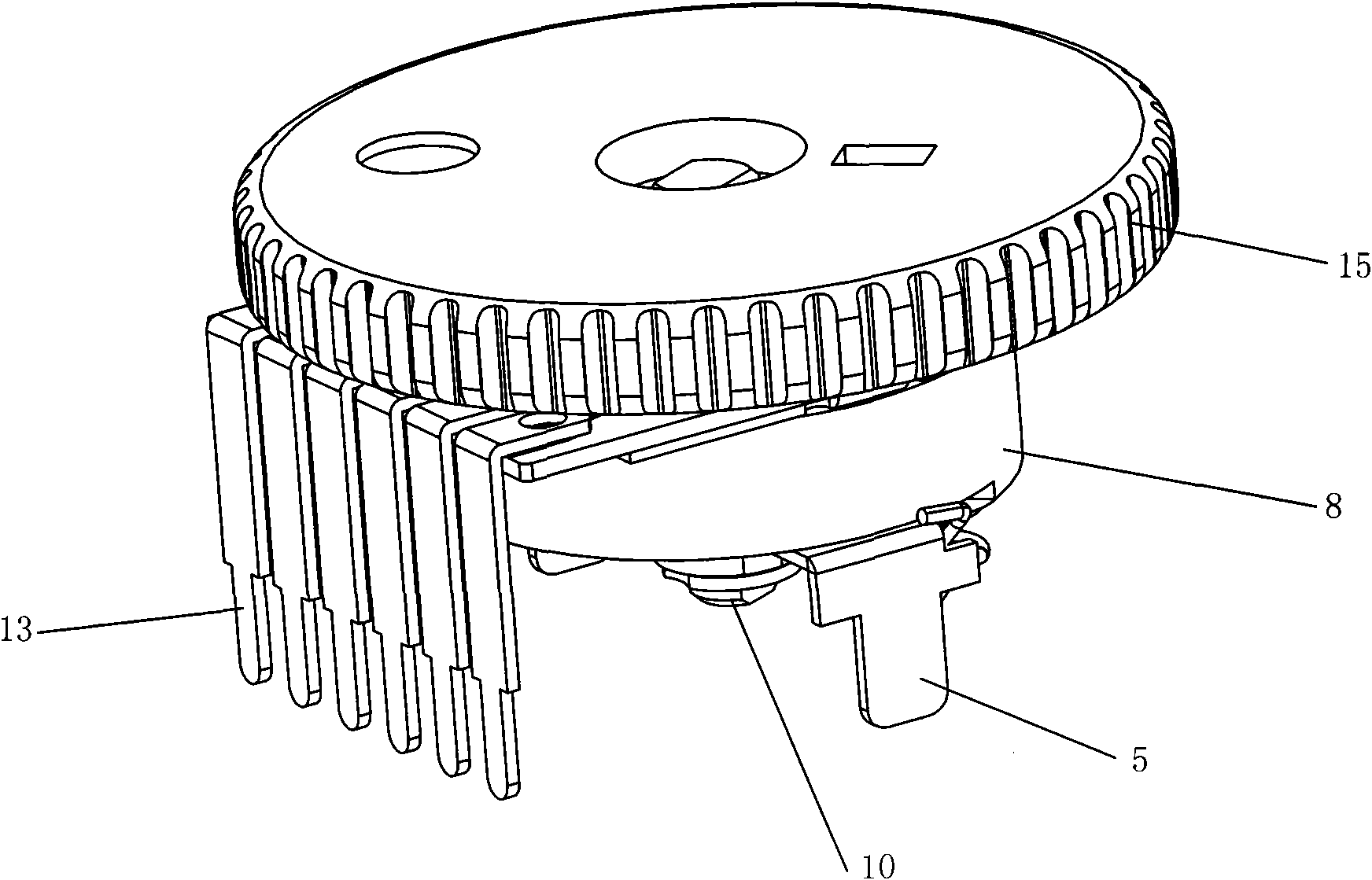

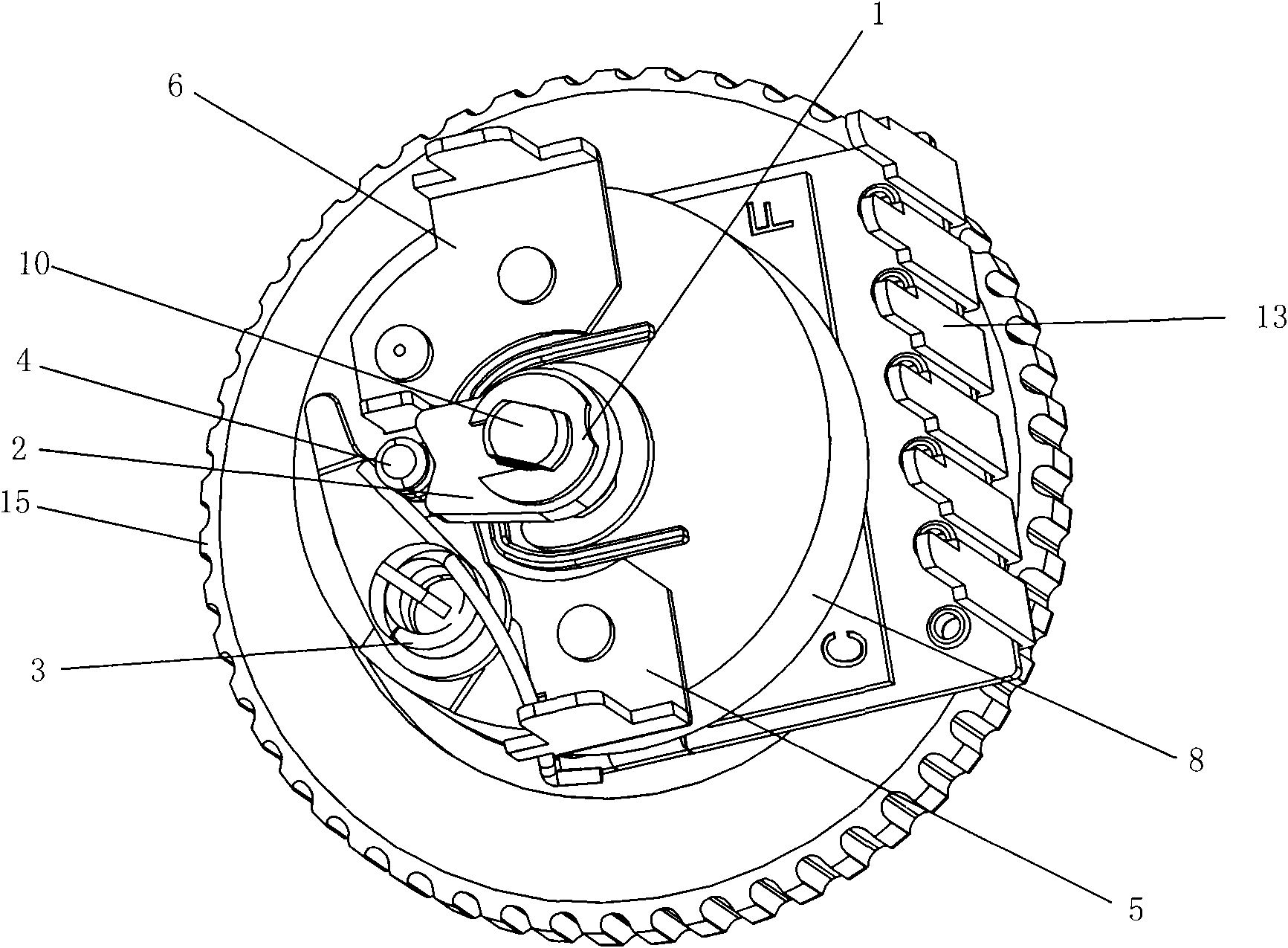

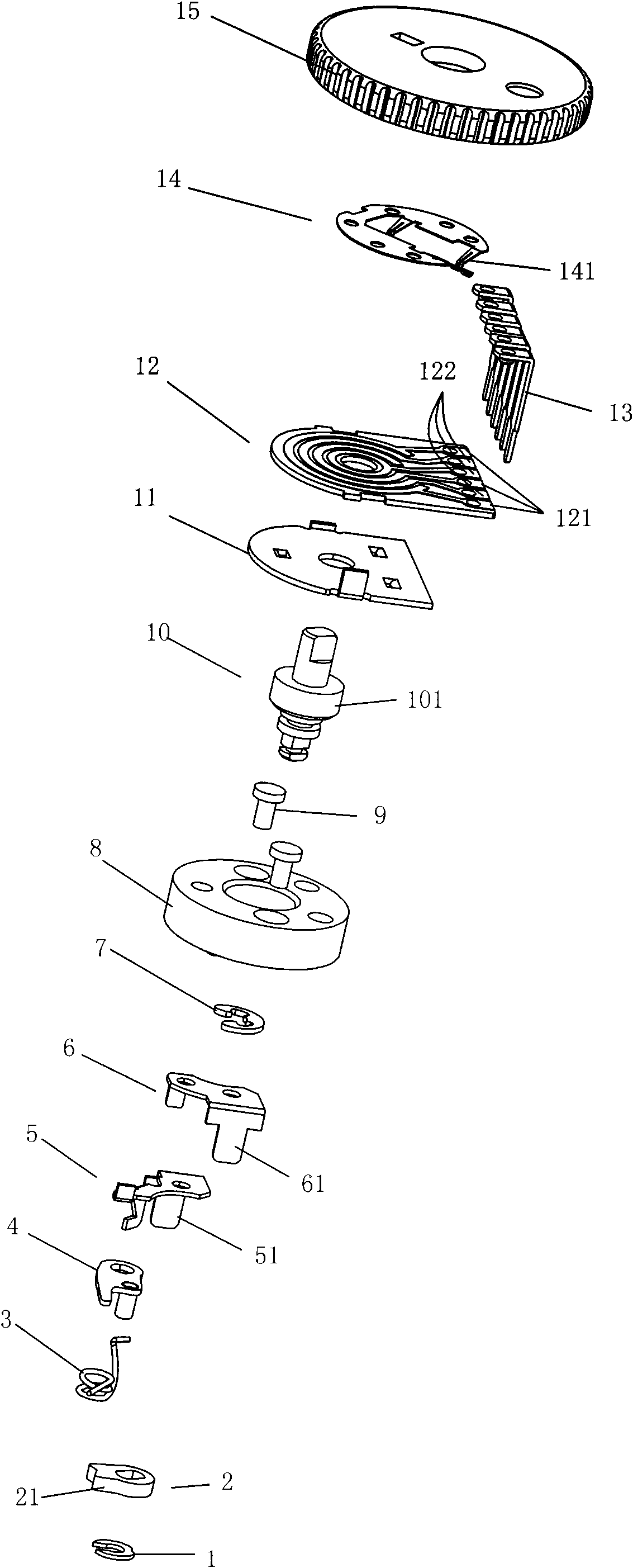

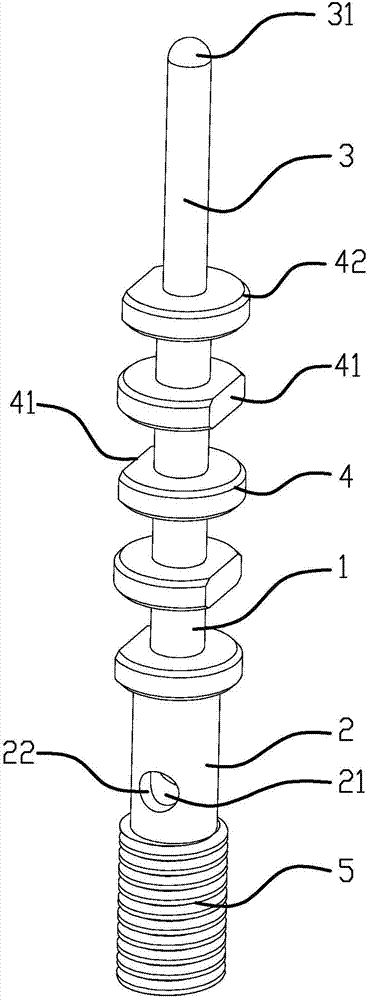

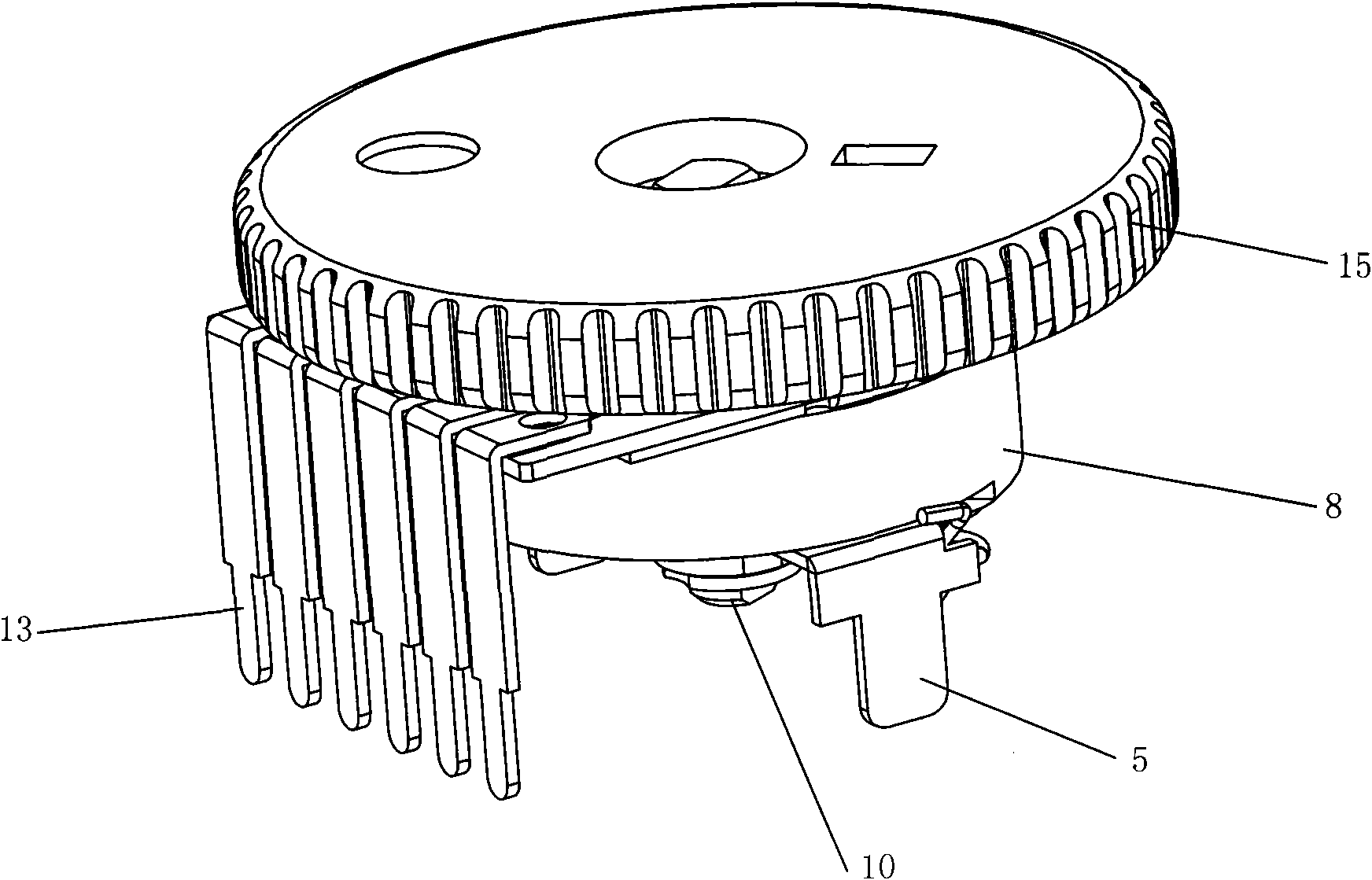

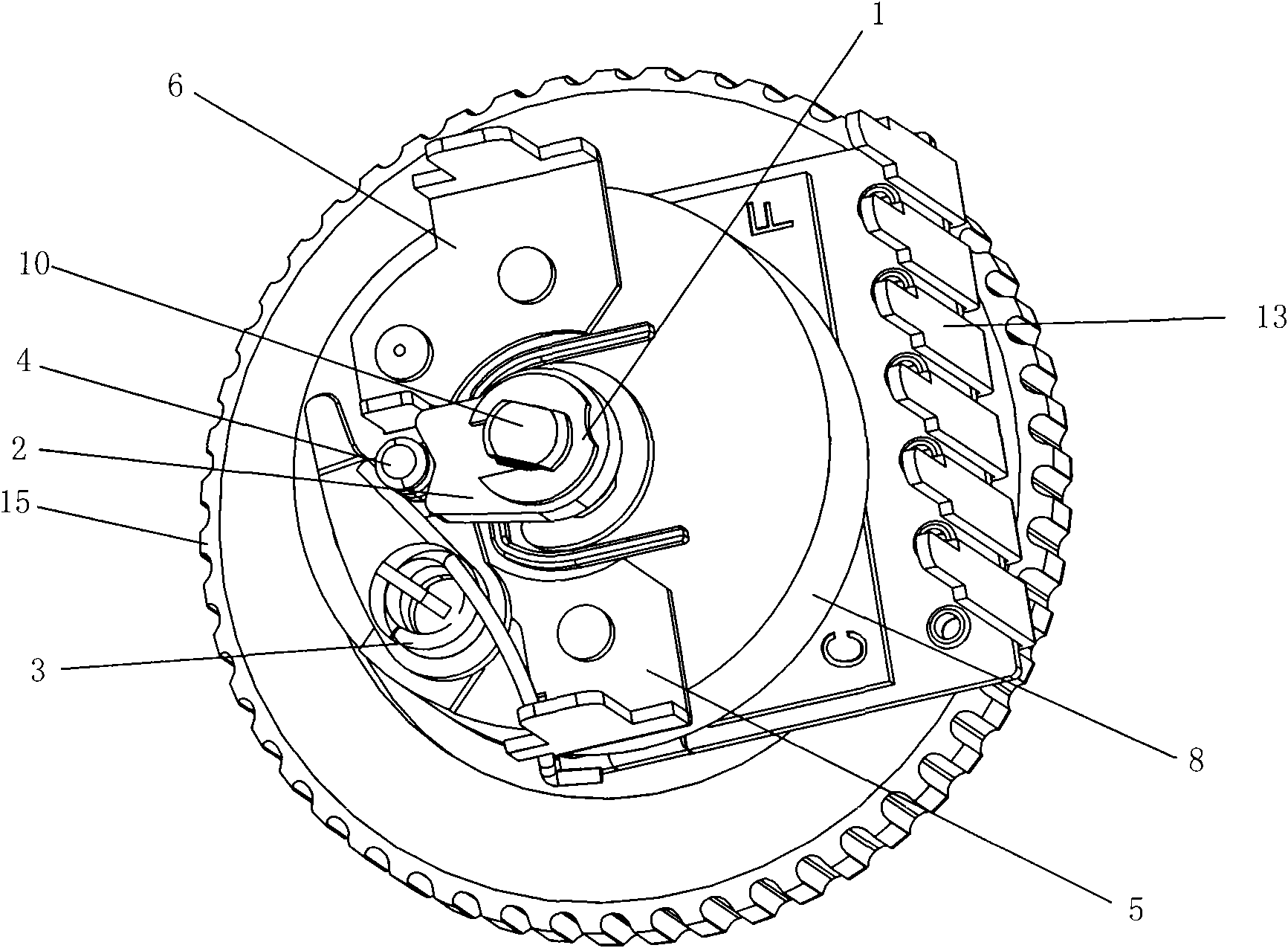

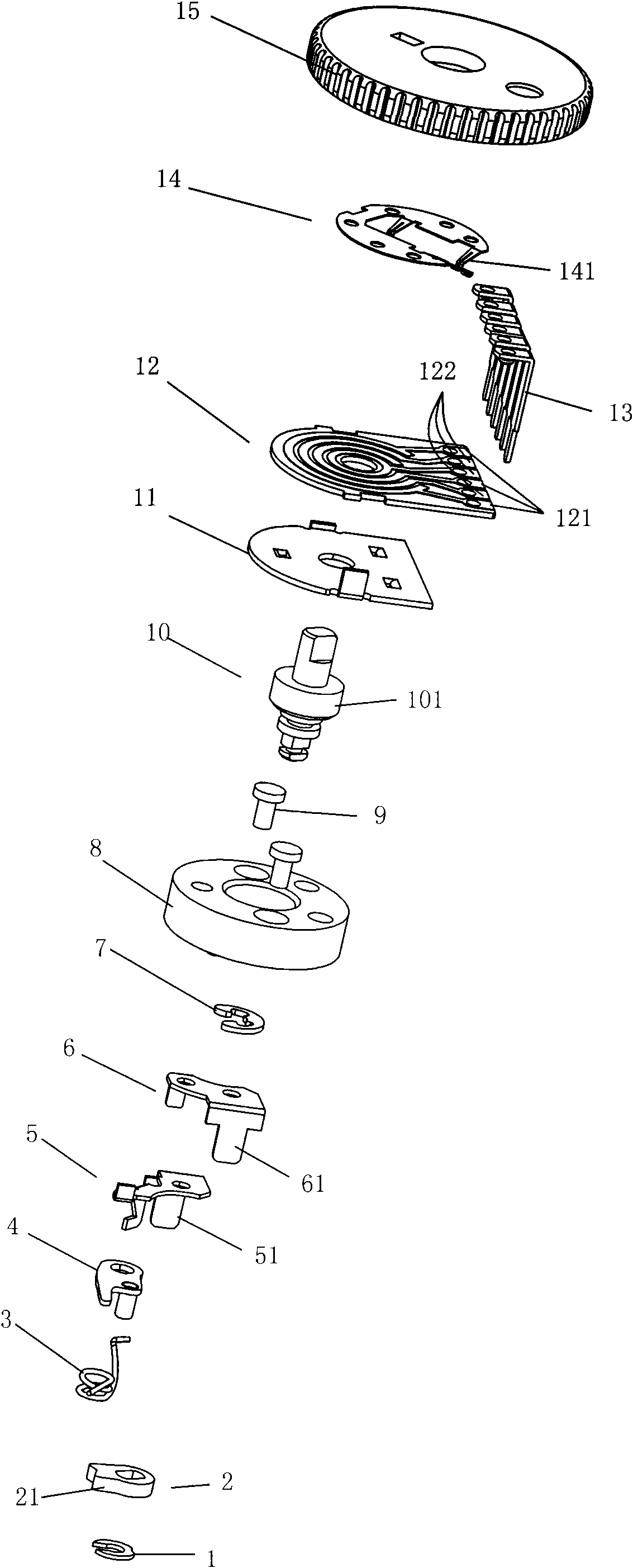

Thin dual-channel potentiometer with switch

InactiveCN101807462AIncreasing the thicknessImprove performanceResisitors with sliding contactElectrical stabilityElectrical and Electronics engineering

The invention discloses a thin dual-channel potentiometer with a switch, relating to potentiometer and comprises a potentiometer unit and a switch unit. The potentiometer unit comprises a knob, a folding mover, a terminal, a resistor chip, a support board, a shaft, a body and a clamp ring; the switch unit comprises a left switch end piece, a right switch end piece, a switching piece, a spring, a convex plate and a clamp piece; the folding mover is provided with two brushes and a mechanical switch, thereby realizing the integration of dual channel and the mechanical switch and the integration of thin type, dual channel and the mechanical switch; and the upper end of the shaft is riveted and fastened with the knob. A user installs the potentiometer on a circuit board without screwing the knob with the shaft end by using screws, thereby reducing the installation procedures and saving the installation time. The support board is attached to and in clamping connection with a circuit piece, and the body is attached to and in clamping connection with the support board, thereby orderly connecting the body, the support board and the circuit piece into a whole. The thin dual-channel potentiometer with the switch has small shaking during rotating, high electric stability, long service life which is twice that of the current product and wide application range.

