Embedded and assembled composite wall panel

A composite wall, assembled technology, applied in building components, building thermal insulation materials, sound insulation and other directions, can solve the problems of environmental pollution in the production process, difficult to connect the wall panels firmly, and cannot be recycled, etc., to achieve structural stability and lightening. Weight, efficient use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

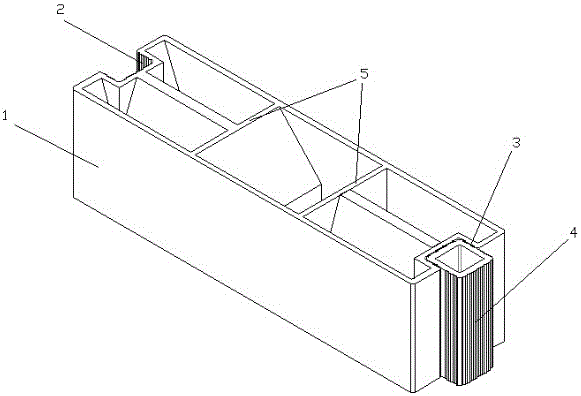

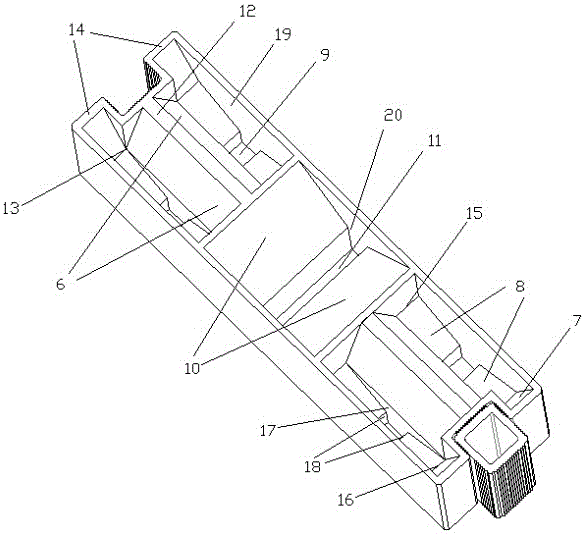

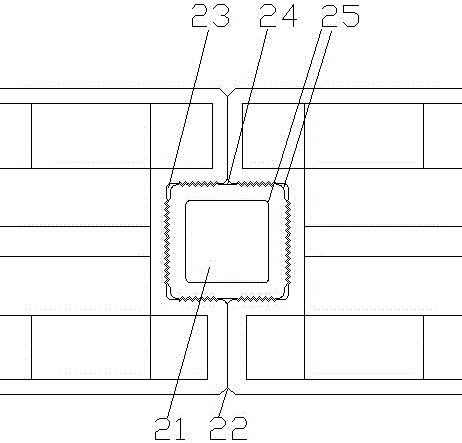

[0036] Example 1, such as figure 1 , 3 As shown, the mosaic-assembled composite wall panel includes a wall panel body 1 and a mounting clip 4, which is framed by the mounting clip 4, the cavity 21 of the mounting clip is hollow, and the corner 25 of the mounting clip is chamfered. The panel body 1 is surrounded by a frame, the wall panel body outer wall corner 22 is chamfered, and there are two straight arm frames 5 of the same thickness perpendicular to the wide outer frame. The wall panel body 1 is divided into three equal parts. The wall panel body 1 There are rectangular installation slots 2 open at the upper and lower ends in the middle of the left and right sides. The concave outer wall of the rectangular installation slot 2 has serrated teeth 3 on three sides. The installation strip 4 has a concave outer wall corresponding to the rectangular installation slot. The occlusal teeth are inserted vertically between the two wall panel bodies 1 during assembly, and are inlaid wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com