Aluminium pot, composite bottom of aluminium pot and method for manufacturing composite bottom of aluminium pot

A production method and technology of aluminum pot, which are applied in the direction of special materials for cooking utensils, cooking utensils, household appliances, etc., can solve the problem that the magnetic conductive metal plate and the bottom of the aluminum pot are not firmly combined, affect the thermal conductivity and safety of use, and the gap is easy to open. Water ingress and moisture seepage, etc., to achieve the effect of extensive use value and promotion value, free and flexible application control, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

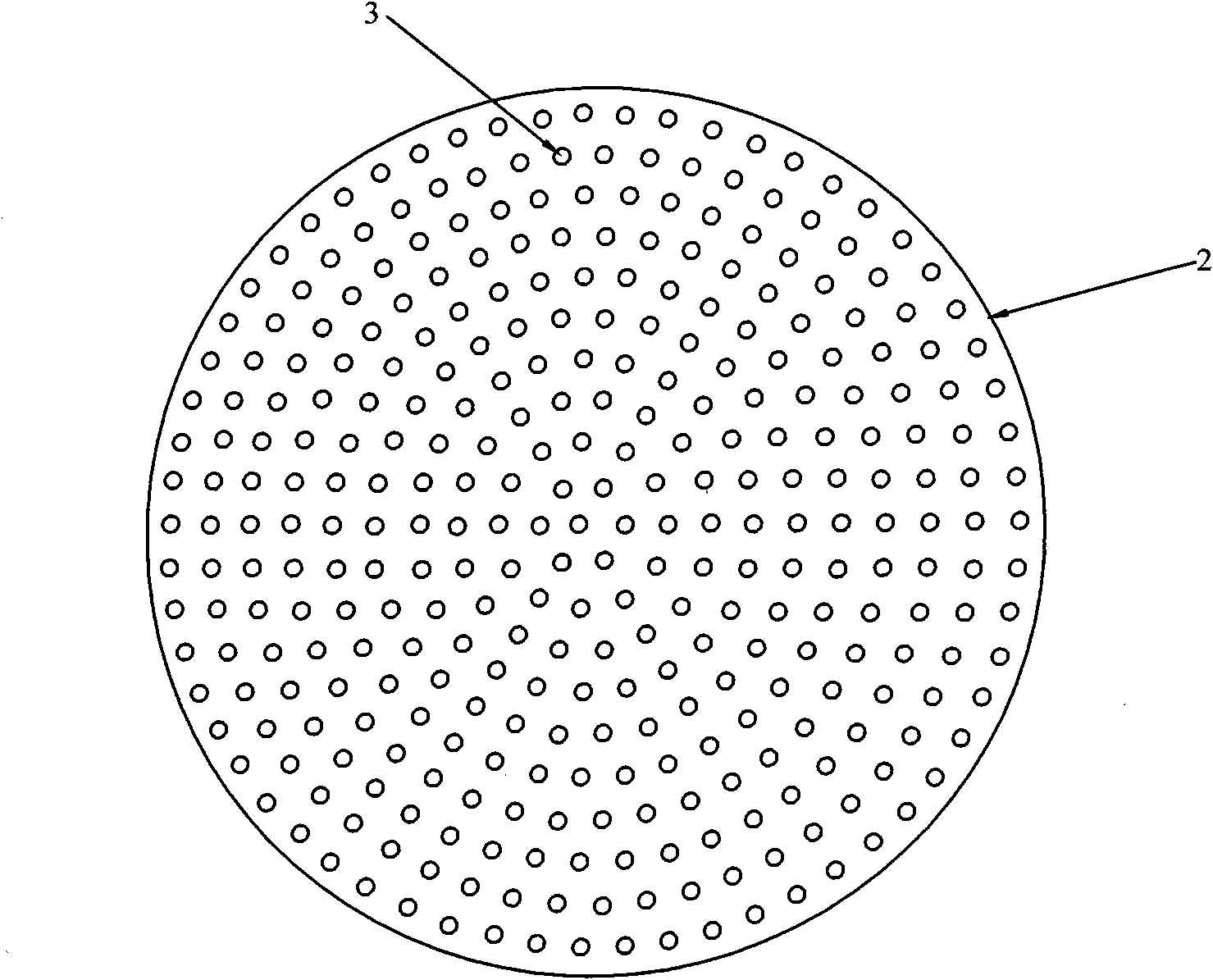

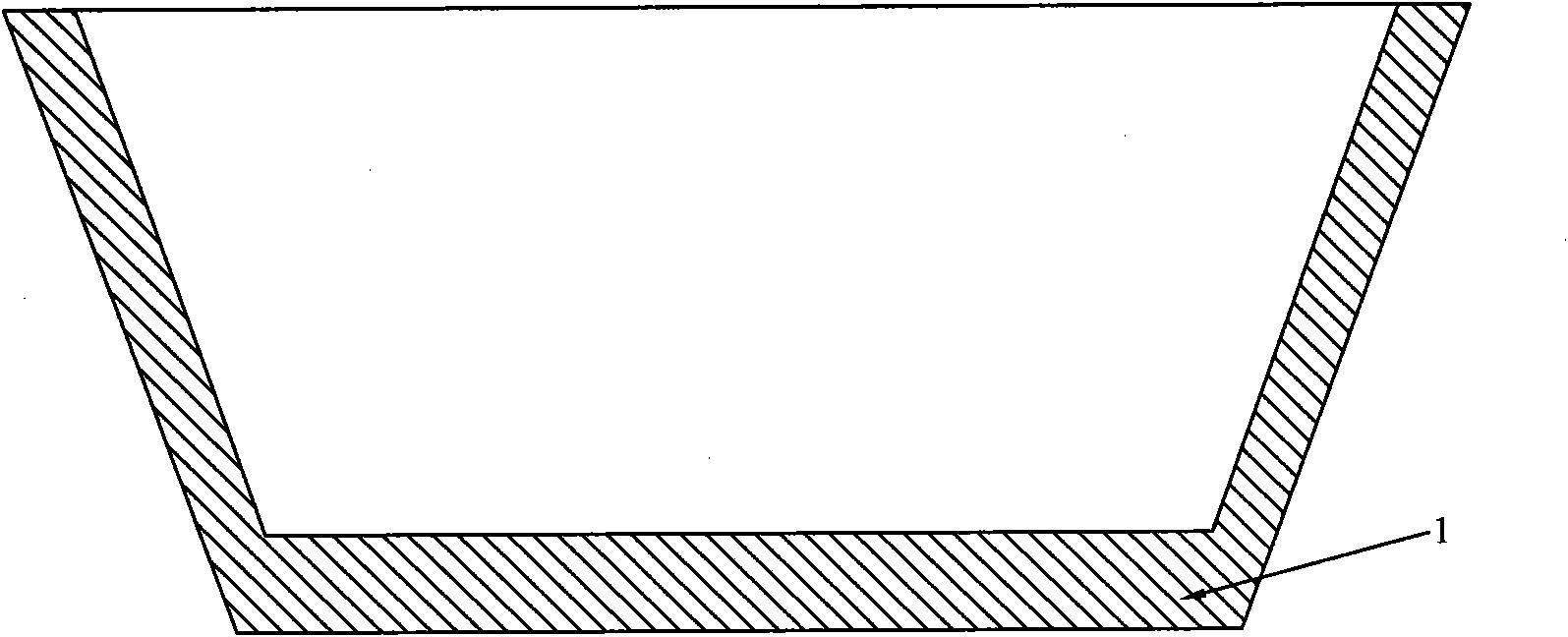

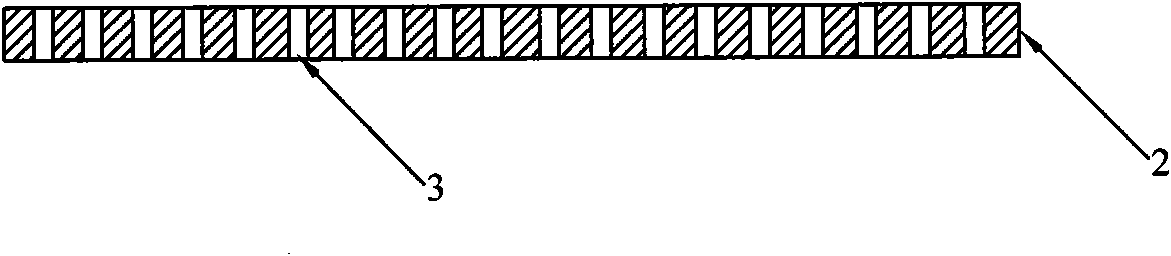

[0020] see Figure 1 to Figure 2 As shown, the present invention provides a composite aluminum pot bottom, comprising a magnetically conductive metal plate 2 compositely connected to the bottom 1 of an aluminum pot, wherein the magnetically conductive metal plate is provided with a plurality of through holes 3, the The magnetically conductive metal plate is pressed and fixedly connected to the bottom of the aluminum pot, the diameter of the through hole is not more than 3.5 mm, and the magnetically conductive metal plate is a stainless iron plate or a steel plate. The present invention also provides an aluminum pan that is firm, durable, high in flatness, fully bonded to the heating surface of the induction cooker, uniform in heat conduction, and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com