Owner:东莞市庆恒电子有限公司

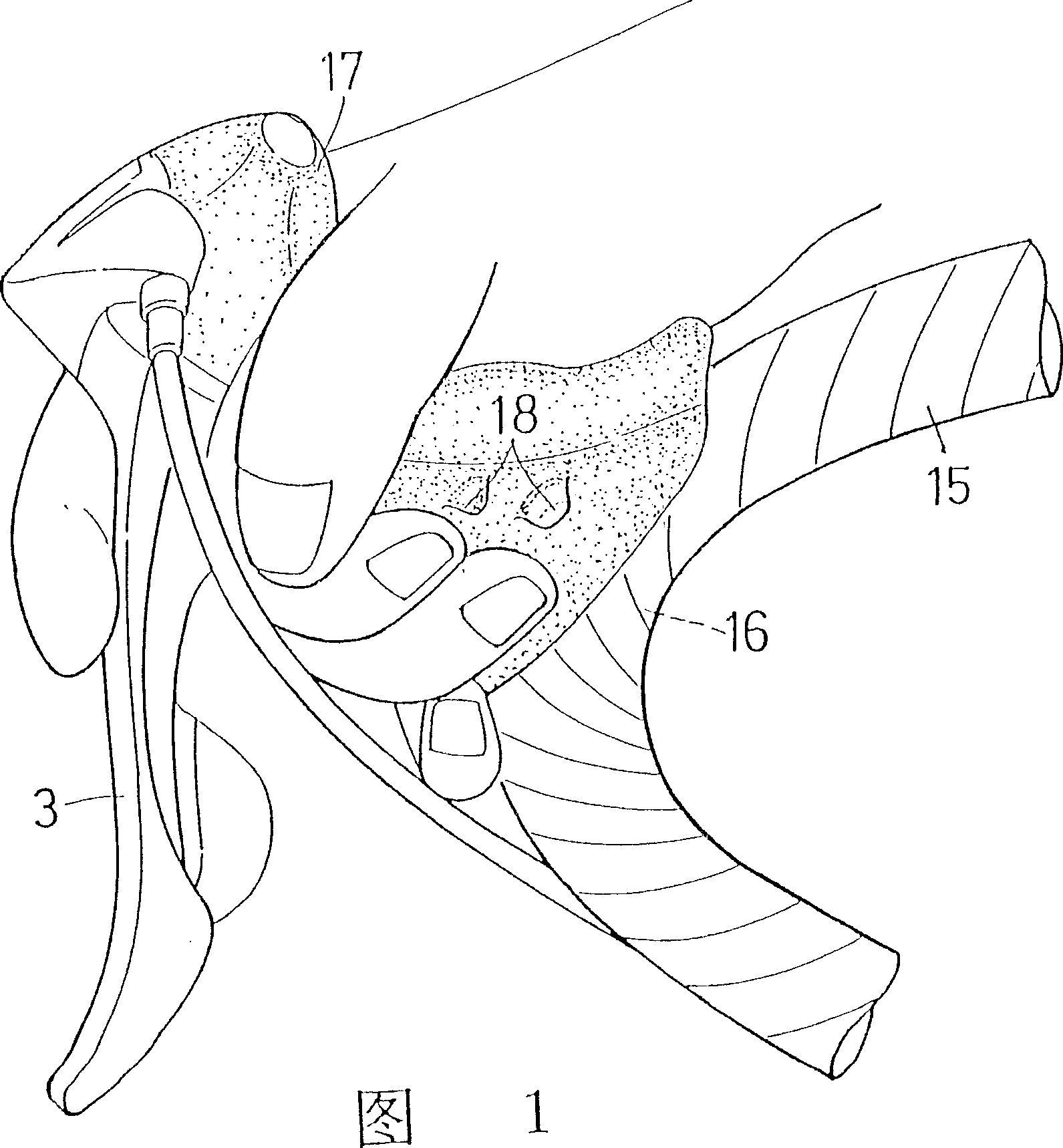

Toilet tank attachment bracket with unitary spring arm

ActiveCN1738950AConnection flatConnect for a professional lookWater closetsFlushing devicesEngineeringMechanical engineering

An attachment system for mounting a flush tank to a toilet bowl includes a bracket disposed between the tank and the bowl. The bracket has a generally planar body defining a central opening receiving a tubular flush extension extending from the tank into an opening in a bowl extension. The bracket is fastened to the tank by a large nut threaded to the tank extension. The bracket is mounted to the bowl at two slots opening at opposite side edges of the bracket by two bolts disposed through openings in the bowl extension. The bracket has a unitary pair of upwardly extending spring arms contacting the bottom wall of the flush tank and a unitary pair of lower spring arms contacting the bowl extension. The spring arms are deflectable between the flush tank and the toilet bowl to accommodate for warping or mold variations between the tank and the bowl.

Owner:KOHLER CO

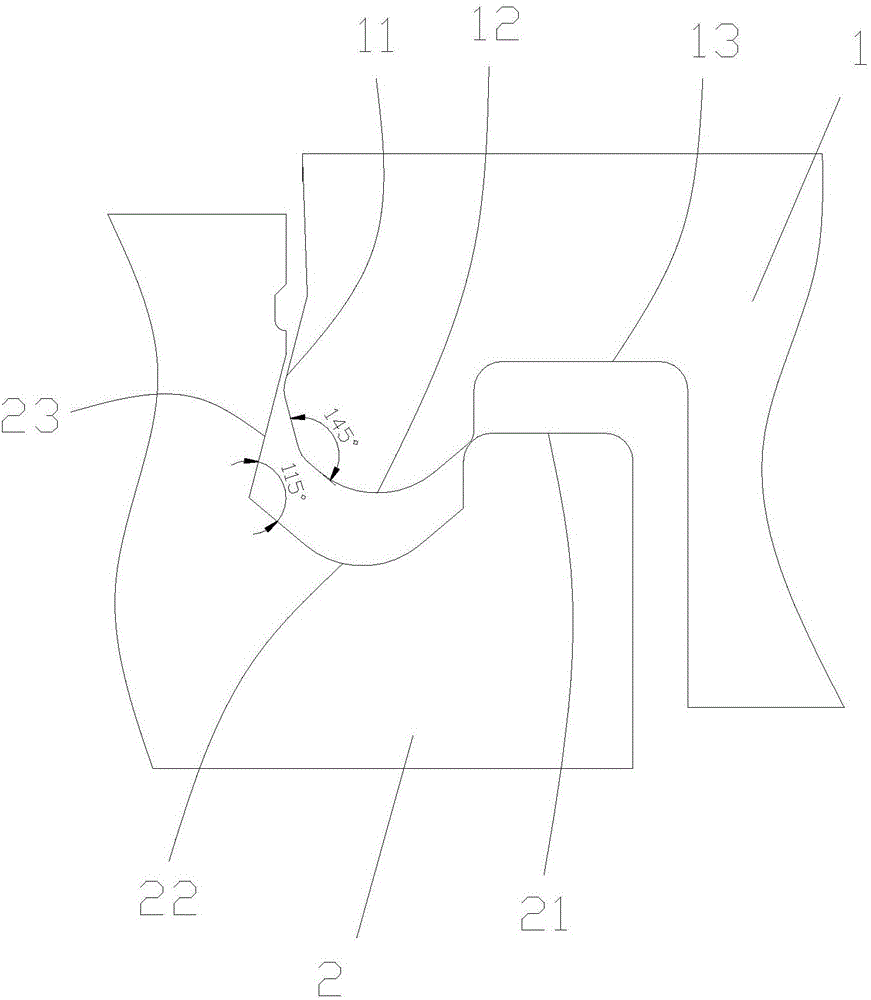

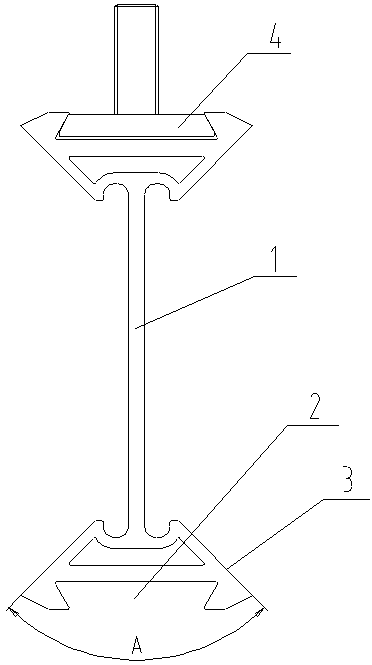

Floor fastener capable of preventing inflation and shrinkage

The invention provides a floor fastener capable of preventing inflation and shrinkage and relates to the technical field of floors. The fastener comprises a male fastener and a female fastener; a first boss is arranged at the lower side of the end part of the male fastener, a second boss part is arranged at the inner side, which is close to the first boss par, of the lower side of the end part of the male fastener, and a groove part is arranged at the inner side, which is close to the second boss part, of the lower side of the end part of the male fastener; the upper side of the end part of the female fastener is provided with a boss part, a first boss part is arranged at the inner side, which is close to the boss part, of the upper side of the end part of the female fastener, and a second groove part is arranged at the inner side, which is close to of the first groove part, of the upper side of the end part of the female fastener. The included angle between the first boss part and the second boss part is 140 degrees to 150 degrees, and the included angle between the first groove part and the second groove part is 110 degrees to 120 degrees. When the fastener is connected with the floor, the first boss part of the male fastener is matched with the second groove part of the female fastener of the female fastener, the second boss part of the male fastener is matched with the first groove part of the female fastener, and the groove part of the male flacon is matched with the boss part of the female fastener. The floor fastener capable of preventing inflation and shrinkage prevents deformation due to thermal expansion and contraction, and is strong is tensile ability, convenient to install, low in production coat and simple in technology.

Owner:ANHUI HANHUA BUILDING MATERIALS TECH

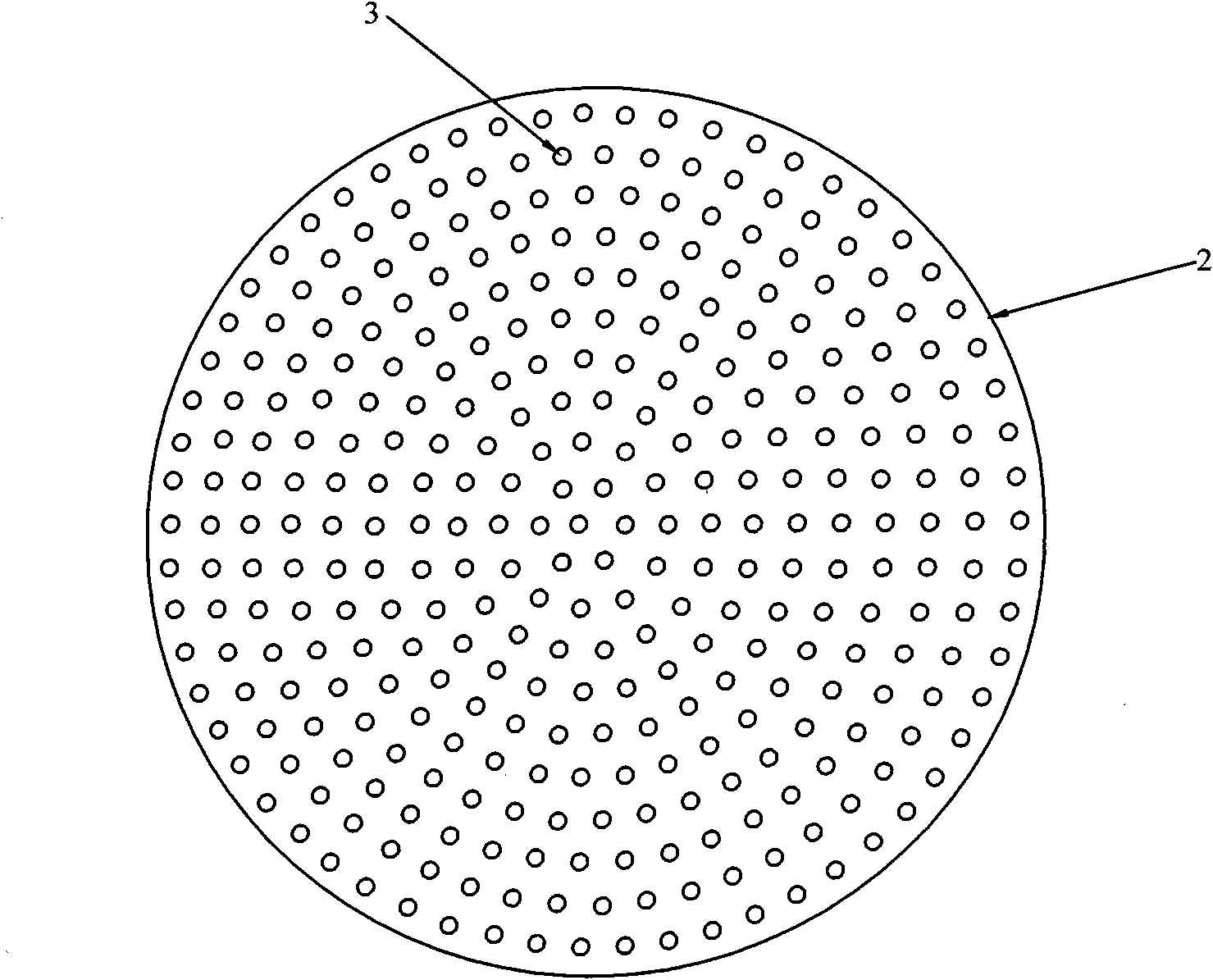

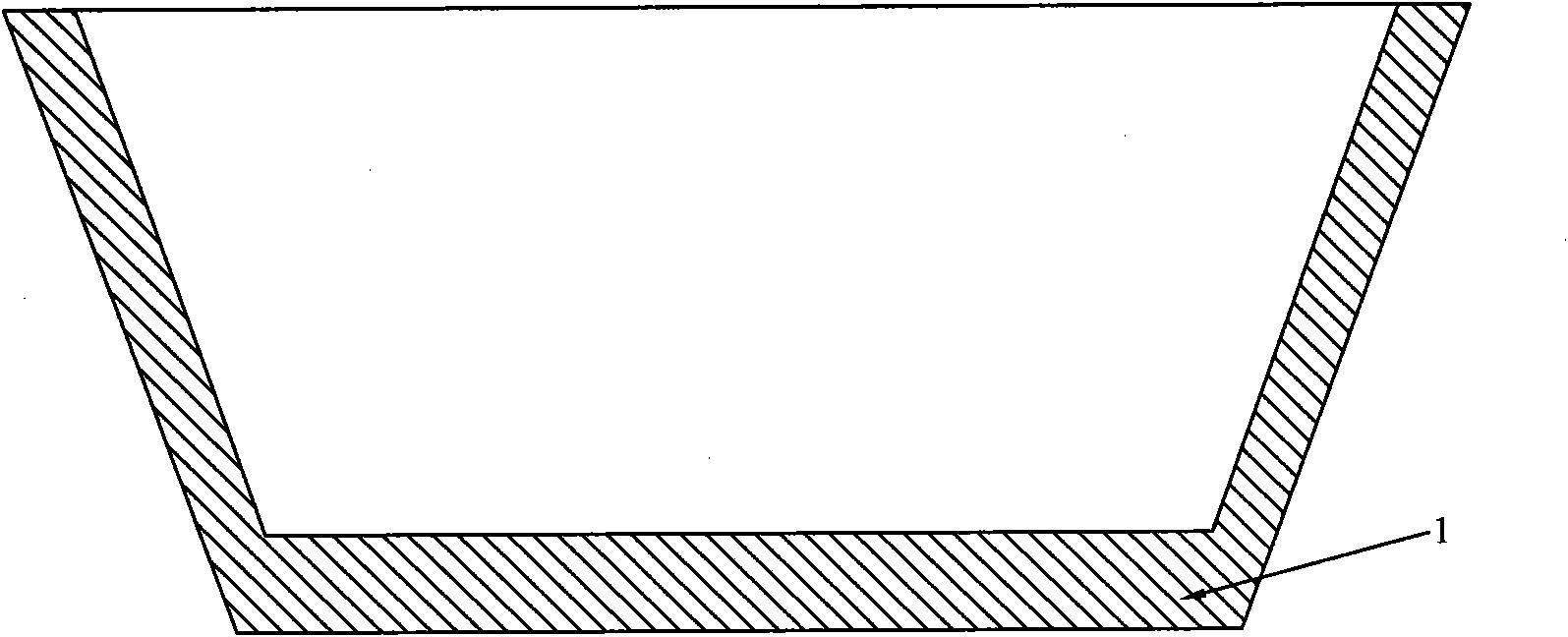

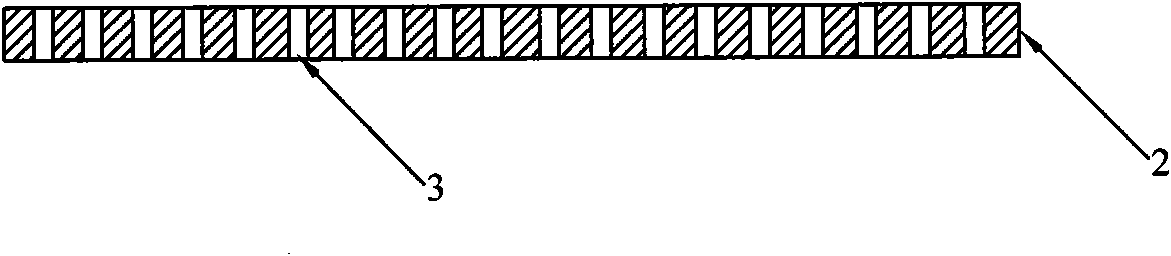

Aluminium pot, composite bottom of aluminium pot and method for manufacturing composite bottom of aluminium pot

InactiveCN102805562AFree and flexible application controlFreedom and flexibility in controlCooking-vessel materialsMetal-working apparatusMetalMagnet

The invention discloses a composite bottom of an aluminium pot, comprising a magnet-conducting metal plate. The magnet-conducting metal plate is compounded and connected with the bottom of the aluminium pot in pressing and fixing way and provided with a plurality of through holes. The invention further discloses the aluminium pot with the composite bottom and a method for manufacturing the composite bottom of the aluminium pot. The method comprises the following steps: (1) providing the magnet-conducting metal plate which matches with the bottom of the aluminium pot; (2) disposing a plurality of through holes on the magnet-conducting metal plate; and (3) connecting the magnet-conducting metal plate with the bottom of the aluminium pot in a pressing and fixing way by using a large-tonnage pressing machine. Because the magnet-conducting metal plate is provided with a plurality of through holes and connected with the bottom of the aluminium pot in a pressing and fixing way to realize the compounding of the bottom of the aluminium pot, the magnet-conducting metal plate and the bottom of the aluminium pot can be connected more firmly and smoothly, and the aluminium pot with the composite bottom is safer and more practical. The method for manufacturing the composite bottom of the aluminium pot is simpler and easier to operate and has low cost.

Owner:胡程韶

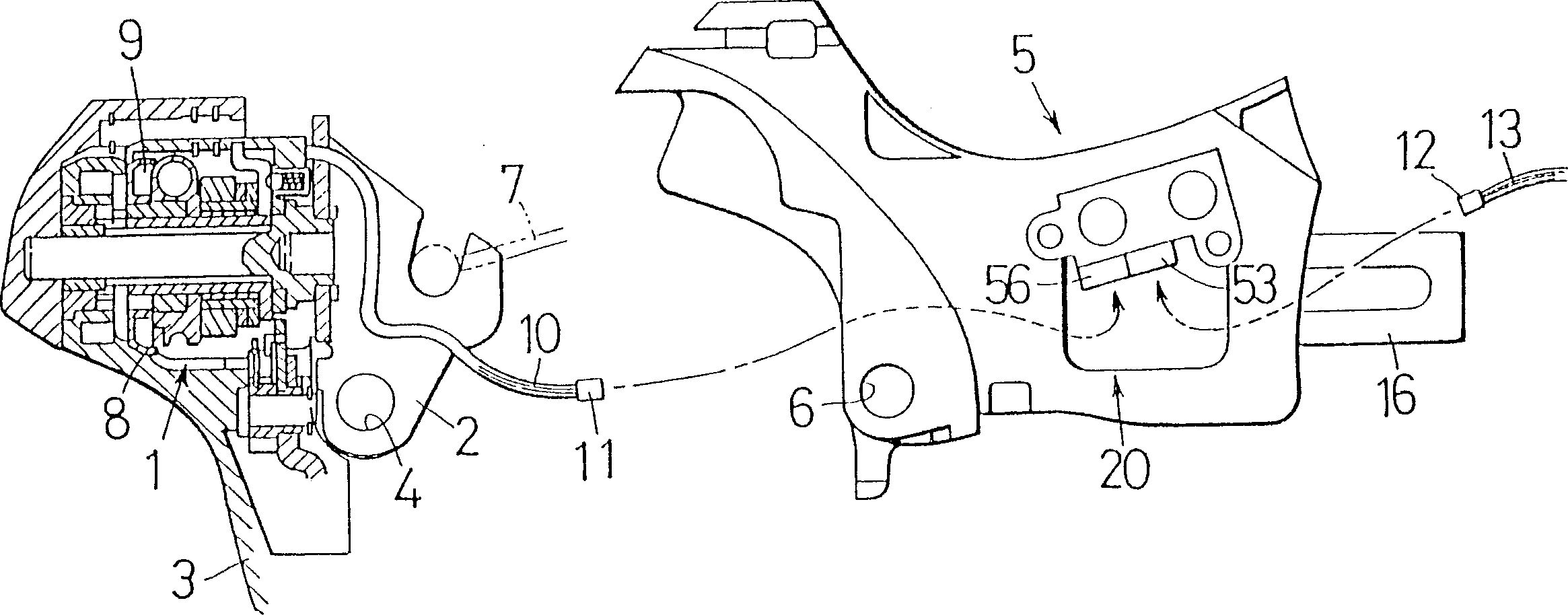

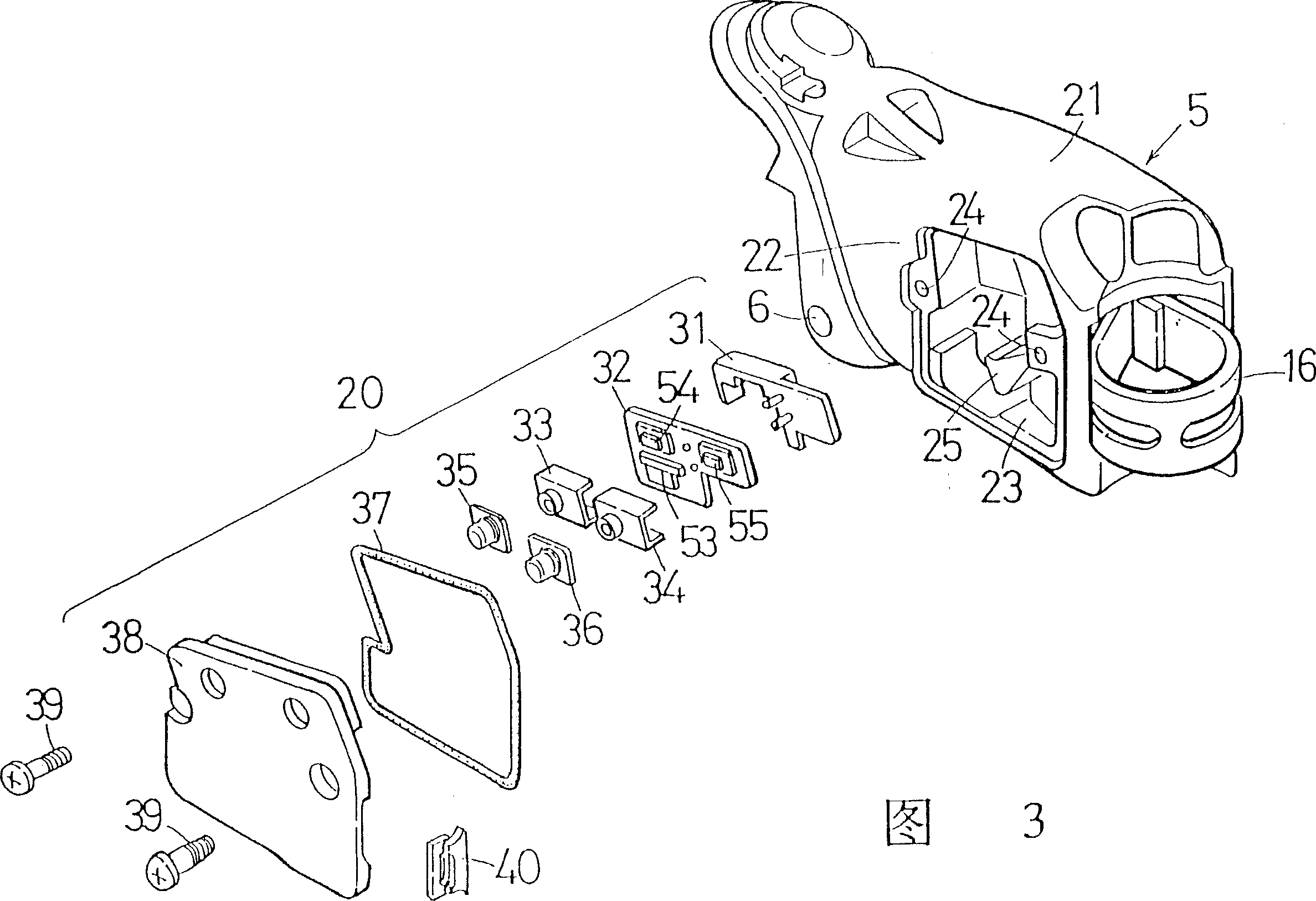

Tape cable connector for bicycle

InactiveCN1439564ASimple structureReduce parts countElectrically conductive connectionsOptical signalElectricityEngineering

An electrical cable connector (11, 12) for bicycles that has a simple structure, low cost, and excellent shielding against shocks, moisture, and the like is disclosed. The connector (11, 12) includes a connector body (60) which has a top surface and a bottom surface, and has a slit (61) which forms a passageway between the top and bottom surfaces. The top surface includes an inclined portion (62) which extends from the slit (61) to a flat terminal section (63). A flat cable (10, 13) extends along the bottom surface, through the slit (61), and along the top surface such that a terminal (65) at the end of the flat cable (10, 13) is positioned on the flat terminal section (63). In a disclosed application, the connector (11, 12) plugs into a female connector (53, 56) of a switch unit (20) of a bicycle lever bracket (5).

Owner:SHIMANO INC

Method for forming annular end tooth edge line of arc-shaped end tooth vertical mill

Owner:SOUTHWEST JIAOTONG UNIV +1

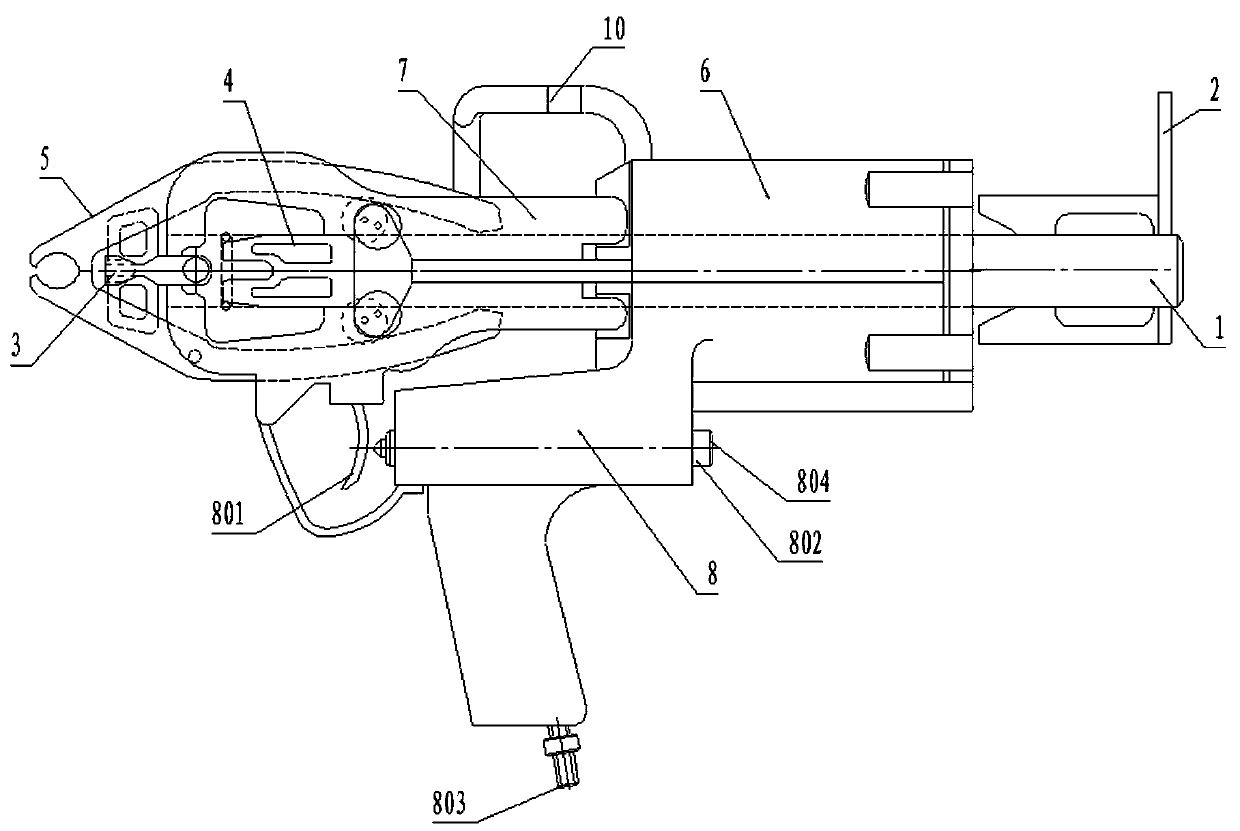

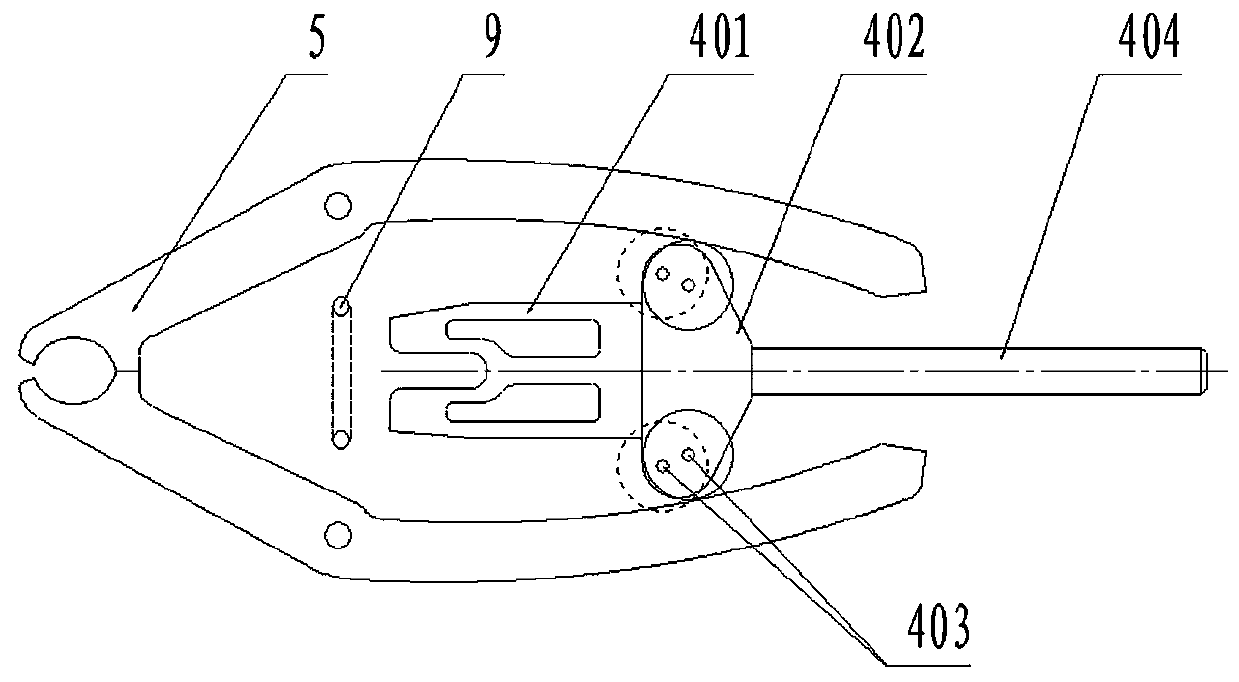

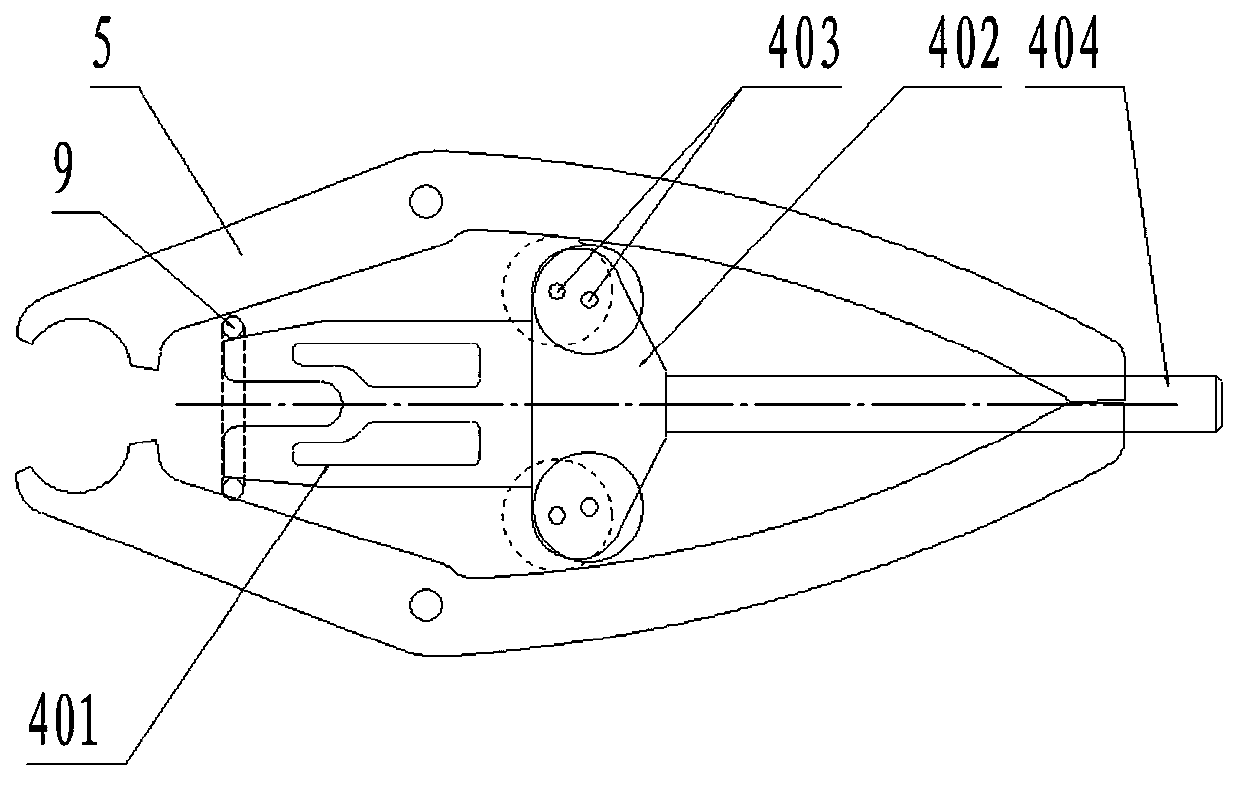

Pneumatic anchor net continuous-buckling machine for double-ring forming

PendingCN109707420ALight weightReduce volumeAnchoring boltsClimate change adaptationEngineeringUltimate tensile strength

The invention discloses a pneumatic anchor net continuous-buckling machine for double-ring forming. The pneumatic anchor net continuous-buckling machine comprises a nail feeding guide rail, a nail feeder, a buckling nail retreating stopper, a nail pushing assembly, a forming clamp, an air cylinder, a whole machine bracket, a pneumatic control assembly and buckling nails movably sleeving the nail feeding guide rail; the nail feeding guide rail is mounted on one side of the whole machine; the nail feeder is in an L shape and comprises a nail feeding body, a nail feeding push frame and a nail feeding sliding groove; the buckling nail retreating stopper is mounted on the front part of the whole machine and comprises a retreating-stopping bracket and a retreating-stopping blocking column; the nail pushing assembly is mounted between the buckling nail retreating stopper and the air cylinder, and the nail pushing assembly comprises a nail pushing sheet, a nail pushing connecting block, a tensioning pulley and a nail pushing connecting column; and the pneumatic control assembly comprises a trigger, an air exhaust seat and an air inlet, the air inlet is externally connected with a work airsource. The pneumatic anchor net continuous-buckling machine is simple in structure, low in weight and convenient to move, automatic and mechanized anchor net continuous-buckling operation is realized, the defects of infirm bundling, large labor intensity, tedious work and poor safety caused by manual iron wire bundling are avoided, the work efficiency is greatly improved, and the cost is lowered.

Owner:安徽宏昌机电装备制造有限公司

Waterproof roll with bonding material

InactiveCN109049870AMake a waterproof barrierGood adhesionRoof covering using flexible materialsSynthetic resin layered productsButt jointEngineering

The invention discloses a waterproof roll with a bonding material. Butt joint inclined planes are arranged at left and right connection end parts of the waterproof roll in parallel; the waterproof roll comprises a base cloth layer composed of a plurality of layers of fabrics; the plurality of layers of fabrics are connected through threading a wire material; waterproof layers with flowability arestuck on upper and lower side faces of the base cloth layer under pre-set temperature; each waterproof layer comprises glass silk cloth and modified asphalt coated on the surface of the glass silk cloth; a waterproof film layer is stuck on the surface of the waterproof layer on the upper side face of the base cloth layer; each butt joint inclined plane is coated with an adhesive layer; a plastic coating film, a coating base cloth layer and a sticky waterproof coating layer are arranged on the outer surface of each adhesive layer. The problem that bulges are formed at connection parts when thewaterproof roll is paved can be improved, the flatness and aesthetic degree of pavement are improved, the problem that water is deposited on the surface after construction is improved and a construction speed can be further improved.

Owner:天津宇屹新材料科技发展有限公司

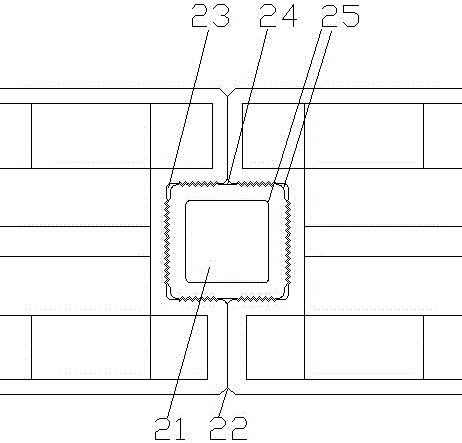

Mosaic assembled composite wall panel

ActiveCN105863158BImprove installation efficiencyHigh strengthSound proofingBuilding insulationsRelative displacementEngineering

The invention belongs to building wall panels and particularly relates to an embedded and assembled composite wall panel. According to the technical scheme, the embedded and assembled composite wall panel comprises a wall panel body and mounting clamping strips, the wall panel body is enclosed, two straight arm frames which are perpendicular to a width-direction outer frame and of the same thickness divide the wall panel body into three equal parts, the centers of the two sides of the wall panel body are vertically provided with rectangular mounting clamping grooves which are open in the upper ends and the lower ends, the sawtooth-shaped teeth are formed in three faces of the concave outer wall of each rectangular mounting clamping groove, the mounting clamping strips are provided with teeth in occlusion with the outer walls of the rectangular mounting clamping grooves, and in the splicing process, the mounting clamping strips are in embedded occlusion with the rectangular mounting clamping grooves in the two sides. The embedded and assembled composite wall panel aims to be convenient to splice and detach, relative displacement between connected wall panels and mechanical bending and turning generated at the joint of the connected wall panels are prevented, the structure is stable, and connection is firm.

Owner:浙江昱美创新建筑科技有限公司

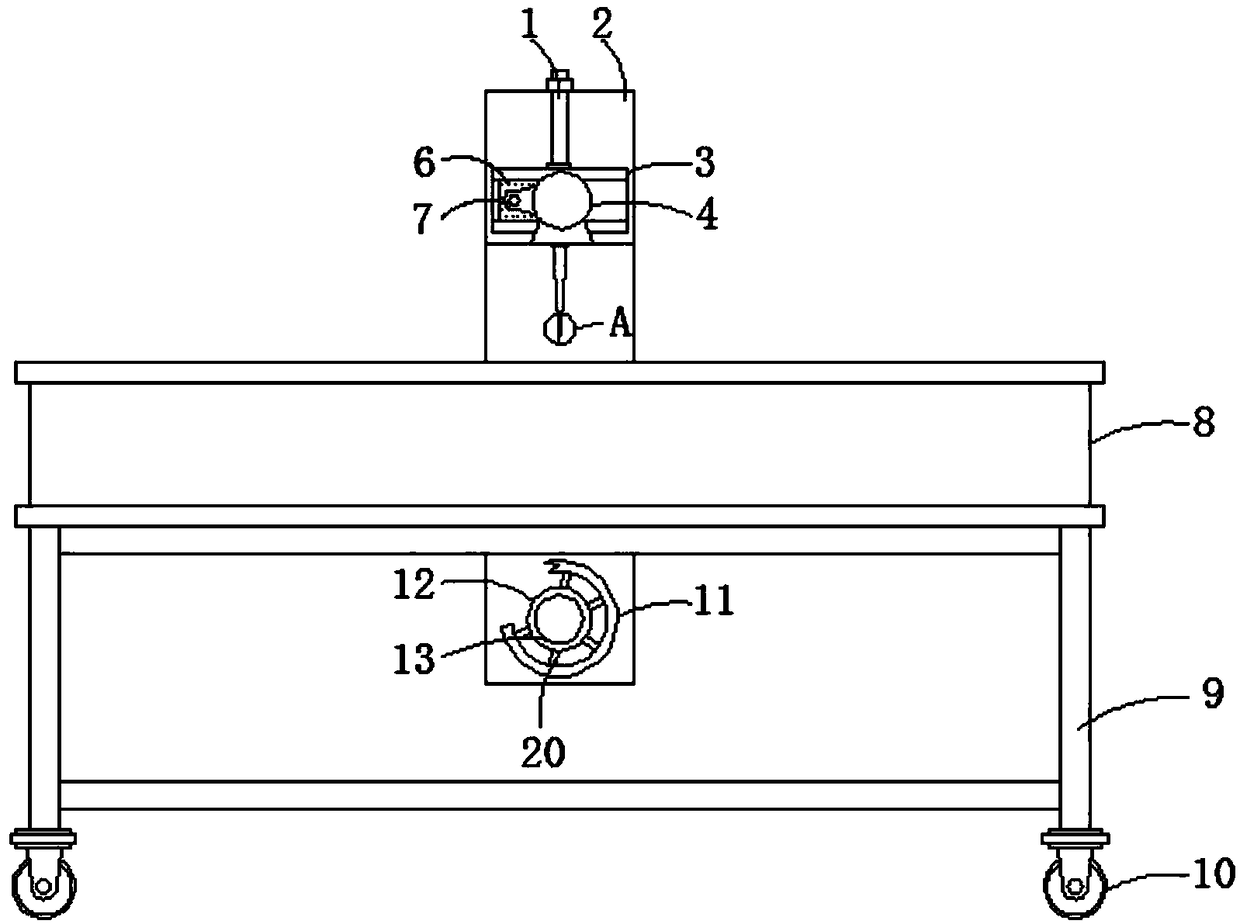

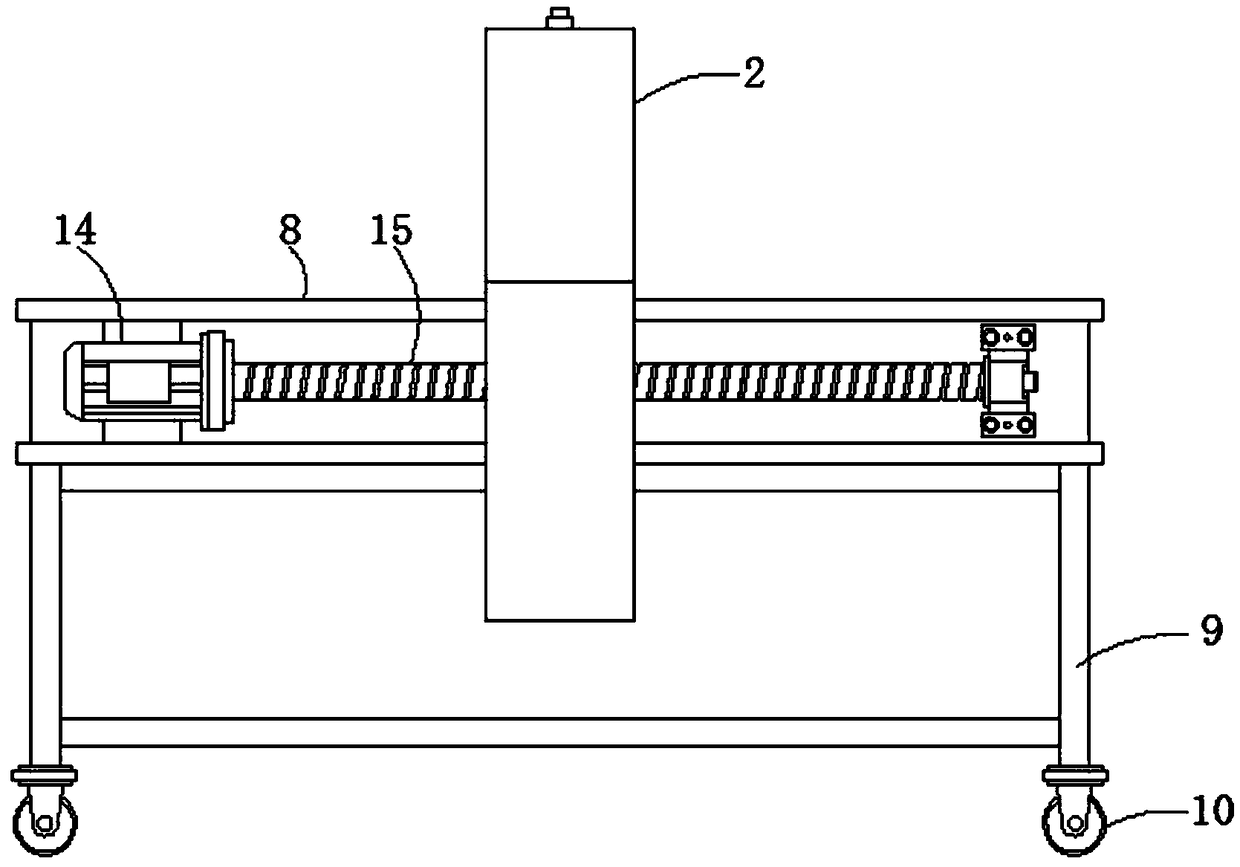

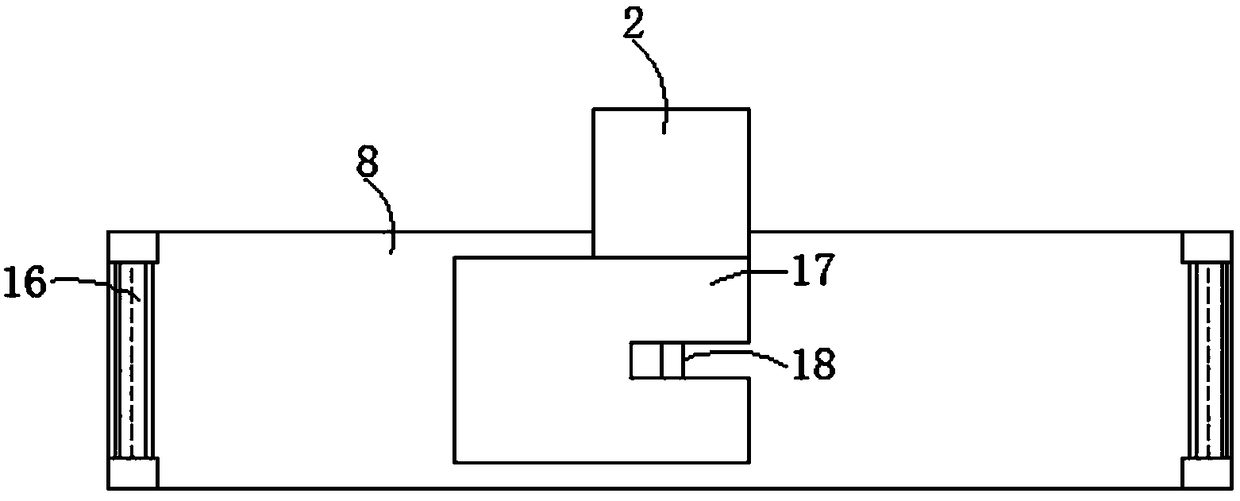

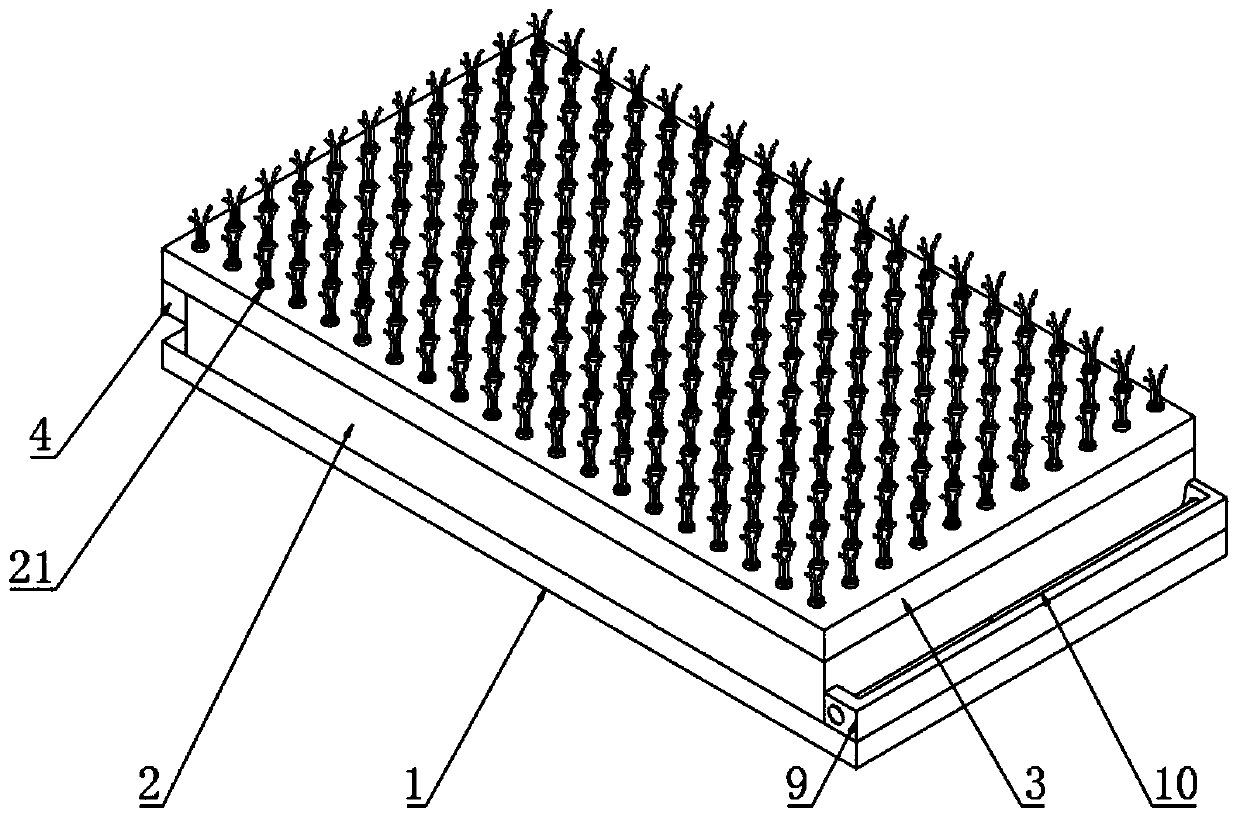

Mobile non-woven washable undercollar cloth connecting device

InactiveCN108249196AConnection flatAvoid the problem of pressing the interlining with both handsWebs handlingSewing needleEngineering

The invention discloses a mobile non-woven washable undercollar cloth connecting device. The mobile non-woven washable undercollar cloth connecting device comprises a workbench, wherein rubber bands are arranged at the two ends of the workbench respectively, a mounting seat is connected in the rear of the workbench in a sliding manner, a first motor is fixedly arranged inside the mounting seat byvirtue of a motor fixing seat, the rear of the first motor is rotatably connected with a driving arm by virtue of a rotating shaft, the rear of the driving arm is rotatably connected with a sliding block by virtue of a rotating shaft, the sliding block is connected with a sliding seat in a sliding manner, a work drum is arranged at the middle part of the sliding seat in a penetrating manner, a sewing needle is arranged at the lower end of the work drum, and a needle hole is formed in the sewing needle. The mobile non-woven washable undercollar cloth connecting device disclosed by the inventionhas the advantages that a pressure plate is arranged, the pressure plate is fixedly connected with the mounting seat, the pressure plate is driven to move relative to the workbench when the mountingseat moves relative to the workbench, and in a process that the pressure plate advances, two pieces of non-woven washable undercollar cloth are laminated, so that the two pieces of non-woven washableundercollar cloth are connected more smoothly.

Owner:长兴瑞韬纺织科技有限公司

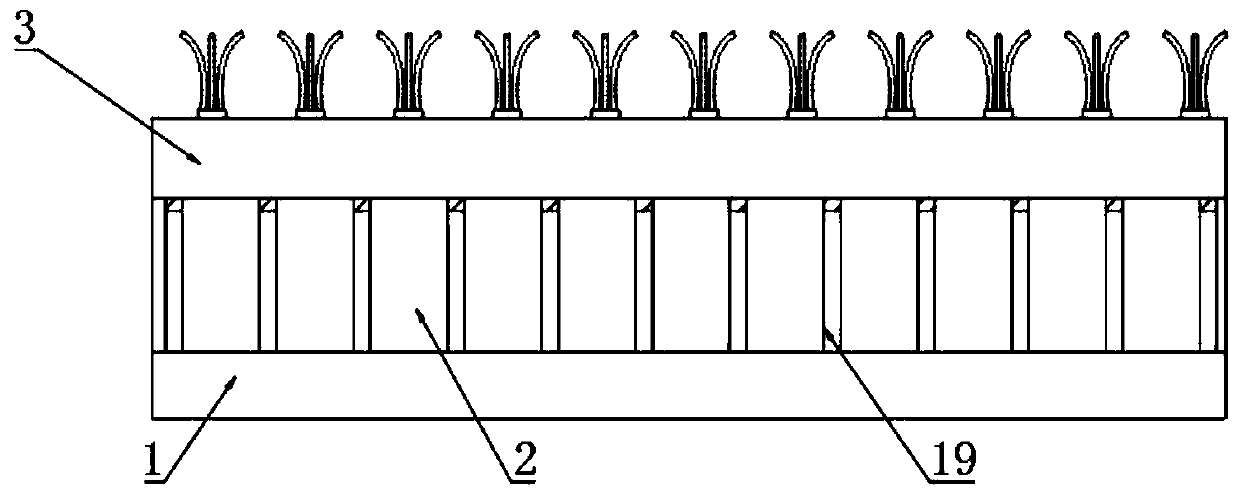

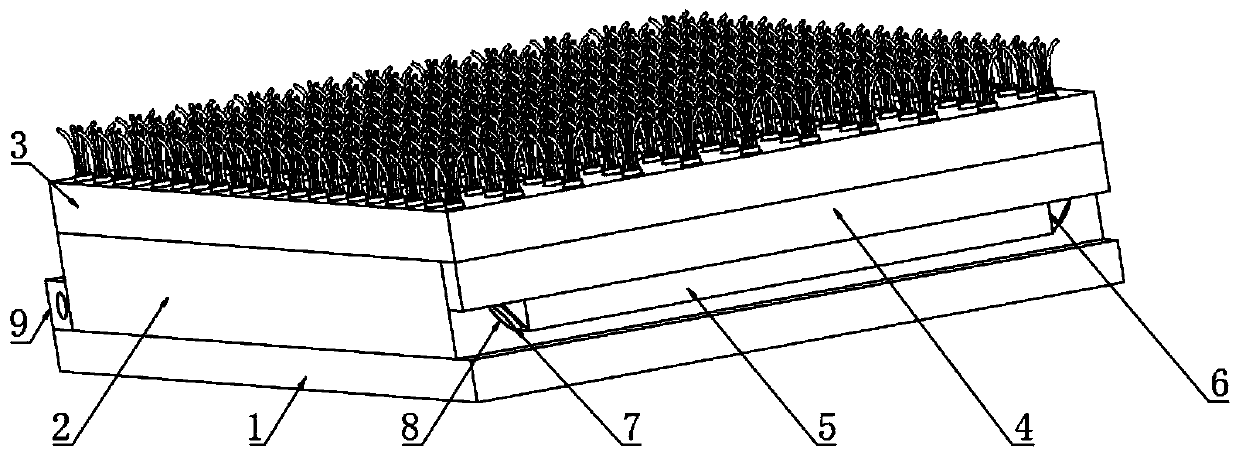

Artificial lawn block convenient to fix and connect

The invention discloses an artificial lawn block convenient to fix and connect. The lawn block comprises a base cloth layer, wherein a nylon water absorption pad is sewn in the middle of the top end of the base cloth layer, the middle of the top end of the nylon water absorption pad is provided with a grass layer in a sewing mode, a connecting block is arranged in the middle of one end of the nylon water absorption pad, the middle of the bottom end of the connecting block is provided with a convex block, inclined blocks are correspondingly arranged at the middles of the two ends of the convexblock, round holes are correspondingly formed in the middles of the inner walls of the inclined blocks and the middles of the inner walls of the convex block, and rings are arranged at the edge partsof the round holes on the outer surfaces of the inclined blocks. The lawn block is scientific and reasonable in structure, and safe and convenient to use, the connecting block, the convex block, the inclined blocks, the round holes, a fixing block, a groove and an inclined groove are arranged so as to facilitate connecting between two artificial lawn blocks, so that the connecting difficulty between the two artificial lawn blocks is reduced, the two artificial lawn blocks can be connected more smoothly, and the phenomenon of uneven connection of the two artificial lawn blocks can be prevented.

Owner:HANGZHOU BAOLI SPORTS FACILITIES ENG

Material transportation guide rail

Owner:晋中贝斯特机械制造有限公司

Automobile instrument panel transmission cam

The invention discloses an automobile instrument panel transmission cam which comprises a rotating portion, a mounting portion and a connecting portion, wherein the two ends of the rotating portion extend outwards to form the mounting portion and the connecting portion. Multiple cam portions are arranged on the rotating portion in a protruding mode, cross sections are formed in the cam portions, and the cross sections of the cam portions are distributed alternately and parallel to each other. Counter bored holes are formed in the end portion of the mounting portion along the axis, wire outlets are formed in the peripheral surface of the mounting portion, and the wire outlets are communicated with the counter bored holes. The connecting portion is made of steel. The automobile instrument panel transmission cam is simple in structure, good in stability, and excellent in mechanism performance.

Owner:NINGBO YONGSHOCK PRECISION MACHINERY COMPANY

Waterproof coiled material coated with adhering material in #-shaped manner

The invention discloses a waterproof coiled material coated with an adhering material in a #-shaped manner. Butt joint slopes are parallelly arranged at the left connecting end and the right connecting end of the waterproof coiled material. The waterproof coiled material comprises a base cloth layer, waterproof layers, a waterproof membrane layer, adhesive layers, a coating base cloth layer and adhesive waterproof coating layers, wherein the base cloth layer comprises multiple layers of cloth, and the multiple cloth layers are connected through penetrating threads; the waterproof layers with flowability under set temperature are adhered to the upper side and the lower side of the base cloth layer, and each waterproof layer comprises glass wool cloth and modified asphalt coating the surfaceof the glass wool cloth; the waterproof membrane layer is adhered to the surface of the waterproof layer on the upper side of the base cloth layer; the butt joint slopes are coated with the adhesivelayers, and plastic coating films are arranged outside the adhesive layers; the adhesive waterproof coating layers are laid in different zones in a #-shaped manner. The waterproof coiled material hasthe advantages that the problem of protruding ridges at joints during waterproof coiled material laying can be improved, laying flatness and attractiveness can be increased, the surface water accumulation problem after construction can be improved, construction speed can be further increased, and processing cost can be lowered reasonably.

Owner:天津宇屹新材料科技发展有限公司

Thin dual-channel potentiometer with switch

InactiveCN101807462BIncreasing the thicknessImprove performanceResisitors with sliding contactEngineeringElectrical stability

The invention discloses a thin dual-channel potentiometer with a switch, relating to potentiometer and comprises a potentiometer unit and a switch unit. The potentiometer unit comprises a knob, a folding mover, a terminal, a resistor chip, a support board, a shaft, a body and a clamp ring; the switch unit comprises a left switch end piece, a right switch end piece, a switching piece, a spring, a convex plate and a clamp piece; the folding mover is provided with two brushes and a mechanical switch, thereby realizing the integration of dual channel and the mechanical switch and the integration of thin type, dual channel and the mechanical switch; and the upper end of the shaft is riveted and fastened with the knob. A user installs the potentiometer on a circuit board without screwing the knob with the shaft end by using screws, thereby reducing the installation procedures and saving the installation time. The support board is attached to and in clamping connection with a circuit piece, and the body is attached to and in clamping connection with the support board, thereby orderly connecting the body, the support board and the circuit piece into a whole. The thin dual-channel potentiometer with the switch has small shaking during rotating, high electric stability, long service life which is twice that of the current product and wide application range.

Owner:东莞市庆恒电子有限公司

Plate heat exchanger with several modules connected by plate strips

The heat exchanger (1) has modules (1a,1b) that are arranged next to one another such that contact surface (9a) of cuboidal module (1a) is arranged adjacent to contact surface (9b) of cuboidal module (1b). The fittings are provided for supplying and discharging heat-exchanging media. The headers are provided for distributing and collecting heat-exchanging media to and / or form the passages. The adjacent sides of modules are covered by the cover sheets (5). The contact surfaces of the modules are joined with one another through adhesive. An independent claim is included for method for producing plate heat exchanger.

Owner:LINDE AG

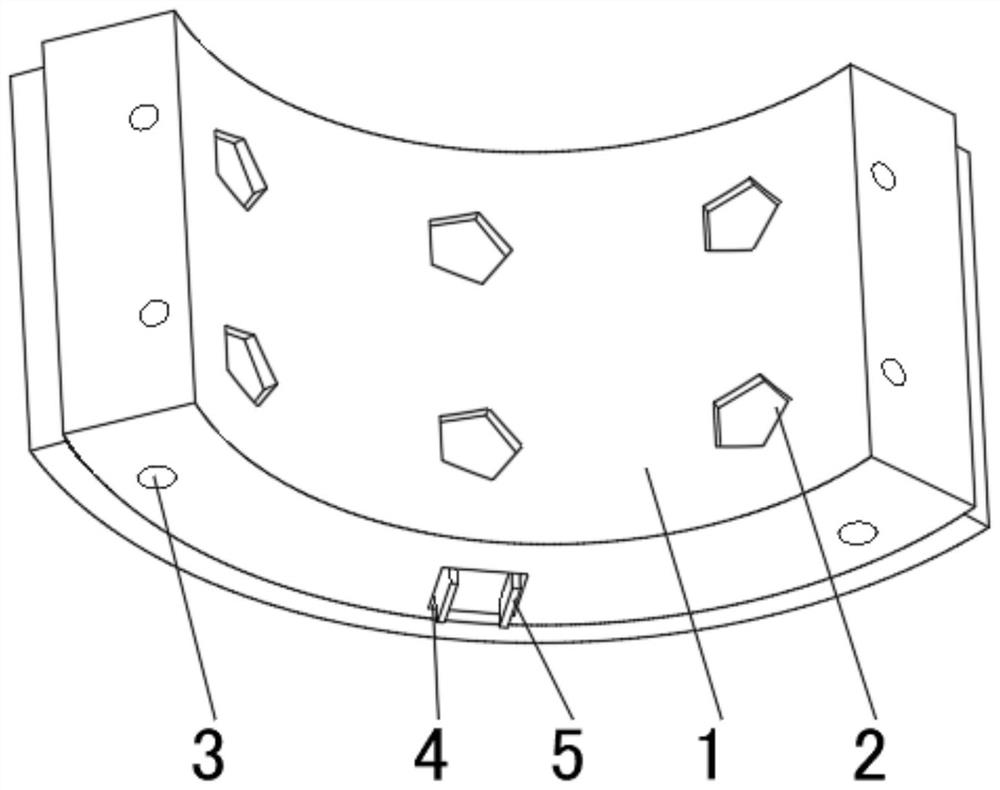

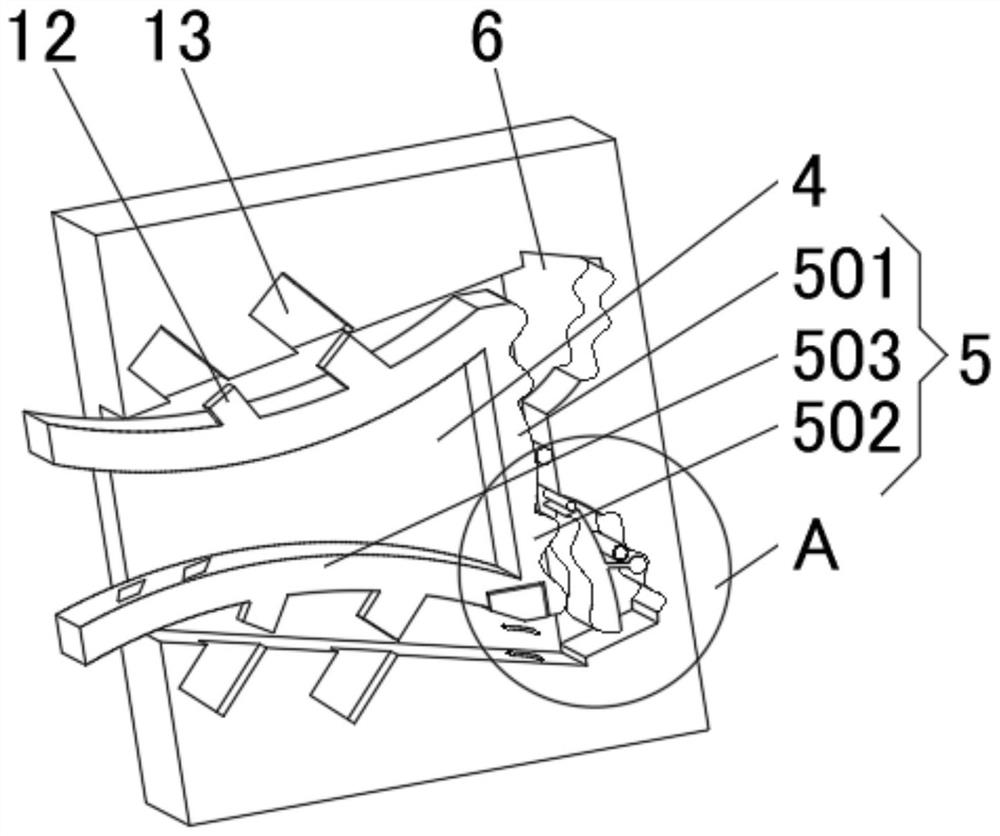

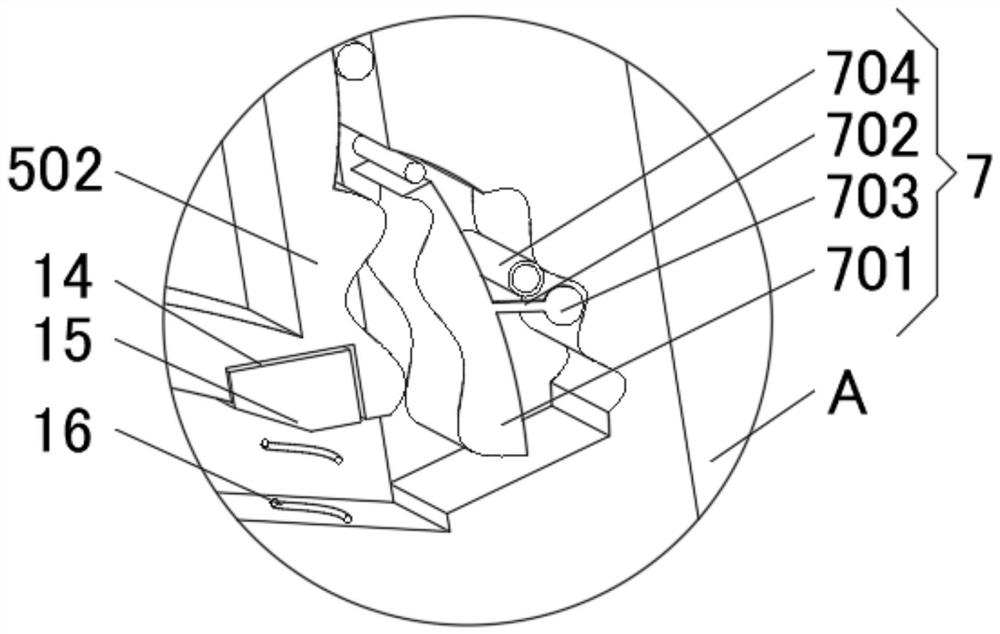

Automatic calibration shield segment

InactiveCN112682068AGuaranteed alignmentEasy alignment and calibrationMining devicesUnderground chambersClassical mechanicsMechanical engineering

The invention discloses an automatic calibration shield segment. The segment comprises an arc-shaped segment body, an annular groove and a longitudinal groove, a calibration groove is formed in one side of the arc-shaped segment body, the calibration groove is a table-shaped groove, a clamping frame is rotatably connected to one side of the inner wall of the calibration groove, and swing grooves are symmetrically formed in one side of the inner wall of the calibration groove. Position correcting devices are installed in the swing grooves, and calibration plates are symmetrically installed on the side, away from the calibration groove, of the arc-shaped segment body. The invention relates to the technical field of tunnel construction. According to the automatic calibration shield segment, the purpose of facilitating calibration between shield segments is achieved, the installation difficulty of the shield segments is reduced, unevenness between the shield segments can be avoided, the butt joint position of the shield segments is automatically calibrated, the inspection work after the shield segments are installed is reduced, the tunnel construction efficiency is improved, damage caused by collision between the shield segments is reduced, the service life of a tunnel is prolonged, and the firmness degree of connection between the shield segments is improved.

Owner:杨亚玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com